Discover the Diameter of 55 Gallon Drum: Your Sourcing Guide (2025)

Introduction: Navigating the Global Market for diameter of 55 gallon drum

Navigating the complexities of sourcing the right diameter of a 55-gallon drum can be a pivotal challenge for international B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The demand for these versatile containers spans various industries, from chemicals to food processing, and understanding the nuances of their specifications is crucial for ensuring compatibility with your products. This comprehensive guide delves into the essential aspects of 55-gallon drums, including types, dimensions, applications, and supplier vetting processes, all tailored to empower you in making informed purchasing decisions.

International buyers often face hurdles in identifying reliable suppliers and understanding the specific requirements of different drum types—be it steel, plastic, or fiber. This guide addresses these challenges head-on, providing insights into how to assess product suitability based on dimensions and materials, as well as how to navigate the logistics of global shipping and compliance with local regulations.

By equipping yourself with the knowledge contained in this guide, you will be better positioned to streamline your procurement processes, reduce costs, and enhance the efficiency of your operations. Whether you’re in Nigeria looking for bulk chemical storage solutions or in Germany sourcing food-grade containers, understanding the diameter and specifications of 55-gallon drums is key to optimizing your supply chain. Let’s explore how you can leverage this information to elevate your business.

Understanding diameter of 55 gallon drum Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel Drum | Made from cold-rolled steel, available in open or closed head | Chemicals, oils, food products | Pros: Durable, reusable, high strength. Cons: Heavier, more expensive than plastic. |

| Plastic Drum | Constructed from HDPE, lightweight, often UV resistant | Chemicals, pharmaceuticals, food storage | Pros: Lightweight, resistant to corrosion. Cons: Limited temperature range, potential for permeation. |

| Fiber Drum | Made from layers of kraft paper, often with a removable lid | Dry goods, powders, non-hazardous materials | Pros: Lightweight, recyclable. Cons: Less durable, not suitable for liquids. |

| UN Rated Drum | Meets UN standards for hazardous materials | Transporting dangerous goods | Pros: Compliance with international shipping laws. Cons: Typically more expensive due to certification. |

| Custom Drum | Tailored dimensions and features per buyer specifications | Specialized storage and transport needs | Pros: Perfect fit for unique applications. Cons: Longer lead times, potentially higher costs. |

What are the characteristics of Steel Drums and their suitability for B2B buyers?

Steel drums are the industry standard for bulk storage and transport, typically measuring between 22-24.5 inches in diameter and 33-36.75 inches in height. Their robust construction allows them to handle a wide range of products, including chemicals, oils, and food items. B2B buyers should consider the weight and cost implications, as steel drums are heavier and generally more expensive than their plastic counterparts. However, their durability and reusability make them a preferred choice for long-term storage.

How do Plastic Drums differ and what are their key B2B applications?

Plastic drums, primarily made from high-density polyethylene (HDPE), are lightweight and resistant to corrosion, with diameters similar to steel drums. They are ideal for storing chemicals, pharmaceuticals, and food products but may have limitations regarding temperature and permeation. Buyers should assess the compatibility of the drum material with their specific products, as well as the potential for UV degradation. While generally more affordable, the suitability for certain applications can vary.

What makes Fiber Drums a viable option for certain B2B applications?

Fiber drums are constructed from multiple layers of kraft paper, making them lightweight and recyclable, typically used for dry goods and powders. Their open-head design allows for easy filling and access, but they are not suitable for liquids. B2B buyers should consider their environmental impact and cost-effectiveness, as fiber drums can be a more sustainable choice. However, they lack the durability of steel or plastic drums, which may limit their application scope.

Why choose UN Rated Drums for hazardous materials?

UN rated drums are specially designed to meet United Nations standards for transporting hazardous materials, ensuring compliance with international shipping regulations. They are typically made from steel or plastic and come in various sizes, including the standard 55-gallon format. Buyers must prioritize safety and legal compliance when transporting dangerous goods, making these drums essential. However, the added certification can lead to higher costs, which should be factored into the purchasing decision.

What are the benefits and considerations for Custom Drums?

Custom drums offer tailored dimensions and features to meet specific buyer requirements, making them ideal for specialized storage and transport needs. These drums can be manufactured in various materials, including steel, plastic, and fiber, depending on the application. While they provide a perfect fit for unique products, buyers should be prepared for longer lead times and potentially higher costs. Customization adds value but requires careful planning and specification to ensure the drums meet all operational needs.

Key Industrial Applications of diameter of 55 gallon drum

| Industry/Sector | Specific Application of diameter of 55 gallon drum | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Chemical Manufacturing | Transporting and storing bulk chemicals | Ensures safe and compliant handling of hazardous materials | UN-rated drums required for compliance with international standards |

| Food and Beverage | Storing and transporting food-grade liquids | Maintains product integrity and safety for consumables | FDA-compliant materials crucial for food safety regulations |

| Oil and Gas | Storing crude oil and petroleum products | Provides a durable and efficient solution for bulk storage | Consider compatibility with various petroleum products |

| Pharmaceuticals | Transporting active pharmaceutical ingredients (APIs) | Ensures purity and safety during transit and storage | Stainless steel options preferred for high-purity requirements |

| Construction | Storing dry materials like sand, gravel, or cement | Facilitates easy access and transportation of construction materials | Open-head designs beneficial for bulk material handling |

How is the Diameter of a 55 Gallon Drum Utilized in Chemical Manufacturing?

In the chemical manufacturing sector, the diameter of the 55-gallon drum is critical for transporting and storing bulk chemicals. These drums often meet UN-rated standards, ensuring they can safely contain hazardous materials. For international buyers, particularly in Africa and the Middle East, sourcing compliant drums is essential to avoid regulatory issues. The diameter allows for efficient filling and dispensing, optimizing storage space while maintaining safety protocols.

What Role Do 55 Gallon Drums Play in the Food and Beverage Industry?

In the food and beverage industry, 55-gallon drums are commonly used for storing and transporting food-grade liquids such as oils, syrups, and sauces. The diameter is designed to facilitate easy pouring and mixing, ensuring product integrity. For buyers in Europe and South America, selecting FDA-compliant materials is crucial to adhere to food safety standards. The ability to clean and reuse these drums adds significant value, reducing waste and costs.

Why Are 55 Gallon Drums Essential for the Oil and Gas Industry?

The oil and gas industry relies on 55-gallon drums for the storage of crude oil and various petroleum products. Their robust construction allows for safe storage and transportation, minimizing the risk of leaks or spills. For international buyers, especially in regions like Nigeria, it is vital to consider the compatibility of the drum material with different petroleum products to ensure safety and efficiency during operations.

How Do Pharmaceutical Companies Benefit from Using 55 Gallon Drums?

Pharmaceutical companies utilize 55-gallon drums for transporting active pharmaceutical ingredients (APIs) and other sensitive materials. The diameter of these drums is essential for maintaining purity and safety during transit. Buyers in Europe must prioritize sourcing stainless steel options that meet high-purity requirements, as contamination can severely impact product efficacy. The drums’ design also allows for easy handling and storage within controlled environments.

What Advantages Do 55 Gallon Drums Offer in the Construction Sector?

In the construction sector, 55-gallon drums are often used to store dry materials such as sand, gravel, or cement. The open-head design facilitates easy access, making it simple to scoop or pour out materials as needed. For buyers in South America and Africa, sourcing durable drums that can withstand the rigors of construction sites is crucial. The diameter allows for stacking and efficient use of space, optimizing logistics and storage solutions.

3 Common User Pain Points for ‘diameter of 55 gallon drum’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Drum Size for Specific Applications

The Problem: Many international B2B buyers struggle with selecting the appropriate diameter of a 55-gallon drum that meets their specific needs. For instance, a chemical manufacturer may require a drum that fits certain automated filling machines or that is compatible with their existing storage systems. Choosing the wrong size can lead to inefficiencies, increased costs, and potential safety hazards, particularly when handling hazardous materials.

The Solution: To mitigate this issue, buyers should first assess their operational requirements. It’s essential to measure the dimensions of the existing equipment and storage facilities before making a purchase. Consider utilizing a standardized checklist that includes not only the diameter but also the height and weight capacity of the drums. Engage with suppliers who offer customization options for drum sizes or configurations, particularly those who understand the specific needs of different sectors, such as chemicals, pharmaceuticals, or food processing. Additionally, requesting samples or prototypes for testing compatibility can help ensure the drums will meet operational expectations.

Scenario 2: Challenges with Drum Compatibility and Material Selection

The Problem: B2B buyers often face challenges in selecting the right material for their 55-gallon drums, especially when dealing with a diverse range of products. For example, a company in South America may need to ship both corrosive chemicals and food-grade liquids, requiring different drum materials and diameters. The wrong material can lead to product contamination, leakage, or even regulatory non-compliance.

The Solution: To navigate this complexity, buyers should conduct a thorough compatibility analysis of the materials they plan to store or transport. Start by consulting the Material Safety Data Sheets (MSDS) for each product to determine the appropriate drum material—steel for oils and chemicals, plastic for water-based substances, or fiber for dry goods. Suppliers should provide detailed specifications on their products, including UN ratings for hazardous materials. Furthermore, consider investing in multi-use drums with interchangeable liners for diverse applications, ensuring compliance with local regulations while maximizing efficiency.

Scenario 3: Inefficiencies in Shipping and Storage Due to Drum Dimensions

The Problem: A common pain point for international buyers is the inefficiency in shipping and storage caused by the dimensions of 55-gallon drums. For instance, a business in the Middle East might find that their current drum dimensions do not optimize pallet space, leading to higher shipping costs and wasted storage capacity. This inefficiency can significantly affect profit margins, especially in competitive markets.

The Solution: To address this issue, buyers should consider optimizing their logistics by calculating the best arrangement of drums on pallets. A standard 48” x 48” pallet can typically hold four 55-gallon drums, but variations in drum diameter can affect the stacking and shipping efficiency. Engage with logistics experts to analyze the layout and identify whether an alternative drum size or configuration could provide better space utilization. Additionally, consider investing in collapsible or stackable drum options that maintain the same volume but reduce space when not in use. This strategic approach can lead to significant cost savings in both storage and transportation while ensuring compliance with shipping regulations.

Strategic Material Selection Guide for diameter of 55 gallon drum

What Are the Key Properties of Steel Drums for 55-Gallon Applications?

Steel drums, particularly those made from cold-rolled carbon steel, are renowned for their strength and durability. They typically have a temperature rating that allows them to withstand extreme conditions, making them suitable for a wide range of applications, including hazardous materials. Their corrosion resistance can be enhanced through coatings, which is crucial for maintaining the integrity of the drum when storing chemicals or liquids.

Pros and Cons of Steel Drums

The primary advantage of steel drums is their robustness, which allows for safe transport and storage of a variety of materials. However, they are heavier than their plastic counterparts, which can increase shipping costs. Additionally, the manufacturing process can be complex, leading to higher initial costs.

Impact on Application

Steel drums are ideal for transporting liquids and solids, especially hazardous materials, due to their strength and UN-rated compliance. However, they may not be suitable for corrosive substances unless specifically lined or treated.

Considerations for International Buyers

International buyers should be aware of compliance standards such as ASTM for steel drums. Countries like Germany have stringent regulations regarding the transport of hazardous materials, which may affect the choice of drum.

How Do Plastic Drums Compare in Terms of Performance and Cost?

Plastic drums, particularly those made from high-density polyethylene (HDPE), offer excellent chemical resistance and are lightweight, making them easy to handle. They generally have a lower temperature rating compared to steel but are effective for many applications, especially non-hazardous materials.

Pros and Cons of Plastic Drums

The key advantage of plastic drums is their resistance to corrosion and lower manufacturing costs. However, they may not be suitable for high-temperature applications and can be less durable than steel drums.

Impact on Application

Plastic drums are commonly used for storing chemicals, food products, and liquids that do not require the strength of a steel drum. They are particularly effective for non-corrosive substances.

Considerations for International Buyers

For B2B buyers in Africa and South America, it is important to ensure that the plastic drums meet local food safety regulations, especially if they are used for food storage. Compliance with standards such as FDA and USDA is essential.

What Are the Benefits of Fiber Drums for Specific Applications?

Fiber drums are constructed from layers of kraft paper and offer a lightweight alternative for dry goods. They are generally not suitable for liquids but can handle semi-solid materials effectively.

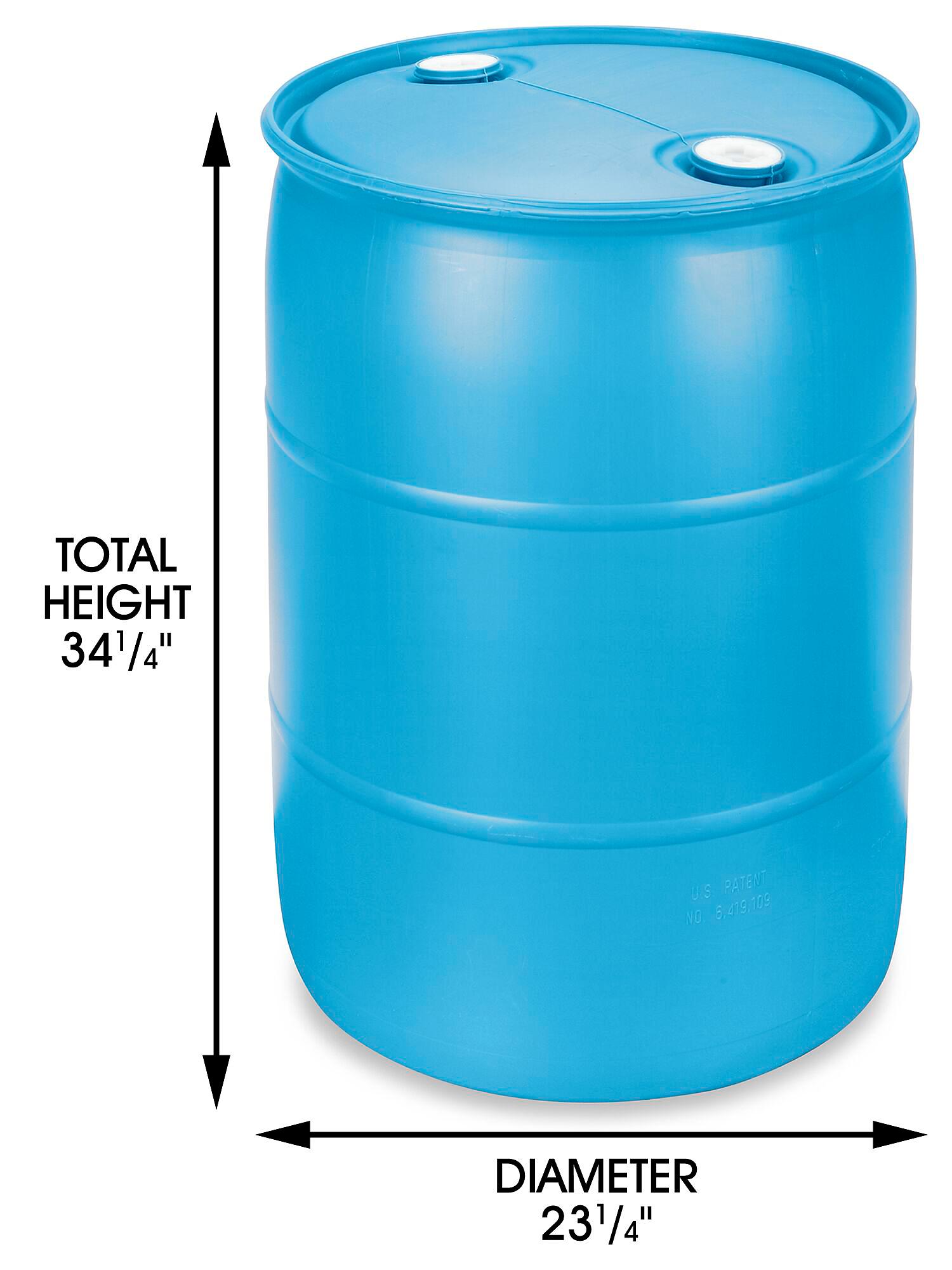

A stock image related to diameter of 55 gallon drum.

Pros and Cons of Fiber Drums

The primary advantage of fiber drums is their lightweight nature, which reduces shipping costs. However, they are less durable than steel or plastic options and can be susceptible to moisture damage.

Impact on Application

Fiber drums are ideal for packaging dry products like powders, grains, and other non-liquid materials. They are not recommended for hazardous materials or liquids.

Considerations for International Buyers

Buyers should check for compliance with international packaging standards, especially if the drums are used for shipping goods across borders. In Europe, adherence to DIN standards may be necessary.

Summary of Material Selection for 55-Gallon Drums

| Material | Typical Use Case for diameter of 55 gallon drum | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Transporting hazardous liquids and solids | High strength and durability | Heavier, higher shipping costs | High |

| Plastic | Storing chemicals and food products | Lightweight and corrosion-resistant | Lower temperature rating, less durable | Medium |

| Fiber | Packaging dry goods and powders | Lightweight, reducing shipping costs | Susceptible to moisture damage | Low |

| Stainless Steel | High-purity products like pharmaceuticals | Excellent corrosion resistance, reusable | Higher cost, limited to specific uses | High |

This guide provides a strategic overview of the materials commonly used for 55-gallon drums, helping international B2B buyers make informed decisions tailored to their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for diameter of 55 gallon drum

What Are the Main Stages in the Manufacturing Process of a 55 Gallon Drum?

The manufacturing process of a 55-gallon drum involves several key stages, each crucial to ensuring the drum’s quality and functionality. Understanding these stages can help B2B buyers make informed decisions when sourcing drums.

How Is Material Prepared for 55 Gallon Drum Production?

The first stage of manufacturing begins with material preparation. The type of drum—steel, plastic, or fiber—determines the initial materials.

- Steel Drums: Cold-rolled steel sheets are sourced, typically low-carbon or stainless steel. These sheets are cut to precise dimensions, ensuring uniformity.

- Plastic Drums: High-density polyethylene (HDPE) is commonly used. The plastic is heated and molded using blow-molding techniques, where air is introduced to shape the material into a drum.

- Fiber Drums: Layers of kraft paper are prepared, which are then rolled and glued to form the drum body.

These materials undergo inspection to ensure they meet required specifications before moving to the next stage.

What Are the Key Techniques Used in Forming 55 Gallon Drums?

After material preparation, the forming stage takes place, which involves shaping the raw materials into the final drum design.

- For Steel Drums: The cut sheets are rolled into cylindrical shapes and welded together. Reinforcing hoops may be added for additional strength. This process ensures the drum can withstand pressure and weight during transport and storage.

- For Plastic Drums: The blow-molding process creates a seamless structure, providing a lightweight yet durable option. The mold is designed to ensure that the final product has the desired diameter and height.

- For Fiber Drums: The rolled paper is formed into a cylinder, and the bottom is attached using adhesive or mechanical fasteners.

How Is the Assembly Process Conducted for 55 Gallon Drums?

The assembly stage involves adding components that define the drum’s functionality.

- Closed-Head Drums: These come with a permanently attached top, featuring threaded closures (plugs or bungs) for filling and emptying. The assembly ensures a secure seal, crucial for transporting hazardous materials.

- Open-Head Drums: These drums have a removable lid, secured by a locking ring. They are easier to access and are suitable for semi-solid materials.

At this stage, quality checks are performed to ensure that all parts fit correctly and function as intended.

What Finishing Techniques Are Used on 55 Gallon Drums?

The final stage of the manufacturing process is finishing, which can include painting, coating, or lining the interior.

- Steel Drums: These are often painted or coated to prevent corrosion, especially if they are to be used for chemicals or other corrosive materials. The interior may be lined with protective coatings to maintain product integrity.

- Plastic Drums: The color is usually molded in, but additional UV-resistant coatings may be applied to enhance durability.

- Fiber Drums: These may have a polyethylene lining to accommodate wet products, ensuring that the contents do not permeate through the walls.

These finishing techniques not only enhance the aesthetic appeal but also ensure the drum’s longevity and safety.

What International Standards Govern Quality Assurance for 55 Gallon Drums?

Quality assurance is critical in the manufacturing of 55-gallon drums, particularly for international B2B buyers. Various standards govern the production process and help ensure the safety and reliability of these containers.

Which International Standards Should B2B Buyers Be Aware Of?

The manufacturing of 55-gallon drums is subject to several international standards:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent product quality. Manufacturers must demonstrate their ability to provide products that meet customer and regulatory requirements.

- CE Marking: This certification indicates that the product meets EU safety, health, and environmental protection standards.

- API Standards: For drums used in the oil and gas industry, API standards provide guidelines for the safe handling of hazardous materials.

Understanding these standards helps B2B buyers assess potential suppliers and ensure compliance with international regulations.

What Are the Key Quality Control Checkpoints During Drum Manufacturing?

Quality control is integrated throughout the manufacturing process, with specific checkpoints to ensure compliance with standards.

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival at the manufacturing facility. Any defective materials are rejected to prevent quality issues later in the process.

- In-Process Quality Control (IPQC): During manufacturing, inspectors monitor the production process to ensure that each stage meets the required specifications. This includes checking dimensions, weights, and materials used.

- Final Quality Control (FQC): After assembly, the finished drums undergo comprehensive testing. This may include pressure testing for leaks, dimensional checks, and evaluations of surface finishes.

These checkpoints are critical for maintaining the integrity of the manufacturing process and ensuring that the final product meets quality standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for mitigating risks associated with procurement.

What Steps Should Buyers Take to Assess Supplier QC?

- Conduct Supplier Audits: Regular audits can help assess whether the supplier adheres to ISO and other relevant standards. This can include reviewing their quality management systems and processes.

- Request Quality Reports: Suppliers should provide documentation detailing their quality control processes, including inspection reports and compliance certifications.

- Engage Third-Party Inspectors: Hiring third-party inspection services can provide an unbiased evaluation of the supplier’s processes and products. This is particularly useful for high-stakes procurement where product integrity is paramount.

By taking these steps, buyers can ensure that they are sourcing from reliable manufacturers who prioritize quality and compliance.

What Nuances Should International B2B Buyers Consider Regarding QC and Certifications?

Navigating the complexities of quality assurance and certifications can be challenging for international buyers.

How Do Regional Regulations Impact Quality Assurance Practices?

Different regions may have varying regulations and standards that impact the manufacturing and quality control of 55-gallon drums.

- Africa: Buyers should be aware of local regulations regarding hazardous materials and ensure that suppliers comply with both local and international standards.

- South America: Understanding the import/export regulations and certifications required for specific materials can help avoid compliance issues.

- Middle East: Given the prevalence of oil and gas industries, API certifications are particularly relevant for buyers in this region.

- Europe: Compliance with CE marking and other EU regulations is crucial, as non-compliance can lead to significant penalties.

By understanding these regional nuances, buyers can make informed decisions and mitigate risks associated with sourcing.

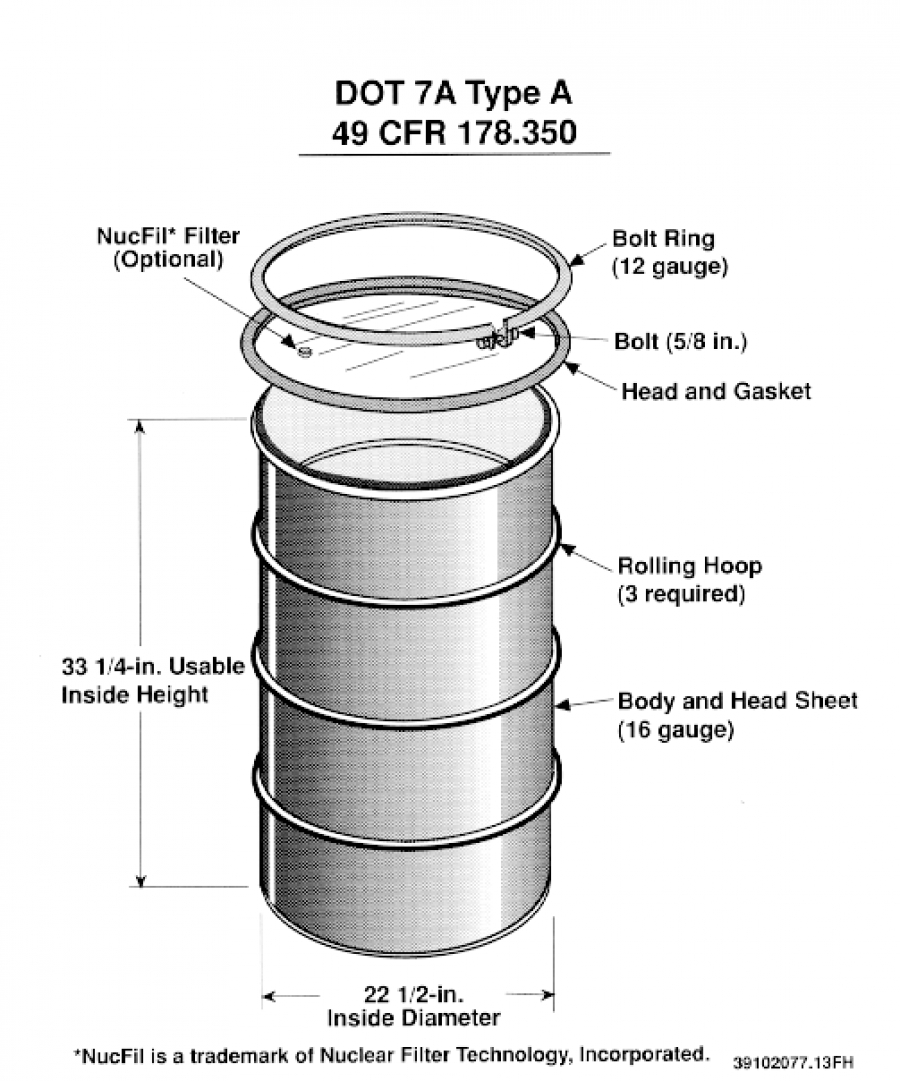

A stock image related to diameter of 55 gallon drum.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices related to 55-gallon drums is essential for international B2B buyers. By focusing on these aspects, buyers can ensure they are sourcing high-quality products that meet their specific needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diameter of 55 gallon drum’

To effectively source the right 55-gallon drum for your needs, especially as an international B2B buyer from regions like Africa, South America, the Middle East, or Europe, following a structured checklist can streamline your procurement process. This guide will help ensure that you make informed decisions tailored to your specific requirements.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the specifications of the 55-gallon drum you require. Consider the material (steel, plastic, or fiber), type (open-head or closed-head), and any specific dimensions, particularly the diameter, which typically ranges from 22-3/8 inches to 24-1/2 inches. Establishing these parameters early on will help you narrow down potential suppliers and avoid costly mistakes.

Step 2: Understand Regulatory Compliance

Ensure that the drums meet international safety and transportation standards, especially if you are dealing with hazardous materials. Look for UN ratings on the drums, which indicate they have passed certain performance tests. This step is crucial for maintaining safety and compliance during shipping and storage.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers before making any commitments. Request detailed company profiles, case studies, and references from buyers in similar industries or regions. Pay attention to their experience with the specific type of drum you need, as this can significantly impact the quality and reliability of the product.

- Check Certifications: Verify that suppliers have the necessary certifications, such as ISO or specific safety certifications relevant to the drum material.

- Assess Production Capacity: Understand the supplier’s ability to meet your order volumes, especially if you anticipate needing large quantities.

Step 4: Request Samples

Before placing a bulk order, request samples of the 55-gallon drums you intend to procure. This allows you to assess the quality, durability, and suitability of the drums for your intended use. Pay attention to the craftsmanship, material integrity, and any specific features that may affect performance.

Step 5: Negotiate Pricing and Terms

Once you have identified potential suppliers and tested samples, engage in negotiations regarding pricing, payment terms, and delivery schedules. Be transparent about your budget constraints and volume needs, as many suppliers may offer discounts for larger orders. It’s essential to establish a clear agreement to avoid misunderstandings later on.

Step 6: Plan for Logistics and Shipping

Consider the logistics of transporting the drums from the supplier to your location. Assess factors such as shipping costs, lead times, and customs regulations that may apply to your region. A well-planned logistics strategy will help minimize delays and ensure that you receive your drums in a timely manner.

Step 7: Establish a Quality Control Process

After receiving your order, implement a quality control process to inspect the drums before they enter service. Check for compliance with your initial specifications, including dimensions and material quality. This step is vital to ensure that you are using safe and effective products in your operations.

By following this checklist, you can enhance your sourcing process for 55-gallon drums, ensuring that you select the right product for your business needs while minimizing risks and maximizing efficiency.

Comprehensive Cost and Pricing Analysis for diameter of 55 gallon drum Sourcing

What Are the Key Cost Components in Sourcing 55 Gallon Drums?

When sourcing 55-gallon drums, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type of drum significantly impacts the material cost. Steel drums are typically more expensive due to the cost of steel, while plastic drums may offer a lower initial price. Fiber drums are generally the most economical option for dry goods.

-

Labor: Labor costs depend on the manufacturing location. Regions with lower labor costs, such as parts of Africa and South America, may offer more competitive pricing. However, ensure that the quality of workmanship aligns with your product requirements.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and maintenance. Efficient manufacturing processes can reduce these overhead costs, which may be reflected in the final price.

-

Tooling: The cost of molds and equipment necessary for drum production can be significant, especially for custom designs. For large orders, suppliers may amortize these costs over the volume, lowering the per-unit price.

-

Quality Control (QC): Ensuring that drums meet specific standards, especially for hazardous materials, requires robust QC measures. The associated costs can vary depending on certification requirements (e.g., UN-rated drums).

-

Logistics: Shipping costs can significantly influence the total price. Factors such as distance, mode of transport, and whether the drums are filled or empty can affect logistics expenses.

-

Margin: Suppliers will incorporate a profit margin that varies based on market conditions and the perceived value of their product. Understanding market dynamics can aid in negotiating better terms.

How Do Price Influencers Affect 55 Gallon Drum Costs?

Several factors can influence the pricing of 55-gallon drums:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk discounts. Understanding the MOQ can help buyers plan their purchases effectively.

-

Specifications and Customization: Custom features, such as specific coatings or sizes, can raise the price. Clearly defining your requirements can help suppliers provide accurate quotes.

-

Material Quality and Certifications: Higher-quality materials and certifications (like FDA approval for food-grade drums) can increase costs. Ensure that your supplier can provide the necessary documentation to justify these higher prices.

-

Supplier Factors: Supplier reputation, reliability, and geographic location can affect pricing. Established suppliers may charge more for their experience and assurance of quality.

-

Incoterms: The terms of shipping and delivery (e.g., FOB, CIF) can affect pricing. Understanding these terms can help you estimate total costs accurately.

What Are the Best Buyer Tips for Negotiating Prices on 55 Gallon Drums?

International B2B buyers can optimize their sourcing strategy by employing several negotiation and cost-efficiency tips:

-

Negotiate Prices: Don’t hesitate to negotiate terms and prices with suppliers. Building a relationship can lead to better deals and terms, especially for repeat purchases.

-

Consider Total Cost of Ownership (TCO): When evaluating drum prices, consider the TCO, which includes purchase price, maintenance, and disposal costs. A lower initial price may not always be the best value if the drum has a shorter lifespan.

-

Be Aware of Pricing Nuances: Prices can vary significantly based on geographic location, currency fluctuations, and economic conditions. For example, drums sourced from Germany may come with higher quality assurance but at a premium price compared to those from Nigeria.

-

Understand Local Regulations: Different regions have varying compliance and safety regulations that can affect pricing. Ensure that your supplier is aware of and compliant with the regulations in your target market.

Disclaimer on Indicative Prices

Prices for 55-gallon drums can vary widely based on the factors outlined above. Therefore, it is essential for buyers to obtain multiple quotes and conduct thorough market research before finalizing any purchase.

Alternatives Analysis: Comparing diameter of 55 gallon drum With Other Solutions

Understanding Alternatives to the Diameter of a 55 Gallon Drum

When considering storage and transportation solutions, the diameter of a 55-gallon drum is a critical factor. However, there are several alternatives that may offer benefits depending on specific use cases and requirements. This analysis will compare the standard 55-gallon drum with alternative storage solutions to help B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Diameter Of 55 Gallon Drum | Alternative 1: Intermediate Bulk Container (IBC) | Alternative 2: 30-Gallon Drum |

|---|---|---|---|

| Performance | High strength and durability, versatile in use | Excellent for larger volumes, easy to stack | Suitable for smaller volumes, easier to handle |

| Cost | Moderate | Higher initial investment but better for bulk | Lower cost compared to 55-gallon drums |

| Ease of Implementation | Standardized size, readily available | Requires forklift for handling, more complex setup | Easy to transport and store, less complicated |

| Maintenance | Low maintenance, reusable | Requires regular cleaning and inspection | Low maintenance, reusable |

| Best Use Case | Bulk liquids and solids | Large-scale operations needing bulk storage | Small to medium operations, limited space |

Detailed Breakdown of Alternatives

What Are Intermediate Bulk Containers (IBCs)?

Intermediate Bulk Containers (IBCs) typically hold 275 to 330 gallons and are designed for the bulk storage and transport of liquids and solids. They are made from high-density polyethylene, often housed in a metal frame for added durability.

Pros: IBCs allow for the storage of larger volumes, which can reduce the frequency of handling and transportation. Their stackable design optimizes space in warehouses and during transport.

Cons: The upfront cost is generally higher than 55-gallon drums, and they require specialized equipment like forklifts for handling. Additionally, they can be more complex to clean and maintain due to their larger size.

What Are 30-Gallon Drums?

30-gallon drums are smaller alternatives to the standard 55-gallon drum, often used in industries that require less bulk storage. They are available in various materials, including steel, plastic, and fiber.

Pros: The smaller size makes them easier to handle, transport, and store, especially in environments with limited space. They are also typically less expensive than their larger counterparts.

Cons: While they are versatile, their smaller volume means that they are less efficient for bulk storage. This can lead to increased handling and shipping costs if used for larger quantities of products.

How Should B2B Buyers Choose the Right Solution?

Selecting the right storage solution involves evaluating specific operational needs, including the type of material being stored, volume requirements, and available handling equipment. For bulk operations where space and volume are not constraints, IBCs may offer a more efficient solution. Conversely, for smaller operations or where space is limited, 30-gallon drums could provide the flexibility and cost-effectiveness required.

Ultimately, understanding the unique advantages and limitations of each option will empower B2B buyers to make informed decisions tailored to their operational strategies.

Essential Technical Properties and Trade Terminology for diameter of 55 gallon drum

What Are the Key Technical Properties of a 55 Gallon Drum Diameter?

Understanding the technical specifications of a 55-gallon drum is essential for B2B buyers who need to ensure that their products are stored and transported safely and efficiently. Here are some critical properties to consider:

1. Material Grade

The most common materials for 55-gallon drums are steel, stainless steel, plastic (HDPE), and fiber. Each material has unique properties affecting durability, resistance to chemicals, and suitability for various applications. For instance, steel drums are ideal for hazardous materials, while HDPE drums are often used for food-grade products. Selecting the appropriate material based on your product’s compatibility is crucial to avoid contamination or degradation.

2. Diameter Tolerance

The standard diameter of a 55-gallon drum ranges from 22-3/8 inches to 24-1/2 inches, depending on the material and design. Tolerance refers to the acceptable range of variation in this measurement. For B2B buyers, understanding diameter tolerance is vital for ensuring that drums fit in designated storage areas and are compatible with existing equipment, such as pumps or filling machines.

3. Weight Capacity

A filled 55-gallon drum can weigh approximately 500 pounds, depending on the density of the contents. Knowing the weight capacity is crucial for logistics, as it affects transportation methods, storage solutions, and handling processes. Buyers should consider the weight of the drum when planning shipments to avoid exceeding weight limits imposed by carriers.

4. UN Rating

A UN rating indicates that a drum meets international standards for transporting hazardous materials. This rating is essential for compliance with safety regulations and can significantly impact shipping costs and logistics. Buyers should confirm that the drums they purchase have the appropriate UN rating for their specific needs, particularly in regions with stringent safety regulations.

5. Head Type: Open vs. Closed

Understanding the difference between open-head and closed-head drums is critical for selecting the appropriate container. Open-head drums allow easy access for filling and dispensing, while closed-head drums are better for low-viscosity liquids. The choice between these types can influence the handling and storage of materials, which is essential for operational efficiency.

What Are Common Trade Terms Related to 55 Gallon Drums?

In the world of B2B transactions, understanding industry jargon can facilitate smoother communication and negotiations. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of 55-gallon drums, an OEM may provide customized solutions tailored to specific client requirements, such as unique sizes or materials.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum quantity that a supplier is willing to sell. Understanding MOQs is vital for buyers, especially in regions where shipping costs can be high. Buyers should evaluate their needs against the MOQ to ensure cost-effectiveness in procurement.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing for specific quantities of products, such as 55-gallon drums. This is a critical step in the procurement process, allowing buyers to compare costs and terms from different suppliers.

4. Incoterms

These are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help B2B buyers understand shipping responsibilities, insurance requirements, and potential liabilities, ensuring clarity in contracts related to drum purchases.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. For buyers, understanding lead times is crucial for inventory management and planning, especially when dealing with international suppliers that may have longer shipping durations.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions regarding the procurement and use of 55-gallon drums, ensuring compliance, efficiency, and cost-effectiveness in their operations.

Navigating Market Dynamics and Sourcing Trends in the diameter of 55 gallon drum Sector

What Are the Key Market Drivers for the 55 Gallon Drum Sector?

The global market for 55-gallon drums is shaped by several critical drivers. One significant factor is the increasing demand for bulk storage solutions across various industries, including chemicals, food and beverage, and pharmaceuticals. The drum’s versatility in storing liquids, solids, and powders makes it an essential item for businesses looking to optimize their storage and transportation processes. Additionally, the rise in international trade, particularly from regions like Africa and South America, has amplified the need for durable and reliable packaging solutions. Emerging technologies such as IoT-enabled tracking systems are enhancing the logistics of drum management, providing buyers with real-time data to optimize supply chains.

Moreover, sustainability is becoming a pivotal trend in sourcing practices. As businesses strive to minimize their environmental impact, there is a growing demand for drums made from recyclable materials and those that comply with environmental regulations. In Europe and the Middle East, regulatory pressures are driving companies to adopt more sustainable practices, influencing their sourcing decisions. International buyers must stay informed about these trends to select suppliers that align with their operational goals and corporate social responsibility (CSR) commitments.

How Can International Buyers Ensure Sustainability and Ethical Sourcing in Their 55 Gallon Drum Purchases?

Sustainability and ethical sourcing are increasingly essential considerations for B2B buyers in the 55-gallon drum sector. The environmental impact of manufacturing and disposing of these drums is significant, making it crucial for buyers to prioritize eco-friendly options. Drums made from recycled materials or those that can be reused multiple times help reduce waste and lower carbon footprints. Buyers should look for suppliers that provide certifications such as ISO 14001, which indicates a commitment to environmental management.

In addition, ethical supply chains are vital for maintaining brand integrity and consumer trust. International buyers should seek manufacturers who adhere to fair labor practices and have transparent sourcing processes. Certifications like Fair Trade or those demonstrating compliance with local labor laws can serve as indicators of a supplier’s commitment to ethical practices. By prioritizing suppliers that focus on sustainability and ethical sourcing, businesses can not only enhance their brand reputation but also contribute to a more sustainable future.

What Is the Evolution of the 55 Gallon Drum and Its Importance in Today’s Market?

A stock image related to diameter of 55 gallon drum.

The 55-gallon drum has a rich history that dates back to the early 20th century when it was standardized for mass production. Originally crafted from wood, the transition to steel and later plastic marked a significant evolution in its design and functionality. The standardization of the 55-gallon drum was driven by the need for efficient shipping and storage solutions during the industrial boom, particularly for oil and chemical products.

Today, the 55-gallon drum remains a cornerstone in various industries due to its durability, versatility, and ease of handling. Its design has adapted to meet the needs of modern logistics, including variations like open-head and closed-head configurations tailored for specific applications. Understanding the historical context of the 55-gallon drum can help international B2B buyers appreciate its enduring significance and make informed purchasing decisions that align with their operational requirements and sustainability goals.

Conclusion

Navigating the market dynamics and sourcing trends in the 55-gallon drum sector requires international buyers to stay informed about evolving trends and sustainability practices. By understanding the key drivers of the market, prioritizing ethical sourcing, and recognizing the drum’s historical significance, businesses can make strategic decisions that enhance their operational efficiency and support their sustainability objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of diameter of 55 gallon drum

-

How do I determine the diameter of a 55-gallon drum for my product?

To determine the appropriate diameter for a 55-gallon drum, consider the material and the type of product you plan to store or transport. Steel drums typically have a diameter of 22-3/8 to 24-1/2 inches, while plastic and fiber drums may vary slightly. It’s essential to consult the manufacturer’s specifications to ensure compatibility with your product, especially if you’re shipping hazardous materials that may require UN-rated containers. Accurate measurements are crucial for maximizing storage efficiency and ensuring safe handling. -

What is the best type of 55-gallon drum for hazardous materials?

For hazardous materials, a UN-rated closed-head steel drum is often the best choice. These drums are designed to securely contain low-viscosity liquids, preventing leaks and spills during transport. Ensure that the drum meets specific UN standards for the type of material you intend to ship. Consult with suppliers to verify that the drum’s dimensions and materials align with the safety requirements of your product, especially when shipping internationally to regions like Africa and South America. -

What customization options are available for 55-gallon drums?

Customization options for 55-gallon drums include material choice (steel, plastic, fiber), color, and interior lining. Some suppliers offer drums with specific coatings to enhance chemical resistance or comply with food-grade standards. If your business requires unique dimensions or features, such as additional bungs or vent holes, discuss these needs with your supplier. Customization can improve product safety and compliance, especially in diverse markets across Europe and the Middle East. -

How do I verify the reliability of a supplier for 55-gallon drums?

To verify a supplier’s reliability, conduct thorough research by checking their certifications, client testimonials, and industry experience. Look for suppliers who have established quality management systems, such as ISO certification, to ensure they meet international standards. Request samples of their products and inquire about their production processes. Additionally, engaging with other businesses in your region can provide insights into their experiences, particularly for B2B buyers in Nigeria or Germany who may have specific regional considerations. -

What are the minimum order quantities (MOQs) for 55-gallon drums?

Minimum order quantities for 55-gallon drums can vary significantly based on the supplier and the type of drum. Typically, MOQs range from 50 to several hundred units, particularly for custom orders. It’s beneficial to discuss your needs with potential suppliers, as some may offer flexibility for smaller orders, especially for first-time buyers. Understanding MOQs is crucial for budgeting and planning logistics, especially for international shipments where freight costs can be substantial. -

What payment terms should I expect when purchasing 55-gallon drums internationally?

Payment terms for international purchases of 55-gallon drums can vary, but common options include upfront payment, letter of credit, or net payment terms (e.g., 30 or 60 days). Ensure you clarify payment methods with your supplier before finalizing the order. It’s also wise to consider currency exchange rates and transaction fees that may impact your overall costs. Establishing clear payment terms helps prevent misunderstandings and facilitates smoother transactions, especially when dealing with suppliers in different regions. -

How can I ensure the quality of 55-gallon drums I purchase?

To ensure the quality of your purchased 55-gallon drums, request certifications that demonstrate compliance with industry standards, such as UN ratings for hazardous materials. Conduct quality checks upon receipt, including inspecting for leaks, structural integrity, and appropriate labeling. Partnering with reputable suppliers who offer guarantees or warranties can also provide peace of mind. Regular communication with your supplier about quality expectations and any issues encountered can foster a long-term, reliable relationship. -

What logistical considerations should I keep in mind when shipping 55-gallon drums internationally?

When shipping 55-gallon drums internationally, consider factors such as compliance with local regulations, shipping methods, and costs. Ensure that the drums are properly packed and secured to prevent damage during transit. Understanding the import/export regulations in both your country and the destination country is crucial, especially for hazardous materials. Collaborate with logistics providers experienced in international shipping to navigate customs requirements effectively, ensuring a smooth delivery process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for diameter of 55 gallon drum

Why Is Strategic Sourcing Important for 55 Gallon Drums?

In the competitive landscape of international trade, understanding the specifications and strategic sourcing of 55-gallon drums is essential for effective supply chain management. The diameter and material of these drums directly influence their capacity, shipping efficiency, and compatibility with various products. By leveraging strategic sourcing, buyers can ensure they select the right drum type—be it steel, plastic, or fiber—that meets their specific needs while optimizing costs.

How Can B2B Buyers Optimize Their Procurement Process?

B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, must focus on the full lifecycle of the 55-gallon drum. This includes not only initial procurement but also considerations for reuse, recycling, and compliance with international standards. By establishing strong relationships with reliable suppliers, businesses can mitigate risks and enhance their operational efficiency.

What’s Next for International B2B Buyers?

As the global demand for reliable and versatile packaging solutions continues to grow, international buyers should proactively evaluate their sourcing strategies for 55-gallon drums. Engaging with suppliers who prioritize quality, compliance, and sustainability will be key to staying competitive. Now is the time to take action—review your current sourcing practices and explore new partnerships to ensure your business remains agile and prepared for future challenges.