Your Ultimate Guide to Sourcing Used Cnc Milling Machine

Introduction: Navigating the Global Market for used cnc milling machine

Navigating the global market for used CNC milling machines is essential for businesses aiming to enhance their manufacturing capabilities while managing costs effectively. In today’s competitive landscape, the demand for precision engineering and efficient production processes is paramount. Used CNC milling machines offer an attractive solution for international B2B buyers, enabling them to access advanced technology at a fraction of the cost of new equipment. This guide is designed to empower buyers from diverse regions, including Africa, South America, the Middle East, and Europe, to make informed sourcing decisions that align with their operational needs.

This comprehensive resource covers a wide array of topics pertinent to the acquisition of used CNC milling machines. Buyers will gain insights into different types of machines, the materials they can process, and the manufacturing and quality control standards that should be considered. Additionally, we will explore reputable suppliers, provide a breakdown of cost considerations, and analyze the current market trends affecting availability and pricing.

Our goal is to equip you with the knowledge necessary to navigate the complexities of purchasing used CNC milling machines, ensuring that you can optimize your production efficiency while minimizing investment risks. Whether you are in Egypt looking for specific capabilities or in France seeking competitive pricing, this guide will serve as a valuable tool in your sourcing strategy.

Understanding used cnc milling machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vertical CNC Milling | Spindle mounted vertically; ideal for drilling and face milling. | Aerospace, automotive components. | Pros: Space-efficient, versatile. Cons: Limited depth for large parts. |

| Horizontal CNC Milling | Spindle mounted horizontally; capable of handling larger workpieces. | Heavy machining, mold making. | Pros: Greater cutting efficiency, better chip removal. Cons: Requires more floor space. |

| CNC Bed Mill | Large work surface with a fixed bed; suitable for heavy-duty machining. | Large parts manufacturing, prototyping. | Pros: High stability, ideal for heavy materials. Cons: Slower operation, higher initial cost. |

| 5-Axis CNC Milling | Ability to move the tool and workpiece on five axes simultaneously. | Complex geometries in aerospace, medical devices. | Pros: High precision, reduced setup times. Cons: More expensive, requires skilled operators. |

| CNC Router | Specializes in cutting softer materials; often used for engraving. | Sign making, woodworking, plastics. | Pros: Cost-effective for soft materials, easy to use. Cons: Limited to softer materials, less robust for heavy-duty tasks. |

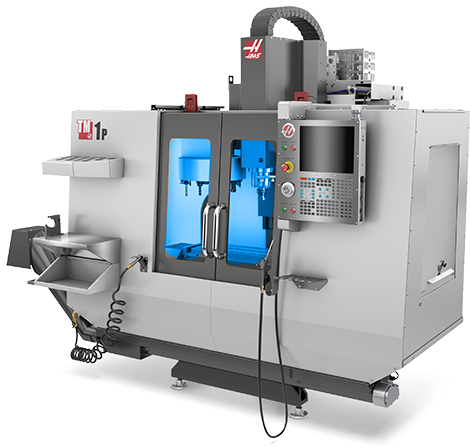

Vertical CNC Milling

Vertical CNC milling machines feature a spindle that is oriented vertically, allowing for a wide range of operations such as drilling, tapping, and face milling. They are particularly suited for smaller workpieces and intricate designs, making them popular in industries like aerospace and automotive. When purchasing, buyers should consider the machine’s spindle speed, tooling options, and overall footprint, as these factors can significantly impact operational efficiency and space utilization.

Horizontal CNC Milling

Horizontal CNC milling machines are designed with a spindle that is aligned horizontally, providing a robust platform for machining larger and heavier workpieces. This type is ideal for applications requiring high material removal rates, such as mold making and heavy machining. Buyers should evaluate the machine’s cutting capabilities, tool change systems, and maintenance requirements to ensure optimal performance for their specific needs.

CNC Bed Mill

CNC bed mills offer a large work surface and a fixed bed, making them suitable for heavy-duty machining tasks. They are particularly effective for manufacturing large parts or prototypes, providing excellent stability and precision. When considering a bed mill, buyers should assess the machine’s rigidity, feed rates, and compatibility with various materials to ensure it meets their operational demands and production goals.

5-Axis CNC Milling

5-axis CNC milling machines are advanced tools that can manipulate the cutting tool and workpiece across five axes simultaneously. This capability allows for the creation of complex geometries often required in aerospace and medical device manufacturing. Buyers should focus on the machine’s accuracy, software compatibility, and operator training requirements, as these factors are crucial for maximizing productivity and minimizing errors in high-precision applications.

CNC Router

CNC routers are specialized milling machines designed primarily for cutting softer materials like wood, plastics, and composites. They are commonly used in sign making and woodworking industries due to their cost-effectiveness and ease of use. For B2B buyers, it is essential to consider the router’s cutting speed, material compatibility, and software options to ensure it aligns with their production capabilities and desired outcomes.

Related Video: Don’t Buy a Used CNC Machine Until You Watch This

Key Industrial Applications of used cnc milling machine

| Industry/Sector | Specific Application of used CNC Milling Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Component Manufacturing | High precision and reduced waste | Certification of machine; compatibility with materials |

| Automotive | Prototype Development | Faster turnaround times and cost-effective scaling | Proven track record in automotive applications |

| Medical Devices | Custom Part Production | Enhanced customization for patient-specific needs | Compliance with health regulations; precision capabilities |

| Electronics | PCB and Enclosure Fabrication | Improved accuracy and reduced assembly time | Machine’s capability to handle small tolerances |

| Construction & Heavy Machinery | Tooling and Equipment Parts Manufacturing | Increased durability and reliability of tools | Heavy-duty construction standards; service availability |

Aerospace Industry

In the aerospace sector, used CNC milling machines are essential for manufacturing complex components such as turbine blades and structural parts. These machines provide the high precision required to meet stringent safety and performance standards, significantly reducing material waste. For international buyers, particularly from regions like Europe and the Middle East, sourcing machines with appropriate certifications and a proven history in aerospace applications is crucial. Additionally, compatibility with various aerospace-grade materials should be a key consideration.

Automotive Industry

Used CNC milling machines are widely utilized in the automotive industry for prototype development and production of intricate components like engine blocks and transmission housings. The ability to quickly produce high-quality prototypes can dramatically shorten development cycles and reduce costs. Buyers from South America and Africa should focus on sourcing machines that have demonstrated reliability in automotive applications, ensuring they can handle the rigorous demands of mass production while maintaining precision.

Medical Devices

In the medical device industry, used CNC milling machines are employed to create custom parts such as surgical instruments and implants. The ability to produce highly customized components tailored to individual patient needs is a significant advantage. Buyers must ensure that the machines comply with health regulations and possess the precision necessary for such sensitive applications. This is particularly important for buyers in Africa and Europe, where regulatory compliance can vary significantly.

Electronics Sector

In the electronics industry, used CNC milling machines are crucial for fabricating printed circuit boards (PCBs) and enclosures. The precision and speed of these machines help reduce assembly times and improve product reliability. International buyers should consider the machine’s ability to handle small tolerances and intricate designs, which are often required in electronics manufacturing. Additionally, sourcing from reputable suppliers with experience in electronics applications can ensure quality and reliability.

Construction & Heavy Machinery

In the construction and heavy machinery sector, used CNC milling machines are used for manufacturing tooling and equipment parts. These machines enhance the durability and reliability of tools, essential for demanding construction environments. Buyers should prioritize machines that meet heavy-duty construction standards and have a robust service network for maintenance and support. This is particularly important for buyers in Africa and the Middle East, where machinery uptime can significantly impact project timelines.

Related Video: How milling on a 4-axis CNC machine works

Strategic Material Selection Guide for used cnc milling machine

When selecting materials for used CNC milling machines, international B2B buyers must consider various factors that influence both performance and compatibility with specific applications. Below is an analysis of four common materials used in CNC milling, along with their properties, pros and cons, and considerations for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

Aluminum Alloys

Key Properties: Aluminum alloys are lightweight yet strong, offering excellent machinability and corrosion resistance. They typically have a temperature rating of up to 600°F (316°C), making them suitable for a variety of applications.

Pros & Cons: The primary advantage of aluminum alloys is their low weight, which can enhance the speed and efficiency of machining processes. However, they can be more expensive than some steel options and may not withstand high-stress applications as well.

Impact on Application: Aluminum is compatible with various media, including water and oil, making it ideal for automotive and aerospace components. Its corrosion resistance is particularly beneficial in humid environments.

Considerations for Buyers: Buyers should ensure compliance with regional standards such as ASTM and DIN for quality assurance. In regions like Europe, where environmental regulations are stringent, opting for aluminum can align with sustainability goals.

Stainless Steel

Key Properties: Stainless steel is known for its high corrosion resistance and strength, with temperature ratings often exceeding 1500°F (815°C). It is durable and maintains its properties under various environmental conditions.

Pros & Cons: The durability of stainless steel makes it suitable for demanding applications, such as medical devices and food processing. However, it is heavier and more challenging to machine, which can increase manufacturing costs and complexity.

Impact on Application: Stainless steel’s compatibility with aggressive media, including acids and bases, makes it ideal for chemical processing applications. Its hygienic properties are essential in food and pharmaceutical industries.

Considerations for Buyers: Buyers in regions like the Middle East, where high temperatures can impact material performance, should prioritize high-grade stainless steel. Compliance with international standards like JIS is crucial for ensuring product quality.

Carbon Steel

Key Properties: Carbon steel is a versatile material with a high strength-to-weight ratio. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications.

Pros & Cons: Carbon steel is relatively low-cost and easy to machine, making it a popular choice for many industries. However, it is prone to rust and corrosion if not properly treated, which can limit its use in certain environments.

Impact on Application: This material is widely used in manufacturing components that do not require high corrosion resistance, such as structural parts and tooling. It is compatible with various media but may require protective coatings in corrosive environments.

Considerations for Buyers: Buyers from South America should be aware of local corrosion challenges and may need to invest in protective coatings. Understanding regional compliance standards is also essential for ensuring the longevity of the material.

Titanium Alloys

Key Properties: Titanium alloys are known for their exceptional strength-to-weight ratio and high corrosion resistance. They can perform well at elevated temperatures, making them suitable for aerospace and medical applications.

Pros & Cons: The main advantage of titanium is its strength and lightweight nature, which is ideal for high-performance applications. However, it is one of the more expensive materials and can be difficult to machine, leading to higher manufacturing costs.

Impact on Application: Titanium’s compatibility with aggressive chemicals and high-temperature environments makes it ideal for aerospace and biomedical applications. Its biocompatibility is crucial for medical implants.

Considerations for Buyers: Buyers in Europe, particularly in the aerospace sector, should ensure compliance with stringent aerospace standards. The high cost may necessitate a thorough cost-benefit analysis before procurement.

Summary Table

| Material | Typical Use Case for used cnc milling machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Automotive and aerospace components | Lightweight and corrosion-resistant | Higher cost than some steels | Medium |

| Stainless Steel | Medical devices and food processing | High corrosion resistance | Difficult to machine | High |

| Carbon Steel | Structural parts and tooling | Low cost and easy to machine | Prone to rust and corrosion | Low |

| Titanium Alloys | Aerospace and biomedical applications | Exceptional strength-to-weight ratio | Expensive and hard to machine | High |

This guide serves as a strategic material selection framework for international B2B buyers, helping them make informed decisions based on the unique requirements of their applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for used cnc milling machine

The manufacturing and quality assurance processes for used CNC milling machines are critical factors for international B2B buyers. Understanding these processes helps buyers make informed decisions, ensuring they acquire machinery that meets their operational needs and quality expectations. Here, we delve into the key stages of manufacturing, quality control standards, and actionable insights for buyers.

Manufacturing Processes

1. Material Preparation

The initial stage involves selecting the right materials, often steel, aluminum, or composites, depending on the machine’s intended use. Suppliers typically conduct a thorough assessment of material properties, including hardness, tensile strength, and corrosion resistance. Buyers should inquire about the source of the materials and whether they comply with international standards.

Key Techniques:

– Cutting and Machining: Precision cutting tools are used to shape the raw materials into components of the CNC machine.

– Heat Treatment: This process enhances the mechanical properties of materials, improving durability and performance.

2. Forming

In this stage, components are shaped into their final forms. This can involve various methods, such as casting, forging, or machining. Each method has its advantages and implications for quality.

Key Techniques:

– CNC Machining: Utilizes computer-controlled machines to achieve high precision in forming components.

– Welding: Often used for assembling larger structures and ensuring the integrity of joints.

3. Assembly

Once the components are formed, they are assembled into the complete CNC milling machine. This stage requires skilled technicians to ensure that all parts fit and function correctly.

Key Techniques:

– Precision Alignment: Ensures that all moving parts are correctly aligned to avoid operational issues.

– Integration of Electronics: Installing control systems, sensors, and drives, which are crucial for the machine’s functionality.

4. Finishing

The final stage focuses on surface treatments and coatings to enhance aesthetics and protect against wear and corrosion.

Key Techniques:

– Painting and Coating: Provides a protective layer and can improve appearance.

– Polishing: Enhances surface finish for better performance and visual appeal.

Quality Assurance

Quality assurance is vital for ensuring that used CNC milling machines meet both regulatory and customer expectations. Buyers should be aware of the standards and practices in place to ensure quality.

Illustrative Image (Source: Google Search)

International Standards:

– ISO 9001: This widely recognized standard focuses on quality management systems, ensuring that manufacturers have consistent quality processes.

– CE Marking: Indicates that the machine complies with European health, safety, and environmental protection standards.

Industry-Specific Standards:

– API (American Petroleum Institute): Relevant for machines used in oil and gas industries, ensuring they meet specific operational standards.

Quality Control Checkpoints:

– Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to catch defects early.

– Final Quality Control (FQC): Comprehensive testing of the final product to ensure it meets all standards before shipment.

Common Testing Methods

Several testing methods are employed to verify the quality of used CNC milling machines:

- Dimensional Inspection: Ensures that all components meet specified dimensions using tools like calipers and gauges.

- Functional Testing: Verifies that the machine operates according to its specifications under real-world conditions.

- Non-Destructive Testing (NDT): Methods such as ultrasonic or magnetic particle testing are used to detect internal flaws without damaging the components.

Verifying Supplier Quality Control

International B2B buyers must take proactive steps to verify the quality control measures of their suppliers:

- Supplier Audits: Conducting on-site audits can provide valuable insights into the supplier’s quality management processes and facilities.

- Quality Reports: Requesting detailed quality assurance reports can help buyers assess the consistency and reliability of the supplier’s quality processes.

- Third-Party Inspections: Engaging independent inspection agencies to evaluate the machinery can provide an unbiased assessment of quality.

Quality Control Nuances for International Buyers

For buyers from Africa, South America, the Middle East, and Europe, understanding regional nuances in quality assurance is crucial:

- Regulatory Variations: Different regions have varying regulations regarding machinery safety and quality. Familiarizing oneself with local regulations can prevent compliance issues.

- Logistical Considerations: Transportation conditions can affect the quality of used machinery. Ensuring that suppliers have robust packaging and shipping protocols can mitigate risks.

- Cultural Aspects: Understanding cultural business practices can enhance communication and negotiation with suppliers, leading to better quality outcomes.

Conclusion

For international B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, a thorough understanding of the manufacturing processes and quality assurance protocols for used CNC milling machines is essential. By focusing on the manufacturing stages, familiarizing themselves with international quality standards, and actively verifying supplier quality, buyers can ensure they make informed purchasing decisions that align with their operational needs and quality expectations.

Related Video: The World’s Largest Bevel Gear CNC Machine- Modern Gear Production Line. Steel Wheel Manufacturing

Comprehensive Cost and Pricing Analysis for used cnc milling machine Sourcing

When sourcing used CNC milling machines, a thorough understanding of the cost structure and pricing dynamics is crucial for international buyers. This analysis delves into the various cost components and price influencers that can significantly impact the sourcing process, particularly for businesses in Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The condition and type of materials used in the machine’s construction play a pivotal role in determining its price. Used machines may have varying degrees of wear, which can affect the material integrity and longevity.

-

Labor: The labor cost associated with refurbishing, testing, and shipping used CNC milling machines can vary widely depending on the region. In countries with higher labor costs, like those in Western Europe, prices may reflect this additional expense.

-

Manufacturing Overhead: This includes costs related to the production facilities, utilities, and administrative expenses incurred by the seller. Overhead can vary based on the supplier’s location and operational efficiency.

-

Tooling: Often, used machines come with or require specific tooling. The availability and cost of these tools can influence the overall price. Buyers should consider whether the necessary tooling is included in the price or if it needs to be sourced separately.

-

Quality Control (QC): Ensuring that a used CNC milling machine meets quality standards requires investment in quality control processes. Machines with documented QC certifications may command higher prices due to the assurance of their operational reliability.

-

Logistics: Shipping costs can vary significantly based on the origin and destination of the machine. International buyers must consider import duties, taxes, and freight charges, which can all contribute to the total cost.

-

Margin: Suppliers typically include a profit margin in their pricing, which can fluctuate based on demand, competition, and market conditions. Understanding the market landscape can help buyers negotiate better deals.

Price Influencers

Several factors can influence the pricing of used CNC milling machines:

-

Volume/MOQ: Suppliers often provide discounts for bulk purchases. Buyers should evaluate their production needs to negotiate favorable terms based on minimum order quantities (MOQs).

-

Specifications/Customization: Customized machines or those with specific features may come at a premium. Buyers should clearly define their requirements to avoid unnecessary costs.

-

Quality and Certifications: Machines that come with certifications (e.g., ISO standards) or a proven track record may be priced higher due to their perceived reliability and performance.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers may charge more for their products due to their brand value and service guarantees.

-

Incoterms: The terms of shipping and delivery (Incoterms) can significantly impact the overall cost. Buyers should understand these terms to avoid unexpected charges and to clarify responsibilities for shipping risks.

Buyer Tips

-

Negotiation: Effective negotiation can lead to significant cost savings. Buyers should be prepared to discuss terms, explore alternative offers, and leverage competing suppliers to secure the best deal.

-

Cost-Efficiency: Assessing the total cost of ownership (TCO) is essential. This includes not only the initial purchase price but also operational costs, maintenance, and potential downtime.

-

Pricing Nuances: International buyers should be aware of regional pricing variations. For instance, machines sourced from Europe may include higher shipping costs but could offer superior quality and compliance with international standards.

-

Market Research: Conducting thorough market research can provide insights into current pricing trends and help buyers make informed decisions. Understanding local market conditions in regions like Egypt or France can also aid in effective negotiations.

Disclaimer

Prices for used CNC milling machines are indicative and can vary based on numerous factors including market conditions, machine condition, and geographical location. Buyers are encouraged to conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential used cnc milling machine Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘used cnc milling machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for used cnc milling machine

When considering the purchase of a used CNC milling machine, understanding its technical properties and the associated trade terminology is crucial for making informed decisions. Below are essential specifications and terms that every international B2B buyer should be familiar with.

Critical Specifications

-

Material Grade

– Definition: This refers to the type and quality of materials used in the construction of the CNC milling machine, such as cast iron or steel.

– B2B Importance: The material grade affects the machine’s durability, stability, and overall performance. Buyers should ensure that the material meets their specific operational needs, especially in demanding environments. -

Tolerance

– Definition: Tolerance indicates the permissible limit of variation in a physical dimension, essential for precision machining.

– B2B Importance: High precision is often a key requirement in manufacturing. Understanding the tolerance levels of a CNC milling machine helps buyers evaluate if it can meet their production standards, especially in sectors like aerospace or automotive. -

Spindle Speed

– Definition: This is the maximum speed at which the spindle can rotate, typically measured in revolutions per minute (RPM).

– B2B Importance: Higher spindle speeds can improve productivity and allow for faster cutting. Buyers should assess their production needs and ensure the machine’s spindle speed aligns with their operational requirements. -

Axis Configuration

– Definition: This refers to the number of axes the machine operates on, commonly 3-axis, 4-axis, or 5-axis configurations.

– B2B Importance: The axis configuration determines the complexity of parts that can be machined. For businesses needing to produce intricate components, understanding this specification is vital for ensuring the machine can handle their specific applications. -

Feed Rate

– Definition: The feed rate is the speed at which the cutting tool is fed into the workpiece, usually measured in inches per minute (IPM).

– B2B Importance: An optimal feed rate enhances machining efficiency and can affect the surface finish of the workpiece. Buyers should match the feed rate capabilities of the machine with their production processes.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM implications can help buyers source parts more effectively and assess the reliability of the machine based on the reputation of the OEM. -

MOQ (Minimum Order Quantity)

– Definition: This is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is essential for budget planning and inventory management. It can also affect negotiations, especially for bulk purchases. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and availability for specific products.

– Importance: An RFQ helps buyers gather competitive pricing and terms from various suppliers, enabling informed decision-making. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law.

– Importance: Familiarity with Incoterms is crucial for understanding shipping responsibilities, costs, and risk management in international transactions. -

Reconditioning

– Definition: The process of restoring a used CNC machine to a condition that meets or exceeds its original specifications.

– Importance: Buyers should inquire about any reconditioning processes performed on the machine, as this can significantly impact its performance and lifespan.

By understanding these technical specifications and industry terms, international B2B buyers can navigate the complexities of purchasing a used CNC milling machine, ensuring they choose the right equipment for their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the used cnc milling machine Sector

Market Overview & Key Trends

The used CNC milling machine market is witnessing significant transformation, driven by several global factors. Firstly, the increasing demand for precision manufacturing across various sectors, including aerospace, automotive, and electronics, is propelling the growth of this market. International B2B buyers are prioritizing advanced technology and efficiency, leading to a surge in the acquisition of pre-owned CNC machines that can offer high performance at a lower cost.

Current trends indicate a shift towards digitalization in the sourcing process. Platforms that provide comprehensive data on machine specifications, condition, and historical performance are gaining traction. Additionally, the rise of Industry 4.0 has prompted companies to seek machines that are compatible with IoT technologies, enhancing operational efficiency and data analytics capabilities. Buyers from Africa, South America, the Middle East, and Europe should focus on suppliers who offer not only quality machines but also robust support for integration with modern manufacturing processes.

Emerging markets are also influencing sourcing dynamics. In regions like Africa and South America, local manufacturers are increasingly looking to upgrade their machinery to remain competitive. This creates opportunities for exporters of used CNC machines to these regions, but it requires an understanding of local regulations, import duties, and market demands. Meanwhile, European buyers are often concerned with compliance and the quality assurance of second-hand machines, making it essential to choose reputable suppliers with transparent histories.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal concern for B2B buyers in the used CNC milling machine sector. The environmental impact of manufacturing processes and the lifecycle of machinery is under scrutiny, prompting companies to adopt more sustainable practices. Buyers should consider the carbon footprint associated with the production and transportation of machines, as well as the energy efficiency of the equipment itself.

Ethical sourcing is equally important. Companies are increasingly aware of the need for transparent supply chains that uphold ethical standards. This includes ensuring that machines are sourced from manufacturers who adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management can serve as indicators of a supplier’s commitment to sustainability.

Furthermore, buyers should explore options for ‘green’ materials and technologies in the machines they procure. This may include machines that are designed for energy efficiency, or those that incorporate recyclable materials. By prioritizing sustainability and ethical sourcing, B2B buyers not only enhance their corporate responsibility but also appeal to a growing base of environmentally conscious consumers.

Brief Evolution/History

The evolution of CNC milling machines can be traced back to the early 1950s, with the advent of numerical control technology. Initially, these machines were primarily utilized in large-scale industrial applications. However, as technology advanced, CNC milling machines became more accessible and versatile, leading to their widespread adoption across various manufacturing sectors.

In recent years, the market for used CNC milling machines has gained momentum, driven by the need for cost-effective solutions in an increasingly competitive landscape. The transition from traditional to CNC technology has paved the way for the refurbishment and resale of older models, allowing businesses to leverage advanced manufacturing capabilities without the prohibitive costs associated with new machinery. This trend is particularly prominent among international B2B buyers looking to enhance productivity while managing capital expenditures effectively.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of used cnc milling machine

-

How do I vet suppliers of used CNC milling machines?

Vetting suppliers is crucial to ensuring quality and reliability. Start by researching their reputation through online reviews and industry forums. Request references from past clients, and verify their business credentials, such as registration and financial stability. Utilize platforms like Alibaba or ThomasNet that provide ratings and reviews. Additionally, consider visiting the supplier’s facility or using third-party inspection services to assess the machines’ condition before purchase. -

Can I customize a used CNC milling machine to meet my specific needs?

Many suppliers offer customization options for used CNC milling machines. Discuss your specific requirements directly with the supplier, including modifications to software, tooling, and machine configurations. Ensure that the supplier has experience with such customizations and can provide documentation of previous projects. However, be mindful that extensive customization may lead to longer lead times and increased costs. -

What are the typical minimum order quantities (MOQ) and lead times for used CNC milling machines?

MOQs for used CNC milling machines can vary significantly based on the supplier and machine condition. Some suppliers may not have a minimum order requirement, while others might require purchasing multiple units. Lead times typically range from a few weeks to several months, influenced by machine availability and required refurbishments. Always confirm these details upfront to align your production schedule accordingly.

Illustrative Image (Source: Google Search)

-

What quality assurance certifications should I look for when buying used CNC milling machines?

Quality assurance certifications are vital indicators of machine reliability and performance. Look for suppliers that provide ISO certifications, CE markings, or other relevant industry standards. These certifications assure that the machines meet safety and quality benchmarks. Additionally, request detailed maintenance records and inspection reports to verify the machine’s condition and history. -

How can I ensure smooth logistics for importing used CNC milling machines?

Logistics can be complex when importing used machinery. Work with suppliers who have experience in international shipping and can provide assistance with customs clearance. Choose a reliable freight forwarder to handle transportation, and ensure they are familiar with the regulations of your country. It’s also essential to factor in shipping insurance to protect your investment during transit. -

What should I do if there is a dispute with the supplier after purchasing a used CNC milling machine?

In the event of a dispute, first, communicate directly with the supplier to resolve any issues amicably. Maintain a record of all correspondence and agreements. If the matter remains unresolved, refer to any contracts or terms of sale that outline dispute resolution procedures. Consider mediation or arbitration as alternatives to litigation, which can be costly and time-consuming. -

Are there specific payment terms I should negotiate with suppliers?

Payment terms can vary widely among suppliers. Standard practices include a deposit upfront, followed by the balance upon delivery or after inspection. Negotiate terms that offer security, such as using an escrow service to hold funds until you receive and inspect the machine. Ensure that all payment conditions are clearly documented to avoid misunderstandings later. -

How do I assess the total cost of ownership for a used CNC milling machine?

The total cost of ownership includes not only the initial purchase price but also maintenance, operational costs, and potential downtime. Factor in expenses such as tooling, software upgrades, and training for operators. Research the machine’s energy consumption and any anticipated repair costs. A thorough assessment will help you make an informed decision that aligns with your budget and operational needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for used cnc milling machine

In summary, strategic sourcing of used CNC milling machines offers significant advantages for international B2B buyers, especially in emerging markets like Africa and South America, as well as established regions such as Europe and the Middle East. Key takeaways include understanding the importance of supplier relationships, evaluating the total cost of ownership, and leveraging market insights to negotiate favorable terms.

Buyers should focus on quality assurance and after-sales support, ensuring that the machinery not only meets production needs but also adheres to safety and regulatory standards in their respective regions. Furthermore, staying informed about technological advancements and market trends will empower buyers to make data-driven decisions that enhance operational efficiency.

Looking ahead, the demand for used CNC milling machines is set to grow as industries seek cost-effective solutions without compromising on quality. Buyers are encouraged to proactively engage with suppliers, participate in industry events, and utilize digital platforms to broaden their sourcing options. By embracing a strategic approach, B2B buyers can capitalize on the opportunities presented by the global marketplace, driving their businesses forward in an increasingly competitive landscape.