Top 6 Acp Panel Manufacturers,Aluminium Composite Panel List and Guide: …

Introduction: Navigating the Global Market for acp panel manufacturers,aluminium composite panel

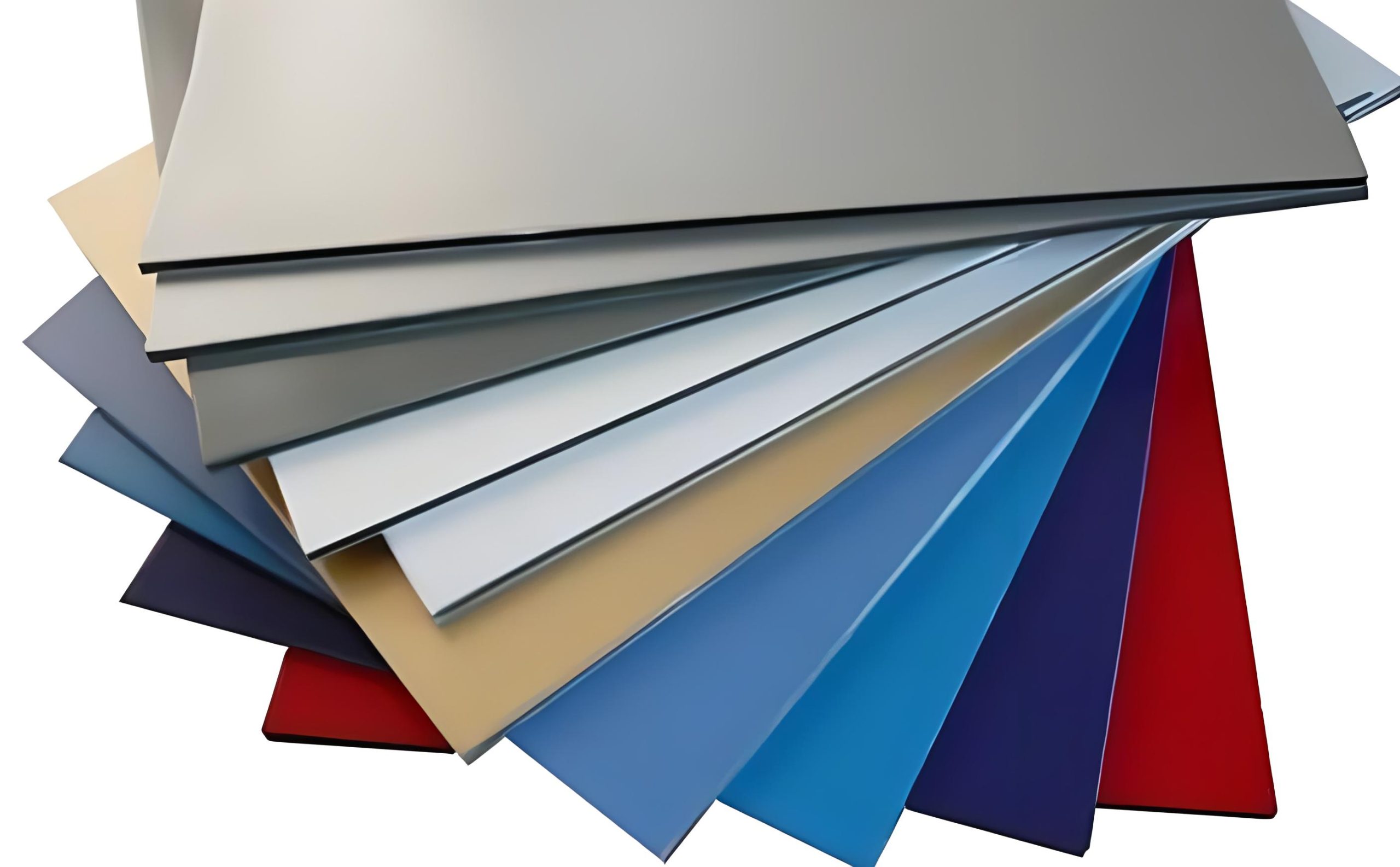

In the competitive landscape of construction and design, sourcing high-quality aluminum composite panels (ACP) is a critical challenge for international B2B buyers. With applications ranging from modern architectural facades to vibrant signage, the demand for reliable ACP panel manufacturers is on the rise. This guide offers a comprehensive overview of the global market for ACP manufacturers, detailing various types of panels, their applications, and essential criteria for supplier vetting.

Navigating the complexities of international trade can be daunting, especially for buyers in regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Germany. Understanding the nuances of product specifications, quality certifications, and pricing structures is paramount for making informed purchasing decisions.

This guide empowers B2B buyers by providing actionable insights into the ACP market, enabling them to identify reputable manufacturers, assess product quality, and negotiate competitive pricing. With a focus on critical factors such as durability, environmental compliance, and customization options, this resource serves as a valuable tool for businesses seeking to enhance their procurement strategies and optimize project outcomes. By leveraging the information presented, buyers can confidently navigate the global market, ensuring they select the best aluminum composite panels that meet their specific needs and standards.

Top 10 Acp Panel Manufacturers,Aluminium Composite Panel Manufacturers & Suppliers List

1. Alutec – Aluminium Composite Panels

2. Vanco Panel – Aluminium Composite Panels

Domain: vancopanel.com

Registered: 2008 (17 years)

Introduction: Aluminium Composite Panel (ACP) products including: Fire-rated Aluminium Composite Panel, PVDF Aluminium Composite Panel, PE Aluminium Composite Panel, Brush Aluminium Composite Panel, Wooden Aluminium Composite Panel, Marble Aluminium Composite Panel, Metal Composite Panel, Billboard Aluminium Coil. Quality warranty of 10-20 years, ISO production & management system, SGS, Cisro, Exova, and Intert…

3. Yaret – Aluminum Composite Panels

Domain: yaretacp.com

Registered: 2024 (1 years)

Introduction: Yaret specializes in the research, development, production, and sales of aluminum composite panels, solid aluminum panels, aluminum honeycomb panels, and colored aluminum coils. They offer customized solutions for various projects and have over 25 years of experience in the industry. Yaret’s products include:

– Aluminum Composite Panel

– Colored Aluminum Coil

– Solid Aluminum Panel

– Aluminum Hone…

4. MakerStock – Aluminum Composite Panels

Domain: makerstock.com

Registered: 2012 (13 years)

Introduction: Aluminum Composite Panels (ACP) – White

Price: $6.25 for 1/8″ / 3mm / 12″ x 12″; $9.45 for 1/8″ / 3mm / 12″ x 20″; $10.45 for 1/8″ / 3mm / 12″ x 24″; $15.75 for 1/8″ / 3mm / 18″ x 24″; $20.25 for 1/8″ / 3mm / 24″ x 24″; $29.75 for 1/8″ / 3mm / 24″ x 36″; $8.45 for 1/4″ / 6mm / 12″ x 12″; $13.95 for 1/4″ / 6mm / 12″ x 20″; $15.95 for 1/4″ / 6mm / 12″ x 24″; $23.45 for 1/4″ / 6mm / 18″ x 24″; $30.95…

5. Wenzhou Jixiang – Aluminum Composite Panels

Domain: alusignpanel.com

Registered: 2013 (12 years)

Introduction: Aluminum Composite Panel (ACP) products offered by Wenzhou Jixiang include: PVDF Aluminum Composite Panel, PE (polyester) Aluminum Composite Panel, A2 FR Aluminum Composite Panel, FEVE Aluminum Composite Panel, PVDF Nano Aluminum Composite Panel, Fireproof (FR) Aluminum Composite Panel, Timber & Stone Aluminum Composite Panel, Brushed Aluminum Composite Panel, Mirror Aluminum Composite Panel, A2 F…

6. Nglantz – Aluminum Composite Panels

Understanding acp panel manufacturers,aluminium composite panel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PE Coated Aluminum Composite Panel | Lightweight, cost-effective, and easy to fabricate. | Signage, interior applications | Pros: Affordable, good for temporary use. Cons: Less durable than PVDF panels. |

| PVDF Coated Aluminum Composite Panel | High resistance to weathering and UV rays, durable finish. | Exterior cladding, architectural facades | Pros: Long-lasting, maintains color integrity. Cons: Higher cost than PE panels. |

| Brushed Aluminum Composite Panel | Unique aesthetic with a metallic finish, often anodized. | High-end commercial spaces, decorative applications | Pros: Visually appealing, good for branding. Cons: More expensive, requires careful handling. |

| High Gloss Aluminum Composite Panel | Reflective surface, vibrant colors, and modern look. | Retail environments, high-visibility signage | Pros: Eye-catching, enhances brand visibility. Cons: Prone to scratches, may require maintenance. |

| Fire-Retardant Aluminum Composite Panel | Composed of non-combustible materials, meets safety standards. | High-rise buildings, public infrastructure | Pros: Enhanced safety, compliance with regulations. Cons: Typically higher cost and weight. |

What are the Characteristics and Suitability of PE Coated Aluminum Composite Panels?

PE Coated Aluminum Composite Panels are known for their lightweight and cost-effective nature, making them an ideal choice for businesses looking for budget-friendly solutions. These panels are primarily used in signage and interior applications where durability is less of a concern. When purchasing, buyers should consider the panel’s longevity in relation to its intended use, as these panels are more suited for temporary displays than long-term installations.

Why Choose PVDF Coated Aluminum Composite Panels for Exterior Applications?

PVDF Coated Aluminum Composite Panels are designed for high durability and excellent resistance to weathering and UV rays. They are commonly used for exterior cladding and architectural facades, making them perfect for buildings exposed to harsh environmental conditions. Buyers should weigh the initial investment against the long-term benefits of reduced maintenance and replacement costs, as these panels offer superior longevity compared to their PE counterparts.

What Makes Brushed Aluminum Composite Panels a Popular Choice for Commercial Spaces?

Brushed Aluminum Composite Panels provide a unique aesthetic appeal with their metallic finish, often enhanced by anodization. This quality makes them particularly popular in high-end commercial spaces and decorative applications where appearance is paramount. When considering these panels, buyers should take into account the handling and installation requirements, as they can be more prone to damage and require careful treatment.

How Do High Gloss Aluminum Composite Panels Enhance Brand Visibility?

High Gloss Aluminum Composite Panels are characterized by their reflective surfaces and vibrant colors, making them highly effective for retail environments and high-visibility signage. These panels can significantly enhance brand visibility and attract customers. However, buyers should be aware of their susceptibility to scratches and the potential need for regular maintenance to keep the panels looking pristine.

What are the Benefits of Using Fire-Retardant Aluminum Composite Panels in Construction?

Fire-Retardant Aluminum Composite Panels are specifically engineered with non-combustible materials to meet stringent safety standards, making them essential for high-rise buildings and public infrastructure projects. While they may come at a higher cost and weight, their enhanced safety features are invaluable for compliance with fire regulations. Buyers should prioritize these panels in applications where safety is a critical concern, balancing the upfront costs with the potential for risk mitigation.

Key Industrial Applications of acp panel manufacturers,aluminium composite panel

| Industry/Sector | Specific Application of acp panel manufacturers,aluminium composite panel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Facade cladding for commercial buildings | Enhances aesthetic appeal and provides weather resistance | Certification standards (ISO, CE), thickness, and finishes |

| Signage & Advertising | Digital printing for promotional signage | Lightweight, durable, and excellent for outdoor advertising | Print compatibility, color options, and UV resistance |

| Interior Design | Wall panels for commercial interiors | Offers modern aesthetics while being easy to maintain | Fire ratings, surface finishes, and customization options |

| Automotive | Lightweight body panels for vehicles | Reduces overall weight, improving fuel efficiency | Material specifications, compliance with safety regulations |

| Retail | Point-of-purchase displays and shelving | Increases product visibility and enhances brand image | Custom sizes, ease of installation, and durability |

How Are Aluminium Composite Panels Used in Construction and Architecture?

Aluminium composite panels (ACP) are extensively used in the construction and architecture sectors for facade cladding. Their lightweight nature, combined with excellent durability and weather resistance, makes them an ideal choice for both new builds and refurbishments. International buyers, particularly in regions like Africa and the Middle East, should consider local climate conditions when sourcing ACP, ensuring that the panels meet specific certifications for fire safety and environmental standards.

What Role Do ACP Panels Play in Signage and Advertising?

In the signage and advertising industry, ACP panels are favored for their ability to facilitate high-quality digital printing. They are lightweight and durable, making them suitable for both indoor and outdoor promotional displays. Businesses in South America and Europe should focus on sourcing panels that offer UV resistance and compatibility with various printing methods to ensure longevity and vibrant colors in their signage.

Why Are ACP Panels Important in Interior Design?

In interior design, ACP panels serve as stylish wall coverings that enhance the visual appeal of commercial spaces. They are easy to maintain and can be customized in terms of color and finish, which is crucial for businesses looking to create a unique atmosphere. When sourcing for interior applications, buyers should prioritize fire ratings and surface finishes that align with their design goals and local regulations.

How Do ACP Panels Benefit the Automotive Industry?

The automotive industry utilizes ACP panels for lightweight body construction, contributing to improved fuel efficiency without compromising structural integrity. This application is particularly relevant for manufacturers aiming to meet stringent environmental standards. Buyers in this sector should ensure that the materials comply with safety regulations and specific performance criteria, such as impact resistance and corrosion resistance.

What Advantages Do ACP Panels Offer in Retail Settings?

In retail environments, ACP panels are used for point-of-purchase displays and shelving, enhancing product visibility and customer engagement. Their lightweight yet sturdy design allows for easy installation and reconfiguration, which is essential for dynamic retail layouts. Businesses should consider customization options and the ease of installation when sourcing ACP for retail applications to maximize their marketing effectiveness.

3 Common User Pain Points for ‘acp panel manufacturers,aluminium composite panel’ & Their Solutions

Scenario 1: Navigating Quality Assurance in ACP Sourcing

The Problem: B2B buyers often face the challenge of ensuring the quality and compliance of aluminum composite panels (ACP) sourced from manufacturers, especially those in international markets. Inconsistent quality can lead to project delays, increased costs, and potential safety hazards, which can be particularly concerning in regions with stringent building regulations, such as Germany or the Middle East. Moreover, many manufacturers may not provide transparent information regarding certifications and quality management systems, making it difficult for buyers to assess reliability.

The Solution: To mitigate these risks, buyers should prioritize manufacturers that have internationally recognized certifications such as ISO 9001 or CE markings. Conducting thorough due diligence by requesting documentation of these certifications can help ensure that the ACPs meet the necessary quality and safety standards. Additionally, establishing a relationship with suppliers who are willing to provide samples for testing before large-scale purchases is vital. This proactive approach allows buyers to assess the material’s performance in real-world applications, ensuring it meets their project requirements. Engaging with local representatives or agents familiar with the market can also provide insights into reliable suppliers.

Scenario 2: Understanding Customization Options for ACP Panels

The Problem: Many buyers, especially those in niche markets like signage or architectural design, often struggle with the limitations of standard ACP offerings. They may require specific colors, finishes, or dimensions that are not readily available in off-the-shelf products. This can lead to frustration and delays in project timelines, as they might have to compromise on design or seek alternative materials.

The Solution: To address this issue, B2B buyers should engage directly with manufacturers to discuss their specific needs for customization. Many reputable ACP manufacturers offer bespoke solutions, including a variety of finishes (such as brushed or high gloss) and custom sizes. Establishing clear communication about design requirements and project timelines can ensure that the manufacturer understands the urgency and importance of these specifications. Additionally, requesting a prototype or mock-up can provide valuable insights into how the customized panel will perform and fit within the overall project context.

Scenario 3: Managing Supply Chain and Logistics Challenges

The Problem: Sourcing ACP panels from international manufacturers can present significant supply chain and logistics challenges, including lengthy lead times, unpredictable shipping costs, and potential delays at customs. For B2B buyers in regions such as Africa or South America, these issues can compound, leading to extended project timelines and budget overruns, which can affect client satisfaction and profitability.

The Solution: To streamline the logistics process, buyers should work closely with manufacturers that have a proven track record of efficient supply chain management. Establishing clear timelines and understanding the manufacturer’s shipping capabilities can help set realistic expectations. Additionally, considering manufacturers with local warehouses or distribution centers can significantly reduce lead times and shipping costs. Utilizing a freight forwarder who specializes in international shipping can also help navigate customs regulations and ensure timely delivery. Finally, maintaining regular communication with the manufacturer throughout the shipping process can help address any potential issues before they escalate, ensuring a smoother experience overall.

Strategic Material Selection Guide for acp panel manufacturers,aluminium composite panel

What Are the Common Materials Used in ACP Panel Manufacturing?

Aluminum Composite Panels (ACP) are popular in various industries due to their unique properties and versatility. The selection of materials used in ACP manufacturing significantly influences product performance, durability, and suitability for specific applications. Below, we analyze four common materials used in ACP production from a B2B perspective.

1. Polyethylene Core

Key Properties:

Polyethylene (PE) cores are lightweight and provide excellent thermal insulation. They typically have a temperature rating of up to 80°C and are resistant to moisture and chemicals.

Pros & Cons:

The primary advantage of PE is its cost-effectiveness, making it an attractive option for projects with budget constraints. However, PE cores may not offer the same level of fire resistance as other materials, which can limit their use in high-risk applications.

Impact on Application:

PE cores are compatible with various printing methods, including digital and screen printing, making them suitable for signage and advertising applications. However, they may not be ideal for environments requiring stringent fire safety standards.

Considerations for International Buyers:

When sourcing PE core ACPs, international buyers must ensure compliance with local fire safety regulations, especially in regions like Europe, where standards such as EN 13501 are critical.

2. Fire-Retardant Core

Key Properties:

Fire-retardant cores are designed to resist ignition and slow the spread of flames. They typically have a temperature rating of up to 120°C and exhibit enhanced fire resistance.

Pros & Cons:

The main advantage of fire-retardant cores is their ability to meet stringent fire safety regulations, making them suitable for high-rise buildings and public spaces. However, these materials are generally more expensive and may require more complex manufacturing processes.

Impact on Application:

Fire-retardant ACPs are ideal for applications in commercial and residential buildings where safety is paramount. They are compatible with various finishes and can be used in both interior and exterior settings.

Considerations for International Buyers:

Buyers from regions with strict fire safety codes, such as Germany, should prioritize fire-retardant cores and verify compliance with standards like DIN 4102.

3. Aluminum Skin

Key Properties:

Aluminum skins provide excellent durability and corrosion resistance, with a thickness typically ranging from 0.5mm to 1.5mm. They can withstand harsh weather conditions and have a high strength-to-weight ratio.

Pros & Cons:

The durability of aluminum skins makes them suitable for a wide range of applications, from architectural facades to interior design. However, the cost of high-quality aluminum can be significant, impacting overall project budgets.

Impact on Application:

Aluminum skins are highly compatible with various coatings, allowing for a range of aesthetic finishes. They are ideal for applications requiring both visual appeal and structural integrity.

Considerations for International Buyers:

B2B buyers should ensure that the aluminum used complies with international standards such as ASTM B209 for aluminum sheet and plate, especially when sourcing from different countries.

4. PVDF Coating

Key Properties:

Polyvinylidene fluoride (PVDF) coatings provide exceptional weather resistance and color retention, withstanding UV radiation and extreme temperatures.

Pros & Cons:

The main advantage of PVDF coatings is their long-lasting finish and minimal maintenance requirements, making them ideal for exterior applications. However, the application process can be more complex and costly compared to standard coatings.

Impact on Application:

PVDF-coated ACPs are particularly suited for architectural applications, providing an attractive and durable finish that can enhance building aesthetics.

Considerations for International Buyers:

Buyers should verify that PVDF coatings meet local environmental regulations, particularly in regions like Europe where VOC emissions are strictly regulated.

Summary Table of Material Selection for ACP Panel Manufacturers

| Material | Typical Use Case for ACP Panel Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene Core | Signage, POP displays | Cost-effective | Limited fire resistance | Low |

| Fire-Retardant Core | High-rise buildings, public spaces | Meets stringent fire safety standards | Higher cost and manufacturing complexity | High |

| Aluminum Skin | Architectural facades, interior design | Excellent durability and corrosion resistance | Higher material cost | Medium |

| PVDF Coating | Exterior building applications | Long-lasting finish and low maintenance | Complex application process | High |

This guide provides a comprehensive overview of the materials commonly used in ACP manufacturing, helping international B2B buyers make informed decisions based on their specific project requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for acp panel manufacturers,aluminium composite panel

What Are the Main Stages in the Manufacturing Process of Aluminum Composite Panels (ACP)?

The manufacturing process of aluminum composite panels (ACP) involves several critical stages, each designed to ensure the final product meets the stringent quality and performance standards expected by B2B buyers.

Material Preparation

The first stage involves the careful selection and preparation of raw materials. ACPs typically consist of two thin layers of aluminum enclosing a non-aluminum core, often made from polyethylene or fire-resistant materials. The aluminum sheets are sourced from reputable suppliers, ensuring they meet specific alloy standards, such as 1100 or 3003. Prior to processing, materials undergo a thorough inspection to check for defects, ensuring only the highest quality materials proceed to the next stage.

Forming

Once materials are prepared, they are subjected to forming processes. This includes cutting the aluminum sheets to the required dimensions and applying any necessary surface treatments. Techniques such as anodizing or painting enhance the aluminum’s resistance to corrosion and improve aesthetic appeal. Advanced forming technologies, such as CNC machining, ensure precision cuts and shapes, allowing for customized designs that meet specific project requirements.

Assembly

In the assembly stage, the aluminum sheets are bonded to the core material using high-strength adhesives. This is a crucial step, as the bond strength affects the panel’s durability and performance. Manufacturers may utilize techniques like extrusion or laminating to ensure a uniform and robust bond. The assembly process is closely monitored to ensure alignment and adhesion quality.

Finishing

The finishing stage involves applying protective coatings and conducting final quality checks. Coatings can include PVDF (polyvinylidene fluoride) or polyester finishes that enhance durability and aesthetics. Additionally, panels undergo surface cleaning and inspection for any defects, ensuring that the final product is visually appealing and free from imperfections.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance is paramount in ACP manufacturing, as it directly impacts product performance and longevity. International standards such as ISO 9001 provide a framework for consistent quality management systems. Additionally, ACP manufacturers may need to comply with specific certifications relevant to their target markets, such as CE certification for the European Union or local standards that may apply in regions like Africa or South America.

Key Quality Control Checkpoints

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure adherence to quality standards. Common checkpoints include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival at the manufacturing facility. It ensures that all materials meet specified standards before they enter the production line.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor the quality of the product at various stages. This includes checking for dimensional accuracy, bond strength, and surface quality.

-

Final Quality Control (FQC): At this stage, finished panels undergo a comprehensive inspection. This includes tests for physical properties, surface defects, and overall performance characteristics, ensuring that the panels meet all specified standards before shipment.

Which Testing Methods Are Commonly Used in ACP Manufacturing?

B2B buyers should be aware of the common testing methods employed to assess the quality of ACPs. These may include:

-

Adhesion Tests: Assess the strength of the bond between the aluminum sheets and the core material.

-

Weather Resistance Tests: Evaluate the panel’s performance against environmental factors, such as UV exposure and temperature variations.

-

Fire Resistance Tests: For panels designed for use in high-risk environments, fire resistance tests ensure compliance with safety standards.

-

Impact Resistance Tests: Measure the durability of panels under physical stress, ensuring they can withstand typical handling and installation conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is crucial. Here are several actionable steps:

-

Request Documentation: Suppliers should provide detailed quality assurance documentation, including certifications, testing reports, and compliance with international standards.

-

Conduct Audits: Engaging in regular audits of suppliers can help ensure adherence to quality standards. This may involve on-site visits to assess manufacturing processes and QC practices directly.

-

Third-Party Inspections: Utilizing third-party inspection services can provide an unbiased assessment of product quality. These services can conduct tests and inspections, offering an additional layer of assurance.

-

Review Feedback and References: Investigating previous projects and customer testimonials can provide insights into the supplier’s reliability and quality performance.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various quality control nuances when sourcing ACPs. Differences in regional standards and regulations can affect product quality and compliance. For instance, European buyers may prioritize CE certification, while those in Africa or South America might focus on local certifications that ensure adherence to regional building codes.

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Establishing clear communication channels and expectations upfront can help mitigate potential misunderstandings.

Conclusion

Understanding the manufacturing processes and quality assurance practices of aluminum composite panel manufacturers is essential for B2B buyers. By focusing on key stages of production, quality control standards, and verification methods, buyers can make informed decisions that align with their project requirements and ensure the procurement of high-quality ACP products. This diligence not only fosters strong supplier relationships but also contributes to the success of construction and architectural projects globally.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘acp panel manufacturers,aluminium composite panel’

Introduction

This guide serves as a practical sourcing checklist for B2B buyers looking to procure aluminum composite panels (ACP) from manufacturers. The aim is to streamline the purchasing process by providing actionable steps that ensure you select the right supplier for your specific needs. By following this checklist, you can mitigate risks, enhance product quality, and ensure a successful procurement experience.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial before initiating contact with suppliers. This includes determining the desired thickness, dimensions, color options, and core material (e.g., polyethylene or mineral-filled). Having precise specifications will help you communicate effectively with manufacturers and receive accurate quotes.

- Key Considerations:

- Identify the intended use (e.g., signage, building facades).

- Determine performance requirements, such as fire resistance and weatherproofing.

Step 2: Research Potential Manufacturers

Conduct thorough research on various manufacturers specializing in ACP. Look for companies with a solid reputation in the industry, positive customer reviews, and a proven track record of quality. This initial research will help you compile a list of potential suppliers who meet your criteria.

- Where to Look:

- Industry-specific directories and trade shows.

- Online platforms that feature manufacturer ratings and reviews.

Step 3: Verify Supplier Certifications

Before making any commitments, it’s essential to verify the certifications and standards that suppliers adhere to. Look for ISO certifications, CE marking, and any relevant local regulations that ensure the quality and safety of the products.

- Why This Matters:

- Certifications indicate a manufacturer’s commitment to quality and compliance.

- They can help you avoid potential legal issues related to product safety.

Step 4: Request Samples for Evaluation

Always request product samples before finalizing your order. Evaluating physical samples allows you to assess the material’s quality, finish, and suitability for your project. It’s also an opportunity to test the manufacturer’s responsiveness and customer service.

- What to Test:

- Surface finish and color consistency.

- Durability and resistance to various environmental factors.

Step 5: Compare Pricing and Payment Terms

Once you have shortlisted potential suppliers, compare their pricing structures and payment terms. Ensure that the quoted prices reflect the quality and specifications you require. Be cautious of unusually low prices that may indicate compromised quality.

- Considerations:

- Look for transparency in pricing, including shipping and handling costs.

- Assess payment terms that suit your cash flow and risk tolerance.

Step 6: Evaluate Lead Times and Delivery Options

Understanding lead times is vital for planning your project timeline. Discuss delivery options with potential suppliers to ensure they can meet your deadlines. Confirm whether they have the capability for both standard and expedited shipping if needed.

- Important Questions:

- What are the typical production lead times?

- Are there options for tracking shipments?

Step 7: Establish Communication and Support Channels

Finally, ensure that you establish clear communication channels with your chosen supplier. Good communication is key to addressing any concerns that may arise during the procurement process. Verify their support structure for post-purchase inquiries or issues.

- What to Confirm:

- Availability of dedicated account representatives.

- Responsiveness to queries and support during the project.

By following these steps, you can effectively navigate the sourcing process for aluminum composite panels, ensuring you select a reliable manufacturer that meets your needs.

Comprehensive Cost and Pricing Analysis for acp panel manufacturers,aluminium composite panel Sourcing

What Are the Key Cost Components in ACP Manufacturing?

Understanding the cost structure of aluminum composite panel (ACP) manufacturing is crucial for B2B buyers seeking to optimize their procurement strategies. The main cost components include:

-

Materials: The primary input is the aluminum sheets and the core material, typically polyethylene. The price of aluminum fluctuates based on global market trends, which can significantly affect overall costs. High-quality materials can also come at a premium, particularly those with additional certifications for durability and environmental standards.

-

Labor: Labor costs encompass wages for skilled workers involved in the manufacturing process. This includes machine operators, quality control staff, and assembly workers. In regions with higher labor costs, such as parts of Europe, total costs may increase accordingly.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. High overhead can arise from inefficient processes or older machinery. Manufacturers often seek to optimize these costs through automation and improved production techniques.

-

Tooling: Initial investment in tooling for custom designs can be significant. The costs vary depending on the complexity of the tooling needed for specific panel specifications.

-

Quality Control (QC): Ensuring product quality is vital. Effective QC processes can incur additional costs, but they ultimately save money by reducing defects and returns.

-

Logistics: Shipping costs can vary dramatically based on the distance to the buyer, shipping methods, and the volume of the order. Incoterms also play a vital role in determining who bears these costs.

-

Margin: Manufacturers typically mark up their prices to ensure profitability, which can vary based on market conditions, competition, and perceived value.

How Do Price Influencers Affect ACP Panel Sourcing?

Several factors influence the pricing of ACP panels that buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often come with discounted pricing. Understanding a manufacturer’s MOQ can help buyers negotiate better terms.

-

Specifications and Customization: Custom sizes, colors, and finishes will typically increase costs. Buyers should clearly define their requirements to get accurate quotes.

-

Material Quality and Certifications: Panels that meet specific certifications (like ISO, CE) may have higher prices due to the costs associated with maintaining these standards.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established manufacturers may charge more due to their proven track record and quality assurance processes.

-

Incoterms: Understanding shipping terms can help buyers manage additional costs effectively. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can influence the total landed cost of goods.

What Are the Best Tips for Buyers to Ensure Cost Efficiency?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Pricing: Don’t hesitate to negotiate prices, especially when placing large orders or forming long-term partnerships. Many suppliers are willing to adjust pricing to secure consistent business.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with installation, maintenance, and durability. Higher quality panels may have a higher upfront cost but can result in lower TCO due to their longevity.

-

Understand Pricing Nuances: Be aware of regional pricing differences. For instance, suppliers in Europe may have higher prices due to stricter regulations and labor costs, while manufacturers in Asia may offer lower prices but require careful consideration of shipping and import duties.

-

Request Samples: Before placing large orders, request samples to assess quality and suitability. This can prevent costly mistakes later.

-

Stay Informed About Market Trends: Regularly monitor market trends in aluminum pricing and manufacturing costs. This knowledge can give buyers leverage in negotiations and help them make informed purchasing decisions.

Disclaimer on Pricing

Prices for aluminum composite panels can vary widely based on the aforementioned factors and are subject to change. Buyers should always request current quotes and be aware that indicative prices may not reflect final costs due to fluctuations in materials, shipping, and other variables.

Alternatives Analysis: Comparing acp panel manufacturers,aluminium composite panel With Other Solutions

When considering the best materials for construction and design projects, B2B buyers often explore various alternatives to aluminum composite panels (ACP). These alternatives may offer different advantages depending on the specific needs of a project, such as aesthetic appeal, structural integrity, and cost-effectiveness. Below, we will compare ACP panels with two viable alternatives: solid aluminum panels and glass panels.

| Comparison Aspect | Acp Panel Manufacturers, Aluminium Composite Panel | Solid Aluminum Panels | Glass Panels |

|---|---|---|---|

| Performance | Lightweight, durable, and weather-resistant | High strength, corrosion-resistant | High transparency and aesthetic appeal |

| Cost | Generally cost-effective for large projects | Higher initial investment | High cost, especially for installation |

| Ease of Implementation | Easy to cut and install; minimal specialized tools needed | Requires more robust tools and skilled labor | Complex installation; requires framing |

| Maintenance | Low maintenance; resistant to fading and weather damage | Low maintenance; durable | Requires regular cleaning; can chip or break |

| Best Use Case | Signage, cladding, interior and exterior applications | Facades, structural components | Windows, curtain walls, and decorative elements |

What Are the Advantages and Disadvantages of Solid Aluminum Panels?

Solid aluminum panels are known for their strength and durability. They provide excellent resistance to environmental factors, making them suitable for a variety of applications, including facades and structural elements. However, they tend to be heavier than ACP panels, which can increase transportation and installation costs. Solid aluminum also requires specialized tools for cutting and shaping, which may complicate the installation process.

How Do Glass Panels Compare to ACP Panels?

Glass panels offer unmatched aesthetic appeal and are often used in modern architectural designs to create transparent facades. Their ability to allow natural light into spaces is a significant advantage. However, glass panels come with higher costs due to material and installation requirements. Additionally, they require more maintenance to keep them clean and free from damage, as they can chip or break more easily than aluminum composites.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting the appropriate material for a project, B2B buyers should consider various factors including performance, cost, ease of installation, maintenance requirements, and the intended use case. Aluminum composite panels offer a balanced solution with good performance and cost-effectiveness, particularly for signage and cladding applications. However, if a project demands higher aesthetic value or structural integrity, solid aluminum or glass panels may be more suitable despite their higher costs and installation complexities. Ultimately, understanding the specific requirements of each project will help buyers make informed decisions that align with their business goals.

Essential Technical Properties and Trade Terminology for acp panel manufacturers,aluminium composite panel

What Are the Key Technical Properties of Aluminium Composite Panels (ACP)?

Aluminium Composite Panels (ACP) are favored in various industries for their unique combination of properties. Understanding these specifications is crucial for B2B buyers, as they directly influence product performance, cost, and suitability for specific applications.

-

Material Grade

The material grade of an ACP typically refers to the type of aluminum used in its construction. Common grades include 1100 and 3003, with 1100 being the most common for its excellent corrosion resistance and lightweight properties. This specification is vital for buyers seeking durability and performance, especially in harsh environmental conditions. -

Thickness Tolerance

ACP panels generally come in various thicknesses, with common nominal values being 3mm and 6mm. The thickness tolerance, often specified as +/-0.2mm, indicates the allowable variation in panel thickness. This is significant for manufacturers and builders, as it affects the panel’s structural integrity and the ease of installation. -

Density

The density of ACP, often around 0.84 lbs/ft², indicates the weight of the panel relative to its size. A lower density means easier handling and installation, making ACP a preferred choice for large-scale projects. Buyers should consider density in relation to the project’s structural requirements and logistical constraints. -

Surface Finish

The surface finish of ACP can vary from PVDF (Polyvinylidene Fluoride) to polyester coatings. Each finish offers different aesthetics and durability levels. For example, PVDF-coated panels provide superior UV resistance and longevity, making them ideal for outdoor applications. Understanding these finishes helps buyers select the right product for their specific aesthetic and functional needs. -

Fire Rating

Many ACPs are available with specific fire ratings, which indicate their resistance to flames and heat. This property is critical for compliance with building codes and safety regulations. Buyers in regions with stringent safety standards, such as Europe, must prioritize fire-rated products to ensure compliance and safety.

What Are Common Trade Terms in the ACP Industry?

Familiarity with industry terminology can streamline communication and negotiation processes for B2B buyers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces components or products that are marketed by another company under its own brand. In the ACP industry, buyers often work with OEMs to customize panels for specific projects or applications. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to avoid over-purchasing or under-purchasing, which can affect project budgets and timelines. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. In the ACP sector, submitting an RFQ can help buyers compare prices, specifications, and lead times from multiple manufacturers. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Familiarity with these terms is essential for B2B buyers involved in cross-border trade of ACPs to mitigate risks and ensure smooth logistics. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For ACPs, this can vary significantly based on the manufacturer’s location and production capacity. Understanding lead times is critical for project planning and timely execution.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing aluminium composite panels, ensuring they select the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the acp panel manufacturers,aluminium composite panel Sector

What Are the Current Market Dynamics and Key Trends Affecting ACP Panel Manufacturers?

The aluminum composite panel (ACP) market is witnessing dynamic growth driven by several global factors. The construction sector’s resurgence, particularly in emerging economies across Africa, South America, and the Middle East, is a significant driver. These regions are increasingly investing in infrastructure projects, leading to heightened demand for lightweight, durable, and aesthetically pleasing materials like ACPs. Additionally, the trend towards modern architectural designs emphasizes the use of ACPs for cladding, signage, and interior applications, thereby expanding their market reach.

Technological advancements are reshaping sourcing practices in the ACP sector. The integration of digital platforms for procurement allows international buyers to access a broader range of manufacturers and products. This shift enhances transparency and competition, enabling buyers to negotiate better pricing and terms. Moreover, innovations in manufacturing processes, such as automated production lines and enhanced coating technologies, are improving the quality and reducing the cost of ACPs, further appealing to B2B buyers.

Another critical trend is the increasing focus on customization. Buyers are now seeking tailored solutions that cater to specific project requirements, such as color, finish, and size. This demand for bespoke products is prompting manufacturers to invest in flexible production capabilities. As a result, international buyers from regions like Nigeria and Germany can benefit from more personalized service and quicker turnaround times, enhancing overall project efficiency.

How Are Sustainability and Ethical Sourcing Influencing the ACP Panel Sector?

Sustainability has become a cornerstone of the ACP manufacturing process. As global awareness of environmental issues rises, B2B buyers are prioritizing suppliers that adhere to sustainable practices. The environmental impact of ACPs is largely linked to their production processes and materials used. Manufacturers that utilize recycled materials or employ energy-efficient methods are gaining a competitive edge in the market.

Ethical sourcing is equally important. Buyers are increasingly scrutinizing their supply chains to ensure that materials are sourced responsibly, with minimal environmental degradation and fair labor practices. Certifications such as ISO 14001 for environmental management and LEED (Leadership in Energy and Environmental Design) ratings are becoming essential for manufacturers aiming to appeal to conscientious buyers. Additionally, the use of green materials, like low-VOC (volatile organic compounds) coatings and non-toxic polyethylene cores, is gaining traction, allowing buyers to fulfill their sustainability goals while maintaining quality standards.

Incorporating these sustainable practices not only aligns with buyers’ values but also enhances brand reputation and marketability. By choosing ACP manufacturers that prioritize sustainability, international buyers can contribute to a more eco-friendly construction industry while benefiting from innovative and high-quality products.

What Is the Brief Evolution of the ACP Panel Industry?

The aluminum composite panel industry has evolved significantly since its inception in the 1960s. Originally developed for its lightweight and durable properties, ACPs quickly found applications in building facades, signage, and interior design. Over the decades, advancements in technology have led to improvements in the manufacturing processes, resulting in panels that are not only more durable but also more aesthetically versatile.

In the 1990s, the introduction of new coating techniques allowed for a wider range of colors and finishes, making ACPs a popular choice for modern architecture. The turn of the century saw a growing emphasis on sustainability, prompting manufacturers to adopt greener practices and materials. Today, the industry continues to innovate, focusing on customization, enhanced performance, and sustainable sourcing, catering to a diverse global market that values both functionality and environmental responsibility.

Frequently Asked Questions (FAQs) for B2B Buyers of acp panel manufacturers,aluminium composite panel

-

1. How do I choose the right aluminum composite panel (ACP) for my project?

Selecting the right ACP involves considering several factors such as the panel’s thickness, coating type, and intended application. For exterior use, panels with a PVDF coating offer superior weather resistance and durability. If your project involves digital printing or signage, look for panels with enhanced ink adhesion features. Additionally, consider the color and finish options available, as these will affect aesthetics. Always request samples to evaluate quality and suitability for your specific needs before placing a bulk order. -

2. What are the typical minimum order quantities (MOQs) for aluminum composite panels?

MOQs for ACP can vary significantly between manufacturers. Generally, MOQs can range from 100 to 500 square meters, depending on the supplier’s production capabilities and your specific requirements. When sourcing from international suppliers, be sure to confirm the MOQ during initial discussions, as some manufacturers may offer flexibility for first-time buyers or larger projects. Understanding MOQs will help you budget appropriately and avoid unnecessary inventory costs. -

3. What are the payment terms typically offered by ACP manufacturers?

Payment terms can vary widely among ACP manufacturers. Common practices include a 30% deposit upon order confirmation, with the remaining 70% due prior to shipment. Some suppliers may offer different arrangements, such as letter of credit or payment upon delivery. It is crucial to clarify payment terms early in negotiations to ensure mutual understanding and avoid potential cash flow issues. Always consider using secure payment methods to protect your financial interests. -

4. How can I ensure the quality of aluminum composite panels before purchasing?

To ensure quality, request product certifications and test reports from potential suppliers. Look for certifications like ISO 9001 for quality management and CE marking for compliance with European safety standards. Additionally, consider asking for samples to evaluate the panel’s finish, durability, and resistance to weather conditions. Establishing a clear quality assurance process with your supplier can help mitigate risks associated with subpar products. -

5. What is the typical lead time for ordering aluminum composite panels from manufacturers?

Lead times can vary based on factors such as order size, manufacturing location, and current production schedules. Generally, you can expect lead times to range from 2 to 6 weeks for standard orders. For customized panels, lead times may extend further. It’s advisable to communicate your project timelines clearly with manufacturers and establish a timeline for production and delivery to avoid delays in your project schedule. -

6. How do I vet potential aluminum composite panel suppliers effectively?

Vetting suppliers requires thorough research and due diligence. Start by checking their manufacturing capabilities, certifications, and industry reputation. Request references from previous clients to gauge their reliability and customer service. Additionally, consider visiting their production facility if possible, or utilize third-party inspection services for quality assurance. Engaging in direct communication to assess responsiveness and professionalism can also provide insights into their business practices. -

7. What customization options are available for aluminum composite panels?

Most ACP manufacturers offer a range of customization options including panel size, thickness, color, and finish. You may also request specific coatings for enhanced performance, such as anti-graffiti or fire-retardant finishes. Some suppliers can accommodate custom printing or branding on the panels. Be sure to discuss your specific requirements with the manufacturer during the inquiry phase to ensure they can meet your needs. -

8. What logistics considerations should I be aware of when importing ACP panels?

When importing ACP panels, consider factors like shipping costs, customs duties, and import regulations in your country. Ensure your supplier is familiar with international shipping processes and can provide necessary documentation, such as invoices and certificates of origin. Engaging a reliable freight forwarder can facilitate smoother logistics and help navigate potential challenges. Additionally, assess the packaging methods used to prevent damage during transit, as ACP panels can be susceptible to dents and scratches.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for acp panel manufacturers,aluminium composite panel

In navigating the complex landscape of aluminum composite panel (ACP) manufacturing, strategic sourcing emerges as a critical factor for international B2B buyers. By leveraging relationships with reputable manufacturers, such as those from China, buyers can ensure access to high-quality ACP products that meet stringent certifications like ISO and CE. Understanding the diverse applications of ACP—from digital printing to architectural facades—enables buyers to make informed decisions that align with their project needs.

Moreover, the focus on sustainability and innovation in the ACP industry highlights the importance of sourcing from manufacturers that prioritize environmentally responsible practices. As demand for durable, lightweight, and visually appealing materials grows, so does the potential for cost savings and efficiency improvements through strategic partnerships.

Looking ahead, international buyers from regions such as Africa, South America, the Middle East, and Europe are encouraged to explore opportunities for collaboration and sourcing. By engaging with established ACP manufacturers and staying abreast of market trends, businesses can position themselves for success in a competitive landscape. Embrace the future of construction and design with strategic sourcing—your projects deserve the best in quality and reliability.