Master Sourcing the Best CNC Tube Bending Machine for Your

Introduction: Navigating the Global Market for cnc tube bending machine

In an increasingly interconnected global marketplace, the demand for precision manufacturing equipment such as CNC tube bending machines has surged. These machines are essential for producing complex shapes and components across various industries, including automotive, aerospace, construction, and energy. For B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding the intricacies of sourcing CNC tube bending machines is critical for maintaining competitive advantage and ensuring operational efficiency.

This guide serves as a comprehensive resource, designed to equip international buyers with the insights necessary for informed decision-making. It covers an array of topics, including the different types of CNC tube bending machines available, the materials they can process, and the manufacturing and quality control standards that define industry excellence. Furthermore, we will explore the landscape of suppliers, pricing strategies, and market trends, enabling buyers to navigate their sourcing journeys with confidence.

By delving into frequently asked questions and addressing common concerns, this guide empowers B2B buyers to make strategic investments that align with their operational needs. Whether you are a manufacturer in Nigeria seeking to enhance production capabilities or a supplier in Colombia looking to expand your product offerings, understanding the global market for CNC tube bending machines is essential for fostering growth and innovation in your business.

Understanding cnc tube bending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rotary Draw Bender | Utilizes a rotating mechanism for precise bends | Automotive, Aerospace, HVAC | Pros: High accuracy, versatile; Cons: Higher initial cost, complex setup. |

| Press Bender | Employs hydraulic pressure to bend tubes | Construction, Furniture Manufacturing | Pros: Cost-effective, easy operation; Cons: Limited bend radius, slower speed. |

| Mandrel Bender | Features a mandrel for maintaining tube integrity | Oil & Gas, Marine, Heavy Machinery | Pros: Excellent for tight bends, maintains shape; Cons: More expensive, requires skilled operators. |

| Electric Bender | Powered by electric motors for automated bending | Electronics, Medical Equipment | Pros: Energy-efficient, low maintenance; Cons: Limited to smaller tube sizes, higher upfront cost. |

| Hybrid Bender | Combines hydraulic and electric technologies | Aerospace, Robotics | Pros: Flexibility, high performance; Cons: Complexity in maintenance, potential for higher costs. |

Rotary Draw Bender

The Rotary Draw Bender is known for its precision and versatility, making it a favorite in industries like automotive and aerospace. This machine uses a rotating mechanism that allows for complex bends with high accuracy. B2B buyers should consider the initial investment, as these machines tend to have a higher upfront cost. However, their ability to produce intricate designs efficiently can lead to significant long-term savings and improved production quality.

Press Bender

The Press Bender is a more straightforward option that uses hydraulic pressure to bend tubes. It is commonly employed in construction and furniture manufacturing. Buyers often find this type appealing due to its cost-effectiveness and ease of operation, especially for less complex bending tasks. However, it may have limitations in terms of bend radius and speed, which could affect production timelines.

Mandrel Bender

For industries like oil and gas, the Mandrel Bender is essential as it utilizes a mandrel to maintain tube integrity during the bending process. This type is ideal for creating tight bends without compromising the tube’s shape. While it offers excellent performance, buyers should be aware of the higher costs associated with these machines and the need for skilled operators to manage them effectively.

Electric Bender

The Electric Bender is increasingly popular due to its energy efficiency and low maintenance needs. This machine is particularly suited for the electronics and medical equipment sectors where precision is crucial. However, it is typically limited to smaller tube sizes, which may not meet the needs of all buyers. The higher upfront cost can be a consideration, but the operational savings may justify the investment over time.

Hybrid Bender

Combining the best of both worlds, the Hybrid Bender integrates hydraulic and electric technologies to offer flexibility and high performance. This type is well-suited for aerospace and robotics applications where precision and adaptability are essential. While it can deliver superior results, potential buyers should weigh the complexity of maintenance and the possibility of higher costs against the benefits of enhanced production capabilities.

Related Video: CNC Tube Bending Machine [Square & Rectangular Profiles/Tubes] – Section Bending

Key Industrial Applications of cnc tube bending machine

| Industry/Sector | Specific Application of cnc tube bending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Manufacturing exhaust systems | Enhances efficiency and precision in production | Look for machines with high bending accuracy and flexibility. |

| Construction | Fabrication of scaffolding and handrails | Reduces material waste and labor costs | Ensure compatibility with local standards and regulations. |

| Oil & Gas | Production of piping systems | Increases durability and safety of installations | Evaluate suppliers with experience in high-pressure applications. |

| HVAC | Creation of ductwork and tubing | Improves energy efficiency and airflow control | Consider machine capabilities for various material thicknesses. |

| Furniture & Interior Design | Custom furniture frames and decor elements | Allows for innovative designs and customization | Seek machines that can handle diverse materials and shapes. |

Automotive Industry

In the automotive sector, CNC tube bending machines are integral for the production of exhaust systems, roll cages, and chassis components. These machines provide the precision necessary to create complex shapes that meet stringent safety and performance standards. For international buyers, particularly in Africa and South America, sourcing machines that offer both high accuracy and flexibility is crucial. Additionally, understanding local automotive regulations can help ensure compliance and avoid costly modifications.

Construction Industry

CNC tube bending machines are widely used in the construction industry for fabricating scaffolding, handrails, and structural supports. By utilizing these machines, businesses can significantly reduce material waste and labor costs, leading to improved project profitability. Buyers from the Middle East and Europe should consider the machine’s ability to work with various materials, as well as its compliance with local safety standards. This ensures that the produced components are both durable and regulatory-compliant.

Oil & Gas Industry

In the oil and gas sector, CNC tube bending machines are essential for producing piping systems that must withstand high pressures and corrosive environments. These machines enhance the durability and safety of installations, which is critical in this industry. For B2B buyers in regions like Africa and the Middle East, it is important to evaluate suppliers who specialize in high-pressure applications and can provide machines with the necessary certifications for safety and quality.

HVAC Industry

CNC tube bending machines play a vital role in the HVAC industry by allowing for the efficient creation of ductwork and tubing. This technology helps improve energy efficiency and airflow control in heating and cooling systems. Buyers from Europe should focus on sourcing machines that can handle various material thicknesses and configurations, as this flexibility can lead to better system designs and improved energy performance.

Furniture & Interior Design Industry

In the furniture and interior design sectors, CNC tube bending machines facilitate the creation of custom furniture frames and decorative elements. This capability allows designers to experiment with innovative shapes and styles, catering to unique customer demands. Buyers in South America should prioritize machines that can accommodate diverse materials and shapes, ensuring that they can deliver distinctive, high-quality products that stand out in a competitive market.

Related Video: CNC tube bending machine with integrated cut system | BLM GROUP

Strategic Material Selection Guide for cnc tube bending machine

When selecting materials for CNC tube bending machines, international B2B buyers must consider a variety of factors that can significantly impact performance, cost, and compliance. Below is an analysis of four common materials used in tube bending applications, including their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Steel

Key Properties:

Steel is known for its high tensile strength and durability. It can withstand high temperatures and pressures, making it suitable for a variety of applications. Additionally, certain grades of steel offer good corrosion resistance, especially when treated or alloyed.

Pros & Cons:

Steel is relatively cost-effective and widely available, which can reduce lead times. However, it can be heavy, which may complicate handling and transport. The manufacturing complexity can increase with certain steel grades, particularly those requiring specialized welding or machining processes.

Impact on Application:

Steel is compatible with a wide range of media, including gases and liquids, making it versatile for various industries. However, its weight can be a drawback in applications where lighter materials are preferred.

Considerations for Buyers:

Buyers should ensure compliance with international standards such as ASTM for the U.S. market or EN standards in Europe. Additionally, they should consider local sourcing options to minimize costs and lead times.

Aluminum

Key Properties:

Aluminum is lightweight and has excellent corrosion resistance, making it ideal for applications where weight is a critical factor. It also has good thermal conductivity and can withstand moderate pressures.

Pros & Cons:

The primary advantage of aluminum is its low weight, which can lead to lower shipping costs and easier handling. However, it is generally more expensive than steel and may not be suitable for high-pressure applications due to lower tensile strength.

Impact on Application:

Aluminum is commonly used in the automotive and aerospace industries due to its favorable weight-to-strength ratio. It is compatible with various media but may require additional coatings for enhanced corrosion resistance in aggressive environments.

Considerations for Buyers:

International buyers should be aware of the varying grades of aluminum and their respective standards (e.g., ASTM, JIS). Additionally, sourcing aluminum locally can mitigate the impact of tariffs and reduce delivery times.

Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance and high strength, making it suitable for harsh environments. It can withstand high temperatures and has a long lifespan, reducing the need for frequent replacements.

Pros & Cons:

While stainless steel is durable and resistant to rust and corrosion, it is generally more expensive than both carbon steel and aluminum. The manufacturing process can be complex, requiring specialized equipment and techniques.

Impact on Application:

Stainless steel is ideal for applications involving corrosive substances, such as in the food and beverage or pharmaceutical industries. Its compatibility with a wide range of media makes it a preferred choice for many industrial applications.

Considerations for Buyers:

Buyers should ensure compliance with relevant standards, such as ISO and ASTM, particularly for food-grade applications. Understanding local regulations regarding stainless steel grades is crucial for ensuring product safety and compliance.

Copper

Key Properties:

Copper is known for its excellent electrical conductivity and thermal properties. It is relatively malleable and can be easily formed into various shapes, making it suitable for intricate designs.

Pros & Cons:

Copper’s high conductivity makes it ideal for electrical applications, but it is prone to corrosion and may require protective coatings. It is also more expensive than steel and aluminum, which can impact overall project budgets.

Impact on Application:

Copper is primarily used in electrical and plumbing applications, where its conductivity and malleability are advantageous. However, its susceptibility to corrosion limits its use in certain environments.

Considerations for Buyers:

International buyers should be aware of the varying standards for copper materials, such as ASTM B75 or EN 1976. Additionally, understanding local market conditions and sourcing options can help mitigate costs.

Summary Table

| Material | Typical Use Case for cnc tube bending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components in automotive | Cost-effective and durable | Heavy and complex manufacturing | Medium |

| Aluminum | Aerospace and automotive applications | Lightweight and corrosion-resistant | Higher cost than steel | High |

| Stainless Steel | Food and beverage processing equipment | Excellent corrosion resistance | More expensive and complex to manufacture | High |

| Copper | Electrical and plumbing applications | High conductivity and malleability | Prone to corrosion | High |

This guide provides a comprehensive overview of material selection for CNC tube bending machines, enabling international B2B buyers to make informed decisions that align with their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc tube bending machine

Manufacturing a CNC tube bending machine involves several intricate processes, each designed to ensure precision and quality. For international B2B buyers, understanding these processes can facilitate better supplier selection and enhance the overall procurement strategy.

Manufacturing Processes

Material Preparation

The first stage in the manufacturing of CNC tube bending machines involves the careful selection and preparation of materials. Typically, high-grade steel or aluminum alloys are used due to their strength and durability. Key techniques in this stage include:

- Material Inspection: Before fabrication, materials undergo rigorous inspection to ensure they meet specified standards. This includes checking for defects and verifying material specifications.

- Cutting: The raw materials are cut to precise lengths using laser cutting or saw cutting techniques, ensuring accuracy for the next forming stage.

Forming

Once materials are prepared, the forming stage begins, where the actual bending of the tubes occurs. This is critical for the machine’s performance. Key processes include:

- Bending: CNC tube bending machines utilize various techniques such as rotary draw bending, roll bending, and mandrel bending. These methods ensure that the tubes maintain their integrity and do not deform during the bending process.

- Programming: The bending operations are programmed using CAD/CAM software, allowing for complex geometries to be produced with high precision. This step is vital for reducing errors and enhancing repeatability.

Assembly

After forming, the components of the CNC tube bending machine are assembled. This stage often includes:

- Component Integration: Various machine parts, such as the bending head, tube supports, and control systems, are integrated. Each component must fit perfectly to ensure smooth operation.

- Wiring and Electronics: Electrical systems are installed, including motors, sensors, and control panels, which are essential for the machine’s functionality.

Finishing

The final stage is finishing, which ensures that the machine is not only operational but also aesthetically pleasing and protected against corrosion. Key techniques include:

- Surface Treatment: Processes such as powder coating or anodizing are applied to enhance durability and appearance.

- Final Inspection: A thorough inspection of the finished machine is conducted to ensure all parts function correctly and meet the specified quality standards.

Quality Assurance

Quality assurance is crucial in manufacturing CNC tube bending machines. It ensures that the machines meet international and industry-specific standards, which is particularly important for B2B buyers operating in diverse regulatory environments.

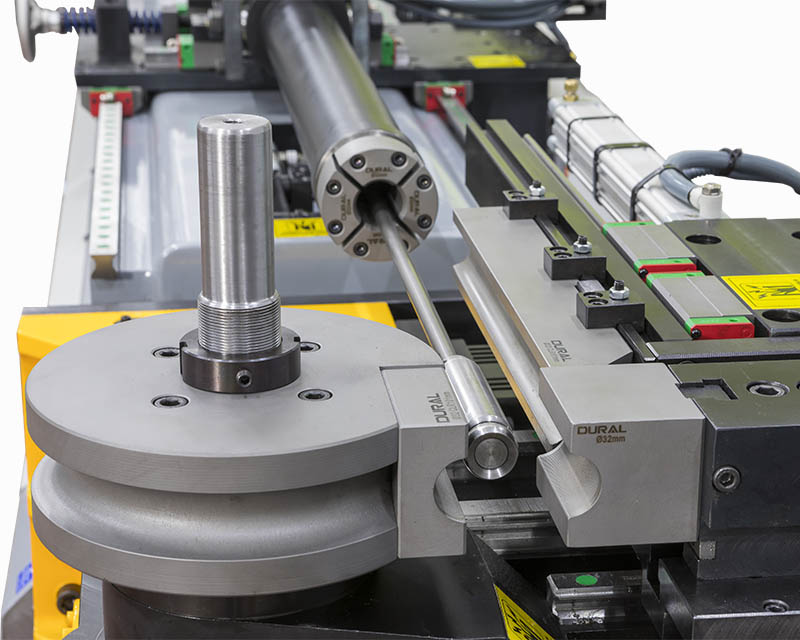

Illustrative Image (Source: Google Search)

Relevant International Standards

B2B buyers should be aware of several key standards that suppliers must adhere to:

- ISO 9001: This standard focuses on quality management systems and is critical for ensuring consistent quality in manufacturing processes.

- CE Marking: In Europe, CE marking indicates that the machine meets health, safety, and environmental protection standards.

- API Standards: For industries such as oil and gas, compliance with American Petroleum Institute (API) standards is essential for products used in these sectors.

QC Checkpoints

Quality Control (QC) involves various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet quality specifications before processing begins.

- In-Process Quality Control (IPQC): Regular checks are performed during manufacturing to identify and rectify defects early in the process.

- Final Quality Control (FQC): After assembly and finishing, the complete machine is tested for functionality, safety, and compliance with specifications.

Common Testing Methods

Testing methods used in the QC process may include:

- Dimensional Inspection: Using precision measuring tools to ensure components meet design specifications.

- Functional Testing: Operating the machine to verify that all functions perform as intended.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic or X-ray testing to detect internal defects without damaging the components.

Verifying Supplier QC

B2B buyers can take several actionable steps to verify the quality control processes of suppliers:

- Supplier Audits: Conducting on-site audits of potential suppliers can provide insight into their manufacturing capabilities and QC practices. This is particularly important for buyers in regions like Africa and South America, where standards may vary.

- Requesting Quality Reports: Suppliers should provide documentation of their quality assurance processes, including inspection reports and certifications.

- Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased evaluation of the supplier’s QC processes and product quality, ensuring compliance with international standards.

QC and Certification Nuances for International Buyers

B2B buyers from Africa, South America, the Middle East, and Europe should be aware of the following nuances:

- Regional Standards Variability: Different regions may have varying standards and certifications. Understanding local regulations can help buyers ensure compliance.

- Language Barriers: Documentation provided by suppliers may not always be in English or the buyer’s native language. It’s advisable to request translations or clarification on critical compliance documents.

- Cultural Considerations: Building strong relationships with suppliers through regular communication can facilitate better understanding and adherence to quality standards.

By understanding the manufacturing processes and quality assurance practices involved in CNC tube bending machines, international B2B buyers can make informed decisions that align with their operational needs and compliance requirements. This knowledge not only aids in supplier selection but also enhances the overall procurement strategy, ensuring that the machines acquired meet the highest standards of quality and performance.

Related Video: Amazing Production Process with Modern Machines and Skilful Workers

Comprehensive Cost and Pricing Analysis for cnc tube bending machine Sourcing

When sourcing CNC tube bending machines, understanding the comprehensive cost structure and pricing dynamics is essential for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This section delves into the various cost components, price influencers, and actionable buyer tips to ensure a successful procurement process.

Cost Components

-

Materials: The choice of materials significantly impacts the overall cost of CNC tube bending machines. High-quality steel and aluminum alloys are commonly used, but sourcing these materials can vary in price based on local availability and market demand. Buyers should explore suppliers who can provide competitive pricing for bulk purchases.

-

Labor: Labor costs are an essential factor in the manufacturing process. Regions with lower labor costs may offer more competitive pricing, but it’s crucial to assess the skill level and training of the workforce. High-skilled labor can lead to better machine quality and performance.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Understanding the overhead structure of potential suppliers can help buyers gauge the sustainability of their pricing.

-

Tooling: Custom tooling requirements can add significant costs. Buyers should clearly define specifications to avoid unexpected tooling charges. Engaging with suppliers early in the design phase can help in optimizing tooling costs.

-

Quality Control (QC): Investing in quality control processes ensures that the machines meet industry standards and specifications. While this may increase upfront costs, it can prevent costly failures or reworks in the future.

-

Logistics: Shipping and handling can vary widely depending on the origin of the machine and the destination. Consider factors like shipping methods, import duties, and local transportation costs, which can significantly affect total expenses.

-

Margin: Supplier margins vary based on market conditions and competition. Understanding the typical markup in your region can help buyers negotiate better deals.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Purchasing in larger volumes typically yields lower per-unit costs. Buyers should analyze their needs and consider group purchasing options with other companies to meet MOQs.

-

Specifications/Customization: Custom features and specifications can drive up costs. Standard models are generally more affordable, so it’s beneficial to evaluate whether the additional features are necessary for your operations.

-

Materials: The choice between standard and premium materials can influence the price. Buyers should assess the impact of material selection on the machine’s longevity and performance to make informed decisions.

-

Quality/Certifications: Machines certified to international standards (ISO, CE) may come at a premium but can ensure compliance and reliability. Buyers should weigh the cost against the potential benefits of certification.

-

Supplier Factors: The reputation and reliability of suppliers play a critical role in pricing. Established suppliers may offer higher prices due to their track record, but they often provide better support and warranty options.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for cost calculation. They define responsibilities in shipping, which can affect the total cost of ownership. Buyers should clarify these terms with suppliers to avoid unexpected costs.

Buyer Tips

-

Negotiation: Approach negotiations with a clear understanding of your budget and the market rates. Leverage multiple quotes from different suppliers to strengthen your bargaining position.

-

Cost-Efficiency: Consider the total cost of ownership (TCO), which includes not just the purchase price but also maintenance, operational costs, and potential downtime. Investing in higher-quality machines may reduce long-term costs.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, currency fluctuations and local economic conditions can affect the pricing landscape in Africa, South America, the Middle East, and Europe.

-

Disclaimer for Indicative Prices: Pricing for CNC tube bending machines can vary based on numerous factors, including market conditions, supplier negotiations, and specific buyer requirements. It is advisable to conduct thorough research and obtain detailed quotes from multiple suppliers to establish a reliable budget.

By understanding these cost components and price influencers, B2B buyers can make informed decisions when sourcing CNC tube bending machines, ultimately leading to more effective procurement strategies and better investment outcomes.

Essential Technical Properties and Trade Terminology for cnc tube bending machine

When navigating the procurement process for CNC tube bending machines, understanding the essential technical properties and trade terminology is crucial for making informed decisions. Here’s an overview of key specifications and terms that international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be familiar with.

Critical Technical Properties

-

Material Grade

– Definition: The classification of the material used for the tubing, which can include stainless steel, aluminum, copper, and more.

– B2B Importance: Selecting the right material grade is vital for ensuring the durability and performance of the bent tubes. Buyers must consider factors such as corrosion resistance, strength, and the specific application requirements to avoid costly errors in production. -

Bending Radius

– Definition: The minimum radius that a tube can be bent without compromising its integrity.

– B2B Importance: A critical factor in design and manufacturing, the bending radius affects both aesthetics and functionality. Buyers should ensure that the CNC tube bending machine can accommodate the required bending radius for their specific applications, especially in industries like automotive and aerospace.

Illustrative Image (Source: Google Search)

-

Tolerance

– Definition: The permissible limit of variation in a physical dimension or measured value, expressed in millimeters or inches.

– B2B Importance: Precision is key in many applications. A tight tolerance ensures that the bent tubes will fit correctly in assemblies. Buyers must clarify tolerance requirements with suppliers to ensure the final products meet their specifications. -

Production Capacity

– Definition: The maximum number of tubes that can be bent within a specific time frame, often measured in pieces per hour.

– B2B Importance: Understanding the production capacity helps buyers assess whether a machine can meet their operational demands. This is particularly important for businesses with high-volume requirements or tight deadlines. -

Control System

– Definition: The technology used to operate the CNC tube bending machine, which can include PLC (Programmable Logic Controller) or advanced software interfaces.

– B2B Importance: A user-friendly and flexible control system can greatly enhance productivity and ease of operation. Buyers should evaluate the control systems’ compatibility with their existing processes and staff expertise.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify reliable suppliers and ensure they are purchasing quality components that meet industry standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is essential for budgeting and inventory planning. Buyers should negotiate this term to ensure that it aligns with their production needs and financial constraints. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and availability for specific products or services.

– Importance: RFQs are a vital part of the procurement process. Buyers should provide detailed specifications to receive accurate quotes, which facilitate better decision-making. -

Incoterms (International Commercial Terms)

– Definition: A series of predefined commercial terms published by the International Chamber of Commerce, which define responsibilities of sellers and buyers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, insurance, and customs clearance. This can prevent misunderstandings and additional costs during the import process. -

Lead Time

– Definition: The time taken from placing an order to the delivery of the product.

– Importance: Lead time is crucial for planning and can impact production schedules. Buyers should communicate their timelines clearly to suppliers to ensure timely delivery.

By understanding these technical properties and trade terms, B2B buyers can navigate the complexities of purchasing CNC tube bending machines more effectively, ensuring they choose the right equipment for their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the cnc tube bending machine Sector

Market Overview & Key Trends

The CNC tube bending machine market is experiencing notable growth, driven by rising demand for precision engineering across various industries, including automotive, aerospace, and construction. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly influenced by the increasing automation in manufacturing processes, which enhances productivity and reduces labor costs. Key trends impacting sourcing decisions include the integration of Industry 4.0 technologies, such as IoT and AI, which allow for real-time monitoring and predictive maintenance, thus optimizing machine performance.

Another significant trend is the shift towards custom solutions. Buyers are increasingly seeking machines that can handle diverse bending requirements, from complex geometries to varying material specifications. This trend is especially prevalent in emerging markets where local manufacturers are looking to enhance their capabilities to compete globally. Additionally, the rise of digital platforms is transforming the way buyers source machines, facilitating easier access to a wider range of suppliers and enabling price comparison and product reviews.

Market dynamics also reveal a growing emphasis on cost-effective solutions. Buyers are more inclined towards sourcing from manufacturers that offer competitive pricing without compromising on quality. This has resulted in a more extensive evaluation of supply chain networks, prompting buyers to consider suppliers that can provide both affordability and reliability in machine performance.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal consideration for international B2B buyers in the CNC tube bending machine sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, including the use of energy-efficient machines and recycling programs for waste materials.

Ethical sourcing is equally important. Buyers are encouraged to evaluate the entire supply chain for transparency and compliance with labor standards. Engaging with suppliers who hold recognized ‘green’ certifications, such as ISO 14001 (Environmental Management) or those using eco-friendly materials, can significantly enhance a company’s reputation and appeal to environmentally-conscious customers. Furthermore, the adoption of sustainable technologies, such as machines that utilize biodegradable lubricants or have a lower carbon footprint, is becoming a key differentiator in supplier selection.

Incorporating sustainability into procurement strategies not only contributes to corporate social responsibility goals but can also lead to cost savings in the long run. By reducing energy consumption and material waste, companies can improve their bottom line while fulfilling their environmental commitments.

Brief Evolution/History

The CNC tube bending machine has evolved significantly since its inception in the mid-20th century. Initially, manual bending techniques dominated the market, which were labor-intensive and prone to inaccuracies. The introduction of CNC technology revolutionized this sector, enabling precise control over bending angles and dimensions. This technological advancement allowed manufacturers to produce complex shapes with high repeatability, catering to the evolving demands of various industries.

As industries have advanced, so too have the capabilities of CNC tube bending machines. Modern machines are now equipped with advanced software and automation features, allowing for seamless integration into smart manufacturing environments. This evolution reflects the broader trends of digital transformation and Industry 4.0, positioning CNC tube bending machines as critical tools in the quest for efficiency and precision in manufacturing processes.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc tube bending machine

-

What criteria should I use to vet suppliers of CNC tube bending machines?

When vetting suppliers, consider their industry experience, reputation, and customer reviews. Request references from previous clients and assess their technical expertise in producing CNC tube bending machines. Certifications such as ISO 9001 can indicate quality management systems. Additionally, evaluate their responsiveness and communication skills, as these are crucial for long-term partnerships. For international transactions, verify their export capabilities and compliance with your country’s import regulations. -

Can CNC tube bending machines be customized to meet specific requirements?

Yes, many manufacturers offer customization options for CNC tube bending machines to cater to unique specifications, such as bending radius, material type, and production volume. When discussing customization, clearly outline your needs and expectations. A reputable supplier will provide you with design options and prototypes if necessary. Ensure that customization does not compromise the machine’s efficiency and durability by asking for case studies or examples of similar projects they have completed. -

What are the typical minimum order quantities (MOQs) and lead times for CNC tube bending machines?

MOQs can vary significantly based on the supplier and the complexity of the machine. Some manufacturers may require a minimum of one unit, while others might set higher thresholds. Lead times typically range from a few weeks to several months, depending on the machine’s specifications and customization level. It is advisable to discuss these factors upfront and consider potential delays in international shipping and customs clearance when planning your production schedule. -

What payment terms should I expect when sourcing CNC tube bending machines?

Payment terms can vary widely among suppliers, but common practices include a deposit upon order confirmation, with the balance due before shipment. Some suppliers may offer financing options or payment through letters of credit, especially for larger orders. Always clarify payment terms in the contract to avoid misunderstandings. Additionally, consider using an escrow service for significant transactions to ensure security for both parties. -

How can I ensure the quality of CNC tube bending machines before purchase?

To ensure quality, request detailed specifications, including material certifications and performance metrics. Ask for a factory visit or video inspection to observe the manufacturing process. Many suppliers can provide sample parts or machines for testing before finalizing your order. Additionally, inquire about the warranty and after-sales support, as these factors are indicative of the supplier’s confidence in their product quality. -

What certifications should I look for in CNC tube bending machines?

Look for certifications that demonstrate compliance with international quality and safety standards, such as CE marking for the European market and UL certification in North America. ISO certifications, particularly ISO 9001 for quality management and ISO 14001 for environmental management, are also critical. If you are operating in specific industries like aerospace or automotive, ensure the machines meet relevant sector-specific standards. -

What logistics considerations should I keep in mind when importing CNC tube bending machines?

Consider the logistics of shipping, including freight costs, insurance, and customs duties. Collaborate with a logistics partner experienced in international trade to navigate these complexities. Ensure that the supplier provides proper packaging and documentation to facilitate smooth customs clearance. Additionally, factor in lead times for shipping, as international transport can introduce delays that impact your production schedule. -

How should disputes with suppliers be managed effectively?

To manage disputes effectively, establish clear communication channels and document all agreements in writing. Include clauses in your contract that outline procedures for conflict resolution, such as mediation or arbitration, to avoid lengthy legal battles. If issues arise, approach the supplier directly to discuss your concerns and seek a mutually beneficial solution. Maintaining a professional demeanor and focusing on resolution can often lead to satisfactory outcomes for both parties.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cnc tube bending machine

In conclusion, the strategic sourcing of CNC tube bending machines is paramount for international B2B buyers aiming to optimize their operations. Key takeaways from this guide highlight the importance of evaluating supplier capabilities, understanding regional market dynamics, and leveraging technology for enhanced efficiency. By prioritizing partnerships with manufacturers that offer robust after-sales support and customization options, businesses can ensure they remain competitive in their respective markets.

Furthermore, strategic sourcing enables companies to mitigate risks associated with supply chain disruptions, particularly in the evolving global landscape. Buyers from Africa, South America, the Middle East, and Europe should focus on establishing strong relationships with suppliers who are not only capable but also aligned with their long-term goals.

As we look ahead, the demand for CNC tube bending machines is expected to grow, driven by advancements in automation and sustainability. Now is the time for B2B buyers to seize opportunities in emerging markets, explore innovative solutions, and invest in technologies that will future-proof their operations. Take action today by assessing your sourcing strategies and engaging with trusted suppliers to drive your business forward.