Discover 12 Essential Bolt Types for Smart Sourcing (2025)

Introduction: Navigating the Global Market for bolt types

In an increasingly interconnected world, sourcing the right bolt types for your projects can be a complex challenge. Whether you are a manufacturer in South America, a construction firm in Africa, or an engineering company in Europe, understanding the nuances of various fasteners is crucial. This guide offers a comprehensive overview of bolt types, covering their diverse applications, materials, and specifications, tailored to the needs of international B2B buyers.

With a focus on practical insights, we delve into the different categories of bolts—including hex bolts, carriage bolts, and lag screws—and discuss their specific uses in various industries. Additionally, we provide guidance on supplier vetting processes to ensure you partner with reliable manufacturers who meet international standards. Cost considerations are also addressed, enabling you to make informed financial decisions that align with your project budgets.

This guide empowers B2B buyers from Africa, South America, the Middle East, and Europe by equipping them with the knowledge necessary to navigate the global market for bolt types effectively. By understanding the intricacies of these fasteners, you can enhance your procurement strategy, streamline operations, and ultimately drive your business success in a competitive landscape.

Understanding bolt types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hex Bolts | Hexagonal head for wrench tightening | Construction, machinery assembly | Pros: Versatile and strong; Cons: May require nuts and washers. |

| Carriage Bolts | Domed head with a square neck | Wood-to-wood and metal-to-wood connections | Pros: Prevents pull-through; Cons: Limited to specific applications. |

| Lag Bolts | Wood-threaded with a pointed tip | Heavy-duty applications like decking | Pros: Excellent load-bearing; Cons: Not compatible with nuts. |

| U-Bolts | U-shaped, threaded ends | Pipework support, automotive applications | Pros: Easy installation; Cons: Limited to specific shapes. |

| Eye Bolts | Circular ring at the head for securing lines | Rigging, anchoring, hoisting | Pros: Versatile for lifting; Cons: Requires careful load calculations. |

What Are Hex Bolts and Their Applications in B2B Purchases?

Hex bolts are characterized by their hexagonal heads, allowing for easy tightening with a wrench. They are widely used in construction and machinery assembly due to their strength and versatility. When purchasing hex bolts, B2B buyers should consider the material (often stainless or alloy steel), size specifications, and whether they will require accompanying nuts and washers for secure fastening. Their adaptability makes them a staple in many industrial applications.

How Do Carriage Bolts Function in Various Industries?

Carriage bolts feature a domed head and a square neck that prevents the bolt from turning when tightened. They are commonly utilized in wood-to-wood and metal-to-wood connections, making them ideal for furniture assembly and construction projects. Buyers should focus on the length and diameter when selecting carriage bolts, as well as the material, which can affect durability and corrosion resistance. Their unique design helps prevent pull-through, but they are limited to specific fastening applications.

What Makes Lag Bolts Ideal for Heavy-Duty Applications?

Lag bolts are designed with wood threads and a pointed tip, making them particularly effective for heavy-duty applications such as decking and flooring. They provide excellent load-bearing capabilities, making them suitable for construction projects that require strong, stable connections. B2B buyers should consider the wood type and thickness when selecting lag bolts, as they are not compatible with nuts. Their robustness is a significant advantage, but they may not be suitable for all fastening needs.

Why Choose U-Bolts for Pipe Support and Automotive Applications?

U-bolts, with their U-shaped design and threaded ends, are commonly used for supporting pipes and in automotive applications. Their straightforward installation process makes them a popular choice among B2B buyers looking for efficient fastening solutions. When purchasing U-bolts, it’s essential to evaluate the diameter and length to ensure compatibility with the intended application. While they offer ease of use, their functionality is primarily limited to specific shapes and configurations.

How Do Eye Bolts Enhance Rigging and Anchoring Operations?

Eye bolts are distinguished by their circular ring at the head, which allows for secure attachment of ropes and chains. They are widely used in rigging, anchoring, and hoisting applications across various industries, including shipping and construction. Buyers should assess the load capacity and material when selecting eye bolts, as these factors are crucial for safety and performance. While eye bolts provide versatility, careful load calculations are necessary to prevent overloading and ensure operational safety.

Key Industrial Applications of bolt types

| Industry/Sector | Specific Application of bolt types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Infrastructure | Use of hex bolts for structural frameworks | Provides strong, reliable connections for safety | Ensure compliance with local building codes and standards |

| Automotive | Eye bolts in vehicle assembly for safety harnesses | Enhances safety and stability in vehicle design | Consider corrosion resistance and weight specifications |

| Manufacturing | Flange bolts in machinery assembly | Distributes load effectively, reducing wear | Focus on material durability and compatibility with machinery |

| Oil & Gas | U-bolts for pipeline support | Ensures secure attachment of pipes, preventing leaks | Evaluate environmental resistance and load-bearing capacity |

| Renewable Energy | Elevator bolts in wind turbine installations | Facilitates secure assembly for high-wind environments | Prioritize sourcing from certified suppliers for quality assurance |

How Are Bolt Types Utilized in Construction and Infrastructure Projects?

In the construction and infrastructure sector, hex bolts are commonly used to create robust structural frameworks. These bolts ensure reliable connections between steel beams and other components, which is crucial for safety and stability in buildings and bridges. International buyers need to ensure that the sourced bolts comply with local building codes and standards to avoid costly rework and safety issues.

What Role Do Eye Bolts Play in the Automotive Industry?

Eye bolts are integral to vehicle assembly, particularly for securing safety harnesses and other components. Their design allows for the attachment of ropes or chains, enhancing the stability and safety of vehicles. For international automotive manufacturers, sourcing eye bolts with high corrosion resistance and appropriate weight specifications is critical to ensure long-lasting performance in varying environmental conditions.

How Are Flange Bolts Applied in Manufacturing?

In manufacturing, flange bolts are widely used for machinery assembly due to their ability to distribute load evenly. This characteristic reduces wear on the machinery, prolonging its lifespan and ensuring efficient operation. Buyers should focus on the material durability and compatibility with existing machinery when sourcing flange bolts, especially in regions with varying climatic conditions.

Why Are U-Bolts Important in the Oil & Gas Sector?

U-bolts play a vital role in the oil and gas industry by providing secure attachment for pipelines. Their design allows for effective support, which is essential in preventing leaks and maintaining system integrity. Buyers in this sector must evaluate the environmental resistance and load-bearing capacity of U-bolts to ensure they can withstand the demanding conditions often encountered in oil and gas applications.

How Do Elevator Bolts Contribute to Renewable Energy Solutions?

Elevator bolts are crucial in the assembly of wind turbines, where they secure various components against high winds. Their design facilitates a strong and reliable connection, which is essential for the operational efficiency of wind energy systems. When sourcing elevator bolts, international buyers should prioritize certified suppliers to ensure the quality and reliability necessary for renewable energy applications.

3 Common User Pain Points for ‘bolt types’ & Their Solutions

Scenario 1: Sourcing Quality Bolts for Critical Applications

The Problem: International B2B buyers often face the challenge of sourcing high-quality bolts that meet specific industrial standards and applications. For instance, a construction firm in South America may require stainless steel bolts for a project in a coastal area, where corrosion resistance is crucial. However, they might find it difficult to identify suppliers who can guarantee the quality and material specifications required for such an environment. This can lead to delays, increased costs, and potentially compromised safety standards.

The Solution: To effectively source the right bolt types, buyers should prioritize suppliers who provide detailed product specifications, including material certifications and quality assurance processes. Conducting thorough research on potential suppliers, including reviewing customer testimonials and industry certifications, can help ensure they meet stringent standards. Additionally, buyers should engage in direct communication with suppliers to clarify any doubts regarding bolt specifications and applications. Utilizing platforms that specialize in B2B procurement can also enhance visibility of reputable suppliers, ensuring that quality is not sacrificed for cost.

Scenario 2: Understanding the Right Bolt Types for Specific Projects

The Problem: A common pain point for B2B buyers is the confusion surrounding which bolt types are suitable for specific projects. For example, a manufacturing company in Africa might be uncertain about whether to use hex bolts or carriage bolts for assembling their machinery. This lack of clarity can lead to improper fastening, increased maintenance costs, and potential equipment failure, impacting operational efficiency.

The Solution: B2B buyers should invest time in understanding the various bolt types and their applications. Creating a reference guide that outlines the properties and ideal uses of each bolt type can serve as a valuable resource for teams involved in procurement and engineering. Additionally, collaborating with engineers during the selection process can ensure that the chosen bolts align with project requirements. For instance, hex bolts are preferable for high-tension applications, while carriage bolts are ideal for wood-to-wood connections. Leveraging online tools and databases that detail bolt specifications and applications can further enhance decision-making.

Scenario 3: Managing Inventory and Reducing Downtime

The Problem: B2B companies often struggle with managing inventory levels of different bolt types, leading to production delays when specific fasteners are unavailable. For instance, a construction firm in the Middle East may find that they have an excess of lag bolts but are short on U-bolts, which are critical for their current project. This mismatch can result in increased downtime, impacting project timelines and costs.

The Solution: Implementing an inventory management system that tracks bolt usage and forecasts needs based on project schedules can significantly mitigate this issue. Buyers should categorize bolt types according to their frequency of use and project requirements, allowing for better purchasing decisions. Additionally, establishing relationships with multiple suppliers can provide flexibility in sourcing and ensure that critical fasteners are readily available. By utilizing just-in-time (JIT) inventory strategies, companies can reduce storage costs while ensuring they have the necessary bolt types on hand when needed. Regularly reviewing and adjusting inventory levels based on project demand can lead to enhanced operational efficiency and reduced downtime.

Strategic Material Selection Guide for bolt types

What Are the Key Properties of Common Bolt Materials?

When selecting bolts for international B2B applications, understanding the properties of various materials is crucial for ensuring optimal performance. Here, we analyze four common materials used in bolt manufacturing: stainless steel, alloy steel, low carbon steel, and titanium.

How Does Stainless Steel Perform in Bolt Applications?

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, high tensile strength, and ability to withstand elevated temperatures. It typically maintains its properties in environments with humidity and exposure to chemicals, making it suitable for various applications.

Pros & Cons: The primary advantage of stainless steel bolts is their durability and resistance to rust and corrosion, which extends their lifespan in harsh conditions. However, they are more expensive than other materials, which can impact budget considerations for large-scale projects. Manufacturing complexity can also be higher due to the need for specialized equipment.

Impact on Application: Stainless steel bolts are ideal for applications in marine environments, chemical processing, and food industries due to their compatibility with a wide range of media. However, they may not be suitable for applications requiring high strength at elevated temperatures without additional heat treatment.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM A193 or DIN 931. Additionally, understanding local market preferences for stainless steel grades (e.g., 304 vs. 316) is essential for meeting specific application needs.

What Are the Advantages of Using Alloy Steel for Bolts?

Key Properties: Alloy steel bolts are made from a mixture of steel and other elements, such as chromium, molybdenum, or nickel. This composition enhances their strength and toughness, making them suitable for high-stress applications.

Pros & Cons: The key advantage of alloy steel bolts is their superior strength-to-weight ratio, which allows for the design of lighter structures without compromising integrity. However, they can be prone to corrosion unless properly treated with coatings or finishes, which adds to manufacturing complexity and cost.

Impact on Application: Alloy steel bolts are commonly used in automotive and aerospace applications, where high strength and reliability are critical. They can also be used in construction for structural components but require careful consideration of environmental conditions to prevent corrosion.

Considerations for International Buyers: Buyers in South America and Africa should be aware of local standards such as ASTM A325 or JIS B1180, ensuring that the alloy specifications meet regional safety and quality requirements.

Why Choose Low Carbon Steel for Cost-Effective Bolt Solutions?

Key Properties: Low carbon steel bolts are characterized by their malleability and ductility, making them easy to manufacture and shape. They typically have lower tensile strength compared to alloy steel but can be treated to improve performance.

Pros & Cons: The main advantage of low carbon steel bolts is their cost-effectiveness, making them an ideal choice for projects with budget constraints. However, their susceptibility to rust and corrosion limits their use in outdoor or high-moisture environments unless coated.

Impact on Application: Low carbon steel bolts are suitable for general-purpose applications, including furniture assembly and light construction. However, they may not perform well in high-stress or corrosive environments, which can lead to premature failure.

Considerations for International Buyers: Buyers from regions like Africa should consider local availability and compliance with standards such as ASTM A307. Understanding the market for coated versus uncoated options can also influence procurement decisions.

What Makes Titanium an Exceptional Choice for Specialized Applications?

Key Properties: Titanium bolts are known for their exceptional strength-to-weight ratio and outstanding corrosion resistance, even in extreme environments. They can withstand high temperatures and are non-magnetic, making them suitable for specialized applications.

Pros & Cons: The primary advantage of titanium bolts is their lightweight nature combined with high strength, making them ideal for aerospace and medical applications. However, they are significantly more expensive than other materials, which can limit their use in more general applications.

Impact on Application: Titanium bolts are commonly used in aerospace, military, and high-performance automotive applications, where weight savings and corrosion resistance are paramount. Their compatibility with various media makes them versatile, but their cost can be a limiting factor.

Considerations for International Buyers: Buyers in Europe and the Middle East should ensure compliance with aerospace and military standards, such as ASTM F136. Understanding the specific applications where titanium is required can help in making informed purchasing decisions.

Summary Table of Bolt Materials

| Material | Typical Use Case for bolt types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Marine, chemical processing, food industry | Excellent corrosion resistance | Higher cost, manufacturing complexity | High |

| Alloy Steel | Automotive, aerospace, construction | Superior strength-to-weight ratio | Prone to corrosion without treatment | Medium |

| Low Carbon Steel | General-purpose applications | Cost-effective, easy to manufacture | Susceptible to rust, limited high-stress use | Low |

| Titanium | Aerospace, military, high-performance | Exceptional strength-to-weight ratio | Very high cost, limited general application | High |

In-depth Look: Manufacturing Processes and Quality Assurance for bolt types

What Are the Main Stages of Bolt Manufacturing Processes?

The manufacturing of bolts involves several critical stages, each contributing to the final product’s quality and reliability. Understanding these stages is essential for B2B buyers to ensure they are sourcing high-quality fasteners suitable for their specific applications.

Material Preparation: What Materials Are Used for Bolt Production?

The first step in the manufacturing process is material preparation, which typically involves selecting the right type of metal or polymer. Common materials for bolts include:

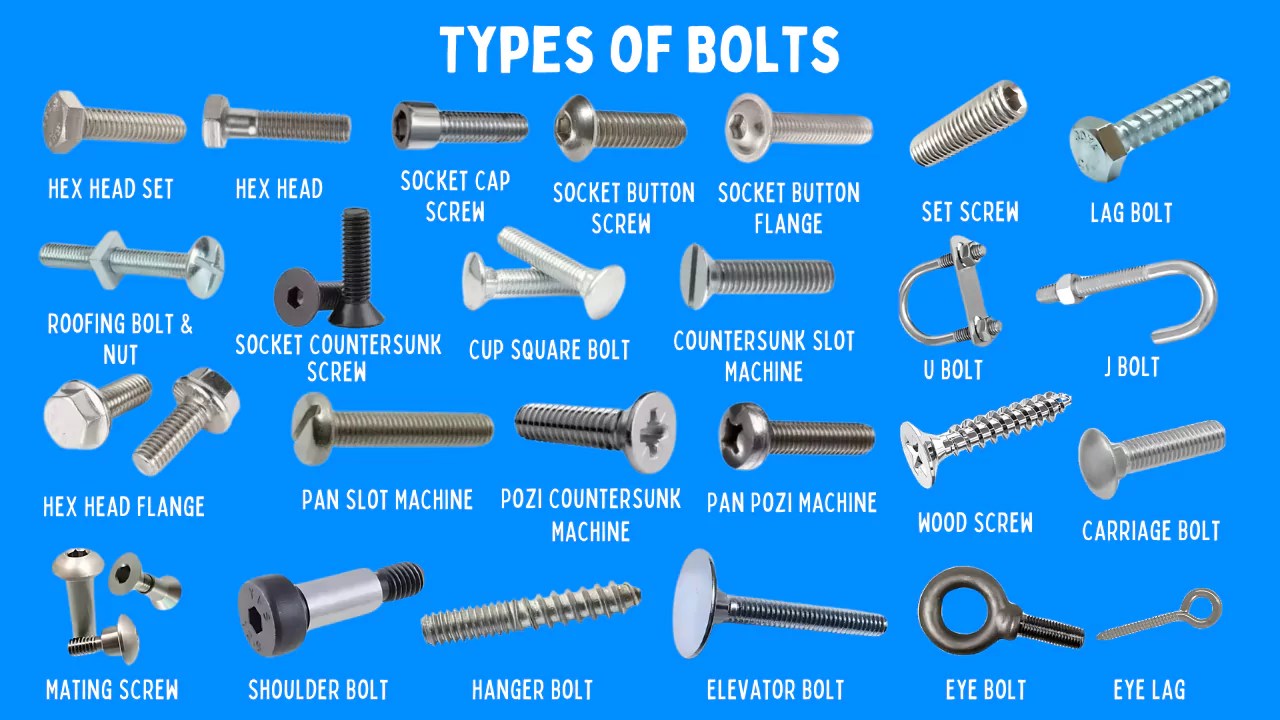

A stock image related to bolt types.

- Stainless Steel: Known for its strength and corrosion resistance, ideal for outdoor and marine applications.

- Alloy Steel: Offers enhanced strength and durability, commonly used in heavy-duty applications.

- Low/Medium Carbon Steel: Provides good tensile strength and is often used in general-purpose applications.

- Titanium: Lightweight and corrosion-resistant, suitable for aerospace and high-performance applications.

- Polymers: Such as nylon, used when chemical resistance is more critical than strength.

The chosen material is then cut into appropriate lengths and shapes, often in the form of wire or bars, ready for the next stages.

How Are Bolts Formed During Production?

The forming stage involves shaping the raw material into the desired bolt configuration. This can be achieved through several techniques:

- Cold Heading: A process where metal is shaped at room temperature, allowing for precise dimensions and excellent surface finish.

- Hot Forging: Used for larger bolts, this technique involves heating the material and then shaping it, which improves ductility and reduces brittleness.

- Machining: Some bolts are produced through machining processes, where excess material is removed to achieve the final shape and dimensions.

Each technique has its advantages, and the choice depends on the type of bolt being produced, its intended use, and cost considerations.

What Happens During the Assembly Phase?

In the assembly phase, any additional components such as washers or nuts are integrated with the bolt. This may involve:

- Thread Rolling: This process enhances the strength of the threads and improves the bolt’s performance.

- Heat Treatment: Depending on the material, heat treatment processes like quenching or tempering may be applied to achieve the desired hardness and strength.

Quality assurance is critical during this phase to ensure that all components fit correctly and function as intended.

How Is the Finishing Process Conducted for Bolts?

The finishing stage enhances the appearance and durability of the bolts. Common finishing techniques include:

- Plating: Applying coatings such as zinc or nickel to protect against corrosion.

- Anodizing: Often used for aluminum bolts, this process increases resistance to corrosion and wear.

- Polishing: Improves the aesthetic appeal and reduces surface roughness.

Finishing not only impacts the visual quality but also plays a crucial role in the bolt’s longevity and performance.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance in bolt manufacturing is vital for ensuring that products meet specific performance and safety standards. Here are some internationally recognized standards and certifications relevant to the industry:

- ISO 9001: This certification ensures that manufacturers adhere to quality management principles, including strong customer focus, the involvement of top management, and a process approach.

- CE Marking: Required for products sold within the European Economic Area, ensuring compliance with EU safety, health, and environmental protection standards.

- API (American Petroleum Institute) Standards: Particularly relevant for bolts used in the oil and gas sector, ensuring products meet stringent safety and quality requirements.

What Are the Key QC Checkpoints in Bolt Production?

Quality control (QC) is integrated at various stages of the manufacturing process, with specific checkpoints to ensure the highest standards are met:

- Incoming Quality Control (IQC): At this stage, raw materials are inspected for compliance with specifications before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during production helps identify issues early, preventing defective products from moving forward.

- Final Quality Control (FQC): After production, bolts undergo a final inspection to ensure they meet all specified requirements before shipment.

Each checkpoint serves as a safeguard, ensuring that only high-quality products reach the market.

What Common Testing Methods Are Used for Bolt Quality Assurance?

To verify the quality and performance of bolts, several testing methods are commonly employed:

- Tensile Testing: Measures the force required to pull the bolt to failure, ensuring it can withstand intended loads.

- Hardness Testing: Evaluates the material’s resistance to deformation, which is crucial for determining its durability.

- Torque Testing: Assesses the maximum torque that can be applied to the bolt before failure, essential for applications where proper tightening is critical.

- Corrosion Resistance Testing: Determines the bolt’s performance in various environmental conditions, particularly for outdoor applications.

These tests provide valuable data that B2B buyers can use to assess product quality.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers need to ensure that their suppliers maintain rigorous quality control standards. Here are several ways to verify supplier QC:

- Supplier Audits: Conducting regular audits of suppliers can help assess their manufacturing processes and quality control measures.

- Reviewing QC Reports: Requesting documentation related to QC processes, including inspection reports and testing results, provides insight into the supplier’s practices.

- Third-Party Inspections: Engaging independent inspection agencies can offer an unbiased assessment of the manufacturer’s compliance with quality standards.

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, it is crucial to understand the nuances of local regulations and standards that may affect quality assurance.

What Are the QC Certification Nuances for International B2B Buyers?

When sourcing bolts from international suppliers, B2B buyers should be aware of the following nuances:

- Regional Standards: Different regions may have unique certification requirements, such as the ANSI standards in the United States or the DIN standards in Germany. Familiarity with these can aid in effective supplier evaluation.

- Traceability Requirements: Some industries, particularly aerospace and automotive, require detailed traceability of materials and processes. Buyers should ensure that suppliers can provide this information.

- Language Barriers: Documentation and certification may be in different languages, potentially complicating verification processes. Buyers should seek suppliers that can provide clear, translated documentation.

By understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing bolts, ensuring they select reliable suppliers who meet their quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bolt types’

In the dynamic world of international B2B procurement, sourcing the right bolt types is critical for ensuring the integrity of your projects. This step-by-step checklist is designed to guide you through the process of acquiring bolts effectively, ensuring you make informed decisions that align with your technical requirements and business objectives.

Step 1: Define Your Technical Specifications

Understanding your specific needs is the first step in sourcing bolts. Clearly outline the dimensions, materials, and load requirements for the bolts you need. Consider factors such as:

– Material Type: Are you looking for stainless steel for corrosion resistance or carbon steel for strength?

– Bolt Size and Length: Ensure these meet the design requirements of your project.

Step 2: Research Different Bolt Types

Familiarize yourself with the various bolt types that suit your application. Different bolts serve different purposes, and knowing which type is appropriate can save you time and money. For example:

– Hex Bolts: Commonly used for general applications with nuts.

– Lag Bolts: Ideal for heavy-duty applications in wood.

Step 3: Evaluate Supplier Certifications

Before committing to a supplier, verify their certifications. This step ensures that the supplier adheres to international standards and quality controls. Look for:

– ISO Certifications: Indicates adherence to quality management principles.

– Industry-Specific Certifications: Such as ASTM or SAE, which confirm compliance with specific material and manufacturing standards.

Step 4: Request Samples for Testing

Always request samples before placing a bulk order. Testing samples allows you to verify the quality and performance of the bolts in real-world conditions. Pay attention to:

– Material Integrity: Check for any signs of corrosion or defects.

– Dimensional Accuracy: Ensure that the samples meet your specified dimensions.

Step 5: Assess Lead Times and Shipping Logistics

Understanding the lead times and shipping logistics is essential to avoid project delays. Discuss with potential suppliers about their production capacity and shipping timelines. Consider:

– Geographic Location: Suppliers from nearby regions may offer shorter lead times.

– Shipping Options: Evaluate air vs. sea freight based on your urgency and budget.

Step 6: Negotiate Pricing and Terms

Once you have identified suitable suppliers, engage in negotiations to secure the best pricing and terms. This step can significantly impact your overall project budget. Focus on:

– Volume Discounts: Ask about pricing tiers based on order quantities.

– Payment Terms: Clarify upfront payments, net terms, and any potential discounts for early payment.

Step 7: Establish a Quality Control Process

After placing your order, establish a quality control process to ensure that the bolts received meet your specifications. This may include:

– Receiving Inspection: Check for quantity, dimensions, and visible defects upon arrival.

– Documentation: Ensure all certifications and test reports accompany the shipment for verification.

By following this practical sourcing guide, B2B buyers from Africa, South America, the Middle East, and Europe can streamline their procurement process for bolt types, ensuring they select the right products for their projects while minimizing risks and costs.

Comprehensive Cost and Pricing Analysis for bolt types Sourcing

Understanding the cost structure and pricing for bolt types is essential for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. This analysis will delve into the various cost components, pricing influencers, and provide actionable tips to enhance your procurement process.

What Are the Key Cost Components in Bolt Sourcing?

The overall cost structure for bolts can be broken down into several key components:

- Materials: The choice of materials significantly impacts costs. Common materials include stainless steel, carbon steel, and polymers. Each material has its price point based on availability and market demand.

- Labor: Labor costs vary depending on the region and the complexity of manufacturing processes. Skilled labor may command higher wages, especially in countries with stricter labor regulations.

- Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Overhead can fluctuate based on factory location and local economic conditions.

- Tooling: Custom tooling for specific bolt designs can be a significant upfront cost. Buyers should consider whether the tooling cost will be amortized over a large volume order.

- Quality Control (QC): Ensuring product quality through rigorous QC processes can add to the overall cost. Suppliers with ISO certifications or those who adhere to strict quality standards may charge higher prices.

- Logistics: Shipping costs are crucial, especially for international buyers. Factors such as shipping method, distance, and customs duties can significantly affect the total cost.

- Margin: Suppliers will incorporate a profit margin into their pricing, which can vary widely based on competition and market conditions.

How Do Volume and Customization Affect Bolt Pricing?

- Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for larger orders. Understanding the MOQ can help buyers negotiate better pricing. Consider pooling orders with other companies to meet MOQ requirements if necessary.

- Specifications and Customization: Custom bolts tailored to specific applications will generally incur higher costs. Buyers should weigh the necessity of customization against potential savings from standard products.

- Quality and Certifications: Higher quality bolts with certifications (e.g., ISO, ASTM) command premium prices. However, investing in quality can reduce the Total Cost of Ownership (TCO) by minimizing failures and replacements.

- Supplier Factors: Supplier reliability, reputation, and geographical location can influence pricing. Local suppliers may offer cost advantages in logistics but may lack the specialization that overseas suppliers provide.

What Buyer Tips Can Enhance Cost-Efficiency in Bolt Procurement?

- Negotiate Pricing: Always approach suppliers with negotiation in mind. Presenting multiple sourcing options can create leverage for better pricing.

- Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Assess factors such as durability, maintenance, and warranty that can impact long-term costs.

- Be Aware of Pricing Nuances: International buyers should understand the implications of Incoterms on pricing, as they define responsibilities in shipping and logistics. This knowledge can prevent unexpected costs.

- Analyze Market Trends: Keep an eye on global material prices, exchange rates, and geopolitical factors that may affect costs. Being informed allows for better timing in purchasing decisions.

- Build Relationships with Suppliers: Strong relationships can lead to better service and potentially lower prices. Regular communication can also ensure that you are the first to know about price changes or special offers.

Are There Any Disclaimers Regarding Indicative Prices?

While this analysis provides a comprehensive overview of cost structures and pricing influences, it is essential to note that prices can fluctuate based on market conditions, supplier negotiations, and specific order requirements. Buyers should always seek updated quotes from suppliers to ensure accurate budgeting and decision-making.

Alternatives Analysis: Comparing bolt types With Other Solutions

Exploring Alternatives to Bolt Types in Fastening Solutions

In today’s fast-paced industrial environment, B2B buyers must evaluate various fastening solutions to meet their operational needs. While traditional bolt types remain a staple in construction and manufacturing, there are alternative solutions that may offer distinct advantages depending on the application. Understanding these alternatives can aid international buyers in making informed purchasing decisions.

Comparison Table of Bolt Types and Alternatives

| Comparison Aspect | Bolt Types | Structural Adhesives | Rivets |

|---|---|---|---|

| Performance | High tensile strength; reliable in dynamic loads | Excellent for continuous loads; offers flexibility | Strong shear strength; permanent fastening |

| Cost | Generally low-cost, especially in bulk | Higher initial cost; cost-effective over time for large areas | Moderate cost; requires specific tools for installation |

| Ease of Implementation | Easy installation with standard tools | Requires surface preparation; curing time needed | Requires specialized tools and training for application |

| Maintenance | Requires periodic checks; risk of loosening | Minimal maintenance once cured | Permanent; no maintenance required unless failure occurs |

| Best Use Case | Structural applications, machinery assembly | Bonding dissimilar materials, vibration-prone environments | Aircraft manufacturing, metal sheeting |

What Are the Advantages and Disadvantages of Structural Adhesives?

Structural adhesives provide a robust alternative to traditional bolts, particularly when bonding dissimilar materials such as metal to plastic or glass. They excel in applications where a smooth finish is desired, eliminating the need for protruding fasteners. However, their installation often requires surface preparation and curing time, which can extend project timelines. Additionally, while the initial cost may be higher than bolts, the long-term benefits in terms of durability and reduced maintenance can justify the investment.

How Do Rivets Compare to Bolt Types?

Rivets are a permanent fastening solution that offers high shear strength, making them ideal for applications like aircraft manufacturing and metal sheeting. Unlike bolts, which can be removed and replaced, rivets are designed to be a permanent solution, providing a strong bond between materials. This characteristic makes rivets less versatile but highly effective in high-stress environments. However, the installation of rivets requires specialized tools and training, which can increase the overall project cost and complexity.

Conclusion: How Can B2B Buyers Choose the Right Fastening Solution?

When selecting a fastening solution, B2B buyers should carefully consider the specific requirements of their projects. Factors such as load-bearing capacity, material compatibility, installation ease, and long-term maintenance should guide their decision-making process. While bolt types offer versatility and reliability, alternatives like structural adhesives and rivets can provide unique advantages in specific scenarios. Ultimately, the choice will depend on the specific application, budget constraints, and the desired longevity of the fastening solution. By evaluating these factors, buyers can ensure they select the most effective fastening method for their needs.

Essential Technical Properties and Trade Terminology for bolt types

What Are the Key Technical Properties of Bolt Types?

When sourcing bolts, understanding their technical properties is essential for ensuring they meet the requirements of your applications. Here are critical specifications to consider:

1. Material Grade

Material grade indicates the strength and corrosion resistance of the bolt. Common materials include stainless steel, alloy steel, and carbon steel. For instance, bolts made from stainless steel are ideal for environments prone to rust, while alloy steel offers enhanced strength for heavy-duty applications. Selecting the appropriate material grade not only ensures durability but also impacts the overall safety and performance of your assembly.

2. Thread Pitch and Diameter

Thread pitch refers to the distance between threads, while diameter indicates the size of the bolt. Both specifications are crucial for compatibility with nuts and threaded holes. Inaccurate thread dimensions can lead to assembly failures, increased wear, and compromised structural integrity. For international buyers, especially those in regions with specific standards, confirming these measurements is vital to avoid costly errors.

3. Tolerance Levels

Tolerance levels define the permissible limits of variation in bolt dimensions. These specifications are critical for achieving proper fit and function in mechanical assemblies. Tight tolerances are often required in precision applications, while looser tolerances may suffice for general construction purposes. Understanding tolerance requirements helps ensure that the bolts you procure will meet the necessary operational standards.

4. Finish and Coating

The finish or coating on a bolt affects its corrosion resistance and aesthetic appeal. Common finishes include galvanization, which provides a protective zinc layer, and black oxide, which offers a sleek appearance while reducing friction. Selecting the right finish is essential for enhancing the longevity of the bolt, particularly in harsh environments, and can also be a deciding factor in compliance with local regulations.

5. Load Rating

Load rating is a measure of the maximum load a bolt can handle before failure. This specification is particularly important for structural applications, where bolts must withstand significant forces. Understanding load ratings helps you select bolts that can safely support the intended weight, thereby preventing potential failures that could lead to costly downtime or safety hazards.

What Are Common Trade Terms in Bolt Procurement?

Familiarizing yourself with industry terminology can streamline the procurement process and enhance communication with suppliers.

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components that are used in another company’s end products. In the context of bolts, understanding the OEM’s specifications can help ensure that you are purchasing components that meet the required standards for your applications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is essential for budget planning and inventory management. Knowing the MOQ helps you negotiate better deals and ensures that you can meet your operational needs without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products. When purchasing bolts, issuing an RFQ allows you to compare prices, terms, and conditions from multiple vendors, ensuring that you secure the best deal.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping and delivery obligations. Understanding these terms is crucial for international B2B buyers, as they clarify who bears the risk during transit and the cost implications involved.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the products. For businesses operating on tight schedules, understanding lead times is critical to avoid project delays.

By mastering these technical properties and industry terms, international B2B buyers can make more informed decisions when sourcing bolts, ultimately enhancing their operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the bolt types Sector

What Are the Key Market Drivers and Trends in the Bolt Types Sector?

The global bolt types market is currently experiencing significant growth, driven by several factors including industrial expansion, increased infrastructure projects, and the rising demand for durable and high-performance fasteners. As economies in Africa, South America, the Middle East, and Europe continue to develop, the need for reliable fastening solutions in construction, automotive, and manufacturing sectors is becoming increasingly critical.

Emerging technologies such as automation in manufacturing processes and the use of advanced materials are reshaping sourcing trends. International B2B buyers are now focusing on suppliers who incorporate smart technologies into their production lines, enhancing efficiency and reducing lead times. Additionally, the trend towards online sourcing platforms has made it easier for buyers from diverse regions to access a wider range of bolt types, compare prices, and evaluate suppliers based on performance metrics.

Another key dynamic in the market is the rising importance of customization. Buyers are seeking suppliers who can offer tailored solutions that meet specific project requirements, which often involves bespoke bolt dimensions, materials, and coatings. This shift highlights the necessity for suppliers to be agile and responsive to customer needs, fostering stronger relationships in the B2B landscape.

How Can International Buyers Ensure Sustainability and Ethical Sourcing in the Bolt Types Sector?

Sustainability is increasingly becoming a priority for international B2B buyers, particularly as environmental regulations tighten globally. The production of bolts and fasteners can have a significant environmental impact, from resource extraction to manufacturing processes. Buyers are encouraged to select suppliers that demonstrate a commitment to reducing their carbon footprint through sustainable practices, such as using recycled materials or adopting energy-efficient manufacturing technologies.

A stock image related to bolt types.

Ethical sourcing is equally vital. Buyers should prioritize suppliers that maintain transparent supply chains, ensuring that all materials are sourced responsibly and that labor practices meet international standards. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Furthermore, opting for ‘green’ materials, such as fasteners made from biodegradable polymers or recycled metals, can significantly contribute to a company’s sustainability goals. By aligning with suppliers who prioritize these aspects, international buyers not only enhance their corporate social responsibility (CSR) profile but also respond to the growing consumer demand for environmentally friendly products.

A stock image related to bolt types.

How Have Bolt Types Evolved Over Time to Meet B2B Needs?

The evolution of bolt types has been closely tied to advancements in technology and changing market demands. Initially, bolts were primarily made from iron and steel, designed for basic fastening needs. However, as industries evolved, so did the materials and designs of bolts. The introduction of high-strength alloys and corrosion-resistant coatings has enabled bolts to perform in demanding environments, such as marine and chemical applications.

In recent years, the rise of lightweight materials and the integration of smart technology have further transformed the sector. For example, the development of bolts with embedded sensors allows for real-time monitoring of tension and stress, which is particularly valuable in critical applications like aerospace and automotive industries. This historical progression reflects the need for fasteners to adapt continually to meet the rigorous demands of modern applications, ensuring reliability and safety in various industries worldwide.

By understanding these market dynamics and trends, international B2B buyers can make informed decisions that align with their operational needs and sustainability goals, ultimately driving business success in the bolt types sector.

Frequently Asked Questions (FAQs) for B2B Buyers of bolt types

-

How do I choose the right bolt type for my application?

Selecting the appropriate bolt type involves understanding the materials and load requirements of your project. For instance, if you’re fastening metal to wood, consider using carriage bolts or lag bolts. For heavy-duty applications, hex bolts may be preferable. Additionally, assess environmental factors such as corrosion resistance; stainless steel bolts are ideal for humid conditions. Always consult with suppliers who can provide specifications to ensure that the bolt type meets your project’s needs. -

What is the best bolt type for high-stress applications?

For high-stress applications, hex bolts are typically the best choice due to their strength and ability to withstand high tension. They are available in various grades, with Grade 8 or higher being suitable for critical applications. U-bolts are also effective for securing pipes or cables under tension. Always verify the load ratings and material specifications to ensure that the selected bolt can handle the operational stress in your specific application. -

What factors should I consider when sourcing bolts internationally?

When sourcing bolts internationally, consider factors such as material quality, compliance with local standards, and the supplier’s reputation. Verify the manufacturer’s certifications and quality assurance processes. Additionally, understand shipping logistics, including customs regulations and tariffs, which can affect overall costs. It’s also prudent to inquire about lead times and the supplier’s ability to meet your demand consistently. -

How can I vet a bolt supplier to ensure quality?

Vetting a bolt supplier is essential for maintaining quality. Start by checking their certifications, such as ISO or ASTM compliance, which indicates adherence to industry standards. Request samples to assess the quality of materials and finishes. Additionally, seek references from other businesses that have sourced from them. An in-depth review of their production processes, including quality control measures, will provide further assurance of their reliability. -

What customization options are available for bolts?

Many suppliers offer customization options for bolts, including specific lengths, diameters, and finishes. You can also request specific threading types or coating for enhanced corrosion resistance. Discuss your requirements with suppliers to explore available options. Customization may involve minimum order quantities (MOQs), so clarify these details upfront to avoid unexpected costs. -

What is the typical minimum order quantity (MOQ) for bolts?

Minimum order quantities (MOQs) for bolts can vary widely depending on the supplier and the type of bolt. Generally, MOQs can range from as low as 100 pieces to several thousand for custom orders. It’s advisable to communicate your needs with potential suppliers to negotiate MOQs that align with your project requirements. Additionally, consider the cost implications of ordering larger quantities to benefit from bulk pricing. -

What payment terms should I expect when purchasing bolts internationally?

Payment terms for international bolt purchases can vary based on supplier policies and the nature of the transaction. Common terms include advance payment, letters of credit, or payment upon delivery. Discuss these terms upfront to ensure clarity and avoid misunderstandings. Be aware of currency fluctuations and additional fees that may apply when dealing with international transactions. -

How can I ensure quality assurance during the bolt manufacturing process?

To ensure quality assurance during the manufacturing process, request regular updates and reports from the supplier. Establish key performance indicators (KPIs) that the supplier must meet, such as dimensional tolerances and material properties. Consider conducting on-site inspections or third-party audits to verify compliance with your quality standards. Implementing a robust quality assurance process helps mitigate risks associated with product defects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for bolt types

What Are the Key Takeaways for B2B Buyers in Bolt Sourcing?

In conclusion, strategic sourcing of bolts requires a comprehensive understanding of the various types and materials available in the market. Buyers should prioritize factors such as load capacity, environmental resistance, and compatibility with existing systems when selecting bolts. Bolts like hex, carriage, and lag bolts serve distinct applications, and understanding these nuances can lead to improved project outcomes. Furthermore, engaging with reputable suppliers who can provide both quality and compliance is crucial for maintaining operational integrity.

How Can International Buyers Enhance Their Sourcing Strategy?

As international B2B buyers, especially from Africa, South America, the Middle East, and Europe, the emphasis should be on fostering relationships with local and global suppliers who can offer competitive pricing and reliable delivery. With the rising demand for sustainability, consider suppliers who provide eco-friendly options, such as recycled materials.

What Does the Future Hold for Bolt Sourcing?

Looking ahead, the landscape for bolt sourcing will likely evolve with advancements in manufacturing technologies and material science. Embrace digital platforms for sourcing, which can offer greater transparency and efficiency. This proactive approach will not only streamline your procurement processes but also ensure that your business remains agile in a competitive market. Take the next step in optimizing your sourcing strategy today, as it can significantly impact your operational success and overall growth.