Unlock Cost Savings: The Complete Meshing Wire Guide (2025)

Introduction: Navigating the Global Market for meshing wire

In today’s rapidly evolving global market, sourcing high-quality meshing wire presents a formidable challenge for international B2B buyers. Whether you operate in construction, agriculture, or manufacturing, finding the right mesh products—tailored to specific applications like security, filtration, or architectural design—can significantly impact your operational efficiency and project outcomes. This comprehensive guide serves as an essential resource, detailing the various types of meshing wire available, including woven, welded, and expanded options, alongside their diverse applications across industries.

This guide empowers buyers from Africa, South America, the Middle East, and Europe—such as those in Saudi Arabia and Poland—by providing in-depth insights into supplier vetting processes, cost considerations, and quality standards. By understanding the landscape of meshing wire, including its material compositions like stainless steel, aluminum, and galvanized options, you can make informed purchasing decisions that align with your business needs.

Furthermore, we will explore market trends, innovative applications, and practical tips for optimizing procurement strategies, ensuring you have the necessary knowledge to navigate this competitive sector. As you delve into this guide, you will gain the confidence to identify reliable suppliers, negotiate effectively, and ultimately enhance your product offerings with high-quality meshing wire solutions.

Understanding meshing wire Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Woven Wire Mesh | Flexible, made of interlaced wires; various opening sizes | Filtration, insect screening, architectural designs | Pros: Versatile, customizable; Cons: May not be as strong as welded mesh for heavy-duty applications. |

| Welded Wire Mesh | Wires welded at intersections; provides structural integrity | Construction, reinforcement, animal enclosures | Pros: Durable, permanent structure; Cons: Less flexible, can be heavier and costlier. |

| Expanded Metal Mesh | Sheet metal cut and stretched; diamond-shaped openings | Security applications, ventilation, walkways | Pros: Lightweight, strong, and slip-resistant; Cons: Limited to specific shapes and sizes. |

| Hardware Cloth | Woven mesh with smaller openings; typically galvanized | Animal fencing, garden protection, strainers | Pros: Cost-effective, easy to handle; Cons: Less durable for heavy-duty applications. |

| Vinyl Coated Wire Mesh | Galvanized mesh with a PVC coating for enhanced corrosion resistance | Outdoor fencing, garden trellises, pet enclosures | Pros: Weather-resistant, aesthetic appeal; Cons: Higher initial cost, potential for wear over time. |

What Are the Characteristics of Woven Wire Mesh?

Woven wire mesh is created through the interlacing of wires, forming a flexible and adaptable fabric. This type of mesh is available in various opening sizes, making it suitable for a wide range of applications, including filtration and architectural designs. For B2B buyers, the customization options are a significant advantage, as they can tailor the mesh to specific needs. However, it may not provide the structural strength required for heavy-duty applications compared to welded variants.

Why Choose Welded Wire Mesh for Industrial Applications?

Welded wire mesh consists of wires that are permanently joined at their intersections, creating a robust and stable structure. This type is particularly well-suited for construction and reinforcement tasks, as it offers high durability and reliability. B2B buyers should consider welded wire mesh for projects that demand long-term performance. However, its rigidity and weight can be drawbacks, especially for applications requiring flexibility.

How Does Expanded Metal Mesh Enhance Security?

Expanded metal mesh is produced by cutting and stretching sheet metal, resulting in a diamond-shaped pattern that provides excellent strength-to-weight ratio. This type of mesh is commonly used in security applications, such as fencing and walkways, due to its slip-resistant properties. For B2B buyers, expanded metal mesh is an effective choice for enhancing safety without compromising on weight. However, its design limits customization options, which may not suit all projects.

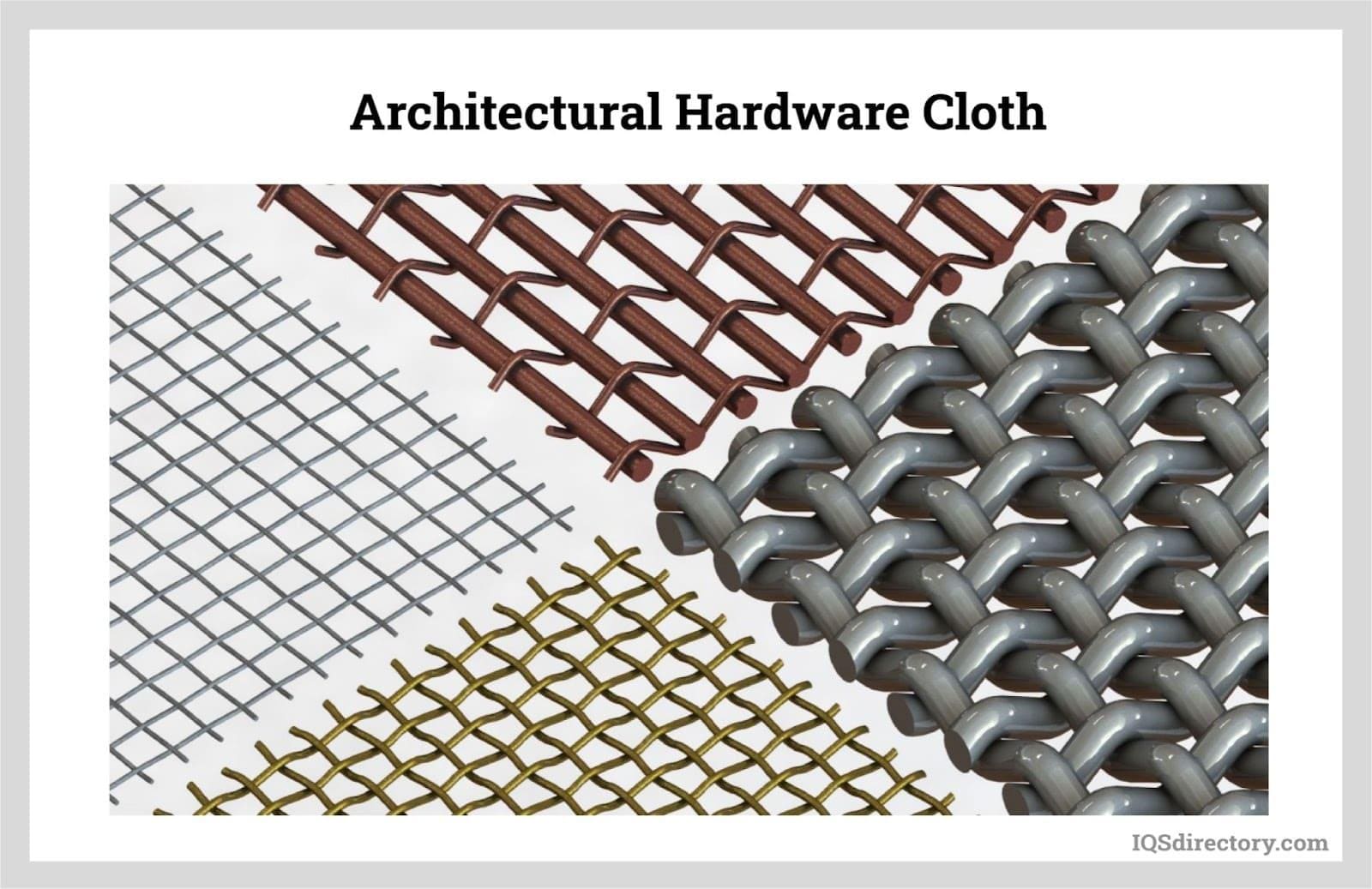

What Are the Benefits of Using Hardware Cloth?

Hardware cloth is characterized by its smaller openings and is often galvanized for rust resistance. It is primarily used in fencing applications, garden protection, and various strainers. This type of mesh is cost-effective and easy to handle, making it appealing for small-scale projects. Nevertheless, B2B buyers should note that hardware cloth may not withstand heavy-duty demands, limiting its application in more rigorous environments.

Why Consider Vinyl Coated Wire Mesh for Outdoor Applications?

Vinyl coated wire mesh combines the strength of galvanized wire with a PVC coating that enhances its corrosion resistance, making it ideal for outdoor use. This type of mesh is popular for garden trellises, fencing, and pet enclosures due to its aesthetic appeal and durability. B2B buyers should weigh the higher initial investment against the long-term benefits of reduced maintenance and replacement costs. However, potential wear over time should also be factored into purchasing decisions.

Key Industrial Applications of meshing wire

| Industry/Sector | Specific Application of meshing wire | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Reinforcement in concrete structures | Increases structural integrity and durability | Ensure compliance with local building codes and standards. |

| Agriculture | Animal enclosures and fencing | Protects livestock while allowing airflow | Consider wire gauge and coating for weather resistance. |

| Food & Beverage Processing | Filtration and separation in processing systems | Enhances product quality and safety | Look for mesh that meets food safety regulations. |

| Automotive | Grilles and screens for ventilation and protection | Improves engine performance and longevity | Source materials that withstand high temperatures. |

| Mining & Minerals | Safety barriers and equipment protection | Reduces risk of accidents and equipment damage | Evaluate mesh strength and corrosion resistance. |

How is meshing wire utilized in construction and architecture?

In the construction and architecture sectors, meshing wire is primarily used as reinforcement in concrete structures. It enhances the structural integrity and durability of buildings and other constructions, making them more resilient to stress and environmental factors. B2B buyers from regions like Africa and the Middle East should ensure that the meshing wire complies with local building codes and standards, which can vary significantly. Additionally, considering the type of wire (e.g., stainless steel vs. galvanized) is essential for long-term performance.

What are the agricultural applications of meshing wire?

In agriculture, meshing wire is commonly employed for animal enclosures and fencing. It provides a secure environment for livestock while allowing for adequate airflow and visibility. This is particularly important in regions like South America, where climate conditions can vary. Buyers should consider the wire gauge and coating to ensure durability against weather conditions and animal interactions, which can impact the longevity of the fencing solution.

How does meshing wire benefit food and beverage processing?

Meshing wire plays a vital role in the food and beverage processing industry, where it is used for filtration and separation processes. This application is crucial for enhancing product quality and safety, as it prevents contaminants from entering the production line. International buyers, particularly from Europe, must ensure that the wire mesh meets stringent food safety regulations, which can differ by country. It is also essential to select the right mesh size to optimize filtration efficiency without compromising flow rates.

What role does meshing wire play in the automotive industry?

In the automotive sector, meshing wire is utilized in grilles and screens for ventilation and protection of engine components. This application contributes to improved engine performance and longevity by ensuring adequate airflow while safeguarding against debris. B2B buyers in regions like Europe should source materials that can withstand high temperatures and corrosive environments to ensure optimal performance over time.

How is meshing wire used in mining and minerals?

In the mining and minerals sector, meshing wire is essential for creating safety barriers and protecting equipment from damage. This application is critical for reducing the risk of accidents and ensuring the safety of personnel. Buyers should evaluate the strength and corrosion resistance of the meshing wire, particularly in harsh environments, to ensure it meets the demanding requirements of mining operations.

3 Common User Pain Points for ‘meshing wire’ & Their Solutions

Scenario 1: Sourcing Quality Meshing Wire for Diverse Applications

The Problem: International B2B buyers often face the challenge of sourcing high-quality meshing wire that meets specific application requirements. For instance, a construction firm in Poland may need stainless steel wire mesh for a filtration system, while a manufacturer in South Africa requires galvanized wire mesh for agricultural fencing. The difficulty lies not only in finding suppliers who offer the right specifications but also in ensuring that the wire mesh adheres to local standards and regulations. This can lead to project delays, increased costs, and potential compliance issues.

The Solution: To address this sourcing challenge, buyers should develop a clear specification sheet that outlines the required characteristics of the meshing wire, including material type, gauge, mesh size, and finish. Engaging with multiple suppliers and requesting samples can help in assessing the quality of the mesh. It is also advisable to verify the supplier’s credentials and their adherence to local and international standards. Utilizing platforms that connect buyers with vetted suppliers can streamline the sourcing process, ensuring that buyers find reliable options that meet their specific needs.

Scenario 2: Understanding Mesh Specifications and Their Impact on Performance

The Problem: Another common pain point for B2B buyers is the confusion surrounding mesh specifications, which can significantly affect the performance of the wire mesh in its intended application. For example, a company in Saudi Arabia might select a wire mesh based solely on the gauge without considering the opening size or the wire’s tensile strength. This oversight can lead to inadequate filtration or structural failure, resulting in costly rework and operational inefficiencies.

The Solution: To mitigate this issue, buyers should invest time in understanding the relationship between mesh specifications and their applications. A practical approach is to consult technical resources or engage with industry experts who can clarify how different mesh sizes, wire diameters, and materials affect performance. Additionally, utilizing detailed product catalogs that provide comprehensive information on specifications and performance metrics can guide buyers in making informed decisions. Conducting pilot tests with selected wire mesh samples before full-scale procurement can also help validate the suitability of the chosen specifications.

Scenario 3: Managing Cost-Effectiveness in Meshing Wire Purchases

The Problem: Cost management is a critical concern for B2B buyers, especially in regions with fluctuating market conditions. A manufacturer in South America might struggle with balancing the need for high-quality meshing wire with budget constraints. High-quality materials often come at a premium, and buyers may feel pressured to compromise on quality to stay within budget, risking product performance and longevity.

The Solution: To achieve cost-effectiveness without sacrificing quality, buyers should consider bulk purchasing options or establishing long-term contracts with suppliers. This can lead to better pricing and consistent supply. Additionally, conducting a thorough cost-benefit analysis of different materials and specifications will help buyers understand the long-term value of investing in higher-quality meshing wire. Exploring alternative materials or innovative wire mesh solutions that may offer better performance at a similar cost can also provide additional savings. Finally, collaborating with suppliers to identify potential cost-saving opportunities, such as optimized shipping methods or payment terms, can further enhance budget management.

Strategic Material Selection Guide for meshing wire

What Are the Key Properties of Common Meshing Wire Materials?

When selecting meshing wire for various applications, understanding the properties of different materials is crucial for international B2B buyers. Here, we analyze four common materials used in wire mesh production: stainless steel, galvanized steel, aluminum, and brass.

A stock image related to meshing wire.

How Does Stainless Steel Perform in Meshing Applications?

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, making it suitable for harsh environments. It can withstand high temperatures and pressures, ensuring durability in demanding applications.

Pros & Cons: The main advantage of stainless steel is its longevity and strength, which often justifies its higher cost. However, it can be more expensive to manufacture and may require specialized welding techniques, which could complicate production.

Impact on Application: Stainless steel is ideal for applications involving food processing, pharmaceuticals, and marine environments, where hygiene and corrosion resistance are paramount.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM A240 or EN 10088. Understanding local regulations regarding food safety and corrosion resistance is also essential.

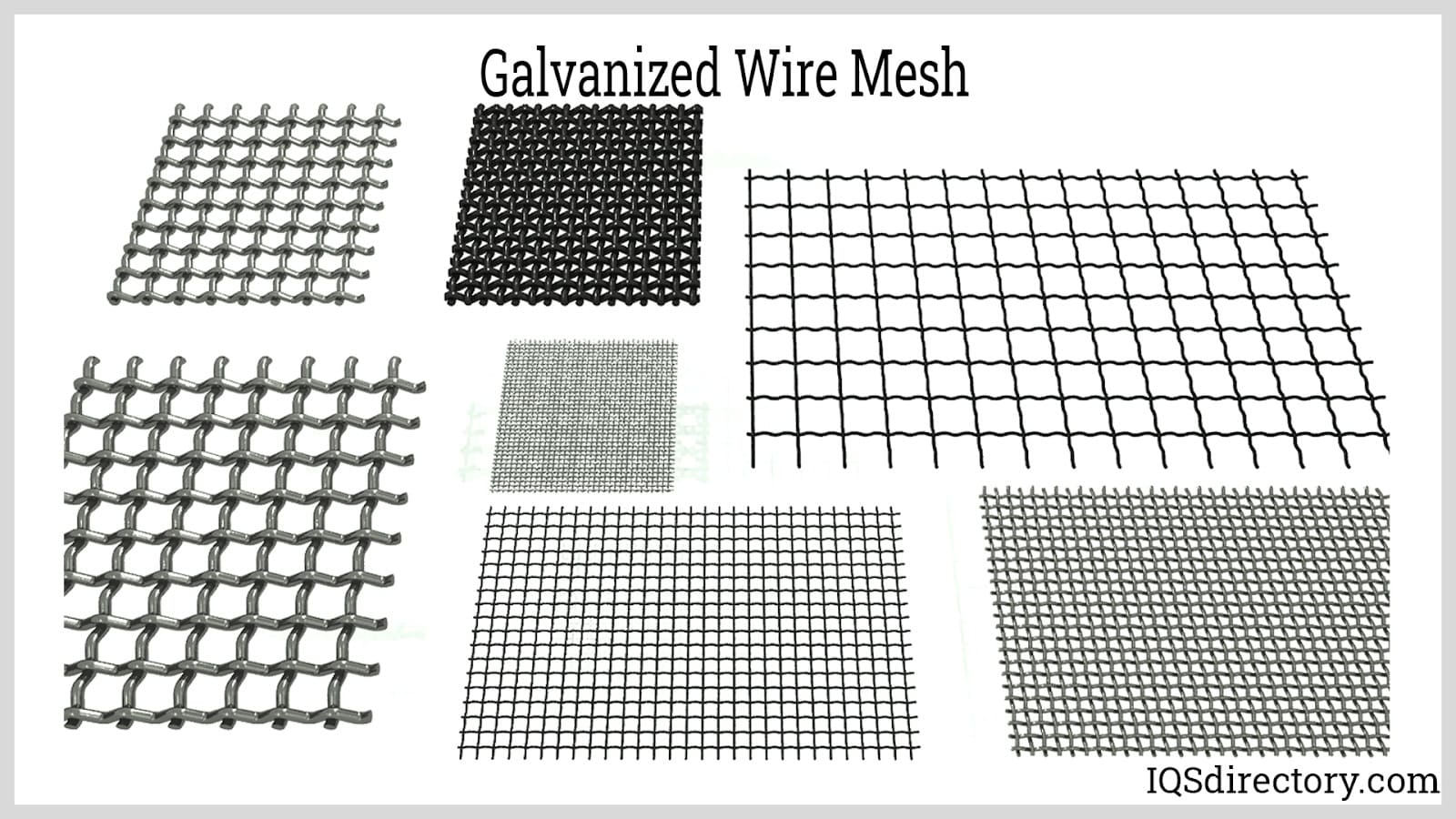

What Benefits Does Galvanized Steel Offer for Wire Mesh?

Key Properties: Galvanized steel features a protective zinc coating that enhances its corrosion resistance, making it suitable for outdoor applications. It can handle moderate temperatures and pressures.

Pros & Cons: The primary advantage is its cost-effectiveness compared to stainless steel while still providing decent durability. However, the zinc coating can wear off over time, especially in aggressive environments, leading to potential rusting.

Impact on Application: Galvanized steel is commonly used in construction, fencing, and agricultural applications, where moderate durability and cost efficiency are required.

Considerations for International Buyers: Buyers in Africa and South America should be aware of local environmental conditions that may affect the longevity of galvanized products. Compliance with ASTM A123 for hot-dip galvanizing is also recommended.

Why Choose Aluminum for Wire Mesh Applications?

Key Properties: Aluminum is lightweight and resistant to corrosion, making it easy to handle and install. It has a lower strength compared to steel but can be suitable for applications where weight is a concern.

Pros & Cons: The key advantage of aluminum is its lightweight nature and resistance to rust, which makes it ideal for architectural applications. However, its lower strength may not be suitable for heavy-duty applications.

Impact on Application: Aluminum mesh is frequently used in decorative applications, insect screens, and lightweight fencing.

Considerations for International Buyers: Buyers in Europe and the Middle East should consider compliance with relevant standards like EN 573 for aluminum alloys. Additionally, understanding local preferences for aesthetics can influence material choice.

What Are the Advantages of Brass in Wire Mesh?

Key Properties: Brass offers excellent corrosion resistance and has antimicrobial properties, making it suitable for specific applications. It has moderate strength and can withstand moderate temperatures.

Pros & Cons: The primary advantage of brass is its aesthetic appeal and resistance to tarnishing. However, it is generally more expensive than other metals and may not be suitable for high-stress applications.

Impact on Application: Brass is often used in decorative mesh applications, medical equipment, and architectural elements.

Considerations for International Buyers: Buyers from regions like Saudi Arabia should ensure compliance with ASTM B36 for brass products. Understanding the local market’s aesthetic preferences can also guide purchasing decisions.

Summary Table of Meshing Wire Materials

| Material | Typical Use Case for meshing wire | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals, marine | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Galvanized Steel | Construction, fencing, agricultural | Cost-effective with decent durability | Zinc coating may wear off over time | Medium |

| Aluminum | Decorative applications, insect screens | Lightweight and rust-resistant | Lower strength compared to steel | Medium |

| Brass | Decorative mesh, medical equipment | Aesthetic appeal and antimicrobial | Higher cost and not suitable for heavy-duty applications | High |

This strategic material selection guide provides international B2B buyers with actionable insights into the properties, advantages, and limitations of various meshing wire materials, ensuring informed purchasing decisions tailored to specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for meshing wire

What Are the Main Stages of Manufacturing Meshing Wire?

The manufacturing process for meshing wire is intricate and involves several key stages, each critical to producing high-quality products that meet diverse applications. Understanding these stages can help B2B buyers ensure they are sourcing from reputable suppliers.

1. Material Preparation

The first step in the manufacturing process is material preparation. Wire mesh is typically made from various metals, including stainless steel, carbon steel, aluminum, and copper. The choice of material depends on the intended application, such as corrosion resistance for outdoor use or strength for industrial applications.

During this stage, raw materials are sourced and inspected for quality. It’s essential for buyers to verify that suppliers adhere to international standards such as ISO 9001, which dictates quality management principles. This ensures that the materials used are reliable and meet the required specifications.

2. Forming Techniques: How Is Meshing Wire Created?

Once the materials are prepared, the next stage involves forming the wire into mesh. There are two primary techniques used: woven and welded.

-

Woven Mesh: In this method, wires are interlaced in a crisscross pattern. This technique is often used for applications requiring flexibility, such as insect screens or decorative uses. The weaving process can be adjusted to create various opening sizes and wire diameters, enhancing versatility.

-

Welded Mesh: This technique involves welding the wires at their intersections, creating a more robust and permanent structure. Welded wire mesh is preferred for applications that demand higher strength and durability, such as fencing or concrete reinforcement.

Buyers should inquire about the specific forming techniques used by their suppliers, as this can significantly impact the product’s performance and suitability for various applications.

3. Assembly: How Are Different Mesh Types Combined?

In some cases, meshing wire may require additional components or features, such as frames or coatings for enhanced functionality. The assembly stage involves combining these elements to create the final product. For instance, PVC coatings can be applied to galvanized steel wire mesh to improve weather resistance.

B2B buyers should assess the supplier’s ability to customize products based on specific needs, including dimensions, patterns, and additional features. This customization can be a significant advantage in competitive markets.

4. Finishing: What Treatments Enhance Durability?

The final stage in the manufacturing process is finishing, which includes surface treatments that enhance the wire mesh’s durability and performance. Common finishing processes include:

- Galvanization: This involves coating the wire with a layer of zinc to prevent rust and corrosion, making it suitable for outdoor applications.

- Powder Coating: A process that applies a protective layer of powder to the surface, providing additional color and resistance to wear and tear.

Quality finishes are crucial for ensuring longevity and performance in various environments. Buyers should request information on the finishing processes used and verify that they align with their specific application needs.

What Quality Assurance Practices Should B2B Buyers Look For?

Quality assurance (QA) is a fundamental aspect of the manufacturing process that ensures the final product meets specified standards and requirements. For international B2B buyers, understanding the QA practices employed by suppliers is essential.

International Standards: How Do They Impact Quality Assurance?

Reputable manufacturers adhere to international quality standards such as ISO 9001. This standard outlines the requirements for a quality management system, ensuring consistent product quality and customer satisfaction.

In addition to ISO standards, industry-specific certifications may be required, such as CE marking for products sold in Europe or API certification for applications in the oil and gas industry. Buyers should request documentation verifying compliance with relevant standards to ensure product reliability.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically segmented into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This phase involves inspecting raw materials upon arrival at the manufacturing facility. Ensuring that materials meet specified standards is critical to preventing defects in the final product.

-

In-Process Quality Control (IPQC): During production, regular inspections are conducted to monitor the manufacturing process and identify any deviations from quality standards. This proactive approach helps address issues before they escalate.

-

Final Quality Control (FQC): The final inspection occurs before products are shipped to clients. This stage verifies that all products meet the required specifications and standards.

Buyers should inquire about the QC processes in place and request access to inspection reports, which can provide insights into the reliability and consistency of the supplier’s products.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control measures is crucial for international buyers to ensure product reliability and compliance with standards. Here are several actionable steps:

1. Conduct Supplier Audits

Regular audits of suppliers can help assess their manufacturing practices and quality control measures. During an audit, buyers can evaluate the manufacturing facility, observe processes, and review compliance with international standards.

2. Request Quality Reports

Buyers should ask suppliers for detailed quality reports that outline inspection results, certifications, and any corrective actions taken for non-compliance. This documentation can help build confidence in the supplier’s capabilities.

3. Utilize Third-Party Inspection Services

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These organizations can conduct inspections at various stages of the manufacturing process, ensuring that products meet the required specifications before shipment.

What Are the Quality Control Nuances for International Buyers?

For B2B buyers from regions like Africa, South America, the Middle East, and Europe, there are several nuances to consider in the quality control process:

-

Cultural and Regulatory Differences: Understanding regional regulations and cultural expectations can aid in the selection of suppliers. Compliance with local standards is essential for ensuring market acceptance.

-

Communication Barriers: Clear communication regarding quality expectations is vital. Buyers should ensure that language and cultural differences do not impede understanding of quality requirements.

-

Supply Chain Logistics: International buyers must consider the logistics of transporting wire mesh products. Quality assurance practices should include considerations for how products are handled during shipping to prevent damage.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for meshing wire can significantly benefit B2B buyers. By focusing on material preparation, forming techniques, assembly, finishing, and stringent quality control practices, buyers can make informed decisions that enhance their supply chain and ensure product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘meshing wire’

When sourcing meshing wire for your business needs, it’s essential to follow a systematic approach to ensure you choose the right product and supplier. This guide provides a practical checklist to assist international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, in making informed purchasing decisions.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements for the meshing wire. This includes specifications such as:

– Material Type: Decide if you need stainless steel, galvanized steel, or other materials based on durability and corrosion resistance.

– Wire Diameter: Specify the thickness of the wire, as this will affect strength and application.

– Mesh Size and Pattern: Determine the required opening size and pattern (e.g., welded or woven) depending on the intended use, whether for filtration, security, or architectural design.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in meshing wire. Look for:

– Industry Experience: Suppliers with a proven track record in your specific industry can offer valuable insights and tailored solutions.

– Product Range: Ensure they offer a variety of mesh sizes, materials, and custom options to meet your unique needs.

Step 3: Evaluate Supplier Certifications

Verification of supplier certifications is crucial for ensuring quality and compliance with industry standards. Check for:

– ISO Certification: This indicates that the supplier adheres to international quality management standards.

– Material Certifications: Ensure that the materials meet your region’s safety and quality regulations, especially if the mesh will be used in critical applications.

Step 4: Request Samples for Testing

Before making a bulk order, request samples of the meshing wire. This step allows you to:

– Assess Quality: Examine the physical properties, such as tensile strength and flexibility.

– Test Compatibility: Ensure the product meets your operational requirements by conducting tests relevant to your application.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers to compare pricing structures and terms. Pay attention to:

– Volume Discounts: Inquire about price breaks for larger orders, which can significantly reduce costs.

– Payment Terms: Assess the flexibility of payment options and terms, especially if you are working with international suppliers.

Step 6: Check References and Reviews

Don’t hesitate to ask for references from other clients, particularly those in your industry or region. Look for:

– Customer Feedback: Reviews can provide insights into the supplier’s reliability, product quality, and customer service.

– Case Studies: Successful projects or testimonials can demonstrate the supplier’s capability to meet specific needs.

Step 7: Finalize the Order and Logistics

Once you have selected a supplier, ensure that all details are clearly outlined in the contract. Key considerations include:

– Lead Times: Confirm production and delivery timelines to align with your project schedule.

– Shipping Arrangements: Discuss shipping methods and costs to ensure timely and cost-effective delivery to your location.

By following this structured approach, you can confidently source meshing wire that meets your specifications while ensuring a smooth procurement process.

Comprehensive Cost and Pricing Analysis for meshing wire Sourcing

What Are the Key Cost Components in Meshing Wire Sourcing?

When sourcing meshing wire, understanding the cost structure is critical for international B2B buyers. The primary cost components include:

-

Materials: The type of metal used (e.g., stainless steel, galvanized steel, aluminum) significantly influences pricing. Specialty materials or custom alloys can lead to higher costs.

-

Labor: Labor costs vary by region and can affect the overall manufacturing price. Countries with higher labor costs may not be as competitive as those with lower labor rates.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and maintenance. Efficient manufacturing processes can help minimize these costs.

-

Tooling: If custom mesh specifications are required, tooling costs for specialized equipment can add to the total price. This is particularly relevant for unique patterns or sizes.

-

Quality Control (QC): Ensuring the quality of meshing wire through rigorous testing and compliance checks incurs additional costs. Certifications and quality standards can also affect pricing.

-

Logistics: Shipping costs can vary based on distance, mode of transport, and packaging requirements. International shipping often involves customs duties and tariffs that can further impact the final cost.

-

Margin: Suppliers will add their profit margin on top of the total production costs, which can vary widely based on market competition and supplier reputation.

How Do Price Influencers Affect Meshing Wire Costs?

Several factors can influence the pricing of meshing wire, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger order volumes often lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, which can be a significant cost-saving strategy.

-

Specifications and Customization: Custom specifications (like wire diameter, mesh size, and pattern) can increase costs due to additional manufacturing processes. It’s essential to balance requirements with budget constraints.

-

Material Quality and Certifications: Higher quality materials typically command higher prices. Additionally, certifications (such as ISO or ASTM standards) can lead to increased costs but may be necessary for compliance in certain industries.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their quality assurance and dependable service.

-

Incoterms: Understanding the chosen Incoterms (International Commercial Terms) is crucial, as they define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs. This can significantly affect the total cost of ownership.

What Are the Best Buyer Tips for Cost-Efficiency in Meshing Wire Sourcing?

To maximize cost-efficiency when sourcing meshing wire, consider the following strategies:

-

Negotiate: Engage in negotiations with suppliers to secure better pricing, especially for larger orders. Building relationships with suppliers can also lead to improved terms over time.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as longevity, maintenance, and potential operational costs to determine the true value of the product.

-

Research Market Trends: Stay informed about market trends and pricing fluctuations. Understanding the demand and supply dynamics can provide leverage during negotiations.

-

Explore Local Suppliers: For buyers in regions like Africa and South America, local suppliers may offer cost advantages due to reduced shipping and logistics expenses. Additionally, local sourcing can help mitigate import tariffs.

-

Consider Quality vs. Cost: While it may be tempting to choose the lowest-priced option, ensure that the quality meets your application requirements. Poor-quality wire can lead to failures and increased costs in the long run.

Disclaimer on Indicative Prices

Prices for meshing wire can fluctuate based on market conditions, supplier pricing strategies, and regional economic factors. Always consult with suppliers for the most accurate and current pricing information tailored to your specific needs.

Alternatives Analysis: Comparing meshing wire With Other Solutions

When exploring the options for industrial and commercial applications, it’s essential to evaluate meshing wire alongside alternative solutions. This analysis will provide international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, with a clear understanding of how meshing wire stacks up against other technologies.

Comparison Table: Evaluating Meshing Wire Against Alternatives

| Comparison Aspect | Meshing Wire | Expanded Metal | Hardware Cloth |

|---|---|---|---|

| Performance | High strength and durability; versatile in various applications. | Good strength-to-weight ratio; ideal for security applications. | Effective for filtration; less durable than wire mesh. |

| Cost | Moderate initial cost; long-term savings due to durability. | Generally lower upfront cost; may require replacement sooner. | Low cost; best for budget-sensitive projects. |

| Ease of Implementation | Easy to install; requires minimal tools. | More complex installation; may need special tools for cutting. | Very easy to cut and shape; user-friendly. |

| Maintenance | Low maintenance; resistant to corrosion when galvanized. | Moderate maintenance; can be prone to rust without treatment. | Low maintenance but needs replacement if damaged. |

| Best Use Case | Ideal for architectural, industrial, and security applications. | Best suited for fencing and security barriers. | Optimal for animal enclosures and gardening applications. |

What are the Pros and Cons of Expanded Metal as an Alternative to Meshing Wire?

Expanded metal offers a unique alternative to meshing wire, characterized by its distinctive pattern formed by cutting and stretching metal sheets. Pros include its excellent strength-to-weight ratio and effective airflow, making it suitable for security applications. However, cons include its more complicated installation process and the potential for rusting if not properly treated.

How Does Hardware Cloth Compare to Meshing Wire?

A stock image related to meshing wire.

Hardware cloth is a woven mesh that provides a cost-effective solution for various applications. Advantages of hardware cloth include its affordability and ease of installation, as it can be easily cut to size and shaped for specific projects. However, it may not offer the same durability or strength as meshing wire, which can be a drawback for more demanding applications.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Choosing the right solution depends on the specific requirements of your project. For those prioritizing durability and versatility, meshing wire is often the superior choice. However, if budget constraints are paramount, hardware cloth might be appealing. Conversely, for applications where security is a top priority, expanded metal could be the best fit. By assessing performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions that align with their operational needs and budgetary constraints.

Essential Technical Properties and Trade Terminology for meshing wire

What Are the Essential Technical Properties of Meshing Wire?

When sourcing meshing wire, B2B buyers must understand several key technical properties that influence performance, durability, and suitability for specific applications. Here are the critical specifications:

-

Material Grade

The material of the wire mesh significantly affects its strength and corrosion resistance. Common materials include stainless steel, galvanized steel, aluminum, and copper. Each material has unique properties that cater to different environments—stainless steel is preferred for its resistance to rust and high tensile strength, making it ideal for food processing or marine applications. -

Wire Diameter

The diameter of the wire used in mesh construction directly impacts its strength and load-bearing capacity. A thicker wire typically offers greater durability but may also increase weight and cost. Buyers must balance the required strength against other factors like application needs and budget constraints. -

Mesh Opening Size

This refers to the size of the gaps between the wires in the mesh. It is crucial for applications requiring filtration or separation. Smaller openings are suitable for filtering fine particles, while larger openings may be used for security applications. Understanding the specific requirements of your project will help in selecting the right mesh opening size. -

Weld Type

The method used to connect the wires—woven or welded—affects the mesh’s overall integrity and performance. Welded wire mesh provides a stronger and more permanent solution, making it suitable for heavy-duty applications. Woven mesh, on the other hand, offers flexibility and is often used in lighter applications. -

Coating and Finish

The surface treatment of meshing wire, such as galvanization or PVC coating, plays a vital role in its resistance to environmental factors. Coatings can enhance corrosion resistance and longevity, making them essential for outdoor applications. Understanding the environmental conditions your mesh will face helps in selecting the appropriate coating. -

Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions. High tolerance levels ensure that the mesh will fit properly in its intended application without compromising structural integrity. Buyers should assess the tolerance requirements based on the precision needed in their projects.

What Are Common Trade Terms Related to Meshing Wire?

Familiarity with industry jargon can facilitate smoother transactions and clearer communication between buyers and suppliers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for ensuring compatibility with existing machinery or systems. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their procurement strategy, especially when dealing with international suppliers who may have different standards. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It is a vital tool for comparing offers and ensuring that all quotes are based on the same specifications, which is particularly important when dealing with complex products like wire mesh. -

Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, helping to prevent misunderstandings in global trade agreements. -

Lead Time

This term refers to the time taken from placing an order to delivery. Understanding lead times is essential for effective project planning and inventory management, particularly in regions with varied logistics capabilities. -

Certification Standards

Various certifications exist to ensure the quality and safety of wire mesh products, such as ISO or ASTM standards. Buyers should verify that their suppliers comply with relevant certification standards to ensure product reliability and performance.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing meshing wire, ultimately enhancing project efficiency and success.

Navigating Market Dynamics and Sourcing Trends in the meshing wire Sector

What Are the Current Market Dynamics and Key Trends in the Meshing Wire Sector?

The global meshing wire market is experiencing significant growth driven by various factors. Key market drivers include the increasing demand for durable and versatile materials across industries such as construction, agriculture, automotive, and electronics. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding regional market dynamics is crucial. In regions like Saudi Arabia and Poland, the push for infrastructural development and urbanization has led to heightened demand for wire mesh in construction projects.

Emerging trends in B2B sourcing include the adoption of advanced manufacturing technologies such as 3D printing and automated welding processes. These technologies enhance production efficiency and enable the customization of wire mesh products to meet specific application needs. Additionally, digital transformation in supply chain management, including the use of AI and machine learning for demand forecasting, is reshaping how businesses source meshing wire. Buyers are increasingly leveraging e-commerce platforms to access a broader range of suppliers and products, making it essential to evaluate vendor reliability and product quality.

How Is Sustainability and Ethical Sourcing Impacting the Meshing Wire Industry?

Sustainability is becoming a pivotal consideration for B2B buyers in the meshing wire sector. The environmental impact of manufacturing processes, particularly in metal production, necessitates a focus on ethical sourcing practices. Buyers are increasingly seeking suppliers who demonstrate commitment to sustainability through responsible sourcing of raw materials, reduced carbon footprints, and adherence to environmental regulations.

The use of ‘green’ certifications, such as ISO 14001 for environmental management, is gaining traction among manufacturers. These certifications assure buyers that suppliers are committed to minimizing their environmental impact. Furthermore, the integration of recycled materials in the production of meshing wire is an emerging trend that not only reduces waste but also lowers production costs. Buyers should prioritize partnerships with suppliers who embrace these sustainable practices, as this can enhance their own corporate social responsibility (CSR) profiles.

What Is the Brief Evolution of the Meshing Wire Industry?

A stock image related to meshing wire.

The evolution of the meshing wire industry reflects technological advancements and changing market demands. Initially, wire mesh was primarily utilized in agriculture and construction for basic applications such as fencing and filtration. Over the decades, innovations in manufacturing processes, such as welding and weaving techniques, have expanded the functionality of wire mesh products.

Today, wire mesh is not only a staple in industrial applications but also features prominently in architectural designs and artistic installations. This shift towards multifunctional and aesthetically pleasing wire mesh products aligns with modern trends in construction and design, allowing international B2B buyers to explore a broader array of applications for meshing wire. As the market continues to evolve, staying informed about historical context can help buyers make strategic sourcing decisions that align with current trends and future demands.

Frequently Asked Questions (FAQs) for B2B Buyers of meshing wire

-

How do I solve issues with product quality when sourcing meshing wire?

To ensure high product quality, establish clear specifications and standards before engaging suppliers. Conduct thorough research on potential suppliers, including checking their certifications and quality control processes. Request samples to assess the material and craftsmanship. Additionally, consider implementing a quality assurance (QA) protocol that includes inspections at various stages of production and upon delivery to ensure compliance with your quality expectations. -

What is the best type of meshing wire for construction projects?

The best type of meshing wire for construction projects often depends on the specific application. For structural reinforcement, welded wire mesh made from high-carbon steel is preferred due to its strength and durability. For applications requiring corrosion resistance, galvanized or stainless steel mesh is ideal. Always consider the mesh size, gauge, and coating based on the environmental conditions and load-bearing requirements of your project. -

How can I find reliable suppliers of meshing wire in international markets?

Finding reliable suppliers involves using multiple channels, including trade directories, industry exhibitions, and online marketplaces. Verify supplier credibility through customer reviews, industry certifications, and references. Establish communication to assess their responsiveness and willingness to address your needs. Utilizing third-party inspection services can also help ensure the supplier meets your requirements before placing significant orders. -

What customization options are available for meshing wire products?

Customization options for meshing wire typically include variations in material type, wire diameter, mesh opening size, and coating finishes. Suppliers may also offer bespoke designs tailored to specific applications, such as architectural aesthetics or functional requirements like filtration. Engage directly with suppliers to discuss your needs and explore their capabilities for producing custom solutions that align with your project specifications. -

What is the minimum order quantity (MOQ) for meshing wire, and how does it vary by supplier?

Minimum order quantities for meshing wire can vary significantly based on the supplier, material type, and customization requirements. While some suppliers may have an MOQ as low as 100 square meters for standard products, others may require larger quantities for custom orders. Always clarify MOQ terms with your supplier during negotiations to ensure they align with your purchasing capacity and project timelines. -

What payment terms are typical when purchasing meshing wire internationally?

Typical payment terms for international purchases of meshing wire include options like advance payment, letters of credit, and payment upon delivery. Terms may vary based on supplier policies, order size, and buyer-supplier relationships. It’s crucial to establish clear payment terms upfront to avoid misunderstandings and to consider using escrow services for larger transactions to enhance security. -

How do I handle logistics and shipping when sourcing meshing wire internationally?

To manage logistics effectively, work with suppliers who have experience in international shipping and can provide reliable freight forwarding services. Discuss shipping options, including Incoterms, to clarify responsibilities for costs and risks during transit. Ensure that all customs documentation is prepared in advance to avoid delays. Additionally, consider insurance for high-value shipments to protect against potential losses during transit. -

What are the key factors to consider for compliance and regulations when importing meshing wire?

When importing meshing wire, be aware of specific compliance standards and regulations in your country. Factors include material safety standards, import duties, and potential tariffs. Research the required certifications for your products, such as ISO or ASTM standards, and ensure that your supplier can provide these documents. Engaging a local customs broker can facilitate smoother clearance processes and ensure adherence to all regulatory requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for meshing wire

Why is Strategic Sourcing Essential for Meshing Wire?

In today’s global marketplace, strategic sourcing for meshing wire is crucial for B2B buyers seeking to optimize their supply chains and enhance operational efficiency. By carefully selecting suppliers based on quality, cost, and delivery capabilities, businesses can ensure they receive the right products tailored to their specific applications, whether in construction, agriculture, or industrial settings. Understanding the diverse material options—such as stainless steel, aluminum, and galvanized wire—can significantly impact the durability and performance of the final product.

What Should International Buyers Focus On?

International buyers from regions like Africa, South America, the Middle East, and Europe should prioritize building relationships with reputable suppliers who offer comprehensive product catalogs and customization options. Engaging with local distributors can also provide valuable insights into market trends and emerging applications for meshing wire. Buyers should remain vigilant about compliance with regional regulations and sustainability practices to foster responsible sourcing.

What is the Future of Meshing Wire in Global Markets?

Looking ahead, the demand for versatile meshing wire solutions is expected to grow across various industries. As technological advancements continue to drive innovation, businesses that proactively adapt to changing market needs will gain a competitive edge. Now is the time for international B2B buyers to leverage strategic sourcing initiatives, ensuring they secure high-quality meshing wire that meets their specific requirements. Embrace the future of sourcing—partner with suppliers who are committed to quality, sustainability, and innovation in the meshing wire market.