Maximize Efficiency: The Ultimate Boiler Steam Boiler Guide (2025)

Introduction: Navigating the Global Market for boiler steam boiler

Navigating the global market for boiler steam boilers can be a daunting task for international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe. The complexity of sourcing the right boiler that meets both operational and regulatory standards is a key challenge. This guide aims to demystify the process by providing a thorough overview of steam boiler types, applications, and the essential factors to consider when selecting a supplier.

With a focus on both firetube and watertube boilers, we will delve into their operational mechanisms, efficiency ratings, and common applications across various industries. In addition, we will explore the importance of boiler safety, maintenance, and water treatment, which are crucial for ensuring long-term reliability and performance.

Furthermore, this comprehensive guide will empower B2B buyers to make informed purchasing decisions by outlining the critical steps for vetting suppliers, understanding cost structures, and recognizing regional market trends. Whether you are looking to invest in a new steam boiler system or seeking rental options during peak demand, this guide will serve as an invaluable resource. By leveraging the insights provided, international buyers can confidently navigate the complexities of the steam boiler market, ensuring that their operations run smoothly and efficiently.

Understanding boiler steam boiler Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Firetube Boiler | Combustion gases pass through tubes; simpler design. | Food processing, textile manufacturing | Pros: Lower initial cost, easier maintenance. Cons: Limited steam pressure capacity. |

| Watertube Boiler | Water circulates through tubes; higher pressure capabilities. | Power generation, chemical processing | Pros: Higher efficiency, better for high-pressure applications. Cons: Higher cost and complexity. |

| Modular Boiler | Compact design with multiple modules for scalability. | Temporary needs, industries with fluctuating demands | Pros: Flexible capacity, quick installation. Cons: Potentially higher operating costs. |

| High-Pressure Boiler | Designed for high steam pressure; robust construction. | Oil refining, large-scale manufacturing | Pros: Suitable for demanding applications, efficient energy use. Cons: Expensive to install and maintain. |

| Biomass Boiler | Uses organic materials for fuel; eco-friendly option. | Renewable energy projects, agricultural operations | Pros: Reduced carbon footprint, sustainable. Cons: Requires consistent fuel supply, can have higher upfront costs. |

What are the Characteristics of Firetube Boilers?

Firetube boilers feature a straightforward design where combustion gases flow through tubes surrounded by water. This type is particularly suited for applications where steam demand is moderate, such as in food processing and textile manufacturing. When considering a firetube boiler, B2B buyers should evaluate the initial cost, as these units are typically more affordable. However, it’s essential to note that their steam pressure capacity is limited, which may not meet the needs of all industrial applications.

How Do Watertube Boilers Compare in Terms of Efficiency?

Watertube boilers are engineered with water circulating through tubes heated externally by combustion gases. This design allows for higher steam pressures and greater efficiency, making them ideal for power generation and chemical processing. For B2B buyers, watertube boilers offer a robust solution for high-demand applications, although they come with a higher upfront cost and complexity. It’s crucial to assess the specific steam requirements and operational environment before making a purchase.

What Advantages Do Modular Boilers Offer for Temporary Needs?

Modular boilers consist of multiple smaller units that can be combined to meet varying steam demands. This flexibility makes them particularly advantageous for industries that experience fluctuating needs, such as construction or seasonal manufacturing. While modular boilers can be quickly installed and provide scalable capacity, buyers should be aware that they might incur higher operating costs compared to traditional single-unit boilers. Evaluating the long-term operational strategy is key when considering modular options.

Why Choose High-Pressure Boilers for Demanding Applications?

High-pressure boilers are built to withstand and generate steam at elevated pressures, making them essential for oil refining and large-scale manufacturing processes. They are designed for efficiency in demanding environments, which can lead to significant energy savings. However, B2B buyers must consider the substantial installation and maintenance costs associated with high-pressure boilers. It’s advisable to conduct a thorough cost-benefit analysis in relation to the specific needs of the operation.

How Do Biomass Boilers Contribute to Sustainability?

Biomass boilers utilize organic materials as fuel, positioning them as an eco-friendly option for businesses looking to reduce their carbon footprint. They are particularly suitable for renewable energy projects and agricultural operations. While the sustainability aspect is appealing, buyers should ensure a consistent supply of biomass fuel and be prepared for potentially higher initial costs. Understanding the local availability of biomass resources is crucial for effective operational planning.

Key Industrial Applications of boiler steam boiler

| Industry/Sector | Specific Application of Boiler Steam Boiler | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Steam generation for cooking and sterilization | Ensures food safety and enhances product quality | Compliance with health regulations, energy efficiency |

| Textile Manufacturing | Steam for dyeing and finishing processes | Improves fabric quality and processing speed | Boiler capacity and steam pressure requirements |

| Chemical Processing | Steam for reaction heating and distillation | Increases production efficiency and consistency | Material compatibility and safety standards |

| Power Generation | Steam for turbine operation | Provides reliable energy output | Boiler size, pressure ratings, and fuel type considerations |

| Pharmaceuticals | Steam for sterilization and heating | Ensures product safety and compliance with standards | Quality certifications and reliability of supply |

How is Boiler Steam Boiler Used in the Food and Beverage Industry?

In the food and beverage sector, steam boilers are crucial for cooking processes, sterilization, and pasteurization. The steam generated is used to maintain consistent temperatures, ensuring food safety and enhancing the quality of the final products. For international B2B buyers, especially in Africa and South America, sourcing boilers that comply with local health regulations and offer energy efficiency is essential to minimize operational costs and ensure compliance.

What Role Does Boiler Steam Boiler Play in Textile Manufacturing?

In textile manufacturing, steam boilers are used extensively for dyeing, finishing, and setting processes. The steam provides the necessary heat to achieve optimal dye absorption and fabric treatment, improving both the quality and processing speed of textiles. Buyers from Europe and the Middle East should consider the boiler’s capacity and steam pressure to meet the specific requirements of their production lines, ensuring consistent output and quality.

How is Boiler Steam Boiler Utilized in Chemical Processing?

In chemical processing, steam boilers are employed for heating reactions and distillation processes. The steam generated facilitates temperature control and enhances reaction rates, leading to increased production efficiency and product consistency. International buyers need to focus on material compatibility and safety standards when sourcing boilers, particularly in regions with stringent regulatory requirements.

Why is Boiler Steam Boiler Important for Power Generation?

Steam boilers play a pivotal role in power generation by producing steam that drives turbines for electricity production. Reliable steam generation is critical for maintaining energy output and system efficiency. Buyers must evaluate boiler size, pressure ratings, and fuel type to ensure compatibility with existing systems, particularly in regions like Europe where renewable energy integration is becoming more prevalent.

How Does Boiler Steam Boiler Support the Pharmaceutical Industry?

In the pharmaceutical industry, steam boilers are vital for sterilization processes and providing heat for various production stages. The use of steam ensures that equipment and products are free from contaminants, meeting stringent safety and quality standards. When sourcing boilers, buyers should prioritize quality certifications and the reliability of the supplier to ensure compliance with industry regulations and maintain operational integrity.

3 Common User Pain Points for ‘boiler steam boiler’ & Their Solutions

Scenario 1: Inefficiency Leading to Increased Operational Costs

The Problem:

Many businesses relying on steam boilers face the challenge of inefficiency, resulting in higher operational costs. For instance, a manufacturing plant in South America may experience frequent fluctuations in steam pressure, leading to inconsistent production processes. This inefficiency is often due to outdated technology, poor maintenance practices, or inadequate sizing of the boiler for the specific application, causing excessive fuel consumption and elevated energy bills.

The Solution:

To combat inefficiency, B2B buyers should prioritize investing in high-efficiency steam boilers that are properly sized for their applications. Begin by conducting a thorough assessment of the facility’s steam requirements, considering peak demand and operational cycles. Collaborate with a reputable boiler manufacturer or a consultant who specializes in energy efficiency to evaluate the existing system and identify potential upgrades.

Implementing regular maintenance schedules is also crucial. This includes routine inspections, cleaning of heat exchangers, and monitoring of combustion efficiency. Utilizing advanced control systems can enhance performance by automating operations and optimizing fuel-to-steam ratios. Furthermore, integrating economizers can significantly improve energy recovery by capturing waste heat, thus reducing overall fuel consumption and lowering costs.

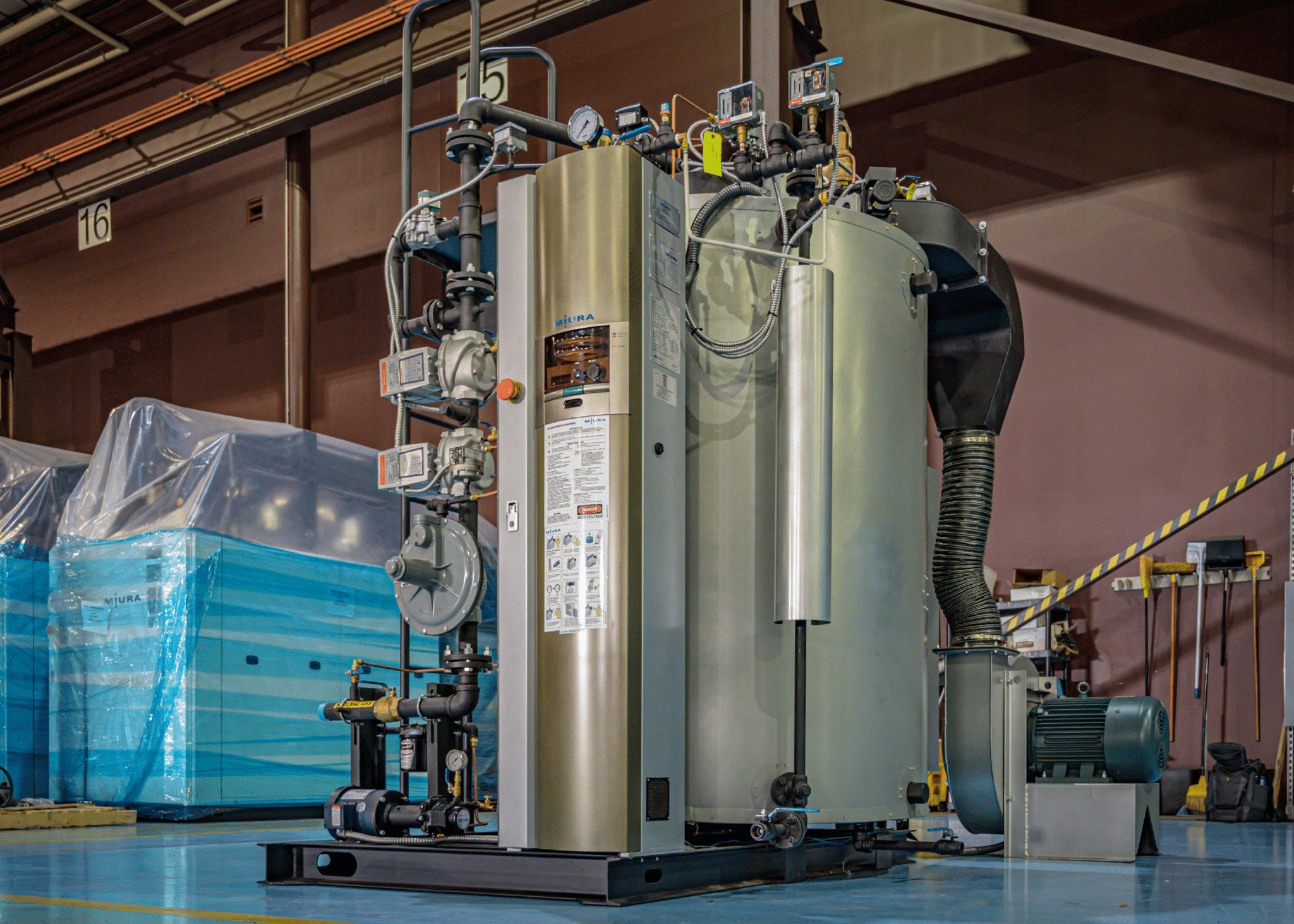

A stock image related to boiler steam boiler.

Scenario 2: Safety Concerns with Boiler Operations

The Problem:

Safety is a paramount concern for businesses operating steam boilers, particularly in regions with stringent regulatory frameworks like Europe. A common scenario involves a facility that experiences sudden pressure spikes or leaks due to inadequate safety measures, leading to potential hazards for employees and costly downtimes. Such incidents can stem from poor maintenance, outdated safety equipment, or lack of proper training for operators.

The Solution:

To enhance safety, B2B buyers must invest in modern steam boiler systems equipped with advanced safety features such as automatic shut-off valves, pressure relief valves, and real-time monitoring systems. It is essential to conduct a comprehensive safety audit of the existing boiler system to identify vulnerabilities.

Additionally, implement a robust training program for all personnel involved in boiler operations. This program should cover emergency procedures, regular maintenance protocols, and safe operating practices. Engaging with professional safety consultants to conduct periodic drills and assessments can further reinforce a culture of safety within the organization.

Regularly reviewing and updating safety policies in line with local regulations ensures compliance and minimizes risk. By prioritizing safety, companies can not only protect their workforce but also avoid significant financial penalties associated with safety violations.

Scenario 3: Water Quality Issues Affecting Boiler Performance

The Problem:

Many B2B buyers encounter problems with water quality, which can severely impact the performance and longevity of steam boilers. For example, a factory in Africa may struggle with high levels of dissolved solids or minerals in the feedwater, leading to scaling, corrosion, and frequent breakdowns. These issues can disrupt production schedules and result in costly repairs.

The Solution:

To mitigate water quality issues, businesses should invest in comprehensive water treatment solutions before the water enters the boiler system. This includes installing reverse osmosis systems to effectively remove impurities and employing water softeners to minimize hardness.

Conducting regular water quality testing is vital to ensure that the treatment processes are effective and that the water meets the required standards for steam generation. Establishing a partnership with a water treatment specialist can provide ongoing support and recommendations tailored to specific water quality challenges.

Additionally, implementing a chemical monitoring system allows for real-time analysis of water quality and chemical levels, ensuring that the boiler operates under optimal conditions. By proactively managing water quality, companies can enhance boiler efficiency, reduce maintenance costs, and extend the lifespan of their steam boiler systems.

Strategic Material Selection Guide for boiler steam boiler

What Are the Key Materials Used in Boiler Steam Boiler Construction?

When selecting materials for steam boilers, international B2B buyers must consider several factors, including performance, durability, cost, and compliance with local standards. Here, we analyze four common materials used in boiler construction: carbon steel, stainless steel, cast iron, and alloy steel. Each material has unique properties and implications for various applications.

How Does Carbon Steel Perform in Boiler Applications?

Key Properties: Carbon steel is known for its high strength and excellent weldability, making it a popular choice for boiler construction. It typically has a temperature rating up to 400°C (752°F) and can withstand significant pressure, making it suitable for high-pressure applications.

Pros & Cons: The advantages of carbon steel include its cost-effectiveness and availability, which make it a go-to material for many manufacturers. However, it has limited corrosion resistance, which can lead to premature failure in harsh environments, necessitating more frequent maintenance.

Impact on Application: Carbon steel is particularly effective in applications where water quality is controlled, as it can corrode if exposed to aggressive media. This material is often used in industrial settings, where the steam produced is used for heating or power generation.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the carbon steel used complies with local standards such as ASTM or DIN. Additionally, they should consider the local climate and water quality, which can affect the longevity of carbon steel boilers.

What Are the Advantages of Stainless Steel in Boiler Construction?

Key Properties: Stainless steel offers excellent corrosion resistance and can withstand higher temperatures, typically rated up to 600°C (1112°F). Its ability to resist scaling and pitting makes it ideal for applications involving aggressive media.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to corrosion, which leads to lower maintenance costs over time. However, stainless steel is generally more expensive than carbon steel, which may be a consideration for budget-conscious buyers.

Impact on Application: Stainless steel is particularly suitable for applications where water quality is poor or where the steam is used in food processing or pharmaceuticals. Its non-reactive nature ensures that it does not contaminate the steam produced.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of the specific grades of stainless steel required for their applications, as compliance with standards like JIS or EN is crucial for performance and safety.

Why Choose Cast Iron for Boiler Steam Boiler Construction?

Key Properties: Cast iron is known for its excellent thermal conductivity and ability to retain heat, making it effective for low-pressure applications. It typically operates at lower temperatures, around 300°C (572°F).

Pros & Cons: The advantages of cast iron include its durability and resistance to thermal shock. However, it is brittle and can crack under high stress, limiting its use in high-pressure applications. Additionally, cast iron is heavier, which can complicate installation.

Impact on Application: Cast iron is often used in residential or small commercial boilers where high efficiency and low maintenance are priorities. Its ability to provide consistent heat makes it suitable for heating applications.

Considerations for International Buyers: Buyers from regions with stringent environmental regulations should ensure that the cast iron used meets local emission standards. Compliance with standards like ASTM can also be critical for ensuring product quality.

What Role Does Alloy Steel Play in Boiler Construction?

Key Properties: Alloy steel combines carbon steel with other elements to enhance properties such as strength, hardness, and corrosion resistance. It can operate at high temperatures and pressures, making it suitable for demanding applications.

Pros & Cons: The key advantage of alloy steel is its versatility and ability to perform well in extreme conditions. However, it can be more expensive and complex to manufacture, which may impact overall project costs.

Impact on Application: Alloy steel is commonly used in high-pressure steam boilers and applications requiring high thermal efficiency. Its robust nature makes it ideal for heavy industrial use.

Considerations for International Buyers: Buyers should be aware of the specific alloy compositions and their compliance with international standards, as these can vary significantly. Understanding local regulations and standards is crucial for ensuring compatibility and performance.

Summary Table of Material Selection for Boiler Steam Boilers

| Material | Typical Use Case for Boiler Steam Boiler | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Industrial heating and power generation | Cost-effective and widely available | Limited corrosion resistance | Low |

| Stainless Steel | Food processing and pharmaceuticals | Excellent corrosion resistance | Higher initial cost | High |

| Cast Iron | Residential and small commercial boilers | Durable with good heat retention | Brittle and heavy | Medium |

| Alloy Steel | High-pressure steam applications | Versatile and strong | More expensive and complex to manufacture | High |

A stock image related to boiler steam boiler.

This strategic material selection guide provides international B2B buyers with valuable insights into the various materials used in boiler steam boiler construction, enabling informed decisions that align with their operational needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for boiler steam boiler

What Are the Main Stages of Manufacturing a Boiler Steam Boiler?

The manufacturing process for steam boilers is intricate and involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial to ensure that the final product meets industry standards and customer requirements.

Material Preparation: What Materials Are Used and How Are They Prepared?

The primary materials used in boiler manufacturing include high-strength steel and other alloys, which are selected for their durability and resistance to high temperatures and pressures. Material preparation involves several steps:

- Material Selection: Engineers choose materials based on the specific requirements of the boiler type (firetube or watertube) and its intended application.

- Cutting and Shaping: Steel sheets and plates are cut into specific dimensions using laser cutting or plasma cutting techniques. This precision is vital for maintaining structural integrity.

- Surface Treatment: The prepared materials undergo surface treatment to remove impurities and prevent corrosion. Processes like sandblasting or chemical cleaning are commonly employed.

How Is the Forming Process Conducted for Steam Boilers?

Forming is the stage where raw materials are transformed into the boiler’s components. This process typically involves:

- Bending and Rolling: Steel plates are bent into cylindrical shapes for the boiler shell. Rolling machines are used to achieve the desired curvature while maintaining material strength.

- Welding: The components are welded together using techniques such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. This is a critical step that demands high skill levels to ensure strong, leak-proof joints.

- Pressure Testing: Before moving on to assembly, components undergo pressure testing to verify their integrity. This step ensures they can withstand operational pressures without failure.

What Does the Assembly Process Entail for Boiler Steam Boilers?

The assembly stage is where all components come together to form the complete boiler system. Key activities include:

- Component Integration: Major components, such as the pressure vessel, burner, economizer, and heat exchanger, are assembled. Each piece must fit perfectly to ensure optimal performance.

- Installation of Safety Features: Safety devices, including pressure relief valves and temperature controls, are installed during assembly. These features are vital for preventing operational hazards.

- Final Assembly Checks: Before moving on to finishing, a thorough inspection is performed to ensure all components are correctly installed and secured.

How Is the Finishing Process Completed for Steam Boilers?

Finishing processes enhance both the aesthetic and functional qualities of the boiler. This stage typically includes:

- Coating and Painting: A protective coating is applied to prevent corrosion and enhance durability. High-temperature paint is often used to withstand the extreme conditions of a boiler environment.

- Insulation: Insulation materials are added to maintain thermal efficiency and protect personnel from heat exposure.

- Final Quality Inspection: The completed boiler undergoes a final inspection to ensure it meets all specifications and safety standards before shipping.

What Quality Assurance Measures Are Essential in Boiler Manufacturing?

Quality assurance (QA) is paramount in boiler manufacturing, ensuring that products meet international and industry standards. Key QA measures include:

Which International Standards Should Buyers Be Aware Of?

For international B2B buyers, familiarizing themselves with relevant quality standards is crucial. The following standards are commonly associated with steam boiler manufacturing:

- ISO 9001: This international standard outlines the requirements for a quality management system, emphasizing continuous improvement and customer satisfaction.

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates compliance with safety and environmental protection standards.

- API Standards: The American Petroleum Institute (API) provides standards that are particularly relevant for steam boilers used in oil and gas applications.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch any potential defects early. Common QC checkpoints include:

- Incoming Quality Control (IQC): This initial check involves inspecting raw materials upon delivery to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): During the manufacturing process, operators perform routine checks on welding, assembly, and pressure testing to confirm adherence to specifications.

- Final Quality Control (FQC): After finishing, the boiler is subjected to rigorous testing, including functional tests, pressure tests, and safety checks, to ensure it operates correctly and safely.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain high-quality standards, B2B buyers should consider the following strategies:

- Conduct Supplier Audits: Regular audits of the supplier’s manufacturing facilities can provide insights into their quality management systems and processes.

- Request Quality Reports: Buyers should ask for detailed QC reports, including results from testing and inspections, to verify compliance with relevant standards.

- Engage Third-Party Inspectors: Utilizing independent third-party inspectors can provide an unbiased assessment of a supplier’s quality control processes and product compliance.

What Nuances Should International Buyers Consider Regarding Quality Control?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Key considerations include:

- Cultural Differences in Standards: Different regions may have varying expectations regarding quality and safety. Buyers should be aware of these differences to avoid misunderstandings.

- Documentation Requirements: International trade often requires extensive documentation. Buyers must ensure that suppliers provide all necessary certificates and compliance documents.

- Logistical Challenges: Shipping and customs regulations can impact the delivery of quality equipment. Buyers should work closely with suppliers to ensure all products meet local regulations and standards.

By understanding the manufacturing processes and quality assurance measures of steam boilers, B2B buyers can make informed purchasing decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘boiler steam boiler’

This guide provides a practical checklist for B2B buyers looking to procure steam boilers. By following these steps, you can ensure that your selection process is thorough, efficient, and aligned with your operational needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical requirements for your steam boiler. Consider factors such as steam capacity, pressure ratings, and the type of fuel you intend to use. Defining these specifications helps narrow down your options and ensures that the boiler will meet your operational demands.

- Capacity Needs: Determine the maximum steam output required for your operations.

- Pressure Requirements: Assess whether you need a high-pressure or low-pressure boiler based on your applications.

Step 2: Research Boiler Types and Technologies

Understanding the various types of steam boilers is crucial for making an informed decision. Familiarize yourself with the differences between firetube and watertube boilers, as well as modular options, to identify which technology best suits your needs.

- Firetube vs. Watertube: Firetube boilers are generally more compact and easier to maintain, while watertube boilers can handle higher pressures and are more efficient for larger applications.

- Modular Options: Consider modular boilers for scalability and flexibility, especially if your steam needs may change over time.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request company profiles, case studies, and references from buyers in similar industries or regions. A reliable supplier should have a proven track record and experience in the specific type of boiler you are considering.

- Supplier Reputation: Look for reviews and testimonials to gauge the supplier’s reliability and customer service.

- Industry Experience: Ensure the supplier has experience in your industry sector, which can be critical for meeting specific regulatory requirements.

Step 4: Check for Compliance and Certifications

Ensure that the steam boilers you are considering comply with local regulations and industry standards. Certifications from recognized organizations can serve as indicators of quality and safety.

- Safety Standards: Verify that the boiler meets safety standards relevant to your region, such as ASME or ISO certifications.

- Environmental Regulations: Check compliance with emissions regulations, especially if you are sourcing from regions with strict environmental laws.

Step 5: Request and Compare Quotes

Once you have shortlisted potential suppliers, request detailed quotes that include all costs associated with the purchase, installation, and maintenance of the boiler. Comparing these quotes will help you identify the best value for your investment.

- Breakdown of Costs: Look for a comprehensive breakdown that includes initial costs, installation fees, and ongoing maintenance expenses.

- Warranty and Support: Consider the warranty terms and the level of after-sales support offered by each supplier.

Step 6: Conduct Site Visits or Virtual Tours

If possible, arrange site visits or virtual tours of the supplier’s facilities to assess their manufacturing processes and quality control measures. This step can provide valuable insights into their operational capabilities.

- Quality Control Practices: Observe their quality assurance processes to ensure they meet industry standards.

- Production Capacity: Evaluate whether they can meet your order timelines and volume requirements.

Step 7: Finalize the Agreement

Once you have selected a supplier, ensure that all terms are clearly outlined in a formal agreement. This should include payment terms, delivery schedules, and service agreements to avoid any misunderstandings later on.

- Clear Terms: Ensure all aspects of the agreement are explicitly detailed, including penalties for non-compliance.

- Review Legal Obligations: Consult with legal counsel if necessary to ensure that the contract protects your interests.

By following this checklist, B2B buyers can navigate the procurement process for steam boilers more effectively, ensuring that they make informed decisions that align with their operational needs and business goals.

Comprehensive Cost and Pricing Analysis for boiler steam boiler Sourcing

What Are the Key Cost Components in Steam Boiler Sourcing?

When sourcing steam boilers, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects the overall cost. Common materials for boiler construction include steel, cast iron, and alloy materials, each varying in price based on market demand and availability.

-

Labor: Labor costs can vary widely depending on the location of manufacturing. Regions with higher labor costs, such as Europe, may have higher total prices compared to those in Africa or South America.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and other indirect expenses. Efficient manufacturing processes can help reduce overhead, impacting the final pricing.

-

Tooling: Customization may require specific tooling, which can add to the initial costs. Buyers should consider how tooling costs will affect their total investment.

-

Quality Control (QC): Ensuring compliance with international standards can incur additional QC costs. Certifications like ISO and ASME can boost a boiler’s marketability but may also raise the price.

-

Logistics: The cost of shipping, including tariffs and handling, can significantly impact the final price. Understanding the logistics landscape in the target market is crucial for accurate cost estimation.

-

Margin: Suppliers typically add a profit margin on top of their costs. This margin can vary based on market conditions and competitive dynamics.

How Do Price Influencers Affect Steam Boiler Costs?

Several factors can influence the pricing of steam boilers:

-

Volume/MOQ (Minimum Order Quantity): Buying in bulk can lead to significant discounts. International buyers should evaluate their needs against suppliers’ MOQ policies to optimize costs.

-

Specifications and Customization: Custom-built boilers will incur higher costs due to specialized materials and manufacturing processes. Buyers should clearly communicate their specifications to avoid unexpected costs.

-

Quality and Certifications: Higher quality standards and certifications typically come with increased costs. Buyers must balance quality requirements with budget constraints.

-

Supplier Factors: Relationships with suppliers can affect pricing. Established partnerships may yield better terms, while new buyers might face higher initial prices.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can significantly impact the total cost. Understanding the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for accurate cost assessments.

What Tips Can Help Buyers Navigate Pricing for International Sourcing?

International B2B buyers should consider the following strategies to enhance cost-efficiency in steam boiler sourcing:

-

Negotiate Wisely: Leverage volume purchases and long-term contracts to negotiate better pricing. Building rapport with suppliers can also facilitate more favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational efficiency, and expected lifespan. A more expensive boiler may offer lower operating costs, leading to overall savings.

-

Be Aware of Pricing Nuances: Different markets have varying pricing structures due to local economic conditions, tariffs, and regulations. Buyers from Africa, South America, the Middle East, and Europe should research these factors to make informed decisions.

-

Conduct Market Research: Understanding market trends and competitor pricing can provide leverage in negotiations. Regularly reviewing supplier performance and market conditions can help buyers stay ahead.

-

Seek Local Expertise: Collaborating with local consultants or industry experts can provide valuable insights into the best practices for sourcing and pricing in specific regions.

Disclaimer on Indicative Prices

Prices for steam boilers can vary significantly based on the aforementioned factors and market conditions. This analysis is intended to provide a general understanding of the cost and pricing landscape. Buyers are encouraged to obtain quotes from multiple suppliers to ensure competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing boiler steam boiler With Other Solutions

Introduction: Why Consider Alternatives to Boiler Steam Boilers?

When evaluating energy solutions for industrial applications, it is essential to consider alternatives to traditional boiler steam boilers. While steam boilers are widely used for their efficiency and reliability, other technologies may provide similar benefits with distinct advantages. This section explores viable alternatives, helping international B2B buyers from Africa, South America, the Middle East, and Europe make informed decisions based on their specific needs.

Comparison Table: Boiler Steam Boiler vs. Alternative Solutions

| Comparison Aspect | Boiler Steam Boiler | Electric Boiler | Heat Pump System |

|---|---|---|---|

| Performance | High-pressure steam production | Lower output, suitable for smaller applications | Moderate output, efficient for heating |

| Cost | Higher initial capital cost | Moderate initial cost, lower operational costs | Higher installation costs but lower operational costs |

| Ease of Implementation | Requires significant infrastructure | Easy to install, minimal space required | Requires space for outdoor unit, complex installation |

| Maintenance | Regular maintenance needed, potential downtime | Low maintenance, fewer parts to service | Requires periodic maintenance, but generally low |

| Best Use Case | Large industrial processes needing high steam | Smaller facilities or applications needing quick heating | Climate-controlled environments, heating, and cooling |

Detailed Breakdown of Alternatives

What are the Benefits and Drawbacks of Electric Boilers?

Electric boilers operate by converting electrical energy into heat, providing a straightforward solution for heating applications. They are particularly advantageous in settings where natural gas or other fuel sources are not readily available. The installation process is relatively simple, requiring less space and no need for extensive piping or fuel storage. However, electric boilers generally produce lower output levels, making them less suitable for large-scale industrial processes. Moreover, while operational costs can be lower, the initial investment may still be significant, especially in regions with high electricity prices.

How Do Heat Pump Systems Compare to Steam Boilers?

Heat pumps function by transferring heat rather than generating it through combustion. This makes them an energy-efficient option, particularly in moderate climates where heating and cooling are required. Heat pumps can significantly reduce energy costs over time due to their high efficiency ratings. However, their installation can be complex and may require substantial upfront investment. Additionally, heat pumps are less effective in extremely cold temperatures, making them less suitable for all geographical locations. They are best utilized in commercial buildings needing both heating and cooling, providing a dual benefit.

A stock image related to boiler steam boiler.

Conclusion: How to Choose the Right Solution for Your Needs

Choosing between a boiler steam boiler and its alternatives depends on several factors, including the specific application, budget constraints, and available infrastructure. For industries requiring large-scale steam production, traditional steam boilers may still be the best fit. In contrast, electric boilers and heat pump systems present viable options for smaller operations or environments where energy efficiency is paramount. B2B buyers should conduct a thorough assessment of their operational needs, energy costs, and long-term goals to select the most appropriate heating solution.

Essential Technical Properties and Trade Terminology for boiler steam boiler

What Are the Essential Technical Properties of a Steam Boiler?

Understanding the technical specifications of steam boilers is critical for international B2B buyers, especially when considering procurement for diverse industrial applications. Here are some key properties to consider:

1. Material Grade: Why Is It Important?

The material used in constructing a steam boiler significantly impacts its durability and performance. Common materials include carbon steel, stainless steel, and alloyed steel. High-grade materials resist corrosion and withstand high-pressure environments, making them essential for industries such as oil and gas, chemical manufacturing, and power generation. Buyers should prioritize boilers made from materials that comply with relevant international standards to ensure reliability and safety.

2. Pressure Rating: What Does It Indicate?

Pressure ratings, typically measured in pounds per square inch (PSI), indicate the maximum pressure the boiler can safely handle. High-pressure boilers are essential for applications that require steam at elevated pressures, such as in power plants or large-scale manufacturing processes. Understanding the pressure requirements of your operations will help you select a boiler that meets your needs and complies with local regulations.

3. Efficiency Rating: How Does It Affect Operational Costs?

Boiler efficiency is a measure of how well a boiler converts fuel into usable steam. It is often expressed as a percentage, with higher ratings indicating better performance and lower operational costs. Buyers should look for boilers with high efficiency ratings, as these will not only reduce fuel consumption but also minimize greenhouse gas emissions, aligning with global sustainability goals.

4. Boiler Capacity: Why Is Sizing Critical?

Boiler capacity, usually measured in BTUs (British Thermal Units) or kW (kilowatts), indicates the amount of steam the boiler can produce in a given time frame. Proper sizing is crucial; an oversized boiler may lead to inefficiencies and increased operational costs, while an undersized boiler may not meet production demands. Buyers must calculate their steam requirements accurately to ensure optimal performance.

5. Turndown Ratio: What Is Its Significance?

The turndown ratio refers to the range of output that a boiler can maintain effectively. A higher turndown ratio allows for more flexibility in operations, enabling the boiler to operate efficiently at varying loads. This is particularly beneficial for industries with fluctuating steam demands, ensuring that energy consumption is optimized and costs are controlled.

What Are Common Trade Terms Related to Steam Boilers?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B space. Here are some key terms that buyers should know:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the boiler industry, OEMs provide high-quality, specialized components that ensure optimal performance and compatibility with various systems. Buyers should seek OEM parts for reliable and efficient boiler operation.

2. MOQ (Minimum Order Quantity): Why Is It Relevant?

MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQs is crucial for budgeting and inventory management. For international buyers, negotiating MOQs can lead to significant cost savings and better supply chain efficiency.

3. RFQ (Request for Quotation): How Does It Facilitate Procurement?

An RFQ is a formal document issued by a buyer to solicit quotes from suppliers for specific products or services. It outlines the required specifications and quantities, helping buyers compare offers effectively. Crafting a detailed RFQ is essential for ensuring that suppliers provide accurate and competitive quotes.

4. Incoterms: How Do They Affect Shipping and Delivery?

Incoterms (International Commercial Terms) are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They outline who is responsible for shipping, insurance, and tariffs, which helps prevent disputes. Familiarity with Incoterms is vital for international buyers to ensure smooth logistics and compliance with trade regulations.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing steam boilers, ultimately enhancing operational efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the boiler steam boiler Sector

What Are the Current Market Dynamics and Key Trends in the Boiler Steam Boiler Sector?

The global boiler steam boiler market is witnessing significant transformations, driven by various factors. Key drivers include the rising demand for energy-efficient systems, regulatory pressure for reduced emissions, and the shift towards renewable energy sources. As industries across Africa, South America, the Middle East, and Europe seek to modernize their operations, there is an increasing reliance on advanced boiler technologies that enhance efficiency and safety.

Emerging trends in B2B sourcing include the adoption of modular steam boilers, which offer flexibility and scalability for businesses facing fluctuating demand. This technology allows for the incremental installation of boiler systems, thereby minimizing upfront costs and maximizing operational efficiency. Additionally, the integration of IoT (Internet of Things) into boiler systems is gaining traction, enabling real-time monitoring and predictive maintenance, which helps to reduce downtime and improve overall system reliability.

International buyers are also placing a greater emphasis on supplier partnerships that can provide comprehensive service offerings, including installation, maintenance, and support. This trend is particularly relevant in regions like Africa and South America, where access to local expertise can significantly influence procurement decisions. As the market evolves, understanding these dynamics will be crucial for B2B buyers to make informed sourcing choices that align with their operational goals.

How Can Sustainability and Ethical Sourcing Impact the Boiler Steam Boiler Sector?

Sustainability has become a pivotal concern for businesses across the globe, and the boiler steam boiler sector is no exception. The environmental impact of traditional boiler systems, particularly concerning emissions and energy consumption, is prompting international B2B buyers to prioritize sustainable solutions. The adoption of ‘green’ certifications, such as ISO 14001 for environmental management, is increasingly influencing purchasing decisions. Buyers are looking for suppliers who can provide certified systems that meet stringent environmental standards.

Moreover, ethical sourcing is gaining importance, as companies seek to ensure that their supply chains are transparent and socially responsible. This means choosing suppliers who adhere to ethical labor practices and sustainable resource management. In the boiler sector, this could involve selecting manufacturers that use recycled materials or those that invest in renewable energy technologies. The trend towards sustainability not only enhances a company’s brand reputation but also aligns with regulatory requirements in many regions, particularly in Europe where environmental regulations are stringent.

What Is the Brief Evolution of the Boiler Steam Boiler Industry?

The boiler steam boiler industry has evolved significantly since its inception in the 18th century. Initially, steam boilers were rudimentary systems primarily used for industrial applications, such as powering steam locomotives and factories. As technology advanced, so did the design and efficiency of boilers. The introduction of firetube and watertube boilers marked a pivotal moment, allowing for greater safety and efficiency in steam production.

In recent decades, the focus has shifted towards energy efficiency and environmental sustainability, prompted by rising fuel costs and increasing regulatory pressures. This evolution has led to the development of advanced technologies, including modular designs and IoT integration, which are now transforming the landscape of steam generation. Today’s boiler steam boiler systems are not only more efficient but also more adaptable, catering to the diverse needs of international B2B buyers across various industries.

Frequently Asked Questions (FAQs) for B2B Buyers of boiler steam boiler

-

How do I solve issues related to boiler steam efficiency?

To enhance boiler steam efficiency, start by conducting a thorough assessment of your current system. Ensure that the boiler is regularly maintained and cleaned to prevent scale buildup, which can impede performance. Implement advanced monitoring systems to track efficiency metrics and adjust operational parameters as necessary. Additionally, consider upgrading to a more efficient boiler type, such as a watertube boiler, which can produce higher pressure steam with less fuel consumption. Regular training for operators on optimal boiler operation can also significantly improve efficiency. -

What is the best type of boiler steam boiler for industrial applications?

The best type of boiler for industrial applications often depends on specific operational needs. Watertube boilers are generally preferred for high-pressure applications due to their ability to handle greater pressures and their efficiency in steam generation. Conversely, firetube boilers are suitable for smaller operations where space is limited and lower pressure is acceptable. When selecting a boiler, consider factors like fuel type, required steam pressure, and the intended application to determine the best fit for your needs. -

How can I ensure the reliability of my boiler steam supplier?

To ensure the reliability of a boiler steam supplier, conduct comprehensive due diligence. Start by verifying the supplier’s certifications and industry reputation through reviews and case studies. Request references from previous clients to assess their experiences. Additionally, evaluate the supplier’s financial stability and ability to provide ongoing support, including maintenance and spare parts. It’s also advisable to visit the supplier’s facilities if possible, to observe their manufacturing processes and quality control measures firsthand. -

What should I consider when customizing a boiler steam system?

When customizing a boiler steam system, consider your specific operational requirements, including the desired steam capacity, pressure levels, and fuel type. Work closely with your supplier to understand the implications of any modifications on efficiency and safety. Additionally, factor in local regulations and standards that may affect the design. Ensure that the customization aligns with long-term operational goals, such as energy efficiency and sustainability, to maximize your investment. -

What are the typical minimum order quantities (MOQs) for boiler steam systems?

Minimum order quantities (MOQs) for boiler steam systems can vary significantly based on the supplier and the complexity of the system. Generally, larger suppliers may have higher MOQs due to manufacturing processes, while niche or specialized manufacturers may offer flexibility for smaller orders. Always discuss your needs with the supplier upfront to negotiate favorable terms. If you are unsure, consider starting with a pilot project to gauge performance before committing to larger quantities. -

What payment terms should I negotiate with boiler steam suppliers?

When negotiating payment terms with boiler steam suppliers, aim for conditions that support your cash flow. Common terms include a deposit upfront (usually 20-30%), with the balance due upon delivery or installation. Consider requesting extended payment terms, especially for larger orders, to provide flexibility. It’s also prudent to clarify the terms regarding penalties for late payments or discounts for early settlements. Ensure that all payment terms are documented in the contract to avoid disputes later. -

How do I ensure quality assurance (QA) for my boiler steam system?

To ensure quality assurance for your boiler steam system, request documentation of the supplier’s QA processes and certifications, such as ISO 9001. Establish clear specifications and testing protocols that the system must meet before delivery. Consider involving a third-party inspector to conduct audits during manufacturing and after installation. Regular maintenance and performance evaluations post-installation are also crucial to maintaining quality and addressing any issues promptly. -

What logistics considerations should I keep in mind when sourcing boiler steam systems internationally?

When sourcing boiler steam systems internationally, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Ensure that the supplier provides comprehensive documentation for customs clearance to avoid delays. Evaluate the total landed cost, including shipping, duties, and taxes, to understand the financial implications. Additionally, establish clear communication channels with the supplier to track shipping progress and address any potential issues that may arise during transit.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for boiler steam boiler

Why Is Strategic Sourcing Essential for Boiler Steam Boiler Purchases?

In today’s competitive landscape, strategic sourcing is paramount for international B2B buyers seeking to optimize their investments in steam boilers. Buyers from Africa, South America, the Middle East, and Europe must prioritize efficiency, reliability, and compliance with regional regulations when selecting boiler systems. Understanding the differences between firetube and watertube boilers is crucial, as this knowledge can guide buyers in making informed decisions that align with their operational needs.

What Are the Key Takeaways for B2B Buyers?

- Efficiency Matters: Prioritize boilers with high efficiency ratings, such as those featuring economizers and advanced control systems, which can significantly reduce operational costs.

- Regulatory Compliance: Ensure that the chosen steam boiler meets local emissions standards and safety regulations, particularly in regions with stringent environmental laws.

- Supplier Relationships: Establish strong partnerships with reputable manufacturers and service providers for reliable support, maintenance, and emergency services.

What Does the Future Hold for Boiler Steam Boiler Buyers?

As the global market evolves, the demand for sustainable and innovative steam boiler technologies is likely to increase. Buyers should stay informed about emerging trends, such as the integration of smart technologies and alternative fuels. By leveraging strategic sourcing, businesses can not only enhance their operational efficiency but also contribute to a more sustainable future. Engage with suppliers who are committed to innovation and responsiveness to position your organization for success in the dynamic energy landscape.