Discover the Types of US Power Plugs: A Complete Guide (2025)

Introduction: Navigating the Global Market for types of us power plugs

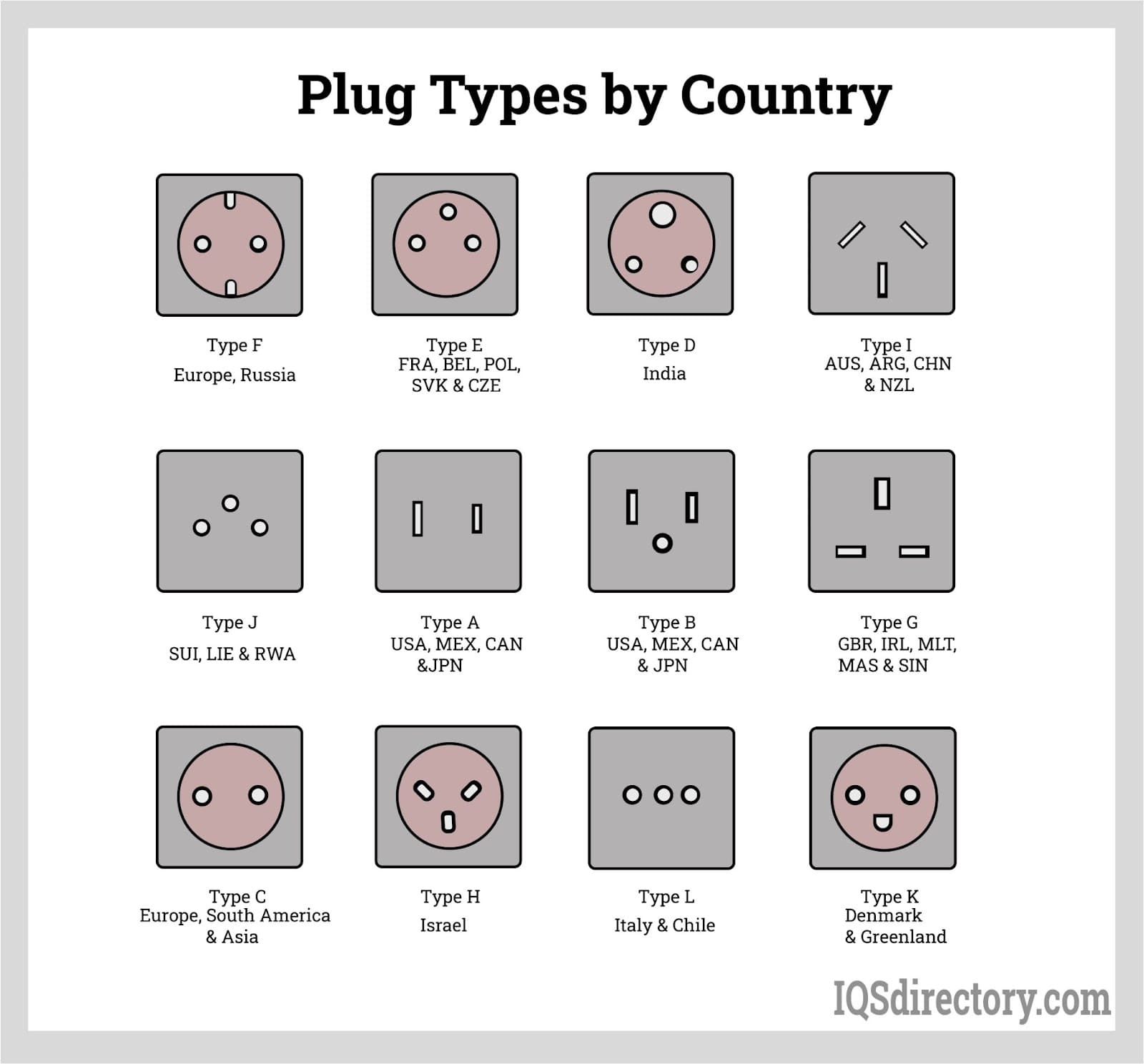

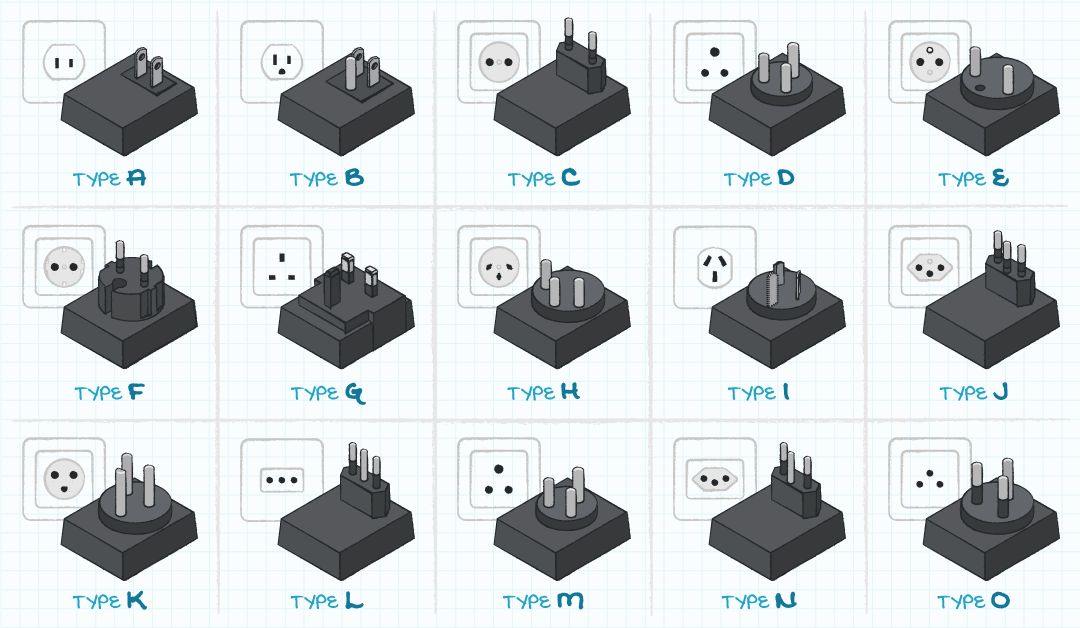

In today’s interconnected world, navigating the complexities of sourcing electrical components, such as types of US power plugs, presents significant challenges for international B2B buyers. Whether you are importing machinery from the United States or ensuring your products meet compatibility standards in regions like Africa, South America, the Middle East, or Europe, understanding the nuances of power plug types is crucial. This guide delves into the two primary types of power plugs used in the US—Type A and Type B—providing insights into their specifications, applications, and implications for your business operations.

As the demand for seamless global trade continues to rise, so does the necessity for informed purchasing decisions. This comprehensive resource covers everything from the technical specifications of US power plugs to practical applications in various industries. It also includes expert advice on vetting suppliers, understanding cost factors, and ensuring compliance with international standards. By equipping B2B buyers with essential knowledge, this guide empowers you to make confident choices, ultimately enhancing your operational efficiency and product reliability.

In an era where electrical compatibility can make or break business relationships, leveraging this information will help you navigate the global market with ease, ensuring your products are ready for diverse electrical environments.

Understanding types of us power plugs Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type A | Two flat parallel pins | Small appliances, chargers | Pros: Widely used; Cons: Limited grounding, less safe for high-power devices. |

| Type B | Two flat parallel pins + grounding pin | Computers, larger appliances | Pros: Enhanced safety with grounding; Cons: Bulkier, may not fit all devices without adapters. |

| NEMA 5-15 | Standardized for 120V, 15A | General office equipment | Pros: High compatibility; Cons: Limited to North America, not suitable for high wattage. |

| NEMA 5-20 | Similar to NEMA 5-15 but with a T-shaped slot | Heavy-duty appliances | Pros: Supports higher loads; Cons: Requires specific plugs, less universal. |

| Universal Travel Adapter | Multiple plug configurations | International travel | Pros: Versatile for various regions; Cons: May not support high-wattage devices. |

What are the Characteristics of Type A Power Plugs?

Type A plugs feature two flat parallel pins and are commonly used in smaller appliances and chargers. They operate on a standard voltage of 120V and are prevalent in North America. B2B buyers should consider the limited grounding capabilities of Type A plugs, which can pose safety risks when used with high-power devices. For businesses sourcing equipment intended for the U.S. market, ensuring compatibility with Type A plugs is crucial, especially for portable devices.

How Does Type B Power Plug Differ from Type A?

Type B plugs include two flat parallel pins and a grounding pin, enhancing safety for larger appliances and office equipment. This plug type is essential for any business dealing with high-power electronics, as the grounding feature helps prevent electrical shocks. When purchasing equipment, B2B buyers should ensure that devices are compatible with Type B sockets, particularly for environments where safety is a priority, such as in laboratories or manufacturing facilities.

A stock image related to types of us power plugs.

What is the NEMA 5-15 Plug and Its Applications?

The NEMA 5-15 plug is a standardized connector designed for devices operating at 120V and 15A. It is widely used for general office equipment, making it a vital consideration for B2B buyers looking to equip their workplaces. Its high compatibility across various devices simplifies procurement processes. However, businesses should note that this plug is limited to North American markets and may not be suitable for high-wattage applications, necessitating careful evaluation of power requirements.

Why Choose the NEMA 5-20 Plug for Heavy-Duty Appliances?

The NEMA 5-20 plug features a similar design to the NEMA 5-15 but includes a T-shaped slot for accommodating higher power loads. This plug is ideal for heavy-duty appliances and equipment, making it a suitable choice for B2B buyers in sectors such as manufacturing and construction. While its ability to support higher wattage is a significant advantage, the requirement for specific plugs may limit its universal application, which should be considered when sourcing equipment.

How Do Universal Travel Adapters Benefit International Buyers?

Universal travel adapters accommodate multiple plug configurations, making them highly versatile for international travel. They are particularly beneficial for B2B buyers who need to operate devices across different regions, including Africa, South America, and Europe. While they offer convenience, businesses should be cautious as these adapters may not support high-wattage devices. Understanding the specifications of the equipment being used is essential to ensure safe and effective operation.

Key Industrial Applications of types of us power plugs

| Industry/Sector | Specific Application of types of US power plugs | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics Manufacturing | Powering assembly line machinery | Ensures consistent operations and minimizes downtime | Compatibility with existing systems, voltage ratings, and safety standards |

| Hospitality | Charging stations for guest electronics | Enhances guest experience and convenience | Durability, ease of use, and compliance with local regulations |

| Medical Equipment | Powering diagnostic and treatment devices | Critical for patient safety and operational efficiency | Reliability, voltage compatibility, and certifications for medical use |

| Telecommunications | Powering network infrastructure | Supports uninterrupted communication services | Adaptability to various devices, safety standards, and scalability |

| Construction | Powering tools and equipment at job sites | Improves productivity and project timelines | Ruggedness, voltage requirements, and compliance with safety regulations |

How Are Types of US Power Plugs Used in Electronics Manufacturing?

In electronics manufacturing, types A and B US power plugs are essential for powering assembly line machinery and testing equipment. These plugs provide a stable 120V supply necessary for the operation of sensitive electronic devices. International B2B buyers, particularly from regions like Africa and South America, must ensure that their machinery is compatible with US voltage standards. A common challenge is sourcing plugs that meet both local and US standards, ensuring safety and operational efficiency.

What Role Do US Power Plugs Play in the Hospitality Industry?

In the hospitality sector, US power plugs are widely used in charging stations for guest electronics, such as smartphones and laptops. This convenience significantly enhances the guest experience, encouraging longer stays and repeat visits. For international buyers, sourcing robust and user-friendly power solutions is crucial. Considerations include the durability of the plugs, compliance with local electrical standards, and the ability to accommodate a variety of plug types used by international guests.

How Are US Power Plugs Critical in Medical Equipment?

In the medical field, types A and B power plugs are vital for powering diagnostic and treatment devices. Ensuring a reliable power supply is critical for patient safety, as any interruption can lead to severe consequences. International buyers in the medical sector must prioritize sourcing plugs that meet stringent safety and reliability standards. This includes ensuring that the plugs are certified for medical use and compatible with the specific voltage requirements of their equipment.

Why Are US Power Plugs Important for Telecommunications?

Telecommunications infrastructure relies heavily on US power plugs for powering networking devices and servers. A stable power supply is crucial for maintaining uninterrupted communication services, especially in regions with less reliable electricity. B2B buyers from the Middle East and Europe should focus on sourcing adaptable power solutions that can handle varying loads and comply with international safety standards. This ensures scalability and reliability in their communication networks.

How Do US Power Plugs Benefit the Construction Industry?

In the construction industry, types A and B power plugs are used to power tools and equipment at job sites. This application is vital for improving productivity and ensuring timely project completion. International buyers must consider the ruggedness of the plugs and their ability to withstand harsh environments. Additionally, compliance with local safety regulations and voltage requirements is crucial to avoid accidents and equipment failures on-site.

3 Common User Pain Points for ‘types of us power plugs’ & Their Solutions

Scenario 1: Navigating Voltage and Frequency Compatibility for International Equipment

The Problem: B2B buyers from regions such as Africa and South America often encounter challenges when their equipment does not match the voltage and frequency standards of the United States. Many electrical devices are designed for 220-240V and 50Hz, which can lead to malfunctions or even damage when plugged into the US’s 120V and 60Hz outlets. This is particularly concerning for businesses that rely on consistent operational efficiency, such as manufacturing or IT companies, as downtime can be costly.

The Solution: To mitigate this issue, it is crucial for buyers to thoroughly assess the voltage and frequency specifications of their devices prior to travel or importation. Investing in dual-voltage devices that support both 110-240V can provide flexibility. For those with single-voltage appliances, sourcing a reliable voltage converter or transformer is essential. It’s advisable to choose converters with a higher wattage rating than the appliance’s consumption to prevent overheating. Additionally, buyers should consider establishing relationships with local suppliers in the US who can provide verified converters, ensuring their equipment operates safely and effectively upon arrival.

Scenario 2: Understanding Plug Types and Sourcing the Right Adaptors

The Problem: Many international B2B buyers may not be aware of the differences between plug types A and B used in the US. Misunderstandings can lead to situations where devices cannot be plugged into the available sockets, causing delays in operations or additional costs for last-minute purchases of adaptors. This is a frequent issue for companies sending teams to the US for conferences, trade shows, or project work.

The Solution: Buyers should conduct thorough research on the plug type requirements for their specific devices and ensure they have the appropriate adaptors before traveling. It is beneficial to purchase universal travel adapters that accommodate both types A and B plugs, thus eliminating the need for multiple adaptors. Companies can also source these adapters in bulk from reputable suppliers to equip their teams efficiently. For larger installations, investing in socket outlets that accept multiple plug types can simplify operations and reduce the reliance on individual adaptors.

Scenario 3: The Risk of Overloading Circuits with Improper Equipment

The Problem: Businesses that utilize multiple devices simultaneously may face the risk of overloading circuits if they do not consider the power ratings of their equipment when using US power plugs. This is especially pertinent for companies in the technology sector, where multiple devices may need to be charged or powered at once. An overloaded circuit can lead to tripped breakers, damaging equipment and causing costly interruptions.

The Solution: To prevent circuit overload, B2B buyers should evaluate the total amperage of all devices they plan to use. This can be done by checking the ratings on the equipment’s power supply and ensuring that the total does not exceed the circuit’s capacity (typically 15-20 amps in US residential settings). Utilizing power strips with surge protection can help manage multiple devices safely. Moreover, businesses should consider working with electrical engineers to design or modify their workspace to accommodate safe and efficient power distribution, ensuring that all equipment operates within safe limits.

Strategic Material Selection Guide for types of us power plugs

What Are the Common Materials Used in US Power Plugs?

When selecting materials for US power plugs, it’s crucial to consider their properties, advantages, disadvantages, and compliance with international standards. Here, we analyze four common materials used in the manufacturing of power plugs: thermoplastic, thermoset, metal alloys, and rubber.

How Does Thermoplastic Perform in Power Plug Applications?

Key Properties: Thermoplastics, such as polyvinyl chloride (PVC) and acrylonitrile butadiene styrene (ABS), are known for their excellent electrical insulation properties and temperature resistance, typically up to 85°C. They also exhibit good impact resistance and can be molded into complex shapes.

Pros & Cons: The primary advantage of thermoplastics is their cost-effectiveness and ease of manufacturing, allowing for high-volume production. However, they may not withstand extreme temperatures or prolonged exposure to UV light, leading to potential degradation over time.

Impact on Application: Thermoplastics are suitable for standard household appliances and electronic devices. However, they may not be ideal for applications requiring high durability or exposure to harsh environments.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with standards such as ASTM D256 for impact resistance. In Europe, adherence to DIN standards is essential for quality assurance.

What Role Do Thermoset Materials Play in Power Plug Manufacturing?

Key Properties: Thermosetting plastics, such as phenolic and epoxy resins, are characterized by their high thermal stability and resistance to deformation under heat. They can withstand temperatures exceeding 150°C and are generally more rigid than thermoplastics.

Pros & Cons: The durability and heat resistance of thermosets make them ideal for high-performance applications. However, they are more expensive to manufacture and less flexible, which can complicate the production process.

Impact on Application: Thermosets are particularly suited for industrial applications where high mechanical strength and thermal stability are required, such as in heavy machinery or commercial electrical systems.

Considerations for International Buyers: Compliance with JIS standards in Japan or ASTM standards in the USA is critical for ensuring product safety and reliability. Buyers should also consider the higher manufacturing costs associated with thermosets.

How Are Metal Alloys Utilized in Power Plugs?

Key Properties: Metal alloys, commonly copper and aluminum, are used for the conductive pins in power plugs. Copper offers excellent electrical conductivity and corrosion resistance, while aluminum is lighter and more cost-effective.

Pros & Cons: The primary advantage of metal alloys is their superior conductivity, which enhances the efficiency of power transmission. However, they are susceptible to corrosion, especially in humid environments, which can lead to electrical failures.

Impact on Application: Metal alloys are essential for ensuring reliable connections in power plugs, particularly in high-load applications. However, they may require protective coatings to prevent oxidation.

Considerations for International Buyers: Buyers in the Middle East and Europe should ensure that the metal components meet relevant corrosion resistance standards, such as ASTM B117 for salt spray testing. Compliance with RoHS regulations is also vital for environmental considerations.

What Advantages Does Rubber Offer in Power Plug Design?

Key Properties: Rubber materials, particularly silicone and natural rubber, are flexible, durable, and highly resistant to extreme temperatures and environmental conditions. They can operate effectively in a range of temperatures from -40°C to 200°C.

Pros & Cons: The flexibility and resilience of rubber make it ideal for protective coverings and seals in power plugs. However, rubber can be more expensive and may degrade when exposed to certain chemicals or UV light over time.

Impact on Application: Rubber is often used in outdoor or industrial power plugs where exposure to harsh conditions is expected. Its insulating properties also enhance safety.

Considerations for International Buyers: Compliance with international standards like IEC 60884-1 for safety and performance is crucial. Buyers should also consider the specific environmental conditions in their region when selecting rubber materials.

Summary Table of Material Selection for US Power Plugs

| Material | Typical Use Case for types of us power plugs | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic | Household appliances | Cost-effective and easy to mold | Limited temperature resistance | Low |

| Thermoset | Industrial applications | High thermal stability | More expensive and less flexible | High |

| Metal Alloys | Conductive pins in plugs | Superior electrical conductivity | Susceptible to corrosion | Medium |

| Rubber | Outdoor and industrial plugs | Flexible and durable | Can degrade with certain chemicals | Medium |

This analysis provides a comprehensive overview of the materials used in US power plugs, helping international B2B buyers make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for types of us power plugs

What Are the Key Manufacturing Processes for Types of US Power Plugs?

The manufacturing of US power plugs, specifically types A and B, involves several critical stages to ensure product quality and safety. Understanding these processes is essential for international B2B buyers who are sourcing electrical components.

How Are Materials Prepared for Power Plug Manufacturing?

The manufacturing process begins with material preparation. The primary materials used for US power plugs include high-grade thermoplastics for the casing and copper or brass for the pins.

- Material Selection: Suppliers must ensure that the materials meet specific electrical and safety standards, such as UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission) certifications.

- Material Testing: Before production, raw materials are subjected to tests for electrical conductivity, thermal resistance, and mechanical strength to ensure they are suitable for electrical applications.

What Are the Forming Techniques Used in Power Plug Production?

After material preparation, the next step is the forming process, which shapes the materials into the desired components.

- Injection Molding: This is the primary method for creating the plastic casing of the plugs. High-quality molds are used to produce consistent and precise shapes.

- Metal Stamping: For the pins, metal stamping techniques are employed to form the flat parallel pins (Type A) and the grounding pin (Type B). This method ensures uniformity and helps reduce production costs.

How Is the Assembly of US Power Plugs Performed?

The assembly stage involves putting together the various components of the plug.

- Automated Assembly Lines: Many manufacturers use automated assembly lines to enhance efficiency. Components are fed into machines that perform tasks like inserting pins into the plastic casing and securing them.

- Manual Assembly: In some cases, especially for quality control, manual assembly is employed. Skilled workers inspect each plug during assembly to ensure that all components fit correctly and securely.

What Finishing Techniques Are Applied to Power Plugs?

Finishing processes are crucial for aesthetics and functionality.

- Surface Treatment: Plugs undergo surface treatments to enhance durability and electrical safety, including coatings to prevent corrosion.

- Quality Inspections: After finishing, plugs are inspected for any defects. This includes checking for sharp edges and ensuring that the plastic casing is free from cracks.

What Quality Assurance Measures Are Essential for Power Plugs?

Quality assurance (QA) is vital in ensuring that power plugs meet international safety and performance standards.

Which International Standards Should B2B Buyers Be Aware Of?

For international B2B buyers, understanding relevant quality standards is crucial.

- ISO 9001: This standard focuses on quality management systems and is applicable to manufacturers of electrical components. Compliance indicates a commitment to continuous improvement and customer satisfaction.

- CE Marking: This certification is essential for products sold in the European market. It indicates compliance with health, safety, and environmental protection standards.

- UL Certification: This is particularly important for products sold in the USA, ensuring that they meet safety standards set by Underwriters Laboratories.

What Are the Key Quality Control Checkpoints in Power Plug Manufacturing?

Quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process is essential. This includes regular inspections at different stages to catch defects early.

- Final Quality Control (FQC): Before shipping, a final inspection of the finished products is conducted to verify that they meet all quality standards and specifications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial.

What Steps Should Be Taken to Conduct Supplier Audits?

- Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to assess their manufacturing capabilities and quality control practices firsthand. This includes reviewing documentation, production processes, and quality control checkpoints.

- Requesting Quality Reports: Buyers should request detailed quality assurance reports, including compliance certifications and inspection results.

- Third-Party Inspections: Engaging third-party inspection agencies can provide unbiased verification of the manufacturer’s quality control processes. This is especially important for buyers in regions where regulatory requirements are stringent.

What Common Testing Methods Are Used to Ensure Power Plug Safety and Performance?

Testing methods for power plugs are designed to ensure safety and compliance with international standards.

- Electrical Testing: This includes tests for dielectric strength, insulation resistance, and current-carrying capacity to ensure that plugs can safely handle the electrical loads they are designed for.

- Mechanical Testing: Mechanical stress tests assess the durability and resilience of plugs, ensuring they can withstand physical impacts and stresses during use.

- Heat Testing: This testing checks for overheating under normal operating conditions, ensuring that plugs do not pose a fire hazard.

What Unique Considerations Should International Buyers Keep in Mind?

B2B buyers from different regions should be aware of nuances in quality control and compliance:

- Regional Compliance: Different regions have specific compliance requirements. For example, while CE marking is crucial for the European market, UL certification is vital for the US market.

- Cultural Considerations: Understanding cultural differences in business practices can facilitate better communication and negotiations with suppliers.

- Local Regulations: Buyers should be familiar with local electrical safety regulations in their respective countries to ensure that imported power plugs comply with these laws.

By understanding these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when sourcing US power plugs, ensuring that they are investing in safe, reliable, and compliant products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of us power plugs’

In this guide, we aim to provide international B2B buyers with a practical checklist for sourcing US power plugs. Understanding the types of power plugs used in the United States, specifically Type A and Type B, is essential for ensuring compatibility with electrical appliances. By following this step-by-step checklist, buyers can streamline their procurement process and make informed decisions.

Step 1: Identify Your Power Plug Requirements

Begin by determining the specific power plug types needed for your electrical devices. The US primarily uses Type A (two flat parallel pins) and Type B (two flat parallel pins plus a grounding pin). Knowing which type your devices require will help you narrow down your sourcing options and avoid compatibility issues.

Step 2: Research Compliance Standards

Ensure that the power plugs you are considering meet the necessary compliance standards for safety and performance. Look for certifications such as UL (Underwriters Laboratories) or CE (Conformité Européenne) that indicate the plugs have been tested for safety. Compliance not only ensures the safety of your devices but also aligns with international trade regulations.

Step 3: Evaluate Supplier Credentials

Thoroughly vet potential suppliers before making a commitment. Request company profiles, check for industry certifications, and ask for references from other businesses that have sourced similar products. This step is crucial to ensure reliability and quality in your supply chain.

Step 4: Assess Product Specifications

Review the technical specifications of the power plugs you are considering. Pay attention to the voltage rating (typically 120V for US plugs) and the frequency (60Hz). Understanding these specifications will help you ensure that the plugs are compatible with your devices and can operate safely in your intended environment.

Step 5: Request Samples for Testing

Before placing a large order, ask suppliers for samples of the power plugs. Testing samples in real-world scenarios allows you to assess their quality and compatibility with your existing equipment. This step minimizes the risk of bulk purchasing faulty products that could disrupt your operations.

Step 6: Negotiate Terms and Pricing

Once you have selected a supplier, engage in negotiations to secure favorable terms and pricing. Discuss bulk order discounts, payment terms, and shipping options. Clear communication about your expectations can lead to a better partnership and potentially lower costs.

Step 7: Plan for After-Sales Support

Consider the after-sales support provided by your supplier. Ensure they offer customer service for issues such as product malfunctions or warranty claims. A reliable support system can save your business time and resources in the event of any complications with the power plugs.

By following this checklist, international B2B buyers can ensure they are well-prepared to procure the correct types of US power plugs, enhancing operational efficiency and maintaining the safety of their electrical devices.

Comprehensive Cost and Pricing Analysis for types of us power plugs Sourcing

What are the Key Cost Components in Sourcing US Power Plugs?

When sourcing US power plugs, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials directly impacts cost. Common materials for power plugs include copper for wiring and durable plastics for casing. Higher quality materials may increase upfront costs but can improve longevity and safety.

-

Labor: Labor costs vary significantly based on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but it’s essential to evaluate the trade-off between cost and quality.

-

Manufacturing Overhead: This includes costs related to the factory environment, utilities, and administrative expenses. Factories with advanced technology may incur higher overhead but can provide better efficiency and lower defect rates.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. Buyers should factor in these costs, particularly for smaller orders, as they can significantly affect the price per unit.

-

Quality Control (QC): Implementing robust QC processes ensures product reliability. However, this adds to the overall cost. Buyers should balance the need for quality with their budget constraints.

-

Logistics: Shipping costs depend on the volume and weight of the plugs, as well as the shipping method chosen. International buyers should consider tariffs and customs duties, which can add to overall expenses.

-

Margin: Suppliers will include their profit margin, which can vary based on market conditions and competition. Understanding the typical margins in the industry can help in negotiations.

How Do Price Influencers Affect the Cost of US Power Plugs?

Several factors influence the pricing of US power plugs, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically benefit from lower per-unit costs. Buyers should assess their needs carefully to optimize order sizes.

-

Specifications and Customization: Custom designs or specifications (like color, branding, or additional safety features) can lead to increased costs. Clear communication of requirements is essential to avoid unexpected expenses.

-

Materials: The choice of materials directly impacts price. High-grade materials may cost more but enhance product durability and compliance with safety standards.

-

Quality and Certifications: Products that meet international safety standards and certifications (like UL or CE) may come at a premium. Buyers should weigh the benefits of compliance against costs.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more but offer better quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) can help buyers anticipate additional costs related to shipping, insurance, and tariffs.

What Buyer Tips Can Enhance Cost Efficiency in Sourcing US Power Plugs?

For B2B buyers from Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiation: Build strong relationships with suppliers to negotiate better terms and prices. Leverage volume purchases or long-term contracts to secure discounts.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes logistics, maintenance, and potential replacement costs. This holistic view can lead to more informed purchasing decisions.

-

Understanding Pricing Nuances: Be aware of fluctuations in raw material prices, currency exchange rates, and global market trends that can affect pricing. Staying informed allows for better timing in purchasing decisions.

-

Consider Local Regulations: Different regions may have specific compliance requirements. Ensuring that products meet local standards can prevent costly delays and rejections upon import.

-

Supplier Audits: Conducting supplier audits can ensure that manufacturers adhere to quality standards and ethical practices, potentially reducing long-term risks and costs.

Disclaimer on Indicative Prices

Prices for US power plugs can vary widely based on the factors outlined above. Buyers should conduct thorough market research and seek multiple quotes to establish a benchmark for fair pricing.

Alternatives Analysis: Comparing types of us power plugs With Other Solutions

When considering the types of US power plugs, it is essential to explore alternative solutions that can fulfill similar needs. This analysis will help international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, to make informed decisions regarding power connections for their electrical devices.

Comparison Table of Power Solutions

| Comparison Aspect | Types Of US Power Plugs | Universal Power Adapter | Wireless Power Transfer |

|---|---|---|---|

| Performance | Reliable for 120V, 60Hz | Compatible with multiple plug types | Limited to specific devices |

| Cost | Generally low cost | Moderate cost | Higher initial investment |

| Ease of Implementation | Simple, plug-and-play | Easy to use, requires minimal setup | More complex, may require additional infrastructure |

| Maintenance | Minimal maintenance | Minimal maintenance | Regular checks and updates needed |

| Best Use Case | Standard US appliances | Traveling, international devices | Future tech, smart devices |

What Are the Advantages and Disadvantages of Universal Power Adapters?

Universal power adapters are a popular alternative for international travelers and businesses that need to connect devices from various countries to US power outlets. The primary advantage of these adapters is their versatility; they can accommodate multiple plug types, making them ideal for businesses operating globally. However, the downside is that they may not always provide a secure connection, leading to potential safety issues. Additionally, they typically do not convert voltage, so they must be paired with dual-voltage devices or used cautiously with single-voltage appliances.

How Does Wireless Power Transfer Compare?

Wireless power transfer represents a cutting-edge alternative to traditional power plugs. This technology allows devices to be charged without physical connections, enhancing convenience and safety by reducing wear on plugs and sockets. The main advantage is the ease of use; users simply place their devices on a charging pad. However, the initial investment for wireless charging infrastructure can be significantly higher than traditional plugs, and its compatibility is currently limited to specific devices. Additionally, the charging speed may not match that of wired connections, which can be a critical factor for businesses relying on fast and efficient charging.

Conclusion: How Should B2B Buyers Choose the Right Power Solution?

A stock image related to types of us power plugs.

When selecting the appropriate power solution, B2B buyers should consider their specific operational needs, geographical presence, and device compatibility. For businesses that primarily operate within the US, standard types of power plugs are the most straightforward and cost-effective solution. Conversely, for companies with a diverse international clientele or operations, investing in universal power adapters can provide the necessary flexibility. Meanwhile, forward-thinking businesses might explore wireless power transfer as a long-term investment in technology, keeping in mind its current limitations and costs. Ultimately, understanding the operational context and future growth plans will guide buyers in making the best choice for their power needs.

Essential Technical Properties and Trade Terminology for types of us power plugs

What Are the Key Technical Properties of US Power Plugs?

When considering the import of US power plugs, understanding their technical specifications is crucial for ensuring compatibility and safety. Here are several critical properties to keep in mind:

-

Voltage Rating (120V)

– US power plugs operate at a standard voltage of 120V. For B2B buyers, this means that any electrical appliance must be compatible with this voltage to function safely. Devices designed for higher voltages (e.g., 220V) may require a voltage converter, which adds complexity and cost to the procurement process. -

Frequency (60 Hz)

– The frequency of electrical supply in the US is 60 Hz. This is significant for devices that rely on frequency for timing, such as clocks and motors. If a device is designed for 50 Hz, it may operate incorrectly or wear out faster when used in a 60 Hz environment, impacting reliability and customer satisfaction. -

Plug Type (A and B)

– The US predominantly uses Type A and Type B plugs. Type A features two flat parallel pins, while Type B includes a third grounding pin. Understanding these types is essential for international buyers to ensure that their equipment can be safely connected to US outlets without the need for additional adapters. -

Material Composition

– Power plugs are typically made from durable materials like thermoplastic for the housing and copper for the conductors. B2B buyers should consider the material grade as it affects durability, heat resistance, and overall safety. Higher-grade materials can prevent overheating and reduce the risk of electrical fires. -

Current Rating (15A)

– US plugs are generally rated for 15 amps. Knowing the current rating is vital for determining the maximum load a plug can handle without overheating. This information helps buyers ensure that their devices do not exceed this limit, preventing potential failures or safety hazards. -

Certification Standards

– Power plugs must meet specific safety standards set by organizations like Underwriters Laboratories (UL) or the American National Standards Institute (ANSI). Compliance with these standards is critical for reducing liability and ensuring that products are market-ready. Buyers should always verify certification to avoid non-compliance issues.

What Are Common Trade Terms Related to US Power Plugs?

Familiarity with industry jargon can streamline negotiations and procurement processes. Here are some essential trade terms relevant to US power plugs:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce components that are used in another company’s end products. For buyers, partnering with an OEM for power plugs can ensure high-quality components tailored to specific requirements. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest number of units a supplier is willing to sell. Understanding this term is crucial for B2B buyers to manage inventory levels effectively and negotiate better pricing on larger orders. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting a price quote for specific products. For buyers, issuing an RFQ for US power plugs allows for comparing offers and ensuring competitive pricing. -

Incoterms (International Commercial Terms)

– These are international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for understanding shipping costs and liabilities when importing power plugs. -

Lead Time

– Lead time refers to the time taken from placing an order until its delivery. Knowing the lead time for US power plugs helps buyers plan their inventory and production schedules more effectively. -

Compliance Standards

– This term refers to the regulations and standards that products must meet to be sold in a particular market. B2B buyers must ensure that any US power plugs meet local compliance requirements to avoid fines and legal issues.

Understanding these technical properties and trade terms will empower international B2B buyers to make informed decisions when procuring US power plugs, ultimately leading to safer and more efficient operations.

Navigating Market Dynamics and Sourcing Trends in the types of us power plugs Sector

What Are the Current Market Dynamics and Key Trends in the Types of US Power Plugs?

The market for US power plugs, specifically Type A and Type B, is significantly influenced by the increasing globalization of trade and the need for international compatibility in electrical appliances. As businesses expand their operations across borders, the demand for power adapters and converters is rising, particularly among B2B buyers in Africa, South America, the Middle East, and Europe. The standard voltage of 120V at 60Hz in the US is often different from the voltages in these regions, which creates a necessity for sourcing appropriate power plugs and adapters.

Emerging trends include the adoption of multi-functional travel adapters that cater to various plug types, facilitating smoother international business operations. Additionally, advancements in technology have led to the development of smart plugs that offer features like energy monitoring and remote control, appealing to tech-savvy companies looking to enhance their operational efficiency. B2B buyers should focus on suppliers that provide not only the necessary hardware but also comprehensive support for understanding compatibility and safety standards.

How Does Sustainability and Ethical Sourcing Impact the Types of US Power Plugs Market?

Sustainability and ethical sourcing have become paramount concerns for international B2B buyers, particularly in the electrical components sector. The environmental impact of manufacturing power plugs, from material extraction to production processes, necessitates a shift towards greener alternatives. Buyers should prioritize suppliers who use recyclable materials and adhere to environmentally friendly manufacturing practices.

Certifications such as RoHS (Restriction of Hazardous Substances) and CE marking are vital indicators of compliance with safety and environmental regulations. By choosing suppliers with these certifications, businesses can ensure that their sourcing aligns with global sustainability goals. Furthermore, engaging with manufacturers that prioritize ethical labor practices not only enhances brand reputation but also mitigates risks associated with supply chain disruptions.

What Is the Brief Evolution and History of Power Plugs in the US?

The evolution of power plugs in the US traces back to the late 19th century when Thomas Edison’s inventions laid the groundwork for electrical distribution systems. Initially, the design of plugs was inconsistent, with various configurations emerging across different regions. In 1910, the introduction of the NEMA (National Electrical Manufacturers Association) standardized plug types, leading to the Type A and Type B configurations that dominate the market today.

The Type A plug, featuring two flat parallel pins, and the Type B plug, which includes a grounding pin, were designed to enhance safety and compatibility. Over the decades, as the demand for electrical appliances surged, these plug types became essential in both residential and commercial applications. Understanding this historical context helps B2B buyers appreciate the importance of compliance with standards that ensure safety and reliability in their operations.

Conclusion

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, navigating the market dynamics of US power plugs involves understanding current trends, prioritizing sustainability, and recognizing the historical evolution of these essential components. By leveraging this knowledge, businesses can make informed decisions that align with their operational needs and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of types of us power plugs

-

How do I ensure compatibility between my appliances and US power plugs?

To ensure compatibility, check the voltage and frequency ratings of your appliances. The US operates on a standard voltage of 120V and a frequency of 60Hz. If your devices are dual voltage (e.g., rated for 100-240V), they will work without a voltage converter; you will only need a plug adapter. For single voltage devices, a transformer or converter is necessary. Always verify the specifications on the device label to prevent damage. -

What is the best type of power plug for my business needs in the US?

The best type of power plug for your business will depend on the equipment you use. Type A plugs (two flat parallel pins) and Type B plugs (two flat pins with a grounding pin) are standard in the US. For devices that require grounding, Type B is preferable. Assess your equipment’s requirements and consider obtaining universal adapters for flexibility when using various plug types. -

What should I consider when sourcing US power plugs for international shipping?

When sourcing US power plugs for international shipping, consider compliance with international safety standards, such as UL or IEC certifications. Investigate the supplier’s production capacity, quality assurance processes, and lead times. Additionally, evaluate their experience with export regulations to ensure that all products can be shipped without delays. Lastly, inquire about bulk pricing and the minimum order quantity (MOQ) to optimize your budget. -

How do I vet suppliers for US power plugs?

To effectively vet suppliers, request product samples to assess quality firsthand. Check for certifications that indicate compliance with safety standards and regulations. Research the supplier’s reputation through reviews and testimonials from previous buyers. It’s also advisable to conduct background checks on their business history and financial stability. Establish clear communication channels to gauge responsiveness and customer service. -

What are the payment terms I should negotiate for purchasing US power plugs?

Payment terms can vary significantly between suppliers. Common options include upfront payment, partial payment upon order confirmation, and balance upon shipment. Ensure that the terms protect your interests, particularly when dealing with new suppliers. Consider using secure payment methods like letters of credit or escrow services for larger orders. Discuss potential discounts for early payment or bulk purchases to enhance your cost efficiency. -

How can I customize US power plugs to meet my specific requirements?

Customization options for US power plugs often include modifications in design, color, or functionality. Discuss your specific needs with suppliers, as many manufacturers offer tailored solutions. Be clear about your requirements, including certifications needed for your target market. Also, inquire about the implications of customization on lead times and costs, as bespoke products may require longer production periods. -

What logistics considerations should I keep in mind when importing US power plugs?

When importing US power plugs, consider shipping methods, customs duties, and import regulations specific to your country. Evaluate the total landed cost, including shipping, insurance, and taxes, to ensure budget compliance. Work with logistics partners experienced in international trade to streamline the process. Additionally, be aware of potential delays due to customs inspections and prepare all necessary documentation in advance. -

What quality assurance measures should I implement when sourcing US power plugs?

Implementing quality assurance measures starts with selecting reputable suppliers who adhere to recognized quality standards. Request documentation for testing and certifications to verify compliance with safety regulations. Conduct regular audits and inspections of incoming shipments to ensure consistency in quality. Establish a clear return policy for defective products, and maintain open lines of communication with suppliers to address any quality issues promptly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of us power plugs

In conclusion, understanding the types of US power plugs—primarily Type A and Type B—is essential for international B2B buyers looking to ensure compatibility and safety in their electrical appliances. The standard voltage of 120V at 60Hz simplifies the process for devices rated for dual voltage, eliminating the need for voltage converters. However, for single-voltage appliances, sourcing the right adapters and transformers is crucial to avoid operational issues and potential hazards.

A stock image related to types of us power plugs.

Strategic sourcing of power plugs and adapters can significantly enhance operational efficiency and reduce costs for businesses engaging in trade with the United States. By proactively identifying reliable suppliers and understanding regional electrical standards, companies from Africa, South America, the Middle East, and Europe can avoid common pitfalls associated with international electrical compatibility.

Looking ahead, as global trade continues to expand, ensuring that your electrical equipment meets US standards will be vital for smooth operations. We encourage international buyers to conduct thorough research and establish partnerships with reputable manufacturers and distributors. This proactive approach will not only safeguard your investments but also enhance your competitive edge in the market.