Discover Cost-Effective Solutions with 55 Gallon Burn Barrel (2025)

Introduction: Navigating the Global Market for 55 gallon burn barrel

Navigating the complexities of sourcing a 55-gallon burn barrel can be a daunting task for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. With varying regulations, environmental concerns, and supplier capabilities, making an informed purchasing decision is crucial. This guide aims to demystify the process by providing a comprehensive overview of the types of burn barrels available, their applications, and essential factors to consider when vetting suppliers.

In this guide, you will explore the different styles of burn barrels, including those with lids, without lids, and those designed for specific environmental conditions. Additionally, we delve into the applications of burn barrels, from waste management in rural areas to controlled burning in urban settings. Understanding the cost implications and the importance of supplier reliability will empower you to negotiate better terms and ensure compliance with local regulations.

By equipping international buyers with actionable insights, this guide serves as a valuable resource for making well-informed decisions that align with your operational needs and sustainability goals. Whether you are a buyer in South Africa seeking efficient waste disposal solutions or a purchasing manager in Spain evaluating suppliers, this guide will help you navigate the global market for 55-gallon burn barrels with confidence.

Understanding 55 gallon burn barrel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Steel Burn Barrel | Made from heavy-duty steel, typically comes with a lid | Waste management, agricultural burning | Pros: Durable, efficient burning; Cons: Can rust over time if not maintained. |

| Perforated Burn Barrel | Features holes for airflow, enhancing combustion | Landscaping, forestry management | Pros: Improved airflow for better burning; Cons: May require more maintenance to prevent clogging. |

| Ash Catcher Burn Barrel | Designed with a built-in ash catcher to minimize debris | Industrial waste disposal | Pros: Reduces cleanup time; Cons: Higher initial cost. |

| Portable Burn Barrel | Lightweight and often collapsible for easy transport | Remote job sites, emergency situations | Pros: Easy to move; Cons: Less durable than stationary options. |

| Customizable Burn Barrel | Adaptable designs with options for additional features | Special projects, specific waste types | Pros: Tailored to specific needs; Cons: Longer lead times for production. |

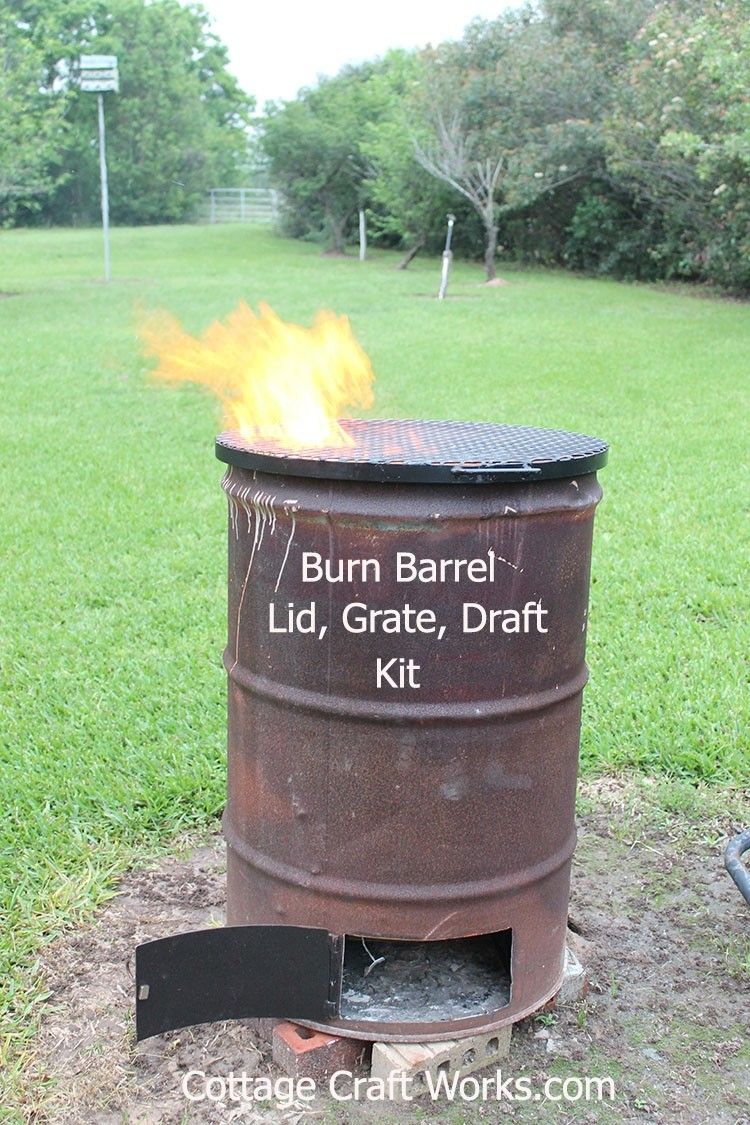

What Are the Characteristics of a Standard Steel Burn Barrel?

The standard steel burn barrel is the most common type used for waste disposal. Typically constructed from heavy-duty steel, it is designed to withstand high temperatures and is often available with a lid to contain smoke and embers. This type is particularly suited for agricultural businesses and municipalities looking to manage waste efficiently. When purchasing, consider the barrel’s thickness and overall durability, as these factors will influence its lifespan and performance.

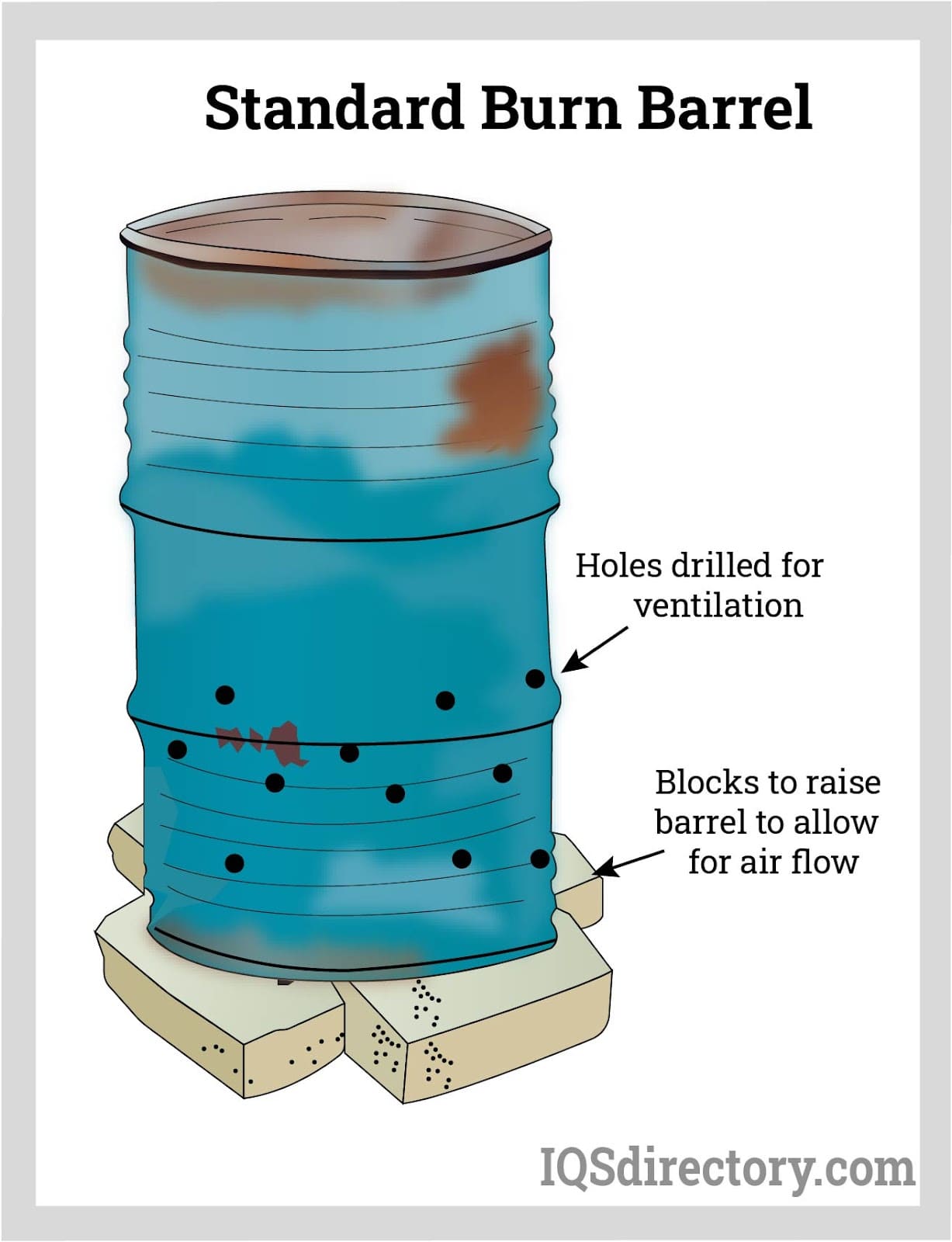

How Does a Perforated Burn Barrel Enhance Combustion?

Perforated burn barrels are characterized by strategically placed holes that allow for increased airflow. This design promotes a more efficient burning process, making it ideal for landscaping and forestry management applications where rapid combustion of organic materials is essential. B2B buyers should evaluate the size and quantity of perforations, as these will affect both combustion efficiency and maintenance requirements.

What Are the Benefits of an Ash Catcher Burn Barrel?

The ash catcher burn barrel includes a built-in feature designed to collect ash and debris during the burning process. This type is particularly beneficial for industrial waste disposal, as it minimizes post-burn cleanup and ensures compliance with environmental regulations. Buyers should consider the ease of cleaning and the capacity of the ash catcher when making a purchasing decision, as these factors can significantly impact operational efficiency.

Why Choose a Portable Burn Barrel for Job Sites?

Portable burn barrels are designed for easy transport, often featuring lightweight materials and collapsible designs. They are particularly useful in remote job sites or emergency situations where waste disposal is necessary but access to traditional disposal methods is limited. When selecting a portable option, buyers should assess the durability and ease of setup, as these elements will affect usability in various environments.

What Are the Advantages of Customizable Burn Barrels?

Customizable burn barrels offer the flexibility to adapt designs according to specific waste disposal needs. This type is particularly advantageous for special projects or industries that require tailored solutions for unique waste types. B2B buyers should be aware of potential lead times for production and the availability of customization options, as these factors can influence project timelines and costs.

Key Industrial Applications of 55 gallon burn barrel

| Industry/Sector | Specific Application of 55 gallon burn barrel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Disposal of agricultural waste and debris | Efficient waste management, reduced labor costs | Material durability, compliance with local regulations |

| Construction | Burning construction waste and debris | Quick disposal, minimizes site clutter | Safety features, capacity for various types of waste |

| Forestry | Burning brush and tree cuttings | Fast reduction of biomass, fire hazard control | Ventilation design, portability for field use |

| Waste Management | Incineration of non-recyclable materials | Eco-friendly disposal, reduced landfill use | Sourcing for eco-friendly materials, emission control |

| Landscaping and Gardening | Disposal of organic waste and yard debris | Clean and efficient waste disposal | Size and accessibility, durability against outdoor elements |

How is a 55 Gallon Burn Barrel Used in Agriculture?

In the agricultural sector, 55-gallon burn barrels are utilized for the disposal of crop residues, weeds, and other organic materials. This method allows farmers to quickly eliminate waste, thereby minimizing the risk of pests and diseases that can arise from decaying matter. International buyers, particularly in regions like South Africa and South America, should consider sourcing barrels that are compliant with local environmental regulations to avoid fines. The durability of the material is crucial, as barrels need to withstand harsh outdoor conditions.

What Role Does a Burn Barrel Play in Construction Waste Management?

In construction, burn barrels serve as an effective solution for the incineration of waste materials such as wood scraps, cardboard, and other debris. This practice not only helps in maintaining a clean job site but also accelerates the waste disposal process, reducing labor costs associated with hauling waste. Buyers from Europe and the Middle East should ensure that the burn barrels they procure come with safety features, such as lids and proper ventilation, to comply with strict safety standards prevalent in these regions.

How Can Forestry Operations Benefit from Using Burn Barrels?

Forestry operations often face challenges with the disposal of brush and tree cuttings. A 55-gallon burn barrel can facilitate the rapid incineration of this biomass, effectively reducing fire hazards and promoting site cleanliness. Buyers in regions prone to wildfires should focus on barrels that provide adequate airflow to promote efficient burning. Additionally, portability is a key consideration for forestry applications, as these barrels may need to be moved across various sites.

What is the Importance of Burn Barrels in Waste Management?

In waste management, 55-gallon burn barrels are increasingly being employed for the incineration of non-recyclable materials. This eco-friendly disposal method helps to significantly reduce the volume of waste that ends up in landfills, aligning with global sustainability goals. International buyers should prioritize sourcing barrels made from eco-friendly materials and equipped with emission control features to meet regulatory standards and enhance their corporate social responsibility initiatives.

How Do Landscaping and Gardening Professionals Utilize Burn Barrels?

Landscaping and gardening professionals use burn barrels to efficiently dispose of organic waste, including leaves, branches, and other yard debris. This method not only streamlines waste management but also contributes to a cleaner work environment. Buyers should consider the size and accessibility of the burn barrels to ensure they meet the demands of their specific landscaping tasks. Durability against outdoor elements is also a significant factor, particularly in diverse climates across Africa and South America.

3 Common User Pain Points for ’55 gallon burn barrel’ & Their Solutions

Scenario 1: Difficulty in Sourcing Durable Burn Barrels for Industrial Use

The Problem: B2B buyers, especially those in industries such as agriculture or waste management, often struggle to find burn barrels that can withstand rigorous use. Many available options may be low-quality or not compliant with local regulations, leading to potential hazards and financial losses. In regions like South Africa or Brazil, where environmental regulations may be stringent, sourcing barrels that meet safety and environmental standards can be a daunting task.

The Solution: When sourcing 55-gallon burn barrels, prioritize suppliers who provide detailed specifications and compliance information. Look for barrels made from heavy-duty materials, like thick steel, that are designed for high-temperature burning. Verify that they meet local environmental regulations, which can be done by asking for certificates of compliance or checking with local regulatory bodies. Consider partnering with established suppliers who have a reputation in your region. They often provide better warranties and customer support, ensuring that your investment is protected and meets operational needs.

Scenario 2: Inadequate Burn Efficiency Leading to Increased Operational Costs

The Problem: Many businesses find that their burn barrels do not operate efficiently, leading to incomplete combustion and higher operational costs. This inefficiency can be particularly problematic in industries such as construction, where waste management is crucial. In regions with limited waste disposal options, like parts of the Middle East, this challenge can lead to compliance issues and increased costs associated with waste management.

The Solution: To enhance burn efficiency, consider barrels that come with built-in air ventilation systems or those designed with specific airflow features. These designs promote better combustion by allowing more oxygen to enter the burn chamber, thus increasing burn temperature and reducing smoke. Additionally, ensure that the burn barrel is placed on a stable, elevated surface to facilitate airflow from the bottom. Regular maintenance, such as cleaning out ash and ensuring air holes are clear, will also significantly improve performance. Educating staff on proper burning practices and the types of materials to use can further optimize the burning process, ultimately reducing costs.

Scenario 3: Safety Concerns with Burn Barrel Operations

The Problem: Safety is a paramount concern for companies using burn barrels, especially in densely populated areas or locations with strict fire regulations. B2B buyers may encounter issues such as flying embers, which can pose fire hazards, or inadequate design leading to structural failures. In regions like Europe, where regulations are particularly stringent, failing to comply with safety standards can result in fines and damage to reputation.

The Solution: To mitigate safety concerns, it is essential to invest in high-quality burn barrels that feature safety enhancements such as lids, mesh screens, and stabilizing legs. Barrels with a lid can help contain sparks and embers, while a mesh screen can prevent larger debris from escaping. Additionally, positioning the barrel away from flammable materials and ensuring it is on a non-flammable surface, such as gravel or concrete, can further reduce risks. Regularly conducting fire safety training for employees is critical to ensure everyone understands the safe operation of burn barrels. Implementing an emergency response plan and ensuring that fire extinguishing equipment is readily available can also help manage risks effectively.

Strategic Material Selection Guide for 55 gallon burn barrel

When selecting materials for a 55-gallon burn barrel, international B2B buyers must consider various factors that impact performance, durability, and compliance with local regulations. Here, we analyze four common materials: steel, stainless steel, plastic, and galvanized metal, focusing on their properties, advantages, disadvantages, and implications for buyers from Africa, South America, the Middle East, and Europe.

A stock image related to 55 gallon burn barrel.

What Are the Key Properties of Steel for Burn Barrels?

Steel is a widely used material for burn barrels due to its high strength and durability. It can withstand high temperatures, making it suitable for incinerating waste. The typical temperature rating for steel barrels can exceed 1,000°F (538°C), which is critical for efficient burning. However, steel is prone to corrosion, especially when exposed to moisture, which can lead to structural failure over time.

Pros: Steel burn barrels are relatively inexpensive and readily available. They can be manufactured easily, making them a cost-effective choice for mass production.

Cons: The main drawback is their susceptibility to rust, particularly in humid environments. Buyers in regions with high moisture levels should consider additional protective coatings.

How Does Stainless Steel Compare for Burn Barrel Applications?

Stainless steel offers superior corrosion resistance and durability compared to regular steel. It can withstand extreme temperatures without degrading, making it ideal for burn barrels that will see frequent use. The temperature rating for stainless steel can also reach up to 2,500°F (1,371°C), allowing for more efficient combustion.

Pros: The longevity of stainless steel barrels is a significant advantage, as they require less maintenance and replacement over time. They are also aesthetically appealing and can be used in more visible settings.

Cons: The cost of stainless steel is considerably higher than that of carbon steel, which may deter budget-conscious buyers. Additionally, manufacturing processes are more complex, potentially leading to longer lead times.

What Role Does Plastic Play in Burn Barrel Design?

While plastic is not a conventional choice for burn barrels, some manufacturers offer high-density polyethylene (HDPE) options. These barrels are lightweight and resistant to corrosion, making them suitable for specific applications where weight is a concern. However, their temperature resistance is limited, typically around 200°F (93°C), which makes them unsuitable for high-heat burning applications.

Pros: Plastic barrels are cost-effective and easy to handle. They are resistant to many chemicals, making them suitable for specific waste types.

Cons: The primary limitation is their low-temperature threshold, which restricts their use for burning applications. They can also be less durable than metal options, leading to a shorter lifespan.

Why Choose Galvanized Metal for Burn Barrels?

Galvanized metal is steel that has been coated with zinc to prevent rusting. This material provides a balance between cost and durability, offering better corrosion resistance than standard steel while remaining more affordable than stainless steel. Galvanized barrels can typically handle temperatures up to 1,000°F (538°C).

Pros: The zinc coating significantly extends the lifespan of galvanized barrels, making them a popular choice for outdoor applications where moisture exposure is common.

Cons: Over time, the zinc can degrade, especially if subjected to extreme heat, which may lead to rust formation. Additionally, galvanized barrels can be heavier than their plastic counterparts.

Summary Table of Material Selection for 55 Gallon Burn Barrels

| Material | Typical Use Case for 55 gallon burn barrel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General waste burning | Cost-effective and widely available | Susceptible to rust | Low |

| Stainless Steel | Frequent use in high-temperature settings | High durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Plastic | Lightweight applications for specific waste | Lightweight and resistant to chemicals | Low-temperature threshold | Low |

| Galvanized Metal | Outdoor burning in humid environments | Good corrosion resistance | Zinc coating degradation over time | Medium |

This strategic material selection guide provides B2B buyers with essential insights into choosing the right burn barrel material, taking into account performance, cost, and regional considerations. Understanding these factors will help international buyers make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 55 gallon burn barrel

What Are the Key Manufacturing Processes for 55 Gallon Burn Barrels?

The manufacturing of 55-gallon burn barrels involves several critical stages, including material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the final product meets safety and performance standards.

How Is Material Prepared for Burn Barrel Production?

The first step in manufacturing burn barrels is material preparation. Typically, high-quality steel sheets are selected for their durability and heat resistance. Suppliers should ensure that the steel meets international specifications, such as ASTM A1011 or equivalent, which guarantees the material can withstand high temperatures and corrosion.

Once the material is selected, it undergoes a series of inspections to check for defects such as rust, cracks, or other imperfections. This initial quality check (Incoming Quality Control – IQC) is crucial for maintaining the integrity of the burn barrel.

What Techniques Are Used in the Forming Process?

The forming process involves several techniques to shape the steel into a functional burn barrel. Common methods include:

-

Rolling: Steel sheets are rolled into cylindrical shapes. This process often utilizes automated machinery to ensure precision and uniformity.

-

Welding: The edges of the rolled sheets are welded together using MIG or TIG welding techniques. This step is vital to creating a strong and leak-proof seam.

-

Cutting: Additional cuts are made for features such as air holes or lids. These modifications enhance airflow and combustion efficiency.

-

Punching and Notching: Some designs may include punched holes for ventilation or notches for the lid. These modifications are essential for optimizing burn efficiency.

How Are Burn Barrels Assembled and Finished?

After forming, the barrels are assembled. This includes attaching lids, handles, and any other components. Assembly can be manual or automated, depending on the scale of production.

The finishing process typically involves:

-

Surface Treatment: Barrels may undergo treatments such as galvanization or powder coating to enhance rust resistance and overall durability.

-

Quality Inspection: Final Quality Control (FQC) checks are performed to ensure that each barrel meets the required specifications and is free from defects.

What Quality Assurance Standards Should B2B Buyers Consider?

For international B2B buyers, understanding the relevant quality assurance standards is crucial. Key standards to consider include:

-

ISO 9001: This international standard outlines requirements for quality management systems. Suppliers adhering to ISO 9001 demonstrate their commitment to consistent quality and customer satisfaction.

-

CE Marking: In Europe, CE marking indicates conformity with health, safety, and environmental protection standards. It is essential for products sold within the European Economic Area (EEA).

-

API Standards: For buyers in the oil and gas sectors, API (American Petroleum Institute) standards may apply, particularly if the burn barrels are used in industrial applications.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is essential for ensuring that the burn barrels meet safety and performance standards. Here are several methods B2B buyers can employ:

What Are the Common QC Checkpoints in Manufacturing?

-

Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Conducting checks during the manufacturing process to identify and rectify defects early.

-

Final Quality Control (FQC): Performing comprehensive inspections before shipment to ensure the final product meets all specifications.

How Can Buyers Conduct Audits and Assessments?

Buyers should consider conducting regular audits of their suppliers. This involves visiting the manufacturing facility to review quality control processes firsthand. During the audit, buyers should assess:

- Compliance with international and local standards.

- The effectiveness of quality control checkpoints.

- Documentation of past quality issues and how they were resolved.

What Role Do Third-Party Inspections Play?

A stock image related to 55 gallon burn barrel.

Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control processes. These agencies often conduct random inspections and tests to verify compliance with international standards, offering an additional layer of assurance to buyers.

What Are the QC Nuances for International B2B Buyers?

When purchasing burn barrels from suppliers in Africa, South America, the Middle East, or Europe, buyers should be aware of regional compliance requirements and potential challenges. Here are some nuances to consider:

-

Cultural Differences: Different regions may have varying expectations regarding quality and service. Understanding local practices can facilitate smoother negotiations and partnerships.

-

Logistics and Supply Chain: Factors such as shipping times, customs regulations, and import duties can affect the procurement process. Buyers should factor these into their planning to avoid delays.

-

Documentation: Ensuring that all relevant certifications and inspection reports are provided with shipments can help avoid compliance issues upon arrival in the destination country.

Conclusion

Understanding the manufacturing processes and quality assurance standards for 55-gallon burn barrels is essential for international B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing processes, buyers can make informed decisions. Additionally, emphasizing quality assurance standards, conducting thorough audits, and engaging third-party inspections can help ensure that the products meet the necessary safety and performance standards across different regions.

Practical Sourcing Guide: A Step-by-Step Checklist for ’55 gallon burn barrel’

This sourcing guide is designed to assist international B2B buyers in procuring 55-gallon burn barrels. Whether you are operating in Africa, South America, the Middle East, or Europe, following this checklist will help you make informed decisions, ensuring you select the right product that meets your operational needs.

Step 1: Define Your Technical Specifications

Start by determining the specific requirements for your burn barrels. Consider factors such as material (steel vs. stainless steel), capacity (55 gallons), and whether you need a lid or additional features like air holes. Clearly defining these specifications will streamline your sourcing process and help you communicate effectively with suppliers.

Step 2: Research Local Regulations and Compliance

Before making any purchases, familiarize yourself with local regulations regarding the use of burn barrels. Different regions have varying laws concerning open burning and waste disposal. Ensuring compliance will prevent potential legal issues and fines, making it critical to check local environmental policies.

Step 3: Evaluate Potential Suppliers

Conduct thorough evaluations of potential suppliers. Request detailed company profiles, product specifications, and customer references, especially from businesses in your region. Look for suppliers with a proven track record in providing burn barrels, as this will enhance your confidence in their reliability and product quality.

- Check for certifications: Ensure the supplier meets relevant industry standards, which can indicate product quality and safety.

- Request samples: If possible, obtain samples to assess the quality and functionality of the burn barrels before placing a bulk order.

Step 4: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers to compare pricing effectively. Consider not only the unit price but also the total cost, including shipping and customs duties if applicable. Additionally, review payment terms to ensure they align with your financial capabilities.

- Assess bulk discounts: Many suppliers offer discounts for larger orders, which can significantly reduce your overall expenditure.

- Negotiate terms: Don’t hesitate to negotiate payment options, such as deposits or payment upon delivery, which can provide additional financial flexibility.

Step 5: Verify Delivery and Shipping Options

Understanding the delivery options available from your chosen suppliers is crucial. Confirm the lead times for delivery and any shipping restrictions that may apply to your region. This information will help you plan your inventory and operational needs effectively.

- Inquire about tracking: Ensure that the supplier provides tracking information for your shipment, allowing you to monitor its progress.

- Consider local distribution centers: If possible, find suppliers that have local warehouses to minimize shipping times and costs.

Step 6: Assess After-Sales Support and Warranty

Finally, evaluate the after-sales support offered by the supplier. A reliable supplier should provide comprehensive customer service and a clear warranty policy. This step is essential for addressing any issues that may arise after your purchase.

- Inquire about service agreements: Some suppliers offer service agreements for maintenance and support, which can be beneficial for long-term operations.

- Read warranty terms carefully: Ensure you understand what is covered under the warranty and the process for claiming it, should the need arise.

By following this practical sourcing checklist, you can enhance your procurement strategy for 55-gallon burn barrels, ensuring that you secure the best products while adhering to regulations and optimizing costs.

Comprehensive Cost and Pricing Analysis for 55 gallon burn barrel Sourcing

What are the Key Cost Components in Sourcing 55 Gallon Burn Barrels?

When sourcing 55-gallon burn barrels, it’s crucial for B2B buyers to understand the various cost components involved. The primary elements include:

-

Materials: The material used for the burn barrel significantly impacts cost. Common materials include steel and stainless steel, with variations in thickness affecting durability and price. For instance, a standard steel drum may cost around $40, while a stainless steel option could exceed $400.

-

Labor: Labor costs include wages for workers involved in manufacturing, assembling, and finishing the burn barrels. Depending on the region, labor rates can vary significantly, affecting the overall pricing structure.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce these overheads, which in turn can lower the price for buyers.

-

Tooling: The cost of specialized tools and machinery required for production also contributes to the overall cost. Custom tooling for unique designs may increase costs, while standardized production can offer savings.

A stock image related to 55 gallon burn barrel.

-

Quality Control (QC): Ensuring that burn barrels meet safety and quality standards necessitates investment in QC processes. Certifications may also be required, especially for international shipping, which could further increase costs.

-

Logistics: Transportation costs, including shipping and handling, can vary based on distance, weight, and mode of transport. Buyers should consider these logistics costs when evaluating supplier quotes.

-

Margin: Finally, suppliers include their profit margin in the final price. Understanding the typical margins in the industry can assist buyers in negotiating better deals.

How Do Price Influencers Affect the Sourcing of 55 Gallon Burn Barrels?

Several factors influence the pricing of burn barrels, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically result in lower per-unit costs. Suppliers may offer discounts for bulk purchases, making it advantageous for businesses that require multiple units.

-

Specifications and Customization: Custom designs or specifications can lead to increased costs. Buyers should weigh the benefits of customization against the additional expense.

-

Material Quality and Certifications: Higher quality materials and necessary certifications (e.g., for safety standards) will raise the price. Buyers in regions with stringent regulations, such as Europe, may need to invest more upfront to comply.

-

Supplier Factors: The reputation and reliability of the supplier can influence costs. Established suppliers may charge a premium for their products due to their perceived quality and service.

-

Incoterms: The chosen Incoterms (International Commercial Terms) affect shipping costs and responsibilities. Understanding these terms is essential for managing total costs effectively.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Burn Barrels?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, implementing the following strategies can enhance cost-efficiency:

-

Negotiation: Engage suppliers in discussions about pricing, especially if making bulk orders. Highlighting long-term partnership potential may encourage suppliers to offer better rates.

-

Total Cost of Ownership (TCO): Evaluate the total cost beyond the initial purchase price, considering factors like maintenance, durability, and disposal costs. Investing in higher-quality barrels may reduce long-term expenses.

-

Pricing Nuances for International Buyers: Currency fluctuations, import tariffs, and regional taxes can impact total pricing. Buyers should factor these elements into their budgeting process to avoid unexpected costs.

-

Research and Compare Suppliers: Conduct thorough research on potential suppliers, comparing prices, quality, and delivery times. Utilizing platforms that consolidate supplier options can streamline this process.

Disclaimer on Indicative Prices

The prices referenced throughout this analysis are indicative and may vary based on market conditions, supplier negotiations, and geographic location. International buyers should conduct their own market research and engage with multiple suppliers to secure the best possible pricing.

Alternatives Analysis: Comparing 55 gallon burn barrel With Other Solutions

When considering waste management solutions, particularly for burning waste, the 55-gallon burn barrel is a popular choice. However, buyers should be aware of alternative methods that may suit their needs better based on performance, cost, and ease of implementation. This section explores viable alternatives, providing insights for B2B buyers from diverse regions including Africa, South America, the Middle East, and Europe.

Comparison Table: 55 Gallon Burn Barrel vs. Alternatives

| Comparison Aspect | 55 Gallon Burn Barrel | Outdoor Fire Pit | Incinerator |

|---|---|---|---|

| Performance | Moderate efficiency for burning small waste; limited air flow may affect combustion. | Good for recreational use; not designed for waste disposal. | Highly efficient; designed for complete combustion of waste. |

| Cost | $60 – $120 (initial cost) | $50 – $300 (varies by design) | $500 – $5,000 (higher upfront investment) |

| Ease of Implementation | Simple setup; requires minimal tools. | Generally easy to set up, but may require more space. | More complex installation; may need permits. |

| Maintenance | Low maintenance; occasional cleaning needed. | Moderate; requires regular cleaning and management of ashes. | High; requires periodic servicing and adherence to regulations. |

| Best Use Case | Ideal for rural areas with limited waste management options. | Best for recreational purposes; not suitable for large waste disposal. | Suitable for high-volume waste management in urban settings. |

What Are the Advantages and Disadvantages of Using an Outdoor Fire Pit?

Outdoor fire pits serve primarily for recreational purposes and social gatherings rather than waste disposal. They are typically designed to create a cozy ambiance and may be aesthetically pleasing. However, they are not efficient for burning large amounts of waste due to limited combustion capabilities. While they may be cheaper than a burn barrel or incinerator, their use is restricted to non-waste applications, making them less viable for businesses focused on waste management.

How Does an Incinerator Compare in Terms of Efficiency?

Incinerators represent a robust alternative for businesses needing to manage large volumes of waste. They are designed for complete combustion, which minimizes the volume of waste significantly and reduces harmful emissions when properly maintained. However, they come with a higher initial cost and require more complex installation and regular maintenance. Additionally, users may need to navigate regulatory requirements to operate an incinerator legally, which could be a barrier for some buyers.

Conclusion: How to Choose the Right Waste Management Solution?

When selecting the right waste management solution, B2B buyers should consider their specific needs, including the volume and type of waste generated, budget constraints, and local regulations. For small-scale operations or rural settings, a 55-gallon burn barrel may suffice. However, for businesses dealing with larger waste volumes or needing a more sustainable solution, investing in an incinerator could prove beneficial despite the higher upfront costs. Understanding the strengths and weaknesses of each alternative will empower buyers to make informed decisions that align with their operational goals and environmental responsibilities.

Essential Technical Properties and Trade Terminology for 55 gallon burn barrel

What Are the Key Technical Properties of a 55 Gallon Burn Barrel?

When evaluating a 55-gallon burn barrel, understanding its technical properties is crucial for B2B buyers. Here are some essential specifications to consider:

-

Material Grade

The most common materials for burn barrels are steel and galvanized steel. Steel is known for its durability and strength, while galvanized steel offers additional rust resistance. For buyers, selecting the right material affects the longevity and safety of the burn barrel, especially in regions with high humidity or varying temperatures. -

Wall Thickness

The wall thickness of a burn barrel typically ranges from 18 to 20 gauge. Thicker walls enhance durability and heat resistance, making the barrel safer to use. Buyers should consider wall thickness based on intended usage—thinner barrels may be sufficient for occasional use, while thicker options are better for frequent burning. -

Weight Capacity

This specification refers to the maximum weight of materials that can be safely burned in the barrel. A standard 55-gallon burn barrel can accommodate around 200 pounds of combustible materials. Understanding weight capacity is vital for compliance with local regulations and ensuring safe operation. -

Ventilation Design

Proper ventilation is necessary to ensure efficient combustion and to minimize smoke emissions. Look for burn barrels with pre-drilled air holes or those designed to promote airflow. Adequate ventilation can significantly enhance burning efficiency, leading to quicker disposal of waste. -

Lid Type

Burn barrels may come with or without lids. A lid is essential for controlling airflow and minimizing the escape of embers. Buyers should assess whether a removable or permanently attached lid better suits their operational needs and safety requirements.

Which Trade Terminology Should B2B Buyers Know When Purchasing a Burn Barrel?

Familiarity with industry jargon can streamline the procurement process. Here are some common terms relevant to burn barrels:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. For B2B buyers, understanding whether a burn barrel is an OEM product can affect warranties, support, and compatibility with other equipment. -

MOQ (Minimum Order Quantity)

This term indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budget planning and inventory management, especially for international buyers looking to optimize shipping costs. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. For buyers interested in bulk purchases of burn barrels, issuing an RFQ can help compare offers and negotiate better terms. -

Incoterms (International Commercial Terms)

These are pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to manage shipping costs, delivery risks, and insurance responsibilities effectively. -

Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. For international buyers, understanding lead times is critical for planning and ensuring that the burn barrels arrive when needed. -

Certification Standards

Many regions have specific safety and environmental standards for burn barrels. Familiarity with relevant certification requirements can help buyers ensure compliance and avoid legal issues, particularly in regulated markets in Europe and North America.

By understanding these technical properties and industry terms, international B2B buyers can make informed purchasing decisions regarding 55-gallon burn barrels, ensuring they meet their operational needs and comply with local regulations.

Navigating Market Dynamics and Sourcing Trends in the 55 gallon burn barrel Sector

What Are the Key Market Dynamics and Trends Influencing the 55 Gallon Burn Barrel Sector?

The global 55-gallon burn barrel market is witnessing significant growth, driven by increasing waste management needs and a growing focus on environmentally friendly disposal methods. In regions such as Africa and South America, where traditional waste disposal options may be limited, burn barrels provide an effective solution for managing agricultural and industrial waste. In Europe and the Middle East, stricter regulations around waste management and emissions are pushing buyers to seek compliant and efficient burn barrels.

Emerging technologies are also reshaping the sourcing landscape. The rise of e-commerce platforms enables international B2B buyers to access a wider array of products and suppliers. Digital marketplaces allow buyers from countries like South Africa and Spain to compare prices, specifications, and reviews easily, enhancing their decision-making process. Additionally, manufacturers are increasingly adopting smart technologies, integrating features such as temperature control and smoke filtration to cater to environmentally conscious consumers.

Furthermore, the market is influenced by fluctuating raw material costs and supply chain dynamics. Buyers should remain vigilant about geopolitical events that may impact steel and manufacturing resources, particularly in regions where sourcing is heavily reliant on imports. As a result, effective demand forecasting and supplier diversification are critical strategies for international buyers to mitigate risks and ensure supply continuity.

How Does Sustainability and Ethical Sourcing Impact the 55 Gallon Burn Barrel Industry?

Sustainability has become a cornerstone of procurement strategies in the 55-gallon burn barrel sector. Buyers are increasingly aware of the environmental impact of their sourcing decisions, focusing on suppliers that prioritize sustainable practices. The importance of ethical supply chains cannot be overstated, especially in markets where transparency and corporate social responsibility are gaining traction. Buyers from Africa, South America, the Middle East, and Europe should seek suppliers that adhere to internationally recognized standards and certifications, such as ISO 14001 for environmental management and Fair Trade for ethical labor practices.

Moreover, the materials used in manufacturing burn barrels are under scrutiny. Buyers are encouraged to opt for barrels made from recycled steel or those that come with eco-friendly coatings, which minimize harmful emissions during combustion. The trend towards ‘green’ certifications is gaining momentum, with consumers increasingly demanding products that not only meet functional needs but also align with their values regarding sustainability. B2B buyers should inquire about the lifecycle of products, including how they are produced, transported, and eventually disposed of, to ensure compliance with their sustainability goals.

What Is the Historical Context of the 55 Gallon Burn Barrel Market?

The 55-gallon burn barrel has its roots in the post-World War II era when surplus steel drums became widely available. Initially, these barrels were repurposed for various industrial uses, including waste disposal. Over time, as environmental regulations began to tighten, the design and functionality of burn barrels evolved. Manufacturers introduced features such as lids and ventilation holes to improve combustion efficiency and reduce smoke emissions.

Today, the burn barrel is not just a waste disposal tool; it has transformed into a versatile solution for both residential and commercial applications. The evolution of this product reflects broader trends in waste management, emphasizing the need for effective, environmentally responsible practices. As international B2B buyers navigate this market, understanding its historical context can provide valuable insights into current innovations and future directions.

Frequently Asked Questions (FAQs) for B2B Buyers of 55 gallon burn barrel

-

How do I select the right supplier for 55-gallon burn barrels?

When sourcing 55-gallon burn barrels, it’s crucial to assess potential suppliers thoroughly. Look for manufacturers with a proven track record in the industry, positive customer reviews, and compliance with international safety standards. Conduct site visits if possible, or request video calls to inspect their production facilities. Additionally, ask for samples to evaluate product quality before making bulk purchases. Utilizing platforms like Alibaba or TradeKey can also help you identify reputable suppliers and compare their offerings. -

What are the common customization options available for burn barrels?

Many suppliers offer customization options for 55-gallon burn barrels, including colors, lid types, and additional features like air holes or ash catchers. It’s essential to communicate your specific requirements clearly to the supplier. Some manufacturers may also provide branding opportunities, allowing you to add your logo or unique design to the barrels. Always request a prototype before finalizing orders to ensure that the customization meets your expectations. -

What are the minimum order quantities (MOQ) for 55-gallon burn barrels?

The minimum order quantity for 55-gallon burn barrels varies by supplier, typically ranging from 50 to 500 units. It is advisable to discuss MOQs upfront to ensure they align with your purchasing needs. If you are a smaller business or just starting, some suppliers may be willing to negotiate or offer smaller test orders. Always consider the impact of shipping costs and storage capacity when planning your order. -

What payment terms should I expect when purchasing burn barrels internationally?

Payment terms for international purchases can vary significantly. Common terms include full payment upfront, a deposit followed by the balance before shipping, or payment on delivery. It’s essential to negotiate these terms before finalizing your order. Using secure payment methods such as letters of credit, PayPal, or escrow services can provide additional protection. Always ensure that the payment terms align with your cash flow and risk management strategies. -

What quality assurance measures should I consider for burn barrels?

Quality assurance is vital when sourcing 55-gallon burn barrels. Inquire whether the supplier adheres to international quality standards such as ISO 9001. Request documentation of any third-party inspections or certifications. It may also be beneficial to establish a quality control process, including inspecting the products upon arrival and before distribution. If possible, consider hiring a third-party inspection service to evaluate the barrels at the supplier’s facility prior to shipping. -

How do logistics and shipping work for sourcing burn barrels internationally?

Logistics for international shipping of burn barrels can be complex. Understand the shipping methods available—air freight is faster but more expensive, while sea freight is cost-effective for larger quantities. Discuss with your supplier about their shipping arrangements, including who bears the freight costs and how customs duties will be handled. Ensure you have the necessary documentation for customs clearance to avoid delays. Partnering with a reliable freight forwarder can simplify the logistics process. -

What are the environmental considerations when sourcing burn barrels?

When purchasing burn barrels, it’s essential to consider their environmental impact. Look for suppliers that utilize sustainable manufacturing practices and materials. Inquire whether the barrels are made from recycled materials and if they comply with environmental regulations in your region. Additionally, consider the disposal methods for barrels at the end of their lifecycle and whether the supplier offers recycling options. -

How can I ensure compliance with local regulations when using burn barrels?

Compliance with local regulations regarding the use of burn barrels is critical. Research the specific laws and guidelines that govern outdoor burning in your region, as they can vary widely, particularly in Europe, Africa, and South America. Ensure that the barrels meet safety standards and are used in accordance with local environmental laws. Consulting with local authorities or legal experts can help you navigate these regulations and avoid potential fines or legal issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 55 gallon burn barrel

What Are the Key Takeaways for Strategic Sourcing of 55 Gallon Burn Barrels?

In conclusion, the strategic sourcing of 55-gallon burn barrels presents a unique opportunity for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Understanding the specifications, such as material quality, design variations, and pricing structures, is essential for making informed purchasing decisions. The ability to source reliable suppliers who can provide high-quality barrels at competitive prices will significantly enhance operational efficiency and waste management capabilities.

How Can Buyers Leverage Strategic Sourcing to Gain Competitive Advantage?

By adopting a strategic sourcing approach, businesses can not only reduce costs but also ensure compliance with environmental regulations, especially in areas prone to wildfires or waste management issues. Engaging with suppliers who understand regional needs and can offer customized solutions—like lids for safety or ventilation options for improved burning—will add value to your investment.

What Should International Buyers Do Next?

As you consider sourcing 55-gallon burn barrels, take the initiative to research potential suppliers and evaluate their offerings. Engage in negotiations that reflect your unique requirements and local conditions. The future of waste management is evolving, and by staying ahead of these trends, you can position your business for success. Start your strategic sourcing journey today to ensure you meet your operational needs effectively while contributing to sustainable practices.