Cut Costs with the Complete Air Drier Buying Guide (2025)

Introduction: Navigating the Global Market for air drier

Navigating the complexities of the global market for air dryers can be a significant challenge for international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe. With varying climate conditions, industrial standards, and market expectations, sourcing the right air dryer is crucial to ensuring operational efficiency and product quality. This guide aims to simplify the purchasing process by providing a comprehensive overview of different types of air dryers, including refrigerated and desiccant models, as well as their specific applications across various industries.

In this guide, you will find actionable insights on how to effectively vet suppliers, understand pricing structures, and evaluate the performance specifications of air dryers. We delve into critical factors such as energy efficiency, maintenance requirements, and the impact of local regulations on your procurement strategy. By addressing these key considerations, this resource empowers B2B buyers to make informed decisions that align with their operational needs and budget constraints.

Whether you are a manufacturer in Brazil seeking reliable moisture removal solutions or a distributor in the Middle East looking to expand your product offerings, this guide serves as a valuable tool. It equips you with the knowledge necessary to navigate the global air dryer market confidently, ensuring that you select the best solutions for your business needs.

Understanding air drier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Refrigerated Air Dryer | Uses cooling to condense moisture; cost-effective and reliable | General manufacturing, automotive, construction | Pros: Efficient moisture removal; low maintenance. Cons: Limited dew point control; not suitable for all industries. |

| Desiccant Air Dryer | Utilizes desiccant material for ultra-low dew points | Pharmaceuticals, food processing, electronics | Pros: High moisture removal efficiency; ideal for critical applications. Cons: Higher operational costs; requires periodic media replacement. |

| Cycling Air Dryer | Operates by cycling on/off to optimize energy use | General industrial applications | Pros: Energy-efficient; can handle varying air demands. Cons: More complex design; potential for increased wear. |

| Non-Cycling Air Dryer | Constant operation without cycling; simpler design | Manufacturing, machining, painting | Pros: Consistent performance; lower upfront costs. Cons: Higher energy consumption; less efficient under varying loads. |

| High-Temperature Air Dryer | Designed to handle elevated temperatures and specific humidity | Aerospace, automotive, and high-heat applications | Pros: Suitable for high-temperature environments; robust design. Cons: Limited availability; specialized applications may increase costs. |

What Are the Key Characteristics of Refrigerated Air Dryers?

Refrigerated air dryers are widely used in various industries due to their ability to efficiently remove moisture from compressed air. They operate by cooling the compressed air, which causes moisture to condense and be removed. Suitable for general manufacturing and construction, these dryers are an excellent choice for businesses seeking reliable moisture control without excessive operational costs. Buyers should consider their specific air quality requirements, as refrigerated dryers may not achieve the ultra-low dew points needed for sensitive applications.

Why Choose Desiccant Air Dryers for Critical Applications?

Desiccant air dryers excel in environments where moisture removal is paramount, such as pharmaceuticals and food processing. These systems use desiccant materials to adsorb water vapor, providing ultra-low dew points that are essential for sensitive processes. While they offer superior moisture control, B2B buyers should be aware of the higher operational costs and the need for periodic media replacement. Evaluating the critical nature of your application will help determine if the investment in a desiccant dryer is justified.

How Do Cycling Air Dryers Optimize Energy Use?

Cycling air dryers are designed to operate efficiently by cycling on and off based on the demand for compressed air. This energy-efficient design is ideal for industries with fluctuating air requirements. Buyers in general industrial applications should consider the energy savings these systems can provide, especially over time. However, the more complex design may lead to increased wear, necessitating careful maintenance and monitoring.

What Are the Advantages of Non-Cycling Air Dryers?

Non-cycling air dryers maintain a constant operation, making them straightforward and easy to use. They are particularly beneficial for applications where consistent air quality is required, such as in machining and painting. Although they tend to have lower upfront costs, buyers should weigh this against potentially higher energy consumption, especially if air demands vary significantly throughout operations.

When Should You Consider High-Temperature Air Dryers?

High-temperature air dryers are specifically engineered to handle elevated temperatures and humidity levels, making them suitable for industries such as aerospace and automotive. These robust systems ensure reliable performance under challenging conditions. However, their specialized nature may limit availability and increase costs. B2B buyers should assess their operational environment and the need for high-temperature capabilities before making a purchasing decision.

Key Industrial Applications of air drier

| Industry/Sector | Specific Application of Air Dryer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Moisture removal in pneumatic systems | Prevents equipment corrosion and downtime | Capacity and efficiency ratings; compatibility with existing systems |

| Food Processing | Drying of air in packaging processes | Ensures product quality and shelf life | Compliance with food safety standards; energy efficiency |

| Pharmaceuticals | Ultra-dry environments for production | Maintains product integrity and efficacy | Low dew point specifications; reliability and maintenance support |

| Automotive | Air drying in spray painting and finishing | Improves surface quality and reduces defects | Quality certifications; adaptability to different processes |

| Electronics | Humidity control in assembly lines | Protects sensitive components from moisture damage | Precision in moisture control; scalability for production needs |

How Are Air Dryers Used in Manufacturing to Solve Problems?

In the manufacturing sector, air dryers are essential for moisture removal in pneumatic systems. Moisture can lead to corrosion, reduced efficiency, and increased downtime of equipment. By integrating air dryers, manufacturers can ensure a consistent supply of dry air, enhancing operational reliability. International buyers should consider the capacity and efficiency ratings of air dryers to match their specific pneumatic system requirements, ensuring compatibility and optimal performance.

What Are the Benefits of Air Dryers in Food Processing Applications?

In food processing, air dryers are used to maintain dry air conditions during packaging processes. This is crucial for preventing moisture-related spoilage, which can compromise product quality and shelf life. By implementing air dryers, businesses can enhance their product integrity and compliance with food safety standards. When sourcing, international buyers should prioritize suppliers that meet stringent food safety regulations and offer energy-efficient solutions to minimize operational costs.

Why Are Air Dryers Critical in Pharmaceuticals?

The pharmaceutical industry requires ultra-dry environments to ensure the integrity and efficacy of products. Air dryers used in this sector help maintain specific low dew points, which are vital for preventing moisture damage during production. For international buyers, it is essential to source air dryers that offer reliable performance and maintenance support, as any failure can lead to significant financial losses and regulatory issues.

How Do Air Dryers Improve Automotive Finishing Processes?

In automotive manufacturing, air dryers play a pivotal role in spray painting and finishing processes. By removing moisture from the air, these dryers help achieve superior surface quality and reduce defects in paint applications. Automotive companies should look for air dryers with quality certifications and those that can adapt to various finishing processes. This adaptability ensures that the equipment can handle different paint types and environmental conditions.

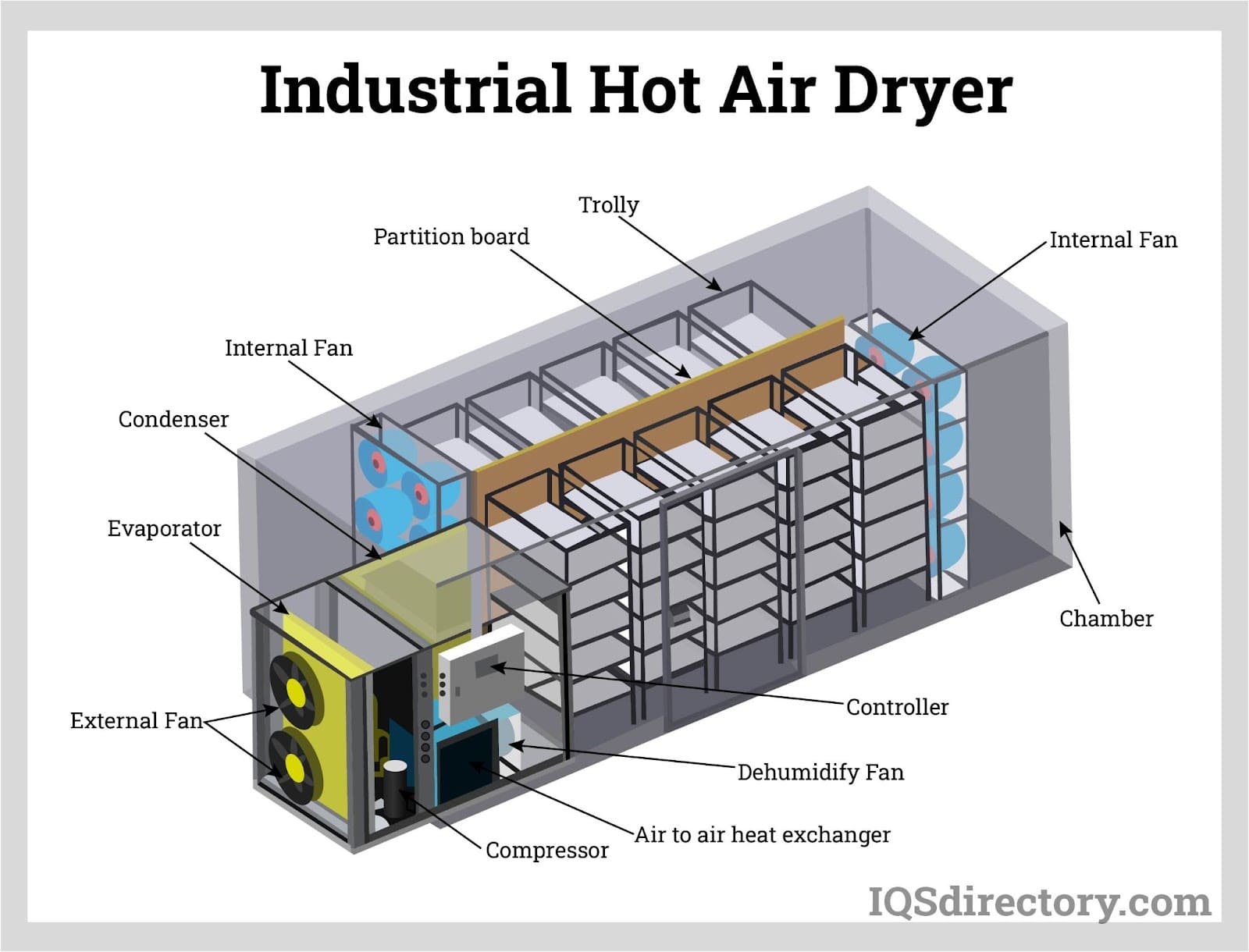

A stock image related to air drier.

What Role Do Air Dryers Play in Electronics Manufacturing?

Air dryers are critical in electronics manufacturing, where humidity control is essential to protect sensitive components from moisture damage. By maintaining a dry atmosphere in assembly lines, air dryers help improve product quality and reliability. International buyers should focus on sourcing air dryers that offer precise moisture control and scalability to meet varying production needs, ensuring they can support both current and future manufacturing demands.

3 Common User Pain Points for ‘air drier’ & Their Solutions

Scenario 1: Inconsistent Air Quality Leading to Production Downtime

The Problem:

Many B2B buyers in sectors such as manufacturing and food processing face the challenge of maintaining consistent air quality. Fluctuations in moisture levels can lead to equipment malfunction, product spoilage, or even safety hazards. For instance, in a food processing plant, excessive moisture can lead to bacterial growth, jeopardizing product safety and quality. Buyers often find themselves in a dilemma: how to ensure that the compressed air they use meets strict quality standards without incurring excessive costs or operational downtime.

The Solution:

To combat inconsistent air quality, B2B buyers should invest in high-quality refrigerated air dryers. These dryers are specifically designed to remove moisture from compressed air effectively. When sourcing air dryers, prioritize models that offer reliable performance under varying load conditions. For example, look for dryers equipped with adjustable dew point settings that can adapt to your specific operational needs. Additionally, consider implementing a preventative maintenance schedule to ensure the air dryer operates optimally over time. This proactive approach will help maintain consistent air quality, reduce the risk of production downtime, and ensure compliance with industry standards.

Scenario 2: High Energy Costs from Inefficient Drying Systems

The Problem:

International buyers often struggle with the high energy costs associated with operating air drying systems. Inefficient dryers can consume excessive amounts of energy, leading to inflated operational expenses. This issue is especially pronounced in regions with high electricity costs, such as parts of Africa and Europe. Buyers may feel trapped between the need for reliable moisture removal and the desire to keep energy expenses in check.

The Solution:

Investing in energy-efficient air dryers can significantly mitigate this problem. Look for models that feature advanced technologies like variable speed drives (VSD) or heat recovery systems. These innovations can optimize energy consumption by adjusting the drying process based on real-time demand. Furthermore, consider conducting an energy audit to assess your current systems and identify areas for improvement. By switching to energy-efficient air dryers and implementing smart energy management practices, businesses can reduce their overall energy costs while maintaining high-quality air supply.

Scenario 3: Difficulty in Selecting the Right Type of Air Dryer

The Problem:

B2B buyers often find it challenging to select the appropriate type of air dryer for their specific applications. With various options available—such as refrigerated, desiccant, and membrane dryers—making the right choice can be overwhelming. Misalignment between the chosen dryer and application needs can lead to inadequate moisture removal, affecting product quality and operational efficiency. Buyers may also fear that a poor choice will result in costly replacements or repairs.

The Solution:

To navigate this challenge, buyers should first conduct a thorough assessment of their operational requirements, including the specific moisture levels needed for their applications. For instance, if ultra-low dew points are essential, desiccant dryers may be the best choice, while refrigerated dryers can suffice for general manufacturing needs. It’s also beneficial to consult with manufacturers or distributors who can provide insights based on industry-specific applications. Additionally, consider investing in modular systems that allow for scalability. This way, you can start with a system that meets your current needs and expand as your operations grow, ensuring that you make a wise investment in your air drying solutions.

Strategic Material Selection Guide for air drier

What Are the Common Materials Used in Air Dryers?

When selecting materials for air dryers, international B2B buyers must consider various factors such as performance, durability, and cost. The choice of material significantly impacts the efficiency and longevity of the air dryer, making it essential to understand the properties and applications of each material.

How Do Different Materials Affect Air Dryer Performance?

Aluminum

Key Properties:

Aluminum is lightweight and has excellent corrosion resistance, making it ideal for air dryer applications. It typically withstands temperatures up to 150°C and pressures around 200 psi.

Pros & Cons:

Aluminum’s durability and resistance to rust make it a popular choice. However, it can be more expensive than other materials and may not be suitable for high-pressure applications.

Impact on Application:

Aluminum is compatible with various media, including compressed air and inert gases. Its lightweight nature allows for easier installation and maintenance.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM and ISO, as aluminum products can vary in quality.

Stainless Steel

Key Properties:

Stainless steel offers exceptional strength and corrosion resistance, withstanding temperatures up to 300°C and pressures exceeding 300 psi.

Pros & Cons:

While stainless steel is highly durable and suitable for high-pressure applications, it is also more costly and may require specialized manufacturing processes.

Impact on Application:

This material is ideal for applications requiring high cleanliness levels, such as pharmaceuticals and food processing, due to its non-reactive nature.

Considerations for International Buyers:

European buyers often prefer stainless steel due to stringent safety and quality standards. Ensuring compliance with DIN standards is crucial for market acceptance.

Carbon Steel

Key Properties:

Carbon steel is known for its strength and ability to withstand high pressures, with ratings up to 400 psi. However, it is susceptible to corrosion if not properly treated.

Pros & Cons:

The primary advantage of carbon steel is its low cost and high strength. However, its susceptibility to rust and the need for protective coatings can increase long-term maintenance costs.

Impact on Application:

Carbon steel is suitable for general industrial applications but may not be ideal for environments where moisture is prevalent without adequate protection.

Considerations for International Buyers:

Buyers in the Middle East should be aware of the high humidity levels that can affect carbon steel’s performance. Compliance with local corrosion resistance standards is essential.

Plastic Composites

Key Properties:

Plastic composites are lightweight and resistant to corrosion, withstanding temperatures up to 80°C and pressures around 150 psi.

Pros & Cons:

These materials are cost-effective and easy to manufacture, but they may not be suitable for high-pressure applications and can degrade under UV exposure.

Impact on Application:

Plastic composites are ideal for low-pressure applications and environments where corrosion is a concern, such as in coastal areas.

Considerations for International Buyers:

In regions like Brazil, where humidity and corrosion are prevalent, buyers should ensure that the selected plastic composites meet local environmental standards.

Summary Table of Material Properties for Air Dryers

| Material | Typical Use Case for air drier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General industrial applications | Lightweight and corrosion-resistant | Higher cost than alternatives | Medium |

| Stainless Steel | High cleanliness applications (pharma) | Exceptional strength and durability | Higher cost and complex manufacturing | High |

| Carbon Steel | General industrial applications | Low cost and high strength | Susceptible to corrosion | Low |

| Plastic Composites | Low-pressure and corrosion-sensitive areas | Cost-effective and lightweight | Limited pressure rating | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them choose the right materials for their air dryer applications based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for air drier

What Are the Key Stages in the Manufacturing Process of Air Dryers?

The manufacturing process of air dryers typically involves several critical stages to ensure the product meets performance standards and quality expectations. For international B2B buyers, understanding these stages can help in evaluating potential suppliers.

-

Material Preparation

The process begins with sourcing high-quality raw materials, such as aluminum or stainless steel, which are essential for the durability and efficiency of air dryers. Suppliers must ensure that materials meet international standards, such as ASTM or ISO certifications, to guarantee quality. Proper documentation of material specifications is crucial for buyers to validate the integrity of the materials used. -

Forming and Machining

Once materials are prepared, they undergo various forming techniques, including cutting, bending, and welding. Advanced CNC (Computer Numerical Control) machines are often employed to achieve precise dimensions and tolerances. This stage may include forming the heat exchangers, which are pivotal in removing moisture from compressed air. Buyers should inquire about the machinery and technologies used, as these can significantly impact the end product’s quality. -

Assembly

The assembly process is where the components come together. This stage typically involves integrating mechanical parts, electronic controls, and safety features. A well-structured assembly line with skilled technicians ensures consistency and reduces the likelihood of defects. Buyers should look for suppliers that employ lean manufacturing principles to minimize waste and enhance efficiency. -

Finishing

After assembly, air dryers undergo finishing processes like painting, powder coating, or anodizing. These treatments not only enhance aesthetics but also protect against corrosion and wear. Buyers should assess the finishing processes used by suppliers, as these can influence the longevity and reliability of the product in different environments.

How Is Quality Assurance Implemented in Air Dryer Manufacturing?

Quality assurance (QA) is a critical component in the manufacturing of air dryers, ensuring that each unit meets the required specifications and international standards. Here’s how QA is typically structured:

-

Adherence to International Standards

Compliance with standards such as ISO 9001 is essential for manufacturers. ISO 9001 outlines the requirements for a quality management system (QMS) that can enhance customer satisfaction through consistent quality. Additionally, industry-specific certifications, such as CE marking for European markets or API for oil and gas applications, are crucial for international buyers. These certifications indicate that products have been tested and meet safety and performance standards. -

Quality Control Checkpoints

Effective QA incorporates several checkpoints during the manufacturing process:

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure they meet quality specifications.

- In-Process Quality Control (IPQC): Regular checks are conducted during manufacturing to catch defects early in the process.

- Final Quality Control (FQC): After assembly and finishing, a comprehensive inspection is performed to ensure the air dryer operates correctly and meets all standards.

- Testing Methods for Quality Assurance

Various testing methods are employed to assess the performance and reliability of air dryers. Common tests include:

- Pressure Testing: Ensures the unit can withstand operational pressures without leaks.

- Temperature and Humidity Testing: Validates the dryer’s efficiency in moisture removal under different conditions.

- Electrical Testing: Checks for safety and functionality of electrical components.

- Performance Testing: Measures the actual dew point and airflow rates to confirm they meet specifications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control measures is crucial for ensuring product reliability. Here are key strategies to achieve this:

-

Conducting Supplier Audits

Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control practices. These audits should evaluate adherence to international standards, production capabilities, and quality assurance measures. -

Requesting Quality Control Reports

Suppliers should be willing to provide documentation of their quality control processes, including inspection reports and compliance certificates. These documents can help buyers assess whether the supplier meets the necessary standards. -

Utilizing Third-Party Inspection Services

Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s operations. These services can perform random inspections during production and provide detailed reports on product quality and compliance with specifications. -

Understanding QC and Certification Nuances

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of the nuances associated with quality control and certification. Different regions may have varying requirements and standards, which can impact the acceptance of products in local markets. Buyers should ensure that suppliers can navigate these complexities and provide products that are compliant with local regulations.

Conclusion

Understanding the manufacturing processes and quality assurance practices for air dryers is essential for B2B buyers looking to make informed purchasing decisions. By focusing on material quality, manufacturing techniques, and rigorous quality control measures, international buyers can select suppliers that deliver reliable and efficient air dryer solutions tailored to their specific needs. Ensuring compliance with international standards and conducting thorough due diligence can lead to successful partnerships and long-term satisfaction with the purchased products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘air drier’

Introduction

When sourcing an air dryer for your business, especially in regions like Africa, South America, the Middle East, and Europe, it is essential to follow a systematic approach. This guide provides a step-by-step checklist to ensure that you select the right air dryer that meets your operational needs, budget constraints, and quality standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider the required airflow rate (CFM), operating pressure, and the specific moisture removal capability. This step ensures that the air dryer will effectively meet the demands of your applications, whether in manufacturing, food processing, or other critical industries.

- Airflow Requirements: Calculate the airflow needs based on your equipment and processes.

- Dew Point Levels: Determine the necessary dew point to avoid moisture-related issues.

Step 2: Research Different Types of Air Dryers

Understanding the types of air dryers available is crucial for making an informed decision. The two main categories are refrigerated air dryers and desiccant air dryers. Each type has its unique benefits and ideal applications.

- Refrigerated Air Dryers: Best for general manufacturing and applications where moderate moisture removal is sufficient.

- Desiccant Air Dryers: Necessary for industries requiring ultra-low dew points, such as pharmaceuticals and electronics.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. This step helps you identify reliable partners who can deliver quality products and services.

- Check Certifications: Ensure that suppliers have relevant certifications, such as ISO, to guarantee compliance with international quality standards.

- Review Customer Feedback: Look for testimonials or reviews that highlight the supplier’s reliability and service quality.

Step 4: Request Quotes and Compare Pricing

Gather quotes from multiple suppliers to get a sense of the market price for the air dryers you are considering. Comparing pricing helps you identify the best value for your investment while ensuring you don’t compromise on quality.

- Consider Total Cost of Ownership: Factor in installation, maintenance, and operational costs when evaluating quotes.

- Negotiate Terms: Don’t hesitate to negotiate pricing and payment terms, especially for bulk orders.

Step 5: Assess After-Sales Support and Warranty

After-sales support can significantly impact your operational efficiency. Ensure that the supplier offers comprehensive support services, including installation, maintenance, and troubleshooting.

- Warranty Coverage: Check the warranty terms to understand what is covered and for how long.

- Availability of Spare Parts: Confirm that spare parts are readily available to minimize downtime in case of repairs.

Step 6: Finalize Your Purchase and Review Documentation

Once you have selected a supplier, finalize your purchase by reviewing all documentation carefully. Ensure that all agreed terms, including specifications, delivery timelines, and payment conditions, are clearly outlined in the contract.

- Keep Records: Maintain a copy of all documents for future reference and warranty claims.

- Plan for Installation: Coordinate with the supplier for the installation process to ensure that it aligns with your operational schedule.

Conclusion

Following this step-by-step checklist will streamline your sourcing process for air dryers. By defining your specifications, researching options, evaluating suppliers, and ensuring robust after-sales support, you can make a well-informed decision that enhances your operational efficiency and product quality.

Comprehensive Cost and Pricing Analysis for air drier Sourcing

What Are the Key Cost Components in Air Dryer Sourcing?

When sourcing air dryers, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The type of materials used in manufacturing air dryers—such as metals, plastics, and specialized components—significantly affects pricing. Higher-quality materials can lead to increased durability and performance, which may justify a higher initial investment.

-

Labor: Labor costs encompass wages, benefits, and overhead associated with the workforce involved in the manufacturing process. Regions with lower labor costs can offer competitive pricing, but this may also impact product quality.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help minimize overhead costs, positively influencing the overall pricing of the product.

-

Tooling: The cost of tools and machinery required for production can vary widely based on the complexity and customization of the air dryer. Custom designs often necessitate specialized tooling, which can add to the initial price.

-

Quality Control (QC): Rigorous quality assurance processes ensure that air dryers meet industry standards and specifications. While this adds to production costs, it is essential for maintaining product reliability, especially in critical applications.

-

Logistics: Shipping, handling, and storage costs play a significant role in the final pricing. These costs can fluctuate based on the shipping distance, mode of transport, and any tariffs or duties applicable in the buyer’s country.

-

Margin: Suppliers add a profit margin to cover their operational costs and risks. Understanding the typical margin for air dryers can help buyers gauge whether a quoted price is competitive.

How Do Price Influencers Impact Air Dryer Pricing?

Several factors can influence the pricing of air dryers, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to significant discounts. Buyers should negotiate MOQs that align with their needs to capitalize on cost savings.

-

Specifications and Customization: Tailored air dryer solutions may incur additional costs. Buyers must weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: Air dryers that meet specific industry certifications or use premium materials will typically command higher prices. Buyers should consider the long-term value of investing in certified products.

-

Supplier Factors: Supplier reputation, reliability, and experience can affect pricing. Established suppliers may charge more due to their proven track record, while emerging suppliers might offer lower prices to gain market share.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can have a significant impact on total costs. Buyers should be aware of who is responsible for shipping, insurance, and tariffs, as these can alter the final price.

What Are Effective Buyer Tips for Air Dryer Sourcing?

To navigate the complexities of air dryer sourcing, international buyers should consider the following tips:

-

Negotiation Strategies: Engage in open discussions with suppliers regarding pricing, terms, and conditions. Leverage volume purchases to negotiate better deals.

-

Focus on Cost-Efficiency: Evaluate not just the purchase price but the Total Cost of Ownership (TCO), which includes installation, maintenance, and energy costs over the product’s lifespan. Investing in energy-efficient models can lead to substantial savings.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, payment terms, and potential import/export restrictions when sourcing air dryers from different regions. This knowledge can prevent unexpected cost increases.

-

Research and Comparison: Utilize online platforms to compare prices and specifications from various suppliers. An informed decision can lead to better pricing and quality.

-

Request Quotes with Detailed Breakdowns: Ask suppliers for itemized quotes that outline all cost components. This transparency can help identify areas for negotiation and clarify the overall value being offered.

Disclaimer for Indicative Prices

Prices for air dryers can vary significantly based on specifications, supplier, and market conditions. The figures provided in examples are indicative and should not be considered final or absolute. Always obtain updated quotes directly from suppliers for the most accurate pricing information.

Alternatives Analysis: Comparing air drier With Other Solutions

When evaluating solutions for moisture removal in compressed air systems, it is essential to consider various alternatives to traditional air dryers. Each method has distinct advantages and disadvantages that can significantly impact operational efficiency, cost-effectiveness, and suitability for specific applications. Here, we compare air dryers with two viable alternatives: Desiccant Dryers and Membrane Dryers.

Comparison Table of Air Dryers and Alternatives

| Comparison Aspect | Air Drier | Desiccant Dryer | Membrane Dryer |

|---|---|---|---|

| Performance | Effective for standard moisture removal | Superior moisture removal, low dew points | Moderate moisture removal, continuous operation |

| Cost | Moderate initial investment | Higher initial and operational costs | Lower initial cost, but potential for higher maintenance costs |

| Ease of Implementation | Generally straightforward installation | More complex installation and setup | Simple installation, minimal space requirements |

| Maintenance | Low to moderate maintenance | Higher maintenance, need to replace desiccants | Low maintenance, but periodic replacement needed |

| Best Use Case | General manufacturing, automotive | Food processing, pharmaceuticals, electronics | Industrial applications with less stringent moisture requirements |

What Are the Advantages and Disadvantages of Desiccant Dryers?

Pros:

Desiccant dryers excel in applications requiring ultra-low dew points, such as food processing and pharmaceuticals. They utilize desiccant materials that adsorb moisture, providing reliable performance in critical environments. This capability ensures high-quality compressed air, which is vital for processes sensitive to humidity.

Cons:

The downside of desiccant dryers is their higher initial and operational costs, as well as the need for more complex installation. Maintenance can also be demanding, requiring regular replacement of desiccant materials to maintain efficiency. As such, they may not be the best choice for all businesses, particularly those with limited budgets or less stringent moisture control needs.

How Do Membrane Dryers Compare in Terms of Performance?

Pros:

Membrane dryers are an excellent choice for applications that require continuous operation without the need for extensive maintenance. They work by using selective permeation to separate moisture from air, making them energy-efficient and straightforward to install. Their compact design is beneficial for businesses with limited space.

Cons:

While membrane dryers are cost-effective in terms of initial investment, they may not achieve the low dew points provided by desiccant dryers. This limitation can be a concern for industries where air quality is critical. Additionally, while maintenance is generally low, periodic replacement of membrane elements can add to long-term costs.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right moisture removal solution involves assessing your specific operational requirements, budget constraints, and the critical nature of your applications. For general manufacturing needs, an air dryer may suffice, offering a balance of performance and cost-effectiveness. However, industries that demand stringent moisture control should consider investing in desiccant dryers despite the higher costs. On the other hand, if space and continuous operation are paramount, membrane dryers may present an optimal solution. By carefully evaluating these alternatives, B2B buyers can make informed decisions that align with their operational goals and financial parameters.

Essential Technical Properties and Trade Terminology for air drier

What Are the Essential Technical Properties of Air Dryers for B2B Buyers?

Understanding the technical specifications of air dryers is crucial for international B2B buyers, especially when sourcing equipment that meets specific operational requirements. Here are some of the key technical properties you should consider:

1. CFM (Cubic Feet per Minute) Rating

The CFM rating indicates the volume of air the dryer can process per minute. It is essential for determining whether the air dryer can meet the demands of your application. Selecting a dryer with a CFM rating that aligns with your air compressor’s output ensures optimal performance and efficiency.

2. Dew Point

The dew point is the temperature at which moisture in the air begins to condense into liquid. This specification is critical for industries requiring dry air, such as pharmaceuticals and food processing. A lower dew point signifies superior moisture removal capabilities, which is vital for preventing equipment corrosion and product spoilage.

3. Power Supply Requirements

Air dryers can operate on different power supplies, such as 115V or 230V, and can be single-phase or three-phase. Understanding the power requirements is essential for compatibility with existing electrical systems. Ensure that the dryer you choose matches your facility’s electrical capabilities to avoid costly upgrades or downtime.

4. Material Grade

The construction material of an air dryer affects its durability and resistance to corrosion. Common materials include aluminum and stainless steel. Selecting a high-grade material is important for longevity, especially in harsh environments. This choice can also impact maintenance costs and overall reliability.

5. Operating Temperature Range

The operating temperature range indicates the ambient temperatures the air dryer can handle. This is particularly important for buyers in regions with extreme weather conditions. Ensuring that the dryer can operate efficiently in your specific climate is essential for maintaining performance.

6. Noise Level

Noise levels are measured in decibels (dB) and can affect workplace comfort. For businesses operating in confined spaces or near sensitive environments, selecting an air dryer with a lower noise output can improve workplace conditions and enhance employee satisfaction.

What Are Common Trade Terms Related to Air Dryers?

Familiarizing yourself with industry jargon can facilitate smoother negotiations and procurement processes. Here are some common terms relevant to air dryers:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for ensuring compatibility and quality when sourcing air dryers or their components.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers budget and plan inventory, especially for larger projects or ongoing maintenance needs.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. When preparing an RFQ for air dryers, include detailed specifications and quantities to receive accurate and competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms can help mitigate risks and clarify shipping responsibilities, especially for international transactions.

5. Desiccant Dryers vs. Refrigerated Dryers

Desiccant dryers utilize materials that absorb moisture, making them suitable for applications requiring ultra-dry air. In contrast, refrigerated dryers cool the air to remove moisture. Understanding these differences helps buyers select the right type of dryer for their specific applications.

6. Warranty and Service Agreements

A warranty is a manufacturer’s promise to repair or replace a product if necessary within a specified period. Service agreements outline the terms of maintenance and support for the equipment. These agreements are essential for ensuring long-term reliability and minimizing operational disruptions.

By understanding these essential technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing air dryers, ensuring that their investments lead to improved operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the air drier Sector

What Are the Current Market Dynamics and Key Trends in the Air Dryer Sector?

The air dryer market is witnessing significant growth, driven by an increasing demand for high-quality compressed air systems across various industries, including manufacturing, food processing, pharmaceuticals, and automotive. Global economic recovery post-pandemic has accelerated industrial activities, particularly in emerging markets in Africa, South America, the Middle East, and Europe. These regions are increasingly investing in advanced technologies to improve operational efficiency and reduce downtime, making air dryers an essential component of their production processes.

Emerging trends in B2B sourcing within this sector highlight a shift towards more integrated and automated systems. Buyers are increasingly looking for solutions that not only provide moisture removal but also enhance energy efficiency. Technologies such as IoT-enabled air dryers are gaining traction, allowing for real-time monitoring and predictive maintenance, which can significantly reduce operational costs. Additionally, there is a growing preference for refrigerated air dryers due to their cost-effectiveness and reliability in various industrial applications.

International B2B buyers should be aware of the regional differences in air dryer technology adoption and supply chain logistics. For example, while Europe may prioritize energy-efficient models, buyers in Africa and South America might focus on more affordable, robust options that can withstand harsh environments. Understanding these market dynamics is crucial for making informed purchasing decisions.

How Important Is Sustainability and Ethical Sourcing in the Air Dryer Sector?

A stock image related to air drier.

Sustainability is becoming a central theme in the air dryer industry, influencing both production methods and purchasing decisions. International B2B buyers are increasingly prioritizing suppliers who adopt environmentally friendly practices and materials. This includes the use of ‘green’ certifications and materials that minimize environmental impact. For instance, manufacturers that utilize recyclable components or energy-efficient technologies are not only appealing to environmentally conscious buyers but may also benefit from government incentives aimed at promoting sustainable practices.

Ethical sourcing is equally critical, as companies aim to ensure that their supply chains are transparent and responsible. This means selecting suppliers who adhere to fair labor practices and comply with environmental regulations. By fostering ethical supply chains, businesses can enhance their brand reputation and build stronger relationships with customers who value corporate social responsibility.

Furthermore, incorporating sustainability into purchasing strategies can lead to significant cost savings over time. Energy-efficient air dryers, for instance, can drastically reduce energy consumption and operational costs, making them a more attractive investment for B2B buyers looking to enhance their bottom line while meeting sustainability goals.

What Is the Brief Evolution and History of Air Dryers in the B2B Context?

The evolution of air dryers can be traced back to the industrial revolution when the need for reliable compressed air systems first emerged. Initially, air dryers were simple devices aimed solely at moisture removal. However, as industries evolved, so did the technology. The introduction of refrigerated air dryers in the mid-20th century marked a significant advancement, providing a more effective method for moisture control.

In recent decades, the development of desiccant air dryers has further transformed the market, allowing for ultra-low dew points essential in sensitive applications like pharmaceuticals and food processing. The advent of smart technology has also begun to reshape the industry, with IoT capabilities enabling enhanced monitoring and efficiency.

Today, the air dryer market is characterized by a diverse range of products tailored to meet the specific needs of various industries. This evolution not only highlights the technological advancements in the sector but also reflects the growing demand for reliable and sustainable solutions among international B2B buyers. Understanding this historical context can assist buyers in making more informed decisions about their air dryer purchases.

Frequently Asked Questions (FAQs) for B2B Buyers of air drier

-

How do I choose the right air dryer for my specific industrial application?

Choosing the right air dryer depends on your specific application needs. For general manufacturing, refrigerated air dryers are typically the best option, as they are cost-effective and suitable for most industrial processes. If your operations require ultra-low dew points, especially in sectors like pharmaceuticals or food processing, desiccant air dryers are the ideal choice. Assess your production requirements, including airflow (CFM), desired dew point, and the presence of contaminants to make an informed decision. -

What are the benefits of using refrigerated versus desiccant air dryers?

Refrigerated air dryers cool compressed air to condense and remove moisture, making them suitable for general applications where humidity control is essential. They are energy-efficient and require less maintenance. In contrast, desiccant air dryers use adsorbent materials to achieve very low dew points, ideal for critical processes in sensitive industries. Understanding these distinctions helps you select the best dryer type for your operational needs, ensuring optimal performance and longevity. -

What factors should I consider when sourcing air dryers from international suppliers?

When sourcing air dryers from international suppliers, consider factors such as product quality, certifications, and supplier reputation. Verify compliance with international standards (e.g., ISO, CE) to ensure reliability. Assess the supplier’s track record in your region, their ability to provide support and maintenance, and their responsiveness to inquiries. Additionally, review shipping terms and potential customs regulations that could impact delivery timelines. -

What are typical minimum order quantities (MOQs) for air dryers from suppliers?

Minimum order quantities (MOQs) for air dryers can vary significantly based on the supplier and the specific model. Many manufacturers may set MOQs ranging from 1 to 10 units, while others might offer flexible terms for larger orders. It’s crucial to communicate your needs upfront and negotiate terms that align with your purchasing strategy, especially if you are testing new products or entering a new market. -

What payment terms should I expect when buying air dryers internationally?

Payment terms for international purchases of air dryers can vary widely. Common options include advance payment, letter of credit, or payment upon delivery. It’s essential to discuss and agree on payment methods that protect both parties. Additionally, consider currency exchange rates and transaction fees that may impact overall costs. Establishing clear payment terms upfront helps prevent misunderstandings and facilitates smoother transactions.

A stock image related to air drier.

-

How can I ensure the quality and reliability of the air dryers I purchase?

To ensure quality and reliability, request product specifications, certifications, and performance data from suppliers. Conduct a thorough vetting process, including reviewing customer testimonials and case studies. If possible, seek samples or visit the supplier’s facility to inspect the manufacturing process. Additionally, inquire about warranty terms and after-sales support to confirm that you will receive ongoing assistance after your purchase. -

What logistics considerations should I be aware of when importing air dryers?

When importing air dryers, logistics considerations include shipping methods, lead times, and customs regulations. Determine whether air or sea freight is more suitable based on your urgency and budget. Understand your country’s import duties and taxes to calculate total landed costs. Collaborating with a logistics partner experienced in international trade can streamline the process, ensuring compliance and timely delivery. -

Can air dryers be customized to meet specific operational needs?

Yes, many manufacturers offer customization options for air dryers to meet specific operational requirements. Customizations may include adjustments to airflow capacity, dew point specifications, or additional features such as integrated filtration systems. Communicate your specific needs to potential suppliers early in the discussion process to explore available options and ensure that the final product aligns perfectly with your operational goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for air drier

What Are the Key Takeaways for B2B Buyers of Air Dryers?

As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the critical role of air dryers in maintaining compressed air quality is essential. By prioritizing strategic sourcing, buyers can ensure they select high-performance air dryers, such as refrigerated and desiccant models, tailored to their specific industrial needs. Investing in quality air drying solutions not only protects equipment from moisture damage but also enhances operational efficiency and product reliability.

How Can Strategic Sourcing Enhance Your Procurement Process?

Strategic sourcing empowers buyers to evaluate multiple suppliers, compare products, and negotiate favorable terms. It allows organizations to tap into global markets, ensuring access to advanced technologies and competitive pricing. This approach is particularly beneficial in regions where local options may be limited or costly, enabling buyers to make informed decisions that align with their operational goals.

What Does the Future Hold for Air Dryer Technology?

Looking ahead, the demand for efficient, energy-saving air drying solutions is expected to grow. As industries become more aware of sustainability practices, innovations in air dryer technology will likely lead to more eco-friendly options. B2B buyers should remain proactive in exploring emerging technologies and evaluating how these advancements can contribute to their long-term success.

In conclusion, leveraging strategic sourcing for air dryers will not only enhance product quality but also drive operational excellence. We encourage international B2B buyers to engage with suppliers, explore diverse offerings, and invest in solutions that meet their evolving needs.