Top 6 Cable And Harness Manufacturers List and Guide: How To Solv…

Introduction: Navigating the Global Market for Cable and Harness Manufacturers

In today’s interconnected world, sourcing cable and harness manufacturers that meet specific needs can be a daunting challenge for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. With the increasing complexity of electrical systems across various industries—from medical and aerospace to automotive and industrial—the demand for reliable, high-quality cable assemblies and wire harnesses has never been greater. This guide serves as a comprehensive resource, detailing the types of cable and wire harnesses available, their applications, and crucial factors to consider when vetting suppliers.

B2B buyers will find actionable insights on evaluating manufacturing capabilities, understanding cost structures, and optimizing supply chain logistics. This guide empowers you to make informed purchasing decisions by providing clarity on the intricacies of the cable and harness manufacturing landscape. Whether you are a startup in Saudi Arabia seeking prototyping services or an established enterprise in Nigeria looking for robust supply chain solutions, this resource is designed to enhance your procurement strategy.

By navigating the complexities of the global market with this guide, buyers can ensure they select partners that not only meet their technical requirements but also align with their business goals, ultimately driving innovation and efficiency in their operations.

Top 10 Cable And Harness Manufacturers Manufacturers & Suppliers List

1. PCA – Wire Harnesses & Battery Cables

Domain: pca-llc.com

Registered: 2000 (25 years)

Introduction: PCA is a leading manufacturer of wire harnesses, battery cables, and custom molded cable assemblies. They offer a wide variety of wire harnesses ranging from single circuit simplicity to over three hundred circuit complexity. Their battery cable assemblies cater to various sectors including lawn and garden, marine, truck/trailer chassis, construction equipment, and recreation vehicles. PCA special…

2. Avalontec – Cable and Wire Harness Solutions

Domain: avalontec.com

Registered: 2000 (25 years)

Introduction: Avalontec offers a wide range of cable and wire harness assemblies designed for various applications, including:

1. Coaxial and Triaxial Cables – For high-quality signal transmission with minimal interference.

2. Flat Ribbon Cable Assembly – Space-saving design providing efficient functionality.

3. RF Cable Assembly – Ensures clear and reliable radio frequency transmission for telecommunications …

3. Wire Harness Manufacturers – Key Players

Domain: us.metoree.com

Registered: 2020 (5 years)

Introduction: 15 Wire Harness Manufacturers in 2025: 1. Omega Leads, Inc., 2. Buckeye Electrical, 3. Molex, LLC. A wire harness is a group of parts responsible for connecting devices, bundled with electric wires, terminals, and connectors. Common applications include automobiles, medical equipment, and production facilities. Types of wire harnesses include low-voltage, high-voltage, and aluminum wire harnesses….

4. Star Engineering, Inc. – Custom Wire Harness Solutions

Domain: starengineeringinc.com

Registered: 2008 (17 years)

Introduction: Star Engineering, Inc. is a leading custom wire harness assembly and cable harness manufacturer in the USA, with nearly 40 years of experience. They provide customized wire harness solutions for various industries, including automotive, medical, telecommunications, consumer electronics, aerospace and defense, industrial machinery, energy, and transportation. Their wire harness assemblies are desig…

5. FORCE America – Custom Wire and Cable Harness Solutions

Domain: forceamerica.com

Registered: 1997 (28 years)

Introduction: Custom Manufactured Wire and Cable Harness Solutions from FORCE America. The product is available only via quote request. They specialize in designing and manufacturing a wide range of wire and cable harness solutions, from simple assemblies to complex custom solutions. Their inventory includes standard connectors and components from top partners for quick turnaround on custom prototypes and order…

6. Custom Cord – Wire Harness & Cable Assemblies

Domain: customcord.com

Registered: 2000 (25 years)

Introduction: Custom Cord & Harness Assemblies specializes in contract manufacturing of commercial and industrial wire harness assemblies, multi conductor cable assemblies, and power cords. They offer custom wire harnesses, cable assemblies, and power cords for various applications, including weatherproof connectors and printed circuit board electronic components. The company emphasizes quick response times, lo…

Understanding Cable and Harness Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Cable Assemblies | Tailored designs for specific applications; high flexibility | Medical devices, aerospace, automotive, industrial machinery | Pros: Customization, adaptability; Cons: Longer lead times, potentially higher costs. |

| Wire Harness Assemblies | Bundled wires with connectors for streamlined installation | Consumer electronics, automotive, industrial equipment | Pros: Simplifies installation; Cons: Complexity can increase failure points. |

| Electromechanical Assemblies | Integration of electrical and mechanical components | Robotics, automation, aerospace | Pros: Space-saving, efficient; Cons: Requires precise engineering, higher complexity. |

| Battery Cable Assemblies | Specialized cables for power distribution and connections | Automotive, marine, renewable energy | Pros: High reliability; Cons: Limited to specific applications, may require custom designs. |

| Over-Molded Cable Assemblies | Enhanced durability with protective molding | Harsh environment applications, military, and aerospace | Pros: Increased protection, longevity; Cons: Higher production costs, longer lead times. |

What Are the Key Characteristics of Custom Cable Assemblies?

Custom cable assemblies are designed to meet specific client requirements, offering flexibility in terms of size, material, and configuration. They are particularly suitable for industries like medical devices and aerospace, where unique specifications are crucial. When considering a custom assembly, B2B buyers should evaluate the manufacturer’s capability to deliver tailored solutions, including prototyping services and engineering support, which are essential for startups or companies lacking in-house expertise.

How Do Wire Harness Assemblies Benefit B2B Buyers?

Wire harness assemblies simplify the installation process by bundling multiple wires and connectors into a single unit, which is especially beneficial in consumer electronics and automotive applications. Buyers should consider the complexity of the harness, as more circuits can increase the likelihood of failure. It is crucial to work with manufacturers who adhere to quality standards to ensure reliability and safety, as any failure in the harness can lead to significant operational disruptions.

What Makes Electromechanical Assemblies Unique?

Electromechanical assemblies combine both electrical and mechanical components, making them ideal for applications in robotics and automation. Their compact design helps save space while enhancing efficiency. B2B buyers must assess the manufacturer’s engineering capabilities, as the production of these assemblies requires precise integration. Additionally, a focus on quality assurance and testing is vital to guarantee the performance of these complex systems.

Why Choose Battery Cable Assemblies for Your Applications?

Battery cable assemblies are critical for effective power distribution, especially in automotive and renewable energy sectors. They are designed to handle high currents and provide reliable connections. Buyers should look for manufacturers that offer a range of customization options and robust testing protocols to ensure the cables meet specific performance standards. Understanding the application requirements will help in selecting the right type of battery cable assembly.

What Are the Advantages of Over-Molded Cable Assemblies?

Over-molded cable assemblies provide additional protection against environmental factors, making them suitable for harsh conditions found in military and aerospace applications. Their durability and longevity are significant advantages. However, buyers should be aware of the potentially higher production costs and longer lead times associated with these assemblies. It is essential to evaluate the manufacturer’s capabilities in over-molding technology to ensure they can meet the required specifications efficiently.

Key Industrial Applications of Cable and Harness Manufacturers

| Industry/Sector | Specific Application of Cable and Harness Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical | Custom cable assemblies for medical diagnostic equipment | Ensures reliability and accuracy in critical medical applications | Compliance with medical standards, quick prototyping capabilities |

| Aerospace | Wire harnesses for avionics systems | Enhances safety and performance in flight operations | Certifications (e.g., AS9100), rigorous testing protocols |

| Military/Defense | Cable assemblies for communication devices and weapon systems | Supports operational readiness and mission-critical functions | ITAR registration, high durability standards |

| Automotive | Wire harnesses for electric vehicle systems | Facilitates advanced functionality and safety in vehicles | Adaptability to new technologies, scalability for mass production |

| Industrial | Custom cable solutions for automation equipment | Improves efficiency and reliability in manufacturing processes | Flexibility in design, ability to meet specific environmental standards |

How Are Cable and Harness Manufacturers Used in the Medical Industry?

In the medical sector, cable and harness manufacturers provide custom cable assemblies that are essential for diagnostic and therapeutic equipment. These assemblies ensure that devices function reliably, which is critical in life-saving situations. For international buyers, especially from regions like Africa and the Middle East, understanding compliance with medical standards and ensuring quick prototyping capabilities is vital. Manufacturers must demonstrate their ability to meet stringent quality controls and provide rapid turnaround times for prototypes to facilitate timely product launches.

What Role Do Cable Assemblies Play in Aerospace Applications?

Aerospace applications require high precision and reliability due to the critical nature of flight operations. Cable harness manufacturers supply wire harnesses for avionics systems that must withstand extreme conditions while ensuring optimal performance. Buyers from Europe and South America must prioritize suppliers with certifications such as AS9100 and those who adhere to rigorous testing protocols. This ensures that the components can handle the demanding environments of aerospace applications, thereby enhancing safety and performance.

How Are Cable Assemblies Utilized in Military and Defense?

In the military and defense sectors, cable and harness manufacturers provide essential cable assemblies for communication devices and weapon systems. These components must be robust and reliable to support mission-critical operations. International buyers, particularly from regions like Saudi Arabia and Nigeria, should focus on suppliers that are ITAR registered and capable of meeting high durability standards. This ensures that the products can withstand harsh operational environments and maintain functionality under pressure.

What Benefits Do Wire Harnesses Offer in the Automotive Sector?

In the automotive industry, particularly with the rise of electric vehicles, wire harnesses are crucial for integrating advanced functionalities. Manufacturers offer customized solutions that enhance safety and performance in vehicles. Buyers need to consider the adaptability of suppliers to new technologies and their capability for scalable production to meet growing demands. This is particularly important for international buyers looking to invest in innovative automotive technologies across diverse markets.

How Do Cable Solutions Enhance Industrial Automation?

Cable and harness manufacturers play a vital role in the industrial sector by providing custom cable solutions for automation equipment. These solutions improve efficiency and reliability in manufacturing processes, which is essential for maintaining competitive advantage. International buyers from South America and Africa should seek manufacturers who offer flexibility in design and can meet specific environmental standards. This ensures that the cables can operate effectively in various industrial conditions, ultimately boosting productivity and reducing downtime.

3 Common User Pain Points for ‘Cable and Harness Manufacturers’ & Their Solutions

Scenario 1: Inconsistent Quality Standards Across Suppliers

The Problem: B2B buyers often face the challenge of sourcing cable and harness assemblies from manufacturers that do not adhere to consistent quality standards. This inconsistency can lead to significant issues, such as product failures, increased warranty claims, and damage to the buyer’s reputation in their respective market. For companies in sectors like aerospace or medical equipment, where precision is paramount, any deviation in quality can have dire consequences.

The Solution: To mitigate this issue, buyers should prioritize manufacturers with established quality certifications, such as IPC standards or ISO certifications. Before finalizing any contracts, conduct thorough assessments, including site visits to manufacturing facilities, to evaluate their quality control processes. Request samples and specifications to ensure they meet your exacting standards. Additionally, consider implementing a Vendor Managed Inventory (VMI) system that allows for ongoing quality monitoring and reduces the risk of receiving subpar products. Building a strong relationship with your chosen manufacturer can also facilitate open communication about quality expectations and improvements.

Scenario 2: Complex Customization Requirements

The Problem: Many B2B buyers require highly customized cable and harness solutions to meet specific application needs, yet they often encounter limitations with manufacturers who lack the capability or flexibility to accommodate these requests. This can result in delays, increased costs, and ultimately, a product that does not meet performance expectations or design specifications.

The Solution: To address this pain point, engage manufacturers who specialize in custom engineering and have a proven track record in your industry. Look for firms that offer comprehensive prototyping services to test and refine designs before full-scale production. Leverage CAD modeling and simulation tools to visualize your specifications, ensuring that the manufacturer fully understands your requirements. During the initial discussions, clearly outline your customization needs, timelines, and budget constraints. Establishing a collaborative partnership with the manufacturer allows for iterative feedback, which can significantly enhance the final product’s functionality and reliability.

Scenario 3: Supply Chain Disruptions and Delivery Delays

The Problem: Global supply chain disruptions have made it increasingly difficult for B2B buyers to secure timely deliveries of cable and harness products. Delays can stem from various factors, including material shortages, shipping issues, or inefficient logistics management. Such interruptions can halt production lines and lead to financial losses, impacting overall business operations.

The Solution: To combat potential delivery delays, buyers should develop a robust supply chain strategy that includes multiple sourcing options. Engage manufacturers who offer advanced logistics management capabilities, such as real-time tracking systems and transparent communication channels. Implementing a Kanban system can help manage inventory levels and streamline production schedules. Additionally, establishing long-term contracts with preferred manufacturers can enhance reliability and ensure priority service during peak demand periods. Regularly reviewing and adapting your sourcing strategy will help mitigate risks associated with supply chain fluctuations and maintain steady production flows.

Strategic Material Selection Guide for Cable and Harness Manufacturers

What Are the Key Materials for Cable and Harness Manufacturing?

When selecting materials for cable and harness manufacturing, it is essential to consider the specific requirements of the application, including performance, durability, and cost. Below, we analyze four common materials used in this industry, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of PVC in Cable and Harness Applications?

Polyvinyl Chloride (PVC) is a widely used material due to its excellent electrical insulation properties and resistance to moisture. PVC can withstand temperatures ranging from -10°C to 70°C, making it suitable for various environments. However, it is less resistant to UV light and extreme temperatures, which can lead to degradation over time.

Pros: PVC is cost-effective, easy to manufacture, and provides good flexibility. It is also resistant to many chemicals, making it suitable for diverse applications.

Cons: The main limitations include its lower temperature tolerance and potential environmental impact, as PVC can release harmful chemicals during production and disposal.

Impact on Application: PVC is compatible with many media, but its limitations in extreme conditions may restrict its use in high-temperature or outdoor applications.

Considerations for International Buyers: Compliance with international standards like ASTM and REACH is crucial, especially in regions like Europe, where regulations are stringent. Buyers should also consider the availability of recycled PVC options.

How Does Polyurethane Compare for Cable and Harness Manufacturing?

Polyurethane (PU) is known for its excellent abrasion resistance and flexibility, making it ideal for applications requiring durability. It can operate effectively in a temperature range of -40°C to 80°C, which is advantageous for various industrial environments.

Pros: PU offers superior flexibility, chemical resistance, and durability, which enhances the lifespan of cable assemblies in harsh conditions.

Cons: The primary drawback is its higher cost compared to PVC and potential challenges in processing, which may require specialized manufacturing techniques.

Impact on Application: PU is suitable for applications exposed to mechanical stress, such as automotive and industrial equipment, where flexibility and resistance to wear are critical.

Considerations for International Buyers: Buyers should ensure compliance with local standards and certifications, especially in regions with strict environmental regulations, such as the EU.

What Role Does Teflon Play in Cable and Harness Applications?

Teflon, or PTFE (Polytetrafluoroethylene), is renowned for its exceptional thermal stability and chemical resistance. It can withstand temperatures from -200°C to 260°C, making it suitable for high-performance applications in aerospace and military sectors.

Pros: Teflon’s key advantages include its non-stick properties, high-temperature tolerance, and resistance to a wide range of chemicals.

Cons: The significant downside is its high cost and complexity in manufacturing, which may not be feasible for all applications.

Impact on Application: Teflon is ideal for applications requiring high reliability and performance, particularly in extreme environments.

Considerations for International Buyers: Teflon products often require compliance with specific military or aerospace standards, making it essential for buyers in these sectors to understand the relevant certifications.

Why Is Copper Still a Preferred Choice in Cable Manufacturing?

Copper remains the standard choice for electrical conductors due to its excellent conductivity and thermal properties. It can handle high current loads and has a melting point of 1,085°C, making it suitable for various electrical applications.

Pros: Copper’s primary advantages include high electrical conductivity, ductility, and resistance to corrosion when properly treated.

Cons: However, copper is relatively heavy and more expensive than alternatives like aluminum, which may be a consideration for weight-sensitive applications.

Impact on Application: Copper is highly effective in power distribution and signal transmission, making it a staple in many industries, including telecommunications and automotive.

Considerations for International Buyers: Buyers should be aware of fluctuating copper prices and consider sourcing from regions with stable supply chains. Compliance with international standards for electrical components is also critical.

Summary Table

| Material | Typical Use Case for Cable and Harness Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General-purpose electrical insulation | Cost-effective and flexible | Lower temperature tolerance | Low |

| Polyurethane | High-durability applications in automotive/industrial | Superior flexibility and abrasion resistance | Higher cost and complex processing | Med |

| Teflon | Aerospace and military applications | Excellent thermal stability | High cost and manufacturing complexity | High |

| Copper | Electrical conductors in power distribution | High electrical conductivity | Heavy and more expensive than aluminum | Med |

This strategic material selection guide provides insights into the properties and implications of various materials for cable and harness manufacturers, aiding international B2B buyers in making informed decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for Cable and Harness Manufacturers

What Are the Key Stages in Cable and Harness Manufacturing Processes?

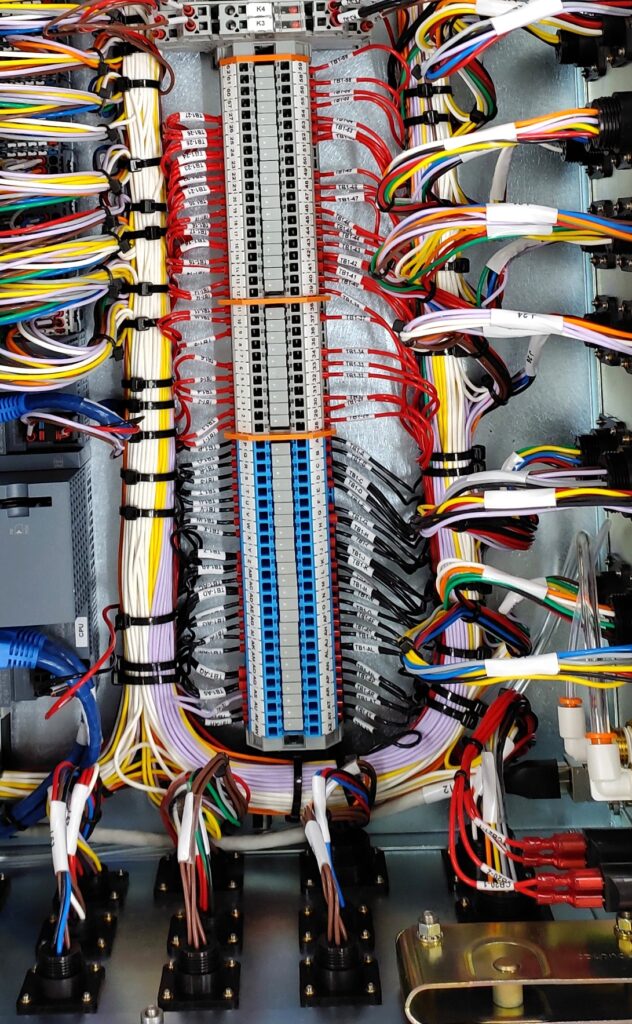

The manufacturing processes for cable and harness assemblies are intricate and require precision at every stage. The typical workflow can be broken down into four main stages: material preparation, forming, assembly, and finishing.

How Does Material Preparation Impact the Final Product?

Material preparation is the foundational step in the manufacturing process. It involves selecting high-quality raw materials, including wires, connectors, and insulation materials, which are critical for ensuring performance and durability. Suppliers often perform rigorous material inspections to confirm compliance with specifications. This stage also includes cutting and stripping wires to the necessary lengths, which is done with specialized machinery to maintain consistency and accuracy.

What Techniques Are Used in the Forming Stage?

The forming stage involves shaping and configuring the prepared materials into the desired format. Techniques such as crimping, soldering, and over-molding are commonly employed. Crimping is used to attach connectors to wires securely, while soldering provides a reliable electrical connection. Over-molding enhances durability by providing additional protection against environmental factors. The choice of technique is influenced by the intended application, be it automotive, aerospace, or industrial sectors.

How Is the Assembly Process Conducted for Optimal Quality?

The assembly phase is where all components are brought together. This can be done manually or through automated processes, depending on the complexity and volume of production. For instance, high-volume production may utilize automated machinery to ensure efficiency and reduce human error. During this stage, it’s crucial to follow strict assembly guidelines, as even minor deviations can lead to product failure.

What Quality Control Measures Are Essential in Cable and Harness Manufacturing?

Quality control (QC) is a vital aspect of manufacturing that ensures products meet both international standards and client specifications. Effective QC processes involve multiple checkpoints throughout the manufacturing cycle.

Which International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 are widely recognized in the industry for quality management systems. Compliance with ISO 9001 indicates that a manufacturer has established processes to consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific certifications, such as CE marking for European markets or API certification for oil and gas applications, may also be relevant depending on the application of the cable and harness products.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control typically encompasses three primary checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC: This stage involves inspecting raw materials upon arrival to ensure they meet quality standards before production begins.

- IPQC: During production, ongoing inspections are conducted to monitor processes and identify any deviations from the established protocols. This proactive approach helps catch issues early, reducing waste and rework.

- FQC: Final inspections are performed on completed assemblies to verify that they meet all specified requirements and function correctly under expected conditions.

What Testing Methods Are Commonly Used in Cable and Harness Manufacturing?

Testing methods vary based on the intended application of the cable and harness assemblies. Common testing procedures include:

- Electrical Testing: This verifies the integrity of electrical connections, ensuring that there are no shorts or open circuits.

- Environmental Testing: Products are subjected to extreme temperatures, humidity, and exposure to chemicals to assess their durability and performance in real-world conditions.

- Mechanical Testing: This evaluates the physical strength and flexibility of the assemblies, particularly important for applications in automotive and aerospace industries.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of a supplier’s quality control processes is crucial for B2B buyers, especially when sourcing from international manufacturers. Here are some actionable steps buyers can take:

- Conduct Audits: Regular audits of the manufacturing facility help ensure compliance with quality standards and operational efficiency. Buyers can perform these audits themselves or hire third-party firms to provide an impartial assessment.

- Request Quality Reports: Suppliers should be able to provide detailed reports on their QC processes, including inspection results and testing documentation. This transparency builds trust and confidence in the supplier’s capabilities.

- Engage in Third-Party Inspections: Utilizing third-party inspection services can provide an additional layer of assurance that the products meet quality standards before shipment.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers must navigate various certification requirements that can differ significantly by region. For instance, European clients often require CE certification, which indicates compliance with health, safety, and environmental protection standards. In contrast, buyers in the Middle East may look for specific certifications that cater to local regulations.

Moreover, cultural differences can impact communication and expectations regarding quality. Buyers should establish clear guidelines and expectations upfront to minimize misunderstandings and ensure that the final products align with their requirements.

Conclusion: The Importance of Robust Manufacturing Processes and Quality Assurance

In summary, the manufacturing processes and quality assurance measures for cable and harness assemblies are critical components that directly affect product performance and reliability. B2B buyers must prioritize suppliers who adhere to rigorous manufacturing practices and possess relevant certifications. By understanding the intricacies of these processes and engaging in thorough verification methods, buyers can make informed decisions that align with their operational needs and expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Cable and Harness Manufacturers’

Introduction

Navigating the procurement process for cable and harness manufacturing requires a systematic approach to ensure you select the right supplier for your needs. This guide provides a step-by-step checklist aimed at international B2B buyers in Africa, South America, the Middle East, and Europe. Follow these steps to streamline your sourcing process and secure high-quality products that meet your specifications.

Step 1: Define Your Technical Specifications

Before reaching out to potential suppliers, clearly outline your project requirements. This includes detailed specifications such as cable types, lengths, gauge, insulation materials, and environmental conditions. Precise specifications help suppliers provide accurate quotes and ensure you receive products that meet your performance standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify manufacturers that specialize in cable and harness production. Utilize online directories, industry associations, and trade shows to compile a list of potential partners. Focus on suppliers with a proven track record in your specific industry, as they will better understand your unique requirements.

Step 3: Verify Supplier Certifications

Ensure that potential suppliers hold relevant certifications, such as ISO 9001 for quality management or IPC/WHMA-A-620 for wire harness assembly. Certifications indicate that the supplier adheres to industry standards and best practices, which is crucial for maintaining product quality and compliance with regulatory requirements.

Step 4: Request and Review Samples

Once you have shortlisted suppliers, request product samples to evaluate their quality. Assess the craftsmanship, materials used, and overall performance of the samples in conditions similar to your operational environment. This step is vital for verifying that the supplier can meet your quality expectations before placing a larger order.

Step 5: Evaluate Pricing and Terms

Compare pricing structures among suppliers, but do not make decisions based solely on cost. Consider factors such as minimum order quantities, payment terms, and delivery timelines. Understanding the total cost of ownership, including shipping and potential tariffs, will help you make a more informed decision.

Step 6: Assess Customer Support and Communication

Effective communication is essential throughout the procurement process. Evaluate the responsiveness and professionalism of each supplier’s customer support team. Reliable suppliers should be willing to answer questions, provide updates, and assist you throughout the project lifecycle, ensuring a smooth collaboration.

Step 7: Establish Long-Term Relationships

After selecting a supplier, focus on building a long-term partnership. Regular communication and feedback can foster a collaborative environment that benefits both parties. A reliable supplier can offer insights into product improvements and innovations, potentially enhancing your overall operational efficiency.

By following this checklist, you can systematically approach the sourcing of cable and harness manufacturers, ultimately leading to successful procurement and enhanced operational capabilities.

Comprehensive Cost and Pricing Analysis for Cable and Harness Manufacturers Sourcing

What Are the Key Cost Components for Cable and Harness Manufacturers?

Understanding the cost structure of cable and harness manufacturing is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts overall costs. High-quality conductors, insulation types, and connectors can vary widely in price. Buyers should consider sourcing raw materials that balance cost and performance to optimize their budget.

-

Labor: Labor costs can fluctuate based on geographical location and skill levels. Regions with lower labor costs may provide initial savings, but quality and expertise should not be compromised. Skilled labor is essential for complex assemblies, especially in specialized industries like aerospace and medical.

-

Manufacturing Overhead: This includes the costs associated with factory operations, such as utilities, equipment maintenance, and facility expenses. Efficient manufacturing processes can help mitigate these costs, making it essential to choose manufacturers who employ lean practices.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. However, these costs can be amortized over larger production runs. Understanding the tooling requirements upfront can help buyers plan their budgets more effectively.

-

Quality Control (QC): Rigorous QC processes ensure that products meet industry standards, which can incur additional costs. However, investing in quality assurance can prevent costly returns and enhance product reliability.

-

Logistics: Shipping and handling costs can vary depending on the manufacturing location and destination. Buyers should factor in international shipping complexities, including customs duties and taxes, which can substantially affect the final cost.

-

Margin: Manufacturers typically apply a margin to cover their costs and ensure profitability. Understanding the competitive landscape can help buyers negotiate better pricing.

What Influences Pricing in Cable and Harness Manufacturing?

Several factors play a critical role in determining the pricing of cable and harness assemblies:

-

Volume and Minimum Order Quantity (MOQ): Larger orders usually lead to lower per-unit costs. Manufacturers may offer discounts for bulk purchases, making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Custom designs often incur higher costs due to additional engineering and tooling requirements. Buyers should weigh the necessity of customization against budget constraints.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., IPC standards) can drive up costs. Buyers must assess their quality needs against their budget to find the right balance.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established manufacturers may charge a premium for their experience and proven quality, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The choice of Incoterms affects who bears the shipping and insurance costs. Understanding these terms is crucial for accurate cost projections and risk management.

What Are the Best Negotiation Tips for International Buyers?

For B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings:

-

Leverage Relationships: Building strong relationships with suppliers can result in better pricing and terms. Trust can often lead to favorable negotiations.

-

Focus on Total Cost of Ownership (TCO): Instead of just considering the initial purchase price, evaluate the TCO, which includes maintenance, logistics, and potential downtime costs. A higher upfront cost may be justified by long-term savings.

-

Understand Pricing Nuances: Be aware of the specific challenges and costs associated with international transactions, including currency fluctuations and geopolitical factors that may affect pricing.

-

Request Detailed Quotes: Ensure that quotes break down all cost components to identify areas where savings can be achieved. This transparency can facilitate informed negotiations.

Conclusion: Why Are Indicative Prices Important for Buyers?

While understanding these cost components and price influencers is vital, it is essential to note that pricing can vary significantly based on market conditions and specific project requirements. Therefore, buyers should approach indicative prices as a starting point for negotiation rather than a fixed cost. Engaging in thorough research and building strong partnerships with manufacturers can lead to more favorable terms and ultimately, a successful sourcing strategy.

Alternatives Analysis: Comparing Cable and Harness Manufacturers With Other Solutions

Understanding Alternatives in Cable and Harness Solutions

In the evolving landscape of electrical systems, B2B buyers often explore various solutions for their connectivity needs. While cable and harness manufacturers offer specialized services in creating tailored assemblies, there are alternative technologies and methods that can also fulfill similar requirements. Understanding these alternatives is crucial for making informed decisions based on specific operational needs, budget constraints, and application contexts.

Comparison Table

| Comparison Aspect | Cable And Harness Manufacturers | Alternative 1: PCB (Printed Circuit Board) Assemblies | Alternative 2: Wireless Communication Technologies |

|---|---|---|---|

| Performance | High reliability, tailored designs for specific applications | Excellent for compact designs; high integration levels | Limited range; performance can be affected by interference |

| Cost | Generally higher due to customization and materials | Typically lower for mass-produced units | Can reduce installation costs; potential hidden costs in maintenance |

| Ease of Implementation | Requires engineering expertise for design and assembly | Easier for standardized designs; rapid prototyping available | No physical connections needed; can be complex to integrate |

| Maintenance | Regular inspections needed; durability varies | Typically low, but repairs can be challenging | Minimal maintenance; software updates may be required |

| Best Use Case | Complex applications in aerospace, medical, automotive | Ideal for consumer electronics, compact devices | Suitable for IoT devices, mobile applications, and remote monitoring |

Detailed Breakdown of Alternatives

What Are the Pros and Cons of PCB Assemblies?

Printed Circuit Board (PCB) assemblies present a viable alternative for many electronic applications. The primary advantage of PCBs is their compactness and the ability to integrate multiple functions into a single board, making them perfect for consumer electronics and devices with space constraints. However, they are not suitable for all applications, especially those requiring rugged performance or high customization. Maintenance can be challenging, as repairing a PCB often involves replacing entire sections rather than addressing specific faults.

How Do Wireless Communication Technologies Compare?

Wireless communication technologies, such as Bluetooth and Wi-Fi, offer flexibility and ease of installation by eliminating physical connections. This makes them ideal for applications in the Internet of Things (IoT), where devices need to communicate over distances without the constraints of cabling. However, their performance can be impacted by environmental factors, and they may not be suitable for scenarios demanding high reliability, such as in aerospace or medical applications. Additionally, while installation costs can be lower, ongoing maintenance and software updates can incur hidden expenses.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate solution between cable and harness manufacturers and alternative technologies hinges on understanding your specific application requirements, budget, and operational context. For industries demanding high reliability and customized solutions, cable and harness manufacturers remain the go-to choice. Conversely, for applications prioritizing compactness and flexibility, PCBs or wireless technologies might offer more advantages. B2B buyers should carefully evaluate these options, considering performance, cost, and maintenance to ensure their chosen solution aligns with their strategic objectives and operational efficiency.

Essential Technical Properties and Trade Terminology for Cable and Harness Manufacturers

What Are the Key Technical Properties of Cable and Harness Manufacturing?

In the competitive landscape of cable and harness manufacturing, understanding the essential technical properties is crucial for B2B buyers. These specifications not only determine the performance and reliability of the products but also impact the overall supply chain efficiency.

1. Material Grade

Material grade refers to the classification of materials based on their properties such as tensile strength, conductivity, and corrosion resistance. Common materials include copper for electrical conductivity and thermoplastics for insulation. Selecting the right material grade is vital as it directly influences durability, performance, and compliance with industry standards.

2. Tolerance

Tolerance indicates the permissible limit of variation in a physical dimension or measured value. In cable and harness manufacturing, precise tolerances are critical to ensure proper fit and function within an assembly. For B2B buyers, understanding tolerances can help in evaluating product compatibility and ensuring quality control in the supply chain.

3. Voltage Rating

The voltage rating specifies the maximum voltage that a cable or harness can safely handle. This is crucial for ensuring safety and preventing electrical failures. Buyers need to match the voltage rating with their specific application requirements to avoid costly downtime and potential hazards.

4. Temperature Rating

Temperature rating defines the maximum and minimum temperatures at which a cable can operate effectively. This property is essential for applications in extreme environments, such as industrial or automotive sectors. Buyers must consider temperature ratings to ensure reliability and longevity in their intended applications.

5. Shielding

Shielding is a technique used to protect cables from electromagnetic interference (EMI). This is particularly important in industries like telecommunications and aerospace where signal integrity is paramount. Understanding shielding options helps buyers select the appropriate cables for their projects, thereby enhancing performance and reducing signal loss.

6. Connector Types

Connector types refer to the various configurations and designs used to join cables and harnesses. Different applications may require specific connectors to ensure a secure and efficient electrical connection. Familiarity with connector types allows buyers to make informed decisions that align with their project needs.

What Are Common Trade Terms in Cable and Harness Manufacturing?

Navigating the language of the cable and harness industry can be daunting for non-technical decision-makers. Here are some common jargon and trade terms that are essential to understand.

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces components that are used in another company’s end products. In the cable and harness industry, OEMs often collaborate with manufacturers to create customized solutions that meet specific design requirements. Understanding OEM relationships is crucial for buyers looking for tailored products.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is important for managing inventory and budgeting effectively. It can also affect production schedules and overall supply chain dynamics.

3. RFQ (Request for Quotation)

An RFQ is a formal document used by buyers to solicit price quotes from suppliers for specific products or services. Submitting an RFQ allows buyers to compare offerings and negotiate terms, which is essential for cost-effective purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk distribution, and delivery obligations, enabling smoother cross-border transactions.

5. Lead Time

Lead time is the period between placing an order and receiving the goods. This term is critical for B2B buyers as it impacts project timelines and inventory management. Understanding lead times helps in planning and ensuring that production schedules are met without delays.

6. Vendor Managed Inventory (VMI)

VMI is a supply chain initiative where the supplier manages the inventory levels for the buyer. This arrangement can lead to more efficient inventory management and reduce stockouts. Buyers should consider VMI as a strategy to streamline operations and improve collaboration with suppliers.

By grasping these technical properties and trade terms, B2B buyers can enhance their purchasing strategies and foster successful partnerships within the cable and harness manufacturing industry.

Navigating Market Dynamics and Sourcing Trends in the Cable and Harness Manufacturers Sector

What Are the Current Market Dynamics and Key Trends in the Cable and Harness Manufacturing Sector?

The cable and harness manufacturing sector is undergoing transformative changes driven by technological advancements and increasing global demand. Key market drivers include the rise of electric vehicles (EVs), the expansion of renewable energy sources, and the ongoing digitalization of industries, which require robust connectivity solutions. In regions such as Africa, South America, the Middle East, and Europe, international B2B buyers are increasingly focused on sourcing high-quality, customized cable and wire harness assemblies that meet stringent safety and performance standards.

Emerging trends indicate a growing reliance on automation and smart manufacturing techniques, enabling manufacturers to enhance production efficiency and reduce lead times. Additionally, the integration of Industry 4.0 technologies—such as IoT, AI, and machine learning—facilitates real-time monitoring and predictive maintenance, ensuring higher operational reliability. Furthermore, buyers are increasingly seeking suppliers who can provide advanced prototyping services and rapid turnaround times, allowing for agile responses to market demands.

Another critical trend is the shift towards more complex assemblies that combine electromechanical components, which cater to diverse industries, including automotive, aerospace, and medical. As global supply chains become more interconnected, international buyers must navigate the complexities of sourcing from different regions, balancing factors such as cost, quality, and delivery timelines. This landscape underscores the importance of strategic partnerships with reliable manufacturers capable of delivering tailored solutions that align with specific project requirements.

How Is Sustainability and Ethical Sourcing Shaping the Cable and Harness Manufacturing Sector?

Sustainability and ethical sourcing are increasingly influencing the cable and harness manufacturing sector, driven by growing environmental awareness among consumers and businesses. The environmental impact of manufacturing processes and materials is under scrutiny, prompting manufacturers to adopt greener practices. This includes the use of recyclable materials, reduction of waste during production, and minimizing energy consumption.

For B2B buyers, the importance of ethical supply chains cannot be overstated. Companies are now prioritizing suppliers who demonstrate a commitment to social responsibility, including fair labor practices and transparency in their sourcing methods. Certifications such as ISO 14001 for environmental management and RoHS compliance for hazardous substances are becoming essential criteria in supplier selection. Additionally, the adoption of “green” materials, such as biodegradable plastics and low-emission manufacturing processes, is gaining traction, appealing to environmentally conscious buyers.

By choosing suppliers with strong sustainability credentials, international buyers not only enhance their own brand reputation but also mitigate risks associated with regulatory compliance and potential supply chain disruptions. As the demand for sustainable products continues to rise, manufacturers who invest in eco-friendly practices will likely gain a competitive advantage in the global marketplace.

What Is the Historical Context Behind Cable and Harness Manufacturing?

The evolution of cable and harness manufacturing can be traced back to the early days of electrical engineering in the late 19th century. As industries began to embrace electrical power, the need for reliable connectivity solutions became paramount. The introduction of standardized wire sizes and insulation materials in the early 20th century laid the groundwork for mass production techniques, making it easier to manufacture cables and harnesses at scale.

The sector saw significant advancements post-World War II, driven by technological innovation and the burgeoning electronics industry. The 1980s and 1990s witnessed a shift toward automation in manufacturing processes, enhancing precision and efficiency. More recently, the rise of the digital age and the proliferation of electronic devices have further transformed the landscape, with manufacturers now focusing on complex assemblies that integrate electrical and mechanical components.

Today, cable and harness manufacturers are not only key players in traditional industries but are also at the forefront of emerging markets such as renewable energy and electric mobility. This historical context underscores the importance of adaptability and innovation in meeting the evolving demands of international B2B buyers. As the sector continues to advance, manufacturers must remain agile, leveraging new technologies and sustainable practices to stay competitive in a dynamic marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of Cable and Harness Manufacturers

-

How do I ensure quality when sourcing cable and harness manufacturers?

To ensure quality when sourcing cable and harness manufacturers, start by evaluating their certifications, such as ISO 9001 or IPC standards, which indicate adherence to quality management practices. Request samples and conduct thorough testing to assess the durability and performance of their products. Additionally, consider visiting their facilities or requesting third-party audits to gain insight into their manufacturing processes. Engaging in open communication about quality expectations and having clear quality assurance protocols in place can further mitigate risks. -

What are the key factors to consider when choosing a cable and harness supplier?

When selecting a cable and harness supplier, consider their industry experience, production capabilities, and customization options. Evaluate their ability to meet your specific requirements, such as complex assemblies or rapid prototyping. It’s crucial to assess their logistics capabilities, including shipping times and international trade compliance, especially if you are sourcing from different regions like Africa or South America. Supplier reliability, customer service responsiveness, and pricing structures should also be key considerations. -

What customization options are available for cable and harness assemblies?

Most manufacturers offer extensive customization options for cable and harness assemblies, including variations in wire types, lengths, connectors, and insulation materials. Some may also provide over-molding, potting, or braiding services to enhance durability and performance. It’s advisable to discuss your specific needs with the manufacturer’s engineering team, who can assist in designing tailored solutions that meet your application requirements and comply with industry standards. -

What are typical minimum order quantities (MOQs) for cable and harness products?

Minimum order quantities (MOQs) for cable and harness products can vary widely among manufacturers, often depending on the complexity of the assembly and the materials used. Commonly, MOQs range from 100 to several thousand units. If you are a smaller business or a startup, many manufacturers are willing to negotiate MOQs, especially if you demonstrate potential for long-term collaboration. Discuss your needs upfront to find a supplier that aligns with your order capacity. -

What payment terms should I expect when working with international cable and harness manufacturers?

Payment terms can vary significantly depending on the manufacturer and the country of origin. Common terms include upfront deposits (often 30-50%) followed by the balance upon delivery or net 30-60 days after shipment. Some manufacturers may also offer letter of credit options for international transactions to reduce risk. It’s essential to clarify payment terms in advance and ensure they are documented in your purchase agreement to avoid disputes later. -

How can I manage logistics when sourcing cable and harness products internationally?

Effective logistics management when sourcing internationally involves understanding shipping options, customs regulations, and lead times. Work closely with your supplier to determine the best shipping methods, considering cost and urgency. Establish clear communication regarding delivery schedules and any potential delays. Utilizing freight forwarders can also streamline the process, ensuring compliance with international trade regulations and proper documentation for customs clearance. -

What quality assurance measures should manufacturers implement for cable assemblies?

Manufacturers should implement rigorous quality assurance measures, including in-process inspections, final testing, and adherence to industry standards such as IPC/WHMA-A-620. Regular audits and continuous improvement processes should be in place to identify and rectify any quality issues. Documentation of testing results and traceability of materials is crucial for accountability. Collaborating with clients to establish specific quality benchmarks can further enhance confidence in the product’s reliability. -

How do I assess a manufacturer’s capability for rapid prototyping?

To assess a manufacturer’s capability for rapid prototyping, inquire about their design and engineering processes, including the use of CAD software and rapid tooling techniques. Evaluate their turnaround times for prototype builds and their ability to accommodate design modifications quickly. Request case studies or references from previous clients who have utilized their prototyping services. A manufacturer with a dedicated engineering team and a history of successful prototype projects can significantly reduce time-to-market for your products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Cable and Harness Manufacturers

As the demand for customized cable and wire harness solutions continues to rise across diverse industries, strategic sourcing becomes essential for international B2B buyers. Key takeaways highlight the importance of partnering with manufacturers who not only offer tailored designs but also possess robust engineering capabilities, prototyping services, and a commitment to quality. Engaging with suppliers that emphasize advanced manufacturing technologies and stringent quality standards can significantly enhance supply chain efficiency and product reliability.

Buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize relationships with manufacturers that demonstrate a clear understanding of local market needs and compliance with international standards. This approach will facilitate smoother transitions during product development and ensure timely delivery of high-quality components.

Looking ahead, the landscape of cable and harness manufacturing is poised for transformation with the advent of new technologies and increasing automation. Buyers are encouraged to embrace innovation and seek partnerships that align with their long-term strategic goals. By making informed sourcing decisions today, businesses can secure a competitive edge in tomorrow’s market. Reach out to industry experts and start exploring tailored solutions that drive your success.