Explore Different Types of Outlets: The Ultimate Sourcing Guide (2025)

Introduction: Navigating the Global Market for different types of outlets

In today’s interconnected world, sourcing the right electrical outlets can be a daunting challenge for international B2B buyers. With diverse applications and varying standards across regions, understanding the types of outlets available is essential for ensuring safety and efficiency in electrical installations. This guide offers a comprehensive overview of different outlet types, including standard duplex, GFCI, AFCI, and specialty outlets, along with their specific applications and wiring requirements.

International buyers from Africa, South America, the Middle East, and Europe—such as Germany and Nigeria—will benefit from insights into supplier vetting processes, cost considerations, and compliance with local electrical codes. By demystifying the nuances of outlet selection, this guide empowers businesses to make informed purchasing decisions that align with their operational needs and regulatory standards.

Whether you are equipping a new facility or upgrading existing electrical systems, understanding the intricacies of various outlet types can lead to improved safety, enhanced functionality, and long-term cost savings. Dive into this guide to navigate the global market effectively, ensuring that your electrical infrastructure meets both local requirements and international best practices.

Understanding different types of outlets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 15-Amp Duplex Outlet | Standard outlet with two slots and a grounding hole. | Residential and light commercial use. | Pros: Widely available, cost-effective. Cons: Limited for high-power devices. |

| GFCI Outlet | Monitors electrical flow and cuts off power in case of imbalance. | Bathrooms, kitchens, and outdoor settings. | Pros: Enhances safety, prevents shocks. Cons: More expensive than standard outlets. |

| AFCI Outlet | Detects arc faults to prevent electrical fires. | Bedrooms and living areas. | Pros: Fire prevention, compliance with codes. Cons: Higher installation costs. |

| Combination Outlet | Combines a standard outlet with a switch or other features. | Multi-functional spaces, offices. | Pros: Space-saving, versatile. Cons: Can be complex to install. |

| USB Outlet | Built-in USB ports for direct charging without adapters. | Offices, hotels, and residential areas. | Pros: Convenient for charging devices. Cons: Limited to low-power devices. |

What are the Key Characteristics of 15-Amp Duplex Outlets?

15-amp duplex outlets are the most common type found in residential and light commercial settings. They feature two slots for plugs and a grounding hole, allowing for the connection of standard appliances and devices. These outlets are suitable for powering lamps, electronics, and small appliances. When purchasing, buyers should consider the outlet’s compliance with local electrical codes and the specific amperage requirements of their devices. While they are cost-effective and readily available, they are not suitable for high-power devices, which may require a 20-amp outlet.

How Do GFCI Outlets Enhance Safety in B2B Environments?

Ground Fault Circuit Interrupter (GFCI) outlets are essential in areas where water exposure is likely, such as bathrooms and kitchens. They continuously monitor electrical flow and automatically shut off power if an imbalance is detected, significantly reducing the risk of electric shock. For B2B buyers, especially in sectors like hospitality or healthcare, investing in GFCI outlets is crucial for safety compliance and protecting users. Although they come at a higher cost than standard outlets, the investment is justified by the enhanced safety features they provide.

What Benefits Do AFCI Outlets Offer for Fire Prevention?

Arc Fault Circuit Interrupter (AFCI) outlets are designed to detect dangerous arc faults that can lead to electrical fires. They are particularly recommended for bedrooms and living areas, where the risk of fire due to faulty wiring is higher. B2B buyers should consider AFCI outlets for any commercial or residential projects that require adherence to safety codes. While they may involve higher installation costs, the long-term benefits of fire prevention and insurance savings can outweigh these initial expenses.

Why Choose Combination Outlets for Versatile Applications?

Combination outlets merge the functionality of a standard outlet with additional features like a switch or USB ports. This versatility makes them ideal for multi-functional spaces such as offices or conference rooms, where powering various devices simultaneously is necessary. B2B buyers should evaluate the installation complexity and ensure compatibility with their existing electrical systems. While they maximize space and functionality, potential installation challenges should be weighed against their benefits.

What Advantages Do USB Outlets Provide in Modern Workspaces?

USB outlets are increasingly popular in both residential and commercial settings, allowing for direct charging of mobile devices without the need for plug adapters. This feature is particularly beneficial in offices, hotels, and public spaces where multiple users may need to charge devices simultaneously. B2B buyers should consider the power output of USB outlets to ensure they meet the charging needs of their devices. While they offer convenience, they are limited to lower-power applications, so additional outlets may still be necessary for high-demand devices.

Key Industrial Applications of different types of outlets

| Industry/Sector | Specific Application of Different Types of Outlets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | GFCI Outlets in Medical Facilities | Ensures patient safety by preventing electrical shocks | Compliance with local safety regulations and standards |

| Manufacturing | 20-Amp Outlets for Heavy Machinery | Supports high-power machinery for efficient production | Voltage compatibility and circuit breaker ratings |

| Hospitality | Combination Outlets in Guest Rooms | Enhances guest experience with multiple charging options | Aesthetic design and ease of installation |

| Retail | USB Outlets in Point of Sale Areas | Increases customer satisfaction by providing charging options | Durability and compatibility with existing wiring |

| Construction | Weather-Resistant Outlets on Job Sites | Protects electrical connections in harsh weather | Robust construction and compliance with safety codes |

How Are GFCI Outlets Beneficial in Healthcare Settings?

In healthcare facilities, GFCI (Ground Fault Circuit Interrupter) outlets are crucial for ensuring patient and staff safety. These outlets are designed to detect imbalances in electrical currents and shut off power to prevent electrical shocks, particularly in wet areas like bathrooms or kitchens. For international buyers in regions such as Africa and South America, sourcing GFCI outlets requires an understanding of local electrical codes and safety standards to ensure compliance and reliability.

Why Are 20-Amp Outlets Essential in Manufacturing?

In manufacturing environments, 20-amp outlets are often necessary to support heavy machinery that requires higher power levels. These outlets can handle the electrical load needed for equipment such as industrial ovens, compressors, and other high-demand tools. For businesses in the Middle East and Europe, it is vital to consider the electrical infrastructure when sourcing these outlets, ensuring compatibility with existing circuits and adherence to local voltage standards to avoid operational disruptions.

A stock image related to different types of outlets.

How Do Combination Outlets Enhance Guest Experience in Hospitality?

Combination outlets, which integrate standard power outlets with switches or USB ports, are increasingly popular in hospitality settings. They allow guests to charge multiple devices conveniently while controlling lighting from the same location. For international B2B buyers in Europe, particularly in Germany, aesthetics and ease of installation are key considerations, as these outlets must align with the modern design standards of hotel rooms while providing functionality.

What Role Do USB Outlets Play in Retail Environments?

USB outlets are becoming a staple in retail environments, especially at point-of-sale (POS) stations. They allow customers to charge their devices while shopping, enhancing their overall experience and encouraging longer visits. For B2B buyers in South America, sourcing durable USB outlets that can withstand high traffic and frequent use is essential, along with ensuring that they meet local safety and electrical regulations.

Why Are Weather-Resistant Outlets Important on Construction Sites?

Weather-resistant outlets are vital for construction sites, where electrical connections are often exposed to harsh weather conditions. These outlets prevent moisture-related electrical failures and ensure safety for workers. International buyers in Africa and the Middle East should focus on sourcing robust, weather-resistant options that comply with local safety codes, as well as ensuring that they are suitable for the specific environmental challenges of their respective regions.

3 Common User Pain Points for ‘different types of outlets’ & Their Solutions

Scenario 1: Compatibility Issues with Electrical Sockets in Diverse Markets

The Problem:

International B2B buyers often encounter compatibility issues when sourcing electrical outlets for various regions. For instance, a company based in Germany may wish to expand its operations into Nigeria but is unsure whether the electrical equipment designed for the European market will work with the local socket types. This can lead to substantial delays in project timelines and increased costs due to the need for adapters or even complete redesigns of products. Moreover, understanding the specific electrical standards and regulations in each country can be daunting, leading to compliance issues.

The Solution:

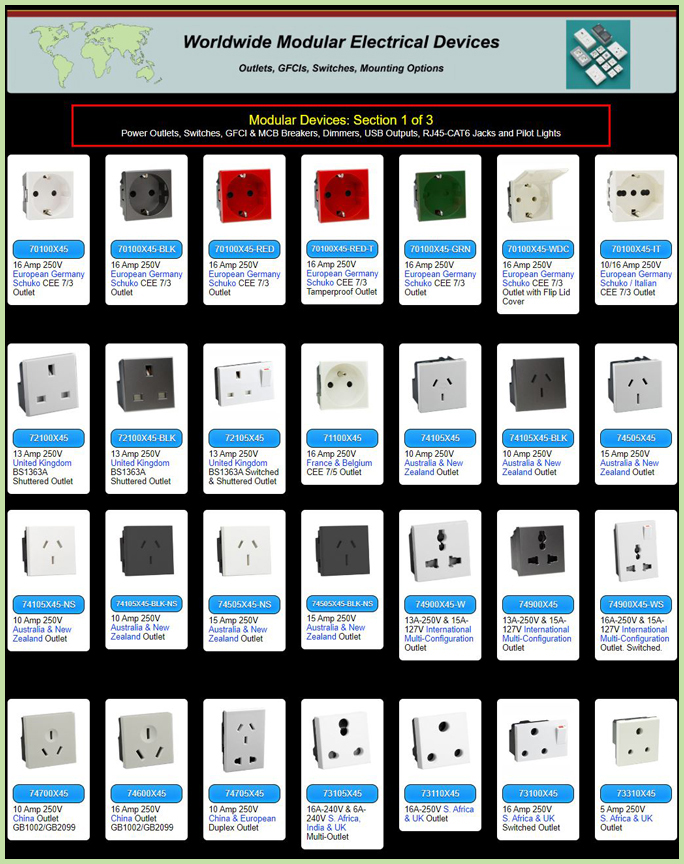

To effectively navigate these compatibility challenges, B2B buyers should invest time in understanding the different electrical standards applicable in their target markets. Start by conducting thorough research on socket types, voltages, and amperages used in countries like Nigeria, South Africa, and Brazil. Utilize resources such as local electrical codes and regulations to ensure compliance.

Additionally, consider sourcing products from manufacturers that specialize in multi-standard outlets or those that provide customizable solutions for various markets. For example, look for manufacturers that offer modular outlet systems that can adapt to multiple plug types. This not only ensures compatibility but also reduces the need for additional inventory management.

Lastly, partnering with local suppliers or electrical contractors can offer valuable insights into the specific needs and preferences of the market, streamlining the purchasing process and enhancing customer satisfaction.

Scenario 2: Safety Concerns with Electrical Outlets in Commercial Settings

The Problem:

Safety is paramount in any commercial environment, yet many B2B buyers overlook the importance of selecting the right type of electrical outlets. In regions with high humidity, such as parts of South America and the Middle East, standard outlets may pose risks of electrical shock or fire hazards. For example, a company operating a manufacturing facility in Brazil may find that using conventional outlets in wet areas leads to frequent outages or dangerous conditions, risking both employee safety and operational continuity.

The Solution:

To mitigate safety concerns, B2B buyers should prioritize GFCI (Ground Fault Circuit Interrupter) outlets and weather-resistant receptacles for environments prone to moisture. These types of outlets are specifically designed to prevent electrical shock by monitoring the flow of electricity and automatically shutting off when an imbalance is detected.

When specifying outlets, ensure that GFCI outlets are installed in areas such as kitchens, bathrooms, and outdoor spaces. Furthermore, consider using tamper-resistant receptacles to enhance safety in facilities with children or where unauthorized personnel might have access.

Engaging with a reputable electrical contractor during the planning phase can provide additional insights into the safest outlet configurations for your specific operational needs, ensuring compliance with local safety regulations.

Scenario 3: Inefficiencies Caused by Outdated Outlet Technologies

The Problem:

In a rapidly evolving technological landscape, businesses often find themselves using outdated outlet technologies that hinder efficiency. For instance, a company in Europe may rely heavily on traditional outlets that do not support USB charging, resulting in employee frustration and decreased productivity as they struggle to keep devices charged. This is particularly relevant in sectors like hospitality, where guest satisfaction is directly impacted by the availability of modern charging options.

The Solution:

To enhance operational efficiency and meet modern demands, B2B buyers should consider integrating USB outlets and smart plugs into their purchasing strategies. USB outlets provide direct charging capabilities for devices without the need for adapters, streamlining the user experience.

Moreover, smart plugs allow for remote control of devices, which can be particularly useful in managing energy consumption and improving overall operational efficiency. When sourcing these products, look for suppliers who offer integrated solutions that combine multiple functionalities into a single outlet.

In addition, conducting a technology audit can help identify areas where outdated outlet systems are hindering productivity. This proactive approach not only prepares your business for future technological advancements but also demonstrates a commitment to providing a user-friendly environment for employees and customers alike.

Strategic Material Selection Guide for different types of outlets

What Are the Key Materials Used in Electrical Outlets?

When selecting materials for electrical outlets, understanding their properties, advantages, and limitations is crucial for ensuring safety, performance, and compliance with international standards. Below, we analyze four common materials used in the manufacture of electrical outlets: thermoplastic, metal, ceramic, and rubber.

How Do Thermoplastic Materials Perform in Electrical Outlets?

A stock image related to different types of outlets.

Thermoplastic materials, such as polycarbonate and nylon, are widely used in electrical outlets due to their excellent electrical insulation properties and durability. These materials can withstand a wide range of temperatures, typically from -40°C to 85°C, making them suitable for various environments.

Pros: Thermoplastics are lightweight, resistant to impact, and cost-effective. They are also easy to mold, which simplifies manufacturing processes.

Cons: While thermoplastics offer good performance, they may not be as heat-resistant as other materials, which can be a concern in high-load applications.

Impact on Application: Thermoplastics are compatible with standard electrical components and can be used in residential and commercial settings.

Considerations for International Buyers: Buyers should ensure compliance with ASTM or IEC standards, especially in regions like Europe and South America, where safety regulations are stringent.

What Advantages Do Metal Materials Offer for Electrical Outlets?

Metal materials, particularly steel and aluminum, are often used for the internal components of electrical outlets due to their strength and conductivity.

Pros: Metals provide excellent durability and are capable of withstanding high temperatures and pressures. They also offer superior grounding capabilities, which is critical for safety.

Cons: The primary disadvantage of metal is its susceptibility to corrosion, especially in humid environments. This can lead to a shorter lifespan if not properly treated or coated.

Impact on Application: Metal components are essential for heavy-duty applications, such as industrial settings where high power loads are common.

Considerations for International Buyers: Buyers in regions like the Middle East should consider corrosion-resistant coatings to enhance longevity, while compliance with local electrical codes is essential.

Why Are Ceramic Materials Important in Electrical Outlet Design?

Ceramic materials are less common but are used for their excellent heat resistance and insulating properties.

Pros: Ceramics can withstand high temperatures and are not prone to melting or deforming under heat, making them ideal for high-load applications.

Cons: The main drawback is their brittleness; ceramics can crack or break if subjected to mechanical stress.

Impact on Application: Ceramics are often used in specialized outlets, such as those for high-temperature equipment.

Considerations for International Buyers: Compliance with international standards is crucial, particularly in Europe, where regulations around high-temperature applications are stringent.

How Does Rubber Contribute to Electrical Outlet Functionality?

Rubber is primarily used in the form of gaskets and seals in electrical outlets to provide moisture resistance and prevent dust ingress.

Pros: Rubber is flexible, durable, and resistant to environmental factors like moisture, making it ideal for outdoor applications.

Cons: Rubber can degrade over time when exposed to UV light or extreme temperatures, which may limit its lifespan.

Impact on Application: Rubber is essential for outlets used in outdoor or wet environments, ensuring safety and functionality.

Considerations for International Buyers: Buyers should look for rubber materials that meet international standards for UV resistance and durability, especially in regions with extreme weather conditions.

Summary Table of Material Selection for Electrical Outlets

| Material | Typical Use Case for different types of outlets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic | Residential and commercial electrical outlets | Lightweight and cost-effective | Limited heat resistance | Low |

| Metal | Industrial heavy-duty outlets | High durability and excellent grounding | Susceptible to corrosion | Medium |

| Ceramic | High-temperature applications | Excellent heat resistance | Brittle and prone to cracking | High |

| Rubber | Outdoor and moisture-resistant outlets | Flexible and moisture-resistant | Degrades under UV exposure | Medium |

This strategic material selection guide provides international B2B buyers with essential insights into the various materials used in electrical outlets, aiding in informed purchasing decisions that comply with regional standards and enhance product performance.

In-depth Look: Manufacturing Processes and Quality Assurance for different types of outlets

What Are the Key Stages in the Manufacturing Process of Electrical Outlets?

Manufacturing electrical outlets involves several critical stages, each essential to ensure the final product meets safety and functionality standards. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Commonly Used in Outlet Manufacturing?

The manufacturing process begins with the selection of high-quality materials. The most common materials used in electrical outlets include:

- Thermoplastics: Often used for the casing due to their durability and insulating properties.

- Copper and Brass: Used for the electrical contacts due to their excellent conductivity.

- Steel: Sometimes used in the structural components of outlets.

These materials are sourced from reliable suppliers who adhere to international quality standards, ensuring consistency and safety in the final product.

How Are Electrical Outlets Formed and Assembled?

Once the materials are prepared, the next step is forming. This process typically includes:

- Injection Molding: Thermoplastic materials are heated and injected into molds to create the outlet casing.

- Stamping: Metal components like contacts are stamped out of sheets of copper or brass.

Following forming, the assembly process begins. This involves:

- Component Assembly: The various parts, including the casing, electrical contacts, and any additional features (like USB ports or tamper-resistant mechanisms), are assembled.

- Wiring: Electrical connections are made to ensure that the outlet can properly conduct electricity.

What Quality Assurance Measures Are Implemented in Outlet Manufacturing?

Quality assurance (QA) is crucial in the manufacturing of electrical outlets to ensure they are safe and reliable. Several international and industry-specific standards guide these processes.

Which International Standards Are Relevant for Electrical Outlet Manufacturing?

Manufacturers typically adhere to international standards such as:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring that manufacturers maintain consistent quality in their products.

- IEC (International Electrotechnical Commission): Sets standards for electrical equipment, ensuring safety and performance.

Additionally, regional certifications such as CE marking in Europe or UL certification in the United States are often required to indicate compliance with safety standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) measures are implemented at various stages of the manufacturing process to catch defects early. Key checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to ensure that each component is being assembled correctly.

- Final Quality Control (FQC): A thorough inspection of the finished product, testing for functionality, safety, and compliance with standards.

What Common Testing Methods Are Used to Ensure Outlet Safety and Reliability?

To guarantee the safety and performance of electrical outlets, several testing methods are employed:

- Dielectric Strength Testing: Ensures that the outlet can withstand high voltages without failure.

- Temperature Rise Testing: Assesses how much heat the outlet generates under load, which is critical for preventing overheating.

- Mechanical Durability Testing: Tests how well the outlet can withstand physical stress and repeated use.

These tests help manufacturers ensure their products can safely handle the demands of everyday use.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers need to ensure that their suppliers maintain high-quality standards. Here are some actionable steps:

- Supplier Audits: Conduct regular audits of suppliers to assess their manufacturing processes and quality control measures.

- Request Quality Reports: Ask suppliers for detailed quality reports, including test results and certifications.

- Third-party Inspections: Engage third-party inspection agencies to evaluate the manufacturing processes and final products before shipment.

What Are the Quality Control and Certification Nuances for International Buyers?

For international B2B buyers, understanding the certification landscape is vital. Different regions may have varying requirements, which can affect shipping and compliance:

- Regional Compliance: Ensure that the products meet the specific electrical safety standards in your region (e.g., CE in Europe, SABS in South Africa).

- Documentation: Request all necessary documentation, including certificates of compliance and test reports, to avoid complications during customs clearance.

How Do Local Market Considerations Affect the Manufacturing and QC of Electrical Outlets?

In markets such as Africa, South America, the Middle East, and Europe, local regulations and market needs can significantly impact manufacturing processes. For instance:

- Voltage and Frequency Standards: Different regions have varying voltage standards (e.g., 220-240V in Europe vs. 110-120V in North America), affecting outlet design and testing requirements.

- Environmental Conditions: Manufacturers may need to consider local environmental factors, such as humidity and temperature, which can influence material selection and testing protocols.

Conclusion: Ensuring Quality and Compliance in Electrical Outlet Manufacturing

Understanding the manufacturing processes and quality assurance measures for electrical outlets is crucial for B2B buyers. By focusing on the material preparation, forming, assembly, and finishing stages, as well as implementing rigorous quality control measures, manufacturers can ensure that their products meet international standards. Buyers should actively engage with suppliers, verify quality control practices, and ensure compliance with regional regulations to guarantee safe and reliable electrical outlets for their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘different types of outlets’

Introduction

Navigating the procurement of electrical outlets for your business can be complex, especially when considering the diverse types available on the market. This guide serves as a practical checklist for B2B buyers from Africa, South America, the Middle East, and Europe, ensuring that you make informed decisions tailored to your specific operational needs. By following these steps, you can streamline your sourcing process and ensure compliance with international standards.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clarify your technical requirements. Identify the types of outlets needed based on your equipment and operational environment.

- Consider amperage ratings: Determine if you need 15-amp or 20-amp outlets, as this will affect compatibility with your devices.

- Assess environmental conditions: Decide whether you need weather-resistant, GFCI, or tamper-resistant outlets based on usage location.

Step 2: Conduct Market Research

Understanding the market landscape is vital for effective sourcing. Research different types of outlets available and their respective suppliers.

- Compare product features: Look for specific attributes like durability, safety certifications, and energy efficiency.

- Identify regional suppliers: Especially in markets like Africa and South America, sourcing locally can reduce shipping times and costs.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, thorough evaluation is crucial.

- Request documentation: Ask for company profiles, product certifications, and compliance with international electrical standards.

- Seek references: Contact other businesses in your industry or region to validate the supplier’s reliability and product quality.

Step 4: Verify Supplier Certifications

Safety and compliance are non-negotiable when dealing with electrical products.

- Check for necessary certifications: Ensure that suppliers provide certification from recognized bodies (e.g., CE, UL) that validate the safety of their products.

- Review warranty policies: A robust warranty can indicate supplier confidence in their product quality and serve as a safety net for your investment.

Step 5: Request Samples for Testing

Obtaining samples allows you to evaluate the product before making a bulk purchase.

- Conduct performance tests: Test the outlets for functionality, durability, and compatibility with your equipment.

- Assess ease of installation: Ensure that the outlets can be easily integrated into your existing systems, minimizing downtime.

Step 6: Negotiate Terms and Pricing

Once you’ve settled on a supplier, focus on negotiating favorable terms.

- Discuss bulk pricing: Leveraging larger order quantities can lead to significant cost savings.

- Clarify payment terms: Establish clear payment terms to manage cash flow effectively and ensure timely deliveries.

Step 7: Plan for Logistics and Delivery

Finally, consider the logistics of transporting your outlets to ensure timely project execution.

- Evaluate shipping options: Determine the most efficient shipping methods to minimize delays.

- Confirm delivery timelines: Establish clear expectations regarding delivery dates to synchronize with your operational schedules.

By following this checklist, international B2B buyers can enhance their sourcing strategy for electrical outlets, ensuring compliance, safety, and efficiency in their operations.

Comprehensive Cost and Pricing Analysis for different types of outlets Sourcing

When sourcing electrical outlets, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. This analysis will explore the various cost components, price influencers, and provide actionable tips for negotiation and cost efficiency.

What Are the Key Cost Components in Electrical Outlet Sourcing?

The cost structure of electrical outlets typically comprises several key components:

-

Materials: The primary materials include plastic, metal, and electronic components. The quality of materials significantly influences the overall cost. For example, tamper-resistant and weather-resistant outlets may require more expensive materials compared to standard duplex outlets.

-

Labor: Labor costs can vary greatly depending on the manufacturing location. Countries with lower labor costs, like some in Africa or South America, may offer competitive pricing, but may also come with trade-offs in quality or delivery timelines.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Custom designs or unique outlet types may require specialized tooling, which can lead to higher initial costs. However, these costs can be amortized over larger production runs.

-

Quality Control (QC): Stringent quality control measures can add to the overall cost but are crucial for ensuring product reliability and compliance with international standards.

-

Logistics: Transportation costs, customs duties, and warehousing also play a significant role in the final price. Incoterms can greatly affect these costs, depending on whether the buyer or seller is responsible for shipping and handling.

-

Margin: Suppliers will typically include a profit margin in their pricing, which can vary based on market demand and competition.

How Do Price Influencers Affect Electrical Outlet Costs?

Several factors can influence the pricing of electrical outlets:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract discounts, reducing the per-unit cost. However, international buyers should ensure they can sell the volume ordered to avoid excess inventory.

-

Specifications and Customization: Custom specifications, such as unique designs or features, can increase costs. Buyers should assess whether the additional features justify the price difference.

-

Quality and Certifications: Outlets that meet higher safety standards or possess certifications (e.g., CE, UL) may command higher prices. Buyers should evaluate the necessity of these certifications based on their target market.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their products due to their proven track record.

What Buyer Tips Can Enhance Cost-Efficiency in Outlet Sourcing?

For international B2B buyers, particularly those from diverse regions, here are some actionable tips:

-

Negotiate Effectively: Building a strong relationship with suppliers can enhance negotiation outcomes. Discussing long-term partnerships or bulk purchasing can lead to more favorable terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the purchase price but also the long-term costs associated with the outlets, such as installation, maintenance, and energy efficiency. This holistic approach can lead to better investment decisions.

-

Understand Pricing Nuances: Be aware that prices can vary widely based on local economic conditions, currency fluctuations, and market demand. Conduct thorough market research to benchmark prices and avoid overpaying.

-

Utilize Incoterms Wisely: Familiarize yourself with Incoterms to determine the best shipping arrangements that minimize risks and costs. Options such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect landed costs.

Disclaimer on Pricing

Prices for electrical outlets can vary significantly based on market conditions and supplier negotiations. This analysis provides a general framework, but buyers should conduct their own market research to obtain accurate and current pricing.

Alternatives Analysis: Comparing different types of outlets With Other Solutions

Understanding Alternatives to Different Types of Outlets

In the realm of electrical solutions, various outlet types are often the go-to for ensuring power accessibility in both residential and commercial environments. However, there are alternative solutions that can achieve similar objectives, providing buyers with options that may better suit their specific needs. This analysis compares traditional electrical outlets with innovative alternatives, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table of Electrical Outlets and Alternative Solutions

| Comparison Aspect | Different Types of Outlets | Smart Plugs | Power Strips with Surge Protection |

|---|---|---|---|

| Performance | Reliable for standard usage, with specific types for different needs (e.g., GFCI, AFCI) | Provides remote control, scheduling, and energy monitoring | Protects devices from power surges, allows multiple devices to connect |

| Cost | Moderate installation costs; prices vary by type | Generally low-cost and easy to find | Affordable options available, but can add up with multiple devices |

| Ease of Implementation | Requires professional installation, especially for GFCI or AFCI | Plug-and-play; easy to set up | Simple to use; can be plugged into any outlet |

| Maintenance | Minimal; may require occasional replacement | Low; firmware updates may be needed | Moderate; check for wear and tear, replace after damage |

| Best Use Case | Best for permanent installations in homes and businesses needing reliable power | Ideal for smart homes and energy management | Suitable for protecting multiple devices in a single location |

Detailed Breakdown of Alternatives

How Do Smart Plugs Compare to Traditional Outlets?

Smart plugs are a modern solution that allows users to control devices remotely via smartphone applications. They are often more cost-effective and straightforward to implement than traditional outlets, requiring no professional installation. The ability to schedule devices and monitor energy usage provides valuable insights into consumption patterns. However, they may not be suitable for heavy-duty appliances and can be limited by the existing outlet’s capacity.

What Advantages Do Power Strips with Surge Protection Offer?

Power strips with surge protection are another alternative that allows multiple devices to be connected to a single outlet while safeguarding them against power spikes. They are typically low-cost and easy to implement, making them accessible for both personal and business use. However, they may not provide the same level of safety as dedicated outlets, especially in wet or high-risk areas where GFCI protection is required. Regular maintenance is necessary to ensure they remain effective, as damaged strips can pose safety risks.

Conclusion: How Should B2B Buyers Choose the Right Electrical Solution?

When selecting the right electrical solution, B2B buyers should consider their specific operational needs, budget constraints, and the long-term goals of their businesses. Traditional outlets are ideal for permanent installations requiring reliability and safety, while smart plugs offer flexibility and energy management for tech-savvy environments. Power strips provide an affordable, short-term solution for managing multiple devices, but they lack the safety features of dedicated outlets. Ultimately, understanding the nuances of each option will empower buyers to make informed decisions that best suit their requirements.

Essential Technical Properties and Trade Terminology for different types of outlets

What Are the Key Technical Properties of Electrical Outlets?

Understanding the technical specifications of electrical outlets is crucial for international B2B buyers to ensure compliance, safety, and efficiency in various applications. Here are some essential technical properties to consider:

1. Amperage Rating: What Does It Mean?

The amperage rating indicates the maximum current an outlet can safely handle. Most outlets are rated for either 15 or 20 amps. For B2B buyers, selecting the appropriate amperage is vital to prevent overheating and equipment failure. Ensure that your appliances match the outlet’s rating to maintain safety and efficiency.

2. Voltage Compatibility: Why Is It Important?

Electrical outlets operate at different voltage levels, commonly 120V or 240V, depending on the region. Buyers must confirm that the voltage compatibility aligns with the local electrical standards to avoid damaging equipment. Understanding voltage requirements is especially critical when sourcing products across different continents, such as Africa and Europe, where standards may vary.

3. Material Grade: How Does It Affect Performance?

The material used in the construction of electrical outlets affects durability and safety. High-quality outlets are typically made from thermoplastic or thermoset materials, which resist heat and environmental factors. For B2B transactions, specifying the material grade can ensure that the products meet industry standards and are suitable for the intended environment.

4. Grounding Mechanism: What Should You Know?

Grounding is essential for electrical safety, preventing electric shock and equipment damage. Outlets may feature different grounding designs, such as a U-shaped hole or a combination with tamper-resistant features. Buyers should prioritize outlets with reliable grounding mechanisms, especially in regions prone to electrical surges or in applications involving sensitive equipment.

5. Weather Resistance: Why Is It Necessary?

For outdoor or damp environments, weather-resistant outlets are crucial. These outlets are designed to withstand moisture and extreme temperatures, reducing the risk of electrical failures. When sourcing products for regions with varied climates, consider weather-resistant specifications to ensure longevity and safety.

6. Tamper Resistance: What Protection Does It Offer?

Tamper-resistant outlets include built-in safety features that prevent unauthorized access, making them ideal for settings with children or public use. This specification is particularly important for buyers in educational or childcare facilities, as it enhances safety without compromising functionality.

What Are Common Trade Terms Related to Electrical Outlets?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms relevant to electrical outlets:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For B2B buyers, understanding OEM relationships can help identify reliable suppliers and ensure product quality.

2. MOQ (Minimum Order Quantity): How Does It Impact Buying Decisions?

MOQ is the minimum quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory planning, particularly for international buyers looking to optimize their supply chain.

3. RFQ (Request for Quotation): Why Is It Important?

An RFQ is a document sent to suppliers requesting a price quote for specific quantities of goods. Crafting a detailed RFQ can lead to better pricing and terms, making it a vital tool for B2B buyers seeking competitive rates.

4. Incoterms (International Commercial Terms): What Should Buyers Know?

Incoterms define the responsibilities of buyers and sellers in international shipping. Understanding these terms can help B2B buyers clarify delivery, risk, and cost responsibilities, ensuring smoother transactions.

5. Lead Time: What Is Its Significance?

Lead time refers to the time it takes for an order to be fulfilled. For B2B buyers, knowing the lead time helps in planning and managing inventory levels, especially when working with international suppliers.

6. Certification Standards: Why Are They Essential?

Certification standards, such as UL or CE, indicate that products meet specific safety and quality requirements. Buyers should ensure that the electrical outlets they source are certified for their intended markets to avoid compliance issues.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing electrical outlets, ensuring safety, compliance, and efficiency in their operations.

Navigating Market Dynamics and Sourcing Trends in the different types of outlets Sector

A stock image related to different types of outlets.

What Are the Current Market Dynamics and Key Trends Affecting Different Types of Outlets?

The global market for electrical outlets is influenced by several key drivers, including rapid urbanization, the proliferation of smart home technology, and increasing demand for energy-efficient solutions. In regions like Africa and South America, expanding infrastructure and a growing middle class are fueling demand for reliable and safe electrical solutions. International B2B buyers should be aware of the emerging trend of smart outlets that integrate IoT capabilities, allowing for remote monitoring and management, which is becoming increasingly popular in Europe and the Middle East.

Another significant trend is the shift towards more sustainable and energy-efficient products. Buyers are increasingly seeking outlets that not only meet safety standards but also contribute to energy savings. This is particularly relevant in regions where energy costs are high or where there is a strong regulatory push for environmental compliance. Understanding these trends will enable international B2B buyers to make informed sourcing decisions that align with market demands.

How Can Sustainability and Ethical Sourcing Impact Your B2B Purchases of Electrical Outlets?

Environmental sustainability is becoming a crucial factor for B2B buyers in the electrical outlet sector. The manufacturing of electrical outlets can have a considerable environmental impact, from resource extraction to waste generation. Therefore, buyers should prioritize suppliers that demonstrate a commitment to sustainability through the use of recycled materials and efficient manufacturing processes.

Ethical sourcing is equally important. Suppliers who adhere to fair labor practices and environmental regulations not only mitigate risks but also enhance their brand reputation. Certifications such as Energy Star and RoHS (Restriction of Hazardous Substances) are indicators of a product’s environmental impact and safety standards. By choosing outlets that carry these certifications, international B2B buyers can ensure that they are sourcing products that align with their values and those of their customers, particularly in markets sensitive to environmental issues.

What Is the Historical Context Behind the Evolution of Electrical Outlets?

The evolution of electrical outlets has been shaped by advancements in electrical engineering and changing consumer needs. Initially, outlets were basic and designed solely for functionality. Over time, the introduction of safety features like Ground Fault Circuit Interrupters (GFCI) and Arc Fault Circuit Interrupters (AFCI) marked a significant shift towards enhancing user safety and preventing electrical fires.

With the rise of technology, the development of smart outlets that can be controlled via mobile devices has transformed the market landscape. These innovations not only provide convenience but also align with the growing trend towards home automation. Understanding this historical context can help B2B buyers appreciate the technological advancements that inform current product offerings and anticipate future trends in the electrical outlet sector.

Frequently Asked Questions (FAQs) for B2B Buyers of different types of outlets

-

1. How do I solve compatibility issues with different types of electrical outlets?

To address compatibility issues, it’s essential to identify the specific outlet types and voltage requirements in your region. Different countries use various plug types and voltage standards, which can affect your equipment. Consider investing in universal adapters or multi-type outlets that can accommodate various plug styles. Additionally, consult with your suppliers about the electrical specifications of your products to ensure they align with the outlets used in your target market. Properly vetting suppliers for compliance with local electrical standards can mitigate these issues. -

2. What is the best electrical outlet type for heavy-duty appliances?

For heavy-duty appliances, a 20-amp outlet is typically the best choice, as it can handle higher loads without overheating. These outlets are designed for devices that require more power, such as refrigerators, air conditioners, and electric dryers. Ensure that your electrical infrastructure is capable of supporting 20-amp circuits, which usually require 12-gauge wiring. When sourcing these outlets, prioritize suppliers that offer high-quality, durable products that meet international safety standards to ensure optimal performance and safety. -

3. How can I ensure the quality of the electrical outlets I purchase?

To ensure quality, start by vetting suppliers based on their certifications and compliance with international standards, such as IEC or UL. Request samples to assess the material and build quality before placing larger orders. Additionally, inquire about the manufacturing process and quality assurance measures in place. Establishing clear quality benchmarks and conducting periodic inspections during production can also help maintain high standards. Building a relationship with reliable suppliers will foster trust and facilitate better quality control. -

4. What are the minimum order quantities (MOQs) I should expect when sourcing electrical outlets?

Minimum order quantities (MOQs) can vary significantly between suppliers and depend on the type of outlet. Generally, MOQs for electrical outlets range from 100 to 1,000 units. It’s essential to discuss your needs with potential suppliers and negotiate terms that suit your business model. If you’re a smaller buyer, consider forming a cooperative with other businesses to meet MOQ requirements without overextending your budget. -

5. What payment terms should I negotiate when purchasing electrical outlets internationally?

When negotiating payment terms, aim for flexible arrangements that support your cash flow. Common terms include a 30% deposit upfront with the balance due upon shipment or delivery. Explore options for letter of credit (LC) for larger orders, which can provide security for both parties. Discuss early payment discounts or installment plans if your supplier is open to them. Always ensure that payment terms are clearly documented in your contract to avoid misunderstandings. -

6. How do I handle logistics for importing electrical outlets from international suppliers?

Managing logistics effectively requires careful planning and coordination. Start by researching freight forwarders with experience in importing electrical goods. They can help you navigate customs regulations, tariffs, and documentation requirements. Consider using Incoterms to clarify the responsibilities of both parties regarding shipping, insurance, and risk. Timing is crucial, so plan your orders based on lead times and ensure your supply chain can accommodate any potential delays. -

7. What are the key considerations for customizing electrical outlets for my market?

Customization of electrical outlets should focus on local market needs, such as plug types, voltage ratings, and safety features. Engage with local stakeholders to understand regulatory requirements and consumer preferences. Discuss customization options with your suppliers, including branding, color schemes, and additional functionalities like USB ports. Conduct market research to gauge demand and test prototypes to ensure they meet expectations before committing to large-scale production. -

8. How can I verify the compliance of electrical outlets with local safety standards?

To verify compliance, request certifications from your suppliers that demonstrate adherence to local and international safety standards, such as CE marking in Europe or SANS in South Africa. Conduct due diligence by checking supplier credentials and previous certifications. Additionally, consider third-party testing services to assess products before importing. Maintaining a checklist of compliance requirements for your target market will help streamline this process and ensure product safety.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for different types of outlets

In the realm of strategic sourcing for electrical outlets, understanding the diverse types and their applications is crucial for international B2B buyers. Each outlet type, from standard 15-amp duplex receptacles to GFCI and AFCI outlets, offers unique benefits tailored to specific environments and usage scenarios. For businesses in Africa, South America, the Middle East, and Europe, prioritizing the right outlets can significantly enhance operational efficiency, safety, and compliance with local regulations.

How Can Strategic Sourcing Enhance Your Supply Chain?

Strategic sourcing empowers companies to optimize their purchasing processes, ensuring that the outlets sourced align with both the technical requirements of their operations and the safety standards of their regions. By leveraging supplier relationships and understanding market dynamics, businesses can secure high-quality products at competitive prices.

What Should You Do Next?

As you move forward, consider conducting a thorough assessment of your electrical needs and the types of outlets required for your operations. Engage with reputable suppliers who can provide insights tailored to your specific market conditions. By making informed decisions today, you can ensure a safer, more efficient future for your electrical systems. Embrace the opportunity to elevate your sourcing strategy and drive your business success in an increasingly interconnected global marketplace.