Your Ultimate Guide to Sourcing Cnc Milling Machine 4 Axis

Introduction: Navigating the Global Market for cnc milling machine 4 axis

In today’s fast-evolving manufacturing landscape, the demand for precision and efficiency has never been higher. Among the technologies at the forefront of this transformation is the 4-axis CNC milling machine. This advanced machinery not only enhances production capabilities but also allows for the creation of intricate parts that meet the stringent quality standards of various industries, including aerospace, automotive, and medical. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the advantages and applications of 4-axis milling technology is crucial for making informed sourcing decisions.

This comprehensive guide aims to equip buyers with essential insights into the world of 4-axis CNC milling machines. It covers various aspects, including the different types of machines available, the materials they can handle, manufacturing and quality control practices, key suppliers in the market, and cost considerations. Additionally, we address frequently asked questions to clarify common concerns and challenges faced by businesses in diverse regions.

By delving into this guide, B2B buyers will be empowered to navigate the global market with confidence, ensuring they choose the right machinery to enhance their production processes. The knowledge gained here will not only facilitate better procurement strategies but also drive innovation and competitiveness in their respective industries.

Understanding cnc milling machine 4 axis Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vertical 4-Axis Mill | Features a vertical spindle and A-axis for rotation | Aerospace, Automotive, Medical | Pros: High precision, space-efficient. Cons: Limited to vertical machining; can be costly. |

| Horizontal 4-Axis Mill | Horizontal spindle, allows for larger workpieces | Heavy machinery, Aerospace components | Pros: Better chip removal, larger work envelope. Cons: Requires more floor space, higher maintenance. |

| 4-Axis CNC Lathe | Combines lathe operations with 4-axis capabilities | Aerospace, Automotive, Custom parts | Pros: Versatile for complex geometries. Cons: Higher setup costs, requires skilled operators. |

| 4-Axis Bridge Mill | Sturdy construction, ideal for heavy materials | Mold making, Aerospace, Construction | Pros: Excellent rigidity, large work area. Cons: Can be expensive, limited portability. |

| Gantry 4-Axis Machine | Large frame, ideal for oversized components | Shipbuilding, Aerospace, Heavy equipment | Pros: Capable of handling large parts. Cons: Requires substantial floor space, high initial investment. |

Vertical 4-Axis Mill

Vertical 4-axis mills utilize a vertical spindle, which allows for the rotation of the workpiece along the A-axis. This configuration is particularly suitable for applications that require high precision, such as in the aerospace and medical industries. Buyers should consider the machine’s footprint and the complexity of the parts they intend to produce, as the vertical orientation may limit certain machining operations compared to horizontal setups.

Horizontal 4-Axis Mill

Horizontal 4-axis mills feature a horizontal spindle, which can accommodate larger workpieces and facilitate better chip removal during machining. This type is widely used in heavy machinery and aerospace components, where robust machining capabilities are essential. Buyers should evaluate the available workspace since horizontal mills typically require more floor space. Additionally, maintenance costs can be higher due to the complexity of the machine.

4-Axis CNC Lathe

4-axis CNC lathes integrate lathe operations with the added functionality of a fourth axis, allowing for the machining of complex geometries. These machines are ideal for producing intricate components in the aerospace and automotive sectors. When purchasing, businesses should consider the types of materials they will be machining and the skill level required for operation, as these lathes can be more complex to program and operate.

4-Axis Bridge Mill

Bridge mills are characterized by their robust construction, making them ideal for machining heavy materials. They are commonly used in mold making and construction applications. Buyers should focus on the rigidity and stability of the machine, as these factors directly affect machining precision. While bridge mills offer a large work area, they can be expensive and may require a dedicated space due to their size.

Gantry 4-Axis Machine

Gantry 4-axis machines are designed to handle oversized components, making them popular in industries such as shipbuilding and aerospace. Their large frame allows for the machining of substantial parts with high precision. However, potential buyers must consider the significant floor space required for installation and the high initial investment. The capacity to produce large parts can outweigh these drawbacks for companies focused on large-scale production.

Related Video: How milling on a 4-axis CNC machine works

Key Industrial Applications of cnc milling machine 4 axis

| Industry/Sector | Specific Application of cnc milling machine 4 axis | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of turbine blades and engine components | High precision and consistency meet stringent aerospace standards | Supplier certifications, experience in aerospace applications, material quality |

| Automotive | Production of complex gearbox housings and engine parts | Efficient production reduces lead times and costs | Capability to handle various materials, precision machining capabilities |

| Medical Devices | Fabrication of custom implants and surgical instruments | Ability to create biocompatible parts with tight tolerances | Compliance with medical standards, expertise in titanium and stainless steel machining |

| Electronics | Production of intricate components like PCBs | Supports miniaturization trends in electronics manufacturing | Advanced technology for precision, reliable supply chain for materials |

| Industrial Equipment | Creation of complex machine parts and fixtures | Increases operational efficiency and reduces setup times | Flexibility in design changes, availability of technical support |

Aerospace Applications

In the aerospace industry, 4-axis CNC milling machines are essential for the manufacturing of turbine blades and engine components. These components require extreme precision and adherence to strict regulatory standards. The ability to machine parts from multiple angles in a single setup minimizes the risk of error and enhances the overall quality of the components. International buyers should prioritize suppliers with relevant certifications and proven experience in aerospace manufacturing to ensure compliance with industry standards.

Automotive Applications

The automotive sector leverages 4-axis CNC milling for the production of intricate gearbox housings and engine parts. This technology allows manufacturers to efficiently create complex geometries that modern vehicles demand for improved performance and efficiency. By reducing lead times and costs associated with multiple setups, businesses can remain competitive. When sourcing, buyers should consider suppliers that can handle a variety of materials and demonstrate precision machining capabilities.

Medical Device Applications

In the medical field, 4-axis CNC milling is utilized for fabricating custom implants and surgical instruments. The ability to work with biocompatible materials like titanium and stainless steel is crucial for creating medical devices that meet stringent safety and efficacy standards. Buyers from the medical industry must ensure that their suppliers comply with medical regulations and have expertise in machining sensitive materials, as this directly impacts patient safety.

Electronics Applications

The electronics industry benefits from 4-axis CNC milling in the production of intricate components, such as printed circuit boards (PCBs). As the trend toward miniaturization continues, the precision offered by 4-axis machines is vital for meeting the demands of modern electronic devices. Buyers should focus on sourcing suppliers that utilize advanced technology for precision machining and maintain a reliable supply chain for the necessary materials.

Industrial Equipment Applications

In the realm of industrial equipment, 4-axis CNC milling is employed to create complex machine parts and fixtures. This capability significantly enhances operational efficiency by reducing setup times and allowing for quick adjustments in design. Businesses looking to source these services should seek suppliers that offer flexibility in design changes and have strong technical support to address any machining challenges that may arise.

Strategic Material Selection Guide for cnc milling machine 4 axis

When selecting materials for CNC milling machines, particularly for 4-axis applications, it is essential to consider the specific properties and characteristics of each material. This section analyzes four common materials used in 4-axis CNC milling, focusing on their performance, advantages, disadvantages, and implications for international B2B buyers.

Aluminum Alloys

Key Properties: Aluminum alloys are lightweight, have excellent corrosion resistance, and can withstand moderate temperatures. They typically have a density of about 2.7 g/cm³ and can be easily machined to high tolerances.

Pros & Cons: The primary advantage of aluminum alloys is their low weight combined with high strength, making them ideal for aerospace and automotive applications. However, they can be more expensive than other materials, and their softness may lead to wear on cutting tools, increasing manufacturing complexity.

Impact on Application: Aluminum is compatible with various media, including air and liquids, and is often used in parts that require thermal conductivity, such as heat exchangers.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is crucial. Buyers should also consider local sourcing options, as aluminum can be more readily available in certain regions, reducing lead times.

Stainless Steel

Key Properties: Stainless steel is known for its high strength, durability, and excellent corrosion resistance. It can withstand high temperatures and pressures, making it suitable for demanding applications.

Pros & Cons: The key advantage of stainless steel is its robustness and resistance to oxidation, which is critical in the medical and food industries. However, it is more challenging to machine than aluminum, leading to higher tooling costs and longer production times.

Impact on Application: Stainless steel is widely used in environments where hygiene is paramount, such as medical devices and food processing equipment. Its compatibility with various chemicals also makes it suitable for chemical processing applications.

Considerations for International Buyers: Buyers must ensure that the stainless steel grades comply with local regulations, such as those set by the European Union (EU) for food safety. Understanding the specific grade requirements (e.g., 304 vs. 316) is essential for proper application.

Titanium Alloys

Key Properties: Titanium alloys are known for their exceptional strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. They are typically used in aerospace and medical applications due to their biocompatibility.

Pros & Cons: The primary advantage of titanium is its strength, which allows for thinner parts without sacrificing durability. However, it is significantly more expensive than aluminum and stainless steel, and its machining can be complex, requiring specialized tools.

Impact on Application: Titanium is ideal for applications in aerospace and medical implants, where performance and biocompatibility are critical. Its resistance to corrosion makes it suitable for marine applications as well.

Considerations for International Buyers: Buyers should be aware of the specific standards for titanium used in aerospace (e.g., ASTM F136) and medical applications (e.g., ISO 13485). Sourcing titanium can also be challenging, as it is less commonly available than aluminum or stainless steel.

Plastics (e.g., Polycarbonate, Nylon)

Key Properties: Engineering plastics like polycarbonate and nylon offer good strength, lightweight properties, and resistance to chemicals and impact. They are often used in applications requiring insulation and low friction.

Pros & Cons: The main advantage of plastics is their lower cost and ease of machining compared to metals. However, they may not withstand high temperatures as well as metals and can be less durable in harsh environments.

Impact on Application: Plastics are widely used in consumer products, electrical housings, and components where weight savings are essential. Their compatibility with various chemicals makes them suitable for many industrial applications.

Considerations for International Buyers: Buyers should consider the specific grades of plastics that meet industry standards, such as ASTM D638 for tensile properties. The availability of certain plastics may vary by region, affecting lead times and costs.

| Material | Typical Use Case for cnc milling machine 4 axis | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Aerospace components, automotive parts | Lightweight and corrosion-resistant | Higher tooling wear | Medium |

| Stainless Steel | Medical devices, food processing equipment | High strength and durability | Difficult to machine | High |

| Titanium Alloys | Aerospace, medical implants | Exceptional strength-to-weight ratio | Expensive and complex machining | High |

| Plastics | Consumer products, electrical housings | Lower cost and easy to machine | Limited high-temperature resistance | Low |

This strategic material selection guide provides B2B buyers with essential insights into common materials used in CNC milling machines, emphasizing the importance of understanding material properties, applications, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc milling machine 4 axis

Manufacturing Processes for 4-Axis CNC Milling Machines

Understanding the manufacturing processes involved in the production of 4-axis CNC milling machines is essential for B2B buyers, particularly those looking for efficiency, precision, and reliability in their procurement. The manufacturing process can be broadly categorized into several stages, each critical to ensuring the quality and performance of the final product.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Raw Materials: The choice of materials is crucial, often involving high-grade metals such as aluminum, steel, or specialized alloys to ensure durability and performance.

– Cutting and Shaping: Raw materials are cut to size using saws or laser cutters. This stage sets the foundation for subsequent processing and must adhere to specific tolerances. -

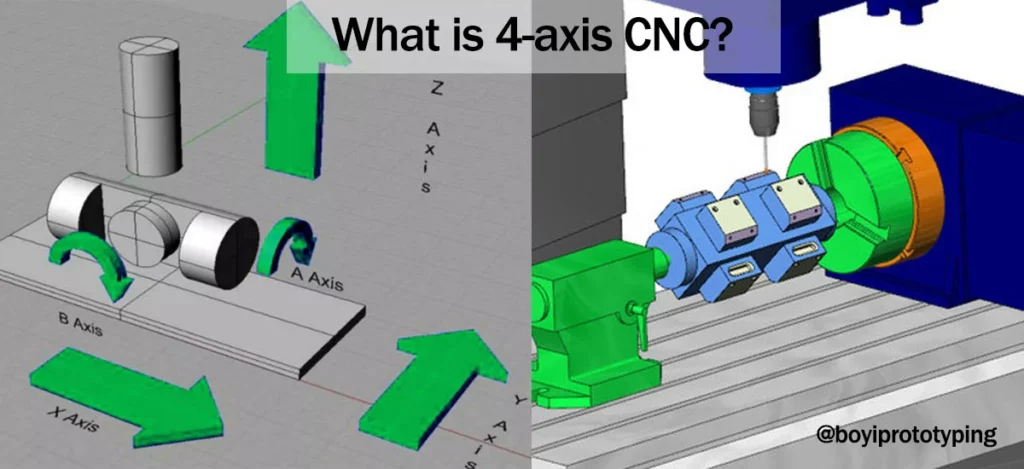

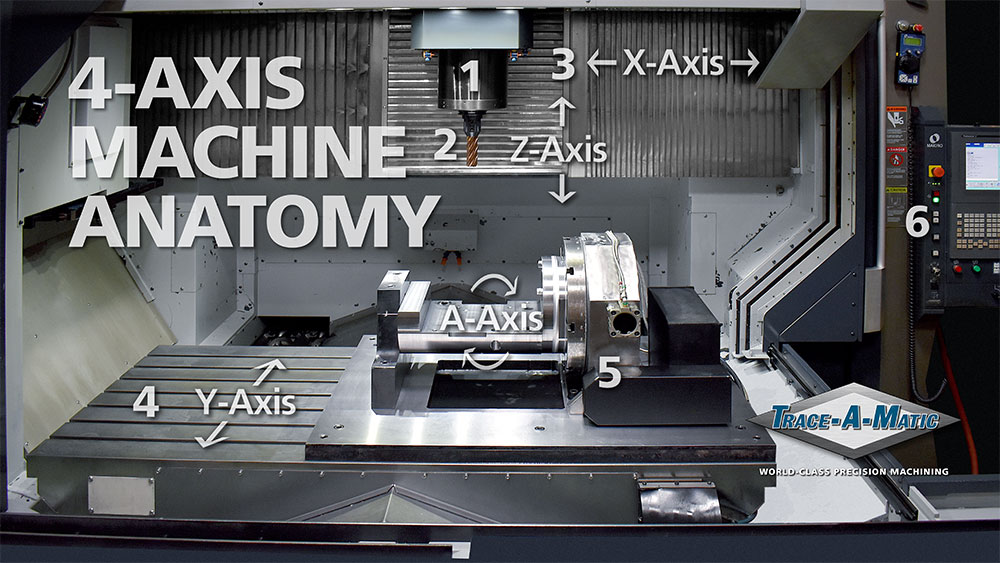

Forming

– CNC Machining: This is the heart of the 4-axis milling process. The machine utilizes its four axes (X, Y, Z, and A) to mill complex shapes and geometries. The ability to rotate the workpiece allows for intricate designs that are impossible with traditional 3-axis machines.

– Drilling and Tapping: Additional operations may include drilling holes or tapping threads, which are performed simultaneously with milling to enhance efficiency. -

Assembly

– Component Integration: After machining, individual components are assembled. This may involve fitting parts such as the spindle, rotary axis, and control systems. Precision in this stage is vital to ensure the machine operates smoothly.

– Calibration: The assembled machine undergoes calibration to confirm all components function correctly. This includes checking the alignment of the axes and ensuring the accuracy of movements. -

Finishing

– Surface Treatment: Techniques like anodizing, painting, or coating are applied to enhance the machine’s durability and aesthetics. This step is particularly important for machines that will operate in harsh environments.

– Final Inspection: A thorough inspection is conducted to ensure that the finished product meets all design specifications and quality standards before it is shipped to customers.

Quality Assurance in Manufacturing

Quality assurance is a critical aspect of the manufacturing process for 4-axis CNC milling machines. It ensures that products meet international standards and customer expectations.

Relevant International Standards

- ISO 9001: This standard outlines the requirements for a quality management system (QMS). Compliance indicates that the manufacturer has established processes for consistent quality, customer satisfaction, and continuous improvement.

- CE Marking: Essential for manufacturers in Europe, CE marking signifies that a product meets EU safety, health, and environmental protection requirements.

- API Standards: Particularly relevant in the oil and gas sector, API standards ensure that products meet specific performance criteria.

Quality Control Checkpoints

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards. This includes checking for material grades and dimensions.

-

In-Process Quality Control (IPQC): During manufacturing, processes are monitored continuously. This may involve real-time inspections of machining operations to catch any deviations early.

-

Final Quality Control (FQC): Before shipping, the finished product undergoes a comprehensive inspection. This includes dimensional checks, performance testing, and verification against specifications.

Common Testing Methods

- Dimensional Inspection: Utilizing tools such as calipers and micrometers to measure critical dimensions and tolerances.

- Functional Testing: Ensuring that all machine functions operate as intended, including movements along all axes.

- Stress Testing: Evaluating the machine’s performance under load conditions to ensure reliability during operation.

Verifying Supplier Quality Control

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is vital. Here are some strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing facilities, processes, and quality control measures in place. This firsthand assessment can reveal the supplier’s commitment to quality.

-

Requesting Quality Reports: Buyers should ask for detailed quality assurance reports that outline inspection results, compliance with international standards, and any corrective actions taken for non-conformities.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the manufacturing processes and the quality of the final products.

Quality Control Nuances for International Buyers

B2B buyers should be aware of specific nuances related to quality control when dealing with international suppliers:

-

Cultural Differences: Understanding cultural approaches to quality can vary significantly. Some regions may prioritize speed over thoroughness, while others may focus strictly on compliance with standards.

-

Documentation Requirements: Different countries may have varying requirements for documentation and certifications. It is essential to ensure that all necessary paperwork accompanies the product shipment, including material certifications and compliance documents.

-

Communication Barriers: Language differences can lead to misunderstandings regarding quality expectations. Establishing clear, written specifications and regular communication can mitigate these risks.

Conclusion

In summary, the manufacturing processes and quality assurance protocols for 4-axis CNC milling machines are intricate and critical for ensuring high-quality outputs. By understanding these processes and implementing thorough verification strategies, international B2B buyers can make informed decisions, ensuring they procure reliable and efficient machines that meet their operational needs.

Comprehensive Cost and Pricing Analysis for cnc milling machine 4 axis Sourcing

When sourcing a 4-axis CNC milling machine, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will cover the key cost components, factors influencing prices, and strategic tips for negotiating favorable terms.

Cost Components

-

Materials: The primary cost driver for a CNC milling machine is the raw materials used in manufacturing. High-quality steel and other alloys are often required for durability and precision, which can significantly impact the overall cost.

-

Labor: Skilled labor is essential in both the manufacturing of the machines and in their operation. Labor costs vary significantly by region, with countries in Europe and North America typically facing higher wage structures compared to regions in Africa and South America.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, maintenance, and administrative costs. Efficient manufacturing processes can help reduce these overheads, influencing the final pricing of the machines.

Illustrative Image (Source: Google Search)

-

Tooling: Custom tooling is often necessary for specialized applications, which can add to the initial investment. Depending on the complexity of the tools required, this cost can vary widely.

-

Quality Control (QC): Ensuring the precision and quality of the machining process often requires rigorous QC measures. This involves both time and resources, which should be factored into the overall cost.

-

Logistics: Shipping costs can fluctuate based on the origin of the machine, destination, and chosen Incoterms. Buyers must consider these logistics costs, especially for international shipments, which may also include tariffs or duties.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can vary based on competition and market demand.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders can lead to significant discounts. Buyers should assess their production needs and negotiate accordingly.

-

Specifications/Customization: Custom machines tailored to specific applications generally come at a premium. Buyers should be clear about their requirements to avoid unnecessary costs.

-

Materials: The choice of materials can greatly influence pricing. Opting for standard materials may reduce costs, while specialized materials can increase them.

-

Quality/Certifications: Machines that meet specific international quality standards or certifications often carry higher price tags. Buyers should weigh the importance of these certifications against their budget.

-

Supplier Factors: The reputation and experience of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer lower prices to build their market presence.

-

Incoterms: Understanding Incoterms is essential for international buyers as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Choosing favorable terms can lead to cost savings.

Buyer Tips

-

Negotiate: Don’t hesitate to negotiate terms and prices. Suppliers often have flexibility, especially with larger orders or long-term contracts.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs over the machine’s lifespan. This holistic view can lead to better investment decisions.

-

Pricing Nuances: Be aware that pricing can vary significantly based on geographical location and market conditions. Buyers from Africa, South America, the Middle East, and Europe should consider local supplier options to potentially reduce costs.

-

Research and Compare: Conduct thorough market research and obtain multiple quotes. This not only provides insight into standard pricing but also aids in identifying the best value offerings.

Disclaimer

Prices can fluctuate based on market conditions, material availability, and technological advancements. It is advisable for buyers to conduct their own research and obtain updated quotes to ensure accurate budgeting and sourcing decisions.

Spotlight on Potential cnc milling machine 4 axis Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘cnc milling machine 4 axis’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for cnc milling machine 4 axis

Understanding the technical properties and terminology associated with 4-axis CNC milling machines is essential for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. Here, we will outline critical specifications and common industry terms that can guide informed purchasing decisions.

Key Technical Properties of 4-Axis CNC Milling Machines

-

Material Grade

The material grade refers to the type of materials that can be machined using the CNC machine. Common materials include aluminum, stainless steel, titanium, and plastics. Understanding material compatibility is crucial as it influences the machine’s cutting capabilities, tool wear, and the final product’s quality. Buyers must ensure that the machine can handle the specific materials relevant to their production needs. -

Tolerance

Tolerance defines the allowable deviation from a specified dimension. In CNC machining, tighter tolerances indicate higher precision, which is essential in industries such as aerospace and medical devices. For B2B buyers, knowing the tolerance levels that a machine can achieve is vital for meeting industry standards and ensuring product quality. -

Spindle Speed

This property indicates how fast the spindle rotates, typically measured in revolutions per minute (RPM). Higher spindle speeds allow for faster material removal rates and better surface finishes. Buyers should consider the spindle speed relative to the materials they plan to work with, as certain materials require specific speeds for optimal machining. -

Cutting Feed Rate

The feed rate is the speed at which the cutting tool moves through the material. It is crucial for determining machining efficiency and the quality of the finished part. A balanced feed rate can enhance productivity while minimizing tool wear. Buyers should evaluate the machine’s capabilities to ensure it aligns with their production goals. -

Axis Configuration

The configuration of the axes (X, Y, Z, and A) directly affects the machine’s ability to create complex geometries. A well-configured 4-axis machine can perform intricate milling operations without needing multiple setups, thus saving time and increasing efficiency. Buyers should assess the specific configuration options available to ensure they meet their design requirements. -

Work Envelope

The work envelope refers to the maximum size of the workpiece that can be accommodated by the machine. Understanding the dimensions of the work envelope is essential for buyers to ensure that it fits their production needs, especially when dealing with large or uniquely shaped components.

Common Industry Terms

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. For B2B buyers, understanding OEM relationships can help in sourcing reliable parts and ensuring compatibility with existing machinery. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for buyers, as it affects inventory management and cost efficiency. Understanding MOQ helps in planning purchases and budgeting accordingly. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and other details for specific products. This process allows buyers to compare offers from different suppliers effectively, ensuring they secure the best deal for their needs. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers to clarify shipping costs, insurance, and the point at which risk transfers from seller to buyer. -

Lead Time

Lead time refers to the amount of time from placing an order to receiving the product. For B2B buyers, shorter lead times can enhance operational efficiency and responsiveness to market demands. Understanding lead times helps in planning production schedules effectively. -

Post-Processing

This term refers to the additional operations performed on a machined part after the initial machining process, such as polishing, coating, or finishing. B2B buyers should consider post-processing capabilities when evaluating CNC machines, as they can significantly impact the final product quality.

Equipped with this knowledge, B2B buyers can make informed decisions that align with their manufacturing needs and industry standards, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the cnc milling machine 4 axis Sector

Market Overview & Key Trends

The global market for 4-axis CNC milling machines is witnessing significant growth, driven by increasing demand for precision engineering and automation across various sectors, including aerospace, automotive, and healthcare. The ability to produce complex geometries with high accuracy is becoming a competitive advantage for manufacturers. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, navigate this landscape, they should be aware of several emerging trends.

Technological Advancements: The integration of Industry 4.0 technologies, such as IoT and AI, is transforming manufacturing processes. Real-time data analytics and predictive maintenance are enhancing machine performance and reducing downtime. Buyers should look for suppliers that offer machines equipped with these smart features.

Sourcing Strategies: There is a growing trend towards localized sourcing to mitigate risks associated with global supply chains. Buyers from regions like Africa and South America are increasingly engaging with local manufacturers to ensure quicker lead times and reduced shipping costs. This shift is also seen in Europe, where sustainability considerations are prompting companies to source materials closer to home.

Customization and Flexibility: As market demands shift, the need for customized solutions is paramount. 4-axis CNC machines that offer flexible configurations and can handle various materials are becoming highly sought after. B2B buyers should prioritize suppliers that can provide tailored solutions to meet specific manufacturing needs.

In summary, understanding these market dynamics will enable international buyers to make informed decisions, ensuring they are aligned with industry trends and technological advancements.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a crucial consideration in the procurement of 4-axis CNC milling machines. The manufacturing process of these machines can have significant environmental impacts, from energy consumption to waste generation. B2B buyers should prioritize sourcing from manufacturers that demonstrate a commitment to sustainability.

Environmental Impact: The CNC machining process can be energy-intensive, and the materials used can also contribute to environmental degradation. Buyers should seek machines that are energy-efficient and utilize sustainable practices in their production processes. This includes the use of recyclable materials and minimizing waste through advanced machining techniques.

Ethical Supply Chains: Establishing ethical supply chains is essential for maintaining brand integrity and compliance with international regulations. Buyers should engage with suppliers who can provide transparency regarding their sourcing practices and labor conditions. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can serve as indicators of a supplier’s commitment to ethical practices.

Green Certifications and Materials: When evaluating suppliers, consider those that offer products made from certified sustainable materials. The use of biodegradable lubricants and recyclable machine components can significantly reduce the environmental footprint of CNC machining operations.

By focusing on sustainability and ethical sourcing, international B2B buyers can contribute to a more responsible manufacturing ecosystem while enhancing their brand reputation.

Brief Evolution/History

The evolution of CNC machining, particularly the transition from 3-axis to 4-axis systems, has been pivotal in enhancing manufacturing capabilities. Initially, CNC machines operated solely on three linear axes, limiting their ability to create complex geometries. The introduction of the fourth axis allowed for rotation around the X-axis, enabling manufacturers to produce intricate designs in a single setup.

This shift not only improved precision and efficiency but also reduced lead times and costs associated with multiple setups. As industries continue to demand higher accuracy and complexity in their components, the 4-axis CNC milling machine has become a standard in modern manufacturing, paving the way for further advancements in automation and smart manufacturing technologies. Understanding this evolution is essential for B2B buyers as they seek to invest in the latest machining technologies that align with their operational goals.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc milling machine 4 axis

-

What should I consider when vetting suppliers for 4-axis CNC milling machines?

When vetting suppliers, prioritize their experience in manufacturing 4-axis CNC milling machines and their reputation in the industry. Request references from previous clients, particularly those in similar markets. Evaluate their production capabilities, quality control processes, and certifications such as ISO 9001. Additionally, consider their ability to provide after-sales support and spare parts availability, which are crucial for ongoing maintenance and operational efficiency. -

Can I customize a 4-axis CNC milling machine to fit my specific production needs?

Yes, many suppliers offer customization options for 4-axis CNC milling machines. This can include adjustments to the machine size, tooling, and software configurations to suit your specific production requirements. Be clear about your needs during initial discussions and request a detailed proposal outlining customization options, potential costs, and timelines. Customization may also impact lead times, so factor this into your planning. -

What are the typical minimum order quantities (MOQ) and lead times for 4-axis CNC milling machines?

MOQs for 4-axis CNC milling machines can vary significantly based on the supplier and the level of customization required. Typically, manufacturers may set an MOQ of one machine, especially for custom designs. Lead times also vary, generally ranging from 8 to 16 weeks, depending on the complexity of the machine and the supplier’s production schedule. Always confirm these details upfront to align your procurement strategy with your production timelines.

Illustrative Image (Source: Google Search)

-

What payment terms should I expect when purchasing a 4-axis CNC milling machine?

Payment terms for 4-axis CNC milling machines usually involve a deposit upfront, often between 30-50% of the total cost, with the balance due upon completion or delivery. Discuss these terms with your supplier, and ensure you understand any financing options they may offer. Additionally, consider using secure payment methods or escrow services to protect your investment, especially when dealing with international suppliers. -

How can I ensure quality assurance and certification compliance for my 4-axis CNC milling machine?

To ensure quality assurance, request documentation of the supplier’s quality management systems and relevant certifications, such as ISO 9001 or CE marking. It’s essential to inquire about their testing procedures and whether they conduct pre-shipment inspections. If possible, visit the supplier’s facility to observe their manufacturing processes and quality control measures firsthand, or consider hiring a third-party inspection service before finalizing your order. -

What logistical considerations should I keep in mind when importing a 4-axis CNC milling machine?

Logistics for importing a 4-axis CNC milling machine involve several factors, including shipping methods, customs clearance, and import duties. Work closely with your supplier to understand the shipping options available and choose one that balances cost and delivery time. Additionally, ensure you are aware of local regulations regarding machinery imports, including any specific documentation required for customs clearance to avoid delays. -

How should I handle disputes with my supplier regarding the 4-axis CNC milling machine?

In the event of a dispute, it is crucial to maintain clear communication with your supplier. Start by addressing the issue directly and documenting all correspondence. Refer to the terms outlined in your contract, including warranties and service agreements. If the issue cannot be resolved amicably, consider mediation or arbitration as stipulated in your contract. Having a clear dispute resolution process can help mitigate potential conflicts and protect your interests. -

What are the common maintenance requirements for a 4-axis CNC milling machine?

Regular maintenance of a 4-axis CNC milling machine is essential to ensure optimal performance and longevity. Key maintenance tasks include routine cleaning, lubrication of moving parts, and inspection of wear components such as belts and bearings. Develop a maintenance schedule based on the manufacturer’s recommendations and ensure that operators are trained to recognize signs of wear or malfunction. Establishing a preventive maintenance program can minimize downtime and reduce repair costs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cnc milling machine 4 axis

In conclusion, the strategic sourcing of 4-axis CNC milling machines presents a pivotal opportunity for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. The ability of 4-axis machining to produce complex geometries with high precision not only enhances product quality but also optimizes manufacturing efficiency. This technology reduces setup times and minimizes the need for multiple fixtures, ultimately leading to cost savings and improved production timelines.

Key takeaways include:

- Versatility and Precision: 4-axis machines can handle a variety of materials and intricate designs, making them suitable across multiple industries, including aerospace, automotive, and medical sectors.

- Strategic Investment: While the initial cost may be higher, the long-term benefits of increased efficiency and reduced production time justify the investment.

- Skilled Workforce Requirement: Successful implementation necessitates a trained workforce, emphasizing the importance of investing in human capital alongside technology.

As we look ahead, the demand for advanced machining solutions will continue to grow, driven by innovation and globalization. International buyers are encouraged to explore partnerships with reputable manufacturers and suppliers to leverage the benefits of 4-axis CNC technology. Embrace this opportunity to enhance your operational capabilities and stay competitive in the evolving marketplace.