Discover NEMA Plug Types: The Complete Sourcing Guide (2025)

Introduction: Navigating the Global Market for nema plug types

In the rapidly evolving landscape of global commerce, one key challenge that international B2B buyers face is sourcing the appropriate NEMA plug types to meet their operational needs. Understanding the nuances of NEMA connectors is crucial for businesses in regions such as Africa, South America, the Middle East, and Europe—including countries like Turkey and Nigeria—where diverse electrical standards can complicate procurement. This comprehensive guide delves into the various types of NEMA plugs, their applications across different industries, and the critical factors to consider when selecting the right connectors for your business.

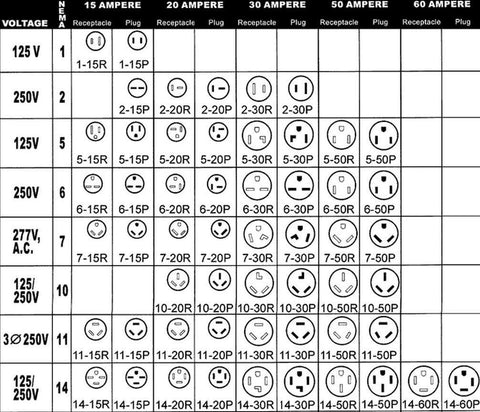

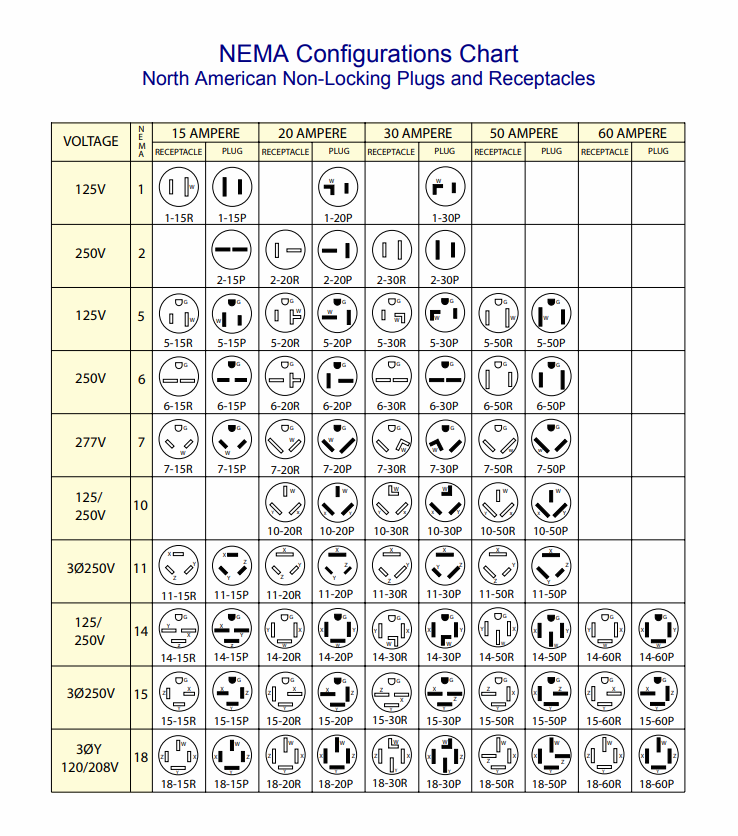

Throughout this guide, we will explore the full spectrum of NEMA plug configurations, including both non-locking and locking types, along with their respective voltage and amperage ratings. Additionally, we will provide insights on supplier vetting, cost considerations, and best practices for ensuring compliance with local electrical codes. By equipping B2B buyers with this knowledge, we aim to empower informed purchasing decisions that enhance operational efficiency and safety.

Navigating the complexities of NEMA plugs doesn’t have to be daunting. With our expert insights and practical advice, international buyers can streamline their sourcing processes, minimize risks, and ultimately drive successful outcomes in their projects.

Understanding nema plug types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| NEMA 5-15 | Standard 15A, 120V, three-prong configuration | Household appliances, IT equipment | Pros: Widely available, compatible with many devices. Cons: Limited to lower power applications. |

| NEMA 6-20 | 20A, 240V, with a T-shaped slot for versatility | Industrial equipment, HVAC systems | Pros: Supports higher power, versatile usage. Cons: Requires specific receptacles, not as common in residential. |

| NEMA L6-30 | Twist-lock design, 30A, 240V, secured connection | Generators, heavy machinery | Pros: Secure connection prevents accidental disconnection. Cons: More expensive, requires compatible receptacles. |

| NEMA TT-30 | 30A, 120V, used mainly for RVs, three-prong design | RV parks, outdoor events | Pros: Compatible with many RVs, easy to use. Cons: Limited to specific applications. |

| NEMA 14-50 | 50A, 240V, four-prong configuration | Electric vehicle charging, kitchen ranges | Pros: High power capacity, widely used for EVs. Cons: Requires specific installation, not suitable for lower power devices. |

What are the characteristics of NEMA 5-15 plugs and their suitability for B2B buyers?

The NEMA 5-15 plug is the most common type used in North America, featuring a three-prong configuration that includes a ground. Rated for 15 amps at 120 volts, it is predominantly found in household appliances and IT equipment, making it an essential choice for businesses that require compatibility with standard power sources. B2B buyers should consider the wide availability and lower cost of these plugs, although they are limited to lower power applications.

How does the NEMA 6-20 plug serve industrial applications?

The NEMA 6-20 plug is designed for higher power applications, rated at 20 amps and 240 volts. Its T-shaped slot allows for compatibility with both NEMA 6-15 and 6-20 receptacles, making it versatile for various industrial settings, including HVAC systems and heavy machinery. B2B buyers should evaluate the need for higher power capacity against the requirement for specific receptacles, as this may limit its use in residential settings.

Why choose NEMA L6-30 connectors for heavy-duty applications?

NEMA L6-30 connectors feature a twist-lock design that ensures a secure connection, making them ideal for generators and heavy machinery. With a rating of 30 amps at 240 volts, these connectors are suited for environments where accidental disconnection could pose safety risks. B2B buyers should consider the higher costs and the necessity for compatible receptacles when selecting this option for industrial applications.

What makes NEMA TT-30 connectors ideal for recreational vehicles?

The NEMA TT-30 plug is specifically designed for RVs, rated at 30 amps and 120 volts. Its three-prong design makes it easy to use in RV parks and outdoor events, ensuring compatibility with many recreational vehicles. While it offers convenience, B2B buyers should note that its applications are limited to the RV sector, which may not meet the needs of businesses outside this niche.

How does the NEMA 14-50 plug cater to electric vehicle charging needs?

The NEMA 14-50 plug is a four-prong connector rated for 50 amps at 240 volts, commonly used for electric vehicle charging stations and kitchen ranges. Its high power capacity makes it an excellent choice for businesses investing in electric vehicle infrastructure. B2B buyers should be aware of the installation requirements and ensure they have the appropriate receptacles, as this plug is not suitable for lower power devices.

Key Industrial Applications of nema plug types

| Industry/Sector | Specific Application of NEMA Plug Types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering Industrial Equipment | Ensures reliable power supply to machinery, minimizing downtime. | Voltage and amperage ratings, compatibility with existing systems. |

| Construction | Temporary Power Supply for Construction Sites | Provides safe and efficient power for tools and equipment on-site. | Weather resistance, portability, and ease of installation. |

| Telecommunications | Connecting Network Equipment | Facilitates stable power for servers and routers, enhancing uptime. | Grounding requirements, compatibility with local standards. |

| Hospitality | Powering Appliances in Hotels and Restaurants | Enhances guest experience with reliable power for amenities. | Compliance with local electrical codes and safety standards. |

| Renewable Energy | Charging Stations for Electric Vehicles | Supports sustainability initiatives and meets growing EV demand. | NEMA type selection based on charging requirements and locations. |

How Are NEMA Plug Types Used in Manufacturing Applications?

In the manufacturing sector, NEMA plug types are essential for powering various industrial equipment, such as conveyor systems, CNC machines, and robotic arms. Their reliable connections minimize the risk of downtime caused by power interruptions. Buyers in this sector must ensure that the plugs match the voltage and amperage ratings of their machinery, as well as compatibility with existing electrical systems. This is particularly crucial for international buyers who may encounter different voltage standards in regions like Africa and Europe.

What Are the Key Benefits of NEMA Plugs in Construction?

Construction sites often require temporary power solutions for tools and equipment, making NEMA plugs vital for safe and efficient operations. These plugs are designed for durability and ease of use, allowing quick connections for power tools and lighting. For B2B buyers in construction, sourcing weather-resistant NEMA plugs that can withstand outdoor conditions is crucial. Additionally, the portability of these plugs ensures they can be easily relocated as projects evolve.

How Do NEMA Plugs Enhance Telecommunications Infrastructure?

In telecommunications, NEMA plug types are used to connect essential network equipment such as servers, routers, and switches. A stable power supply is critical to maintaining uptime and preventing data loss. International buyers should consider grounding requirements and the compatibility of NEMA plugs with local electrical standards to ensure optimal performance. This is particularly important in regions like South America and the Middle East, where electrical infrastructure may vary.

Why Are NEMA Plugs Important in the Hospitality Sector?

The hospitality industry relies on NEMA plug types to power appliances in hotels and restaurants, enhancing the guest experience. Reliable power for amenities such as refrigerators, HVAC systems, and entertainment devices is essential. B2B buyers in this sector must ensure compliance with local electrical codes and safety standards to avoid potential hazards. Additionally, sourcing NEMA plugs that can handle the high power demands of commercial appliances is crucial for operational efficiency.

How Are NEMA Plugs Used in Renewable Energy Applications?

With the rise of electric vehicles (EVs), NEMA plug types are increasingly used in charging stations, supporting renewable energy initiatives. These plugs facilitate efficient charging for EVs, aligning with sustainability goals. Buyers must select the appropriate NEMA type based on the specific charging requirements and location of the stations. This consideration is particularly relevant for businesses in Europe and Africa, where EV adoption is rapidly increasing and infrastructure is evolving.

3 Common User Pain Points for ‘nema plug types’ & Their Solutions

Scenario 1: Misidentifying NEMA Plug Types During Procurement

The Problem: In the fast-paced world of international B2B transactions, procurement managers often face the daunting challenge of correctly identifying and specifying the right NEMA plug types for their electrical equipment. A buyer in Nigeria, for example, may intend to source NEMA 14-50 connectors for electric vehicle charging stations but inadvertently order NEMA 5-15 plugs instead. This misidentification can lead to costly delays, increased shipping fees for returns, and potential compliance issues with local electrical standards.

The Solution: To mitigate the risk of misidentification, B2B buyers should invest in comprehensive training for their procurement teams. This includes utilizing detailed NEMA plug charts that provide clear visual representations of various plug types, their specifications, and applications. Suppliers should be consulted to verify compatibility with the intended equipment. Additionally, establishing a reliable network of local electrical experts can ensure that the selected NEMA plugs meet both international standards and local regulations. Regular audits of existing equipment and plug types within the organization can also help in maintaining an accurate inventory and avoid future procurement errors.

Scenario 2: Incompatibility Issues with Existing Infrastructure

The Problem: B2B buyers in regions like South America may encounter significant compatibility issues when integrating new electrical equipment with existing infrastructure. For instance, a manufacturing facility may purchase state-of-the-art machinery requiring NEMA L6-30 locking plugs, yet the facility is predominantly outfitted with non-locking NEMA 5-20 receptacles. This mismatch not only hinders operational efficiency but also raises safety concerns.

The Solution: A thorough compatibility assessment should be a prerequisite before any new equipment purchase. Buyers must conduct an audit of their current electrical infrastructure, documenting the types of NEMA plugs and receptacles already in use. Once this assessment is complete, buyers can consult with suppliers to identify necessary adapters or converters to bridge the gap between different plug types. Engaging with a qualified electrician to upgrade the facility’s electrical systems to accommodate the new NEMA standards can ensure long-term compatibility and operational safety, reducing the risk of equipment damage and downtime.

Scenario 3: Safety Concerns with Non-Locking Plugs

The Problem: Safety is a paramount concern for B2B buyers, especially in industries such as construction or manufacturing where equipment is frequently moved or subject to vibrations. Buyers may purchase non-locking NEMA plugs, like the NEMA 5-15, for temporary connections, only to discover that these plugs can easily become disconnected, posing a risk of equipment damage or electrical hazards.

The Solution: To enhance safety, B2B buyers should prioritize the use of locking NEMA plugs, such as the NEMA L6 series, especially in environments where equipment is subject to movement or vibration. These plugs feature a locking mechanism that secures the connection, preventing accidental disconnections. Buyers should also develop standard operating procedures that mandate the use of locking connectors for specific applications. Moreover, providing training for personnel on the importance of using the correct plug types and the inherent risks associated with non-locking options can foster a safety-first culture in the workplace. Regular inspections of electrical connections should also be conducted to ensure that all equipment remains compliant and safe to operate.

Strategic Material Selection Guide for nema plug types

What Are the Key Materials Used in NEMA Plug Types?

When selecting NEMA plug types for various applications, the choice of materials is crucial. Different materials offer distinct properties that can significantly impact performance, durability, and overall suitability for specific environments. Below, we analyze four common materials used in NEMA plugs, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

A stock image related to nema plug types.

How Does Thermoplastic Affect NEMA Plug Performance?

Thermoplastics, such as Nylon and Polycarbonate, are widely used in NEMA plugs due to their excellent electrical insulation properties and resistance to impact and abrasion. These materials typically have a temperature rating of up to 100°C and can withstand moderate pressure.

Pros:

– Durability: Thermoplastics are resistant to wear and tear, making them suitable for residential and light industrial applications.

– Cost-Effective: Generally lower in cost compared to metals, which can reduce the overall manufacturing expense.

Cons:

– Temperature Limitations: While they can handle moderate temperatures, they may not be suitable for high-heat applications.

– Chemical Sensitivity: Some thermoplastics can degrade when exposed to harsh chemicals, limiting their use in certain environments.

Impact on Application:

Thermoplastics are ideal for household appliances and light-duty industrial applications, where electrical insulation and resistance to mechanical stress are paramount.

International Considerations:

Buyers in Africa, South America, the Middle East, and Europe should ensure compliance with local electrical standards, such as IEC or EN standards, which may dictate specific material requirements.

What Role Does Metal Play in NEMA Plug Construction?

Metals, particularly copper and brass, are often used for the conductive components of NEMA plugs. These materials provide excellent electrical conductivity and can handle higher temperatures and currents.

Pros:

– High Conductivity: Metals ensure efficient power transmission, making them suitable for high-performance applications.

– Corrosion Resistance: When treated or alloyed, metals can resist corrosion, enhancing longevity.

Cons:

– Cost: Metals can be more expensive than thermoplastics, increasing the overall cost of the plug.

– Weight: Metal components can add weight, which may be a consideration for portable applications.

Impact on Application:

Metal components are essential in applications requiring high power, such as industrial machines and electric vehicle charging stations.

International Considerations:

B2B buyers should be aware of standards like ASTM for metals, ensuring that the materials used meet specific conductivity and corrosion resistance criteria.

How Do Elastomers Enhance NEMA Plug Functionality?

Elastomers, such as silicone and rubber, are often used for sealing and insulation in NEMA plugs. They provide flexibility and resilience, which are critical in preventing moisture ingress and enhancing safety.

Pros:

– Flexibility: Elastomers can withstand bending and twisting without cracking, making them ideal for dynamic applications.

– Moisture Resistance: They effectively seal out moisture, which is essential in outdoor or humid environments.

Cons:

– Temperature Sensitivity: While many elastomers can handle a range of temperatures, extreme heat can degrade their properties.

– Cost Variability: High-quality elastomers can be more expensive than other materials.

Impact on Application:

Elastomers are particularly useful in outdoor applications or environments where moisture is a concern, such as marine or agricultural settings.

International Considerations:

Buyers should check for compliance with international standards like ISO or DIN, particularly for applications in harsh environments.

What Advantages Do Composite Materials Offer for NEMA Plugs?

Composite materials combine different materials to leverage the strengths of each. For NEMA plugs, composites can provide enhanced durability, electrical insulation, and resistance to environmental factors.

Pros:

– Versatility: Composites can be engineered to meet specific performance criteria, making them suitable for a wide range of applications.

– Lightweight: They often weigh less than metals while maintaining strength.

Cons:

– Manufacturing Complexity: The production of composite materials can be more complex, potentially increasing lead times.

– Cost: Depending on the formulation, composites can be more expensive than traditional materials.

Impact on Application:

Composites are ideal for specialized applications where traditional materials may fall short, such as in aerospace or high-performance electrical systems.

International Considerations:

B2B buyers should ensure that composites meet relevant international standards for electrical safety and environmental impact.

Summary Table of Material Properties for NEMA Plug Types

| Material | Typical Use Case for NEMA Plug Types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic | Household appliances, light industrial | Cost-effective and durable | Limited temperature resistance | Low |

| Metal | Industrial machines, EV charging stations | High conductivity | Higher cost and weight | High |

| Elastomer | Outdoor applications, moisture-sensitive areas | Flexibility and moisture resistance | Temperature sensitivity | Medium |

| Composite | Specialized applications, aerospace | Versatile and lightweight | Manufacturing complexity | High |

This guide provides international B2B buyers with actionable insights into the strategic selection of materials for NEMA plug types, ensuring they can make informed decisions tailored to their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for nema plug types

What Are the Main Stages in the Manufacturing Process of NEMA Plug Types?

The manufacturing process for NEMA plugs involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical to ensuring the final product meets the stringent requirements for safety, reliability, and performance.

-

Material Preparation: The first step involves selecting high-quality materials, typically copper for conductors and durable plastics or rubber for insulation and housing. Suppliers must ensure that materials meet international standards for conductivity and heat resistance. Conductors are often coated with nickel or tin to enhance corrosion resistance.

-

Forming: In this stage, the prepared materials are shaped into the required components. Techniques such as stamping and molding are commonly used. For example, metal parts may be stamped out to create the prongs and internal contacts, while plastic housings are molded to form the outer shell of the plugs. Precision in this stage is crucial to ensure a proper fit between plug and receptacle.

-

Assembly: Once all parts are formed, they are assembled. This includes inserting the conductors into the plastic housing and securing them. Automated assembly lines are often used to enhance efficiency and minimize human error. Quality assurance begins here, with inspections to ensure that components fit correctly and that there are no visible defects.

-

Finishing: The final stage involves finishing processes such as polishing, coating, and labeling. This step not only enhances the aesthetic appeal but also provides additional protection against environmental factors. For instance, surface treatments may be applied to improve durability and resistance to wear.

How Is Quality Assurance Implemented During NEMA Plug Manufacturing?

Quality assurance (QA) is paramount in the production of NEMA plugs, ensuring that each product adheres to both international and industry-specific standards. The following outlines the key QA practices and checkpoints:

-

International Standards: Many manufacturers adhere to ISO 9001, which outlines the criteria for a quality management system. This certification demonstrates the company’s commitment to consistent quality and customer satisfaction. Additionally, compliance with CE marking requirements is essential for products sold in the European market, indicating conformity with health, safety, and environmental protection standards.

-

Quality Checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards. For B2B buyers, ensuring that suppliers conduct rigorous IQC can prevent defects from entering the production line.

– In-Process Quality Control (IPQC): During the manufacturing process, random inspections are performed to identify any deviations from quality standards. This may include checking dimensions, electrical conductivity, and ensuring proper assembly.

– Final Quality Control (FQC): After assembly, finished products undergo comprehensive testing, including electrical tests, mechanical durability tests, and safety inspections. This stage ensures that the final product meets all performance and safety criteria before it is shipped. -

Testing Methods: Common testing methods include:

– Electrical Testing: Verifying that the plugs can handle the rated voltage and current without failure.

– Mechanical Testing: Assessing the durability of the plugs under stress conditions, ensuring they can withstand wear and tear.

– Environmental Testing: Subjecting plugs to extreme temperatures and humidity to ensure they perform reliably under different environmental conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe (e.g., Turkey, Nigeria), verifying supplier quality control is critical. Here are some actionable steps to ensure quality:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. During these audits, buyers should assess the supplier’s compliance with international standards, as well as their internal quality assurance protocols.

-

Requesting Quality Reports: Suppliers should provide documentation of their quality control processes, including IQC, IPQC, and FQC reports. These documents should detail testing methods, results, and any corrective actions taken for non-conformance.

-

Engaging Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased assessment of product quality. These inspectors can evaluate the manufacturing facility, conduct product tests, and provide detailed reports, ensuring that the products meet the agreed specifications.

-

Understanding Certification Nuances: Buyers should familiarize themselves with the specific certifications relevant to their regions. For instance, while CE marking is crucial for European markets, other regions may have different standards that need to be adhered to. Understanding these nuances can help buyers select the right suppliers.

What Are the Challenges in Quality Control for International B2B Buyers?

International buyers face unique challenges when it comes to quality control. These may include:

-

Regulatory Differences: Different countries have varying standards and regulations regarding electrical products. Buyers must ensure that their suppliers are compliant with both local and international regulations to avoid potential issues.

-

Cultural Differences: Variations in manufacturing practices and quality expectations can lead to misunderstandings. Establishing clear communication channels and expectations with suppliers is essential.

-

Supply Chain Complexity: Global supply chains can introduce risks related to logistics, including delays and damage during transportation. Buyers should work closely with suppliers to establish robust logistics and handling procedures to mitigate these risks.

-

Time Zone Challenges: Time zone differences can complicate communication and the resolution of quality issues. Utilizing technology for real-time communication can help bridge this gap.

By understanding the manufacturing processes and quality assurance practices related to NEMA plug types, international B2B buyers can make informed decisions, ensuring they partner with reliable suppliers that meet their quality and compliance needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nema plug types’

In this guide, we will outline a practical step-by-step checklist for B2B buyers looking to procure NEMA plug types. Understanding and sourcing the correct NEMA connectors is essential for ensuring compatibility with electrical systems and safety standards in various applications, especially in regions like Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Start by determining the technical requirements for your application. This includes voltage ratings, amperage ratings, and the specific plug configuration needed (e.g., NEMA 5-15, NEMA 14-50). Knowing these specifications helps you avoid compatibility issues later on, ensuring that the plugs you purchase will meet the operational demands of your devices.

- Voltage and Amperage: Confirm the voltage and amperage requirements of your equipment to select appropriate NEMA types.

- Plug Configuration: Identify if you need locking or non-locking connectors based on your application environment.

Step 2: Research NEMA Plug Types

Familiarize yourself with the various NEMA plug types and their applications. Each type has unique characteristics that cater to different electrical needs and environments.

- Common Types: Focus on widely used NEMA types like NEMA 5-15 for residential applications or NEMA L6-30 for industrial settings.

- Application Suitability: Understand which plug types are best suited for your specific requirements, such as heavy-duty use or compatibility with electric vehicles.

Step 3: Evaluate Potential Suppliers

Conduct thorough evaluations of potential suppliers to ensure they meet your requirements. This step is critical to avoid disruptions in your supply chain.

- Supplier Credentials: Request company profiles and check for certifications that validate their compliance with international standards.

- Customer References: Ask for references from other businesses, particularly those in your region or industry, to gauge supplier reliability.

Step 4: Check for Quality Assurance

Quality assurance is vital when sourcing electrical components. Ensure that the NEMA plugs meet the required safety and performance standards.

- Certification Standards: Look for certifications such as UL or CSA to verify that the plugs have passed rigorous testing.

- Material Quality: Assess the materials used in the plugs to ensure durability and resistance to environmental factors, particularly for outdoor applications.

Step 5: Request Samples for Testing

Before finalizing your order, request samples of the NEMA plugs you are considering. This allows you to test compatibility and performance with your existing systems.

- Compatibility Testing: Check if the samples fit well with your devices and meet the specified technical requirements.

- Performance Evaluation: Test the plugs under operational conditions to ensure they can handle the expected load without overheating or failing.

Step 6: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations regarding pricing, delivery terms, and after-sales support.

- Volume Discounts: Discuss potential discounts for bulk orders to optimize your procurement budget.

- Delivery Schedule: Confirm lead times and shipping options, especially if you are operating on tight deadlines.

Step 7: Finalize the Purchase Agreement

After all terms are agreed upon, draft and finalize the purchase agreement. Ensure it includes all necessary details such as pricing, delivery timelines, and warranty information.

- Contract Clarity: Be clear on return policies and support services in case the products do not meet your expectations.

- Legal Compliance: Ensure that the agreement adheres to local and international trade laws relevant to your business operations.

Following this checklist will help you make informed decisions when sourcing NEMA plug types, ultimately leading to successful procurement and operational efficiency.

Comprehensive Cost and Pricing Analysis for nema plug types Sourcing

What Are the Key Cost Components in NEMA Plug Types Sourcing?

When sourcing NEMA plug types, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. For example, high-quality copper for conductors or durable thermoplastics for housing can increase the unit price. Sourcing materials locally may reduce costs, but quality and certification should not be compromised.

-

Labor: Labor costs vary depending on the region and the complexity of the assembly process. In regions with lower labor costs, such as parts of Africa or South America, buyers might find more competitive pricing. However, be mindful of potential trade-offs in quality.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Companies with efficient manufacturing processes can offer more competitive prices, so assessing a supplier’s operational efficiency is essential.

-

Tooling: Custom tooling for specific NEMA configurations can be a significant upfront cost. Buyers should inquire about tooling costs, especially if customization is required for unique applications.

-

Quality Control (QC): Rigorous QC processes can add to the cost but are vital for ensuring product reliability. Look for suppliers who have established QC standards and certifications that meet international standards.

-

Logistics: Transportation costs can vary greatly depending on the origin of the products and the destination. International shipping, customs duties, and insurance must be factored into the total cost.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding typical margins in the industry can help buyers negotiate better deals.

What Factors Influence Pricing of NEMA Plug Types?

Several factors can influence the pricing of NEMA plugs:

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing. Bulk orders often lead to discounts, making it beneficial for buyers to consolidate their orders when possible.

-

Specifications and Customization: Custom specifications can lead to higher prices due to the need for specialized tooling and longer production times. Clearly defining requirements upfront can help control costs.

-

Materials Quality and Certifications: Higher-quality materials and certifications (e.g., UL, CE) can lead to increased prices but may offer better performance and safety assurance, which is crucial for industrial applications.

-

Supplier Factors: Supplier reputation and reliability can affect pricing. Established suppliers may charge more due to their proven track record, but they often provide better customer service and product reliability.

-

Incoterms: The choice of Incoterms can influence logistics costs. Understanding terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential for calculating total landed costs.

How Can International B2B Buyers Optimize Costs When Sourcing NEMA Plug Types?

To optimize costs effectively, buyers should consider the following strategies:

-

Negotiation: Establishing a good relationship with suppliers can lead to better pricing. Negotiating terms, especially for larger orders, can yield significant savings.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO) rather than just the initial purchase price. This includes maintenance, longevity, and energy efficiency of NEMA plugs, which can impact overall costs over time.

-

Understanding Pricing Nuances: Pricing can vary based on local market conditions, currency fluctuations, and geopolitical factors. Buyers should remain informed about these factors, especially when sourcing from regions like Africa or the Middle East.

-

Seek Local Suppliers: Whenever possible, sourcing from local manufacturers can reduce logistics costs and lead to faster delivery times. Additionally, local suppliers may have a better understanding of regional electrical standards.

-

Research and Compare: Conduct thorough research on multiple suppliers to compare prices, quality, and service. Utilize online platforms and industry networks to gather information on potential vendors.

Disclaimer on Pricing

Prices for NEMA plug types can fluctuate based on market conditions, supplier pricing strategies, and international trade dynamics. It is advisable for buyers to request quotes from multiple suppliers and conduct due diligence before making purchasing decisions.

Alternatives Analysis: Comparing nema plug types With Other Solutions

Exploring Alternatives to NEMA Plug Types: A Comparative Analysis

In the realm of electrical connectivity, NEMA plug types have established themselves as a reliable standard, particularly in North America. However, international B2B buyers from regions like Africa, South America, the Middle East, and Europe may encounter varying needs that call for alternative solutions. Understanding these alternatives can help buyers make informed decisions based on performance, cost, ease of implementation, and maintenance.

Comparison Table of NEMA Plug Types and Alternatives

| Comparison Aspect | NEMA Plug Types | IEC 60309 Connectors | CEE 7/7 Connectors |

|---|---|---|---|

| Performance | Reliable for 15-60A; good for residential and light industrial use | High performance; suitable for heavy-duty applications | Versatile; supports various voltage and current ratings |

| Cost | Generally low-cost; widely available | Moderate to high; specialized suppliers required | Low to moderate; commonly used in Europe |

| Ease of Implementation | Easy to install; common in North America | Requires specific installation knowledge | Straightforward installation; compatible with many devices |

| Maintenance | Low maintenance; durable materials | Moderate; may require periodic checks | Low; robust design minimizes wear |

| Best Use Case | Home appliances, EV charging, light industrial | Industrial machinery, construction equipment | General European electrical needs, including appliances |

What Are IEC 60309 Connectors and Their Advantages?

IEC 60309 connectors, also known as “commando” plugs, are designed for high-performance applications, particularly in industrial settings. These connectors can handle higher voltages and currents, making them ideal for heavy-duty machinery and equipment. One of the key advantages is their locking mechanism, which prevents accidental disconnection—a crucial feature in environments where reliability is paramount. However, their higher cost and the need for specialized installation knowledge can be a drawback for some buyers.

How Do CEE 7/7 Connectors Compare?

CEE 7/7 connectors are a popular alternative, especially in European markets. They are versatile and can accommodate various voltage and current ratings, making them suitable for a wide range of applications from residential to commercial use. The CEE 7/7 is designed for safety and reliability, often used for devices like kitchen appliances and power tools. While they are generally low-cost and easy to implement, their compatibility with non-European systems may pose challenges for international buyers.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right electrical connectivity solution involves evaluating your specific requirements against the available options. NEMA plug types are excellent for standard North American applications, but if your operations extend internationally or involve heavy-duty machinery, considering alternatives like IEC 60309 or CEE 7/7 connectors may be beneficial. Assess factors such as performance needs, budget constraints, and installation capabilities to make an informed decision that aligns with your business objectives.

Essential Technical Properties and Trade Terminology for nema plug types

What Are the Key Technical Properties of NEMA Plug Types?

Understanding the technical specifications of NEMA plug types is essential for international B2B buyers to ensure compatibility and safety in electrical applications. Here are some critical specifications to consider:

1. Material Grade

The materials used in NEMA plugs are often thermoplastic or thermoset plastics, and sometimes metal components for durability. The choice of material affects the plug’s resistance to heat, corrosion, and mechanical stress. Buyers should prioritize plugs made from high-grade materials to ensure longevity and reliability, especially in harsh industrial environments.

2. Current Rating

NEMA plugs come with various current ratings, typically ranging from 15A to 60A. The current rating determines how much electrical current the plug can safely handle without overheating. It is crucial for buyers to match the plug’s current rating with the application’s requirements to avoid equipment failure or hazards.

3. Voltage Rating

The voltage rating of NEMA plugs varies from 125V to 600V, depending on the specific type. This rating indicates the maximum voltage the plug can safely operate at. For international buyers, understanding voltage compatibility is vital, especially when importing equipment from regions with different electrical standards.

4. Pin Configuration

NEMA plugs feature distinct pin configurations that dictate their compatibility with outlets. Each NEMA type has a specific layout of pins, which may include grounding pins or different shapes for locking mechanisms. Buyers must ensure that the plug’s configuration aligns with the corresponding outlet to guarantee a secure connection.

5. Temperature Rating

Temperature ratings indicate the maximum operating temperature for NEMA plugs. This specification is particularly important in environments where heat generation is a concern, such as industrial settings. Selecting plugs with adequate temperature ratings helps prevent premature failure.

6. Durability Rating

Durability ratings assess the plug’s ability to withstand mechanical wear and environmental conditions. This includes resistance to impacts, moisture, and exposure to chemicals. For B2B buyers, investing in high-durability plugs can reduce maintenance costs and downtime.

What Are Common Trade Terms Related to NEMA Plugs?

Navigating the landscape of NEMA plug procurement involves understanding various industry terms that can influence purchasing decisions. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces components or products that are sold under another company’s brand. For buyers, working with reputable OEMs ensures product quality and compatibility, especially when integrating NEMA plugs into larger systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is essential for B2B buyers, as it can affect inventory management and cost efficiency. Buyers should negotiate MOQ terms that align with their project needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent by buyers to suppliers to solicit price quotes for specific products or services. For international buyers, issuing RFQs for NEMA plugs can streamline the procurement process and ensure competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping, insurance, and customs duties, thereby minimizing risks in cross-border trade.

5. Certification Standards

Certification standards, such as UL (Underwriters Laboratories) or CE (Conformité Européenne), indicate that a product meets specific safety and quality criteria. Buyers should look for NEMA plugs that have relevant certifications to ensure compliance with local regulations and safety standards.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing NEMA plugs, ultimately enhancing their operational efficiency and safety.

Navigating Market Dynamics and Sourcing Trends in the nema plug types Sector

What Are the Current Market Dynamics and Key Trends in the NEMA Plug Types Sector?

The NEMA plug types sector is experiencing significant growth driven by the increasing demand for standardized electrical connections across various industries. Global drivers include the expansion of the electric vehicle (EV) market, the rise in renewable energy installations, and the growing need for reliable power solutions in both residential and commercial sectors. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, these trends present unique opportunities.

Emerging B2B technology trends include the adoption of smart plug technologies that integrate Internet of Things (IoT) capabilities, allowing for more efficient energy management and monitoring. This is particularly relevant for regions undergoing rapid urbanization, where energy demands are expected to surge. Additionally, the push for industrial automation is driving the need for specialized NEMA connectors that can withstand harsher environments while ensuring safety and reliability.

Moreover, the market dynamics are influenced by regulatory changes aimed at enhancing safety standards and energy efficiency. Buyers should be aware of the certification requirements in their respective regions, as these can impact the sourcing of compliant products. By staying informed about these trends, B2B buyers can make strategic sourcing decisions that align with their operational needs and compliance requirements.

How Can Sustainability and Ethical Sourcing Impact NEMA Plug Types Procurement?

Sustainability is becoming increasingly crucial in the procurement of NEMA plug types, particularly as industries strive to reduce their environmental footprints. The production of electrical components can have significant environmental impacts, including resource depletion and waste generation. B2B buyers must prioritize suppliers that implement sustainable practices, such as using recycled materials or low-impact manufacturing processes.

A stock image related to nema plug types.

Ethical sourcing is also essential, as buyers should ensure that their suppliers adhere to fair labor practices and environmental regulations. This is particularly relevant for international buyers who may be sourcing from regions with varying labor standards. Certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

By prioritizing sustainability and ethical sourcing, B2B buyers not only contribute to environmental preservation but also enhance their brand reputation and customer loyalty. As consumers become more conscious of their purchasing decisions, businesses that demonstrate a commitment to sustainability are likely to gain a competitive edge in the marketplace.

What Is the Historical Context of NEMA Plug Types and Their Evolution?

The NEMA plug types have a rich history that dates back to the formation of the National Electrical Manufacturers Association in 1926. Initially, the lack of standardized electrical connections resulted in compatibility issues across devices and installations. The establishment of NEMA standards aimed to address these concerns by providing uniform plug and receptacle configurations, enhancing safety and usability.

Over the decades, the NEMA standards have evolved to accommodate advancements in technology and changing consumer needs. The introduction of various plug types, including locking and non-locking configurations, has allowed for greater versatility in applications ranging from residential to industrial settings. Today, NEMA connectors are integral to powering a wide array of devices, including EV chargers, machinery, and home appliances.

For B2B buyers, understanding this historical context can provide insights into the reliability and safety of NEMA plug types. As the market continues to evolve, being aware of past developments can inform future sourcing strategies, ensuring that buyers select products that meet current standards while anticipating future innovations.

Frequently Asked Questions (FAQs) for B2B Buyers of nema plug types

-

How do I identify the correct NEMA plug type for my equipment?

To identify the correct NEMA plug type for your equipment, first check the equipment’s specifications for voltage and amperage requirements. Use a NEMA plug chart to match these requirements with the appropriate NEMA configuration. If possible, physically inspect the existing plug and outlet to ensure compatibility. For international buyers, it’s vital to consider local electrical standards and regulations to avoid costly errors. If in doubt, consult with suppliers or manufacturers who can provide detailed technical support. -

What is the best NEMA plug type for industrial applications?

For industrial applications, the NEMA L6 and L14 series are often the best choices due to their locking mechanism that ensures a secure connection. NEMA L6 plugs, rated for 30 amps at 240 volts, are ideal for heavy-duty equipment like generators, while NEMA L14 plugs offer a four-wire configuration suitable for high-demand applications like electric ranges or EV chargers. Always assess the specific power requirements and environmental conditions of your application before making a selection. -

How can I ensure the quality of NEMA plugs when sourcing from suppliers?

To ensure quality when sourcing NEMA plugs, conduct thorough supplier vetting. Check for certifications such as UL or CE, which indicate compliance with safety standards. Request samples before placing bulk orders to assess build quality. Additionally, consider suppliers with a robust quality assurance process, including testing for durability and performance. Engage with other buyers or industry contacts for feedback on supplier reliability. -

What are the minimum order quantities (MOQs) for NEMA plugs?

Minimum order quantities for NEMA plugs can vary widely among suppliers, typically ranging from 100 to several thousand units. It’s essential to clarify MOQs upfront, especially if you are a smaller business or new to importing. Some suppliers may offer flexibility on MOQs for first-time buyers or bulk purchases. Discuss potential options for reducing MOQs, such as combining orders with other products.

A stock image related to nema plug types.

-

What payment terms should I negotiate with NEMA plug suppliers?

When negotiating payment terms with NEMA plug suppliers, aim for terms that balance cash flow and risk. Common arrangements include a 30% deposit upfront with the remaining 70% upon delivery, or net 30 days after receipt of goods. Consider using secure payment methods such as letters of credit or escrow services for larger transactions. Always ensure that payment terms are clearly outlined in the purchase agreement to prevent misunderstandings. -

How do logistics and shipping impact the sourcing of NEMA plugs?

Logistics and shipping play a critical role in sourcing NEMA plugs, particularly for international buyers. Understand the shipping options available, including air freight for faster delivery or sea freight for cost savings on larger orders. Factor in customs regulations and duties that may apply to electrical components in your country. Work with suppliers who have experience in international shipping to streamline the process and minimize delays. -

Can NEMA plugs be customized for specific applications?

Yes, many suppliers offer customization options for NEMA plugs to meet specific application needs. Customizations may include modifications to voltage ratings, amperage, or unique configurations for specialized equipment. Discuss your requirements with potential suppliers and request detailed specifications on available custom options. Be aware that customization may affect lead times and costs, so plan accordingly. -

What are the common challenges faced when sourcing NEMA plugs internationally?

Common challenges when sourcing NEMA plugs internationally include navigating different electrical standards, ensuring product compliance with local regulations, and managing shipping logistics. Additionally, language barriers and cultural differences can complicate communication with suppliers. To mitigate these challenges, conduct thorough research on local standards and establish clear communication channels with suppliers. Engaging a local representative or consultant may also help facilitate smoother transactions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for nema plug types

As the global demand for standardized electrical solutions continues to rise, understanding NEMA plug types becomes crucial for international B2B buyers. The versatility of NEMA connectors, ranging from non-locking options for residential use to locking configurations for industrial applications, allows businesses to select the most appropriate solutions tailored to their operational needs.

How Can Strategic Sourcing Enhance Your NEMA Plug Procurement?

Engaging in strategic sourcing not only streamlines the procurement process but also ensures compliance with safety standards while optimizing costs. By leveraging local suppliers in regions such as Africa, South America, the Middle East, and Europe, businesses can enhance their supply chain resilience and minimize lead times.

What Should International Buyers Consider When Sourcing NEMA Plugs?

It’s imperative for buyers to assess compatibility with existing infrastructure and the specific requirements of their operations. Additionally, staying informed about the latest developments in NEMA standards will provide a competitive edge in a rapidly evolving market.

In conclusion, as the landscape of electrical solutions evolves, proactive engagement in strategic sourcing will empower international buyers to make informed decisions. By prioritizing quality, compatibility, and supplier relationships, businesses can position themselves for success in both current and future markets.