The Ultimate Guide to Switches Electric (2025)

Introduction: Navigating the Global Market for switches electric

Navigating the global market for electric switches presents a unique set of challenges for B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe. With a vast array of products available, sourcing reliable and cost-effective electric switches can often be daunting. This comprehensive guide aims to simplify the purchasing process by covering a broad spectrum of topics, including different types of switches, their applications, supplier vetting strategies, and cost considerations.

International buyers will find actionable insights on selecting the right electric switches tailored to their specific needs, whether for commercial, industrial, or residential projects. With an emphasis on understanding regional compliance standards and product specifications, this guide empowers decision-makers to make informed choices that align with both budgetary constraints and operational requirements.

By addressing common pain points in sourcing and procurement, such as fluctuating prices and varying quality standards, this resource serves as a vital tool for navigating the complexities of the electric switch market. Buyers can leverage this information to enhance their supply chain efficiency and ensure that they partner with trustworthy suppliers who meet their unique demands. Ultimately, this guide is designed to facilitate smarter purchasing decisions, helping businesses thrive in an increasingly interconnected global marketplace.

Understanding switches electric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single Pole Switch | Controls one circuit; simple on/off functionality | Residential and commercial lighting | Pros: Easy installation; cost-effective. Cons: Limited to one circuit control. |

| Three-Way Switch | Allows control of a single light from two locations | Hallways, staircases, large rooms | Pros: Enhances convenience; ideal for large spaces. Cons: More complex wiring. |

| Smart Switch | Wi-Fi or Bluetooth enabled; programmable via apps | Smart buildings, energy management | Pros: Energy efficiency; remote control capabilities. Cons: Higher upfront cost; requires stable internet. |

| Dimmer Switch | Adjusts light intensity; compatible with various bulbs | Ambiance control in commercial spaces | Pros: Energy savings; customizable lighting. Cons: May require specific bulbs; more expensive than standard switches. |

| Double Pole Switch | Controls two circuits; often used for heavy loads | Industrial applications; HVAC systems | Pros: Versatile for high-power applications; safer for dual circuits. Cons: Requires more space; higher installation complexity. |

What Are the Key Characteristics of a Single Pole Switch?

A single pole switch is the most basic type of switch, designed to control one circuit from a single location. Its simplicity makes it a popular choice in residential and commercial lighting applications. B2B buyers should consider its ease of installation and low cost. However, its limitation to controlling only one circuit may not meet the needs of more complex setups.

How Does a Three-Way Switch Enhance Convenience?

Three-way switches enable control of a single light fixture from two different locations, making them ideal for hallways, staircases, and large rooms. This type of switch is particularly useful in commercial spaces where convenience and accessibility are crucial. While they offer significant advantages in usability, buyers must consider the complexity of installation and wiring.

Why Choose a Smart Switch for Modern Applications?

Smart switches are equipped with Wi-Fi or Bluetooth capabilities, allowing users to control lighting remotely through applications. They are becoming increasingly popular in smart building designs and energy management systems. B2B buyers should evaluate the potential for energy savings and the convenience of remote access. However, the higher initial investment and dependency on stable internet connections can be drawbacks.

What Benefits Do Dimmer Switches Provide for Commercial Spaces?

Dimmer switches allow users to adjust light intensity, enhancing ambiance and energy efficiency in commercial settings. They are compatible with various types of bulbs, offering flexibility in lighting design. Buyers should consider the long-term energy savings and aesthetic control they provide. However, dimmer switches may require specific bulbs and can be pricier than standard options.

What Are the Advantages of Using a Double Pole Switch?

Double pole switches control two circuits simultaneously, making them suitable for heavy loads in industrial applications, such as HVAC systems. They offer versatility and increased safety for dual circuit management. B2B buyers must assess the additional space required for installation and the complexity involved, which may be a consideration for smaller projects.

Key Industrial Applications of switches electric

| Industry/Sector | Specific Application of switches electric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Control panels for machinery | Enhanced operational efficiency and safety | Compliance with local electrical standards, durability, and reliability |

| Commercial Buildings | Smart lighting control systems | Energy savings and improved user experience | Compatibility with existing systems, scalability, and ease of installation |

| Agriculture | Automated irrigation systems | Increased crop yield and resource management | Weather resistance, remote control capabilities, and power ratings |

| Telecommunications | Data center power management | Reliable uptime and reduced operational costs | High amperage ratings, safety certifications, and adaptability to various voltages |

| Healthcare | Patient room control systems | Improved patient comfort and operational efficiency | Compliance with healthcare regulations, ease of use, and reliability |

How Are Switches Electric Used in Manufacturing?

In the manufacturing sector, switches electric are integral to control panels that manage machinery operations. These switches facilitate seamless control over equipment, ensuring safe and efficient production processes. International buyers must consider local electrical standards and durability to withstand rigorous industrial environments. Additionally, reliability is crucial, as equipment downtime can lead to significant financial losses.

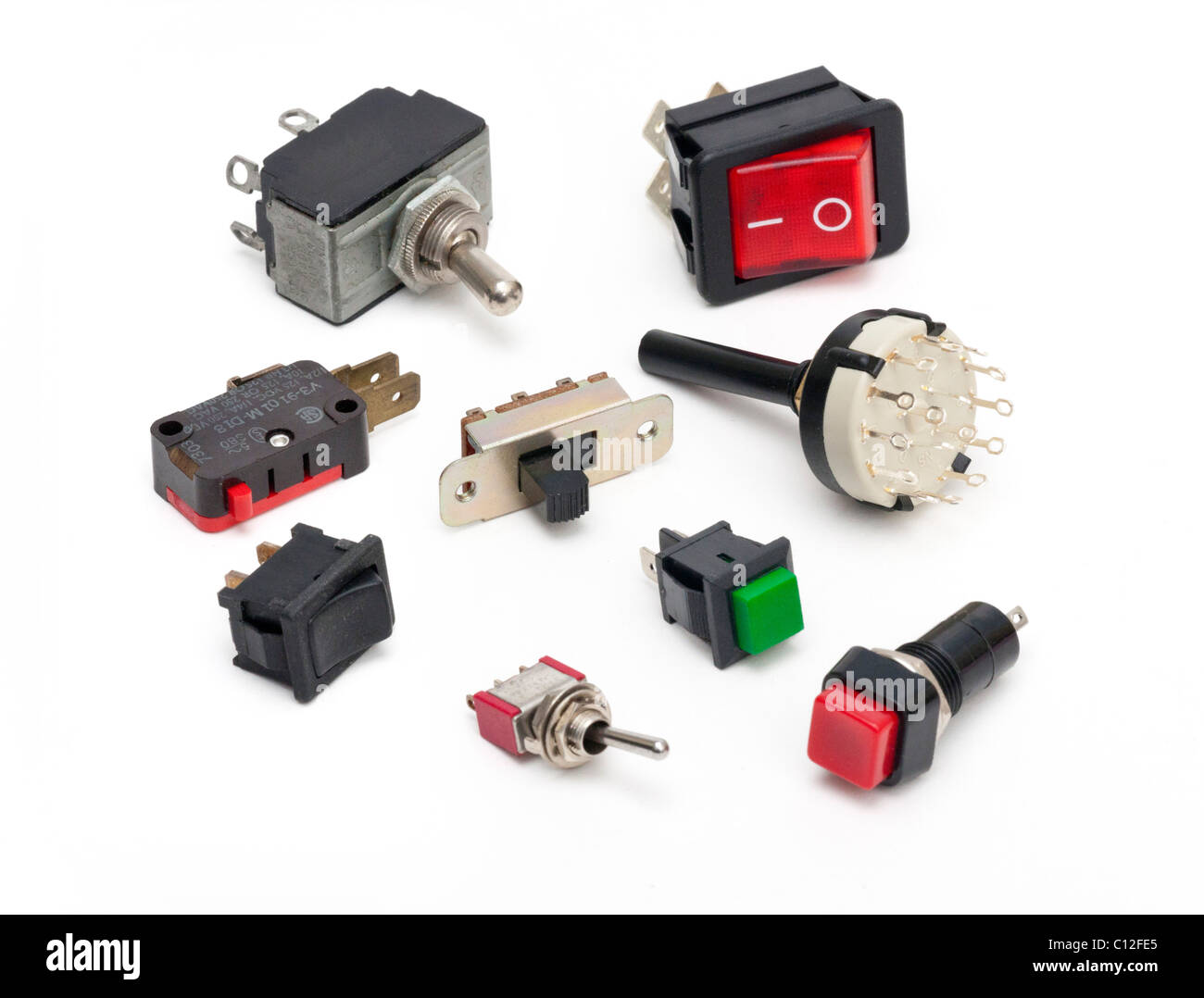

A stock image related to switches electric.

What Role Do Switches Electric Play in Commercial Buildings?

In commercial buildings, smart lighting control systems utilize switches electric to enhance energy efficiency and user experience. By automating lighting based on occupancy or time of day, businesses can significantly reduce energy costs. For buyers, sourcing switches that are compatible with existing systems and scalable for future upgrades is vital. Ease of installation can also impact overall project timelines and costs.

How Are Switches Electric Beneficial in Agriculture?

In agriculture, switches electric are employed in automated irrigation systems, allowing farmers to manage water usage effectively. This technology not only conserves resources but also optimizes crop yield by ensuring plants receive adequate hydration. Buyers from regions like Africa and South America should prioritize weather-resistant switches with remote control capabilities to adapt to varying environmental conditions. Power ratings must also match the demands of the irrigation systems used.

Why Are Switches Electric Essential in Telecommunications?

Telecommunications companies rely on switches electric for power management in data centers. These switches ensure reliable uptime, which is critical for maintaining service levels and minimizing operational costs. Buyers in this sector should focus on switches with high amperage ratings and safety certifications to handle the electrical loads typical in data centers. Additionally, adaptability to various voltages can facilitate integration into diverse systems.

How Do Switches Electric Enhance Healthcare Facilities?

In healthcare settings, switches electric are used in patient room control systems, allowing for efficient management of lighting and other electrical devices. This enhances patient comfort and operational efficiency for healthcare providers. Buyers must ensure compliance with healthcare regulations, focusing on ease of use and reliability to support a safe environment for patients and staff alike.

3 Common User Pain Points for ‘switches electric’ & Their Solutions

Scenario 1: Compatibility Issues with Existing Electrical Systems

The Problem:

International B2B buyers often face compatibility challenges when sourcing electric switches, especially when integrating them into existing electrical systems. For instance, a company in Egypt may be looking to upgrade their lighting control systems but finds that the switches they purchased do not match the local voltage standards or wiring configurations. This can lead to costly installation delays, increased labor costs, and potential safety hazards if the switches are not suitable for the intended application.

The Solution:

To mitigate compatibility issues, buyers should conduct thorough research on local electrical standards and requirements before making a purchase. This involves understanding the specific voltage ratings (e.g., 120V, 240V) and the type of wiring (e.g., single-pole, three-way) used in their region. It’s advisable to engage with local electrical engineers or contractors who can provide insights into the best products available. Furthermore, sourcing switches from reputable manufacturers that offer detailed specifications and compliance certifications (such as UL or IEC) can ensure that the products are reliable and compatible with existing systems. Establishing partnerships with local distributors can also facilitate better support and guidance in selecting the right products.

Scenario 2: Limited Availability of Smart Switches

The Problem:

As businesses strive to adopt smart technologies, many buyers in regions like South America and the Middle East encounter difficulties in finding advanced electric switches that support smart home automation features. The lack of availability of Wi-Fi, Bluetooth, or app-controlled switches limits their ability to integrate energy-efficient solutions that enhance user experience and operational efficiency. This can hinder the modernization of facilities and affect overall productivity.

The Solution:

B2B buyers should prioritize suppliers that specialize in smart electrical solutions and have a proven track record of delivering innovative products. Engaging with manufacturers that offer customization options can also be beneficial, as they may provide tailored solutions that meet specific regional needs. Attending trade shows and industry expos is another effective way to discover new technologies and connect with suppliers offering the latest smart switches. Additionally, considering bulk purchasing agreements can enhance product availability and reduce costs, ensuring that businesses can maintain their competitive edge in a rapidly evolving market.

Scenario 3: High Costs of Quality Electric Switches

The Problem:

Cost is a significant concern for many B2B buyers when sourcing electric switches. Companies in Europe and Africa, for instance, may find that high-quality switches are priced significantly above their budget, impacting project feasibility and ROI. This can lead to a compromise on quality, resulting in increased maintenance costs and potential downtime due to switch failures.

The Solution:

To address cost concerns, businesses should explore bulk purchasing options or establish long-term relationships with manufacturers to negotiate better pricing. It’s also wise to conduct a total cost of ownership analysis, which considers not just the upfront purchase price but also long-term savings from energy efficiency and reduced maintenance needs. Buyers can also look into alternative brands that offer competitive pricing without sacrificing quality. Furthermore, leveraging online marketplaces can provide access to a wider range of products and price comparisons, allowing buyers to make informed decisions that align with their budget constraints while ensuring quality standards are met.

Strategic Material Selection Guide for switches electric

When selecting materials for electric switches, international B2B buyers must consider various factors that affect performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in electric switches, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Which Materials Are Commonly Used for Electric Switches?

1. Thermoplastic Materials

Thermoplastics, such as polycarbonate and nylon, are widely used in electric switch manufacturing due to their excellent electrical insulation properties and impact resistance. They typically have a temperature rating of around 100°C and are resistant to various chemicals.

Pros:

– High durability and resistance to impact and abrasion.

– Lightweight, which can reduce shipping costs.

– Cost-effective for mass production.

Cons:

– Limited temperature resistance compared to thermosetting plastics.

– May degrade under prolonged exposure to UV light unless treated.

Impact on Application:

Thermoplastics are suitable for indoor applications where exposure to harsh environmental conditions is minimal. They are compatible with standard electrical media.

Specific Considerations for International Buyers:

Buyers should ensure compliance with regional standards such as IEC (International Electrotechnical Commission) and UL (Underwriters Laboratories) certifications. In regions like Africa and South America, where electrical infrastructure may vary, ensuring compatibility with local voltage and current ratings is crucial.

2. Metal Alloys

Metal alloys, particularly brass and aluminum, are often used in the components of electric switches, especially for contacts and terminals. These materials provide excellent conductivity and strength.

Pros:

– High conductivity, which enhances electrical performance.

– Excellent mechanical strength and durability.

– Corrosion resistance, especially with brass.

Cons:

– Higher manufacturing complexity and cost.

– Heavier than plastic alternatives, which can increase shipping costs.

Impact on Application:

Metal alloys are ideal for applications requiring high durability and electrical performance, such as industrial settings. They can handle higher current loads effectively.

Specific Considerations for International Buyers:

Buyers must consider the corrosion resistance of metals in humid or saline environments, common in parts of Africa and the Middle East. Compliance with ASTM standards for metal products is also essential.

3. Ceramic Materials

Ceramics are used in high-voltage applications due to their excellent insulating properties and thermal resistance, withstanding temperatures up to 1,000°C.

Pros:

– Exceptional electrical insulation and thermal stability.

– Resistant to chemical corrosion and wear.

Cons:

– Brittle nature can lead to breakage under mechanical stress.

– Higher production costs compared to plastics.

Impact on Application:

Ceramics are suitable for high-voltage and high-temperature applications, such as in power distribution systems. They are less compatible with flexible installations due to their fragility.

Specific Considerations for International Buyers:

In regions with high humidity or temperature fluctuations, such as parts of South America and the Middle East, buyers should ensure that ceramic switches meet relevant safety and performance standards.

4. Composite Materials

Composite materials, often a blend of plastics and fibers, are increasingly used in electric switches for their lightweight and strong properties. They can be engineered to provide specific performance characteristics.

Pros:

– Customizable properties based on application needs.

– Lightweight and resistant to various environmental factors.

Cons:

– Potentially higher costs due to specialized manufacturing processes.

– May require specific handling and installation procedures.

Impact on Application:

Composites are versatile and can be used in a variety of applications, including residential and commercial settings. They can be designed to resist specific environmental challenges.

Specific Considerations for International Buyers:

Buyers should verify that composite switches meet local standards, especially in regions like Europe, where regulations on materials and safety are stringent.

Summary Table of Material Properties for Electric Switches

| Material | Typical Use Case for switches electric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic | Residential and light commercial | High durability and impact resistance | Limited UV resistance | Low |

| Metal Alloys | Industrial and high-load applications | Excellent conductivity and strength | Higher manufacturing complexity | Med |

| Ceramic | High-voltage and high-temperature | Exceptional insulation and thermal stability | Brittle nature | High |

| Composite | Versatile applications | Customizable properties | Potentially higher costs | Med |

By understanding the properties and implications of these materials, international B2B buyers can make informed decisions that align with their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for switches electric

What Are the Main Stages in the Manufacturing Process for Electric Switches?

The manufacturing of electric switches involves several key stages that ensure the final product meets quality and performance standards. Understanding these stages can help international B2B buyers assess supplier capabilities effectively.

-

Material Preparation: The first step involves sourcing high-quality raw materials such as thermoplastics, metals, and conductors. Suppliers should utilize materials that comply with international standards, ensuring durability and safety. For instance, UL-listed materials are preferred, as they indicate compliance with safety standards.

-

Forming: In this phase, raw materials are shaped into the desired components. Techniques such as injection molding and die casting are commonly used. Injection molding allows for precise shaping of plastic parts, while die casting is essential for metal components. Buyers should inquire about the machinery and technology used in this process to ensure efficiency and quality.

-

Assembly: Once the individual components are formed, they undergo assembly. This stage often involves automated processes to enhance speed and accuracy. Manual assembly may also be employed for complex components. B2B buyers should assess whether the assembly lines are designed to minimize defects and ensure consistent product quality.

-

Finishing: The final stage involves surface treatments, such as painting, coating, or plating. These processes not only enhance aesthetics but also protect against environmental factors. Buyers should verify that suppliers adhere to environmental regulations during this stage, particularly in regions with stringent laws.

How Is Quality Assurance Implemented in Electric Switch Manufacturing?

Quality assurance (QA) is critical in the manufacturing of electric switches to ensure they meet safety and performance standards. Understanding the QA processes can help international buyers make informed decisions.

-

What International Standards Should B2B Buyers Be Aware Of?

– ISO 9001: This standard focuses on quality management systems and is essential for manufacturers seeking to demonstrate their commitment to quality. Buyers should look for suppliers certified under ISO 9001, as it indicates a systematic approach to quality.

– CE Marking: For products sold in the European Economic Area, CE marking signifies compliance with health, safety, and environmental protection standards. B2B buyers in Europe should prioritize suppliers who can provide CE certification for their products.

– API and UL Listings: In specific industries, such as oil and gas or electrical components, certifications from organizations like the American Petroleum Institute (API) and Underwriters Laboratories (UL) are crucial. These certifications ensure that products meet rigorous safety and performance standards. -

What Are the Key Quality Control Checkpoints?

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for defects before they enter the manufacturing process. Buyers should inquire about the criteria used for IQC to ensure only high-quality materials are utilized.

– In-Process Quality Control (IPQC): During production, IPQC checks the quality of components at various stages. This ensures that any defects are caught early, reducing waste and rework.

– Final Quality Control (FQC): After assembly, FQC involves comprehensive testing of the final product. This may include electrical testing, safety assessments, and performance evaluations to ensure compliance with standards. -

What Common Testing Methods Are Used?

– Electrical Testing: This includes checking for continuity, insulation resistance, and operational performance under load. Buyers should ensure that suppliers employ standardized testing procedures to guarantee reliability.

– Environmental Testing: Products may undergo tests for temperature extremes, humidity, and exposure to corrosive elements. These tests help ensure switches can perform in various conditions, critical for international markets.

– Lifecycle Testing: Simulating long-term usage helps identify potential failure points. This is particularly important for B2B buyers in industries where reliability is paramount.

How Can B2B Buyers Verify Supplier Quality Control Practices?

International buyers must take proactive steps to ensure their suppliers maintain high-quality standards. Here are actionable strategies to verify supplier QC practices:

-

Conduct Supplier Audits: Regular audits of suppliers’ manufacturing facilities can provide insights into their processes, equipment, and adherence to quality standards. Buyers should develop an audit checklist that includes quality management practices, equipment maintenance, and employee training programs.

-

Request Quality Reports: Suppliers should be able to provide detailed quality reports, including data from IQC, IPQC, and FQC stages. These documents offer transparency and allow buyers to assess the quality assurance processes in place.

-

Engage Third-Party Inspections: Hiring independent inspectors to evaluate supplier facilities and processes can add an extra layer of assurance. Third-party inspections can identify potential issues that may not be apparent during regular audits.

-

Understand Certification Nuances: Different regions have varying regulations and standards. For instance, buyers in Africa may need to consider local certifications alongside international ones. It’s essential to confirm that suppliers understand and comply with the regulatory requirements of the markets they serve.

What Challenges Do B2B Buyers Face in Quality Assurance for Electric Switches?

B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, may face unique challenges in ensuring quality assurance. Understanding these challenges can help buyers navigate the complexities of international procurement.

-

Regulatory Compliance: Different countries have varying regulations concerning electrical products. Buyers must ensure that suppliers can navigate these regulations effectively to avoid non-compliance penalties.

-

Supply Chain Variability: Fluctuations in supply chain logistics can impact the quality of materials and components. Buyers should work closely with suppliers to establish robust supply chain practices that prioritize quality at every stage.

-

Cultural and Communication Barriers: Differences in business practices and communication styles can create misunderstandings regarding quality expectations. Establishing clear communication channels and cultural understanding can mitigate these challenges.

By being informed about manufacturing processes, quality assurance standards, and verification methods, international B2B buyers can make more informed decisions when selecting suppliers for electric switches. Investing time in understanding these aspects is crucial to ensuring product quality, safety, and reliability in their respective markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘switches electric’

The procurement of electric switches is a vital component for businesses involved in electrical installations, construction, and related fields. This checklist aims to guide international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, through the essential steps needed to make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Before diving into the market, it’s crucial to clearly outline your technical requirements. Identify the type of switches you need based on the application—be it residential, commercial, or industrial. Consider factors such as:

– Voltage and Amperage Ratings: Ensure the switches meet the required standards for your projects.

– Switch Type: Decide between toggle, rocker, dimmer, or smart switches based on functionality.

Step 2: Research Market Trends and Innovations

Understanding current trends in the electric switch market can give you a competitive edge. Look for innovations such as energy-efficient designs or smart technology integrations. Key areas to explore include:

– Smart Switch Features: Compatibility with home automation systems like Google Assistant or Amazon Alexa.

– Sustainability: Options that comply with eco-friendly standards, which may appeal to environmentally conscious clients.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and quality. Request company profiles, product catalogs, and case studies from similar industries. Consider:

– Certifications and Standards: Look for UL, CE, or other relevant certifications to verify safety and performance.

– Reputation: Seek reviews and testimonials from previous clients to gauge supplier reliability.

Step 4: Request Samples and Prototypes

Before finalizing your order, always request samples or prototypes. This allows you to assess the quality and functionality of the switches firsthand. Pay attention to:

– Material Quality: Ensure that the switches are made from durable, high-quality materials.

– Ease of Installation: Verify that the design allows for straightforward installation without specialized tools.

Step 5: Verify Pricing and Payment Terms

Understanding the pricing structure is essential for budgeting and cost management. Request detailed quotes from multiple suppliers and analyze:

– Bulk Discounts: Inquire about pricing tiers based on order quantity.

– Payment Flexibility: Look for suppliers that offer favorable payment terms, which can ease cash flow issues.

Step 6: Check for After-Sales Support and Warranty

A reliable supplier should offer robust after-sales support and warranty services. This is important for addressing any issues that may arise post-purchase. Investigate:

– Customer Service Availability: Ensure that support is accessible and responsive.

– Warranty Terms: Look for warranties that cover manufacturing defects and offer reasonable durations.

Step 7: Finalize Logistics and Delivery Options

Once you have selected a supplier, coordinate logistics and delivery to ensure timely arrival. Discuss:

– Shipping Methods: Choose between air, sea, or land transport based on urgency and budget.

– Customs Clearance: Make sure the supplier can assist with documentation to avoid delays in your region.

By following this structured checklist, B2B buyers can streamline their procurement process for electric switches, ensuring they make informed decisions that align with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for switches electric Sourcing

What Are the Key Cost Components in Electric Switch Manufacturing?

When sourcing electric switches, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials for switches include thermoplastics for housing and copper for internal wiring. High-quality materials often lead to increased durability, which can justify higher upfront costs.

-

Labor: Labor costs can vary widely based on location and the complexity of the manufacturing process. For instance, automated manufacturing processes may reduce labor costs but could require significant initial investment.

-

Manufacturing Overhead: This includes costs related to factory utilities, equipment depreciation, and maintenance. Efficient production processes can help minimize these overhead costs, which is beneficial for both manufacturers and buyers.

-

Tooling: The production of custom switches may require specialized tooling. While this can increase initial costs, it allows for tailored solutions that meet specific client needs.

-

Quality Control (QC): Rigorous QC processes ensure that products meet safety and performance standards. While this adds to production costs, it minimizes returns and enhances customer satisfaction.

-

Logistics: Transportation and warehousing costs can vary significantly depending on the distance between the manufacturer and the buyer, as well as the shipping method. Buyers should consider these costs in their total purchasing decisions.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. Understanding the typical margins in your region can aid in effective negotiation.

How Do Price Influencers Affect Electric Switch Sourcing?

Several factors can influence the pricing of electric switches:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounts. Buyers should assess their needs carefully to take advantage of economies of scale.

-

Specifications and Customization: Custom specifications may lead to higher costs due to the need for specialized production processes and materials. Buyers should weigh the benefits of customization against potential cost increases.

-

Material Quality and Certifications: Switches that meet international safety standards or certifications may come with a higher price tag. However, investing in certified products can reduce liability and enhance brand reputation.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more but offer better quality assurance and customer support.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect the final price. Understanding the responsibilities for shipping and risk can help buyers avoid unexpected costs.

What Are the Best Buyer Tips for Cost-Efficient Electric Switch Sourcing?

To navigate the complexities of pricing in the electric switch market, international B2B buyers should consider the following strategies:

-

Negotiate Wisely: Engage suppliers in negotiations, especially for bulk orders. Leverage volume commitments to secure better pricing and terms.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on purchase price, assess the long-term costs associated with the product, including maintenance, energy efficiency, and durability.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying price points due to local economic conditions, tariffs, and demand. Buyers from Africa, South America, the Middle East, and Europe should be aware of these nuances to make informed decisions.

-

Research Local Market Conditions: Understanding local market dynamics can provide insights into fair pricing and help buyers identify potential suppliers.

-

Consider Supply Chain Logistics: Factor in shipping times and costs when selecting suppliers. Efficient logistics can help minimize delays and additional expenses.

Disclaimer on Indicative Prices

A stock image related to switches electric.

Prices for electric switches can fluctuate based on market conditions, supplier policies, and changes in material costs. It is recommended that buyers conduct thorough market research and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing switches electric With Other Solutions

Understanding Alternatives to Electric Switches

When evaluating electrical solutions, it’s essential to consider various alternatives to traditional electric switches. This analysis will help international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, to make informed decisions tailored to their unique operational needs. Here, we compare electric switches with two viable alternatives: smart home automation systems and mechanical relays.

Comparison Table

| Comparison Aspect | Switches Electric | Smart Home Automation Systems | Mechanical Relays |

|---|---|---|---|

| Performance | Reliable and straightforward | High versatility and control | Good for high power applications |

| Cost | Generally low initial cost | Higher initial investment | Low cost but requires more space |

| Ease of Implementation | Simple installation | Requires setup and configuration | Straightforward installation |

| Maintenance | Minimal maintenance required | Software updates needed | Periodic checks recommended |

| Best Use Case | Residential and commercial use | Modern smart homes and offices | Industrial applications |

A stock image related to switches electric.

What Are the Pros and Cons of Smart Home Automation Systems?

Smart home automation systems offer advanced control over lighting and other electrical devices, allowing users to manage settings via smartphones or voice commands. This technology is particularly beneficial for businesses looking to optimize energy consumption and enhance user convenience. However, the initial setup cost can be high, and ongoing maintenance may include software updates and troubleshooting connectivity issues. For B2B buyers in regions with unstable internet connections, the reliance on digital infrastructure can pose challenges.

How Do Mechanical Relays Compare?

Mechanical relays are electromechanical switches used to control high power loads, making them ideal for industrial settings. They are generally low in cost and easy to install. However, relays can be bulkier and require more space than traditional switches. Maintenance is essential as mechanical parts can wear out over time, necessitating periodic checks to ensure proper functionality. For companies focusing on high power applications in sectors such as manufacturing, relays can be a reliable choice.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right electrical solution depends on various factors, including the specific requirements of your business, budget constraints, and long-term operational goals. Electric switches remain a practical choice for straightforward applications, while smart home automation systems can add significant value through enhanced control and efficiency. Mechanical relays are best suited for industrial environments where high power is necessary. Ultimately, international B2B buyers should assess their unique contexts to determine which alternative aligns best with their operational needs and strategic objectives.

Essential Technical Properties and Trade Terminology for switches electric

What Are the Key Technical Properties of Electric Switches?

Understanding the technical properties of electric switches is crucial for B2B buyers, especially when sourcing products from international markets. The following specifications are vital in assessing the quality and suitability of electric switches for various applications.

1. Material Grade: What Should You Look For?

Electric switches are typically made from materials such as thermoplastic, metal, or a combination of both. Thermoplastics provide durability and resistance to heat, while metals can enhance electrical conductivity. Buyers should prioritize switches made from high-grade materials to ensure longevity and reliability, especially in environments with high electrical loads or varying temperatures.

2. Amperage Rating: Why Is It Important?

The amperage rating indicates the maximum current the switch can safely handle. Common ratings include 15A, 20A, and 30A. Selecting a switch with an appropriate amperage rating is critical to prevent overheating and potential failure. For international buyers, understanding local electrical standards is essential, as amperage requirements may vary by region.

3. Voltage Rating: How Does It Affect Performance?

Electric switches are rated for specific voltage levels, typically 120V, 240V, or 277V. A switch must be compatible with the voltage of the electrical system to function correctly. In regions like Europe, where 230V is common, ensuring the right voltage rating can prevent electrical hazards and improve system efficiency.

4. Durability Features: Which Should You Consider?

Durability features such as weather resistance, tamper resistance, and scratch resistance are crucial for switches used in harsh environments. For instance, switches that are weather-resistant are ideal for outdoor applications, while tamper-resistant designs add an extra layer of safety in public or commercial settings. Buyers should assess these features based on their specific use cases.

5. Function Type: What Are the Options?

Electric switches come in various functional types, including single-pole, three-way, and four-way switches. Each type serves different purposes in electrical circuits. Understanding the function type is essential for ensuring the right switch is chosen for the intended application, especially in complex installations.

What Trade Terminology Should International Buyers Know?

Navigating the world of electric switches also requires familiarity with industry jargon. Here are some key terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to companies that manufacture products that are sold by another company under its brand. For buyers, working with OEMs can ensure they receive high-quality products that meet specific standards, which is particularly important for large-scale projects.

2. MOQ (Minimum Order Quantity): Why Is It Relevant?

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for international buyers to manage inventory and ensure they are not overcommitting resources. This can be especially significant for buyers in Africa or South America, where capital constraints may be a concern.

3. RFQ (Request for Quotation): How Should You Use It?

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. It is a critical tool for negotiating favorable terms and understanding market prices. Buyers should provide detailed specifications in their RFQs to receive accurate quotes.

4. Incoterms: What Are They and Why Do They Matter?

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers in shipping goods. Familiarity with terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) is essential for B2B buyers to mitigate risks and clarify shipping responsibilities.

5. UL Listed: What Does This Certification Indicate?

UL Listing indicates that a product has been tested and meets specific safety standards set by Underwriters Laboratories. For international buyers, ensuring that products are UL listed can provide peace of mind regarding safety and compliance with local regulations.

By understanding these technical properties and industry terms, international B2B buyers can make informed decisions when sourcing electric switches, ensuring they choose products that meet their operational needs and compliance standards.

Navigating Market Dynamics and Sourcing Trends in the switches electric Sector

What Are the Current Market Dynamics and Key Trends in the Electric Switches Sector?

The electric switches market is experiencing significant growth driven by several global factors. The rising demand for energy-efficient devices, along with the rapid adoption of smart home technologies, is reshaping the landscape. In regions like Africa and South America, where urbanization is accelerating, the need for reliable and efficient electrical infrastructure is paramount. This presents an opportunity for international B2B buyers to source innovative products that align with local demands.

Emerging trends include the integration of Internet of Things (IoT) capabilities into electric switches, enabling remote control and automation. This shift is particularly relevant for buyers in Europe and the Middle East, where smart technologies are becoming standard in residential and commercial environments. Additionally, the push towards sustainability is influencing sourcing decisions, with buyers increasingly seeking products that comply with green certifications and use environmentally friendly materials.

Market dynamics also reveal a growing emphasis on customization and flexibility in product offerings. B2B buyers are looking for suppliers who can provide tailored solutions that meet specific regional needs, whether it’s adapting to voltage requirements or accommodating local regulations. Collaborations between manufacturers and technology providers are further enhancing product development, making it essential for buyers to stay informed about partnerships that can influence product availability and innovation.

How Can Sustainability and Ethical Sourcing Impact Your B2B Decisions?

The importance of sustainability in the sourcing of electric switches cannot be overstated. As environmental awareness grows, international buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing practices. This includes ensuring that materials are sourced responsibly and that manufacturing processes minimize environmental impact.

Buyers should seek out products that carry reputable green certifications such as Energy Star, RoHS, or similar labels that verify compliance with environmental standards. These certifications not only guarantee the product’s eco-friendliness but also enhance the brand reputation in the marketplace. In regions like Europe, where regulatory frameworks are stringent, sourcing from certified suppliers can mitigate risks and ensure compliance with local laws.

Moreover, the use of sustainable materials, such as recycled plastics and low-impact metals, is becoming a significant differentiator in the market. By choosing products that are designed with sustainability in mind, B2B buyers can contribute to a circular economy while also appealing to environmentally conscious consumers. This strategic alignment with sustainability can lead to improved customer loyalty and competitive advantage in the increasingly eco-aware global market.

What Is the Historical Context of Electric Switches for B2B Buyers?

The evolution of electric switches dates back to the late 19th century, with the first designs focused on basic functionality. As electrical systems became more complex, so did the switches. The introduction of the toggle switch in the early 20th century marked a significant advancement, providing users with improved reliability and ease of use.

In the latter half of the 20th century, the advent of electronic technologies led to the development of more sophisticated switch designs, including dimmers and smart switches. This evolution reflects a broader trend in the electrical industry toward automation and energy efficiency, which remains relevant today. For international B2B buyers, understanding this historical context is crucial for recognizing the trajectory of product innovation and anticipating future trends that will shape sourcing strategies in the electric switches sector.

Frequently Asked Questions (FAQs) for B2B Buyers of switches electric

-

How do I solve compatibility issues when sourcing electric switches for different markets?

To address compatibility issues, first, research the electrical standards in your target market, such as voltage and amperage requirements. Ensure the switches you source comply with local certifications and regulations, such as UL, CE, or IEC standards. Partnering with suppliers who understand regional compliance can help mitigate risks. Additionally, consider customizable options that allow you to adapt products to meet specific requirements, thereby enhancing market acceptance and reducing returns. -

What is the best type of electric switch for industrial applications?

For industrial applications, look for switches that are durable and rated for higher amperages, such as toggle or rotary switches with at least 20 amps capacity. Heavy-duty switches often have weather-resistant features, making them suitable for harsh environments. Additionally, consider smart switches that offer remote control capabilities and energy monitoring, which can enhance operational efficiency. Always check for compliance with industry standards to ensure safety and reliability. -

How can I vet suppliers of electric switches effectively?

Vetting suppliers involves assessing their reputation, product quality, and compliance with international standards. Start by checking customer reviews and ratings on platforms like Alibaba or TradeKey. Request certifications and quality assurance documentation to ensure their products meet safety standards. Conduct a factory audit if possible, and establish communication to gauge responsiveness and support. Building a relationship with reliable suppliers can lead to better terms and collaboration. -

What are the minimum order quantities (MOQ) for electric switches?

MOQs vary significantly among suppliers and depend on the type of switch and customization options. Typically, manufacturers may require MOQs ranging from 100 to 1,000 units. For smaller businesses or those testing new markets, seek suppliers willing to negotiate lower MOQs or consider purchasing from distributors who offer smaller batch options. Understanding your demand forecast can help you negotiate better terms with suppliers. -

What payment terms should I expect when sourcing electric switches internationally?

Payment terms in international trade can vary widely, but common practices include advance payments, letters of credit, and payment upon delivery. Ensure to clarify terms before placing an order. For large orders, consider negotiating partial payments—20-30% upfront and the balance upon shipment or delivery. Utilizing secure payment methods like PayPal or escrow services can offer protection against fraud, especially when dealing with new suppliers. -

How do I ensure the quality of electric switches before shipping?

To ensure quality, implement a rigorous quality assurance (QA) process. Request samples before placing bulk orders to evaluate material and performance. Establish clear quality standards and have them documented in your contract. If possible, consider hiring a third-party inspection service to conduct pre-shipment inspections, which can help identify defects and ensure compliance with your specifications. -

What logistics considerations should I keep in mind when importing electric switches?

Logistics considerations include shipping methods, customs clearance, and local regulations. Choose a reliable shipping partner that offers competitive rates and efficient delivery times. Understand the customs duties and taxes applicable in your country to avoid unexpected costs. Additionally, familiarize yourself with local regulations regarding electrical products to ensure compliance and smooth clearance through customs. -

Can I customize electric switches to meet specific requirements for my projects?

Many manufacturers offer customization options for electric switches, including design, color, and functionality. When sourcing, inquire about the possibility of custom features such as branding, switch type, or additional functionalities like smart technology integration. Customization can differentiate your product offerings in competitive markets and cater to specific customer needs, ultimately enhancing your brand’s appeal.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for switches electric

What Are the Key Takeaways for International B2B Buyers in Electric Switches?

As we wrap up our exploration of electric switches, it’s essential to highlight the strategic advantages of informed sourcing. By prioritizing quality suppliers who adhere to international standards, businesses can ensure safety and reliability in their electrical installations. Leveraging a diverse range of products, including smart switches, can enhance energy efficiency and user convenience, making them particularly attractive in markets focused on sustainability.

How Can Strategic Sourcing Drive Competitive Advantage?

The value of strategic sourcing lies not just in cost savings but in building long-term relationships with manufacturers that provide consistent quality and innovative solutions. Buyers from regions like Africa, South America, the Middle East, and Europe should focus on suppliers that offer robust product support and flexible terms. This approach not only mitigates risks associated with supply chain disruptions but also positions companies to adapt swiftly to market changes.

What Does the Future Hold for Electric Switches?

Looking ahead, the demand for advanced electric switches, particularly those integrating smart technology, is expected to grow. International buyers are encouraged to stay ahead of this trend by exploring partnerships with manufacturers who are committed to innovation. By doing so, businesses can enhance their offerings and meet the evolving needs of their customers. Engage with suppliers today to secure your position in this dynamic market and drive your business’s success forward.