Unlock Efficiency: The Ultimate Guide to US Mains Socket (2025)

Introduction: Navigating the Global Market for us mains socket

In today’s interconnected world, international B2B buyers face the critical challenge of sourcing the appropriate US mains socket solutions to meet their operational needs. Understanding the nuances of electrical standards, such as the type A and B power plugs used in the United States, is essential for businesses aiming to ensure compatibility and reliability in their equipment. This guide serves as a comprehensive resource, detailing the different types of US mains sockets, their applications across various industries, and the intricacies of supplier vetting processes.

By exploring key factors such as voltage requirements, plug compatibility, and sourcing strategies, this guide empowers B2B buyers from Africa, South America, the Middle East, and Europe—including countries like Spain and Nigeria—to make informed purchasing decisions. The insights provided will aid in navigating the complexities of sourcing, ensuring that your operations can seamlessly integrate with US standards while avoiding common pitfalls associated with international procurement.

Furthermore, the guide will delve into cost considerations, potential suppliers, and best practices for maintaining compliance with local regulations. By arming yourself with this knowledge, you can streamline your supply chain and enhance your purchasing strategy, ultimately leading to increased operational efficiency and reduced downtime.

Understanding us mains socket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type A | Two flat parallel pins; no ground pin; typically rated for 15A | Small appliances, chargers, and electronics | Pros: Widely available in the US; suitable for low-power devices. Cons: Lacks grounding, which can be a safety concern for sensitive equipment. |

| Type B | Two flat parallel pins and a round grounding pin; rated for 15A | Commercial equipment, computers, and larger appliances | Pros: Provides grounding, enhancing safety; compatible with Type A sockets. Cons: Less common in some international markets, may require adapters. |

| NEMA 5-15 | Standardized Type B socket; accepts both Type A and B plugs | Office equipment, medical devices, and consumer electronics | Pros: Universally accepted in the US; versatile for different plug types. Cons: Limited to 120V devices, may need converters for international use. |

| NEMA L5-15 | Twist-lock design; provides secure connection; rated for 15A | Industrial applications, generators, and high-power tools | Pros: Reduces accidental disconnection; suitable for outdoor use. Cons: Requires specific sockets; not as widely adopted in consumer markets. |

| NEMA 6-15 | Two horizontal pins and a ground; rated for 15A; used for 240V applications | Heavy machinery, HVAC systems, and industrial equipment | Pros: Supports higher voltage applications; suitable for specialized equipment. Cons: Not compatible with standard US outlets, requiring installation of dedicated circuits. |

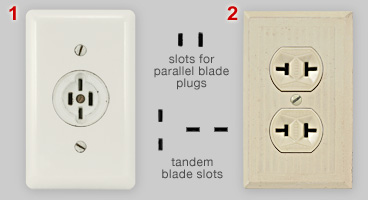

What are the Characteristics of Type A and Type B US Mains Sockets?

Type A sockets are characterized by their two flat parallel pins and lack of a grounding pin, typically rated for 15A at 120V. They are commonly used for small appliances and electronic devices. However, their lack of grounding can pose safety risks, especially for sensitive equipment. Buyers should consider the electrical requirements of their devices and the safety implications when choosing Type A sockets.

Type B sockets, on the other hand, include two flat parallel pins along with a round grounding pin, providing an essential safety feature. Rated for 15A, they are widely used for commercial equipment, computers, and larger appliances. The grounding feature enhances safety, making them suitable for a broader range of applications. Buyers should ensure compatibility with their devices and consider the availability of Type B plugs in their region.

How Does NEMA 5-15 Enhance Versatility for B2B Buyers?

NEMA 5-15 sockets are a standardized Type B design that accepts both Type A and B plugs. This versatility makes them ideal for office equipment, medical devices, and consumer electronics. The universal acceptance in the US simplifies the logistics for international B2B buyers, reducing the need for multiple adapters. However, it is essential to note that these sockets are limited to 120V devices, which may require voltage converters for use with international equipment.

Why Choose NEMA L5-15 for Industrial Applications?

NEMA L5-15 sockets feature a twist-lock design that ensures a secure connection, making them suitable for industrial applications, generators, and high-power tools. Rated for 15A, they are particularly beneficial in environments where accidental disconnection could lead to hazards. Buyers should consider the specific needs of their applications, as these sockets require compatible outlets and are less common in consumer markets.

What are the Benefits and Limitations of NEMA 6-15 for Heavy Machinery?

NEMA 6-15 sockets are designed for higher voltage applications, with two horizontal pins and a ground, rated for 15A at 240V. They are ideal for heavy machinery, HVAC systems, and industrial equipment. While they support specialized applications effectively, they are not compatible with standard US outlets, necessitating the installation of dedicated circuits. B2B buyers should assess the electrical infrastructure of their facilities to determine the feasibility of integrating NEMA 6-15 sockets.

Key Industrial Applications of us mains socket

| Industry/Sector | Specific Application of us mains socket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics Manufacturing | Powering assembly lines for electronic devices | Ensures consistent power supply for production quality | Compliance with voltage and frequency standards; safety certifications |

| Hospitality | Providing power in hotel rooms and conference areas | Enhances guest experience with accessible charging options | Durability, ease of installation, and compatibility with different plug types |

| Healthcare | Powering medical equipment in clinics and hospitals | Critical for patient safety and equipment reliability | Compliance with medical standards; need for backup power solutions |

| Construction | Powering tools and machinery on job sites | Increases operational efficiency and productivity | Robustness for outdoor use; protection against environmental factors |

| Retail | Providing power for point-of-sale systems | Facilitates smooth transactions and customer service | Compatibility with various devices; ease of integration with existing systems |

How is the US Mains Socket Utilized in Electronics Manufacturing?

In the electronics manufacturing sector, US mains sockets are essential for powering assembly lines where electronic devices are produced. These sockets ensure a consistent power supply, which is crucial for maintaining production quality and efficiency. Buyers should consider compliance with local voltage (120V) and frequency (60Hz) standards, as well as safety certifications to prevent electrical hazards. Additionally, sourcing sockets that can accommodate various plug types may be beneficial for international operations.

What Role Do US Mains Sockets Play in the Hospitality Industry?

In the hospitality industry, US mains sockets are commonly found in hotel rooms and conference areas. They provide essential power for guests’ electronic devices, enhancing their experience by enabling easy access to charging options. For B2B buyers, sourcing durable and easy-to-install sockets is vital, as they must withstand frequent use. Compatibility with different plug types is also a key consideration, especially in international settings where diverse clientele may bring various devices.

Why Are US Mains Sockets Important in Healthcare?

In healthcare settings, US mains sockets power critical medical equipment in clinics and hospitals. Reliable electrical supply is vital for patient safety and the effective functioning of medical devices. B2B buyers in this sector must ensure that sourced sockets comply with medical standards, as well as consider the need for backup power solutions to safeguard against outages. This requirement is especially important in regions with unstable electricity supply, such as parts of Africa and South America.

How Are US Mains Sockets Utilized on Construction Sites?

US mains sockets are pivotal for powering tools and machinery on construction sites. They facilitate increased operational efficiency and productivity by providing a reliable power source for various equipment. Buyers should focus on sourcing robust sockets designed for outdoor use, ensuring they are protected against environmental factors like dust and moisture. Additionally, considering safety features that prevent overloads is crucial in this high-risk industry.

What is the Importance of US Mains Sockets in Retail Environments?

In retail environments, US mains sockets are integral to powering point-of-sale systems, which are vital for smooth transactions and enhancing customer service. For businesses, ensuring compatibility with various devices is essential to avoid disruptions during peak hours. B2B buyers should prioritize sourcing sockets that are easy to integrate with existing systems and provide options for upgrading as technology evolves. This adaptability can be a significant competitive advantage in fast-paced retail settings.

3 Common User Pain Points for ‘us mains socket’ & Their Solutions

Scenario 1: Compatibility Issues with Diverse Electrical Equipment

The Problem: International B2B buyers often face compatibility challenges when sourcing equipment that requires US mains sockets. For instance, a company in Nigeria sourcing machinery from the United States may find that the equipment’s power plugs do not fit local sockets, leading to delays in operations and increased costs for adapters or modifications. This mismatch can stem from the differences in plug types (Type A and B in the US) and voltage standards, potentially risking equipment damage or inefficiency.

The Solution: To mitigate compatibility issues, B2B buyers should prioritize sourcing equipment that is explicitly designed for international use. When evaluating suppliers, request detailed specifications about the electrical requirements, including plug types and voltage. Ensure the equipment has a universal power supply (input: 100-240V, 50/60Hz), which can operate across various voltage levels. Additionally, consider investing in high-quality travel or universal adapters that cater to Type A and B sockets. This proactive approach minimizes compatibility risks and allows for seamless integration of US-sourced equipment into local operations.

Scenario 2: Voltage Conversion Challenges in Equipment Use

The Problem: Another prevalent issue arises from the voltage difference between US mains sockets (120V) and the higher voltage systems in many regions, such as Europe (230V) and Africa (220V). A company in Brazil purchasing electronic devices from the US may find that their devices fail to operate correctly or sustain damage due to the voltage discrepancy. This not only results in unexpected costs for replacements but can also lead to significant downtime.

The Solution: To address voltage conversion challenges, B2B buyers should conduct a thorough assessment of their electrical systems before importing any equipment. This includes determining whether the purchased equipment requires a voltage converter. When sourcing, opt for devices that come with multi-voltage capabilities (100-240V), which negates the need for a converter. If the equipment is fixed at 120V, ensure to acquire a reliable voltage converter that can handle the wattage required by the device. Additionally, consider consulting with electrical engineers to ensure that the entire power supply system can support the new equipment efficiently, thus safeguarding investments and maintaining operational continuity.

Scenario 3: Insufficient Knowledge of Regional Electrical Standards

The Problem: Many B2B buyers, particularly those new to importing goods, may lack knowledge about the specific electrical standards in the US, such as the frequency of 60Hz. This can lead to misinformed purchases where equipment that operates optimally at 50Hz is sourced from the US, resulting in malfunction or inefficiency. For example, a manufacturing company in South Africa might purchase a motor designed for 60Hz, only to find it operates poorly or overheats when used in their local 50Hz environment.

The Solution: To counteract the lack of knowledge regarding regional electrical standards, B2B buyers should invest in training and resources that clarify international electrical specifications. It is crucial to engage with knowledgeable suppliers who can provide detailed insights about the frequency and voltage requirements. Buyers should also conduct thorough research, utilizing resources like international standards organizations or electrical engineering professionals, to better understand the implications of using US mains socket equipment. Lastly, consider seeking equipment that is adaptable to both 50Hz and 60Hz frequencies, or specify the required frequency when making purchases to ensure optimal performance and longevity of the equipment.

Strategic Material Selection Guide for us mains socket

When selecting materials for US mains sockets, it’s essential to consider various factors that can impact performance, durability, and compatibility with international standards. Below is an analysis of some common materials used in the manufacturing of US mains sockets, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Thermoplastic Materials for US Mains Sockets?

Thermoplastic materials, such as polycarbonate (PC) and nylon, are widely used in the production of US mains sockets. These materials exhibit excellent electrical insulation properties, high impact resistance, and good thermal stability, typically withstanding temperatures up to 100°C.

Pros: Thermoplastics are lightweight, cost-effective, and can be easily molded into complex shapes, making them suitable for high-volume production. They also offer good resistance to chemicals and UV light, enhancing their longevity.

Cons: While thermoplastics are durable, they may not perform well under extreme temperatures or mechanical stress compared to metals. Additionally, they can be less environmentally friendly due to their petroleum-based origins.

Impact on Application: Thermoplastics are compatible with a wide range of electrical devices, making them a versatile choice for various applications. However, buyers should ensure that the selected thermoplastic complies with relevant safety standards, such as UL and IEC.

How Do Metal Materials Enhance the Performance of US Mains Sockets?

Metal materials, such as brass and aluminum, are often used for the conductive components of US mains sockets. Brass, in particular, is favored for its excellent conductivity and corrosion resistance, making it suitable for high-current applications.

Pros: Metals provide superior strength and durability, ensuring a long service life. They also offer excellent thermal conductivity, which can help dissipate heat generated during operation.

Cons: Metals can be heavier and more expensive than thermoplastics. They are also prone to corrosion if not properly coated or treated, which can compromise performance over time.

Impact on Application: Metal components are essential for ensuring reliable electrical connections. Buyers should consider the environmental conditions in which the sockets will be used, as exposure to moisture or corrosive substances can affect metal performance.

What Are the Benefits of Composite Materials in US Mains Socket Design?

Composite materials, which combine plastics and metals, are becoming increasingly popular in the design of US mains sockets. These materials aim to leverage the strengths of both components, offering enhanced performance and durability.

Pros: Composites can provide excellent electrical insulation while maintaining high mechanical strength. They are also lighter than pure metals and can be designed to resist environmental stressors.

Cons: The manufacturing process for composite materials can be more complex and costly. Additionally, the performance of composites can vary significantly based on the specific formulation used.

Impact on Application: Composites are suitable for applications requiring both electrical insulation and mechanical strength. Buyers should ensure that the composites used meet relevant industry standards, such as ASTM or DIN.

What Should International B2B Buyers Consider When Selecting Materials for US Mains Sockets?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several considerations are crucial when selecting materials for US mains sockets. Compliance with local and international standards (e.g., UL, IEC, ASTM) is paramount to ensure safety and reliability. Additionally, understanding the specific environmental conditions in the target market—such as humidity, temperature fluctuations, and exposure to corrosive elements—can influence material selection.

Furthermore, buyers should consider the cost implications of sourcing materials. While cheaper materials may reduce initial costs, they could lead to higher long-term expenses due to maintenance or replacement needs. Establishing relationships with reliable suppliers who can provide high-quality materials that meet compliance standards is essential for ensuring product success in diverse markets.

| Material | Typical Use Case for US Mains Socket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic | Housing and insulation components | Lightweight and cost-effective | Less durable under extreme conditions | Low |

| Metal (Brass) | Conductive components | Excellent conductivity and strength | Prone to corrosion without treatment | Medium |

| Composite | Structural and insulating components | Combines strengths of plastics/metals | Manufacturing complexity and cost | High |

This analysis provides a comprehensive overview of the materials used in US mains sockets, equipping international B2B buyers with the insights needed to make informed decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for us mains socket

What Are the Main Stages in the Manufacturing Process of US Mains Sockets?

The manufacturing of US mains sockets involves several key stages, ensuring both functionality and safety for end-users. Understanding these stages can help international B2B buyers assess potential suppliers effectively.

Material Preparation

The first step in the manufacturing process is material preparation. High-quality thermoplastics and metals are typically sourced for the production of mains sockets. These materials must comply with international safety standards, ensuring durability and resistance to heat. Suppliers often conduct incoming quality control (IQC) checks on raw materials to verify their quality before they proceed to the next stage.

How Are US Mains Sockets Formed?

Once the materials are prepared, the next stage is forming. This involves shaping the thermoplastics into the socket’s body using injection molding techniques. Injection molding allows for high precision and repeatability, essential for producing components that fit securely with standard plugs. Metal components, such as the prongs and internal wiring, are manufactured separately, typically through stamping or machining processes.

What Does the Assembly Process Entail?

After forming, the assembly stage begins. This includes integrating the plastic housing with the metal components. Automated assembly lines are often utilized to enhance efficiency and ensure consistency. During this phase, manufacturers may also implement in-process quality control (IPQC) to catch any defects early in the production process, thereby reducing waste and ensuring product integrity.

How Is the Finishing of US Mains Sockets Achieved?

Finishing processes are crucial for both aesthetic and functional aspects. This stage typically involves surface treatments to enhance resistance to wear and tear, as well as painting or coating for visual appeal. A final inspection is conducted to ensure that all products meet the required specifications before packaging and shipment.

What International Standards Govern Quality Assurance for US Mains Sockets?

Quality assurance is vital in the manufacturing of US mains sockets to ensure safety and compliance. For international B2B buyers, understanding these standards is crucial.

Understanding ISO 9001 and Other Standards

ISO 9001 is a widely recognized international standard for quality management systems (QMS). Manufacturers of US mains sockets often pursue ISO 9001 certification to demonstrate their commitment to quality. In addition to ISO standards, products must also comply with industry-specific regulations such as CE marking in Europe, which indicates compliance with health, safety, and environmental protection standards.

How Are Quality Control Checkpoints Implemented?

Quality control checkpoints are established throughout the manufacturing process to ensure that products meet specified standards. Key checkpoints include:

- Incoming Quality Control (IQC): Checks on raw materials before production begins.

- In-Process Quality Control (IPQC): Ongoing inspections during various stages of manufacturing, particularly during assembly.

- Final Quality Control (FQC): Comprehensive testing of finished products before they are packaged and shipped.

What Common Testing Methods Are Used to Ensure Product Quality?

B2B buyers should be aware of the various testing methods used to ensure the safety and reliability of US mains sockets.

Electrical Safety Testing

Electrical safety tests, such as dielectric strength tests, are crucial for determining whether the socket can handle the voltage levels without risk of failure. Additionally, manufacturers often conduct tests for short-circuit protection to ensure the safety of end-users.

Mechanical Testing

Mechanical testing evaluates the physical durability of the sockets, including stress tests to assess how well they can withstand force and wear over time.

Environmental Testing

Given the diverse climates in regions like Africa and South America, environmental testing is essential. This includes assessing the product’s performance under various temperature and humidity conditions to ensure reliability in all environments.

How Can B2B Buyers Verify Supplier Quality Control Processes?

When sourcing US mains sockets from international suppliers, B2B buyers must implement strategies to verify quality control processes effectively.

What Should Be Included in Supplier Audits?

Conducting thorough supplier audits is one of the most effective ways to verify quality control. Audits should cover aspects such as:

- Compliance with international standards (ISO, CE, etc.).

- Presence of quality management systems.

- Documentation of quality control processes and results.

How to Utilize Quality Reports and Third-Party Inspections?

Requesting quality reports from suppliers can provide insights into their testing and quality assurance processes. Additionally, engaging third-party inspection services can offer an unbiased assessment of the manufacturer’s capabilities. These inspections can be critical for ensuring that the products meet the necessary standards before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating the nuances of quality control can be particularly challenging for B2B buyers from diverse regions.

Understanding Regional Compliance Requirements

Different regions may have specific compliance requirements that manufacturers must meet. For example, European buyers will look for CE certification, while buyers in Africa may prioritize local certifications. Understanding these requirements can help buyers avoid costly mistakes and ensure product compliance.

The Importance of Clear Communication

Clear communication with suppliers is essential. B2B buyers should ensure that they articulate their quality requirements and expectations explicitly. This helps to align both parties and reduces the risk of misunderstandings that could impact product quality.

In conclusion, understanding the manufacturing processes and quality assurance protocols for US mains sockets is crucial for international B2B buyers. By focusing on material preparation, forming, assembly, finishing, and stringent quality control measures, buyers can make informed decisions when selecting suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘us mains socket’

In this practical sourcing guide, international B2B buyers looking to procure US mains sockets will find a step-by-step checklist designed to streamline the purchasing process. This guide aims to ensure that buyers can make informed decisions, minimize risks, and achieve optimal results in their sourcing endeavors.

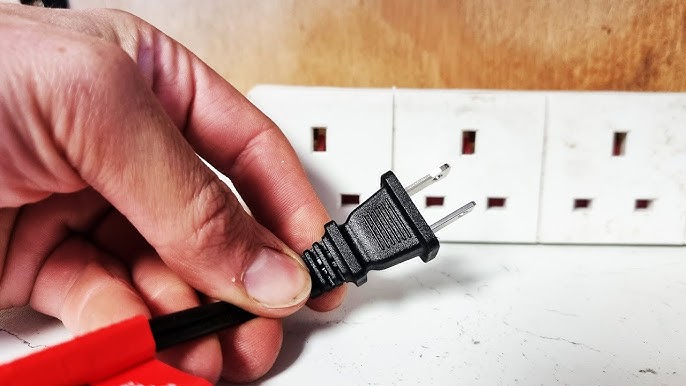

A stock image related to us mains socket.

Step 1: Define Your Technical Specifications

Understanding your needs is crucial. Begin by outlining the specific requirements for the US mains socket, including the type (A or B), voltage (120V), and frequency (60Hz). This clarity will help in communicating effectively with suppliers and ensuring that the products meet your operational standards.

- Consider compatibility: Ensure that the sockets will work with the devices you plan to connect.

- Assess safety standards: Look for specifications that comply with local and international safety regulations.

Step 2: Research Reliable Suppliers

Identifying trustworthy suppliers is essential. Conduct thorough research to find manufacturers or distributors with a solid reputation in the industry. Use platforms like Alibaba, Global Sources, and industry-specific directories to identify potential partners.

- Check reviews and ratings: Look for feedback from other B2B buyers to gauge supplier reliability.

- Evaluate experience: Prefer suppliers with experience in exporting to your region, especially if you are in Africa, South America, the Middle East, or Europe.

Step 3: Verify Supplier Certifications

Ensure compliance and quality assurance. Request documentation that verifies the supplier’s compliance with relevant certifications, such as UL (Underwriters Laboratories) or CE (Conformité Européenne). These certifications indicate that the products have been tested for safety and performance.

- Ask for test reports: Request recent test reports that validate the certifications.

- Confirm validity: Verify the authenticity of certifications through the issuing organizations.

Step 4: Request Samples for Evaluation

Testing the product is key to making informed decisions. Before placing a bulk order, request samples of the US mains sockets. This step allows you to assess the quality and functionality firsthand.

- Evaluate build quality: Check for durability and materials used.

- Test compatibility: Ensure the samples work seamlessly with your devices.

Step 5: Inquire About Pricing and Payment Terms

Understanding financial aspects is crucial for budget management. Obtain detailed pricing information, including shipping costs, taxes, and any applicable tariffs. Discuss payment terms to find arrangements that suit both parties.

- Negotiate terms: Don’t hesitate to negotiate for better pricing, especially for larger orders.

- Consider payment security: Choose secure payment methods that protect your investment.

Step 6: Assess Shipping and Delivery Options

Timely delivery is vital for operational efficiency. Confirm shipping methods and delivery timelines with your supplier. Understanding these logistics will help you plan your inventory and operations accordingly.

- Evaluate shipping partners: Ensure the supplier works with reputable logistics companies.

- Discuss customs procedures: Familiarize yourself with any customs requirements for importing electrical components into your region.

Step 7: Establish Clear Communication Channels

Effective communication can prevent misunderstandings. Set up clear lines of communication with your supplier. Establish regular check-ins and updates throughout the sourcing process to ensure everything is on track.

- Utilize multiple platforms: Use email, phone, or messaging apps to stay in touch.

- Clarify expectations: Ensure both parties are aligned on timelines, quality, and specifications.

By following this checklist, international B2B buyers can navigate the complexities of sourcing US mains sockets more effectively, ensuring they secure high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for us mains socket Sourcing

What Are the Key Cost Components in Sourcing US Mains Sockets?

Understanding the cost structure for sourcing US mains sockets is crucial for international B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials such as plastics for casing, copper for wiring, and metals for connectors. Prices can fluctuate based on market demand and availability, which can significantly impact the overall cost.

-

Labor: Labor costs vary by region and can be a significant portion of the total cost. Countries with lower labor costs may provide more competitive pricing, but this can sometimes compromise quality.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with the production facility. Efficient manufacturing processes can reduce overhead costs and improve profit margins.

-

Tooling: Initial setup costs for molds and specialized equipment can be substantial, particularly for customized sockets. This cost is often amortized over larger production runs, making bulk orders more economical.

-

Quality Control (QC): Ensuring product quality is essential, especially for electrical components. QC processes can add to costs but are necessary to avoid recalls and ensure compliance with international standards.

-

Logistics: Shipping costs can vary dramatically based on the distance from the manufacturing site to the buyer’s location, the chosen shipping method, and the volume of the order.

-

Margin: Suppliers typically add a profit margin to cover business risks and operational costs. This margin can vary based on competition, market demand, and buyer negotiation.

How Do Price Influencers Affect the Cost of US Mains Sockets?

Several factors can influence the pricing of US mains sockets:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer lower prices for larger orders. Understanding the MOQ can help buyers negotiate better deals and reduce per-unit costs.

-

Specifications and Customization: Custom sockets that meet specific requirements or certifications may incur additional costs. Buyers should clearly outline their needs to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as UL or CE) can increase costs but are crucial for safety and compliance in various markets. Buyers should weigh the importance of these factors against their budget.

-

Supplier Factors: The reputation and reliability of suppliers can influence price. Established suppliers may charge a premium, but they often provide better quality assurance and customer service.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can affect total costs. Terms like CIF (Cost, Insurance, and Freight) or FOB (Free on Board) can shift responsibility and costs between the buyer and supplier, impacting overall pricing.

What Are Effective Buyer Tips for Cost-Efficient Sourcing?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, adopting strategic approaches can lead to cost savings:

-

Negotiate Effectively: Building strong relationships with suppliers can facilitate better negotiation outcomes. Consider discussing long-term partnerships to secure favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the purchase price. Consider maintenance, potential downtime, and energy efficiency when evaluating the overall cost of the sockets.

-

Understand Pricing Nuances: Be aware that prices may vary significantly based on regional market conditions. Conduct thorough market research to ensure you are getting competitive pricing.

-

Leverage Local Knowledge: Engaging with local representatives or consultants can provide insights into the supplier landscape and help navigate cultural nuances in negotiations.

Disclaimer on Pricing

Please note that prices for US mains sockets can vary widely based on the factors discussed above. It is advisable for buyers to obtain multiple quotes and conduct comprehensive market analysis before making purchasing decisions.

Alternatives Analysis: Comparing us mains socket With Other Solutions

Understanding Alternatives to the US Mains Socket

In the global landscape of electrical infrastructure, the US mains socket (Type A and B) presents unique characteristics that may not align with the requirements of all international B2B buyers. As businesses expand into diverse markets such as Africa, South America, the Middle East, and Europe, it becomes imperative to evaluate alternative solutions that can meet varying operational needs. This analysis compares the US mains socket with two viable alternatives: the European mains socket (Type C and E) and the Universal socket.

Comparison Table of Mains Socket Alternatives

| Comparison Aspect | Us Mains Socket | European Mains Socket (Type C/E) | Universal Socket |

|---|---|---|---|

| Performance | 120V, 60Hz | 230V, 50Hz | Supports multiple voltages and frequencies |

| Cost | Moderate (specific to US markets) | Moderate to high (depends on installation) | Higher initial cost but versatile |

| Ease of Implementation | Straightforward for US-based systems | Requires adaptation for non-European devices | Requires no adaptation for various devices |

| Maintenance | Low | Low to moderate (depends on region) | Low (generally durable) |

| Best Use Case | North America, some Caribbean nations | Europe, parts of Asia and Africa | International travel and multi-device environments |

What Are the Pros and Cons of the European Mains Socket?

A stock image related to us mains socket.

The European mains socket, encompassing Type C and E, operates at a voltage of 230V and a frequency of 50Hz. Its higher voltage allows for improved energy efficiency in many industrial applications, potentially lowering operational costs over time. However, for businesses using equipment designed for lower voltages, this may necessitate the use of voltage converters, adding complexity and cost. Additionally, while Type C plugs are compatible with Type E sockets, this can lead to confusion in installations where multiple plug types exist.

How Does the Universal Socket Compare?

The Universal socket is designed to accommodate a wide array of plug types, making it a highly flexible option for international businesses. It supports various voltages and frequencies, which is advantageous for companies importing equipment from different regions. However, the initial investment in universal sockets can be higher, and there may be concerns about compatibility with specific devices, particularly those requiring grounding. The ease of use and adaptability of the universal socket often outweigh these drawbacks, making it a strong contender for companies focused on global operations.

Conclusion: How Should B2B Buyers Choose the Right Socket Solution?

When selecting the appropriate socket solution, B2B buyers should consider their operational geography, the types of devices they will be using, and any potential future expansions into new markets. The US mains socket is ideal for businesses operating solely within the US and its territories, while the European mains socket is more suited for those engaging with European markets. For companies with a global reach, the universal socket offers the most flexibility, allowing seamless integration of various devices regardless of origin. Ultimately, the choice should align with the company’s operational needs and future growth strategies.

Essential Technical Properties and Trade Terminology for us mains socket

What Are the Essential Technical Properties of US Mains Sockets?

When sourcing US mains sockets, understanding the technical specifications is crucial for ensuring compatibility and safety in your operations. Here are the key properties to consider:

1. Voltage and Frequency Specifications: Why Do They Matter?

The standard voltage for US mains sockets is 120V with a frequency of 60Hz. This is significantly lower than the 220-240V systems prevalent in many African and European countries. For B2B buyers, ensuring that electrical devices can operate within these parameters is essential to prevent damage and ensure functionality. Devices labeled with a voltage range of 100-240V can operate safely in both environments.

2. Socket Type: What Are Types A and B?

US mains sockets primarily utilize Type A and Type B configurations. Type A has two flat parallel pins, while Type B includes a grounding pin. Understanding these types is vital for international buyers to ensure that their equipment will fit and function correctly. For example, Type B sockets are generally more secure and are recommended for devices requiring grounding.

3. Material Grade: How Does It Affect Durability?

The materials used in the construction of sockets—commonly thermoplastic and copper—impact durability and safety. High-grade materials can withstand heat and wear, which is crucial for commercial applications. Buyers should verify that the products meet international safety standards to avoid potential hazards.

4. Tolerance Levels: What Should Buyers Look For?

Tolerance levels refer to the acceptable limits of variation in dimensions and electrical characteristics. A tight tolerance ensures that plugs fit snugly in sockets, minimizing the risk of electrical arcing. For B2B transactions, ensuring that suppliers can provide detailed tolerance specifications is critical for maintaining quality control.

5. Current Rating: Why Is It Important?

The current rating, typically measured in amperes (A), indicates how much electrical current a socket can safely handle. US mains sockets usually have ratings of 15A or 20A. For international buyers, choosing sockets with appropriate current ratings based on the devices they plan to connect is essential to avoid overheating and potential fire hazards.

What Are Common Trade Terms Related to US Mains Sockets?

Understanding the terminology used in the industry can facilitate smoother transactions and better negotiations. Here are some common terms:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, working with OEMs can ensure high-quality components tailored to specific needs, especially when sourcing sockets for large-scale projects.

2. MOQ (Minimum Order Quantity): How Does It Affect Purchasing?

MOQ is the smallest quantity of a product that a supplier is willing to sell. For international buyers, understanding the MOQ can impact budgeting and inventory planning. It’s essential to negotiate this term to align with your operational needs.

3. RFQ (Request for Quotation): Why Is It Essential?

An RFQ is a document that a buyer sends to suppliers requesting a price quote for specific products or services. This is a critical step in the procurement process, enabling buyers to compare pricing and terms from multiple suppliers.

4. Incoterms: What Are They and Why Do They Matter?

Incoterms, or International Commercial Terms, define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, which is crucial for buyers from Africa, South America, the Middle East, and Europe to ensure compliance and avoid unexpected costs.

5. Certification Standards: What Should Buyers Look For?

Certification standards, such as UL (Underwriters Laboratories) or CE (Conformité Européenne), indicate that products meet specific safety and quality requirements. For international buyers, ensuring that US mains sockets carry the appropriate certifications is vital for compliance with local regulations.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing US mains sockets, ensuring compatibility, safety, and efficiency in their operations.

Navigating Market Dynamics and Sourcing Trends in the us mains socket Sector

What Are the Current Trends Influencing the US Mains Socket Market?

The US mains socket market is shaped by various global drivers, including technological advancements, consumer preferences, and regulatory changes. One significant trend is the increasing demand for smart home technology, which integrates with US type A and B sockets. As consumers in Africa, South America, the Middle East, and Europe seek more connected devices, B2B buyers must ensure compatibility with existing infrastructure in the US. Furthermore, the rise of e-commerce and digital marketplaces is altering sourcing strategies, allowing buyers to access a wider range of products and suppliers.

The market dynamics are also influenced by economic factors such as currency fluctuations and trade agreements. For instance, the US-Mexico-Canada Agreement (USMCA) has implications for sourcing components and manufacturing, particularly for companies in North America. B2B buyers should consider these economic contexts when sourcing US mains sockets, as they can impact pricing and availability.

Additionally, sustainability is becoming a key driver in the sourcing of electrical components, with buyers increasingly looking for energy-efficient solutions. This shift is compounded by the rise in regulatory requirements for energy consumption and waste management, pushing manufacturers to innovate and improve their product offerings.

How Important Is Sustainability and Ethical Sourcing in the US Mains Socket Sector?

Sustainability and ethical sourcing are critical considerations for international B2B buyers in the US mains socket market. The environmental impact of electrical components is substantial, from resource extraction to manufacturing processes. As such, companies are increasingly prioritizing eco-friendly materials and sustainable production methods.

Buyers should look for suppliers who offer products certified by recognized environmental standards, such as Energy Star or RoHS (Restriction of Hazardous Substances). These certifications not only indicate compliance with environmental regulations but also demonstrate a commitment to reducing ecological footprints. Additionally, sourcing from manufacturers with transparent supply chains ensures that ethical labor practices are upheld, which is particularly important for buyers from regions with stringent corporate social responsibility (CSR) expectations.

By choosing sustainable and ethically sourced products, companies can enhance their brand reputation and appeal to environmentally conscious consumers. Furthermore, as global markets evolve, those who adopt sustainable practices are likely to gain a competitive advantage in the marketplace.

What Is the Historical Context of the US Mains Socket Market?

The evolution of the US mains socket market dates back to the early 20th century, with the introduction of type A and B plugs, which have since become the standard. Initially designed to accommodate the 110-120 V electrical systems prevalent in the US, these sockets have undergone various modifications to improve safety and functionality.

Over the decades, the increasing proliferation of electrical devices has led to a growing need for reliable and efficient power solutions. This historical context is crucial for B2B buyers, as understanding the origins and developments in the market can inform sourcing decisions and highlight potential areas for innovation. As the market continues to evolve, staying informed about historical trends can provide valuable insights into future developments and opportunities.

In conclusion, navigating the US mains socket market requires an understanding of current trends, a commitment to sustainability, and awareness of historical influences. International B2B buyers should leverage this knowledge to make informed sourcing decisions that align with both market demands and ethical considerations.

Frequently Asked Questions (FAQs) for B2B Buyers of us mains socket

-

How do I choose the right US mains socket for my business needs?

When selecting US mains sockets, consider the type of devices you plan to connect. The US primarily uses Type A and Type B sockets, with a standard voltage of 120V and frequency of 60Hz. Ensure your devices are compatible with this voltage to avoid damage. Additionally, assess the quality and certifications of the sockets to ensure compliance with international safety standards. Engaging with reliable suppliers who offer product guarantees can also help mitigate risks associated with quality. -

What is the best way to find reliable suppliers for US mains sockets?

Conduct thorough research on potential suppliers by leveraging B2B platforms, industry trade shows, and local business directories. Look for suppliers with established reputations and positive reviews from previous clients. Request references and check their production capabilities, certifications, and quality assurance processes. Additionally, consider visiting their facilities if possible, or conducting virtual audits to evaluate their operations and compliance with international standards. -

What customization options are available for US mains sockets?

Many manufacturers offer customization options for US mains sockets, including color, size, and configuration to meet specific client requirements. You can also request unique branding features, such as logos or product labeling. Discuss these options during initial negotiations and ensure that the supplier can accommodate your needs without compromising on safety or compliance standards. -

What are the typical minimum order quantities (MOQs) for US mains sockets?

Minimum order quantities can vary significantly between suppliers, typically ranging from 100 to 1,000 units. Smaller suppliers may offer lower MOQs, while larger manufacturers may require higher orders to justify production costs. It’s essential to clarify MOQs upfront to align with your budget and inventory needs. If you are unsure about committing to a high MOQ, consider negotiating sample orders first. -

How should I negotiate payment terms with suppliers of US mains sockets?

Effective negotiation of payment terms is crucial for maintaining cash flow. Common terms include upfront deposits (20-30%) with the balance payable before shipping. Consider discussing alternative terms like net 30 or net 60 days to ease financial pressure. Utilize secure payment methods and ensure that the terms are documented in a formal contract to protect both parties involved.

A stock image related to us mains socket.

-

What quality assurance measures should I expect from suppliers of US mains sockets?

Reputable suppliers should have comprehensive quality assurance processes in place, including regular product testing and certifications from recognized bodies. Request documentation of their quality control practices, such as ISO certifications or compliance with UL standards. Additionally, inquire about their return and warranty policies to ensure you are protected against defective products. -

How can I ensure smooth logistics for importing US mains sockets?

To ensure smooth logistics, establish a clear shipping timeline and understand the associated costs, including tariffs and customs duties. Work closely with your supplier to coordinate shipment details and choose reliable freight forwarders with experience in handling electrical components. Familiarize yourself with local import regulations to prevent delays at customs. Consider using Incoterms (like FOB or CIF) to clarify responsibilities for shipping and insurance. -

What are the common challenges in sourcing US mains sockets internationally?

Common challenges include variations in voltage and plug types, which can lead to compatibility issues with devices from different regions. Additionally, language barriers and differing regulations may complicate communication and compliance. To mitigate these challenges, invest in thorough research and maintain open communication with suppliers. Establishing relationships with local agents can also facilitate smoother transactions and help navigate regional nuances.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for us mains socket

What Are the Key Takeaways for International B2B Buyers of US Mains Sockets?

In conclusion, understanding the nuances of sourcing US mains sockets is crucial for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. As highlighted, the predominant socket types A and B operate at 120V and 60Hz, which may require adapters and potentially voltage converters for devices from regions with different standards. Buyers should prioritize sourcing from reliable manufacturers who comply with international safety and quality standards to ensure seamless integration and operation of devices.

How Can Strategic Sourcing Enhance Your Supply Chain?

Strategic sourcing not only helps in securing competitive pricing but also ensures reliability in supply chains. By leveraging insights into regional requirements and compliance standards, businesses can mitigate risks associated with electrical components. Establishing long-term partnerships with suppliers can facilitate smoother transactions and better support services.

What’s Next for International Buyers?

As the global market continues to evolve, staying ahead of trends in electrical standards and technology is essential. International B2B buyers are encouraged to explore partnerships with suppliers who can offer innovative solutions and comprehensive support. By doing so, companies can enhance operational efficiency and expand their market reach. Take proactive steps today to secure a reliable supply of US mains sockets that meet your business needs.