Top 7 Plastic Pallet Manufacturers List and Guide: How To Solve S…

Introduction: Navigating the Global Market for Plastic Pallet Manufacturers

In today’s competitive landscape, sourcing reliable plastic pallet manufacturers is a critical challenge for international B2B buyers. The transition from traditional wooden pallets to innovative plastic alternatives is gaining momentum, driven by the need for enhanced durability, hygiene, and sustainability. This guide serves as a comprehensive resource, offering insights into various types of plastic pallets, their applications across diverse industries, and essential factors to consider when vetting suppliers. By exploring the nuances of material selection, cost considerations, and performance specifications, we empower decision-makers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Brazil—to make informed purchasing decisions.

Understanding the global market for plastic pallet manufacturers is essential for optimizing supply chains and improving operational efficiency. This guide not only highlights the advantages of plastic pallets, such as their resistance to moisture and ease of cleaning but also provides strategic recommendations on how to evaluate potential suppliers. By leveraging this knowledge, B2B buyers can navigate the complexities of the market, ensuring they choose the right products that align with their specific logistical and environmental needs. Prepare to delve into the world of plastic pallets and discover how to enhance your supply chain management effectively.

Top 10 Plastic Pallet Manufacturers Manufacturers & Suppliers List

1. TranPak – Corona 48×40 Plastic Pallet

Domain: tranpak.com

Registered: 1999 (26 years)

Introduction: TranPak offers a variety of plastic pallets including stackable, rackable, export, shipping, and custom plastic pallets. Key specifications for featured products include:

1. **Corona 48×40**: Dimensions – 48″ x 40″ x 5.5″, Floor Capacity – 5,000 lbs, Forklift Capacity – 3,000 lbs, Weight – 22 lbs, Material – HDPE/PP Recycled.

2. **Corona + Base 48×40**: Dimensions – 48″ x 40″ x 6.0″, Floor Capaci…

2. PHS Inc. – EXP 100 Plastic Pallet

Domain: phsinc.com

Registered: 2004 (21 years)

Introduction: Plastic Pallets: Premier is a global leading manufacturer of American-made plastic pallets. Key products include: 1. EXP 100 PLASTIC PALLET – Dynamic Capacity: 2,200 lbs, Static Capacity: 3,500 lbs, Dimensions: 48″ x 40″ x 5.2″, Pallets Per Stack: 78 TL / 75 LTL, Truckload Qty: 2,340 LTL, Material: PE, PP, Color: BLACK, Type: 4-Way Entry, Price: $16.95. 2. EXP 112 EURO PLASTIC PALLET – Dynamic Cap…

3. ProStack – Plastic Pallets and Racks

Domain: prostack.com

Registered: 1999 (26 years)

Introduction: Buy Plastic Pallets Online | Plastic Pallet Manufacturer Products: Bottled Water Rack Products, ProStack Product Series, 4 Pocket Modular Rack, 4-G NRB Modular Rack, 2 Pocket Modular Rack, 3 Pocket Modular Rack, Metric Modular Rack, Bottle-Up Product Series, Single Wide 2-Tray Rack, Double Wide 4-Tray Retail Rack, Double Wide 5-Tray Retail Rack, Single Wide 4-Tray Rack, Multi Pack Double Wide 3-Tr…

4. Gorilla Pallets – Durable Plastic Export Pallets

Domain: gorillapallets.com

Registered: 2004 (21 years)

Introduction: Gorilla Pallets offers a variety of durable plastic pallets, specializing in export pallets. Key products include: GP-ET2 4444B (44 x 44 x 5.2 inches, Static Capacity: 4409 lbs, Dynamic Capacity: 2205 lbs, $17.99 each, minimum order of 50), GP-ET2 4832A (48 x 32 x 5.2 inches, Static Capacity: 4409 lbs, Dynamic Capacity: 2205 lbs, $17.99 each, minimum order of 50), GP-ET2 4840A (48 x 40 x 5.2 inche…

5. IQS Directory – Plastic Pallets

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Plastic pallets are sturdy platforms designed for the storage and transportation of products. They are highly valued for their strength, durability, and chemical resistance, making them suitable for warehouses, factories, shipping companies, and various other businesses. Key features include high hygiene and sanitation levels, resistance to cross-contamination, and suitability for industries such …

6. Nelson Company – Plastic Pallets

Domain: nelsoncompany.com

Registered: 1999 (26 years)

Introduction: Plastic Pallets – 306 options available. Durable and lightweight. Fast delivery from multiple US shipping points. Made from 100% recycled materials. Resistant to water, mold, and bug infestations. Exempt from ISPM-15 requirements for export. Key specifications include various sizes (e.g., 48×40, 48×32, 42×42), weights (e.g., 11.0 lbs to 66.0 lbs), static and dynamic load capacities (e.g., static l…

7. Craemer – Durable Plastic Pallets

Domain: craemer.com

Registered: 1999 (26 years)

Introduction: Craemer plastic pallets are designed for durability and efficiency, featuring the following key details:

– Dimensions: Available in US-Standard Industrial Pallets (48″ x 40″), Euro Pallets (1200 x 800 mm), Industrial Pallets (1200 x 1000 mm), Half Pallets (800 x 600 mm), Pallet Collars, and Pallet Lids.

– Applications: Suitable for various sectors including Food Packaging, Retail, Pharma and Che…

Understanding Plastic Pallet Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stackable Plastic Pallets | Designed for vertical stacking, maximizing storage efficiency | Warehousing, distribution, retail | Pros: Space-saving, efficient handling. Cons: Limited load stability when stacked. |

| Rackable Plastic Pallets | Engineered to withstand heavy loads in racking systems | Manufacturing, automotive, logistics | Pros: High load capacity, ideal for warehouse racking. Cons: Heavier and may cost more. |

| Nestable Plastic Pallets | Designed to fit into one another when empty, reducing transport volume | Export, food and beverage, pharmaceuticals | Pros: Space-efficient during transport, lightweight. Cons: Less robust under heavy static loads. |

| Heavy-Duty Plastic Pallets | Constructed for maximum durability and high load-bearing capacity | Industrial, chemical, and automotive sectors | Pros: Long lifespan, excellent for heavy items. Cons: Higher upfront investment. |

| Custom Plastic Pallets | Tailored design to meet specific requirements of different industries | Specialized manufacturing, retail display | Pros: Meets unique needs, flexibility in design. Cons: Longer lead times, potentially higher costs. |

What Are the Characteristics of Stackable Plastic Pallets?

Stackable plastic pallets are specifically designed to optimize space by allowing pallets to be stacked on top of each other. This feature is especially beneficial in warehousing and retail environments where maximizing vertical storage is crucial. They typically have a uniform shape and dimensions that facilitate easy handling and transport. Buyers should consider the stability of the stack when loaded, as improper stacking can lead to safety hazards.

How Do Rackable Plastic Pallets Differ in Design?

Rackable plastic pallets are built to endure heavy loads while being stored on racking systems. Their design includes reinforced corners and a sturdy base, making them suitable for applications in manufacturing and logistics. When purchasing rackable pallets, businesses should assess the weight capacity and compatibility with existing racking systems to ensure safety and efficiency in storage operations.

Why Choose Nestable Plastic Pallets for Export?

Nestable plastic pallets are engineered to fit neatly into one another when empty, significantly reducing the volume during transport. This is particularly advantageous for companies involved in export, as it lowers shipping costs. However, while they offer great space efficiency, buyers should be aware that these pallets may not perform as well under heavy static loads, making them less suitable for certain applications.

What Makes Heavy-Duty Plastic Pallets Ideal for Industrial Use?

Heavy-duty plastic pallets are crafted for maximum durability and are capable of supporting significant weight, making them ideal for industrial applications. They are often used in sectors such as chemicals and automotive, where robust material handling is essential. When considering these pallets, businesses should evaluate the trade-off between their higher upfront costs and the long-term savings from reduced replacements and maintenance.

How Can Custom Plastic Pallets Meet Unique Business Needs?

Custom plastic pallets provide tailored solutions to meet the specific requirements of various industries, such as specialized manufacturing or retail display. These pallets can be designed with unique dimensions, features, or materials that align with a company’s operational needs. While the flexibility in design can be a major advantage, buyers should factor in longer lead times and potentially higher costs when opting for custom solutions.

Key Industrial Applications of Plastic Pallet Manufacturers

| Industry/Sector | Specific Application of Plastic Pallet Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Transporting and storing perishable goods | Enhanced hygiene, ease of cleaning, and compliance with food safety regulations | Durability, resistance to moisture, and FDA compliance standards |

| Pharmaceutical | Handling and storage of medical supplies and drugs | Ensures product integrity, prevents contamination, and maintains compliance | Chemical resistance, traceability features, and custom sizes available |

| Automotive | Parts handling and assembly line support | Reduces damage during transport, enhances efficiency in assembly processes | Load capacity, compatibility with existing systems, and durability |

| Retail Distribution | Display and transportation of consumer goods | Improves product visibility, protects items during transit | Design flexibility, weight considerations, and stackability |

| Agriculture | Storing and transporting agricultural products | Minimizes spoilage, enhances cleanliness, and supports sustainability | Resistance to chemicals, UV protection, and ease of handling |

How are Plastic Pallet Manufacturers Used in the Food and Beverage Industry?

In the food and beverage sector, plastic pallets are crucial for transporting and storing perishable goods. Their non-porous surfaces prevent moisture absorption, making them easy to clean and sanitize. This is vital for compliance with stringent food safety regulations. International buyers should prioritize pallets that meet FDA standards and offer durability against the rigors of cold storage and transportation.

What Role Do Plastic Pallets Play in the Pharmaceutical Industry?

Plastic pallets are essential in the pharmaceutical industry for handling and storing sensitive medical supplies and drugs. They help maintain product integrity and prevent contamination, crucial for regulatory compliance. Buyers in this sector should look for pallets made from materials with high chemical resistance and those that can provide traceability features to meet industry regulations.

How Do Plastic Pallets Benefit the Automotive Sector?

In the automotive industry, plastic pallets are used extensively for parts handling and assembly line support. They reduce the risk of damage during transport and improve efficiency in assembly processes. B2B buyers should consider load capacities, compatibility with existing systems, and the durability of the pallets to withstand the heavy demands of automotive manufacturing.

Why are Plastic Pallets Important for Retail Distribution?

For retail distribution, plastic pallets facilitate the display and transportation of consumer goods. They improve product visibility while protecting items during transit. Buyers should focus on design flexibility, weight considerations, and stackability to optimize space in warehouses and transport vehicles, ensuring efficient operations.

What Advantages Do Plastic Pallets Offer in Agriculture?

In agriculture, plastic pallets are used to store and transport agricultural products, minimizing spoilage and enhancing cleanliness. They support sustainability initiatives by being reusable and recyclable. Buyers should seek pallets that offer resistance to chemicals and UV protection, as well as ease of handling for efficient operations in various agricultural settings.

3 Common User Pain Points for ‘Plastic Pallet Manufacturers’ & Their Solutions

Scenario 1: Difficulty in Customization for Specific Industry Needs

The Problem: B2B buyers often find that their unique product handling requirements are not met by standard plastic pallets. Industries such as pharmaceuticals or food processing have stringent regulations that necessitate specific dimensions, weight capacities, and hygienic standards. The inability to customize pallets can lead to inefficiencies in storage, transportation, and even product integrity, ultimately affecting the bottom line.

The Solution: To address these challenges, buyers should engage directly with plastic pallet manufacturers that offer bespoke design services. It’s crucial to provide detailed specifications, including load capacity, size, and material requirements, to ensure the manufacturer understands your needs. Look for manufacturers who have experience in your specific industry, as they will be more adept at navigating compliance and performance standards. Additionally, requesting prototypes can help verify that the pallets meet your operational demands before committing to a bulk order. Collaborating closely with your chosen manufacturer can lead to innovative solutions tailored to your unique challenges.

Scenario 2: Concerns Over Durability and Lifespan of Plastic Pallets

The Problem: A common concern among B2B buyers is the perceived fragility of plastic pallets compared to their wooden counterparts. Many buyers worry that plastic pallets may not withstand heavy loads, extreme temperatures, or harsh handling, which could result in costly damage or product loss during transit or storage.

The Solution: To mitigate these concerns, buyers should conduct thorough research on the types of plastics used in the pallets. Materials like High-Density Polyethylene (HDPE) and Polypropylene (PP) are known for their strength and durability. Requesting data sheets that detail the mechanical properties of the pallets, including dynamic and static load capacities, can provide assurance of their performance. Additionally, consider investing in pallets that come with warranties or performance guarantees. Engaging with suppliers that have a solid track record of customer satisfaction and product longevity can further alleviate concerns. Regularly scheduled maintenance and inspections can also help extend the lifespan of your plastic pallets.

Scenario 3: Challenges with Sustainability and Environmental Impact

The Problem: Increasingly, businesses are held accountable for their environmental impact, and many B2B buyers are seeking sustainable solutions in their supply chain. Traditional plastic pallets may raise concerns regarding their recyclability and carbon footprint, making it difficult to align with corporate sustainability goals.

The Solution: Buyers should proactively seek out manufacturers that specialize in eco-friendly plastic pallets made from recycled materials. Inquire about the sourcing of the plastics used and the manufacturing processes that reduce waste and energy consumption. Look for certifications that validate the sustainability of the pallets, such as those from recognized environmental organizations. Furthermore, consider establishing a take-back program with your supplier for end-of-life pallets, facilitating recycling and promoting a circular economy. By prioritizing sustainable practices in your procurement process, you can enhance your brand reputation while contributing positively to environmental stewardship.

By addressing these common pain points with targeted solutions, B2B buyers can make informed decisions that enhance their supply chain efficiency, product integrity, and commitment to sustainability.

Strategic Material Selection Guide for Plastic Pallet Manufacturers

What Are the Key Properties of Common Materials Used in Plastic Pallet Manufacturing?

When selecting materials for plastic pallets, manufacturers often consider several polymer types, each with distinct properties that influence performance, durability, and cost. Understanding these materials is crucial for B2B buyers aiming to optimize their supply chain and meet industry standards.

High-Density Polyethylene (HDPE)

HDPE is a widely used material known for its exceptional strength and rigidity. It can withstand high temperatures and is resistant to moisture, making it ideal for heavy-duty applications across various industries, including automotive and food processing. The material’s impact resistance ensures longevity, even with frequent reuse.

Pros: HDPE pallets are durable, resistant to corrosion, and easy to clean, which is vital for industries requiring strict hygiene standards.

Cons: The manufacturing process for HDPE can be more complex, leading to higher initial costs compared to other materials.

Impact on Application: HDPE is particularly suitable for environments where load-bearing capacity is critical, such as in warehouses and distribution centers.

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is essential, especially in regions like Europe and the Middle East, where regulations are stringent.

Polypropylene (PP)

Polypropylene is a lightweight and cost-effective material that offers excellent chemical resistance. It is particularly beneficial in environments exposed to aggressive substances.

Pros: The flexibility and high impact tolerance of PP make it suitable for dynamic and static load scenarios, reducing shipping costs due to its lighter weight.

Cons: While PP is durable, it may not withstand extreme temperatures as effectively as HDPE, limiting its application in high-heat environments.

Impact on Application: PP pallets are ideal for industries such as chemicals and pharmaceuticals, where exposure to various substances is common.

Considerations for International Buyers: Buyers in regions like South America and Africa should ensure that PP pallets meet local compliance standards, particularly in industries with strict safety requirements.

Polyethylene Terephthalate (PET)

PET is known for its durability and resistance to high temperatures and chemicals. This material is often used in industries with stringent hygiene and safety standards, such as pharmaceuticals and food processing.

Pros: PET pallets maintain dimensional stability under heavy loads and do not warp easily, making them suitable for cleanroom applications.

Cons: The cost of PET can be higher than both HDPE and PP, which may deter some manufacturers from selecting it.

Impact on Application: PET is particularly effective in environments requiring high hygiene standards, such as food and beverage industries.

Considerations for International Buyers: Buyers should verify that PET pallets comply with relevant health and safety regulations in their respective regions, especially in Europe, where standards are rigorous.

Acrylonitrile Butadiene Styrene (ABS)

ABS is a strong and impact-resistant material that also offers good chemical durability. It is often used in demanding logistics operations and distribution centers.

Pros: ABS pallets can withstand rough handling and elevated temperatures, making them reliable for heavy industrial use.

Cons: The manufacturing complexity can lead to higher costs, and the material may not be as widely available as others.

Impact on Application: ABS is suitable for applications where durability and resistance to wear and tear are critical.

Considerations for International Buyers: Manufacturers should ensure that ABS pallets meet international standards, particularly in regions where operational safety is paramount.

Summary Table of Material Selection for Plastic Pallet Manufacturers

| Material | Typical Use Case for Plastic Pallet Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Density Polyethylene (HDPE) | Heavy-duty applications in automotive and food processing | Exceptional strength and moisture resistance | Higher initial manufacturing costs | Medium |

| Polypropylene (PP) | Chemical and pharmaceutical industries | Lightweight and excellent chemical resistance | Limited performance in extreme temperatures | Low |

| Polyethylene Terephthalate (PET) | Food and beverage industries requiring high hygiene standards | High durability and dimensional stability | Higher cost compared to HDPE and PP | High |

| Acrylonitrile Butadiene Styrene (ABS) | Heavy industrial use and demanding logistics operations | Strong and impact-resistant | Higher manufacturing complexity and cost | Medium |

This guide serves as a foundation for B2B buyers to make informed decisions regarding the selection of plastic pallets, ensuring they choose materials that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for Plastic Pallet Manufacturers

What Are the Main Stages in the Manufacturing Process of Plastic Pallets?

The manufacturing process for plastic pallets typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is essential for ensuring that the final product meets industry standards and customer requirements.

-

Material Preparation: The process begins with sourcing high-quality raw materials, primarily various types of plastics like High-Density Polyethylene (HDPE) and Polypropylene (PP). These materials are carefully selected based on their properties, such as strength, chemical resistance, and weight. The plastics are often delivered in pellet form, which are then processed in bulk. Manufacturers may also incorporate recycled plastics to enhance sustainability and reduce costs.

-

Forming: The prepared materials undergo various forming techniques, predominantly injection molding, extrusion, and thermoforming. Injection molding is the most common method, where heated plastic is injected into molds to form the desired shape. This technique allows for high precision and repeatability in pallet design. Extrusion is used for creating specific shapes and profiles, while thermoforming involves heating a plastic sheet until pliable and then shaping it over a mold. Each method has its advantages, with injection molding being favored for its efficiency and ability to produce complex designs.

-

Assembly: After forming, pallets are assembled, which may involve adding components such as reinforcement elements or top caps. Depending on the design, some pallets are produced as a single piece, while others require assembly of multiple parts. This stage is crucial for ensuring that the pallets can support the intended loads and are compatible with various handling equipment.

-

Finishing: The final stage includes quality checks, surface treatments, and labeling. Pallets may undergo processes like surface texturing for better grip or additional treatments to enhance resistance to UV light and chemicals. This stage also involves preparing the pallets for shipping, which may include stacking and wrapping for protection during transportation.

How Is Quality Assurance Implemented in Plastic Pallet Manufacturing?

Quality assurance (QA) is a vital aspect of plastic pallet manufacturing, ensuring that products meet both international standards and customer specifications. Manufacturers often adhere to established quality management systems, such as ISO 9001, which provides a framework for consistent quality improvement.

-

International Standards: Compliance with international standards is crucial for B2B buyers, particularly those operating across borders. Standards such as ISO 9001 focus on quality management systems, while others like CE mark and API standards may apply depending on the application and industry. Buyers should inquire about a manufacturer’s certifications to ensure compliance with relevant regulations.

-

Quality Control Checkpoints: Effective quality control involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet predefined specifications.

– In-Process Quality Control (IPQC): During manufacturing, periodic checks are conducted to monitor the process and identify any deviations from standards.

– Final Quality Control (FQC): Once pallets are completed, they undergo thorough inspection and testing to verify they meet performance criteria, such as load capacity and durability. -

Common Testing Methods: Various testing methods are employed to assess the quality of plastic pallets. These include load testing, impact resistance tests, and moisture absorption tests. Load testing evaluates how much weight a pallet can support before failure, while impact resistance tests determine how well the pallet withstands drops or shocks. Additionally, moisture absorption tests assess the material’s ability to resist environmental conditions.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must ensure that their suppliers maintain robust quality control practices to avoid costly issues down the line. Here are some actionable steps to verify supplier QC:

-

Conduct Supplier Audits: Regular audits are an effective way to assess a supplier’s quality management practices. During an audit, buyers can evaluate production processes, quality control measures, and compliance with international standards. It is advisable to engage third-party auditing services for an impartial evaluation.

-

Request Quality Reports: Buyers should request detailed quality reports from suppliers, including data on testing results and compliance with standards. These reports can provide insights into the consistency and reliability of the products.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can further validate supplier claims regarding quality. These inspectors can conduct independent assessments of the manufacturing process and the final products, ensuring they meet the required specifications.

-

Understand Certification Nuances: For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of certifications is essential. Different regions may have specific standards or regulations, and suppliers must be able to demonstrate compliance with these to facilitate smooth cross-border transactions.

Why Is Quality Assurance Particularly Important for International B2B Buyers?

For international B2B buyers, especially those operating in diverse and regulatory-heavy markets like Saudi Arabia, Brazil, and various European countries, quality assurance is paramount. It not only ensures product reliability but also mitigates risks associated with compliance and safety. Poor-quality pallets can lead to significant operational challenges, including product damage, supply chain disruptions, and regulatory penalties.

By focusing on suppliers that prioritize quality control and adhere to international standards, buyers can ensure they receive durable, reliable products that meet their logistical needs. As the demand for plastic pallets continues to grow globally, understanding the manufacturing processes and quality assurance measures in place will enable buyers to make informed decisions that align with their operational goals.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Plastic Pallet Manufacturers’

In the competitive landscape of international logistics and supply chain management, selecting the right plastic pallet manufacturer is crucial for efficiency and cost-effectiveness. This guide provides a step-by-step checklist designed to help B2B buyers navigate the sourcing process effectively, ensuring they make informed decisions that align with their operational needs and sustainability goals.

Step 1: Define Your Technical Specifications

Before reaching out to manufacturers, clearly outline your specific requirements. Consider factors such as load capacity, dimensions, and the type of plastic used. Defining these parameters will enable you to communicate your needs effectively and ensure that the pallets you choose are suitable for your intended applications.

Step 2: Research Potential Suppliers

Conduct thorough research to compile a list of potential plastic pallet manufacturers. Look for companies with a strong reputation in the industry, focusing on their experience and range of products. Utilize online resources, industry publications, and trade shows to gather information and identify suppliers that meet your criteria.

Step 3: Evaluate Supplier Certifications

It’s essential to verify that potential suppliers hold the necessary certifications and adhere to industry standards. Certifications such as ISO 9001 for quality management or compliance with food safety standards (if applicable) ensure that the manufacturer maintains high production standards. This step minimizes risks associated with product quality and safety.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the pallets you are considering. Testing these samples under your operational conditions will provide insight into their performance, durability, and suitability for your specific application. Look for signs of quality such as resistance to impact, moisture, and chemicals, which are critical for long-term use.

Step 5: Assess Production Capabilities and Lead Times

Understanding a manufacturer’s production capacity and lead times is vital to ensure they can meet your supply demands. Inquire about their manufacturing processes, inventory levels, and turnaround times. Suppliers with robust production capabilities can offer flexibility and reliability, helping you avoid disruptions in your supply chain.

Step 6: Evaluate Pricing and Payment Terms

Discuss pricing structures and payment terms with shortlisted suppliers. While cost is a significant factor, consider the overall value, including quality, service, and warranty options. Compare quotes from multiple suppliers to ensure you are getting a competitive price without compromising on quality.

Step 7: Check References and Reviews

Finally, gather feedback from previous clients to gauge the reliability and service quality of potential suppliers. Request references and look for online reviews or testimonials. Engaging with other businesses that have worked with the manufacturer can provide valuable insights and help you make a more informed decision.

By following this checklist, B2B buyers can streamline their sourcing process for plastic pallets, ensuring they select manufacturers that align with their operational needs and sustainability objectives.

Comprehensive Cost and Pricing Analysis for Plastic Pallet Manufacturers Sourcing

What Are the Key Cost Components in Plastic Pallet Manufacturing?

When sourcing plastic pallets, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of plastic significantly influences cost. High-Density Polyethylene (HDPE) and Polypropylene (PP) are common choices, with HDPE often commanding a higher price due to its durability and resistance to harsh conditions. Buyers should evaluate the long-term benefits of investing in higher-quality materials.

-

Labor: Labor costs can vary widely depending on the region and the level of automation in the manufacturing process. In regions with higher labor costs, manufacturers may pass these expenses onto buyers. Conversely, automated production facilities may offer more competitive pricing.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and equipment maintenance. Efficient manufacturing processes can reduce overhead, leading to lower prices for buyers.

-

Tooling: Custom designs or specific pallet configurations may require specialized tooling, which can add to the initial costs. It’s essential to factor in these costs when considering custom pallets.

-

Quality Control (QC): Robust QC processes ensure product reliability and compliance with industry standards, which can influence pricing. Manufacturers that invest in stringent QC may charge more but provide better assurance of product performance.

-

Logistics: Shipping costs can vary based on distance, weight, and shipping methods. International buyers should be aware of potential tariffs and customs fees, which can significantly impact total costs.

-

Margin: Each manufacturer has its pricing strategy and profit margins, which can be influenced by market competition and demand. Understanding these factors can help buyers negotiate better pricing.

How Do Price Influencers Affect Plastic Pallet Costs?

Several factors can influence the pricing of plastic pallets, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders generally lead to lower per-unit costs. Buyers should consider consolidating orders to meet MOQs for better pricing.

-

Specifications and Customization: Custom pallets tailored to specific needs can incur additional costs. Buyers should weigh the benefits of customization against the potential price increase.

-

Material Quality and Certifications: Higher-quality materials and products that meet specific certifications (e.g., FDA, ISO) can command premium prices. Buyers must evaluate whether these certifications are necessary for their operations.

-

Supplier Factors: Supplier reliability, reputation, and service quality can affect pricing. Established suppliers may charge more but provide better assurance of product quality and after-sales support.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. These terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, influencing overall cost.

What Buyer Tips Can Help Negotiate Better Pricing?

To maximize value when sourcing plastic pallets, consider the following buyer tips:

-

Negotiate Terms: Engaging in discussions about pricing, payment terms, and delivery can lead to more favorable conditions. Leverage bulk purchasing to negotiate lower rates.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price, but also long-term factors such as durability, maintenance, and potential replacement costs. Higher upfront costs may lead to savings in the long run.

-

Research Market Trends: Stay informed about market dynamics, including material costs and manufacturing trends, to better understand pricing fluctuations and timing for purchases.

-

Explore Local Suppliers: For international buyers, sourcing from local manufacturers can minimize logistics costs and tariffs, potentially leading to better pricing.

-

Request Multiple Quotes: Obtaining quotes from several manufacturers helps identify competitive pricing and provides leverage in negotiations.

Disclaimer on Indicative Prices

Prices for plastic pallets can vary significantly based on the factors outlined above. Buyers are encouraged to conduct thorough research and consult with multiple suppliers to obtain accurate and competitive pricing tailored to their specific needs and circumstances.

Alternatives Analysis: Comparing Plastic Pallet Manufacturers With Other Solutions

Understanding Alternative Solutions for Material Handling Needs

In today’s global supply chain landscape, businesses are continually seeking efficient and cost-effective solutions for their material handling needs. While plastic pallets have become increasingly popular due to their durability and versatility, it’s essential to evaluate alternative options that might better suit specific operational requirements. This analysis compares plastic pallet manufacturers with wooden pallets and metal pallets, highlighting key aspects that B2B buyers should consider when making procurement decisions.

Comparison Table

| Comparison Aspect | Plastic Pallet Manufacturers | Wooden Pallets | Metal Pallets |

|---|---|---|---|

| Performance | High durability, moisture-resistant, easy to clean | Prone to rot and splintering, harder to maintain | Very durable, can withstand heavy loads, resistant to moisture |

| Cost | Moderate initial investment, long-term savings due to reusability | Lower upfront costs, but higher maintenance and replacement costs | High initial investment, potential for long-term savings in durability |

| Ease of Implementation | Easy to integrate into existing systems, many standard sizes available | Requires careful handling, may need treatment against pests | Heavy and may require specialized handling equipment |

| Maintenance | Low maintenance, easily cleaned, resistant to pests | High maintenance, susceptible to damage and requires regular inspection | Low maintenance, but can rust if not properly treated |

| Best Use Case | Ideal for food, pharmaceuticals, and logistics | Suitable for general warehousing and retail | Best for heavy-duty industrial applications |

Detailed Breakdown of Alternatives

Wooden Pallets

Wooden pallets have long been a staple in logistics and warehousing due to their low initial costs. However, they come with significant drawbacks, including susceptibility to moisture, rot, and splintering, which can compromise product safety. Maintenance is a major concern; wooden pallets require regular inspections and treatment to prevent pest infestations. While they may be suitable for less demanding applications, businesses in sectors like food and pharmaceuticals may find them inadequate due to hygiene concerns.

Metal Pallets

Metal pallets, typically made from aluminum or steel, offer superior strength and durability, making them suitable for heavy-duty applications. They are resistant to moisture and pests, which can be a considerable advantage in industries requiring stringent hygiene standards. However, their high initial cost can be a barrier for many businesses, and their weight may necessitate specialized handling equipment. While they excel in durability and longevity, the upfront investment may not be justified for companies with lighter loads or less demanding environments.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the right material handling solution, B2B buyers must consider their specific operational requirements, including load capacity, industry standards, and budget constraints. Plastic pallets offer a balanced approach, combining cost-effectiveness with low maintenance and high durability, making them ideal for diverse industries such as food and pharmaceuticals. In contrast, wooden pallets may suffice for less critical applications, while metal pallets are best reserved for heavy-duty needs. Ultimately, understanding the unique advantages and limitations of each option will empower businesses to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for Plastic Pallet Manufacturers

What Are the Key Technical Properties of Plastic Pallets?

Understanding the essential technical properties of plastic pallets is crucial for B2B buyers, especially when selecting the right products for their supply chain needs. Here are some key specifications:

1. Material Grade

Plastic pallets are typically made from various types of plastics, including High-Density Polyethylene (HDPE), Polypropylene (PP), and Polyethylene Terephthalate (PET). Each material offers distinct advantages in terms of strength, durability, and chemical resistance. For example, HDPE is known for its robustness and ability to withstand heavy loads, making it ideal for industries like automotive and food processing. Selecting the right material grade can significantly influence the pallet’s longevity and performance in specific applications.

2. Load Capacity

This specification indicates the maximum weight a pallet can safely support. Load capacity is categorized into dynamic (the weight supported during movement) and static (the weight supported when stationary). Understanding load capacities helps businesses ensure their pallets can handle the products they transport or store, preventing costly damages or accidents.

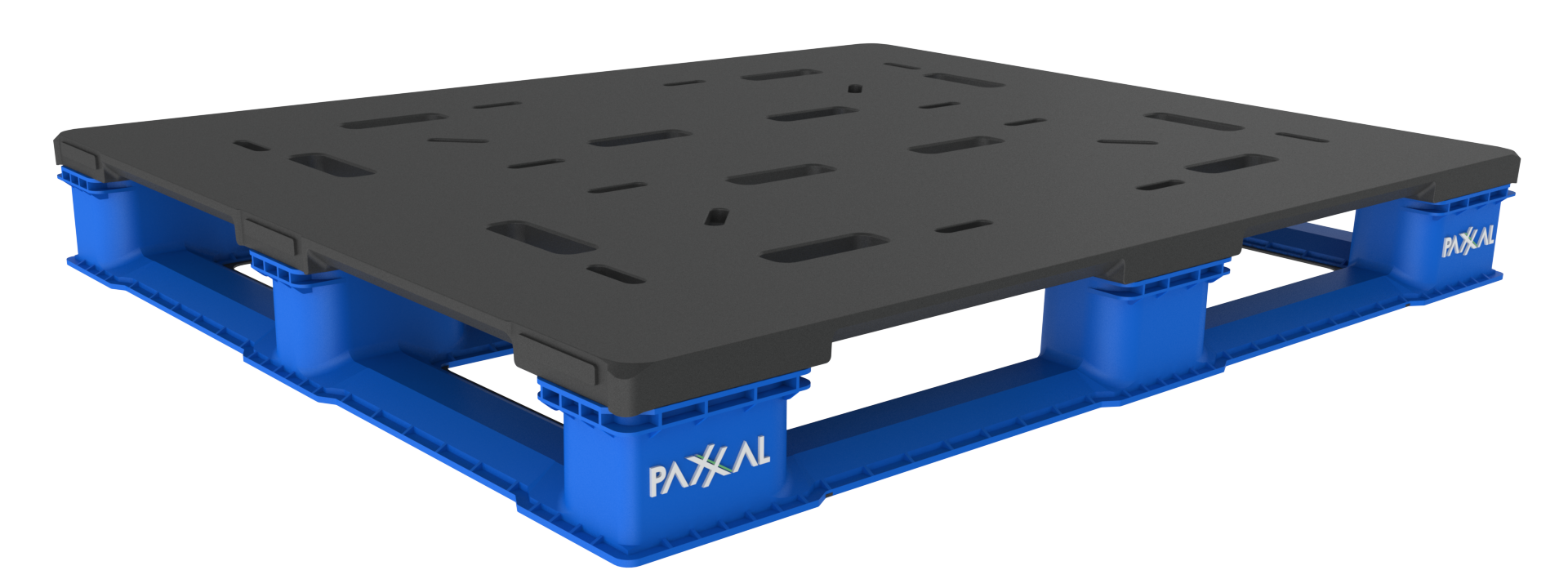

3. Dimensions and Design

Pallet dimensions (length, width, and height) and design features (such as nestability or stackability) affect how pallets fit into existing storage and transportation systems. Common standard sizes, like 40″ x 48″, facilitate compatibility with forklifts and racking systems. Custom dimensions may also be available to meet specific needs, providing flexibility in logistics planning.

4. Tolerance

Tolerance refers to the allowable variation in the pallet’s dimensions. This specification is critical for ensuring that pallets fit correctly in automated systems and storage solutions. High tolerance levels help maintain consistency across batches, which is essential for operational efficiency in large-scale logistics.

5. Chemical Resistance

The ability of a plastic pallet to resist various chemicals is a vital property, especially in industries like pharmaceuticals and food processing. Buyers should consider the types of chemicals their pallets may encounter during use and choose materials that can withstand exposure to these substances without degrading.

What Are Common Trade Terms Used in the Plastic Pallet Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the procurement process. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of plastic pallets, an OEM may produce pallets that are branded by a retailer or distributor. Understanding OEM relationships can help buyers assess the quality and sourcing of products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell at one time. Knowing the MOQ is important for budgeting and inventory management, especially for businesses with fluctuating demand or those looking to test products before making larger commitments.

3. RFQ (Request for Quotation)

An RFQ is a formal document requesting pricing and other details from suppliers for specific products. This process is crucial for obtaining competitive pricing and ensuring that buyers receive the best value for their purchases.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for managing logistics, costs, and risks associated with the shipping of plastic pallets across borders.

5. Custom Pallet Solutions

This term refers to pallets that are designed and manufactured to meet specific customer requirements, such as unique sizes, load capacities, or features. Custom solutions can enhance efficiency and effectiveness in logistics but may involve longer lead times and higher costs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing plastic pallets, ensuring they select products that align with their operational needs and industry standards.

Navigating Market Dynamics and Sourcing Trends in the Plastic Pallet Manufacturers Sector

What Are the Key Trends Shaping the Plastic Pallet Manufacturers Market?

The global market for plastic pallets is experiencing significant growth, driven by various factors including increased demand for hygienic and durable materials in industries such as food and beverage, pharmaceuticals, and logistics. As international B2B buyers look to optimize their supply chains, the transition from traditional wooden pallets to plastic options is becoming more appealing due to their resistance to rot, ease of cleaning, and longer lifespan.

Emerging technologies such as IoT (Internet of Things) and RFID (Radio-Frequency Identification) are revolutionizing how plastic pallets are tracked and managed. These technologies enhance visibility throughout the supply chain, enabling real-time monitoring of pallet locations and conditions, which is particularly valuable for businesses operating in regions with complex logistics networks, like Africa and South America. Additionally, the rise of automation in warehousing is pushing manufacturers to design pallets that are compatible with automated handling systems, further driving innovation.

Sourcing trends are also evolving, with international buyers increasingly seeking suppliers who can provide customized solutions tailored to specific industry needs. This demand for customization is particularly pronounced in markets like the Middle East and Europe, where regulatory compliance and product specifications can vary widely. Buyers are encouraged to engage with manufacturers that offer a comprehensive range of pallet types, including stackable, nestable, and rackable options, to ensure flexibility in their operations.

How Are Sustainability and Ethical Sourcing Reshaping the Plastic Pallet Sector?

Sustainability is a critical concern for B2B buyers, particularly in regions where environmental regulations are stringent. The plastic pallet industry is responding to this demand by focusing on eco-friendly materials and processes. Many manufacturers now produce pallets from recycled plastics or bioplastics, which not only reduce waste but also meet the growing consumer demand for sustainable products.

Ethical sourcing is equally important, as buyers seek to ensure that their supply chains are not only environmentally responsible but also socially ethical. Certifications such as ISO 14001 for environmental management and FSC (Forest Stewardship Council) for responsible sourcing are becoming standard considerations in procurement decisions. Buyers should prioritize manufacturers who can provide transparency regarding their sourcing practices and demonstrate commitment to sustainability, as this can enhance brand reputation and customer loyalty.

Moreover, the shift towards circular economy practices is encouraging manufacturers to develop pallets that can be reused or recycled at the end of their lifecycle. This trend aligns with the broader global movement towards reducing plastic waste and promoting responsible consumption, making it an essential factor for B2B buyers aiming to meet corporate sustainability goals.

How Has the Plastic Pallet Industry Evolved Over Time?

The evolution of the plastic pallet industry can be traced back to the mid-20th century when the limitations of wooden pallets, such as susceptibility to moisture and pests, became apparent. Initially, plastic pallets were seen as a niche product, primarily used in specific industries with stringent hygiene requirements, like pharmaceuticals and food processing.

However, as manufacturing processes improved and the benefits of plastic pallets became more widely recognized, their adoption grew across various sectors. Today, plastic pallets are celebrated for their durability, lightweight nature, and ability to withstand harsh conditions, making them a preferred choice for diverse applications. The ongoing innovation in material science and production technology continues to drive the market forward, ensuring that plastic pallets remain a vital component of modern supply chains worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of Plastic Pallet Manufacturers

-

How do I select the right plastic pallet for my business needs?

Selecting the right plastic pallet involves assessing your specific requirements, including load capacity, dimensions, and the environment in which the pallets will be used. Consider factors such as the type of products you handle, whether they require hygiene standards (as in food and pharmaceuticals), and if you need features like nestability for storage efficiency. Research the different types of plastics used in pallet manufacturing—like HDPE for durability or polypropylene for chemical resistance—to ensure they align with your operational needs. -

What are the advantages of using plastic pallets over wooden pallets?

Plastic pallets offer numerous advantages, including resistance to moisture, rot, and pests, making them ideal for industries with strict hygiene requirements. They are also easier to clean, which is crucial for food and pharmaceutical applications. Additionally, plastic pallets are generally lighter, which can reduce shipping costs, and they have a longer lifespan, providing better value over time. Their consistent quality and lack of splinters enhance safety in handling and transportation. -

What customization options are available for plastic pallets?

Many plastic pallet manufacturers provide customization options, including size, color, and design features. You can request specific dimensions to match your storage systems or unique designs that cater to your product’s shape. Manufacturers may also offer branding options, allowing your logo to be integrated into the pallet. Discussing your specific needs with manufacturers can lead to tailored solutions that enhance your operational efficiency and brand visibility. -

What are the typical minimum order quantities (MOQs) for plastic pallets?

Minimum order quantities (MOQs) for plastic pallets can vary significantly among manufacturers and depend on the type of pallet and customization options. Generally, MOQs can range from a few dozen to several hundred pallets. It’s essential to communicate your requirements with suppliers to find options that suit your budget and inventory needs. Some manufacturers may offer lower MOQs for standard pallets while requiring higher quantities for custom designs. -

How can I verify the credibility of a plastic pallet manufacturer?

Verifying a manufacturer’s credibility involves conducting thorough research. Look for industry certifications, customer testimonials, and case studies that demonstrate their experience and reliability. It’s also advisable to request references from previous clients and assess the manufacturer’s financial stability. Engaging in direct communication can provide insights into their customer service and responsiveness, ensuring they align with your business values. -

What payment terms should I expect when purchasing plastic pallets?

Payment terms for plastic pallets typically vary by manufacturer and may include options such as upfront payment, partial deposits, or payment upon delivery. Some manufacturers might offer credit terms for established businesses. It’s crucial to clarify these terms during negotiations to avoid any misunderstandings. Ensure you also discuss any additional costs, such as shipping or customs duties, particularly for international orders. -

What quality assurance practices should I look for in plastic pallet manufacturers?

Quality assurance (QA) practices are vital when selecting a plastic pallet manufacturer. Look for suppliers that implement rigorous testing protocols, including load testing, impact resistance, and environmental resilience. Certifications such as ISO 9001 can indicate a commitment to quality management systems. Additionally, inquire about their manufacturing processes to ensure they comply with industry standards, which can significantly affect the durability and safety of the pallets. -

What logistics considerations should I keep in mind when importing plastic pallets?

When importing plastic pallets, logistics considerations include shipping options, customs regulations, and delivery timelines. It’s essential to understand the shipping costs and ensure that the pallets can be transported efficiently without incurring damage. Familiarize yourself with the import duties and taxes applicable in your country, and work with a reliable freight forwarder to navigate customs processes. Planning for these factors can help streamline your supply chain and avoid delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Plastic Pallet Manufacturers

In the evolving landscape of supply chain management, plastic pallets have emerged as a vital component for businesses seeking efficiency and sustainability. The strategic sourcing of plastic pallets offers significant advantages, including cost reduction, enhanced durability, and improved hygiene standards. By transitioning from traditional wooden pallets to plastic alternatives, companies can mitigate risks associated with rot, splinters, and pest infestations, which are prevalent challenges in various industries.

International buyers from regions such as Africa, South America, the Middle East, and Europe should consider the diverse range of plastic pallet solutions available. Customization options and varying material strengths cater to specific industry needs, from food and beverage to pharmaceuticals and automotive. This flexibility not only supports operational efficiency but also aligns with sustainability goals through the use of recycled materials.

As the demand for reliable and eco-friendly logistics solutions grows, investing in strategic sourcing for plastic pallets will be crucial. We encourage global buyers to engage with trusted manufacturers and explore innovative pallet designs that optimize their supply chain processes. The future of material handling is bright, and with the right partnerships, businesses can thrive in a competitive market.