Enhance Quality: The Complete Guide to Austenitic Steel (2025)

Introduction: Navigating the Global Market for austenitic steel

As international B2B buyers delve into the complexities of sourcing austenitic steel, one of the key challenges they face is navigating the diverse landscape of grades and applications. Known for its exceptional corrosion resistance and high strength, austenitic stainless steel is a critical material across various industries, including automotive, aerospace, and medical. This comprehensive guide aims to empower buyers by elucidating the different types of austenitic steel, their specific applications, and the crucial factors to consider when vetting suppliers.

Understanding the nuances of austenitic steel—from the common 304 grade to specialized high-alloy variants—can significantly impact your purchasing decisions. Additionally, we will explore cost implications, sourcing strategies, and the importance of aligning with suppliers who meet international quality standards.

This guide is tailored for B2B buyers from Africa, South America, the Middle East, and Europe, providing actionable insights that facilitate informed decisions. Whether you’re looking to optimize supply chains or enhance product offerings, this resource is designed to help you leverage the strengths of austenitic steel effectively. By the end, you’ll be equipped with the knowledge to confidently navigate the global market and make strategic purchases that align with your business goals.

Understanding austenitic steel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 304 | Contains 18% chromium and 8% nickel; excellent corrosion resistance | Food processing, kitchen equipment, chemical containers | Pros: Versatile, cost-effective; Cons: Less resistant to pitting corrosion in chloride environments. |

| 316 | Contains molybdenum for enhanced corrosion resistance | Marine applications, pharmaceutical equipment | Pros: Superior resistance to pitting; Cons: Higher cost than 304. |

| 321 | Titanium-stabilized for improved high-temperature performance | Aerospace, automotive exhaust systems | Pros: Excellent resistance to oxidation; Cons: More expensive due to alloying elements. |

| 904L | High nickel and molybdenum content; excellent resistance to acids | Chemical processing, oil and gas industries | Pros: Exceptional corrosion resistance; Cons: High cost and difficult to weld. |

| 310 | High chromium and nickel for extreme heat resistance | Furnace components, heat exchangers | Pros: Maintains strength at high temperatures; Cons: More expensive and may require specialized welding techniques. |

What are the Characteristics of 304 Austenitic Steel?

304 stainless steel is the most commonly used austenitic steel due to its balanced composition of 18% chromium and 8% nickel. This combination provides excellent corrosion resistance, making it ideal for food processing and kitchen equipment. When purchasing 304 steel, buyers should consider its limitations in chloride environments, where pitting corrosion can occur. Overall, 304 offers a cost-effective solution for a variety of applications, but it may not be suitable for highly corrosive environments.

Why Choose 316 Austenitic Steel for Marine Applications?

316 stainless steel is recognized for its superior corrosion resistance, particularly in marine environments, due to the addition of molybdenum. This type is widely used in pharmaceutical and food processing equipment, where hygiene and corrosion resistance are critical. While 316 steel is more expensive than 304, its long-term durability and resistance to pitting make it a worthwhile investment for applications exposed to harsh conditions.

What Makes 321 Austenitic Steel Suitable for Aerospace?

321 stainless steel is titanium-stabilized, which enhances its performance in high-temperature applications, such as aerospace and automotive exhaust systems. This type is particularly beneficial where oxidation resistance is crucial. B2B buyers should be aware of the higher costs associated with 321 steel due to its alloying elements. However, its durability and performance in extreme conditions often justify the expense.

How Does 904L Austenitic Steel Stand Out in Chemical Processing?

904L stainless steel is characterized by its high nickel and molybdenum content, providing exceptional resistance to acids and chlorides. It is commonly used in chemical processing and oil and gas industries, where corrosion resistance is paramount. The primary consideration for buyers is the high cost and the challenges associated with welding this alloy. Despite these factors, 904L remains a top choice for critical applications requiring high durability.

Why is 310 Austenitic Steel Ideal for High-Temperature Applications?

310 stainless steel is known for its high chromium and nickel content, which grants it excellent strength and oxidation resistance at elevated temperatures. This makes it suitable for furnace components and heat exchangers. Buyers should note that while 310 offers significant advantages in high-temperature settings, it comes with a higher price tag and may require specialized welding techniques. This type is ideal for applications demanding both strength and heat resistance.

Key Industrial Applications of austenitic steel

| Industry/Sector | Specific Application of austenitic steel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical | Surgical instruments and implants | High corrosion resistance and biocompatibility | Certification for medical use, compliance with industry standards |

| Automotive | Exhaust systems and fuel lines | Durability under high temperatures and corrosive environments | Supplier reliability, material certifications, pricing stability |

| Aerospace | Engine components and structural parts | Lightweight yet strong, excellent resistance to extreme conditions | High-quality standards, testing certifications, lead times |

| Food Processing | Processing equipment and storage tanks | Hygiene and ease of cleaning, prevents contamination | Compliance with food safety regulations, surface finish quality |

| Chemical Processing | Reactors and pipelines | Resistance to harsh chemicals and high temperatures | Material grade selection, sourcing from reputable suppliers |

How is Austenitic Steel Used in the Medical Industry?

In the medical sector, austenitic stainless steel is critical for manufacturing surgical instruments and implants. Its high corrosion resistance and biocompatibility make it ideal for applications where hygiene is paramount. International B2B buyers should consider sourcing materials that meet stringent medical certifications and industry standards, as these factors are crucial for ensuring patient safety and compliance with regulations. Additionally, the ability to customize components for specific surgical applications can provide a competitive edge.

What Role Does Austenitic Steel Play in Automotive Applications?

Austenitic stainless steel is widely used in automotive exhaust systems and fuel lines due to its ability to withstand high temperatures and corrosive environments. This material enhances the longevity and reliability of automotive components, which is essential for reducing maintenance costs and improving vehicle performance. B2B buyers in the automotive sector should prioritize suppliers that offer consistent quality and certifications, as well as those who can provide competitive pricing and reliable delivery schedules.

Why is Austenitic Steel Important in Aerospace Engineering?

In aerospace, austenitic stainless steel is utilized for engine components and structural parts because of its lightweight nature and exceptional strength under extreme conditions. The material’s resistance to oxidation and high-temperature performance are crucial for maintaining safety and efficiency in flight operations. Buyers from the aerospace industry must ensure that their suppliers adhere to rigorous quality standards and can provide comprehensive testing certifications, as even minor defects can have significant repercussions.

How is Austenitic Steel Beneficial in Food Processing?

In the food processing industry, austenitic stainless steel is favored for its hygienic properties and ease of cleaning, making it ideal for processing equipment and storage tanks. Its corrosion resistance prevents contamination, ensuring food safety and quality. B2B buyers should focus on sourcing materials that comply with food safety regulations and have a high-quality surface finish to minimize bacterial growth. Establishing relationships with suppliers who understand these requirements is vital for maintaining operational efficiency.

What Applications of Austenitic Steel Exist in Chemical Processing?

Austenitic stainless steel is commonly used in chemical processing for constructing reactors and pipelines due to its ability to withstand harsh chemicals and high temperatures. This durability is essential for maintaining process integrity and safety in chemical plants. Buyers in this sector should consider the specific grade of austenitic steel required for their applications, as well as the reputation of their suppliers for providing high-quality materials that meet industry standards. Ensuring a reliable supply chain is also crucial for uninterrupted operations.

3 Common User Pain Points for ‘austenitic steel’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Austenitic Steel

The Problem:

B2B buyers often struggle to find suppliers who provide high-quality austenitic steel that meets their specific requirements. This is particularly challenging for companies in Africa and South America, where access to reliable vendors may be limited. Buyers are often faced with subpar material that can lead to product failures, increased costs, and long lead times. This situation can jeopardize project timelines and affect customer satisfaction, creating a ripple effect throughout the supply chain.

The Solution:

To mitigate sourcing issues, it is essential to establish a robust supplier evaluation process. Buyers should conduct thorough research on potential suppliers by checking certifications (such as ISO 9001) and industry reputation. Forming partnerships with local distributors who have established relationships with manufacturers can provide an avenue for sourcing quality materials. Additionally, leveraging online platforms that specialize in industrial materials can help buyers connect with reputable suppliers globally. When specifying requirements, be clear about the grade of austenitic steel needed (e.g., 304 or 316) and any additional properties such as corrosion resistance or mechanical strength. Regular audits and quality checks can further ensure that the sourced materials consistently meet the expected standards.

Scenario 2: Challenges with Welding and Fabrication of Austenitic Steel

The Problem:

Many B2B buyers face difficulties when it comes to the welding and fabrication of austenitic steel due to its unique properties. Unlike other steel types, austenitic stainless steels cannot be hardened through heat treatment, which can complicate the fabrication process. Additionally, improper welding techniques can lead to issues such as weld decay or reduced corrosion resistance, especially in critical applications within the aerospace or medical sectors.

The Solution:

To overcome these challenges, buyers should invest in training for their fabrication teams on the specific requirements of welding austenitic stainless steel. It is vital to select appropriate filler materials that match the base metal to ensure compatibility and strength. For instance, using low-carbon grades (like 304L) can enhance weldability and reduce the risk of intergranular corrosion. Furthermore, incorporating proper pre-welding and post-welding treatments—such as annealing—can significantly improve the durability of the welded joints. Establishing a relationship with skilled welders who specialize in stainless steel can also yield better results and minimize errors during the fabrication process.

Scenario 3: Understanding Corrosion Resistance in Different Environments

The Problem:

Buyers often misunderstand the corrosion resistance of various austenitic steel grades, leading to inappropriate selections for their specific applications. For instance, while 304 stainless steel offers good general corrosion resistance, it may not be suitable for environments with high chloride exposure, such as coastal areas or chemical processing plants. This oversight can result in premature material failure and unexpected maintenance costs, impacting overall project budgets and timelines.

The Solution:

To ensure the proper selection of austenitic steel grades, buyers must first assess the environmental conditions their products will face. Conducting a thorough risk analysis that considers factors such as temperature, humidity, and chemical exposure is crucial. For applications in corrosive environments, opting for higher alloy grades like 316 or super austenitics can provide the necessary resistance to pitting and crevice corrosion. Additionally, buyers should consult with metallurgical experts or leverage material selection software that can recommend suitable grades based on specific environmental conditions. By prioritizing the right grade of austenitic steel for their applications, companies can enhance product longevity and reduce maintenance requirements, ultimately leading to cost savings.

Strategic Material Selection Guide for austenitic steel

What Are the Key Properties of Common Austenitic Steel Grades?

Austenitic stainless steel is widely recognized for its versatility and exceptional performance across various industries. Below, we analyze four common materials within the austenitic steel category, focusing on their properties, advantages, limitations, and specific considerations for international B2B buyers.

1. 304 Stainless Steel: The Versatile Workhorse

Key Properties:

304 stainless steel is characterized by its composition of 18% chromium and 8% nickel, providing excellent corrosion resistance and good weldability. It can withstand temperatures up to 870°C (1600°F) in intermittent service.

Pros & Cons:

This grade is durable and cost-effective, making it suitable for a wide range of applications, from kitchen equipment to chemical containers. However, it can be susceptible to pitting and crevice corrosion in chloride environments, which may limit its use in certain applications.

Impact on Application:

304 stainless steel is compatible with a variety of media, including food products and chemicals, making it ideal for the food processing and pharmaceutical industries.

Considerations for International Buyers:

Buyers from regions like Africa and South America should be aware of local standards such as ASTM A240 for material specifications. Compliance with these standards ensures quality and safety in applications.

2. 316 Stainless Steel: The Corrosion Resistant Champion

Key Properties:

316 stainless steel contains 16% chromium, 10% nickel, and 2% molybdenum, enhancing its resistance to corrosion, particularly in marine environments. It can handle temperatures up to 925°C (1700°F).

Pros & Cons:

The addition of molybdenum significantly improves resistance to pitting and crevice corrosion, making it suitable for harsh environments. However, it is generally more expensive than 304 stainless steel, which can impact budget considerations.

Impact on Application:

This grade is ideal for applications involving saltwater or acidic conditions, such as in marine and chemical processing industries.

Considerations for International Buyers:

European buyers should ensure compliance with EN 10088 standards, while buyers in the Middle East may need to consider local regulations regarding corrosion resistance in construction materials.

3. 321 Stainless Steel: The High-Temperature Performer

Key Properties:

321 stainless steel is stabilized with titanium, allowing it to resist sensitization during welding. It can withstand temperatures up to 900°C (1650°F) and offers excellent resistance to oxidation.

Pros & Cons:

This grade is particularly advantageous in high-temperature applications, such as in aerospace and power generation. However, its cost is higher due to the titanium stabilization process.

Impact on Application:

321 stainless steel is suitable for applications that involve high temperatures and corrosive environments, such as exhaust systems and heat exchangers.

Considerations for International Buyers:

Buyers should verify compliance with ASTM A240 standards and consider the availability of materials in their local markets, especially in regions with stringent aerospace regulations.

4. 904L Stainless Steel: The Super Austenitic Solution

Key Properties:

904L stainless steel is a high-alloy austenitic steel with 20% chromium, 25% nickel, and 4.5% molybdenum, providing superior resistance to corrosion and stress corrosion cracking.

Pros & Cons:

This grade is highly durable and suitable for extreme environments, making it ideal for chemical processing and oil and gas applications. However, its high cost can be a barrier for some projects.

Impact on Application:

904L is particularly effective in handling sulfuric acid and other aggressive media, making it a preferred choice in the chemical industry.

Considerations for International Buyers:

Buyers in Europe and the Middle East should ensure adherence to EN 10088 standards, while those in Africa should consider local sourcing options to minimize costs.

Summary Table of Austenitic Steel Grades

| Material | Typical Use Case for austenitic steel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 304 | Kitchen equipment, chemical containers | Cost-effective and versatile | Susceptible to pitting in chloride | Medium |

| 316 | Marine applications, chemical processing | Excellent corrosion resistance | Higher cost than 304 | High |

| 321 | Aerospace components, heat exchangers | High-temperature performance | More expensive due to titanium | High |

| 904L | Chemical processing, oil and gas | Superior corrosion resistance | Very high cost | High |

This strategic material selection guide provides essential insights for international B2B buyers, helping them make informed decisions when sourcing austenitic steel for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for austenitic steel

What Are the Main Stages in the Manufacturing Process of Austenitic Steel?

The manufacturing process of austenitic steel involves several critical stages that ensure the final product meets the stringent demands of various industries. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Is Involved?

Material preparation begins with the selection of raw materials, predominantly iron ore, chromium, and nickel. These materials are precisely measured and mixed to achieve the desired chemical composition, which typically includes 16-26% chromium and up to 35% nickel. After mixing, the raw materials undergo melting in electric arc furnaces (EAF) at temperatures exceeding 1,600°C. This process not only melts the metals but also allows for the removal of impurities.

The molten steel is then cast into slabs or billets, which are subsequently cooled and processed further. This initial step is crucial as it sets the foundation for the desired mechanical properties and corrosion resistance of the austenitic steel.

How Is Austenitic Steel Formed?

Once the raw material is prepared, the forming process commences. This is typically achieved through hot rolling, where the steel is heated and passed through rollers to achieve the desired thickness and shape. Hot-rolled austenitic steel is often easier to work with and exhibits enhanced mechanical properties.

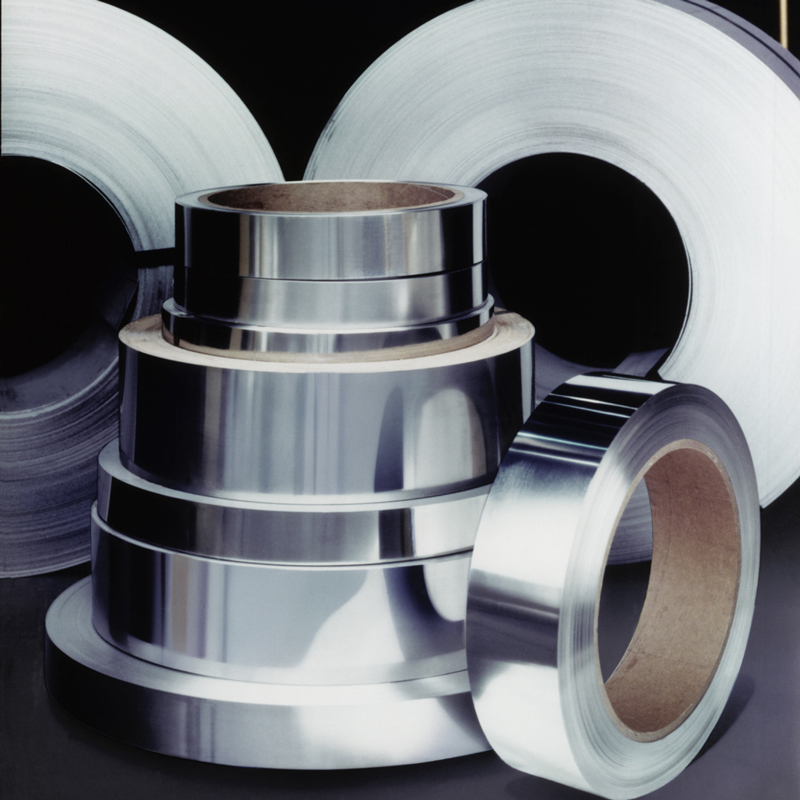

A stock image related to austenitic steel.

Cold rolling may follow hot rolling, especially for products requiring tighter tolerances and improved surface finishes. Cold working increases the strength of the material through strain hardening, which is vital for applications demanding high durability and resistance to deformation.

What Is the Assembly Process for Austenitic Steel Products?

The assembly phase involves cutting, welding, or machining the austenitic steel into specific components or products. Given that austenitic steels exhibit excellent weldability, various welding techniques such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) are commonly employed. Proper welding practices are essential to maintain the integrity and performance of the final product.

Quality assurance during this stage includes visual inspections and non-destructive testing (NDT) methods to identify any potential defects in the welded joints or machined surfaces.

What Finishing Techniques Are Commonly Used?

The finishing stage is crucial for enhancing both the aesthetic and functional properties of austenitic steel products. Techniques such as pickling and passivation remove surface contaminants and enhance corrosion resistance. Mechanical finishing methods like grinding and polishing are also employed to improve surface smoothness and visual appeal.

Additionally, surface treatments such as electroplating or coating may be applied to further enhance corrosion resistance or provide specific functional properties, depending on the end application.

How Is Quality Assurance Implemented in Austenitic Steel Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the austenitic steel products meet international standards and customer requirements.

What International Standards Should B2B Buyers Be Aware Of?

International quality standards such as ISO 9001 provide a framework for effective quality management systems. Compliance with these standards indicates that the manufacturer follows systematic processes to enhance product quality and customer satisfaction.

Industry-specific standards such as CE marking for products sold in the European Economic Area and API (American Petroleum Institute) standards for the oil and gas industry are also crucial. These certifications help ensure that the products adhere to specific safety and performance criteria.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are established at various stages of the manufacturing process. These include:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for compliance with specifications before they enter the production process.

- In-Process Quality Control (IPQC): During manufacturing, real-time monitoring and inspections are conducted to ensure that the processes are within established parameters.

- Final Quality Control (FQC): After production, finished products undergo rigorous testing to verify that they meet the required specifications and standards.

What Common Testing Methods Are Used to Ensure Quality?

Common testing methods for austenitic steel include:

- Mechanical Testing: Evaluates properties such as tensile strength, hardness, and ductility.

- Chemical Composition Analysis: Ensures the material composition matches the specified standards using techniques like X-ray fluorescence (XRF).

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing (UT) and magnetic particle testing (MPT) are used to detect internal and surface defects without damaging the product.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must ensure that their suppliers adhere to stringent quality control measures. Here are actionable steps to verify supplier QC:

What Auditing Practices Should Be Followed?

Conducting supplier audits is an effective way to assess their quality management systems. This can involve reviewing their processes, documentation, and compliance with international standards. Consider implementing regular audits as part of the supplier evaluation process.

How Can Buyers Utilize Quality Reports?

Requesting detailed quality reports from suppliers can provide insights into their QC processes and outcomes. These reports should include information on testing results, compliance certifications, and any corrective actions taken in response to identified issues.

Should Buyers Consider Third-Party Inspections?

Engaging third-party inspection services can add an extra layer of assurance. Independent inspectors can verify that the manufacturing processes and products meet the agreed-upon specifications, providing buyers with peace of mind.

What QC and Certification Nuances Should International B2B Buyers Consider?

International buyers, particularly from Africa, South America, the Middle East, and Europe, must navigate several nuances in QC and certification:

- Regional Standards Compliance: Different regions may have specific standards that products must comply with. Understanding these requirements is crucial for successful market entry.

- Documentation and Traceability: Ensure that suppliers maintain accurate documentation of their QC processes and product traceability. This is essential for audits and regulatory compliance.

- Cultural Considerations: Be aware of cultural differences that may influence communication and expectations regarding quality standards. Establishing clear channels for feedback and collaboration can help bridge these gaps.

By understanding the manufacturing processes and quality assurance practices for austenitic steel, international B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘austenitic steel’

The following practical sourcing guide provides a step-by-step checklist designed specifically for B2B buyers seeking to procure austenitic steel. This comprehensive approach will help you navigate the complexities of sourcing high-quality materials, ensuring that you make informed decisions that meet your technical requirements and business goals.

Step 1: Define Your Technical Specifications

Clearly outline your technical requirements for austenitic steel. Consider factors such as the grade (e.g., 304, 316), thickness, and any specific properties like corrosion resistance or temperature tolerance. This step is crucial as it ensures you communicate effectively with suppliers and receive the right materials for your applications.

- Key Considerations:

- Identify the environmental conditions your steel will face (e.g., exposure to chemicals, high temperatures).

- Specify any necessary certifications for your industry (e.g., ISO, ASTM standards).

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in austenitic steel. Look for companies with a proven track record in your target regions, such as Africa, South America, the Middle East, and Europe. A well-established supplier is more likely to meet your quality standards and deliver on time.

- Action Points:

- Utilize industry directories and trade shows to gather a list of suppliers.

- Check for online reviews and testimonials from other B2B buyers.

Step 3: Evaluate Supplier Certifications

Before making a decision, verify that your chosen suppliers hold relevant certifications. This includes quality management systems (e.g., ISO 9001) and product-specific certifications (e.g., EN 10088 for stainless steels). Certification ensures that the supplier adheres to international quality standards, which is essential for maintaining the integrity of your products.

- What to Look For:

- Request copies of certifications and assess their validity.

- Ensure that the supplier’s certifications are applicable to the specific grades of austenitic steel you require.

Step 4: Request Material Samples

Always ask for material samples before placing a large order. This allows you to test the steel’s properties in real-world conditions, ensuring it meets your specifications for strength, corrosion resistance, and formability. Testing samples can prevent costly mistakes later on.

- Testing Methods:

- Conduct tensile strength tests to assess durability.

- Evaluate corrosion resistance through standardized tests.

Step 5: Negotiate Pricing and Terms

Once you’ve narrowed down your supplier options, engage in negotiations to secure favorable pricing and payment terms. Ensure that you understand the total cost of acquisition, including shipping, taxes, and any potential tariffs, especially when sourcing internationally.

- Negotiation Tips:

- Compare quotes from multiple suppliers to gauge a fair price.

- Be clear about your payment terms and delivery expectations to avoid misunderstandings.

Step 6: Establish a Clear Communication Channel

Maintain open lines of communication with your supplier throughout the sourcing process. Clear communication helps to clarify expectations, timelines, and any potential issues that may arise. It builds a strong relationship that can be beneficial for future orders.

- Best Practices:

- Schedule regular updates during production and shipping phases.

- Use project management tools to track progress and document communications.

Step 7: Review and Finalize the Contract

Before finalizing your order, carefully review the contract to ensure all terms are clearly defined. This includes specifications, delivery schedules, pricing, and penalties for non-compliance. A well-drafted contract protects both parties and establishes clear expectations.

- Contract Essentials:

- Include clauses for quality assurance and return policies.

- Ensure that intellectual property rights are addressed if applicable.

By following this comprehensive sourcing checklist, international B2B buyers can navigate the complexities of procuring austenitic steel effectively, ensuring they receive high-quality materials that meet their specific needs.

Comprehensive Cost and Pricing Analysis for austenitic steel Sourcing

What Are the Key Cost Components in Sourcing Austenitic Steel?

When sourcing austenitic steel, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The raw material cost typically comprises a significant portion of the total expense. Austenitic stainless steels, particularly grades like 304 and 316, contain high levels of chromium and nickel, which are subject to market fluctuations. Buyers should monitor metal commodity prices closely.

-

Labor: Labor costs encompass the wages for skilled workers involved in the manufacturing and processing of austenitic steel. Regions with higher labor costs may affect the overall pricing structure, so buyers should consider sourcing from countries with competitive labor markets.

-

Manufacturing Overhead: This includes expenses related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can reduce overhead, making it a key area for potential savings.

-

Tooling: The cost of specialized tools and equipment used in the production of austenitic steel can be significant. Custom tooling may be necessary for specific applications, increasing initial costs but potentially lowering long-term unit costs.

-

Quality Control (QC): Ensuring high quality in austenitic steel is vital, particularly for industries such as aerospace and medical. Investing in rigorous QC processes can increase costs upfront but saves money by minimizing defects and returns.

-

Logistics: Shipping and handling costs can vary widely based on distance, shipping methods, and the weight of the material. Buyers should consider logistics as an integral part of their total cost, particularly when importing steel from distant suppliers.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding the margin expectations of suppliers can aid in negotiations.

How Do Price Influencers Affect Austenitic Steel Costs?

Several factors influence the pricing of austenitic steel, and international buyers should be aware of these nuances:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk discounts, so buyers should assess their needs against supplier MOQs to optimize pricing.

-

Specifications and Customization: Custom specifications can lead to increased costs. Buyers should ensure that their specifications are necessary and consider standard grades when possible to keep costs down.

-

Quality and Certifications: High-quality austenitic steel often comes with certifications (e.g., ASTM, ISO), which can increase costs. Buyers should evaluate the necessity of these certifications based on their industry requirements.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium but offer better quality assurance and service.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can significantly affect landed costs. Understanding the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for accurate budgeting.

What Are Effective Tips for Negotiating Austenitic Steel Prices?

B2B buyers, especially from Africa, South America, the Middle East, and Europe, can adopt several strategies to optimize their sourcing of austenitic steel:

-

Leverage Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, consider the total cost of ownership, which includes maintenance, logistics, and potential downtime costs. This approach can justify paying a higher initial price for better quality.

-

Negotiate Volume Discounts: If planning to make repeat purchases, negotiating for volume discounts can lead to significant savings over time. Suppliers often favor long-term partnerships that ensure a steady order flow.

-

Explore Alternative Suppliers: Researching multiple suppliers can uncover competitive pricing and alternative solutions. Consider suppliers from emerging markets where labor and material costs may be lower.

-

Stay Informed on Market Trends: Keeping abreast of global market conditions for steel prices can provide leverage during negotiations. Buyers should be aware of seasonal fluctuations and geopolitical factors affecting prices.

-

Be Clear on Specifications: Provide precise specifications and requirements to avoid misunderstandings that could lead to unnecessary costs. Clarity can streamline the manufacturing process and reduce lead times.

Disclaimer on Pricing

Please note that the prices for austenitic steel can vary significantly based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing austenitic steel With Other Solutions

Understanding Alternatives to Austenitic Steel

When considering materials for industrial applications, austenitic steel is frequently the first choice due to its outstanding strength, corrosion resistance, and versatility. However, it’s essential for B2B buyers to explore alternative materials that may better suit specific project requirements or budget constraints. In this analysis, we will compare austenitic steel with two viable alternatives: ferritic stainless steel and carbon steel. Each material has its unique advantages and limitations that can influence procurement decisions.

Comparison Table

| Comparison Aspect | Austenitic Steel | Ferritic Stainless Steel | Carbon Steel |

|---|---|---|---|

| Performance | Excellent corrosion resistance; high strength; non-magnetic | Good corrosion resistance; moderate strength; magnetic | High strength; excellent toughness; limited corrosion resistance |

| Cost | Generally higher due to alloy content | Lower than austenitic; budget-friendly | Typically the lowest cost option |

| Ease of Implementation | Requires skilled labor for welding; good formability | Easier to work with; good weldability | Easy to fabricate and weld; versatile |

| Maintenance | Low maintenance due to corrosion resistance | Moderate maintenance; prone to rust without protective coatings | High maintenance; requires protection against rust |

| Best Use Case | Medical, automotive, aerospace applications | Automotive exhaust systems, household appliances | Construction, manufacturing, heavy machinery |

Detailed Breakdown of Alternatives

What Are the Benefits and Limitations of Ferritic Stainless Steel?

Ferritic stainless steel is a strong alternative to austenitic steel, particularly for applications requiring magnetic properties, such as automotive exhaust systems. It offers decent corrosion resistance at a lower cost, making it suitable for budget-conscious projects. However, ferritic steel is generally less ductile than austenitic steel and may not perform as well in high-temperature environments. This could limit its use in applications where extreme conditions are a factor.

How Does Carbon Steel Compare to Austenitic Steel?

Carbon steel is known for its high tensile strength and versatility, making it a popular choice in construction and manufacturing. It is significantly cheaper than both austenitic and ferritic stainless steels, which can be advantageous for large-scale projects. However, carbon steel has limited corrosion resistance, which necessitates protective coatings or treatments to prolong its lifespan in corrosive environments. This increased maintenance requirement can offset its initial cost savings in the long run.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When deciding between austenitic steel and its alternatives, international B2B buyers must carefully assess their specific needs, including performance requirements, budget constraints, and application environments. While austenitic steel offers superior corrosion resistance and strength, alternatives like ferritic stainless steel and carbon steel can provide cost-effective solutions for less demanding applications. Buyers should consider not only the initial purchase price but also the long-term maintenance costs and performance expectations to ensure they select the most suitable material for their projects.

Essential Technical Properties and Trade Terminology for austenitic steel

What Are the Key Technical Properties of Austenitic Steel?

Austenitic steel is a widely used alloy in various industries due to its unique properties. Understanding these properties is crucial for B2B buyers, especially when evaluating materials for specific applications.

1. Material Grades: How Do They Influence Performance?

Material grades such as 304 and 316 are essential identifiers in austenitic steel. Grade 304, often referred to as “18/8,” contains 18% chromium and 8% nickel, offering excellent corrosion resistance and formability. Grade 316, with added molybdenum, provides superior resistance to pitting and crevice corrosion, making it suitable for marine environments. Choosing the right grade ensures optimal performance in your specific application.

2. Tolerance: Why Is Precision Important?

Tolerance refers to the allowable deviation from a specified dimension. In austenitic steel applications, precise tolerances are crucial for components that require exact fitting, such as medical devices or automotive parts. Poor tolerances can lead to assembly issues, increased costs, and compromised safety. Always verify the manufacturer’s tolerance specifications to ensure compatibility with your design requirements.

3. Yield Strength: What Does It Mean for Your Applications?

Yield strength indicates the maximum stress that a material can withstand without permanent deformation. Austenitic steels typically exhibit lower yield strength compared to other stainless steels but compensate with excellent ductility and formability. For B2B buyers, understanding yield strength is vital when selecting materials for load-bearing applications, ensuring they meet performance standards without failure.

4. Corrosion Resistance: How Does It Impact Longevity?

Austenitic stainless steels are known for their high corrosion resistance, primarily due to their chromium content. This property is essential for industries like food processing, pharmaceuticals, and marine applications, where exposure to corrosive environments is common. Evaluating corrosion resistance helps buyers choose materials that will reduce maintenance costs and prolong the lifespan of their products.

What Are Common Trade Terms Associated with Austenitic Steel?

Familiarizing yourself with trade terminology can facilitate smoother transactions and communication with suppliers.

1. OEM (Original Equipment Manufacturer): What Role Do They Play?

OEMs are companies that produce parts or equipment that may be marketed by another manufacturer. In the context of austenitic steel, an OEM may require specific grades and tolerances to meet their product specifications. Understanding OEM requirements helps B2B buyers ensure they procure materials that align with their production needs.

2. MOQ (Minimum Order Quantity): How Does It Affect Purchasing Decisions?

A stock image related to austenitic steel.

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it impacts inventory management and cash flow. Suppliers of austenitic steel may set MOQs based on production costs, so understanding these limits is essential for effective procurement strategies.

3. RFQ (Request for Quotation): Why Is It Important?

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific quantities of austenitic steel. This document helps buyers compare offers and negotiate better terms. A well-prepared RFQ ensures that all necessary specifications are included, minimizing miscommunication and optimizing procurement outcomes.

4. Incoterms: What Do They Mean for International Shipping?

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions. For austenitic steel, understanding Incoterms is essential for clarifying who bears the shipping costs, insurance, and risk during transport. Familiarity with these terms can help buyers avoid unexpected charges and ensure smooth logistics.

By understanding these technical properties and trade terminology, B2B buyers can make informed decisions when sourcing austenitic steel, ensuring they select the right materials for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the austenitic steel Sector

What Are the Current Market Dynamics and Key Trends in the Austenitic Steel Sector?

The global austenitic steel market is experiencing robust growth, driven by rising demand across various sectors, including automotive, aerospace, and construction. The market’s expansion is supported by the increasing need for high-performance materials that offer excellent corrosion resistance and durability. Notably, austenitic stainless steel, particularly the 304 and 316 grades, dominates this sector due to its superior mechanical properties and versatility.

Emerging trends in B2B technology, such as digital supply chain management and advanced analytics, are reshaping sourcing strategies for international buyers. Companies are increasingly leveraging data-driven insights to optimize procurement processes, reduce costs, and enhance supplier relationships. For buyers in regions like Africa, South America, the Middle East, and Europe, understanding local market conditions and regulatory frameworks is crucial. This knowledge can facilitate better sourcing decisions and mitigate risks associated with supply chain disruptions.

Additionally, the shift towards automation and smart manufacturing processes is influencing the production of austenitic steel. This trend allows for more precise control over material properties, thus catering to the specific needs of diverse industries. As sustainability becomes a priority, B2B buyers are also focusing on sourcing from manufacturers who employ eco-friendly practices and adhere to international quality standards.

How Is Sustainability and Ethical Sourcing Impacting the Austenitic Steel Industry?

The environmental impact of steel production has prompted a significant shift towards sustainability in the austenitic steel sector. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing carbon footprints and minimizing waste. This includes adopting energy-efficient manufacturing processes and utilizing recycled materials in production.

Ethical sourcing is becoming a cornerstone of B2B procurement strategies. Buyers are encouraged to evaluate suppliers based on their adherence to ethical labor practices and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and the ResponsibleSteel™ certification can guide buyers in identifying trustworthy partners.

Furthermore, the demand for “green” materials is rising, with buyers seeking austenitic steel that meets stringent environmental standards. This shift not only reflects growing consumer awareness but also aligns with corporate social responsibility goals. By investing in sustainable supply chains, companies can enhance their brand reputation and meet regulatory requirements, ultimately leading to long-term profitability.

What Is the Historical Context of Austenitic Steel in B2B Transactions?

Austenitic stainless steel has a storied history that dates back to the early 20th century when it was first developed for its superior corrosion resistance and mechanical properties. The introduction of the 304 grade in the 1920s marked a significant milestone, as it quickly became the standard for various industrial applications due to its excellent formability and weldability.

Over the decades, advancements in metallurgy and production techniques have allowed for the development of specialized grades, such as 316, which offers enhanced resistance to pitting and crevice corrosion. The diversification of austenitic stainless steel grades has enabled manufacturers across various sectors to address specific challenges, making it a staple in the B2B landscape.

Today, the legacy of austenitic steel continues to evolve, with innovations aimed at improving performance and sustainability. For international buyers, understanding the historical development of these materials can provide valuable insights into their applications and the future direction of the industry.

Frequently Asked Questions (FAQs) for B2B Buyers of austenitic steel

-

How do I select the right grade of austenitic steel for my application?

Selecting the appropriate grade of austenitic steel involves understanding your specific application requirements, including corrosion resistance, temperature tolerance, and mechanical properties. Common grades like 304 and 316 are suitable for general use, but for more specialized applications (e.g., marine environments), consider 316 for its enhanced corrosion resistance. Always assess the environmental conditions and any regulatory standards that may apply to your industry to ensure compliance and durability. -

What are the key differences between 304 and 316 austenitic stainless steel?

The primary difference between 304 and 316 austenitic stainless steel lies in their composition and corrosion resistance. While 304 contains 18% chromium and 8% nickel, 316 includes 16% chromium, 10% nickel, and 2% molybdenum, which enhances its resistance to pitting and crevice corrosion. This makes 316 a better choice for applications exposed to saltwater or harsh chemicals, such as in marine and chemical processing industries. -

What factors should I consider when vetting a supplier for austenitic steel?

When vetting suppliers, consider their industry reputation, certification standards (like ISO 9001), and experience in providing austenitic steel. Request samples to evaluate quality and consistency, and inquire about their production capabilities and lead times. Additionally, assess their customer service responsiveness and willingness to provide technical support, as these factors can significantly impact your sourcing experience and project timelines. -

What is the typical minimum order quantity (MOQ) for austenitic steel?

The MOQ for austenitic steel can vary widely depending on the supplier and the specific grade requested. Generally, MOQs range from 1 ton to 5 tons for standard grades. However, for customized or specialty grades, suppliers may have higher MOQs due to the additional processing involved. Always discuss your needs with the supplier to find a mutually agreeable MOQ that suits your purchasing strategy. -

What payment terms should I expect when sourcing austenitic steel internationally?

Payment terms can vary by supplier and region, but common arrangements include net 30, net 60, or payment upon delivery. For international transactions, consider using letters of credit or escrow services to mitigate risks. Always clarify any potential additional costs, such as customs duties or shipping fees, upfront to avoid surprises later in the process. Negotiating favorable terms can enhance your cash flow management. -

How can I ensure the quality of austenitic steel before purchasing?

To ensure quality, request certification documents such as mill test reports (MTRs) that verify the chemical and mechanical properties of the steel. Conduct third-party inspections if necessary, particularly for large orders or critical applications. It’s also beneficial to establish a quality assurance protocol with your supplier, including regular audits and feedback mechanisms to maintain standards throughout your purchasing relationship. -

What logistics considerations should I keep in mind when importing austenitic steel?

When importing austenitic steel, consider shipping costs, lead times, and customs regulations in both the exporting and importing countries. Collaborate with logistics partners who have experience in handling steel products to optimize transportation routes and minimize delays. Be aware of potential tariffs and ensure all documentation is accurate to facilitate smooth customs clearance, which can prevent costly hold-ups. -

Can I customize the dimensions and specifications of austenitic steel products?

Yes, many suppliers offer customization options for austenitic steel products, including variations in thickness, width, and length. Discuss your specific requirements with potential suppliers, as they may have different capabilities for customization. Be prepared to provide detailed specifications and volume estimates, as custom orders often require longer lead times and may affect pricing structures.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for austenitic steel

A stock image related to austenitic steel.

As the demand for austenitic stainless steel continues to rise across various industries, understanding the nuances of strategic sourcing becomes crucial for international buyers. Key takeaways highlight the significance of selecting the right grade based on specific application requirements, particularly for sectors like automotive, aerospace, and medical. With its exceptional corrosion resistance, formability, and high strength, austenitic steel remains a top choice for manufacturers.

For B2B buyers in Africa, South America, the Middle East, and Europe, forging strong relationships with reputable suppliers is essential. This can enhance supply chain resilience and ensure access to high-quality materials that meet international standards. Additionally, considering factors such as alloy content, production methods, and potential trade agreements can lead to cost-effective procurement strategies.

Looking ahead, the global market for austenitic stainless steel is projected to grow, driven by innovations in manufacturing processes and expanding applications. Now is the time for international buyers to capitalize on these trends. By leveraging strategic sourcing practices, businesses can position themselves to not only meet current demands but also adapt to future market shifts. Engage with suppliers who understand your unique needs and explore new opportunities for collaboration that align with your growth objectives.