Top 6 Fiber Cable Manufacturers List and Guide: How To Solve Scen…

Introduction: Navigating the Global Market for Fiber Cable Manufacturers

In an era where seamless connectivity is paramount, sourcing reliable fiber cable manufacturers presents a significant challenge for international B2B buyers. The complexities of navigating diverse suppliers, understanding product specifications, and ensuring compliance with regional standards can be daunting, particularly for companies in Africa, South America, the Middle East, and Europe, including key markets like Germany and Brazil. This comprehensive guide serves as a vital resource, equipping decision-makers with the knowledge needed to make informed choices about fiber optic cables.

Throughout this guide, we will explore various types of fiber cables, including indoor, outdoor, and specialized options tailored for specific applications. We will delve into the nuances of supplier vetting, offering strategies to assess quality, reliability, and service capabilities. Additionally, we will provide insights into cost considerations, ensuring that buyers understand the financial implications of their choices.

By empowering B2B buyers with actionable insights and detailed information, this guide aims to simplify the procurement process and enhance the overall purchasing experience. With a clear understanding of the global fiber cable market, businesses can confidently engage with manufacturers, ensuring their connectivity needs are met with precision and efficiency. Whether you’re upgrading existing infrastructure or embarking on new projects, this resource will be invaluable in navigating the complexities of fiber cable sourcing.

Top 10 Fiber Cable Manufacturers Manufacturers & Suppliers List

1. Corning – Fiber Optic Cables

Domain: corning.com

Registered: 1991 (34 years)

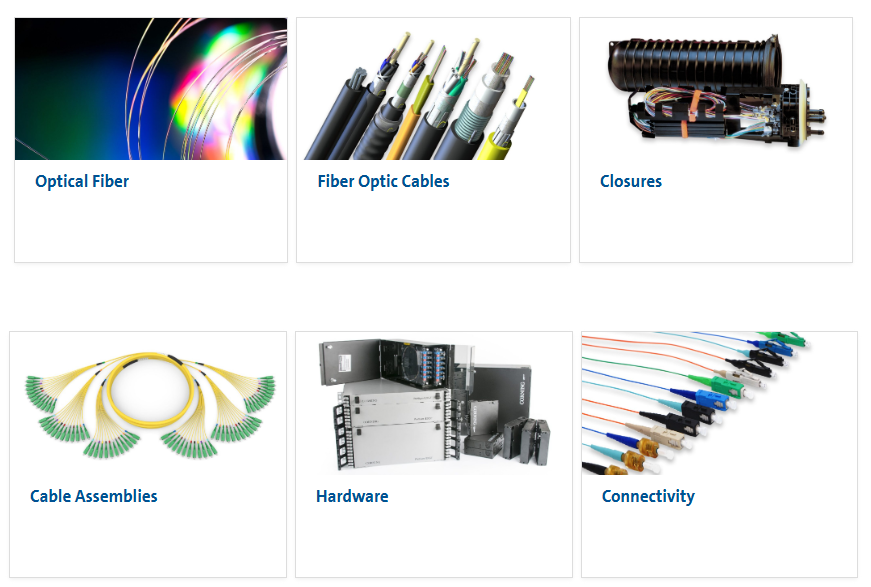

Introduction: Corning offers a variety of fiber optic cables designed for different environments and applications. Key product categories include: 1. Outdoor Cables: Engineered for demanding outdoor conditions, available as Aerial, Duct, Direct Buried, and Microduct. 2. Indoor/Outdoor Cables: Flame-retardant cables suitable for both outdoor and indoor use, including Aerial, Duct, Direct Buried, Low Smoke Zero H…

2. Fibertronics – Custom Cable Assemblies & Fiber Optic Solutions

Domain: fibertronics.com

Registered: 2000 (25 years)

Introduction: Custom Cable Assembly Manufacturing, Fiber Optic Cable Assemblies, Fiber Optic Patch Cables, Fiber Optic Pigtails, Fiber Optic Loopbacks, Custom Cable Assemblies, Mode Conditioning Cables, MPO/MMC Multi-Fiber Solutions, Splitters / Couplers, Flex Circuit Adapters & Attenuators, Adapter Plates, Adapters / Mating Sleeves, Attenuators, Connectors, Patch Panels and Splicing, Fiber Optic Patch Panels, …

3. Corning – Fiber Optic Cable

Domain: gcabling.com

Registered: 2021 (4 years)

Introduction: 1. Corning: Fiber Optic Cable Manufacturer, Optical Fiber Supplier, Headquarters: Corning, NY, Established: 1851, Employees: ~58,000, Annual Sales: $250 Million+, Main Products: Fibre Optic Cable, Optical Fiber, Fiber Connector. 2. Panduit: Fiber Optic Cable Manufacturer, Patch Cord Supplier, Headquarters: Tinley Park, IL, Established: 1955, Employees: 1000+, Annual Sales: $250 Million+, Main Prod…

4. Industrial Fiber Optics – Custom Fiber Optic Solutions

Domain: i-fiberoptics.com

Registered: 1998 (27 years)

Introduction: Industrial Fiber Optics specializes in manufacturing polymer and large-core silica optical fiber cable assemblies. Key products include: 1. Customized Fiber Optic Connectors 2. Custom Fiber Optic Assemblies 3. Custom Light Pipes, LED Mounts, and Lens Caps 4. Prototype Research & Fabrication Capabilities 5. High-Quality Fiber Optic Connectors (POF and silica solutions) 6. Complete Cable Assembly So…

5. OFS – Glass and Cables

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: OFS manufactures glass in Norcross, GA and cables in Carrollton, GA. Prysmian produces glass in NC and cables in Lexington, SC. CommScope uses OFS glass and makes cables in NC. Corning manufactures both glass and cables in NC. AFL produces cables in SC and can use various types of glass. STL (Sterlite) has a new cable plant in SC. Superior Essex cables are made in Bronwood, TX, but may use non-US …

6. IbisWorld – Single-Mode Fiber Optic Cables

Domain: ibisworld.com

Registered: 1997 (28 years)

Introduction: Fiber optic cables, specifically single-mode fiber, which can transmit signals over long distances and at high bandwidths, are the primary products manufactured in the Fiber-Optic Cable Manufacturing industry in the US.

Understanding Fiber Cable Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Loose Tube Cables | High fiber count, flexible design, suitable for outdoor use | Telecommunications, Data Centers | Pros: Durable, high capacity. Cons: More complex installation. |

| Ribbon Cables | Flat design, high density, ideal for mass fusion splicing | Broadband networks, FTTH installations | Pros: Space-efficient, faster splicing. Cons: Requires specialized handling. |

| Indoor/Outdoor Cables | Flame-retardant, versatile for both environments | Campus networks, Hybrid installations | Pros: Dual-use, compliant with safety standards. Cons: May be more costly. |

| Microduct Cables | Compact design, ideal for dense installations | Urban networks, High-rise buildings | Pros: Space-saving, easy to install. Cons: Limited fiber counts. |

| Aerial Cables | Designed for overhead installation, self-supporting | Rural and suburban deployments | Pros: Cost-effective, easy to maintain. Cons: Vulnerable to environmental factors. |

What Are Loose Tube Cables and Their Applications in B2B?

Loose tube cables are characterized by their high fiber count and flexible design, making them ideal for outdoor installations. They consist of multiple fibers housed in a protective tube that allows for expansion and contraction, which is essential in varying temperature conditions. These cables are widely used in telecommunications and data centers due to their durability and capacity to handle significant data traffic. Buyers should consider installation complexity and environmental factors when choosing loose tube cables.

How Do Ribbon Cables Stand Out for Fiber Optic Solutions?

Ribbon cables feature a flat design that allows for a higher density of fibers within a smaller space, making them particularly suitable for mass fusion splicing. This design is advantageous for broadband networks and fiber-to-the-home (FTTH) installations, where space efficiency and speed of installation are critical. However, buyers must be aware that ribbon cables require specialized handling and installation techniques, which can increase initial setup costs.

What Makes Indoor/Outdoor Cables Versatile for B2B Buyers?

Indoor/outdoor cables are designed to meet both outdoor and indoor environmental conditions, featuring a flame-retardant jacket that adheres to safety standards. This versatility makes them suitable for campus networks and hybrid installations where cables transition between different environments. While they offer compliance and flexibility, buyers should consider the potential for higher costs compared to standard cables.

Why Choose Microduct Cables for Dense Network Environments?

Microduct cables are compact and designed to fit into tight spaces, making them ideal for urban networks and high-rise buildings. Their design allows for easy installation and future scalability, as additional micro cables can be added without extensive rewiring. While they save space and facilitate quick deployment, buyers should note that microduct cables typically have lower fiber counts, which may limit their use in high-capacity applications.

What Are the Key Benefits of Aerial Cables in Fiber Optic Installations?

Aerial cables are specifically designed for overhead installations, often self-supporting to reduce installation costs. They are widely used in rural and suburban deployments where trenching is not feasible. While aerial cables are cost-effective and easy to maintain, buyers should consider their vulnerability to environmental factors such as wind and ice, which can impact their longevity and performance.

Key Industrial Applications of Fiber Cable Manufacturers

| Industry/Sector | Specific Application of Fiber Cable Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | High-speed internet infrastructure | Enhanced data transmission speeds and reliability | Fiber type (single-mode vs. multimode), environmental conditions, installation ease |

| Healthcare | Medical imaging and data transfer | Improved diagnostic capabilities and patient care | Compliance with safety standards, flexibility for upgrades, and durability in harsh environments |

| Manufacturing & Industry | Automation and control systems | Streamlined operations and reduced downtime | Compatibility with existing systems, robustness against interference, and installation support |

| Transportation | Smart transportation systems and traffic management | Increased safety and efficiency in transport logistics | Scalability for future expansions, environmental ratings, and ease of maintenance |

| Hospitality | PoE (Power over Ethernet) lighting and communication systems | Enhanced guest experience and energy efficiency | Compliance with local regulations, integration with existing infrastructure, and aesthetic considerations |

How Are Fiber Cable Manufacturers Applied in Telecommunications?

In the telecommunications sector, fiber cable manufacturers play a pivotal role in establishing high-speed internet infrastructure. These cables facilitate rapid data transmission, which is essential for both residential and commercial users. The primary challenge addressed by fiber cables is the need for higher bandwidth capabilities compared to traditional copper cables. For international buyers, especially in emerging markets in Africa and South America, sourcing fiber cables that can withstand local environmental conditions while providing reliable performance is crucial. Buyers should also consider the compatibility of the cables with existing network infrastructure.

What Role Does Fiber Cable Play in Healthcare?

In healthcare, fiber cables are integral for medical imaging and data transfer applications. They enable the transmission of large volumes of data quickly, which enhances diagnostic capabilities and patient care. Fiber optics solve issues related to signal degradation and electromagnetic interference, which are critical in a hospital setting. Buyers in the healthcare sector should prioritize sourcing cables that comply with stringent safety standards and can operate efficiently in environments with varying temperature and humidity levels.

How Is Fiber Cable Used in Manufacturing and Industry?

Manufacturing and industrial sectors utilize fiber cables for automation and control systems. These cables support the seamless communication between machines, sensors, and control systems, leading to streamlined operations and reduced downtime. The main challenges addressed include the need for robust, interference-resistant solutions that can handle the demanding conditions of manufacturing environments. Buyers should focus on sourcing cables that are compatible with existing automation systems and can withstand harsh industrial conditions.

What Are the Applications of Fiber Cable in Transportation?

In the transportation sector, fiber cables support smart transportation systems and traffic management solutions. These cables facilitate real-time data transmission for traffic monitoring, enhancing safety and efficiency. The challenges addressed include the need for reliable communication links in dynamic environments. For international buyers, especially in the Middle East and Europe, sourcing cables that can scale with future expansions and are rated for environmental resilience is essential.

How Do Fiber Cables Enhance Hospitality Services?

In the hospitality industry, fiber cables are increasingly utilized for PoE lighting and communication systems. This technology not only enhances the guest experience through better connectivity but also improves energy efficiency. The primary issues resolved involve the integration of power and data transmission into a single cable, simplifying installations. Buyers should consider compliance with local regulations, the ability to integrate with existing systems, and the aesthetic impact of the installations when sourcing fiber cables for hospitality applications.

3 Common User Pain Points for ‘Fiber Cable Manufacturers’ & Their Solutions

Scenario 1: Complicated Installation Processes for Fiber Optic Cables

The Problem: B2B buyers often encounter difficulties during the installation of fiber optic cables, particularly in complex environments such as urban areas or industrial sites. This can lead to delays, increased costs, and potential damage to the cables if not handled correctly. Factors such as the need for specialized tools, knowledge of local regulations, and the integration with existing infrastructure can complicate the installation process, leading to frustration for both buyers and contractors.

The Solution: To mitigate these challenges, buyers should prioritize manufacturers that offer comprehensive installation support and training. Choosing a supplier that provides detailed installation guides, video tutorials, and access to experienced technicians can significantly ease the process. Moreover, consider opting for cables designed for easier installation, such as those with FastAccess® technology, which allows for quicker deployment without compromising durability. Finally, engaging in pre-installation consultations with the manufacturer can help identify potential obstacles and develop tailored solutions that align with the specific installation environment.

Scenario 2: Ensuring Compatibility with Existing Infrastructure

The Problem: Many businesses face the challenge of ensuring that new fiber optic cables are compatible with their existing infrastructure. This is particularly pertinent for companies that have older systems that may not support the latest fiber technologies. The mismatch can result in underperformance, increased latency, or even complete system failures, leading to operational downtimes and lost revenue.

The Solution: B2B buyers should conduct a thorough compatibility assessment before purchasing fiber optic cables. This involves collaborating closely with manufacturers who can provide detailed specifications and compatibility information for their products. Buyers should also inquire about options for hybrid cables that can seamlessly integrate with both legacy systems and modern infrastructures. Additionally, leveraging the expertise of the manufacturer’s technical support team during the selection process can help ensure that the chosen cables meet the operational requirements of existing networks, thus preventing future complications.

Scenario 3: Addressing Environmental and Durability Concerns

The Problem: Environmental conditions can significantly impact the performance and longevity of fiber optic cables. Buyers operating in regions with extreme temperatures, high humidity, or exposure to harsh chemicals must select cables that can withstand these conditions. Failing to do so can lead to frequent failures, necessitating costly replacements and disrupting business operations.

The Solution: To address these environmental challenges, B2B buyers should focus on sourcing fiber optic cables specifically designed for their local conditions. This means selecting cables that are rated for outdoor use, have protective jackets, and possess features such as UV resistance or water-blocking capabilities. Buyers should also consult with manufacturers about the specific environmental factors in their region and ask for recommendations tailored to those conditions. By investing in high-quality, durable cables from reputable manufacturers, businesses can ensure reliable performance and minimize the risk of premature cable failures, ultimately leading to cost savings and enhanced operational efficiency.

Strategic Material Selection Guide for Fiber Cable Manufacturers

What Are the Key Materials for Fiber Cable Manufacturing?

Fiber optic cables are essential for modern communication systems, and the choice of materials significantly impacts their performance and suitability for various applications. This section analyzes four common materials used in fiber cable manufacturing: glass, plastic, aramid yarn, and polyethylene. Each material has unique properties, advantages, and challenges that B2B buyers must consider, especially in diverse international markets.

How Does Glass Fiber Impact Fiber Cable Performance?

Glass fiber is the most widely used material in fiber optic cables due to its excellent light transmission properties. It typically has a high temperature rating, often exceeding 85°C, and can withstand significant pressure and mechanical stress. Glass fibers exhibit low attenuation, which means they can transmit signals over long distances without significant loss.

Pros: The durability and performance of glass fibers make them ideal for long-haul applications. They are resistant to environmental factors like moisture and temperature fluctuations, ensuring reliable performance in various conditions.

Cons: However, glass fibers are more fragile than their plastic counterparts, making them susceptible to damage during installation. Additionally, the manufacturing process can be complex and costly, which may impact pricing for international buyers.

Impact on Application: Glass fibers are compatible with various media, including data and telecommunications, making them suitable for high-speed internet and telecommunications infrastructure.

What Role Does Plastic Play in Fiber Cable Manufacturing?

Plastic optical fibers (POFs) are increasingly popular for short-distance applications due to their flexibility and ease of installation. They typically have lower temperature ratings, around 70°C, and are less sensitive to bending than glass fibers.

Pros: The manufacturing process for plastic fibers is generally simpler and less expensive, making them a cost-effective option for short-range applications. Their flexibility allows for easier handling and installation in tight spaces.

Cons: However, plastic fibers have higher attenuation rates compared to glass, limiting their use in long-distance applications. They are also more susceptible to environmental degradation, which can affect performance over time.

Impact on Application: POFs are ideal for consumer electronics and indoor networking, where high bandwidth is not as critical, making them suitable for applications like home networking and automotive systems.

Why Is Aramid Yarn Important in Fiber Cable Design?

Aramid yarn is commonly used as a strength member in fiber optic cables, providing additional tensile strength and protection against physical damage. This material is lightweight and has excellent resistance to temperature and chemicals.

Pros: The inclusion of aramid yarn enhances the durability of fiber optic cables, making them suitable for outdoor and harsh environments. Its lightweight nature also reduces the overall weight of the cable, facilitating easier installation.

Cons: While aramid yarn improves strength, it can increase manufacturing complexity and costs. Additionally, its performance may be compromised in extreme environmental conditions if not properly protected.

Impact on Application: Aramid yarn is particularly beneficial in outdoor applications where cables are exposed to mechanical stress, such as aerial installations or direct burial.

How Does Polyethylene Contribute to Fiber Cable Protection?

Polyethylene (PE) is widely used as an outer jacket material for fiber optic cables, providing excellent moisture resistance and mechanical protection. It is also lightweight and has good chemical resistance.

Pros: PE jackets help protect fiber cables from environmental factors, making them suitable for outdoor installations. They are also relatively inexpensive, contributing to lower overall cable costs.

Cons: However, PE may not offer the same level of fire resistance as other materials, which could be a concern in certain applications. Additionally, it may not withstand extreme temperatures as effectively as other materials.

Impact on Application: Polyethylene jackets are commonly used in outdoor fiber optic cables, particularly in telecommunications and broadband applications where moisture and environmental exposure are concerns.

Summary Table of Material Selection for Fiber Cable Manufacturers

| Material | Typical Use Case for Fiber Cable Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass Fiber | Long-haul telecommunications and data networks | Low attenuation and high durability | Fragility during installation | High |

| Plastic Fiber | Short-range applications like home networking | Cost-effective and flexible | Higher attenuation limits | Low |

| Aramid Yarn | Outdoor and harsh environment installations | Enhanced tensile strength | Increased manufacturing complexity | Medium |

| Polyethylene | Outdoor fiber optic cables for telecommunications | Excellent moisture resistance | Limited fire resistance | Low |

This guide provides a comprehensive overview of the materials used in fiber optic cable manufacturing, highlighting their properties, advantages, and limitations. Understanding these factors is crucial for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, where compliance with standards and local preferences can influence purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for Fiber Cable Manufacturers

What Are the Key Stages in the Manufacturing Process of Fiber Cables?

The manufacturing of fiber optic cables involves several critical stages, each designed to ensure the final product meets stringent performance and quality standards.

Material Preparation

The first step in the manufacturing process is material preparation, which includes sourcing high-quality raw materials such as silica glass for the fiber and various polymers for the cable sheathing. The quality of these materials is paramount as they directly affect the cable’s performance in terms of attenuation and durability. Manufacturers often conduct extensive supplier assessments and material testing to ensure compliance with international standards such as ISO 9001, which outlines requirements for quality management systems.

Forming the Fiber

Once the materials are prepared, the next stage is the formation of the optical fibers. This typically involves a process called the “preform method,” where a glass preform is created using chemical vapor deposition (CVD) techniques. This preform is then heated and drawn into thin fibers through a process known as fiber drawing. The fiber’s diameter is carefully controlled, usually around 125 micrometers for standard single-mode fibers. The drawing process must be meticulously monitored to prevent defects, such as bubbles or variations in thickness.

Assembly of the Cable

After the fibers are produced, they must be assembled into cables. This involves bundling multiple fibers together and encasing them in protective materials. Manufacturers may use various configurations, including loose tube or tight-buffered designs, depending on the intended application. The assembly process includes the addition of strength members, moisture barriers, and outer jackets, which may require specific materials to enhance durability against environmental factors.

Finishing and Quality Control

The final stage is finishing, which involves testing the assembled cables for performance characteristics like tensile strength, flexibility, and environmental resistance. This stage is crucial as it ensures that the cables will perform reliably in real-world applications.

How Is Quality Assurance Implemented in Fiber Cable Manufacturing?

Quality assurance (QA) is integral to fiber cable manufacturing, ensuring that products meet both international standards and customer specifications.

What International Standards Should B2B Buyers Be Aware Of?

Manufacturers typically adhere to international standards such as ISO 9001 for quality management, ISO/IEC 11801 for performance specifications of cabling, and CE marking for compliance with European Union regulations. These standards help ensure that the products are safe, reliable, and of high quality. Additionally, industry-specific certifications may be relevant, such as those from the American Petroleum Institute (API) for cables used in oil and gas applications.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, various tests are performed to monitor the production and identify any defects early. This includes checking the fiber diameter during drawing and the integrity of the cable assembly.

-

Final Quality Control (FQC): After the cables are finished, they undergo comprehensive testing, including attenuation tests, tensile strength assessments, and environmental tests to ensure they can withstand conditions like temperature fluctuations and moisture exposure.

What Testing Methods Are Commonly Used in Fiber Cable Manufacturing?

Testing is a critical aspect of the quality assurance process in fiber optic cable manufacturing. Common testing methods include:

-

Optical Time-Domain Reflectometer (OTDR) Testing: This method assesses the performance of the fiber by sending light pulses and measuring the reflected signals, allowing manufacturers to identify faults and measure attenuation.

-

Mechanical Testing: This includes tensile tests to evaluate the cable’s strength and flexibility, ensuring it can withstand installation stresses.

-

Environmental Testing: Cables are subjected to temperature cycling, humidity, and other environmental factors to simulate real-world conditions and ensure durability.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to ensure that their suppliers maintain rigorous quality control processes. Here are several methods to verify supplier QC:

-

Supplier Audits: Conducting regular audits of suppliers can provide insight into their manufacturing processes, quality assurance practices, and adherence to international standards.

-

Quality Reports: Requesting detailed quality reports and testing data can help buyers assess the reliability of the products. These reports should include results from the various QC checkpoints mentioned earlier.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased evaluation of a supplier’s quality control measures and overall production capabilities.

What Are the Unique QC Considerations for International B2B Buyers?

For international buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, several unique QC considerations must be taken into account:

-

Regulatory Compliance: Different countries may have varying regulatory requirements for fiber optic cables. Buyers should ensure that suppliers are compliant with local regulations, which may include specific certifications.

-

Cultural and Logistical Challenges: Language barriers and different business practices can complicate the verification of quality control measures. Establishing clear communication and understanding cultural nuances is essential for successful partnerships.

-

Shipping and Handling Risks: The journey from manufacturer to buyer can introduce risks that may affect cable integrity. Buyers should ensure that their suppliers have robust packaging and handling procedures in place to mitigate these risks.

In summary, understanding the manufacturing processes and quality assurance practices of fiber cable manufacturers is vital for B2B buyers. By being informed about the stages of production, quality control checkpoints, testing methods, and verification strategies, buyers can make more informed decisions and select suppliers that align with their quality expectations and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Fiber Cable Manufacturers’

Introduction

Sourcing fiber cable manufacturers requires a strategic approach to ensure quality, reliability, and compliance with industry standards. This guide provides a step-by-step checklist to assist international B2B buyers—particularly from Africa, South America, the Middle East, and Europe—in navigating the complexities of fiber optic procurement. By following these steps, buyers can make informed decisions that align with their technical needs and business objectives.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the fiber cables meet your operational requirements. Consider factors such as fiber type (single-mode vs. multimode), cable count, and environmental conditions (indoor vs. outdoor applications). This clarity will help you communicate effectively with potential suppliers and avoid costly mismatches.

Step 2: Research Potential Manufacturers

Conduct thorough research to identify reputable fiber cable manufacturers. Look for companies with a strong market presence and positive reviews from other B2B buyers. Utilize online resources, industry forums, and trade shows to gather insights and compile a list of potential candidates who align with your specifications.

Step 3: Evaluate Supplier Certifications

Before proceeding with a supplier, verify their industry certifications and compliance with international standards. Look for certifications such as ISO 9001 for quality management and TL 9000 specific to telecommunications. These credentials not only indicate a commitment to quality but also ensure that the products will perform reliably in your intended applications.

Step 4: Request Samples and Technical Data

Obtaining samples allows you to assess the quality and suitability of the fiber cables firsthand. Additionally, request technical data sheets that provide detailed information on the product’s performance characteristics. This step is essential for verifying that the cables meet your specific requirements, particularly in terms of durability and signal integrity.

Step 5: Assess Pricing and Terms of Service

Price is a critical factor, but it should not be the sole determinant in your decision-making process. Compare pricing models among suppliers while also evaluating their terms of service, including warranties and return policies. Understand the total cost of ownership, which includes installation, maintenance, and potential downtime costs associated with inferior products.

Step 6: Check References and Previous Projects

Reach out to previous clients or industry peers who have worked with the manufacturers you are considering. Inquire about their experiences regarding product performance, delivery timelines, and customer service. This feedback can provide invaluable insights into the reliability and reputation of the supplier.

Step 7: Finalize and Negotiate Contracts

Once you’ve selected a suitable manufacturer, it’s time to finalize the contract. Ensure that all agreed-upon terms, including pricing, delivery schedules, and quality assurance measures, are clearly outlined. Negotiate any additional terms that may provide further protection for your investment, such as penalties for late delivery or non-compliance with specifications.

By following this checklist, B2B buyers can streamline their sourcing process, minimize risks, and establish partnerships that contribute to their long-term success in the fiber optic industry.

Comprehensive Cost and Pricing Analysis for Fiber Cable Manufacturers Sourcing

What Are the Key Cost Components in Fiber Cable Manufacturing?

When sourcing fiber optic cables, understanding the cost structure is vital for B2B buyers. The primary components influencing the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The core of fiber optic cable production involves high-quality raw materials, including glass fibers and protective jackets. The type of fiber—single-mode versus multimode—will also affect costs significantly. For instance, single-mode fibers typically command a higher price due to their advanced technology and performance characteristics.

-

Labor: Skilled labor is essential for the manufacturing process, particularly in handling and installing complex fiber optic systems. Labor costs vary by region, and factors like local wage rates and the availability of skilled technicians can influence pricing.

-

Manufacturing Overhead: This includes costs associated with facilities, equipment maintenance, and utilities. Manufacturers with advanced, automated production lines may achieve lower overhead costs per unit, benefiting buyers through competitive pricing.

-

Tooling: Investment in specialized tooling and machinery can be substantial, but it is critical for producing high-quality fiber optic cables. Manufacturers often amortize these costs over large production runs, which can lead to lower prices for bulk orders.

-

Quality Control: Ensuring compliance with industry standards and certifications is crucial. Rigorous QC processes can add to production costs but are essential for maintaining product reliability, especially in critical applications.

-

Logistics: Transportation and warehousing costs can vary widely based on the distance from the manufacturing facility to the buyer’s location and the chosen shipping method. Buyers should consider logistics costs as part of the total price.

-

Margin: Finally, manufacturers will include a profit margin in their pricing. This margin can fluctuate based on market demand, competition, and the manufacturer’s reputation.

How Do Price Influencers Affect Fiber Cable Sourcing?

Several factors significantly influence the pricing of fiber optic cables:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced per-unit pricing due to economies of scale. Buyers should negotiate MOQs that align with their project needs to optimize costs.

-

Specifications and Customization: Custom cables designed to meet specific project requirements typically incur higher costs. It’s essential to balance the need for customization with budget constraints.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., ISO, RoHS) can lead to increased costs but are often necessary for compliance and performance in demanding environments.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established manufacturers may charge premium prices for their products due to perceived quality and reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital as they define the responsibilities of buyers and sellers regarding shipping and delivery. Different terms can significantly affect total costs and risk exposure during transportation.

What Tips Can Buyers Use to Optimize Fiber Cable Pricing?

To maximize value when sourcing fiber optic cables, buyers should consider the following strategies:

-

Negotiation: Don’t hesitate to negotiate prices, especially for larger orders. Establishing a good relationship with suppliers can lead to better pricing and terms over time.

-

Cost-Efficiency: Evaluate the total cost of ownership, not just the initial purchase price. Consider long-term performance, maintenance, and replacement costs when selecting products.

-

Pricing Nuances for International Buyers: When sourcing from manufacturers in different countries, be aware of currency fluctuations, import duties, and taxes that can affect final costs.

-

Research and Compare Suppliers: Conduct thorough market research to compare different suppliers based on quality, pricing, and service. Utilize online platforms and industry contacts to gather insights.

-

Stay Informed on Market Trends: Keeping up with industry trends can provide leverage in negotiations and help buyers anticipate price changes due to supply chain disruptions or shifts in demand.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on various factors, including market conditions and specific buyer requirements. Always seek quotes from multiple suppliers to ensure competitive pricing and optimal sourcing decisions.

Alternatives Analysis: Comparing Fiber Cable Manufacturers With Other Solutions

Understanding Alternative Solutions to Fiber Cable Manufacturers

In today’s rapidly evolving telecommunications landscape, businesses often seek alternatives to traditional fiber optic solutions. While fiber cables offer unparalleled performance in data transmission, other technologies can fulfill similar needs based on specific application requirements. This analysis compares fiber cable manufacturers with two viable alternatives: Copper Cable Solutions and Wireless Communication Technologies.

Comparison Table

| Comparison Aspect | Fiber Cable Manufacturers | Copper Cable Solutions | Wireless Communication Technologies |

|---|---|---|---|

| Performance | High bandwidth, low attenuation, long-distance | Moderate bandwidth, higher attenuation | Variable bandwidth, affected by distance and obstructions |

| Cost | Higher initial investment, lower long-term costs | Lower initial costs, higher maintenance | Moderate to high, depending on infrastructure |

| Ease of Implementation | Requires specialized installation | Easier to install and terminate | Quick deployment, minimal installation needs |

| Maintenance | Low maintenance, durable | Moderate maintenance, prone to corrosion | Minimal maintenance, but requires periodic upgrades |

| Best Use Case | Long-distance data transmission, high capacity | Short to medium distance, legacy systems | Areas lacking infrastructure, temporary setups |

What Are the Pros and Cons of Copper Cable Solutions?

Copper cable solutions, such as twisted pair and coaxial cables, serve as a traditional alternative to fiber optics. The primary advantage of copper is its lower initial installation cost, making it attractive for businesses with budget constraints. Additionally, copper cables are easier to install and terminate, allowing for quicker setups. However, copper cables exhibit higher attenuation rates and limited bandwidth compared to fiber, making them less suitable for high-capacity applications. They are also susceptible to environmental factors, such as corrosion, which can increase maintenance requirements over time.

How Do Wireless Communication Technologies Compare?

Wireless communication technologies, including Wi-Fi and cellular networks, offer a flexible and rapidly deployable alternative to wired solutions. The primary advantage of wireless systems is their ease of installation, as they eliminate the need for extensive cabling infrastructure. This is particularly beneficial in remote or temporary setups. However, wireless performance can be inconsistent due to factors like distance, physical obstructions, and interference, which may impact data transmission quality. While these systems can cater to a range of applications, they often lack the reliability and bandwidth capacity of fiber optics, making them less ideal for mission-critical operations.

Choosing the Right Solution: What Should B2B Buyers Consider?

When selecting the appropriate solution for their networking needs, B2B buyers should evaluate several factors, including performance requirements, budget constraints, installation timelines, and long-term maintenance considerations. Fiber optic solutions excel in high-capacity, long-distance applications but require a higher upfront investment and specialized installation. Conversely, copper solutions may be more budget-friendly initially but could incur higher maintenance costs and limitations in performance. Wireless technologies offer flexibility and ease of deployment but may not match the reliability of wired solutions.

Ultimately, the choice between fiber cable manufacturers and alternative technologies should align with the specific operational requirements and future growth plans of the business. By carefully assessing these factors, buyers can make informed decisions that optimize their network infrastructure.

Essential Technical Properties and Trade Terminology for Fiber Cable Manufacturers

What Are the Key Technical Properties of Fiber Cables That B2B Buyers Should Know?

Understanding the essential technical properties of fiber optic cables is crucial for B2B buyers when selecting products that meet their specific needs. Here are some critical specifications:

-

Material Grade

Fiber optic cables are typically made from glass or plastic fibers. The material grade affects the cable’s performance, durability, and transmission capacity. High-grade materials can withstand harsher environmental conditions and provide lower attenuation, which translates to better signal quality over long distances. For B2B buyers, selecting the right material grade ensures that the cables will function optimally in their intended applications, reducing the risk of costly downtime and maintenance. -

Fiber Count

This specification indicates the number of individual fibers within a cable. Common configurations include single-mode and multimode fibers, with counts ranging from a few to several hundred. A higher fiber count allows for greater data transmission capacity, making it ideal for applications requiring high bandwidth, such as data centers and telecommunications networks. Understanding fiber count helps buyers choose cables that can support current and future network demands. -

Bend Radius

The bend radius refers to the minimum radius at which a fiber optic cable can be bent without incurring damage. This property is essential for installation in tight spaces, such as conduits or corners. A lower bend radius allows for more flexible installation options, making it easier to manage cables in complex environments. Buyers should ensure that the bend radius meets the requirements of their installation conditions to avoid performance issues. -

Flame Rating

Cables are often rated for their flame resistance, which is critical for indoor installations. Ratings such as LSZH (Low Smoke Zero Halogen) indicate that the cable produces minimal smoke and no halogens when burned, enhancing safety in case of fire. B2B buyers must consider flame ratings to comply with local safety regulations and standards, particularly in commercial and industrial settings. -

Attenuation

Attenuation measures the loss of signal strength as it travels through the fiber. It is typically expressed in decibels per kilometer (dB/km). Lower attenuation rates mean that the signal can travel longer distances without degradation, which is particularly important for long-haul telecommunications. Buyers should prioritize cables with low attenuation to ensure reliable communication over extended distances.

What Are Common Trade Terms Used in the Fiber Cable Industry?

Familiarity with industry-specific terminology can significantly enhance communication between buyers and manufacturers. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the fiber optic industry, OEMs often provide customized solutions tailored to specific client requirements. Understanding OEM relationships can help buyers secure high-quality, tailored products. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts purchasing decisions, inventory management, and cash flow. Buyers should negotiate MOQs that align with their operational needs to avoid excess inventory or stock shortages. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It is essential for buyers seeking competitive pricing and ensuring they receive the best value for their investments. Crafting a clear RFQ can streamline the procurement process and foster better supplier relationships. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms that outline the responsibilities of buyers and sellers in international trade. They clarify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms helps buyers manage logistics more effectively and mitigate risks associated with global sourcing. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. This term is particularly important in the fiber optic industry, where timely delivery can impact project timelines. Buyers should inquire about lead times to ensure that their procurement aligns with operational schedules.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right fiber optic solutions for their unique business needs.

Navigating Market Dynamics and Sourcing Trends in the Fiber Cable Manufacturers Sector

What Are the Key Trends Influencing the Fiber Cable Manufacturers Market?

The global fiber cable manufacturing sector is witnessing significant shifts driven by advancements in technology, the growing demand for high-speed internet, and the expansion of data centers. A primary market driver is the increasing reliance on digital infrastructure across industries, particularly in developing regions like Africa and South America, where connectivity is essential for economic growth. Emerging technologies such as 5G and IoT are further propelling the need for robust fiber optic networks, creating opportunities for manufacturers to innovate and offer products that cater to these demands.

International buyers are also observing a trend towards customization and modularity in fiber optic solutions. Manufacturers are increasingly offering tailored products to meet specific regional requirements, such as varying environmental conditions and installation methods. For instance, outdoor cables designed to withstand harsh climates are becoming more prevalent, especially in areas prone to extreme weather. Moreover, the rise of sustainability as a core value in procurement processes is influencing sourcing decisions, with companies seeking suppliers committed to eco-friendly practices.

How Does Sustainability Impact Sourcing in the Fiber Cable Sector?

Sustainability is becoming a pivotal consideration for B2B buyers in the fiber cable sector. As the environmental impact of manufacturing processes comes under scrutiny, buyers are increasingly favoring manufacturers that prioritize ethical sourcing and sustainable practices. This includes the use of recyclable materials, energy-efficient production methods, and adherence to stringent environmental regulations.

Certifications such as ISO 14001 for environmental management and compliance with the RoHS (Restriction of Hazardous Substances) directive are becoming essential for manufacturers aiming to differentiate themselves in a competitive marketplace. Additionally, companies are exploring partnerships with suppliers who can provide ‘green’ certifications for their products, ensuring that they align with global sustainability goals. This focus not only enhances brand reputation but also meets the growing consumer demand for environmentally responsible products.

How Has the Fiber Cable Manufacturing Industry Evolved?

The fiber cable manufacturing industry has evolved significantly since its inception in the late 20th century. Initially dominated by a few key players, the market has expanded with technological innovations that have driven down costs and improved performance. The introduction of low-loss optical fibers revolutionized telecommunications, paving the way for widespread adoption of fiber optics in both residential and commercial settings.

Over the years, the industry has witnessed a shift towards more specialized products, with manufacturers developing cables that cater to specific applications, such as harsh environments or high-density installations. As the digital landscape continues to evolve, fiber cable manufacturers are now focusing on integrating advanced technologies like smart sensors and monitoring systems into their products, positioning themselves to meet the future demands of global connectivity. This evolution underscores the importance of staying abreast of market trends and technological advancements for B2B buyers seeking reliable suppliers.

Frequently Asked Questions (FAQs) for B2B Buyers of Fiber Cable Manufacturers

-

How do I choose the right fiber optic cable for my project?

Selecting the appropriate fiber optic cable involves considering several factors, including the installation environment (indoor, outdoor, or both), cable type (single-mode vs. multimode), and specific performance requirements such as bandwidth and distance. Assess the environmental conditions, such as temperature extremes or moisture, to determine if you need outdoor-rated cables. Additionally, evaluate future scalability—higher fiber counts may be beneficial for expanding network needs. Consulting with manufacturers or distributors can provide tailored recommendations based on your project’s unique demands. -

What are the key benefits of using fiber optic cables in my network?

Fiber optic cables offer numerous advantages over traditional copper cables, including higher bandwidth capabilities, longer transmission distances without signal loss, and immunity to electromagnetic interference. These features make fiber optics ideal for high-speed internet services, data centers, and extensive network infrastructures. Additionally, fiber cables are lighter and more durable, often requiring less space for installation and maintenance. These benefits translate into enhanced performance, reliability, and cost-efficiency for businesses investing in modern telecommunications systems. -

What is the minimum order quantity (MOQ) for fiber optic cables?

Minimum order quantities (MOQs) for fiber optic cables can vary significantly between manufacturers and product types. Typically, MOQs can range from a few hundred meters for standard cables to larger quantities for custom solutions. When negotiating with suppliers, consider your project needs and future requirements. Some manufacturers may offer flexible MOQ options, especially for first-time buyers or larger contracts, so it’s essential to communicate your specific needs to secure the best terms. -

How do I ensure the quality of fiber optic cables from suppliers?

To ensure quality, it’s crucial to vet suppliers thoroughly. Look for manufacturers with industry certifications such as ISO 9001, which indicates adherence to quality management principles. Request samples and performance data sheets, and consider third-party testing for assurance. Additionally, check customer reviews and case studies to gauge the supplier’s reputation. Establishing a long-term partnership with a reliable manufacturer can also provide peace of mind regarding the quality and consistency of the products supplied. -

What payment terms should I expect when sourcing fiber optic cables internationally?

Payment terms can vary widely depending on the supplier and the nature of the transaction. Common practices include upfront payments, partial payments, or credit terms based on established relationships. For international transactions, consider using secure payment methods such as letters of credit or escrow services to mitigate risk. Always clarify payment terms before finalizing agreements to ensure transparency and avoid misunderstandings, especially regarding currency exchange rates and transaction fees. -

What logistics considerations should I keep in mind when importing fiber optic cables?

When importing fiber optic cables, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with the specific requirements of importing telecommunications equipment. Ensure compliance with local import regulations, including tariffs and documentation. Additionally, factor in the potential for delays in customs clearance, which can impact project timelines. Establishing a clear communication line with your supplier and logistics partner can help streamline the process. -

Can I customize fiber optic cables for specific applications?

Yes, many manufacturers offer customization options for fiber optic cables to meet specific application requirements. Customizations can include varying fiber counts, cable jackets, connectors, and lengths. When discussing your needs with suppliers, provide detailed specifications regarding your project to receive accurate quotations and lead times. Custom solutions may involve additional costs, so it’s essential to weigh the benefits against your budget and project scope. -

What are the typical lead times for fiber optic cable orders?

Lead times for fiber optic cable orders can range from a few days to several weeks, depending on factors such as the type of cable, customization requirements, and the supplier’s inventory levels. Standard cables may have shorter lead times, while custom orders typically require more time for production and testing. To ensure timely delivery, place orders well in advance of project deadlines and communicate your timeline requirements to the supplier during negotiations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Fiber Cable Manufacturers

What Are the Key Takeaways for Strategic Sourcing in Fiber Cable Manufacturing?

In the rapidly evolving landscape of fiber cable manufacturing, strategic sourcing emerges as a critical component for international B2B buyers. It allows for the procurement of high-quality products that meet specific environmental and operational needs. By partnering with reputable manufacturers, buyers can ensure access to innovative solutions, such as outdoor and indoor fiber options that withstand diverse conditions, enhancing network reliability and performance.

Moreover, understanding the market landscape, including key players and product types, empowers buyers to make informed decisions that align with their long-term goals. This strategic approach not only optimizes costs but also strengthens supply chain resilience, particularly for businesses operating in regions like Africa, South America, the Middle East, and Europe.

How Can Buyers Prepare for Future Fiber Cable Needs?

Looking ahead, the demand for fiber optic solutions will continue to surge as digital transformation accelerates globally. Buyers are encouraged to stay proactive by evaluating emerging technologies and trends, such as increased fiber density and advanced installation techniques. Engaging with suppliers who prioritize innovation and sustainability will be paramount in meeting future connectivity requirements.

Take the next step in fortifying your network infrastructure—partner with leading fiber cable manufacturers today to ensure your organization remains at the forefront of connectivity solutions.