Top 7 Cnc Machine Manufacturers List and Guide: How To Solve Scen…

Introduction: Navigating the Global Market for CNC Machine Manufacturers

In an increasingly competitive global landscape, sourcing CNC machine manufacturers presents a significant challenge for international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe. The complexities of evaluating various suppliers, understanding diverse machine types, and navigating pricing structures can be daunting. This guide aims to simplify the process, offering a comprehensive overview of CNC machine manufacturers, including insights into different machine types, their applications across various industries, and effective strategies for vetting suppliers.

With a focus on actionable insights, this resource empowers decision-makers to make informed purchasing choices that align with their operational needs and budget constraints. Buyers will gain clarity on the factors influencing costs, the latest technological advancements in CNC machining, and the best practices for establishing successful supplier relationships. By addressing the unique challenges faced by businesses in emerging and established markets, this guide serves as a vital tool for enhancing procurement strategies and maximizing return on investment. Whether you’re seeking high-precision equipment for aerospace applications or robust machines for heavy manufacturing, this comprehensive guide will equip you with the knowledge necessary to navigate the global CNC market effectively.

Top 10 Cnc Machine Manufacturers Manufacturers & Suppliers List

1. Prototool – CNC Machines

Domain: prototool.com

Registered: 2004 (21 years)

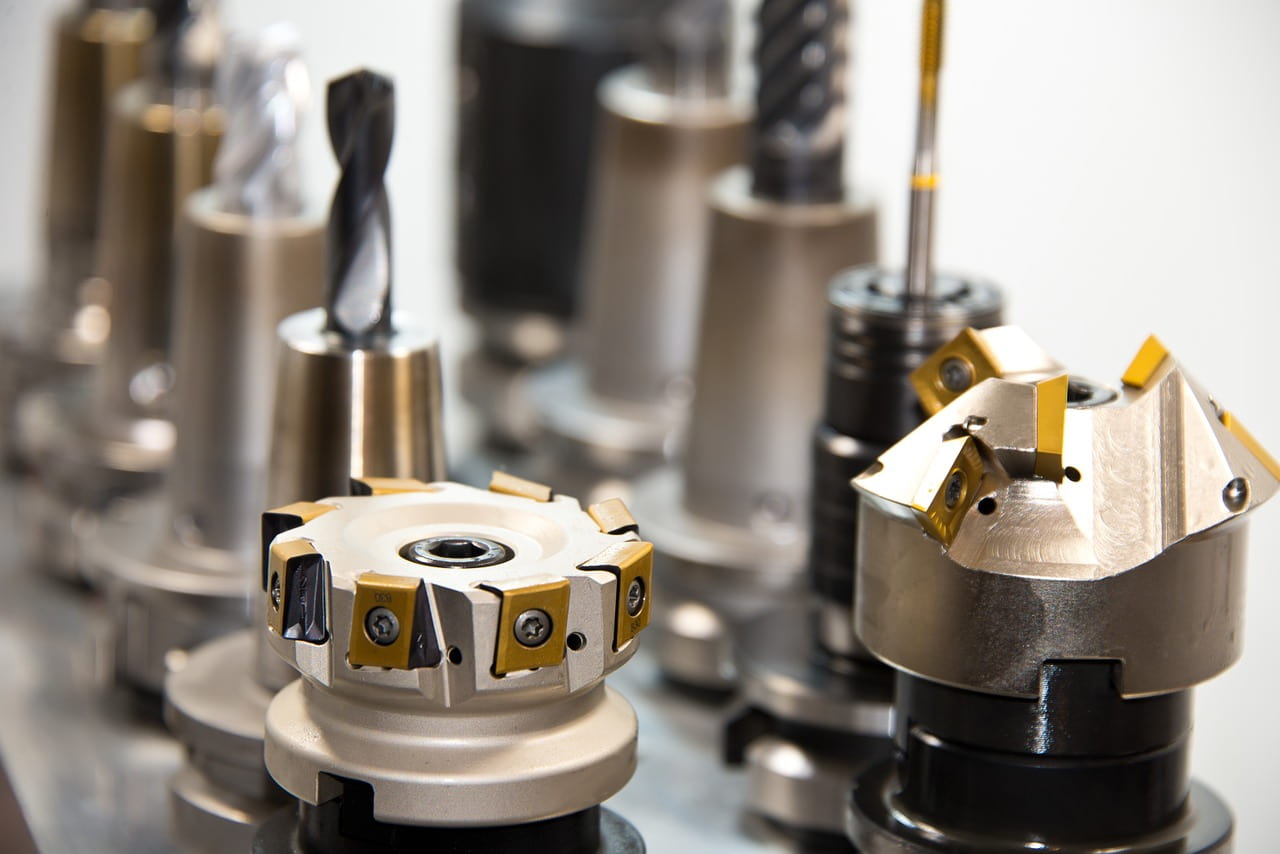

Introduction: CNC machines are automated power tools controlled by computers, used for precision manufacturing of components and parts. They perform various operations such as milling, turning, drilling, cutting, and routing on a range of materials. CNC machines are programmed with CAD/CAM software and G code, allowing for high accuracy and efficiency in production. Common types of CNC machines include: 1. Mill…

2. CNC Machine Compatibility – Complete Manufacturer List

Domain: bobcad.com

Registered: 1996 (29 years)

Introduction: Complete List of Compatible CNC Machine Manufacturers: ABCTech, Brother, EMC, HoneyBee, Mitsubishi, Romero, Testra, Ability Systems, Bridgeport, Emco, Hurco, Mori-Seki, Sabre, Thermwood, Acramatic, Burny, EZ, Hust, NC Studio, Seib-Meyer, Torchmate, ACS, Camsoft, Fadal, Hycut, Nee, Selexx, Tormach, Acu-Rite, Centroid, Fanuc, Hypertherm, Nice, Sharanoa, Toshiba, Adtech, Centurion, FlashCut, Hyundai,…

3. Mazak – CNC Machining Solutions

Domain: mazak.com

Registered: 1998 (27 years)

Introduction: Mazak Corporation offers a diverse range of products including: 5-Axis Machining Centers, Additive Manufacturing (AM), Automation solutions, CNC Turning Centers, Friction Stir Welding (FSW), Horizontal Machining Centers, Multi-Tasking Machines, Swiss-Style Production Turning Machines, and Vertical Machining Centers. Additionally, they provide technology solutions such as CNC Systems, programming a…

4. CNC Machines – Trusted Brands

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Most trusted CNC machine brands mentioned include Makino, Okuma, Haas, and DMG Mori. Users noted that older Okuma lathes are highly reliable and long-lasting, while Haas machines are seen as good starting options but may not endure heavy use without maintenance. DMG Mori is recognized for quality, and Japanese brands are generally considered a safe choice.

5. DMG MORI – CNC Machines for Metalworking

Domain: us.dmgmori.com

Registered: 2013 (12 years)

Introduction: DMG MORI offers a comprehensive range of CNC machines for various applications in metalworking, including turning centers, milling machines, ULTRASONIC and LASERTEC series, additive manufacturing, and grinding. The machines are suitable for materials such as non-ferrous metals, steel, stainless steel, high-strength alloys, plastics, composite materials, glass, and diamond. Key industries served in…

6. Phillips Machine Tools – CNC Milling Machines

Domain: phillipscorp.com

Registered: 1996 (29 years)

Introduction: Phillips Machine Tools India offers a range of CNC milling machines including 5-Axis Gantry Machining Centers, Vertical Milling Machines, Horizontal Milling Machines, Double Column Type, and Compact Mills. They partner with global brands like HAAS, Burkhardt+Weber, AWEA, APEC, and Hermle to provide high precision and fully automated solutions. Key products include: 5-axis VMCs, Drill Tap Centers, …

7. Tormach – Affordable CNC Machines

Domain: tormach.com

Registered: 2002 (23 years)

Introduction: Tormach offers a range of affordable CNC machines, including mills (1500MX, 1100MX, 770MX, 1100M, 770M, PCNC 440), lathes (8L, 15L Slant-PRO), routers (24R, xsTECH Pro Router, xsTECH Router), bandsaws (AF50), plasma tables (1300PL), and automation solutions. Their machines run on single-phase power and utilize the free, open-source control software PathPilot®. Tormach machines are designed to be u…

Understanding CNC Machine Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vertical CNC Mills | Upright spindle orientation, high rigidity | Metalworking, aerospace, automotive | Pros: Efficient for complex parts; Cons: Limited to vertical operations. |

| CNC Lathes | Rotating workpiece, linear tool movement | Precision machining, automotive | Pros: Ideal for cylindrical parts; Cons: Less versatile for complex shapes. |

| Multi-Axis CNC Machines | Capable of simultaneous movement on multiple axes | Aerospace, medical device manufacturing | Pros: High precision and flexibility; Cons: Higher cost and complexity. |

| CNC Plasma Cutters | Uses plasma to cut metal sheets | Metal fabrication, signage | Pros: Fast cutting speed; Cons: Limited to conductive materials. |

| CNC Router | Utilizes a spinning router for cutting | Woodworking, sign making | Pros: Versatile for various materials; Cons: Less precise than mills. |

What Are the Characteristics of Vertical CNC Mills?

Vertical CNC mills are characterized by their upright spindle orientation, allowing for precision machining of complex shapes and features. They are particularly suitable for industries such as metalworking, aerospace, and automotive, where intricate designs and high rigidity are paramount. B2B buyers should consider the machine’s load capacity, tooling options, and software compatibility, as these factors significantly impact operational efficiency and cost-effectiveness.

How Do CNC Lathes Stand Out in the Market?

CNC lathes are designed for turning operations, where the workpiece rotates while the tools remain stationary. This configuration is ideal for producing cylindrical parts with high precision, making them a staple in automotive and precision machining sectors. Buyers should evaluate the lathe’s spindle speed, tooling capabilities, and ease of programming. While CNC lathes excel in their niche, they may not be as versatile for more complex geometries compared to other types of CNC machines.

What Advantages Do Multi-Axis CNC Machines Offer?

Multi-axis CNC machines allow for simultaneous movement across three or more axes, enabling the machining of complex parts in a single setup. This capability is essential in industries like aerospace and medical device manufacturing, where precision and efficiency are critical. B2B buyers should assess the machine’s accuracy, software integration, and maintenance requirements. While they offer unmatched flexibility and precision, the investment can be substantial, and operational training may be necessary.

In What Applications Are CNC Plasma Cutters Most Effective?

CNC plasma cutters utilize high-velocity plasma to cut through conductive materials, such as steel and aluminum. They are primarily used in metal fabrication and signage applications due to their speed and efficiency. When considering a plasma cutter, buyers should focus on cutting thickness capabilities, operational costs, and the type of materials they intend to work with. While plasma cutters provide rapid cutting solutions, they are limited to conductive materials and may not achieve the same precision as other CNC methods.

Why Are CNC Routers Popular Among Woodworkers?

CNC routers use a spinning router to cut various materials, making them highly versatile for woodworking and sign-making applications. Their ability to handle materials like wood, plastic, and composites makes them a popular choice for small to medium-sized businesses. Buyers should consider the router’s cutting area, spindle power, and software compatibility. Although CNC routers offer flexibility and ease of use, they may not deliver the same level of precision as CNC mills for intricate designs.

Key Industrial Applications of CNC Machine Manufacturers

| Industry/Sector | Specific Application of CNC Machine Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision part manufacturing for aircraft components | Enhanced accuracy and reduced waste, leading to cost savings | Certifications for aviation standards, lead times, and support services |

| Automotive | Production of complex engine parts and chassis components | Improved production efficiency and scalability | Supplier reliability, tooling compatibility, and after-sales support |

| Medical Devices | Fabrication of custom implants and surgical instruments | High precision and compliance with health regulations | Material quality, regulatory certifications, and customization capabilities |

| Electronics | PCB milling and enclosures manufacturing | Faster prototyping and reduced time-to-market | Precision tolerances, software integration, and tech support |

| Metal Fabrication | Custom metal parts for construction and machinery | Enhanced durability and performance of end products | Material sourcing, machining capabilities, and delivery timelines |

How Are CNC Machine Manufacturers Applied in the Aerospace Sector?

In the aerospace industry, CNC machine manufacturers are pivotal in producing precision parts for aircraft components, such as wing structures, engine mounts, and fuselage assemblies. The high level of accuracy required minimizes waste and enhances the overall safety and performance of the aircraft. Buyers from regions like Europe and the Middle East must ensure that suppliers meet strict aviation standards and possess the necessary certifications, as compliance is crucial for regulatory approval.

What Role Do CNC Machines Play in Automotive Manufacturing?

CNC machines are extensively used in the automotive sector for the production of complex engine parts and chassis components. Their capability to handle intricate designs enables manufacturers to enhance production efficiency while maintaining high quality. B2B buyers should consider the reliability of suppliers, the compatibility of tooling with existing systems, and the availability of after-sales support to ensure smooth operations and reduced downtime.

How Are CNC Machines Utilized in Medical Device Manufacturing?

In the medical device sector, CNC machine manufacturers facilitate the fabrication of custom implants and surgical instruments that demand exceptional precision and adherence to health regulations. This technology allows for the rapid production of tailored solutions that meet specific patient needs. International buyers must prioritize material quality, regulatory certifications, and the ability to customize designs when sourcing CNC machines for medical applications.

What Advantages Do CNC Machines Offer in Electronics Manufacturing?

CNC machines are instrumental in electronics manufacturing, particularly for PCB milling and the fabrication of enclosures. The ability to produce prototypes quickly and accurately reduces time-to-market, a critical factor in the fast-paced electronics industry. Buyers should assess precision tolerances, software integration capabilities, and the level of technical support offered by manufacturers to ensure they can meet evolving market demands.

How Are CNC Machines Transforming Metal Fabrication?

In metal fabrication, CNC machines are used to create custom metal parts for construction and machinery. These machines provide enhanced durability and performance for end products, which is essential in demanding applications. Buyers should focus on sourcing materials, understanding machining capabilities, and evaluating delivery timelines to ensure they receive high-quality components that meet their project deadlines.

3 Common User Pain Points for ‘CNC Machine Manufacturers’ & Their Solutions

Scenario 1: Struggling with High Maintenance Costs for CNC Machines

The Problem: B2B buyers often find themselves facing escalating maintenance costs for their CNC machines. This issue can stem from a lack of proper training for operators, leading to misuse and premature wear of the equipment. Additionally, the complexity of maintaining various CNC models from different manufacturers can result in confusion and inconsistent maintenance practices. For companies in regions like Africa or South America, where spare parts might be harder to come by, this can translate into significant downtime and lost revenue.

The Solution: To mitigate these costs, buyers should prioritize investing in comprehensive training programs for their operators and maintenance staff. Collaborate with CNC manufacturers that offer robust training resources, including on-site training, webinars, and detailed manuals. Establish a preventive maintenance schedule tailored to the specific models in use, ensuring that maintenance checks are performed regularly to catch minor issues before they escalate. Furthermore, consider forming partnerships with local suppliers or authorized service centers to ensure quick access to spare parts, thereby reducing downtime when repairs are necessary.

Scenario 2: Difficulty in Meeting Diverse Production Needs

The Problem: Many manufacturers face the challenge of adapting their CNC machining processes to meet diverse production requirements, especially when dealing with multiple clients across different industries. This can lead to inefficiencies, as the same machine might not be suitable for varying materials or part complexities. Buyers might struggle to find a single CNC solution that effectively balances versatility with precision, which can hinder their ability to compete in a fast-paced market.

The Solution: Buyers should look for CNC manufacturers that provide customizable machines or modular systems that can be easily adapted for different tasks. Engage in discussions with suppliers about their product range and ask for demonstrations of how specific machines can handle various materials and designs. Additionally, consider investing in software solutions that integrate with CNC machines to streamline production planning and optimize workflows. This will enable your team to better analyze production needs and adjust settings quickly, thereby maximizing efficiency and minimizing waste.

Scenario 3: Navigating the Complexity of CNC Technology Advancements

The Problem: As CNC technology continues to evolve, many buyers find it challenging to keep up with the latest advancements, such as automation and AI integration. This can create a significant gap between what their current machines can do versus what competitors are offering. Buyers may feel overwhelmed by the rapid pace of innovation and unsure about how to evaluate new technologies to determine if they are worth the investment.

The Solution: To effectively navigate these advancements, establish a proactive approach by regularly engaging with CNC manufacturers and industry experts. Attend trade shows, webinars, and workshops to stay informed about the latest technologies and trends. Build a network with other manufacturers to exchange insights and experiences regarding technology adoption. When considering new machines, conduct a thorough cost-benefit analysis that includes potential productivity gains and savings from reduced labor costs through automation. This comprehensive approach will empower buyers to make informed decisions that align with their strategic goals while ensuring they remain competitive in the market.

Strategic Material Selection Guide for CNC Machine Manufacturers

What Are the Key Materials Used in CNC Machine Manufacturing?

When selecting materials for CNC machining, manufacturers must consider various factors including mechanical properties, cost, and application suitability. Here, we analyze four common materials used in CNC machine manufacturing: aluminum, steel, titanium, and plastics. Each material presents unique advantages and challenges, making them suitable for different applications.

How Does Aluminum Benefit CNC Machine Manufacturers?

Aluminum is widely favored in CNC machining due to its lightweight and excellent machinability. Key properties include a high strength-to-weight ratio and good corrosion resistance, making it suitable for applications in automotive and aerospace industries.

Pros: Aluminum is relatively inexpensive, easy to machine, and offers good thermal conductivity. It is also recyclable, which can appeal to environmentally conscious buyers.

Cons: While durable, aluminum is not as strong as steel and can be prone to deformation under high stress or temperature. Additionally, it may require surface treatments to enhance corrosion resistance.

Impact on Application: Aluminum is compatible with a variety of media, including water and oils, making it ideal for parts that require fluid movement or heat exchange.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is crucial. Buyers from Europe may prefer specific alloys like 6061 or 7075, which are known for their mechanical properties.

What Advantages Does Steel Offer in CNC Machining?

Steel is a staple in CNC machining due to its exceptional strength and versatility. It can withstand high pressures and temperatures, making it suitable for heavy-duty applications.

Pros: Steel is highly durable, resistant to wear, and can be heat-treated to enhance its properties. It is also cost-effective for large-scale production.

Cons: Steel is heavier than aluminum, which can be a disadvantage in applications where weight is critical. Machining steel can also be more complex due to its hardness, requiring specialized tooling.

Impact on Application: Steel is compatible with a wide range of media, including corrosive substances, making it suitable for industrial applications.

Considerations for International Buyers: Buyers should be aware of local standards for steel grades, such as DIN EN 10020 in Europe, to ensure compliance and quality.

Why Choose Titanium for CNC Machining?

Titanium is renowned for its strength, low density, and excellent corrosion resistance. These properties make it ideal for high-performance applications, particularly in aerospace and medical industries.

Pros: Titanium is incredibly strong yet lightweight, and it offers superior resistance to corrosion and high temperatures. It is biocompatible, making it suitable for medical implants.

Cons: The primary drawback of titanium is its high cost and difficulty in machining, which can lead to increased production times and expenses.

Impact on Application: Titanium is compatible with aggressive media, making it ideal for applications in harsh environments.

Considerations for International Buyers: Compliance with international standards like ASTM F136 for medical applications is essential. Buyers should also consider the availability of titanium alloys in their regions.

What Role Do Plastics Play in CNC Machining?

Plastics, such as ABS and polycarbonate, are increasingly used in CNC machining due to their lightweight and versatile properties. They are ideal for applications requiring insulation or chemical resistance.

Pros: Plastics are generally low-cost, easy to machine, and available in various colors and finishes. They are also resistant to corrosion and chemicals.

Cons: Plastics can be less durable than metals and may not withstand high temperatures or mechanical stress, limiting their use in heavy-duty applications.

Impact on Application: Plastics are suitable for non-structural components and applications where weight savings are essential.

Considerations for International Buyers: Understanding local regulations regarding plastic materials, such as REACH in Europe, is crucial for compliance.

Summary Table of Material Selection for CNC Machine Manufacturers

| Material | Typical Use Case for CNC Machine Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight, excellent machinability | Less strong than steel | Low |

| Steel | Industrial machinery, structural components | High durability, cost-effective | Heavier, more complex machining | Medium |

| Titanium | Aerospace, medical implants | Strong, lightweight, corrosion-resistant | High cost, difficult to machine | High |

| Plastics | Insulation parts, non-structural components | Low-cost, easy to machine | Less durable, limited high-temperature use | Low |

This guide provides a comprehensive overview of the strategic material selection process for CNC machine manufacturers, enabling international B2B buyers to make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for CNC Machine Manufacturers

What Are the Main Stages in CNC Machine Manufacturing Processes?

CNC machine manufacturing is a complex process that involves several critical stages to ensure precision, efficiency, and quality. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for CNC Manufacturing?

Material preparation is the foundational step in CNC manufacturing. This involves selecting the appropriate raw materials, which may include metals like aluminum, steel, or titanium, as well as plastics or composites. The chosen material is then processed to meet the specific requirements of the CNC machining operations. This can involve cutting raw materials to size, removing impurities, and ensuring that materials comply with international quality standards.

What Techniques Are Used in the Forming Stage?

The forming stage is where the actual machining takes place. CNC machines utilize various techniques, such as milling, turning, and drilling, to shape the material into the desired component. Advanced CNC machining centers may also incorporate multi-axis capabilities, allowing for more complex geometries. The programming of these machines is done using CAD/CAM software, which translates design specifications into machine instructions, ensuring high levels of accuracy and repeatability.

How Is Assembly Conducted in CNC Machine Manufacturing?

Following the forming stage, components are assembled. This stage may involve the integration of various parts, such as motors, sensors, and controllers, into a cohesive unit. Assembly can be manual or automated, depending on the complexity of the machine and the manufacturer’s capabilities. Quality checks during assembly are crucial, as any misalignment can lead to performance issues later on.

What Finishing Processes Are Applied to CNC Machines?

Finishing processes enhance both the aesthetic and functional characteristics of the CNC machine. Techniques such as polishing, anodizing, or powder coating are commonly employed to improve surface finish and corrosion resistance. Additionally, these processes are essential for meeting industry-specific standards, which can vary significantly based on the target market.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is paramount in CNC machine manufacturing, particularly for international B2B buyers. Adhering to recognized international standards such as ISO 9001 ensures that manufacturers follow a structured quality management system. This certification indicates a commitment to consistent quality and continuous improvement.

What Are the Industry-Specific Standards Relevant to CNC Machines?

In addition to general quality standards, industry-specific certifications like CE marking (for compliance with European safety standards) and API certification (for oil and gas industries) are also important. These certifications ensure that the machines not only meet quality criteria but also comply with safety and regulatory requirements in specific industries.

How Are Quality Control Checkpoints Established?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to ensure consistent product quality. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Regular inspections are conducted during the manufacturing process to detect defects early and minimize waste.

- Final Quality Control (FQC): The completed CNC machines undergo rigorous testing to verify that they meet all design specifications and quality standards before shipment.

What Common Testing Methods Are Used in CNC Manufacturing?

Common testing methods include dimensional inspections, functional testing, and stress testing. Dimensional inspections utilize tools like calipers and coordinate measuring machines (CMM) to ensure that the components meet precise specifications. Functional testing evaluates the machine’s performance under operational conditions, while stress testing assesses durability and reliability.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must conduct due diligence to verify the quality control processes of CNC machine manufacturers. This can involve:

- Audits: Conducting on-site audits to assess the manufacturer’s quality management systems and production processes.

- Reviewing Quality Reports: Requesting detailed quality reports and documentation that outline the QC processes and results.

- Third-Party Inspections: Engaging independent inspection services to verify the quality of the machines before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various quality control nuances when dealing with suppliers from different regions. This includes understanding regional certifications, compliance requirements, and the potential for varying quality standards. For example, European buyers may prioritize CE certification, while buyers from the Middle East might focus on API standards.

Additionally, cultural differences in quality perception and communication can impact the buyer-supplier relationship. Establishing clear expectations and maintaining open lines of communication are crucial for mitigating misunderstandings.

Conclusion: Ensuring Quality in CNC Machine Manufacturing

The manufacturing processes and quality assurance practices in CNC machine production are critical for ensuring that the final products meet the high standards required by B2B buyers. By understanding these processes and conducting thorough evaluations of potential suppliers, international buyers can make informed decisions that align with their operational needs and quality expectations. This proactive approach not only minimizes risks but also fosters long-term partnerships with reliable CNC machine manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘CNC Machine Manufacturers’

Introduction

Sourcing CNC machine manufacturers requires a strategic approach to ensure that you select the right supplier for your needs. This guide provides a step-by-step checklist designed for international B2B buyers, helping you navigate the complexities of procurement in this specialized field. By following these steps, you can make informed decisions that align with your business objectives.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, it’s essential to clearly outline your technical requirements. This includes the type of CNC machines needed, their specifications, and any specific features that are critical for your operations.

– Considerations:

– What materials will you be working with?

– What tolerances and precision levels are required?

– Do you need multi-axis capabilities?

Step 2: Research Potential Suppliers

Conduct thorough research to compile a list of potential CNC machine manufacturers. Utilize industry directories, trade shows, and online platforms to find reputable suppliers.

– Key Actions:

– Check online reviews and testimonials.

– Look for manufacturers with a strong presence in your target markets, such as Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– What to Look For:

– Evidence of successful projects.

– Feedback on customer service and support.

– Certifications and compliance with international standards.

Step 4: Verify Supplier Certifications

Ensure that the suppliers you are considering hold relevant certifications that demonstrate quality and compliance with industry standards. This is particularly important in the CNC manufacturing sector, where precision is paramount.

– Key Certifications:

– ISO 9001 for quality management systems.

– CE marking for compliance with European health and safety regulations.

Step 5: Request Detailed Quotes

Once you have narrowed down your list of potential suppliers, request detailed quotes that include pricing, delivery timelines, and terms of service. This will help you compare offers effectively.

– Important Details:

– Breakdown of costs, including shipping and installation.

– Warranty and maintenance agreements.

– Payment terms and financing options.

Step 6: Conduct Site Visits or Virtual Tours

If feasible, arrange site visits or virtual tours of the manufacturing facilities. This step can provide invaluable insights into the supplier’s capabilities and production processes.

– What to Observe:

– Equipment quality and maintenance standards.

– Safety protocols and workplace conditions.

– The overall scale of operations and workforce expertise.

Step 7: Assess After-Sales Support and Service

Finally, evaluate the after-sales support and services offered by the supplier. Good after-sales support can significantly impact your long-term satisfaction and operational efficiency.

– Questions to Ask:

– What training programs are available for your team?

– How does the supplier handle maintenance and spare parts?

– What is the expected response time for service requests?

By following this structured checklist, you can enhance your sourcing strategy for CNC machine manufacturers, ensuring that you make well-informed decisions that support your business needs.

Comprehensive Cost and Pricing Analysis for CNC Machine Manufacturers Sourcing

What Are the Key Cost Components in CNC Machine Manufacturing?

When sourcing CNC machines, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts overall costs. High-grade steel and advanced composites may enhance durability and precision but come at a premium. Evaluating the balance between material quality and cost is essential.

-

Labor: Skilled labor is necessary for both the manufacturing process and post-production support. Labor costs can vary widely based on geographic location, with higher costs typically in regions with strong labor laws and worker protections.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs. Efficient manufacturing processes can help in reducing overhead, impacting the final price.

-

Tooling: Tooling is a substantial upfront investment that influences machine pricing. Custom tooling for specific applications can increase costs but may enhance machine efficiency and performance.

-

Quality Control (QC): Implementing stringent QC processes ensures that products meet industry standards. While this adds to the cost, it can save money in the long run by reducing returns and defects.

-

Logistics: Shipping costs can be significant, especially for international buyers. Factors such as distance, shipping method, and customs duties must be considered when evaluating total costs.

-

Margin: Manufacturers will set margins based on their cost structures, market demand, and competition. Understanding the competitive landscape can help buyers negotiate better pricing.

How Do Price Influencers Affect CNC Machine Sourcing?

Several factors can influence the pricing of CNC machines:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger volumes often leads to discounts. Understanding a supplier’s MOQ can help in negotiating better terms.

-

Specifications and Customization: Customized machines tailored to specific needs can significantly increase costs. Buyers should evaluate whether the added features justify the expense.

-

Material Choices: The type of materials used in the construction of the CNC machine affects pricing. Opting for standard materials can lower costs, while specialized materials can enhance machine capabilities.

-

Quality Certifications: Machines that comply with international quality standards (ISO, CE, etc.) may come at a higher price. However, such certifications can ensure reliability and performance.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their experience and service levels.

-

Incoterms: Understanding shipping terms is vital. Different Incoterms can affect the total landed cost, impacting the final price a buyer pays.

What Negotiation Strategies Can Buyers Use for Cost-Efficiency?

International buyers should adopt several strategies to enhance cost-efficiency:

-

Leverage Total Cost of Ownership (TCO): Assess not only the purchase price but also operational costs, maintenance, and potential downtime. A lower upfront cost may lead to higher TCO if the machine is less efficient or requires more frequent repairs.

-

Research and Benchmarking: Conduct thorough market research to understand standard pricing for specific CNC machines. This knowledge will empower buyers during negotiations.

-

Build Relationships with Suppliers: Establishing a rapport with suppliers can lead to better terms and potential discounts. Long-term partnerships often yield favorable pricing structures.

-

Consider Local Suppliers: For buyers in regions like Africa or South America, sourcing from local manufacturers may reduce shipping costs and lead times, enhancing overall value.

-

Negotiate Payment Terms: Flexible payment terms can improve cash flow, allowing buyers to manage their finances better while acquiring necessary machinery.

What Should International Buyers Know About Pricing Nuances?

For B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, understanding pricing nuances is essential:

-

Currency Fluctuations: Exchange rate volatility can impact the final cost of purchases. Buyers should consider hedging strategies to mitigate risks.

-

Regulatory Considerations: Import tariffs and local regulations can influence the cost structure. Being aware of these can aid in budgeting accurately.

-

Cultural Sensitivity: Understanding cultural differences in negotiation styles can facilitate smoother discussions and potentially better pricing outcomes.

Disclaimer for Indicative Prices

Prices for CNC machines can vary significantly based on numerous factors. The information provided is indicative and should be verified with suppliers for accurate quotes tailored to specific requirements. Always consider obtaining multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing CNC Machine Manufacturers With Other Solutions

Exploring Alternatives to CNC Machine Manufacturers

When considering CNC machine manufacturers, it’s essential to evaluate alternative solutions that can fulfill similar manufacturing and machining needs. Different technologies and methods can provide varying levels of performance, cost-effectiveness, and ease of implementation. This analysis aims to compare CNC machine manufacturers against two viable alternatives: traditional manual machining and additive manufacturing (3D printing).

Comparison Table

| Comparison Aspect | CNC Machine Manufacturers | Traditional Manual Machining | Additive Manufacturing (3D Printing) |

|---|---|---|---|

| Performance | High precision and speed | Moderate precision, slower | Variable precision, depends on the technology used |

| Cost | Higher initial investment | Lower initial cost | Varies widely based on material and technology |

| Ease of Implementation | Requires skilled operators | Easier for basic tasks | Steeper learning curve for complex designs |

| Maintenance | Regular maintenance needed | Low maintenance, but skill-dependent | Minimal maintenance, but requires calibration |

| Best Use Case | Mass production, complex parts | Prototyping, low volume runs | Rapid prototyping, complex geometries |

What Are the Pros and Cons of Traditional Manual Machining?

Traditional manual machining involves using lathes, mills, and drills operated by skilled machinists. One of its primary advantages is the lower initial investment compared to CNC machines. It allows for flexibility in small-scale production and is suitable for custom or one-off jobs. However, the performance is generally slower, and achieving high precision can be challenging without skilled labor. Additionally, it may not be suitable for mass production due to time constraints and labor costs.

How Does Additive Manufacturing Compare to CNC Machines?

Additive manufacturing, or 3D printing, is an innovative approach that builds parts layer by layer from digital models. Its primary advantage is the ability to create complex geometries that would be difficult or impossible with traditional machining methods. It is especially beneficial for rapid prototyping and small production runs, as it allows for quick design iterations. However, the cost can vary significantly based on the materials used and the technology employed (e.g., FDM vs. SLA). Moreover, while it can offer good precision, it may not match the speed and consistency of CNC machining for mass production.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between CNC machine manufacturers and alternative solutions like manual machining or additive manufacturing, it is crucial for B2B buyers to assess their specific production requirements. Factors such as production volume, desired precision, budget constraints, and the complexity of parts should guide the decision-making process. For high-volume and precision demands, CNC machines are likely the best fit, while manual machining may serve low-volume or custom needs effectively. Additive manufacturing stands out for rapid prototyping and intricate designs. Ultimately, understanding the strengths and weaknesses of each option will empower buyers to make informed choices that align with their operational goals.

Essential Technical Properties and Trade Terminology for CNC Machine Manufacturers

What Are the Key Technical Properties Relevant to CNC Machine Manufacturers?

In the competitive landscape of CNC manufacturing, understanding essential technical properties is crucial for making informed purchasing decisions. Here are several critical specifications that B2B buyers should be familiar with:

1. Material Grade

Material grade refers to the quality and type of material used in CNC components, such as metals, plastics, or composites. Different grades possess unique characteristics, such as tensile strength, corrosion resistance, and machinability. For manufacturers, choosing the right material grade is vital for ensuring the durability and performance of the final product, impacting overall production efficiency and operational costs.

2. Tolerance

Tolerance indicates the permissible limit of variation in a physical dimension. It is essential for ensuring that parts fit together correctly and function as intended. In CNC machining, tighter tolerances can lead to higher production costs due to the increased precision required. Understanding tolerance specifications helps buyers assess whether a manufacturer can meet their specific needs, especially in industries like aerospace and medical devices where precision is critical.

3. Surface Finish

Surface finish describes the texture of a manufactured surface, which can influence aesthetic appearance, performance, and adherence of coatings. Common surface finishes include rough, smooth, and polished, each serving different functional and aesthetic purposes. Buyers must consider surface finish requirements as they can directly affect product quality and customer satisfaction.

4. Cycle Time

Cycle time is the total time taken to complete one cycle of manufacturing a part, from start to finish. It encompasses setup time, machining time, and any necessary finishing operations. Reducing cycle time is a primary goal for manufacturers, as shorter cycle times lead to increased productivity and lower costs. Buyers should inquire about a manufacturer’s cycle times to evaluate their efficiency and ability to meet deadlines.

5. Tooling Capability

Tooling capability refers to the range and types of tools that a CNC machine can use during production. This includes milling, turning, and drilling tools, among others. Understanding tooling capabilities is important for buyers as it impacts the versatility and adaptability of the manufacturing process, allowing for various design complexities and material types.

What Are Common Trade Terms Used in CNC Manufacturing?

Navigating the CNC manufacturing landscape also requires familiarity with specific trade terminology. Here are several key terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another company. Understanding OEM relationships is crucial for buyers seeking quality assurance and reliability in components, as these manufacturers often adhere to specific standards and regulations.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. It is an important consideration for B2B buyers, as it can impact budgeting and inventory management. Knowing the MOQ can help companies align their purchasing strategies with production needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from potential suppliers. It typically outlines the specifications and quantities of products required. This term is vital for buyers looking to compare prices and capabilities across different manufacturers, ensuring they select the best option for their needs.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the shipping and delivery of goods. Familiarity with Incoterms is essential for B2B transactions, as they clarify costs, risks, and logistics involved in international trade, helping to avoid misunderstandings and disputes.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is crucial for planning and scheduling production runs. Buyers should assess lead times when evaluating suppliers to ensure they can meet project timelines.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when selecting CNC machine manufacturers, ultimately leading to better project outcomes and stronger supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the CNC Machine Manufacturers Sector

What Are the Key Trends Influencing the CNC Machine Manufacturers Market?

The CNC machine manufacturing sector is witnessing a transformative shift driven by technological advancements and evolving market demands. Key global drivers include the increasing adoption of automation, the rise of Industry 4.0, and the demand for precision manufacturing across various industries such as aerospace, automotive, and healthcare. In particular, international B2B buyers from regions like Africa, South America, the Middle East, and Europe are actively seeking machines that offer enhanced efficiency and lower operational costs.

Emerging technologies such as artificial intelligence (AI), machine learning, and the Internet of Things (IoT) are significantly impacting sourcing trends. These technologies facilitate predictive maintenance, real-time monitoring, and improved production efficiency, making CNC machines more appealing to buyers looking for competitive advantages. Furthermore, the push for customization and flexibility in manufacturing processes is leading manufacturers to offer more modular and adaptable machine designs.

Market dynamics are also being shaped by geopolitical factors, including trade agreements and tariffs, which can affect sourcing strategies. Buyers should be aware of regional supply chain challenges and consider diversifying their supplier base to mitigate risks. The demand for local sourcing options is growing, particularly in emerging markets, where buyers are increasingly favoring suppliers that can offer not only competitive pricing but also localized support and service.

How Is Sustainability Impacting the Sourcing of CNC Machines?

Sustainability is becoming a critical consideration for B2B buyers in the CNC machine manufacturing sector. As global awareness of environmental issues rises, the impact of manufacturing processes on the environment has come under scrutiny. Buyers are now prioritizing suppliers that demonstrate a commitment to sustainable practices, which includes the use of energy-efficient machinery and the adoption of eco-friendly materials.

Ethical sourcing is equally important, with an emphasis on transparent supply chains and responsible sourcing of raw materials. Buyers should look for CNC manufacturers that hold certifications such as ISO 14001 for environmental management systems or utilize materials that are recyclable or have a reduced carbon footprint. This not only enhances a buyer’s brand reputation but also aligns with the growing consumer demand for sustainable products.

Moreover, the integration of renewable energy sources in manufacturing processes is becoming increasingly common. Suppliers that invest in solar or wind energy to power their operations can appeal to environmentally conscious buyers. Overall, sustainability and ethical sourcing are not just trends but essential components of a forward-thinking procurement strategy in the CNC machine manufacturing sector.

What Is the Historical Context of CNC Machine Manufacturing?

The CNC machine manufacturing industry has evolved significantly since its inception in the mid-20th century. Initially developed to automate complex machining tasks, CNC technology has undergone remarkable advancements, transitioning from basic automated systems to sophisticated, computer-controlled machines capable of executing highly intricate designs with precision.

The evolution of CNC machines has been closely linked to the broader trends in manufacturing and technology. The introduction of microprocessors in the 1970s allowed for more complex programming and greater accuracy, leading to widespread adoption in various sectors. As industries began to demand higher efficiency and customization, CNC manufacturers responded by integrating advanced technologies such as robotics and automation into their systems.

Today, CNC machines play a pivotal role in the global manufacturing landscape, serving as essential tools for producing high-quality components in various industries. Understanding this historical context helps international B2B buyers appreciate the technological advancements that have shaped the current market and the opportunities available for optimizing their manufacturing processes.

Frequently Asked Questions (FAQs) for B2B Buyers of CNC Machine Manufacturers

-

1. How do I choose the right CNC machine for my business needs?

Selecting the right CNC machine involves assessing your specific production requirements, including the types of materials you’ll be machining, the complexity of your designs, and your production volume. Start by defining your project specifications and desired tolerances. Research various machine types—such as lathes, mills, and routers—and consider their capabilities, size, and compatibility with existing tools. Additionally, consult with manufacturers to understand customization options and ensure the machine can grow with your business. -

2. What factors should I consider when evaluating CNC machine manufacturers?

When evaluating CNC machine manufacturers, consider their reputation, experience, and customer reviews. Look for certifications that indicate quality assurance, such as ISO standards. Assess their product range to ensure they offer machines that fit your needs. Additionally, inquire about their after-sales support, including training, maintenance services, and availability of spare parts. A solid warranty and customer service track record can also indicate a reliable partner. -

3. What are the typical payment terms offered by CNC machine manufacturers?

Payment terms can vary widely among CNC machine manufacturers, typically ranging from upfront full payment to options like 30-60 days net after delivery. Some manufacturers may offer financing solutions or leasing options to make the investment more manageable. Always discuss payment terms upfront to avoid misunderstandings later. It’s also advisable to establish a payment schedule that aligns with your budget and cash flow needs. -

4. How can I ensure the quality of CNC machines before purchasing?

To ensure quality, request detailed specifications, performance metrics, and certifications from the manufacturer. It’s beneficial to ask for customer testimonials or case studies showcasing the machine’s performance in similar applications. If possible, visit the manufacturer’s facility to observe the machines in action. Additionally, inquire about their quality assurance processes and any warranty or service guarantees that come with the machine. -

5. What is the Minimum Order Quantity (MOQ) for CNC machines?

Minimum Order Quantities (MOQs) for CNC machines can vary based on the manufacturer and the type of machine. Some manufacturers may have no MOQ for standard models, while custom machines might require a higher minimum order. It’s important to communicate your needs clearly and negotiate the MOQ based on your production capabilities. Be aware that lower MOQs might come with higher per-unit costs. -

6. How do I handle international logistics when importing CNC machines?

When importing CNC machines, work closely with a reliable freight forwarder who understands the complexities of international shipping, including customs regulations and tariffs. Ensure that all necessary documentation, such as bills of lading and import permits, is in order. It’s also important to consider insurance for the shipment to cover any potential damage during transit. Lastly, plan for potential delays in customs clearance and coordinate with your manufacturer for timely delivery. -

7. What customization options are typically available for CNC machines?

Customization options for CNC machines can include modifications to size, tooling, software, and automation features. Many manufacturers offer the ability to tailor machines to specific production needs, such as adding specialized tooling for unique materials or integrating advanced software for enhanced programming capabilities. Discuss your requirements with the manufacturer early in the process to explore available options and ensure the machine meets your operational goals. -

8. How can I vet suppliers in the CNC machine industry effectively?

Vetting suppliers in the CNC machine industry involves a multi-step approach. Start by researching their history, reputation, and client base. Request references from other clients, especially those in your industry. Evaluate their production capabilities and quality control processes. Additionally, consider visiting their facilities to assess their manufacturing practices firsthand. Online reviews, industry awards, and participation in trade shows can also provide insights into their reliability and expertise.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for CNC Machine Manufacturers

In the rapidly evolving landscape of CNC machine manufacturing, strategic sourcing emerges as a pivotal element for international B2B buyers. By understanding the diverse range of suppliers, from established brands like Haas and Mazak to emerging manufacturers, buyers can optimize their supply chains and enhance operational efficiency. Key takeaways include the importance of evaluating suppliers based on their technological capabilities, customer support, and adaptability to market demands.

The value of strategic sourcing cannot be overstated; it not only drives cost savings but also fosters innovation and quality improvements. As manufacturers in Africa, South America, the Middle East, and Europe seek to enhance their production capabilities, they must prioritize partnerships that align with their long-term goals.

Looking ahead, the CNC machining sector is poised for growth, driven by advancements in automation and Industry 4.0 technologies. International B2B buyers are encouraged to leverage these innovations to stay competitive. Engaging with suppliers who offer comprehensive solutions, including automation systems and support services, will be crucial. As you navigate this dynamic market, remain proactive in evaluating your sourcing strategies to harness the full potential of CNC manufacturing.