Your Ultimate Guide to Sourcing Industrial Air Compressor

Introduction: Navigating the Global Market for industrial air compressor near me

In the competitive landscape of industrial operations, sourcing the right air compressor is pivotal for enhancing productivity and efficiency. For international B2B buyers, especially those hailing from Africa, South America, the Middle East, and Europe, the phrase “industrial air compressor near me” transcends mere convenience; it represents a strategic advantage. Understanding local suppliers, availability, and specific market conditions can significantly influence operational success and cost-effectiveness.

This guide serves as an extensive resource for navigating the complexities of the industrial air compressor market. It delves into various types of compressors, including rotary screw and reciprocating models, and discusses their suitability for different applications. Furthermore, it examines materials and manufacturing quality control, ensuring that buyers are equipped with the knowledge to select durable and efficient equipment.

Cost considerations are also covered, providing insights into budget planning and potential savings. The guide highlights reputable suppliers across regions, facilitating connections that can streamline procurement processes. Additionally, it addresses common FAQs that buyers might have, empowering them to make informed decisions based on their unique operational needs.

By leveraging this comprehensive information, B2B buyers can navigate the global market more effectively, ensuring they invest in the right air compressor that meets their requirements while maximizing return on investment.

Understanding industrial air compressor near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rotary Screw Compressor | Continuous operation, high efficiency, low maintenance | Manufacturing, automotive, food processing | Pros: High reliability, energy-efficient. Cons: Higher initial cost. |

| Reciprocating Compressor | Piston-driven, versatile, available in single or multi-stage | Construction, HVAC, automotive repair | Pros: Cost-effective, good for intermittent use. Cons: Noisy, requires more maintenance. |

| Rotary Vane Compressor | Compact design, simple construction, low operating costs | Food and beverage, pharmaceutical industries | Pros: Compact, low maintenance. Cons: Limited pressure capabilities. |

| Oil-Free Compressor | Uses no oil for lubrication, produces clean air | Electronics, food processing, pharmaceuticals | Pros: No contamination risk, quieter operation. Cons: Higher cost, lower durability. |

| Variable Speed Drive (VSD) Compressor | Adjusts motor speed based on demand, energy-efficient | Any industry with fluctuating air demands | Pros: Energy savings, optimal performance. Cons: More complex, potentially higher initial investment. |

Rotary Screw Compressor

Rotary screw compressors are designed for continuous operation, making them ideal for industries requiring a steady airflow, such as manufacturing and automotive sectors. They utilize two rotating helical screws to compress air, resulting in high efficiency and low maintenance needs. When considering a rotary screw compressor, buyers should evaluate their air demand, as these systems are best suited for applications that require consistent pressure and volume.

Reciprocating Compressor

Reciprocating compressors operate using pistons and can be configured in single or multi-stage designs. Their versatility allows them to serve a wide range of applications, from construction sites to automotive repair shops. For B2B buyers, the initial cost is generally lower than rotary screw compressors, but they may require more frequent maintenance and can be noisier, making it essential to assess the operating environment and application needs before purchasing.

Rotary Vane Compressor

Rotary vane compressors feature a compact design and simple construction, making them a popular choice in industries like food and beverage, where space is often limited. They work by using rotating vanes to compress air, which results in relatively low operating costs. Buyers should consider the pressure requirements of their applications, as rotary vane compressors may not be suitable for high-pressure needs.

Oil-Free Compressor

Oil-free compressors are designed to produce clean air without the risk of oil contamination, making them ideal for sensitive applications such as electronics manufacturing and food processing. Although they come at a higher price point, their ability to maintain air quality is invaluable. Buyers should weigh the benefits of clean air against the potential for increased costs and reduced durability compared to traditional oil-lubricated compressors.

Variable Speed Drive (VSD) Compressor

VSD compressors are engineered to adjust their motor speed according to air demand, making them highly energy-efficient and suitable for industries with variable air needs. They provide optimal performance while reducing energy costs. However, their complexity and higher initial investment should be considered, particularly for businesses that may not experience significant fluctuations in air demand. Buyers should evaluate their air consumption patterns to determine if a VSD compressor is the right fit for their operations.

Related Video: How does an Air Compressor work? (Compressor Types) – Tutorial Pneumatics

Key Industrial Applications of industrial air compressor near me

| Industry/Sector | Specific Application of industrial air compressor near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering pneumatic tools for assembly lines | Increases productivity and efficiency in production | Ensure compressor matches required PSI and CFM for tools |

| Automotive | Spray painting and surface preparation | Achieves high-quality finishes and reduces waste | Consider air quality and filtration systems for paint work |

| Food & Beverage | Packaging and bottling processes | Enhances operational speed and reliability | Compliance with food safety standards is crucial |

| Construction | Operating pneumatic equipment for construction tasks | Improves job site productivity and reduces manual labor | Evaluate portability and power source options |

| Oil & Gas | Control systems for drilling operations | Increases accuracy and safety in operations | Consider environmental conditions and compressor durability |

Manufacturing

In the manufacturing sector, industrial air compressors are essential for powering pneumatic tools used on assembly lines. These compressors provide the necessary air pressure to operate tools such as drills, riveters, and impact wrenches, which are vital for efficient production. By integrating compressors that are correctly sized for the specific tools used, manufacturers can significantly increase productivity and reduce downtime. International buyers should pay close attention to the compressor’s PSI (pounds per square inch) and CFM (cubic feet per minute) ratings to ensure compatibility with their equipment.

Automotive

In the automotive industry, air compressors play a critical role in spray painting and surface preparation. Compressed air is used to operate spray guns that apply paint evenly, creating high-quality finishes while minimizing overspray and waste. For B2B buyers in regions like South America and Europe, it is important to consider the quality of the compressed air, as contaminants can affect paint adhesion and durability. Investing in a reliable filtration system alongside the compressor can enhance the overall painting process and ensure compliance with environmental standards.

Food & Beverage

The food and beverage industry utilizes air compressors in packaging and bottling processes. Compressed air is vital for conveying products, operating filling machines, and sealing packages. The reliability of compressed air systems ensures that production lines run smoothly, enhancing operational speed. Buyers in Africa and the Middle East should prioritize compressors that meet food safety standards, including those that provide oil-free air to prevent contamination. Additionally, understanding the local regulatory requirements for food processing is essential for compliance.

Construction

In construction, industrial air compressors are used to operate pneumatic equipment, such as nail guns, jackhammers, and concrete vibrators. These tools increase productivity by allowing for quicker and more efficient work on job sites. For international buyers, especially those in regions with challenging terrains, it is important to evaluate the portability of the compressors and their power source options, such as electric versus diesel. Ensuring adequate airflow and pressure for the specific tools being used is critical to maximizing efficiency.

Oil & Gas

Within the oil and gas sector, air compressors are integral to control systems for drilling operations. Compressed air is used to actuate valves and control mechanisms, enhancing the precision and safety of drilling activities. For buyers from Europe or the Middle East, selecting durable compressors that can withstand harsh environmental conditions is essential. Additionally, understanding the compressor’s maintenance requirements and service availability in remote locations can significantly impact operational reliability.

Related Video: Air Compressor (Basics, Parts, Diagram, Working & Applications) Explained with Animation

Strategic Material Selection Guide for industrial air compressor near me

When selecting materials for industrial air compressors, it’s crucial to consider their properties, advantages, and disadvantages, especially for international B2B buyers. The following analysis covers four common materials used in the manufacturing of industrial air compressors: Aluminum, Cast Iron, Stainless Steel, and Composite Materials. Each material has unique characteristics that impact performance, durability, and cost.

Aluminum

Key Properties:

Aluminum is lightweight and has excellent thermal conductivity. It typically has a temperature rating of up to 200°C and can withstand moderate pressures, making it suitable for various compressor applications.

Pros & Cons:

The primary advantage of aluminum is its low weight, which facilitates easier handling and installation. It also resists corrosion, which is beneficial in humid environments. However, aluminum is less durable than other materials like cast iron and can be more expensive due to the manufacturing processes involved.

Impact on Application:

Aluminum is compatible with many media types, including air and non-corrosive gases. However, it may not be suitable for high-pressure applications due to its lower strength compared to steel.

Considerations for International Buyers:

Buyers should ensure compliance with local standards such as ASTM or EN for material specifications. In regions like Africa and South America, where humidity may be high, aluminum’s corrosion resistance can be a significant advantage.

Cast Iron

Key Properties:

Cast iron is known for its high strength and durability, with temperature ratings often exceeding 300°C. It can handle high pressures, making it a popular choice for heavy-duty applications.

Pros & Cons:

The primary benefit of cast iron is its robustness, which leads to a longer lifespan for compressors. However, it is significantly heavier than aluminum, complicating installation and transport. Additionally, cast iron is prone to rusting if not properly maintained.

Impact on Application:

Cast iron is suitable for high-pressure air applications and can handle abrasive media. Its durability makes it ideal for continuous use in industrial settings.

Considerations for International Buyers:

Buyers should be aware of the weight implications for shipping and installation. Compliance with standards like DIN or JIS is essential, especially in Europe and the Middle East, where regulations are stringent.

Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance and can withstand high temperatures (up to 500°C) and pressures. It is known for its strength and durability.

Pros & Cons:

The key advantage of stainless steel is its resistance to corrosion and staining, making it ideal for environments where cleanliness is critical. However, it is more expensive than both aluminum and cast iron, and its manufacturing can be complex.

Impact on Application:

Stainless steel is compatible with a wide range of media, including corrosive gases. Its high strength makes it suitable for high-pressure applications, ensuring reliability in demanding environments.

Considerations for International Buyers:

Buyers must consider the cost implications, as stainless steel can be significantly more expensive. Compliance with international standards is crucial, particularly in regions with strict regulations like Europe.

Composite Materials

Key Properties:

Composite materials, often made from a combination of polymers and reinforcements, can be engineered for specific applications. They typically offer good temperature resistance and can be lightweight.

Pros & Cons:

The main advantage of composites is their ability to be tailored for specific applications, offering a balance of strength and weight. However, they may not be as durable as metals and can have limitations in high-temperature and high-pressure applications.

Impact on Application:

Composites are suitable for low to moderate pressure applications and can be used in environments where corrosion is a concern. They are not recommended for high-stress applications.

Considerations for International Buyers:

Understanding the specific properties of the composite material is essential, as standards may vary by region. Buyers should ensure that the materials meet local compliance requirements.

Summary Table

| Material | Typical Use Case for industrial air compressor near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight compressors for moderate pressure systems | Lightweight and corrosion-resistant | Less durable than cast iron | Medium |

| Cast Iron | Heavy-duty compressors for high-pressure applications | High strength and durability | Heavy and prone to rust | Low |

| Stainless Steel | Clean environments requiring corrosion resistance | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Composite Materials | Low to moderate pressure applications | Tailored properties and lightweight | Less durable and limited pressure | Medium |

This guide provides a comprehensive overview of strategic material selection for industrial air compressors, ensuring that international B2B buyers can make informed decisions tailored to their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for industrial air compressor near me

The manufacturing processes and quality assurance (QA) protocols for industrial air compressors are critical components that international B2B buyers must understand. This knowledge is essential for ensuring that the compressors meet operational requirements and comply with international standards. Below is an in-depth analysis of the typical manufacturing stages, quality assurance measures, and actionable insights for buyers from Africa, South America, the Middle East, and Europe.

Manufacturing Processes

Main Stages of Manufacturing

-

Material Preparation

– Raw Material Selection: The manufacturing process begins with selecting high-quality raw materials, typically metals such as aluminum and steel, which are crucial for durability and performance.

– Cutting and Machining: Raw materials are cut to size and machined to achieve the required specifications. This includes processes such as turning, milling, and drilling to form parts like cylinders, pistons, and frames. -

Forming

– Casting and Forging: Components may undergo casting or forging processes to create complex shapes. For example, cast iron is often used for compressor housings due to its strength and vibration dampening properties.

– Welding and Joining: Parts are welded or joined using techniques such as MIG or TIG welding to ensure structural integrity. Proper welding is critical to withstand high pressures during operation. -

Assembly

– Component Assembly: Once individual parts are prepared, they are assembled into the compressor unit. This stage involves careful alignment and fitting of parts, including motors, air tanks, and control systems.

– Integration of Systems: Integration of electrical and pneumatic systems occurs here, ensuring that all components work seamlessly together. -

Finishing

– Surface Treatment: To enhance corrosion resistance and aesthetics, compressors undergo surface treatments such as powder coating or anodizing.

– Final Assembly: The compressor is assembled with all final components, including gauges, valves, and fittings. This stage may also include the installation of safety features.

Quality Assurance

International Standards and Industry-Specific Certifications

B2B buyers should prioritize suppliers that adhere to recognized international standards and certifications. Key standards include:

- ISO 9001: This is a global standard for quality management systems that outlines requirements for consistent quality and customer satisfaction.

- CE Marking: For products sold in the European market, CE marking demonstrates compliance with safety, health, and environmental protection standards.

- API Standards: Relevant for compressors used in oil and gas industries, API standards ensure that products meet specific operational and safety requirements.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– At this initial stage, raw materials and components are inspected for quality and compliance with specifications. Buyers should inquire about the material certification and test reports for incoming materials. -

In-Process Quality Control (IPQC)

– Throughout the manufacturing process, regular inspections are conducted to ensure that each stage meets quality standards. This might include monitoring machining tolerances and assembly accuracy. -

Final Quality Control (FQC)

– Before shipment, the final product undergoes comprehensive testing. This includes pressure testing, performance testing, and functional checks to confirm that the compressor operates as intended.

Common Testing Methods

- Pressure Testing: Ensures the compressor can withstand operational pressures without leaks.

- Vibration Analysis: Evaluates mechanical stability and identifies potential issues before the product is delivered.

- Operational Testing: Involves running the compressor under normal conditions to validate performance metrics such as CFM and PSI.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality assurance practices is vital. Here are effective methods to ensure compliance:

- Supplier Audits: Conduct regular audits of suppliers to assess their manufacturing processes, quality control measures, and adherence to international standards. This can be done remotely or on-site.

- Request Quality Reports: Ask for detailed quality assurance reports, including test results and certifications. A reputable supplier should readily provide this documentation.

- Third-Party Inspections: Consider hiring third-party inspection agencies to conduct independent evaluations of the manufacturing processes and final products. This adds an extra layer of assurance.

Quality Control Nuances for International Buyers

-

Cultural and Regulatory Differences: Buyers from regions like Africa and South America should be aware that manufacturing standards and practices may vary significantly. Understanding local regulations and quality expectations is crucial.

-

Communication and Documentation: Effective communication is essential when discussing quality expectations. Ensure that all specifications are documented clearly, and confirm that suppliers can meet these requirements.

-

Building Relationships: Establishing a strong relationship with suppliers can lead to better transparency and collaboration on quality assurance. Regular engagement can help address potential issues proactively.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for industrial air compressors is essential for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with rigorous quality control measures, buyers can ensure they select reliable suppliers. Adhering to international standards and leveraging effective verification methods will further enhance the procurement process, ultimately leading to successful operations and satisfied customers.

Related Video: Amazing factories | Manufacturing method and top 4 processes | Mass production process

Comprehensive Cost and Pricing Analysis for industrial air compressor near me Sourcing

When sourcing industrial air compressors, B2B buyers must navigate a complex cost structure and pricing landscape. Understanding the various cost components and price influencers can empower buyers to make informed decisions and achieve better value for their investments.

Cost Components

-

Materials: The primary materials used in manufacturing air compressors include metals like aluminum and steel, along with various polymers for seals and gaskets. The quality and source of these materials significantly impact the overall cost. For example, high-grade components may lead to higher upfront costs but can enhance durability and performance.

-

Labor: Labor costs vary by region and are influenced by local wage standards. In regions like Europe, where labor costs may be higher, manufacturers might offset these expenses through automation. Conversely, in regions like Africa and South America, lower labor costs could provide a competitive edge, though this might come with varying levels of expertise.

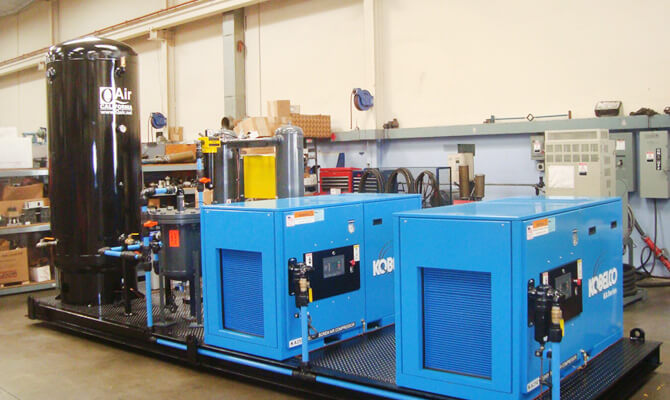

Illustrative Image (Source: Google Search)

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Efficient operations can lower these overheads, allowing manufacturers to offer more competitive pricing.

-

Tooling: The initial investment in tooling can be significant, especially for custom or specialized compressors. Buyers should be aware that unique specifications may lead to increased tooling costs, affecting the overall pricing.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with industry standards. While this may increase costs, it is crucial for maintaining product integrity, especially for applications requiring high precision.

-

Logistics: Shipping and transportation costs are critical, particularly for international buyers. Factors such as distance, mode of transport, and local tariffs can significantly influence overall costs.

-

Margin: Manufacturers typically include a profit margin in their pricing. This margin can vary based on market conditions, competition, and brand reputation.

Price Influencers

-

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Buyers should evaluate their needs and consider negotiating minimum order quantities (MOQ) to optimize pricing.

-

Specifications/Customization: Custom features can lead to higher costs due to specialized manufacturing processes. Buyers should assess whether the additional features justify the price increase.

-

Materials and Quality/Certifications: Higher quality materials and certifications (e.g., ISO, CE) can elevate costs but are essential for certain applications. Buyers should balance cost with the need for compliance and reliability.

-

Supplier Factors: The supplier’s location, reputation, and manufacturing practices can significantly influence pricing. Building relationships with reliable suppliers may lead to better terms and pricing.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. These terms dictate responsibilities for shipping, risk, and insurance, impacting the total landed cost.

Buyer Tips

-

Negotiation: Engage suppliers in negotiations, emphasizing volume commitments or long-term partnerships to secure better pricing.

-

Cost-Efficiency: Always consider the Total Cost of Ownership (TCO), which includes initial purchase price, maintenance, energy consumption, and potential downtime costs. A cheaper compressor may lead to higher operating costs.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, local taxes, and import duties that can affect pricing. Always request quotes in your local currency and clarify all potential extra costs.

Disclaimer

Prices can vary widely based on numerous factors, including market conditions, supplier negotiations, and specific project requirements. This analysis provides a framework for understanding potential costs and pricing dynamics but should not be interpreted as definitive pricing guidance. Always consult multiple suppliers for the most accurate and current pricing information tailored to your unique needs.

Spotlight on Potential industrial air compressor near me Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘industrial air compressor near me’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for industrial air compressor near me

When selecting an industrial air compressor, understanding its technical properties and trade terminology is crucial for making informed purchasing decisions. This section delves into the essential specifications and terms that international B2B buyers should be familiar with, especially those from regions such as Africa, South America, the Middle East, and Europe.

Key Technical Properties

-

Horsepower (HP)

This measurement indicates the power output of the compressor’s motor. Higher horsepower typically means more capability to compress air, which is vital for demanding applications. Buyers should assess their air demand to select an appropriately powered compressor, avoiding underperformance or energy inefficiencies. -

Cubic Feet per Minute (CFM)

CFM is a measure of the volume of air output by the compressor. It is essential for determining whether a compressor can meet the air requirements of specific tools or processes. Accurate CFM ratings help buyers ensure that their compressor will maintain adequate pressure for continuous operations, reducing downtime. -

Pounds per Square Inch (PSI)

PSI measures the pressure of the compressed air. Different applications require different pressure levels, so understanding the PSI rating is critical. A compressor with insufficient PSI may not power certain tools or processes effectively, leading to productivity losses. -

Tank Size

The size of the air storage tank influences how long the compressor can run before needing to cycle back on. Larger tanks can store more compressed air, which is beneficial for applications with high demand. Buyers should evaluate their operational needs to select an optimal tank size that balances space and air supply requirements.

Illustrative Image (Source: Google Search)

-

Noise Level (dBA)

Noise levels, measured in decibels (dBA), are particularly important for workplaces that prioritize a safe and comfortable environment. Compressors with lower noise levels are ideal for indoor operations or near personnel. Buyers should consider this specification to ensure compliance with local regulations and workplace standards. -

Energy Efficiency Ratings

Energy efficiency ratings indicate how effectively a compressor converts electricity into compressed air. Higher efficiency means lower operational costs, which is especially critical for businesses in regions with high energy prices. Understanding these ratings can lead to substantial savings over the compressor’s lifespan.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components or equipment that are sold under another company’s brand name. Understanding OEM relationships is crucial for buyers seeking reliable parts and service support. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. This term is important for buyers to understand to avoid overcommitting to a purchase that exceeds their immediate needs. -

RFQ (Request for Quotation)

An RFQ is a formal document issued by buyers to request price quotes from suppliers. It is essential for comparing options and securing the best pricing for industrial air compressors. Buyers should include detailed specifications in their RFQs to receive accurate quotes. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and costs associated with importing compressors. -

Lead Time

This term refers to the time taken from placing an order to the product’s delivery. Understanding lead times is vital for buyers to plan their projects and ensure that the necessary equipment is available when needed. -

Warranty Period

The warranty period specifies how long the manufacturer guarantees the product against defects or malfunctions. A comprehensive warranty can provide peace of mind and protect buyers from unexpected costs, making it an important consideration in the purchasing process.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can navigate the complexities of purchasing industrial air compressors more effectively, ensuring they make choices that align with their operational needs and budget constraints.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the industrial air compressor near me Sector

Market Overview & Key Trends

The industrial air compressor market is witnessing significant growth globally, driven by the increasing demand for compressed air across various industries such as manufacturing, automotive, and construction. Key drivers include the need for energy-efficient solutions, advancements in technology, and a growing focus on automation. In regions like Africa and South America, the expansion of industries coupled with urbanization is propelling the demand for reliable compressed air systems. Conversely, in Europe and the Middle East, regulations favoring energy efficiency and sustainability are influencing purchasing decisions.

Emerging technologies such as Internet of Things (IoT) and Artificial Intelligence (AI) are reshaping sourcing trends. IoT-enabled compressors allow for real-time monitoring and predictive maintenance, which can significantly reduce downtime and operational costs. Buyers are increasingly looking for suppliers who offer smart solutions that enhance efficiency and provide actionable insights into system performance. Additionally, the rise of Variable Speed Drive (VSD) compressors offers a flexible solution that can adapt to varying demand, leading to substantial energy savings.

The market dynamics are also influenced by geopolitical factors and supply chain disruptions. Buyers should consider suppliers with robust contingency plans and diversified supply chains to mitigate risks. Understanding the local market conditions and regulatory environments in regions like Kenya or Italy can provide B2B buyers with a competitive edge in negotiations and sourcing strategies.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a core consideration for B2B buyers in the industrial air compressor sector. The environmental impact of compressed air systems is significant, as they often consume large amounts of energy. Opting for energy-efficient models, such as those featuring VSD technology, can drastically reduce carbon footprints and operational costs. Furthermore, buyers should prioritize suppliers who adhere to environmental standards and certifications, such as ISO 14001, which demonstrate a commitment to sustainable practices.

Ethical sourcing is equally important, as the demand for transparency in supply chains grows. B2B buyers should inquire about the sourcing of materials used in air compressors, including whether suppliers utilize recycled or sustainably sourced materials. Certifications like Green Seal or Energy Star can also guide buyers in selecting products that meet environmental criteria. By aligning purchasing decisions with sustainable practices, companies not only enhance their brand reputation but also contribute positively to their communities and the environment.

Brief Evolution/History

The industrial air compressor sector has evolved significantly since its inception in the late 19th century. Initially powered by steam, the technology rapidly transitioned to electric power, which allowed for greater efficiency and reliability. The introduction of rotary screw compressors in the mid-20th century revolutionized the industry, providing continuous air supply and improved energy efficiency. As industries have advanced, so have the compressors, incorporating smart technologies and sustainable practices. This evolution reflects broader trends in industrial automation and environmental responsibility, shaping the current landscape where B2B buyers seek innovative, efficient, and sustainable solutions.

In conclusion, understanding market dynamics, embracing sustainability, and recognizing the historical context of industrial air compressors will empower international B2B buyers to make informed decisions that align with their operational goals and ethical standards.

Related Video: Made in the world: Better understanding global trade flows

Frequently Asked Questions (FAQs) for B2B Buyers of industrial air compressor near me

-

What factors should I consider when vetting suppliers for industrial air compressors?

When vetting suppliers, consider their experience in the industry, production capacity, and reputation among previous clients. Request references and case studies to gauge their reliability. It’s also important to assess their certifications (e.g., ISO 9001) and compliance with international standards. Evaluate their ability to provide post-sale support and maintenance services, as well as their financial stability, which can indicate long-term viability as a partner. -

Can I customize the industrial air compressor to fit my specific needs?

Yes, many suppliers offer customization options for industrial air compressors. You can specify requirements such as pressure output, tank size, and additional features like variable speed drives or energy-efficient technologies. Discuss your specific applications with the supplier to ensure they can meet your needs. Be prepared to provide detailed specifications to facilitate the customization process effectively. -

What are the typical minimum order quantities (MOQ) and lead times for industrial air compressors?

Minimum order quantities can vary significantly based on the supplier and the type of compressor. Generally, MOQs for industrial air compressors may range from one unit for standard models to several for customized or specialized units. Lead times typically span from a few weeks to several months, depending on the complexity of the order and current production schedules. Always clarify these details upfront to align with your project timelines. -

What payment terms should I expect when purchasing industrial air compressors?

Payment terms can vary widely among suppliers but often include options such as upfront deposits, payment upon delivery, or financing arrangements. It’s common to encounter terms like 30% upfront and the remainder upon shipment. Ensure you discuss payment methods acceptable to both parties, including international wire transfers or letters of credit, and confirm any potential currency exchange implications. -

What quality assurance measures and certifications should I look for?

Look for suppliers that adhere to international quality standards, such as ISO 9001, which ensures consistent quality in manufacturing. Inquire about testing procedures for their compressors, including pressure tests and performance evaluations. Certifications like CE or UL can indicate compliance with safety and environmental regulations, which is crucial for ensuring the reliability of the equipment in your operations. -

How can I effectively manage logistics when sourcing compressors internationally?

Managing logistics involves coordinating shipping, customs clearance, and delivery schedules. Work closely with your supplier to understand their shipping processes and choose reliable freight forwarders familiar with international trade regulations. Ensure that you have all necessary documentation, such as commercial invoices and packing lists, to facilitate smooth customs clearance. Consider insurance for your shipment to mitigate risks during transit. -

What should I do if a dispute arises with my supplier?

In the event of a dispute, start by reviewing your contract to understand the agreed terms and conditions. Communicate directly with the supplier to resolve issues amicably, focusing on open dialogue and negotiation. If necessary, involve a third-party mediator or arbitrator experienced in international trade disputes. Document all communications and agreements to ensure clarity and protect your interests throughout the resolution process. -

Are there specific warranties or service agreements I should request?

Yes, it’s essential to request warranties that cover defects in materials and workmanship. Standard warranties typically range from one to five years, depending on the supplier and model. Additionally, inquire about service agreements that outline maintenance schedules, response times for repairs, and availability of replacement parts. A good warranty and service agreement can save you significant costs and downtime in the long run.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for industrial air compressor near me

In conclusion, strategic sourcing for industrial air compressors is essential for maximizing operational efficiency and ensuring reliability in various applications. By understanding the different types of compressors—such as rotary screw, reciprocating, and vane—and their specific applications, international B2B buyers can make informed decisions that align with their unique operational needs.

Key takeaways include the importance of assessing air quality requirements, understanding compressor sizing metrics (HP, CFM, PSI), and prioritizing maintenance practices to extend the lifecycle of your equipment. Moreover, evaluating suppliers based on their technological advancements and support services can enhance your sourcing strategy.

As the demand for compressed air systems continues to grow across sectors, particularly in emerging markets in Africa, South America, the Middle East, and Europe, now is the time to invest in strategic sourcing. By fostering partnerships with reputable suppliers and staying informed about industry trends, businesses can secure a competitive edge in their respective markets.

Take action today—evaluate your sourcing strategy and consider how modern air compressor solutions can elevate your business operations.