Master Air Conditioner Power Supply: A Complete Sourcing Guide (2025)

Introduction: Navigating the Global Market for air conditioner power supply

Navigating the complexities of sourcing an efficient air conditioner power supply can be a significant challenge for international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. As businesses strive to enhance their operational environments, understanding the nuances of power supply options—including specifications, compatibility, and regulatory compliance—is crucial. This guide offers a comprehensive overview of air conditioner power supplies, detailing various types, applications, and essential supplier vetting processes, while also addressing cost considerations and installation best practices.

By equipping B2B buyers with insights into the diverse landscape of air conditioner power supply solutions, this resource empowers informed purchasing decisions that can lead to better energy efficiency and operational reliability. Whether you are operating in a rapidly growing market in Africa or navigating the established markets in Europe, our guide is tailored to meet your unique needs. We will delve into factors such as the critical differences between power cord specifications, the importance of regulatory compliance, and the role of local suppliers in ensuring timely delivery and support.

Ultimately, this guide aims to demystify the procurement process, enabling businesses to make strategic decisions that enhance productivity and reduce downtime. With the right knowledge and resources, international buyers can confidently source the optimal air conditioner power supply solutions for their operational requirements.

Understanding air conditioner power supply Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Phase Power Supply | Utilizes a single alternating current (AC) phase; common in residential settings. | Small to medium-sized commercial units. | Pros: Easy installation; cost-effective. Cons: Limited power capacity for larger units. |

| Three-Phase Power Supply | Comprises three AC phases; provides higher efficiency and more power. | Large commercial and industrial applications. | Pros: Supports high-capacity units; improved energy efficiency. Cons: More complex installation and higher costs. |

| Portable Power Supply Units | Standalone units with built-in batteries or generators; often used in temporary setups. | Events, construction sites, and emergencies. | Pros: Flexibility and mobility; no permanent installation needed. Cons: Limited run time; may require refueling or recharging. |

| Dedicated Circuit Power Supply | Specific wiring and breaker for AC units; ensures compliance with electrical codes. | Installation of high-capacity AC units. | Pros: Enhanced safety and reliability; meets regulatory standards. Cons: Requires professional installation; higher upfront costs. |

| Smart Power Supply Systems | Integrates IoT technology for remote monitoring and control; energy-efficient. | Advanced commercial buildings and smart homes. | Pros: Real-time monitoring; potential energy savings. Cons: Higher initial investment; may require specialized knowledge for setup. |

What are the characteristics of a Single-Phase Power Supply?

Single-phase power supplies are the most commonly used type for residential and small commercial air conditioning units. They operate on a single AC phase, making them straightforward to install and less expensive than multi-phase options. These systems are suitable for small to medium-sized applications where power demands are moderate. When purchasing, buyers should consider the power requirements of their AC units, as single-phase supplies may not support larger systems effectively.

When should businesses opt for a Three-Phase Power Supply?

Three-phase power supplies are essential for large commercial and industrial applications that require substantial power. This type of supply is more efficient, reducing energy losses and providing a steady power flow, which is critical for high-capacity air conditioning units. Buyers should assess their facility’s electrical infrastructure and power demands, as the installation can be more complex and costly, but it ultimately leads to better performance and energy efficiency.

What are the benefits of using Portable Power Supply Units?

Portable power supply units offer flexibility and mobility, making them ideal for temporary air conditioning needs, such as at events or construction sites. These standalone systems can operate independently of existing electrical infrastructure, providing immediate cooling solutions. However, buyers should keep in mind that these units have limited run times and may require frequent refueling or recharging, which can be a consideration for long-term projects.

Why choose a Dedicated Circuit Power Supply for AC installations?

A dedicated circuit power supply is specifically wired to accommodate air conditioning units, ensuring compliance with electrical codes and enhancing safety. This setup is particularly beneficial for high-capacity units that demand significant power. Buyers should be prepared for professional installation, as this approach may incur higher upfront costs but ultimately ensures reliability and adherence to safety standards.

How do Smart Power Supply Systems enhance energy efficiency?

Smart power supply systems incorporate IoT technology, allowing for remote monitoring and control of air conditioning units. This innovation can lead to significant energy savings by optimizing performance based on real-time data. While the initial investment may be higher, the long-term benefits in energy efficiency and operational control can make these systems an attractive option for advanced commercial buildings and smart home applications. Buyers should consider their technological capabilities and the potential return on investment when exploring these options.

Key Industrial Applications of air conditioner power supply

| Industry/Sector | Specific Application of Air Conditioner Power Supply | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Cooling systems for production lines | Enhanced equipment performance and longevity | Power capacity, efficiency ratings, and compliance standards |

| Data Centers | Climate control for server rooms | Optimal operational efficiency and equipment protection | Energy efficiency, redundancy options, and scalability |

| Healthcare | Temperature regulation in hospitals | Patient safety and comfort, equipment reliability | Compliance with health regulations and energy efficiency |

| Hospitality | Air conditioning in hotels and resorts | Improved guest comfort and satisfaction | Energy efficiency, maintenance support, and installation flexibility |

| Agriculture | Climate control for greenhouses and storage | Better crop yield and preservation of produce | Environmental impact, energy costs, and durability |

What Are the Key Applications of Air Conditioner Power Supply in Manufacturing?

In the manufacturing sector, air conditioner power supplies are essential for cooling systems that regulate temperatures on production lines. These systems help maintain optimal operating conditions for machinery, preventing overheating and ensuring consistent product quality. Buyers in this sector should consider power capacity and efficiency ratings to ensure that their cooling systems can handle the demands of their operations while adhering to local compliance standards.

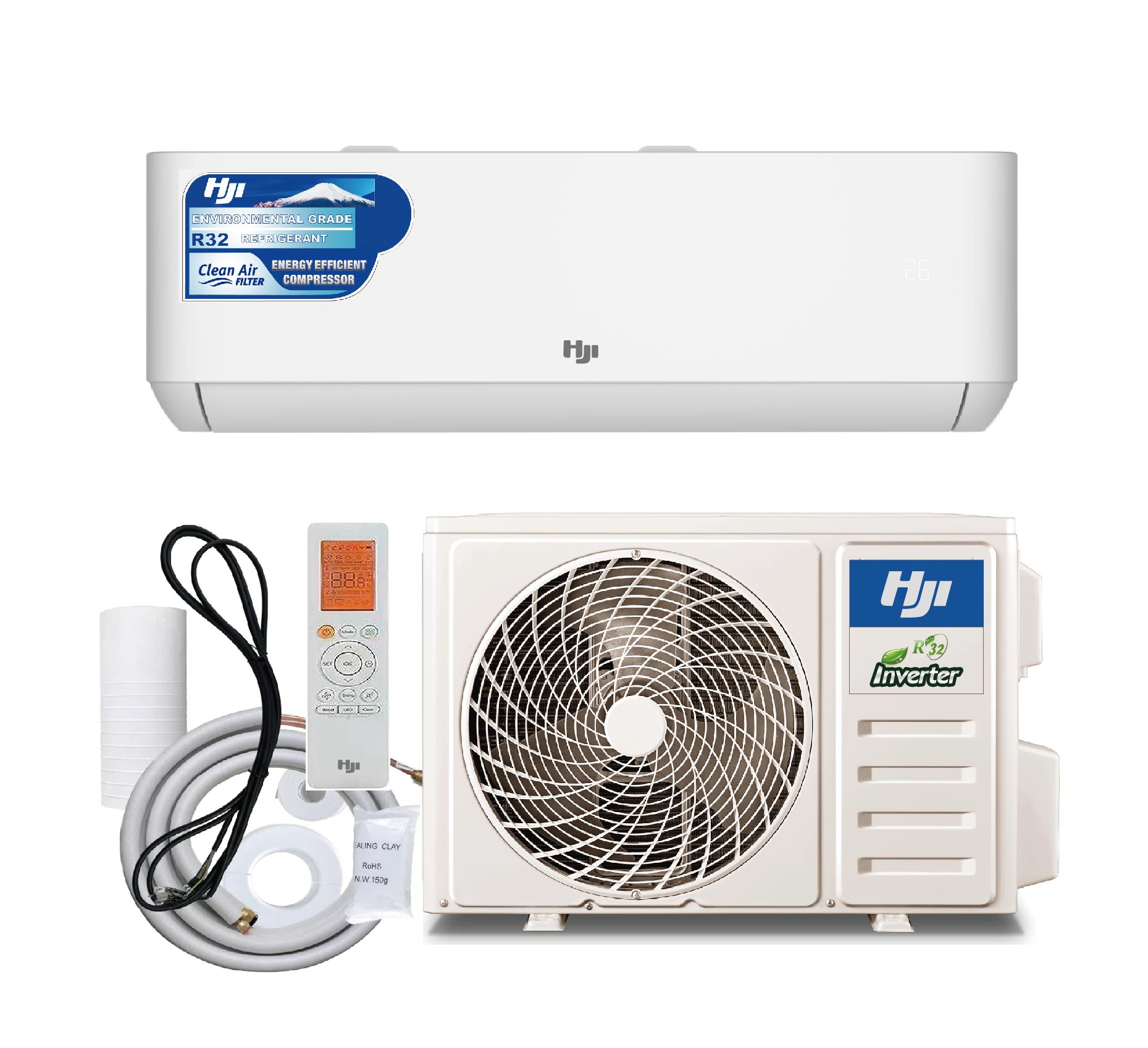

A stock image related to air conditioner power supply.

How Does Air Conditioner Power Supply Benefit Data Centers?

Data centers rely heavily on air conditioner power supplies to maintain climate control in server rooms. Efficient cooling is critical to prevent overheating of servers and ensure optimal operational efficiency. International buyers must prioritize energy efficiency and redundancy options when sourcing power supplies, as these factors significantly impact operational costs and system reliability.

Why is Air Conditioner Power Supply Crucial in Healthcare Settings?

In healthcare, air conditioner power supplies play a vital role in temperature regulation across hospitals. Proper climate control ensures patient comfort and safety while protecting sensitive medical equipment. Buyers should be aware of compliance with health regulations and the energy efficiency of the systems they choose, as these elements are critical for operational sustainability and cost management.

What Are the Benefits of Air Conditioner Power Supply in the Hospitality Industry?

The hospitality sector utilizes air conditioner power supplies to enhance guest comfort in hotels and resorts. A reliable climate control system can significantly improve guest satisfaction, leading to higher retention rates and positive reviews. When sourcing these systems, businesses should focus on energy efficiency, maintenance support, and installation flexibility to optimize their operational effectiveness.

How Does Air Conditioner Power Supply Support Agriculture?

In agriculture, air conditioner power supplies are crucial for climate control in greenhouses and storage facilities. These systems help regulate temperature and humidity levels, which are essential for maximizing crop yields and preserving produce quality. Buyers in this sector should consider the environmental impact, energy costs, and durability of the power supplies to ensure long-term viability and sustainability of their operations.

3 Common User Pain Points for ‘air conditioner power supply’ & Their Solutions

Scenario 1: Insufficient Power Supply for High-Efficiency Units

The Problem: As the demand for energy-efficient air conditioning systems grows, many B2B buyers find themselves facing a significant challenge: existing electrical infrastructure may not support the required power supply. For instance, a business in Africa may purchase a high-capacity 5kW air conditioning unit that requires a dedicated 20-amp circuit, only to discover that their facility’s electrical panel lacks sufficient capacity. This oversight can lead to costly delays in installation and operational inefficiencies, as the unit cannot function optimally without a proper power supply.

The Solution: To avoid this pitfall, it is essential for buyers to conduct a thorough assessment of their electrical infrastructure prior to purchasing new air conditioning units. Start by consulting with a licensed electrician to evaluate the current capacity of your electrical panel and identify any potential upgrades needed. When sourcing air conditioner power supply solutions, ensure that the selected units have compatible power requirements. Opt for systems that offer flexibility, such as multi-split units, which can distribute load across several units, making better use of existing circuits. Additionally, consider investing in smart energy management systems that can optimize energy consumption and reduce the risk of overload.

Scenario 2: Incompatibility with Local Electrical Standards

The Problem: International B2B buyers often face the challenge of navigating varying electrical standards and regulations when sourcing air conditioning units. A company in South America might import an air conditioner designed for European specifications, only to find that it is incompatible with local voltage or plug types. This can result in operational downtime and increased costs due to the need for additional converters or modifications.

The Solution: To mitigate this issue, it is crucial to thoroughly research and understand the local electrical standards before making a purchase. Buyers should consult with local suppliers or experts who can provide insights on compatible air conditioning units and their respective power supply requirements. Additionally, look for suppliers that offer products specifically designed for the target market, ensuring compliance with local voltage and plug configurations. It’s also wise to request documentation that verifies compliance with local regulations and standards, which can save time and resources in the long run.

Scenario 3: Complex Installation Requirements

The Problem: Many B2B buyers underestimate the complexity involved in installing air conditioning systems, especially in commercial settings. A company in the Middle East may find that the location of their existing electrical panel is not conducive to the installation of a new air conditioning unit, necessitating extensive rewiring or the installation of additional circuits. Such complications can lead to project delays and increased labor costs.

The Solution: To streamline the installation process, buyers should engage with experienced HVAC professionals during the planning phase. This collaboration will help identify potential challenges early on, allowing for proactive solutions, such as repositioning the electrical panel or planning for a dedicated power supply. When sourcing power supply components, consider purchasing longer power cords or specialized connectors that facilitate easier installation. Additionally, ensure that the installation team is well-versed in local regulations and best practices, as this knowledge can significantly reduce complications and ensure compliance with safety standards. By investing time in the planning and sourcing process, businesses can minimize installation headaches and ensure a smooth transition to their new air conditioning systems.

Strategic Material Selection Guide for air conditioner power supply

What Are the Key Materials for Air Conditioner Power Supply?

When selecting materials for air conditioner power supply systems, it is essential to consider properties that influence performance, durability, and compliance with international standards. Here, we analyze four common materials used in air conditioner power supply applications: copper, aluminum, PVC, and rubber.

How Does Copper Perform as a Material for Air Conditioner Power Supply?

Key Properties: Copper boasts excellent electrical conductivity, high thermal conductivity, and good corrosion resistance. It can handle high temperatures and pressures, making it suitable for various electrical applications.

Pros & Cons: The primary advantage of copper is its superior conductivity, which leads to lower energy losses during operation. However, copper is relatively expensive compared to other materials, which can increase the overall cost of the power supply system. Its manufacturing complexity also requires specialized techniques, potentially leading to higher production costs.

Impact on Application: Copper is compatible with a wide range of media, making it versatile for different air conditioning systems. Its resistance to corrosion ensures longevity, especially in humid or saline environments, which is particularly relevant for buyers in coastal regions of Africa and South America.

Considerations for International Buyers: Compliance with standards such as ASTM and IEC is crucial. Buyers from Europe, particularly Germany, may prefer copper due to its established reputation for reliability and performance.

What Are the Benefits of Using Aluminum in Air Conditioner Power Supply?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has decent electrical conductivity, though not as high as copper. It can withstand moderate temperatures and pressures.

Pros & Cons: The key advantage of aluminum is its low cost and lightweight nature, making it easier to handle and install. However, its lower conductivity can lead to higher energy losses, and it may require larger cross-sectional areas to achieve the same performance as copper.

Impact on Application: Aluminum is suitable for applications where weight is a critical factor, such as portable air conditioning units. Its corrosion resistance makes it a good choice for humid environments, but care must be taken in applications where it may be exposed to harsh chemicals.

Considerations for International Buyers: Aluminum’s cost-effectiveness appeals to buyers in developing regions like Africa and South America. However, compliance with local standards and regulations is essential to ensure safety and performance.

Why Is PVC a Common Choice for Insulation in Air Conditioner Power Supply?

Key Properties: Polyvinyl chloride (PVC) is a synthetic plastic polymer known for its excellent insulation properties, chemical resistance, and durability. It can operate effectively across a wide temperature range.

Pros & Cons: The primary advantage of PVC is its cost-effectiveness and ease of manufacturing. It provides excellent insulation, reducing the risk of electrical faults. However, PVC can become brittle over time, especially when exposed to UV light, which may limit its lifespan in outdoor applications.

Impact on Application: PVC is often used for insulating wires and cables in air conditioning systems, providing safety and reliability. It is compatible with various media, making it a versatile choice.

Considerations for International Buyers: Buyers should ensure that the PVC used complies with local regulations, particularly regarding fire safety and environmental impact. In Europe, for example, compliance with RoHS and REACH regulations is critical.

How Does Rubber Contribute to Air Conditioner Power Supply Systems?

Key Properties: Rubber is known for its flexibility, durability, and excellent insulation properties. It can withstand a range of temperatures and is resistant to moisture and chemicals.

Pros & Cons: The flexibility of rubber makes it ideal for applications requiring movement or vibration absorption. However, it can be more expensive than other insulating materials, and its performance can degrade over time when exposed to UV light or extreme temperatures.

Impact on Application: Rubber is commonly used for grommets and seals in air conditioning units, protecting electrical connections from moisture and dust. Its compatibility with various media enhances its suitability for different environments.

Considerations for International Buyers: International buyers should consider the specific rubber grades that meet their local standards, especially in regions with extreme weather conditions. Compliance with ASTM or DIN standards may be required.

Summary Table of Material Selection for Air Conditioner Power Supply

| Material | Typical Use Case for air conditioner power supply | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Conductors and wiring | Superior conductivity | High cost | High |

| Aluminum | Conductors and lightweight applications | Lightweight and cost-effective | Lower conductivity | Medium |

| PVC | Insulation for wires and cables | Excellent insulation | Can become brittle over time | Low |

| Rubber | Grommets and seals | Flexibility and durability | Performance degradation over time | Medium |

This guide provides a comprehensive overview of materials used in air conditioner power supply systems, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for air conditioner power supply

What Are the Main Stages of Manufacturing Air Conditioner Power Supplies?

The manufacturing process of air conditioner power supplies involves several critical stages, each essential for ensuring the final product meets quality and performance standards. Here’s a detailed breakdown of these stages:

1. Material Preparation

Material preparation is the first step in the manufacturing process. Quality raw materials, such as copper wires for conductors and high-grade plastics for insulation, are essential. Suppliers must adhere to international material standards to guarantee durability and reliability.

- Sourcing: Ensure that materials are sourced from reputable suppliers who provide certifications for quality and compliance with international standards such as RoHS (Restriction of Hazardous Substances).

- Inspection: Incoming materials undergo rigorous inspection (Incoming Quality Control – IQC) to verify compliance with specifications. This includes checking for electrical conductivity, insulation resistance, and overall material integrity.

2. Forming Techniques in Power Supply Manufacturing

Once materials are prepared, they are subjected to various forming techniques to create the necessary components of the power supply.

- Winding: Copper wires are wound to form transformers, which are vital for voltage conversion. Precision in this process is crucial to maintain efficiency.

- Molding: Plastic components are molded using thermoplastics to create housings and connectors. The molding process should ensure that parts fit together correctly and can withstand environmental factors like heat and moisture.

How Is Assembly Done in Air Conditioner Power Supply Production?

After forming, the assembly of components begins, which is crucial for the functionality of the power supply.

- Component Integration: Various components, including transformers, capacitors, and circuit boards, are integrated. This requires skilled technicians to ensure connections are secure and that the assembly adheres to design specifications.

- Soldering: Soldering techniques must be precise, as poor solder joints can lead to product failures. Automated soldering machines are often used to enhance consistency and reduce defects.

What Are the Finishing Processes for Air Conditioner Power Supplies?

Finishing processes are essential for preparing the power supplies for market readiness.

- Coating and Insulation: Components may undergo coating to protect against corrosion and enhance durability. Insulation is applied to ensure electrical safety.

- Labeling and Packaging: Final labeling includes compliance marks (like CE marking) to indicate adherence to safety and environmental standards. Proper packaging is also crucial to prevent damage during transport.

What Quality Assurance Standards Are Important for Air Conditioner Power Supplies?

Quality assurance is a vital aspect of the manufacturing process, ensuring that products meet both regulatory and customer expectations.

1. International Quality Standards

Many manufacturers adhere to international quality standards such as ISO 9001, which outlines the criteria for a quality management system. Compliance with ISO ensures that the manufacturing process is efficient and that products are consistent in quality.

- ISO 9001 Certification: B2B buyers should look for suppliers with ISO 9001 certification as it reflects a commitment to quality and continuous improvement.

2. Industry-Specific Certifications

In addition to general quality standards, industry-specific certifications are also critical.

- CE Marking: This is mandatory for products sold in the European Economic Area (EEA) and indicates compliance with health, safety, and environmental protection standards.

- API Standards: For products used in specific applications, such as HVAC systems, adherence to API (American Petroleum Institute) standards may be relevant.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integral to ensuring product reliability and safety throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This step ensures that raw materials meet specified standards before they enter production.

- In-Process Quality Control (IPQC): Continuous checks during production help catch any defects early, reducing waste and rework.

- Final Quality Control (FQC): Before products are shipped, they undergo final testing to ensure they meet all specifications and performance criteria.

What Testing Methods Are Commonly Used for Air Conditioner Power Supplies?

Testing methods are critical for verifying the performance and safety of air conditioner power supplies. Common testing methods include:

- Electrical Testing: This involves checking insulation resistance, continuity, and voltage ratings to ensure the product can operate safely under expected conditions.

- Environmental Testing: Products are tested for durability against temperature fluctuations, humidity, and exposure to chemicals, particularly for units intended for harsh environments.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control systems in place.

- Requesting Quality Reports: Suppliers should provide detailed quality reports, including results from inspections and tests conducted at various stages of production.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices and product reliability.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding quality control nuances is crucial:

- Regulatory Compliance: Different regions have varying regulations and standards. Buyers must ensure that suppliers comply with local laws and international standards relevant to their market.

- Cultural and Language Barriers: Effective communication is vital in ensuring that quality expectations are understood and met. Buyers should consider working with suppliers who have experience in international trade and can navigate these barriers effectively.

By understanding the manufacturing processes and quality assurance protocols for air conditioner power supplies, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘air conditioner power supply’

In the competitive landscape of air conditioning systems, ensuring a reliable power supply is crucial for optimal performance and longevity. This practical sourcing guide serves as a step-by-step checklist for B2B buyers focused on procuring air conditioner power supplies, providing actionable insights tailored for international markets, including Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. Understand the power requirements of the air conditioning units you intend to use, including voltage, amperage, and plug type. This information will guide you in selecting the appropriate power supply that meets both operational needs and regulatory standards in your region.

Step 2: Research Regulatory Compliance Requirements

Different regions have specific electrical codes and standards that must be adhered to when installing air conditioning units. Familiarize yourself with these regulations to ensure that your power supply options are compliant. This step is crucial to avoid potential legal issues and ensure the safety of your installation.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to conduct thorough due diligence. Look for suppliers that have a solid reputation in the industry, ideally with experience in your specific market. Request company profiles, case studies, and references from other buyers in similar industries or regions to assess reliability and product quality.

- Key Considerations:

- Check for supplier certifications (e.g., ISO standards).

- Review their customer support and warranty policies.

Step 4: Assess Product Quality and Specifications

Quality is paramount when selecting power supplies for air conditioning units. Review product specifications, including power output, efficiency ratings, and durability. Ensure that the products are designed to handle the specific load requirements of your air conditioning systems without overheating or failing.

Step 5: Request Samples or Prototypes

Whenever possible, request samples or prototypes of the power supplies you are considering. Testing these products in real-world scenarios can provide invaluable insights into their performance and compatibility with your systems. This step helps mitigate risks associated with bulk purchases.

Step 6: Negotiate Pricing and Terms

Once you have identified a suitable supplier and product, engage in price negotiations. Be prepared to discuss volume discounts, payment terms, and shipping options. This step is crucial for optimizing your budget and ensuring that you receive the best value for your investment.

- Negotiation Tips:

- Compare quotes from multiple suppliers.

- Be clear about your expectations regarding delivery timelines and after-sales support.

Step 7: Plan for Installation and Maintenance

Consider the logistics of installation and ongoing maintenance when sourcing your power supply. Collaborate with your installation team to ensure that the chosen power supply integrates seamlessly with your air conditioning units. Additionally, establish a maintenance schedule to prolong the life of both the power supply and the air conditioning systems.

By following this checklist, B2B buyers can effectively navigate the procurement process for air conditioner power supplies, ensuring they meet operational requirements while adhering to regional regulations and quality standards.

Comprehensive Cost and Pricing Analysis for air conditioner power supply Sourcing

What Are the Key Cost Components in Air Conditioner Power Supply Sourcing?

When sourcing air conditioner power supplies, international B2B buyers must understand the underlying cost structure. The primary components include:

-

Materials: The cost of raw materials such as copper for wiring, plastic for casings, and components like capacitors and transformers significantly influence the overall price. Quality materials can enhance durability and efficiency but may come at a higher initial cost.

-

Labor: Labor costs vary by region and impact manufacturing costs. In regions with high labor costs, such as parts of Europe, the overall manufacturing expenses may be higher compared to countries in Africa or South America.

-

Manufacturing Overhead: This includes costs associated with factory operations, maintenance, and utilities. Efficient production processes can help reduce these costs, thereby lowering the final price.

-

Tooling: Custom tooling for specific designs can be a significant upfront investment but may lead to cost savings over time through increased production efficiency.

-

Quality Control (QC): Implementing robust QC measures ensures that the products meet international standards, which may increase costs but can prevent costly recalls and enhance brand reputation.

-

Logistics: Shipping and handling costs, including freight, tariffs, and insurance, are critical in the overall pricing structure. International buyers should consider these costs in their total cost of ownership (TCO).

-

Margin: Supplier margins vary widely based on market conditions and competition. Buyers should be prepared for negotiations that consider both quality and price.

How Do Price Influencers Affect Air Conditioner Power Supply Costs?

Several factors can influence the pricing of air conditioner power supplies:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer discounts for bulk purchases. Understanding MOQ can help buyers negotiate better terms and lower unit prices.

-

Specifications and Customization: Customized power supplies may incur additional costs due to unique specifications. Buyers should assess whether customization is essential for their application.

-

Material Quality and Certifications: Higher quality materials and compliance with certifications (such as CE or UL) can increase costs but are crucial for safety and reliability, especially in regions with strict regulations.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their proven track record, while new entrants may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is vital for international transactions. Different terms can shift responsibilities and costs between buyers and suppliers, impacting the total landed cost.

What Are the Best Negotiation Tips for International B2B Buyers?

For buyers from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to more favorable outcomes:

-

Research and Benchmarking: Conduct thorough market research to understand prevailing prices. This knowledge can empower you during negotiations.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often yield more favorable conditions.

-

Focus on Total Cost of Ownership: Rather than just the upfront price, consider the TCO, which includes installation, maintenance, and operational costs over the product’s lifespan.

-

Be Open to Alternative Suppliers: Consider multiple suppliers to foster competition, which can drive down costs.

-

Leverage Payment Terms: Negotiate favorable payment terms that align with your cash flow needs, as this can provide financial flexibility.

What Should International Buyers Keep in Mind Regarding Pricing Nuances?

Buyers must be aware of various pricing nuances when sourcing air conditioner power supplies internationally:

-

Currency Fluctuations: Exchange rate volatility can affect pricing, so consider locking in prices or using contracts that mitigate currency risk.

-

Cultural Differences: Understanding the cultural context of suppliers can enhance negotiation outcomes. Be aware of communication styles and decision-making processes.

-

Regulatory Compliance: Ensure that the products comply with local regulations in your market, as non-compliance can lead to additional costs and delays.

Disclaimer for Indicative Prices

All prices referenced in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific project requirements. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing air conditioner power supply With Other Solutions

When considering the power supply for air conditioning units, it’s essential to evaluate various alternatives that can achieve similar cooling objectives while potentially offering different benefits. This analysis highlights two viable alternatives to traditional air conditioner power supply systems, allowing international B2B buyers from regions like Africa, South America, the Middle East, and Europe to make informed decisions.

Comparison Table of Air Conditioner Power Supply Alternatives

| Comparison Aspect | Air Conditioner Power Supply | Solar-Powered Air Conditioning | Battery-Powered Air Conditioning |

|---|---|---|---|

| Performance | Reliable, consistent power for high-capacity units | Dependent on sunlight; effective in sunny regions | Provides flexibility, but limited runtime based on battery capacity |

| Cost | Initial installation costs, ongoing electricity bills | Higher upfront costs, but lower operational costs | Moderate to high initial costs; replacement batteries needed |

| Ease of Implementation | Requires professional installation; must comply with electrical codes | Installation can be complex; requires solar panel setup | Easier to install; portable options available |

| Maintenance | Regular checks needed for wear and tear | Minimal maintenance; clean panels periodically | Regular battery checks and replacements necessary |

| Best Use Case | Large commercial spaces needing constant cooling | Off-grid locations or areas with high solar exposure | Remote locations or temporary cooling needs |

What Are the Benefits and Drawbacks of Solar-Powered Air Conditioning?

Solar-powered air conditioning systems utilize solar panels to convert sunlight into electricity, which then powers the AC units. Pros include significant long-term savings on electricity bills and reduced environmental impact, making it an attractive choice for businesses committed to sustainability. However, cons include the high initial setup costs and dependence on solar energy availability, which can be a limitation in regions with inconsistent sunlight.

How Does Battery-Powered Air Conditioning Compare?

Battery-powered air conditioning systems offer a flexible solution that can operate independently from the electrical grid. They are particularly beneficial in remote areas or during power outages. The advantages of this approach include ease of installation and the ability to provide cooling without needing extensive electrical infrastructure. On the downside, disadvantages include limited runtime based on battery capacity and the need for regular battery maintenance and replacement, which can add to the total cost over time.

Making the Right Choice: Which Solution Fits Your Needs?

When evaluating the best power supply for air conditioning, B2B buyers should consider their specific operational requirements, location, and budget constraints. For businesses that prioritize sustainability and have access to ample sunlight, solar-powered air conditioning might offer the best long-term savings. Conversely, for companies requiring immediate and flexible cooling solutions, battery-powered systems could be more suitable. Ultimately, the decision should align with the company’s broader energy strategy, operational needs, and environmental goals, ensuring that the chosen solution enhances efficiency and reduces costs effectively.

Essential Technical Properties and Trade Terminology for air conditioner power supply

What Are the Key Technical Properties of Air Conditioner Power Supplies?

Understanding the technical specifications of air conditioner power supplies is essential for B2B buyers, especially those involved in procurement and installation. Here are several critical specs to consider:

1. Voltage Rating

The voltage rating indicates the electrical potential required for the air conditioning unit to operate effectively. Most residential and commercial air conditioners operate on either 120V or 240V systems. For international buyers, it’s crucial to ensure that the power supply matches the local electrical standards to avoid compatibility issues.

2. Amperage

Amperage, or current rating, specifies the maximum current the power supply can handle without overheating. This is typically expressed in amps (A). For example, a standard air conditioning unit may require a 15A or 20A supply. Understanding this spec helps in selecting the right circuit breakers and wiring, ensuring safety and compliance with local regulations.

3. Cable Length and Type

The length and type of power cable are vital for efficient energy transfer. Longer cable runs may require thicker gauge wires to minimize voltage drop. Common cable types include stranded and solid conductors, with stranded wires being more flexible and easier to work with in installations. This consideration is particularly important in regions with varied installation environments, such as Africa and the Middle East.

4. Plug Configuration

Power supply plugs come in different configurations depending on the region. For instance, European plugs differ from those used in North America. Understanding the plug type is essential for ensuring compatibility with local outlets and avoiding the need for additional adapters, which can complicate installations.

5. Material Grade

The material used for insulation and conductors affects durability and performance. PVC is commonly used for insulation, while copper is favored for conductors due to its excellent conductivity. Buyers should consider these materials, especially in harsh environments where durability is paramount.

What Are Common Trade Terms in the Air Conditioning Supply Industry?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are then sold under another company’s brand. In the air conditioning sector, understanding OEM relationships can help buyers identify quality suppliers and negotiate better pricing.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For international buyers, knowing the MOQ is important for budgeting and inventory planning, especially when sourcing from suppliers in different regions.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specified products. This is a critical step in the procurement process, allowing buyers to compare offers and negotiate terms effectively.

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade to define responsibilities for shipping, insurance, and tariffs. Understanding these terms is essential for B2B buyers engaged in international transactions, as they clarify obligations and reduce the risk of disputes.

5. CE Marking

CE marking indicates that a product meets European safety and environmental standards. For buyers in Europe, ensuring that air conditioning units have CE marking is crucial for compliance with regulatory requirements.

6. Warranty and Support

Warranty terms specify the period during which a product is covered for defects and failures. Understanding warranty conditions and the level of technical support provided by the supplier is essential for ensuring long-term satisfaction and operational reliability.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing air conditioner power supplies, ensuring compatibility, compliance, and cost-effectiveness in their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the air conditioner power supply Sector

What Are the Current Market Dynamics in the Air Conditioner Power Supply Sector?

The air conditioner power supply market is experiencing significant transformations driven by several global factors. Increasing urbanization, particularly in Africa and South America, is leading to a rise in residential and commercial air conditioning installations. This surge is further compounded by climate change, prompting a higher demand for efficient cooling solutions in regions that experience extreme heat. International B2B buyers must be aware of the importance of sourcing high-quality power supplies that can handle the growing power demands of modern air conditioning units.

Emerging technologies, such as smart power management systems, are revolutionizing the way air conditioners are powered. These systems not only enhance energy efficiency but also provide real-time monitoring capabilities, allowing businesses to optimize their energy consumption. Additionally, suppliers are increasingly offering modular power supply solutions, which are flexible and scalable, catering to varying installation needs across different geographical regions.

A stock image related to air conditioner power supply.

For B2B buyers, understanding local regulations and compliance standards is crucial. In Europe, for instance, energy efficiency regulations are becoming stricter, pushing manufacturers to innovate and provide compliant products. Similarly, in the Middle East, where energy costs are rising, sourcing energy-efficient solutions is becoming a priority for businesses looking to reduce operational costs.

How Can Sustainability and Ethical Sourcing Impact B2B Buying Decisions?

Sustainability is no longer just a buzzword; it is a critical factor influencing purchasing decisions in the air conditioner power supply market. The environmental impact of manufacturing processes and product lifecycle management is under scrutiny, prompting buyers to consider suppliers who prioritize eco-friendly practices. Ethical sourcing involves looking beyond the price tag and assessing the environmental footprint of products, including the materials used in power supply units.

Buyers should seek out suppliers that offer ‘green’ certifications, such as ENERGY STAR or ISO 14001, which indicate adherence to environmental management standards. Utilizing materials that are recyclable or produced with minimal environmental impact is becoming increasingly important. For instance, power cords made from sustainable materials not only reduce waste but also appeal to eco-conscious consumers.

Furthermore, businesses that actively engage in sustainable practices are likely to enhance their brand reputation and attract a growing segment of environmentally aware customers. By prioritizing ethical sourcing, international B2B buyers can ensure that their procurement strategies align with global sustainability goals while also meeting local regulatory requirements.

What Is the Historical Context of Air Conditioner Power Supply Development?

The evolution of air conditioner power supply systems can be traced back to the early 20th century when air conditioning was first introduced in industrial settings. Initially, power supply solutions were rudimentary, with limited focus on efficiency and safety. Over the decades, advancements in electrical engineering and technology have led to the development of more sophisticated power supply systems designed to meet the demands of modern air conditioning units.

In recent years, the emphasis has shifted towards energy efficiency and sustainability, reflecting broader societal trends. The introduction of inverter technology in air conditioners has necessitated corresponding advancements in power supply systems, allowing for more efficient energy use and reduced operational costs. As international markets continue to evolve, understanding the historical context of these developments can provide valuable insights for B2B buyers looking to make informed sourcing decisions in the air conditioner power supply sector.

By staying informed about market dynamics, sustainability practices, and historical trends, B2B buyers can better navigate the complexities of sourcing air conditioner power supplies, ensuring they choose solutions that meet both their operational needs and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of air conditioner power supply

-

How do I solve power supply compatibility issues for my air conditioner?

When facing compatibility issues with your air conditioner’s power supply, it’s essential to check the voltage and amperage requirements specified by the manufacturer. Use a dedicated power supply that matches these specifications to avoid damage. If your existing setup doesn’t meet these needs, consider consulting a licensed electrician to assess your electrical system and recommend suitable modifications or upgrades. Additionally, ensure that the power cord and connectors are rated for the required load to prevent overheating or electrical failures. -

What is the best air conditioner power supply configuration for commercial use?

For commercial applications, a three-phase power supply is often the best configuration, as it provides more consistent power and can support larger air conditioning units more efficiently. This setup reduces the risk of voltage drops, ensuring that your units operate optimally during peak usage times. It’s crucial to work with a qualified electrical engineer to design a power supply system that meets local regulations and the specific cooling requirements of your facility. -

How can I vet suppliers for air conditioner power supplies?

When vetting suppliers, prioritize those with a proven track record in the HVAC industry. Check for certifications such as ISO or CE, which indicate adherence to quality standards. Request references from previous clients and assess their experience in international trade, especially if you’re sourcing from different regions like Africa or South America. Additionally, evaluate their customer service, responsiveness, and ability to provide technical support, which are critical for ongoing relationships. -

What are the typical minimum order quantities (MOQs) for air conditioner power supplies?

Minimum order quantities can vary widely among suppliers. Many manufacturers set MOQs based on production costs, which can range from 100 to 1,000 units. However, some suppliers may offer flexibility, especially for first-time buyers or smaller companies. It’s advisable to communicate your needs clearly and negotiate terms that suit your business requirements. Consider potential long-term partnerships to achieve better pricing and lower MOQs. -

What payment terms should I expect when sourcing air conditioner power supplies internationally?

Payment terms can differ significantly based on the supplier’s policies and your negotiation. Common terms include payment in advance, letter of credit, or net 30/60 days after shipment. For international transactions, ensure that you understand the implications of currency exchange rates and any associated fees. It’s wise to establish clear terms upfront and consider using escrow services for large transactions to mitigate risks. -

How do I ensure quality assurance (QA) for air conditioner power supplies?

To ensure quality assurance, request detailed product specifications and compliance certifications from your supplier. Implement a robust inspection process, including pre-shipment inspections to verify that the products meet your standards. Consider collaborating with third-party inspection agencies for impartial assessments. Additionally, establish a return policy for defective units, which will safeguard your investment and encourage suppliers to maintain high-quality standards.

A stock image related to air conditioner power supply.

-

What logistics considerations should I keep in mind when importing air conditioner power supplies?

When importing air conditioner power supplies, it’s crucial to understand shipping costs, customs duties, and import regulations in your country. Choose a reliable freight forwarder who can navigate these complexities and provide transparent pricing. Factor in lead times for production and shipping, especially if sourcing from regions with longer transit times, such as South America or Africa. Also, consider warehousing options if you need to manage inventory efficiently. -

Can I customize air conditioner power supplies to fit specific needs?

Many manufacturers offer customization options for air conditioner power supplies, allowing you to tailor specifications such as voltage, amperage, and connector types. To initiate this process, clearly communicate your requirements and any applicable standards or certifications needed for your region. Keep in mind that custom solutions may involve longer lead times and higher costs, so plan accordingly to align with your project timelines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for air conditioner power supply

What Are the Key Takeaways for B2B Buyers in Air Conditioner Power Supply?

In conclusion, strategic sourcing for air conditioner power supply is essential for international B2B buyers aiming to enhance operational efficiency and reduce costs. By carefully evaluating suppliers based on reliability, product quality, and compliance with local regulations, businesses can secure a sustainable power supply that meets their specific needs. The variety of options, such as 2-prong and 3-prong cords, and varying lengths, provides flexibility for diverse installation scenarios across different regions, particularly in Africa, South America, the Middle East, and Europe.

How Can Strategic Sourcing Impact Your Business?

Investing in strategic sourcing not only ensures the availability of high-quality components but also fosters long-term partnerships with suppliers who understand the nuances of your regional markets. This approach can lead to improved pricing structures and enhanced support services, ultimately driving profitability and customer satisfaction.

What’s Next for International B2B Buyers?

As we look to the future, the demand for energy-efficient and reliable air conditioning solutions will only grow. B2B buyers should actively engage with suppliers to explore innovative power supply technologies that align with sustainability goals. By taking proactive steps today, businesses can position themselves for success in a competitive marketplace. Consider reaching out to potential suppliers to discuss your specific requirements and start building a sourcing strategy that works for you.