Unlock Savings: The Ultimate Guide to Affordable Automatic (2025)

Introduction: Navigating the Global Market for affordable automatic

In today’s competitive landscape, sourcing affordable automatic solutions can pose significant challenges for international B2B buyers, particularly those operating in emerging markets like Africa, South America, the Middle East, and Europe. Companies are often faced with the dual pressure of maintaining cost-efficiency while also ensuring quality and reliability in their procurement processes. This guide aims to demystify the complexities of the global market for affordable automatic products, providing insightful strategies for sourcing, evaluating suppliers, and understanding various applications.

Throughout this comprehensive guide, we will explore the diverse types of affordable automatic products available, from machinery to automation tools, and delve into the practical applications that can drive efficiency in your operations. We will also cover critical aspects of supplier vetting, including assessing capabilities, reliability, and compliance with international standards. Understanding the cost structures associated with these products will empower you to make informed purchasing decisions that align with your budgetary constraints without compromising on quality.

By equipping international B2B buyers with actionable insights and strategies, this guide aims to streamline the procurement process and facilitate smarter decision-making. Whether you are in Nigeria seeking innovative automation solutions or in Vietnam looking for cost-effective machinery, this resource will serve as your roadmap to navigating the global market for affordable automatic products with confidence.

Understanding Search Intent for ‘affordable automatic’

When users search for **”affordable automatic”**, Google’s results indicate a strong **informational intent**. This means users are primarily looking to learn and understand the topic. They want definitions, explanations, and foundational knowledge about ‘affordable automatic’.

Our analysis of the search engine results page (SERP) reveals several key features that shape this article:

* **Presence of Video Content:** No.

* **Shopping Ad Integration:** No.

* **’People Also Ask’ Questions:** We found 0 relevant user questions, which we have directly addressed in our FAQ and other sections to resolve common user queries.

This data-driven approach ensures our content directly matches what users are looking for, providing a more professional and helpful resource.

Understanding affordable automatic Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Entry-Level Automatic | Basic automation features, low cost, user-friendly interfaces | Small manufacturing, startups | Pros: Affordable, easy to implement. Cons: Limited functionality and scalability. |

| Mid-Range Automatic | Enhanced features, moderate pricing, better integration capabilities | Medium-sized enterprises, logistics | Pros: Good balance of cost and features. Cons: May require additional training. |

| High-Volume Automatic | Designed for large-scale operations, robust performance, high investment | Large manufacturing, distribution | Pros: High efficiency, scalable. Cons: Significant upfront costs. |

| Customizable Automatic | Tailored solutions, adaptable to specific business needs | Niche markets, specialized industries | Pros: Flexibility, unique solutions. Cons: Longer lead times, potentially higher costs. |

| Cloud-Based Automatic | Remote access, real-time data analytics, subscription-based pricing | E-commerce, remote operations | Pros: Cost-effective, easy upgrades. Cons: Dependence on internet connectivity. |

What Are the Key Characteristics of Entry-Level Automatic Systems?

Entry-level automatic systems are designed for businesses that are just beginning to explore automation. They typically feature user-friendly interfaces and basic automation capabilities, making them ideal for small manufacturing operations and startups. These systems are generally low-cost, allowing businesses to adopt automation without significant financial risk. However, buyers should be aware that while these systems are affordable, they may lack the scalability and advanced functionalities needed for more complex operations.

How Do Mid-Range Automatic Systems Enhance Business Operations?

Mid-range automatic systems offer a significant upgrade from entry-level options, featuring enhanced capabilities and moderate pricing. These systems are suitable for medium-sized enterprises and logistics operations that require better integration and efficiency. They strike a balance between cost and features, providing businesses with the necessary tools to improve productivity. However, companies may need to invest in additional training to maximize the benefits of these systems, which can be a consideration for budget-conscious buyers.

What Are the Benefits of High-Volume Automatic Systems for Large Enterprises?

High-volume automatic systems are tailored for large-scale operations, providing robust performance and high efficiency. These systems are ideal for large manufacturing and distribution companies that require consistent output and reliability. While they offer significant advantages in terms of scalability and productivity, the investment required can be substantial. B2B buyers should carefully evaluate their operational needs versus the upfront costs to ensure that the benefits justify the investment.

Why Should Businesses Consider Customizable Automatic Solutions?

Customizable automatic systems allow businesses to tailor automation solutions to their specific needs, making them particularly valuable for niche markets and specialized industries. These systems can adapt to unique operational requirements, offering flexibility that standard solutions may not provide. However, buyers should consider the longer lead times and potentially higher costs associated with customization, ensuring that the benefits align with their strategic goals.

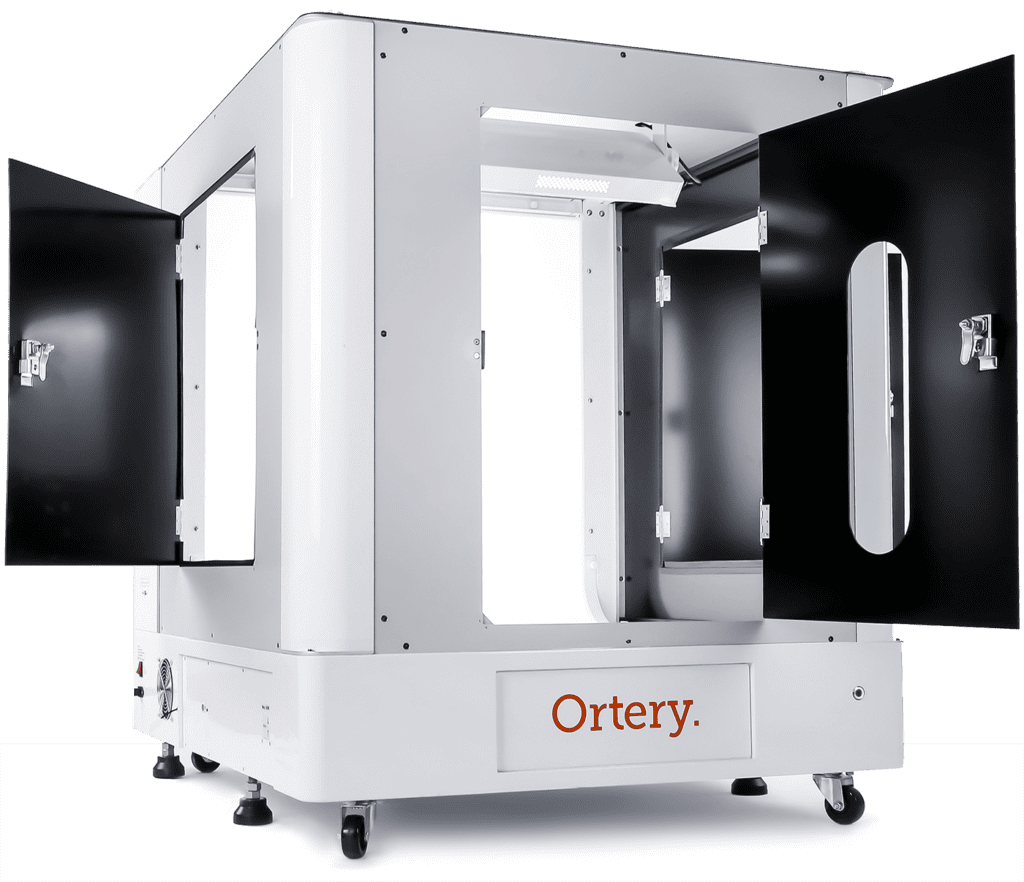

A stock image related to affordable automatic.

What Advantages Do Cloud-Based Automatic Systems Offer?

Cloud-based automatic systems provide businesses with the ability to access automation tools remotely, enabling real-time data analytics and operational management. These systems are particularly beneficial for e-commerce and remote operations, often available through subscription-based pricing. While they can be cost-effective and easy to upgrade, companies must consider their dependence on internet connectivity, which could impact operational reliability. Evaluating the overall infrastructure and internet access is crucial for B2B buyers in this space.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of affordable automatic

| Industry/Sector | Specific Application of Affordable Automatic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automated Assembly Lines | Increased production efficiency and reduced labor costs | Supplier reliability and automation technology compatibility |

| Agriculture | Precision Irrigation Systems | Optimized water usage and improved crop yields | Local climate adaptability and maintenance support availability |

| Logistics and Warehousing | Automated Inventory Management Systems | Enhanced accuracy in stock management and reduced waste | Integration with existing systems and scalability for growth |

| Food Processing | Automatic Packaging Solutions | Consistent quality and extended shelf life of products | Compliance with food safety regulations and machinery durability |

| Construction | Automated Site Monitoring and Management Tools | Improved project tracking and reduced labor costs | Local regulations compliance and technology training for staff |

How is Affordable Automatic Used in Manufacturing and What Problems Does It Solve?

In the manufacturing sector, affordable automatic solutions like automated assembly lines help streamline production processes. These systems reduce labor costs while increasing output efficiency, which is crucial for competitive pricing. International buyers should focus on sourcing from suppliers who demonstrate reliability and provide technology that integrates smoothly with existing systems. This ensures minimal disruption during implementation while maximizing return on investment.

How Does Affordable Automatic Enhance Agricultural Practices?

Affordable automatic systems such as precision irrigation are transforming agricultural practices by optimizing water use and boosting crop yields. This technology addresses the challenges of water scarcity, particularly in regions like Africa and South America, where climate conditions can be unpredictable. Buyers should consider local climate adaptability when sourcing these systems, as well as the availability of maintenance support to ensure long-term functionality and effectiveness.

What Are the Benefits of Automated Inventory Management in Logistics?

In logistics and warehousing, affordable automatic inventory management systems enhance stock accuracy and reduce waste. By automating inventory tracking, businesses can respond more quickly to market demands and minimize overstock or stockouts. For international B2B buyers, it’s essential to assess the scalability of these systems and their ability to integrate with current operations, ensuring that investments can grow with the business.

How Does Affordable Automatic Improve Food Processing Efficiency?

Automatic packaging solutions in the food processing industry provide consistent quality and extend the shelf life of products, addressing consumer demand for freshness and safety. These systems help manufacturers comply with stringent food safety regulations while maintaining operational efficiency. Buyers should prioritize suppliers who understand local compliance requirements and can provide durable machinery, ensuring reliability in high-volume production environments.

What Role Does Automated Site Monitoring Play in Construction?

In construction, affordable automatic site monitoring and management tools enhance project tracking and reduce labor costs. These technologies allow for real-time data collection and analysis, helping project managers make informed decisions quickly. When sourcing these solutions, international buyers must consider compliance with local regulations and ensure that their workforce receives adequate training to utilize the technology effectively, maximizing its benefits on-site.

Related Video: Most Affordable Automatic Compact Slaughter Line for Chicken Processing | Eruis

3 Common User Pain Points for ‘affordable automatic’ & Their Solutions

Scenario 1: The Challenge of Limited Functionality in Budget Automatic Solutions

The Problem: Many B2B buyers, particularly in emerging markets like Nigeria or Vietnam, often find that affordable automatic solutions lack essential features necessary for their operations. For instance, a manufacturing company may purchase an automatic machine that meets their initial budget but later discovers that it cannot handle their specific production needs, resulting in inefficiencies and increased costs. This limitation can lead to frustration and a sense of being trapped in a poor investment, especially when the machine cannot be upgraded or adapted to future needs.

The Solution: To avoid this pitfall, B2B buyers should conduct thorough research before making a purchase. This includes specifying both current and future operational needs. Engage with vendors and request demonstrations of how their products align with your requirements. Additionally, consider machines that allow for modular upgrades or customization options. This foresight ensures that your investment remains viable over time. Always evaluate the total cost of ownership, including potential upgrades, to make informed decisions that balance affordability with functionality.

Scenario 2: Difficulty in Accessing Reliable Support and Maintenance

The Problem: A common pain point for international B2B buyers, especially in regions like South America and the Middle East, is the lack of reliable customer support and maintenance services for affordable automatic solutions. After purchase, companies might find themselves unable to get timely assistance or spare parts, leading to prolonged downtimes that can severely impact productivity and profitability.

The Solution: When sourcing affordable automatic solutions, it is crucial to prioritize vendors that offer robust support networks in your region. Look for companies with a proven track record of providing after-sales service and technical support. Consider evaluating suppliers based on their customer feedback and the availability of local technicians. Additionally, negotiate service agreements that include regular maintenance checks and ensure that spare parts are readily accessible. This proactive approach mitigates risks associated with machine downtime and enhances overall operational efficiency.

Scenario 3: Underestimating Integration Challenges with Existing Systems

The Problem: As businesses often operate with a mix of legacy and modern systems, B2B buyers may encounter significant integration challenges when implementing affordable automatic solutions. For example, a European logistics company might invest in an automatic sorting system that does not seamlessly integrate with their existing inventory management software, resulting in data silos and operational disruptions.

The Solution: To address this challenge, buyers should undertake a comprehensive assessment of their current systems before making a purchase. Engage with IT consultants to map out existing workflows and identify potential integration hurdles. When negotiating with vendors, inquire about compatibility with third-party systems and ensure that they offer integration support as part of their service. Additionally, consider investing in middleware solutions that can bridge gaps between disparate systems. By taking these steps, businesses can ensure a smoother transition and maximize the benefits of their new automatic solutions.

Strategic Material Selection Guide for affordable automatic

What Are the Key Materials for Affordable Automatic Applications?

When selecting materials for affordable automatic applications, international B2B buyers need to consider various factors including performance, cost, and suitability for specific environments. Below, we analyze four common materials used in these applications, highlighting their properties, advantages, disadvantages, and specific considerations for buyers from regions such as Africa, South America, the Middle East, and Europe.

How Does Aluminum Perform in Affordable Automatic Applications?

Aluminum is a lightweight metal known for its excellent corrosion resistance and good thermal conductivity. It typically has a temperature rating of up to 150°C and can handle moderate pressure levels, making it suitable for various automatic systems.

Pros: Aluminum is durable yet lightweight, which can reduce shipping costs and ease installation. Its corrosion resistance makes it ideal for humid or coastal environments.

Cons: While it is generally cost-effective, the manufacturing complexity can increase with intricate designs. Additionally, aluminum may not perform well in high-temperature environments beyond its rating.

Impact on Application: Aluminum is compatible with a range of media, including water and some oils, but may not be suitable for aggressive chemicals.

Considerations for Buyers: Buyers should ensure compliance with international standards like ASTM and DIN. In regions like Nigeria and Vietnam, where humidity is high, aluminum’s corrosion resistance is a significant advantage.

What Are the Benefits of Stainless Steel in Affordable Automatic Systems?

Stainless steel is renowned for its strength and resistance to corrosion, making it a popular choice in various industrial applications. It can withstand temperatures up to 800°C and high-pressure environments, which enhances its versatility.

Pros: Its durability and resistance to rust and corrosion make stainless steel ideal for harsh environments. It also has a high tensile strength, which is beneficial for structural applications.

Cons: The primary downside is its higher cost compared to other materials like aluminum. Additionally, stainless steel can be more challenging to machine, increasing manufacturing complexity.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances, making it suitable for applications in the chemical and food industries.

Considerations for Buyers: Compliance with standards such as ASTM A240 is crucial. In Europe, buyers often prefer stainless steel due to its safety and durability in food processing applications.

Why Choose Plastic Composites for Affordable Automatic Solutions?

Plastic composites, such as reinforced polypropylene or polycarbonate, offer a lightweight and cost-effective alternative for many automatic applications. They typically have a temperature rating of around 80°C and are suitable for low-pressure environments.

Pros: These materials are generally less expensive than metals and can be molded into complex shapes easily, reducing manufacturing costs. Their lightweight nature can also lower shipping expenses.

Cons: Plastic composites may not offer the same level of strength or temperature resistance as metals. They can also be susceptible to UV degradation and may not be suitable for high-stress applications.

Impact on Application: Plastic composites are often used in non-corrosive environments, making them ideal for applications involving water or light oils.

Considerations for Buyers: Buyers should consider local regulations regarding plastic materials, especially in regions with strict environmental policies. In South America, for instance, understanding local recycling laws can impact material selection.

What Role Does Copper Play in Affordable Automatic Systems?

Copper is a highly conductive metal, making it an excellent choice for electrical components in automatic systems. It has a temperature rating of up to 200°C and can handle moderate pressure.

Pros: Copper’s excellent electrical conductivity and thermal properties make it ideal for wiring and heat exchangers. It is also relatively easy to work with, allowing for efficient manufacturing.

Cons: Copper is prone to corrosion in certain environments, which can limit its application. It is also more expensive than aluminum and some plastics.

Impact on Application: Copper is particularly suited for applications involving electrical currents but may not be ideal for corrosive environments without proper coatings.

Considerations for Buyers: Buyers should ensure that copper components meet relevant standards, such as JIS C 3102 in Japan or ASTM B170 in the U.S. In the Middle East, where high temperatures can accelerate corrosion, protective coatings may be necessary.

Summary Table of Material Selection for Affordable Automatic Applications

| Material | Typical Use Case for affordable automatic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight structures and components | Excellent corrosion resistance | Limited high-temperature performance | Medium |

| Stainless Steel | High-strength applications in harsh environments | High tensile strength and durability | Higher cost and machining complexity | High |

| Plastic Composites | Non-corrosive applications and lightweight parts | Cost-effective and easy to mold | Lower strength and UV susceptibility | Low |

| Copper | Electrical components and heat exchangers | Excellent conductivity | Prone to corrosion in harsh environments | Medium |

This guide provides a comprehensive overview of the materials suitable for affordable automatic applications, helping international B2B buyers make informed decisions that align with their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for affordable automatic

What Are the Main Stages of Manufacturing Affordable Automatics?

Manufacturing affordable automatic systems involves a series of well-defined processes that ensure quality and efficiency. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage focuses on sourcing and preparing raw materials. Suppliers often use high-grade metals and polymers that meet international specifications. B2B buyers should ensure that their suppliers provide material certifications, indicating compliance with relevant standards.

-

Forming: In this stage, raw materials are shaped into components using methods such as stamping, casting, or machining. Advanced techniques like CNC (Computer Numerical Control) machining are frequently employed for precision. Buyers should inquire about the technologies used in forming processes to ensure they align with their quality requirements.

-

Assembly: Once components are formed, they are assembled into the final product. This process may involve manual labor or automated systems, depending on the complexity of the product. Efficient assembly lines often employ lean manufacturing principles to minimize waste and reduce costs. Buyers should assess the assembly process for efficiency and effectiveness.

-

Finishing: The final stage involves surface treatments like painting, coating, or polishing to enhance durability and aesthetics. Techniques such as electroplating or powder coating may be used to protect against corrosion. Buyers should verify that finishing processes comply with environmental regulations, especially in regions with strict compliance standards.

Which Quality Control Standards Are Relevant for Affordable Automatics?

A stock image related to affordable automatic.

Quality assurance is crucial for ensuring that affordable automatic products meet international standards. Familiarity with specific quality control (QC) standards can help B2B buyers make informed decisions.

-

ISO 9001: This widely recognized standard sets the framework for quality management systems. Manufacturers aiming for ISO 9001 certification demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

-

Industry-Specific Certifications: Depending on the application, certifications like CE (Conformité Européene) for European markets, and API (American Petroleum Institute) standards for oil and gas equipment may be necessary. These certifications ensure that products are compliant with safety and performance regulations.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control is integrated into various stages of the manufacturing process. Understanding key checkpoints can help B2B buyers evaluate supplier quality assurance practices.

-

Incoming Quality Control (IQC): This checkpoint verifies the quality of raw materials before they enter the manufacturing process. Suppliers should provide detailed reports on inspection results, including any discrepancies and corrective actions taken.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC monitors processes to ensure they adhere to predefined standards. This may involve real-time inspections and testing to catch defects early.

-

Final Quality Control (FQC): After assembly, FQC ensures that the finished product meets all specifications before shipment. This includes functional tests, durability tests, and visual inspections. Buyers should request samples of FQC reports to understand the level of scrutiny applied to the final products.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to mitigate risks.

-

Supplier Audits: Conducting on-site audits provides firsthand insight into the manufacturing processes, quality assurance practices, and overall operational efficiency. Buyers should develop a checklist based on their quality requirements to standardize the audit process.

-

Quality Control Reports: Requesting comprehensive QC reports, including IQC, IPQC, and FQC results, allows buyers to assess the supplier’s quality management effectiveness. These reports should detail any non-conformities and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. This is particularly beneficial for buyers who may not have the resources for on-site inspections.

What Testing Methods Are Commonly Used in Quality Assurance?

To ensure that affordable automatic systems function correctly and meet specifications, various testing methods are employed throughout the manufacturing process. Here are some common techniques:

-

Functional Testing: This method assesses whether the automatic system performs as intended. It typically involves simulating operational conditions to evaluate efficiency, safety, and reliability.

-

Durability Testing: This testing method examines how well products withstand wear and tear over time. It can include stress tests, fatigue tests, and environmental simulations to assess performance under varying conditions.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or radiography allow manufacturers to inspect materials and components without causing damage. This is particularly useful for critical components where integrity is paramount.

What Are the Quality Control Nuances for International Buyers?

B2B buyers from different regions may face unique challenges regarding quality control in manufacturing. Here are some nuances to consider:

-

Cultural Differences: Understanding cultural attitudes toward quality and compliance is crucial. For example, suppliers in some regions may prioritize speed over quality. Building relationships and clear communication can help bridge these differences.

-

Regulatory Compliance: Different markets have distinct regulatory requirements. Buyers must ensure that their suppliers are compliant with local laws and international standards. This may require additional documentation or certifications.

-

Geographic Challenges: Transport logistics can affect product quality. Buyers should discuss how suppliers manage inventory, shipping, and handling to minimize risks associated with product damage during transit.

In conclusion, understanding the intricacies of manufacturing processes and quality assurance practices is essential for international B2B buyers. By focusing on the stages of manufacturing, relevant quality standards, and effective verification methods, buyers can make informed decisions and forge successful partnerships in the affordable automatic sector.

Related Video: BMW 5 Series (2024) PRODUCTION 🇩🇪 Car Manufacturing Process

Practical Sourcing Guide: A Step-by-Step Checklist for ‘affordable automatic’

This practical sourcing guide is designed to assist international B2B buyers in effectively procuring affordable automatic solutions. By following this checklist, buyers can ensure they make informed decisions, minimize risks, and optimize their sourcing processes.

Step 1: Define Your Technical Specifications

Clearly outlining the technical specifications of the affordable automatic solutions you need is essential. This includes understanding the functionalities, capacity, and compatibility with existing systems. By having precise requirements, you can streamline your search and communicate effectively with potential suppliers.

- Identify critical features that meet your operational needs.

- Consider future scalability and integration with other technologies.

Step 2: Research Market Trends

Understanding current market trends can provide insights into pricing, innovations, and potential suppliers. Researching regional trends, especially in Africa, South America, the Middle East, and Europe, can help you identify competitive advantages or challenges in sourcing.

- Utilize industry reports and market analyses to gather data.

- Pay attention to emerging technologies that may enhance the affordability of automatic systems.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct thorough evaluations. Request company profiles, case studies, and references from other businesses in your industry or region. This due diligence helps ensure reliability and quality.

- Look for suppliers with a solid track record and positive customer feedback.

- Verify their production capabilities and quality control measures.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers possess the necessary certifications to meet international quality and safety standards. Certifications not only indicate compliance but also reflect the supplier’s commitment to quality.

- Check for ISO certifications or other relevant industry standards.

- Inquire about their quality assurance processes to gauge their operational integrity.

Step 5: Request Samples and Prototypes

Evaluating physical samples or prototypes is a critical step in the sourcing process. It allows you to assess the quality and functionality of the affordable automatic solutions before making a bulk purchase.

- Ask for samples that reflect the specific products you intend to buy.

- Conduct thorough testing to ensure they meet your operational standards.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations to establish favorable terms. This includes discussing pricing, delivery schedules, warranties, and after-sales support.

- Aim for a win-win situation that fosters a long-term relationship with the supplier.

- Clearly document all agreed terms to avoid misunderstandings in the future.

Step 7: Establish a Communication Plan

Maintaining open lines of communication with your supplier is vital for successful collaboration. Establish a plan for regular updates and feedback, ensuring both parties are aligned throughout the procurement process.

- Schedule periodic check-ins to discuss progress and address any issues.

- Use project management tools to streamline communication and documentation.

By following these steps, international B2B buyers can navigate the complexities of sourcing affordable automatic solutions efficiently and effectively. This checklist not only helps in making informed decisions but also builds a foundation for successful supplier relationships.

Comprehensive Cost and Pricing Analysis for affordable automatic Sourcing

Understanding the cost structure and pricing for affordable automatic sourcing is essential for international B2B buyers seeking to make informed purchasing decisions. By dissecting the various cost components and price influencers, buyers can develop strategies to optimize their procurement processes.

What are the Key Cost Components in Affordable Automatic Sourcing?

-

Materials: The choice of materials significantly impacts the overall cost. High-quality and durable materials generally lead to higher prices, but they can enhance the lifespan and reliability of the sourced products. Buyers should evaluate the balance between material quality and cost-effectiveness.

-

Labor: Labor costs vary by region and can influence pricing. For instance, sourcing from countries with lower labor costs may seem attractive, but it is vital to consider the skill level and productivity of the workforce. This affects the quality of the final product and, consequently, the Total Cost of Ownership (TCO).

-

Manufacturing Overhead: This includes costs associated with production facilities, utilities, and administrative expenses. Understanding these overheads can provide insights into the pricing structure from different suppliers.

-

Tooling: Custom tooling can be a significant initial investment, especially for specialized products. If buyers require unique specifications, they should account for these costs in their budgeting.

-

Quality Control (QC): Implementing effective QC processes can add to the cost but is crucial for ensuring product reliability. Buyers should assess the supplier’s QC measures to avoid potential issues that could lead to additional costs down the line.

-

Logistics: Shipping and handling costs can vary widely depending on the distance, shipping method, and Incoterms used. Evaluating logistics costs is essential for understanding the total expense involved in sourcing products.

-

Margin: Suppliers will add their profit margin to the total cost of production, which can vary based on competition and market demand. Buyers should be prepared to negotiate these margins to achieve a more favorable pricing structure.

What Influences Pricing in Affordable Automatic Sourcing?

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to discounts, as suppliers prefer to maximize output efficiency. Buyers should consider their ordering patterns to negotiate better pricing.

-

Specifications and Customization: Customized products typically incur higher costs due to additional design and manufacturing processes. Buyers should clearly define their needs to avoid unnecessary expenditures.

-

Materials and Quality Certifications: The specific materials used and the certifications obtained can influence both the price and the perceived value of the product. Buyers should weigh the importance of certifications against their budget constraints.

-

Supplier Factors: Supplier reputation, experience, and location can all affect pricing. Buyers should conduct thorough research on potential suppliers to ensure they receive competitive pricing without compromising quality.

-

Incoterms: Understanding Incoterms is crucial for determining who bears the cost and risk at different points in the supply chain. This knowledge can help buyers make better decisions regarding shipping and logistics costs.

What Tips Can Help Buyers Optimize Their Sourcing Costs?

-

Effective Negotiation Strategies: Building a strong relationship with suppliers can lead to better negotiation outcomes. Buyers should approach discussions with clear objectives and be prepared to discuss volume discounts or longer-term contracts.

-

Focus on Cost-Efficiency: Look beyond the initial purchase price. Consider the TCO, which includes installation, maintenance, and operational costs over the product’s lifespan. This holistic view can lead to more sustainable purchasing decisions.

-

Understand Pricing Nuances for International Sourcing: Different regions may have unique pricing structures influenced by local market conditions, tariffs, and trade agreements. Buyers from Africa, South America, the Middle East, and Europe should stay informed about these factors to optimize their sourcing strategies.

-

Review and Compare Multiple Suppliers: Diversifying your supplier base can lead to better pricing options. Regularly reviewing supplier performance and pricing can ensure you are getting the best value.

Disclaimer

The prices and costs discussed in this analysis are indicative and can vary based on market conditions, individual supplier negotiations, and specific buyer requirements. It is advisable for buyers to conduct their own research and seek tailored quotes to understand the precise costs involved in their sourcing endeavors.

Alternatives Analysis: Comparing affordable automatic With Other Solutions

Understanding the Importance of Evaluating Alternatives for ‘Affordable Automatic’ Solutions

In the fast-evolving B2B landscape, particularly for international buyers from regions like Africa, South America, the Middle East, and Europe, evaluating alternatives to a product or method is crucial. The ‘affordable automatic’ solution may meet specific business needs, but understanding how it stacks up against other viable solutions allows buyers to make informed purchasing decisions. This section compares ‘affordable automatic’ with two alternative solutions: ‘Manual Operation’ and ‘Semi-Automatic Systems’.

Comparison Table of ‘Affordable Automatic’ Against Alternative Solutions

| Comparison Aspect | ‘Affordable Automatic’ | Manual Operation | Semi-Automatic Systems |

|---|---|---|---|

| Performance | High | Variable | Moderate to High |

| Cost | Low initial investment | Low initial investment, high labor costs | Moderate initial investment, low labor costs |

| Ease of Implementation | Easy | Difficult | Moderate |

| Maintenance | Low | High | Moderate |

| Best Use Case | Repetitive tasks | Customized tasks | Tasks requiring some human oversight |

What Are the Pros and Cons of Manual Operation?

Manual operation involves human labor performing tasks without automation.

Pros:

– Flexibility: It allows for tailored solutions to unique business challenges since operators can modify their approach based on real-time conditions.

– Low Initial Investment: There are minimal upfront costs associated with manual processes compared to automated solutions.

Cons:

– High Labor Costs: As tasks scale, labor costs can escalate quickly, reducing overall profitability.

– Variable Performance: Human error can lead to inconsistent results, impacting quality and efficiency.

How Do Semi-Automatic Systems Compare?

Semi-automatic systems bridge the gap between manual and fully automated solutions.

Pros:

– Balance of Control and Efficiency: These systems allow operators to maintain some control while benefiting from automation, making them suitable for tasks that require oversight.

– Moderate Initial Investment: While more expensive than purely manual systems, they often require less capital than full automation.

Cons:

– Complex Implementation: Setting up semi-automatic systems can be challenging and may require specialized training for personnel.

– Maintenance Needs: They often require more frequent maintenance than fully automated systems, which can lead to downtime.

How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate solution, B2B buyers must consider their specific operational needs, budget constraints, and the skill level of their workforce. ‘Affordable automatic’ systems are ideal for businesses focused on repetitive tasks that prioritize efficiency and low maintenance. In contrast, if flexibility or customization is critical, manual operations may be more appropriate, albeit at a higher long-term cost. Semi-automatic systems serve as a middle ground, offering a blend of automation and human control, suitable for businesses that need a moderate level of oversight.

Ultimately, conducting a thorough analysis of your operational requirements and future growth plans will guide you in selecting the best solution tailored to your business context.

Essential Technical Properties and Trade Terminology for affordable automatic

What Are the Key Technical Properties of Affordable Automatic Equipment?

Understanding the technical specifications of affordable automatic equipment is crucial for B2B buyers looking to make informed purchasing decisions. Here are some essential properties that should be considered:

1. Material Grade

The material grade refers to the quality and type of materials used in the construction of automatic equipment. Common materials include stainless steel, aluminum, and plastic composites. Material grade influences durability, corrosion resistance, and overall performance. For buyers in regions like Africa and South America, where harsh environmental conditions can affect equipment longevity, selecting the right material grade can lead to cost savings through reduced maintenance and replacement needs.

2. Tolerance

Tolerance is the permissible limit of variation in a physical dimension. It is vital for ensuring that components fit together properly and function as intended. High tolerance precision is essential in automated systems to maintain efficiency and accuracy. For international buyers, understanding tolerance specifications can help in evaluating whether a supplier can meet specific operational needs, which is particularly important in sectors like manufacturing and agriculture.

3. Cycle Time

Cycle time indicates the duration required for a machine to complete one full operation cycle. Shorter cycle times can enhance productivity, making this a significant consideration for buyers focused on efficiency. For markets in Europe and the Middle East, where labor costs may be high, investing in equipment with optimal cycle times can lead to substantial operational savings.

4. Power Consumption

Power consumption refers to the amount of energy the equipment uses during operation. Understanding this metric is crucial for cost management and sustainability efforts. For B2B buyers in regions with high energy costs or stringent energy regulations, selecting equipment with lower power consumption can significantly impact the total cost of ownership.

What Are Common Trade Terms in the Affordable Automatic Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B space. Here are some key terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can be crucial for buyers seeking quality components and ensuring that their equipment meets industry standards. This is especially relevant for international buyers who may be sourcing from multiple countries.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchasing strategy and inventory management. For buyers in emerging markets, understanding MOQs can facilitate better negotiations and help avoid excess inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. Crafting a clear and detailed RFQ can lead to more accurate quotes and better supplier relationships. For B2B buyers, especially in regions like Nigeria and Vietnam, a well-structured RFQ can streamline the procurement process.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in shipping goods. Familiarity with these terms helps buyers understand their obligations regarding shipping, insurance, and tariffs. For international transactions, especially between Europe and Africa, clarity on Incoterms can prevent disputes and ensure smooth logistics.

5. Lead Time

Lead time is the time taken from placing an order to receiving the goods. Understanding lead times is vital for supply chain management, especially for businesses that rely on timely delivery for operational efficiency. B2B buyers should factor in lead times when planning their production schedules to avoid disruptions.

By grasping these technical properties and trade terms, international B2B buyers can enhance their purchasing decisions, ensuring they select equipment that meets their operational needs while navigating the complexities of global trade.

Navigating Market Dynamics and Sourcing Trends in the affordable automatic Sector

What Are the Current Market Dynamics and Key Trends in the Affordable Automatic Sector?

The affordable automatic sector is experiencing significant growth driven by technological advancements, increasing consumer demand for automation, and a shift towards cost-effective solutions. Global trends indicate a rising interest in smart technologies that enhance productivity while minimizing operational costs. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial.

Emerging technologies such as the Internet of Things (IoT) and artificial intelligence (AI) are reshaping the landscape, enabling manufacturers to produce more sophisticated yet affordable automatic systems. This trend is particularly beneficial for businesses looking to optimize processes without incurring substantial capital expenditures. In addition, the integration of cloud-based solutions allows for real-time data analysis, enhancing decision-making capabilities for buyers.

Sourcing trends are also evolving, with a noticeable shift towards localized supply chains. This change is influenced by the need for agility and responsiveness to market demands, especially in regions with unique logistical challenges. B2B buyers are encouraged to consider suppliers that not only offer competitive pricing but also demonstrate a commitment to innovation and sustainability.

How Is Sustainability and Ethical Sourcing Impacting the Affordable Automatic Sector?

Sustainability has become a cornerstone in the purchasing decisions of B2B buyers. The environmental impact of manufacturing processes in the affordable automatic sector is under scrutiny, prompting companies to adopt greener practices. Ethical sourcing has emerged as a critical component of supply chain management, with businesses increasingly prioritizing suppliers who adhere to environmentally friendly practices.

The importance of ethical supply chains cannot be overstated. B2B buyers are now more aware of how their procurement choices affect local communities and the global environment. By choosing suppliers that utilize sustainable materials and production methods, businesses can not only enhance their corporate social responsibility (CSR) profile but also appeal to a growing segment of eco-conscious consumers.

Certifications such as ISO 14001 for environmental management systems and the use of recycled materials are becoming critical criteria for sourcing decisions. Buyers should actively seek suppliers who can provide proof of their sustainable practices and certifications, ensuring alignment with both regulatory requirements and market expectations.

How Has the Affordable Automatic Sector Evolved Over Time?

The evolution of the affordable automatic sector has been marked by rapid technological advancements and changing market needs. Initially dominated by basic automation tools, the sector has transformed significantly, driven by the demand for more complex and integrated systems. Over the past two decades, innovations in manufacturing processes and materials have made automation more accessible to small and medium-sized enterprises (SMEs), especially in developing regions.

This evolution has been supported by increased investment in R&D, leading to the development of cost-effective solutions that cater to diverse industries. As businesses from Africa, South America, the Middle East, and Europe seek to enhance their operational efficiency, the affordable automatic sector is poised for continuous growth, adapting to the needs of a global marketplace that values innovation, sustainability, and ethical practices.

Related Video: “If US no longer wants to lead, Canada will,” Carney proposes global free trade coalition

Frequently Asked Questions (FAQs) for B2B Buyers of affordable automatic

-

How do I solve the challenge of finding affordable automatic suppliers?

To address the challenge of sourcing affordable automatic products, start by leveraging online B2B platforms such as Alibaba, Global Sources, or TradeIndia. These platforms allow you to filter suppliers by region, product type, and price range. Additionally, consider attending international trade shows and exhibitions in your industry to meet potential suppliers in person. Networking with industry peers can also yield referrals to reputable suppliers. Always request samples and review supplier ratings to ensure quality and reliability before making large orders. -

What is the best approach for vetting suppliers of affordable automatic products?

The best approach to vetting suppliers involves a multi-step process. First, check their business licenses and certifications to ensure legitimacy. Next, request references from previous clients, focusing on those in similar markets or industries. Conduct a factory audit or visit the supplier if possible to assess their production capabilities and working conditions. Additionally, evaluate their communication responsiveness and willingness to accommodate your specific needs, as these factors often reflect their reliability as a partner. -

What are the minimum order quantities (MOQs) for affordable automatic products?

Minimum order quantities (MOQs) can vary significantly between suppliers and product types. Many manufacturers may set MOQs to ensure cost-effectiveness, often ranging from 100 to 1,000 units. However, some suppliers may offer flexibility for first-time buyers or smaller businesses. It’s essential to negotiate these terms upfront and assess whether the MOQ aligns with your budget and inventory strategy. Consider pooling orders with other businesses to meet MOQs if you’re looking to diversify your product range without committing to large quantities. -

What payment terms should I expect when purchasing affordable automatic products internationally?

International payment terms can differ widely based on the supplier’s policies and your negotiation. Common terms include upfront payments, letters of credit, or payment upon delivery. Be aware that suppliers from different regions may have varying levels of trust and risk tolerance. For larger orders, a letter of credit can provide security for both parties. Always clarify payment terms in writing and consider the implications of currency exchange rates and transaction fees, particularly when dealing with suppliers from Africa, South America, the Middle East, and Europe. -

How can I customize affordable automatic products to meet my specific needs?

Customization options for affordable automatic products largely depend on the supplier’s capabilities. When discussing your needs, be specific about the features, designs, or branding elements you want. Many suppliers may offer standard customization services for an additional fee, including color adjustments, logo placements, or added functionalities. Ensure you request prototypes to verify that the customizations meet your expectations before placing a larger order. It’s also advisable to discuss timelines for customization to avoid delays in your supply chain. -

What quality assurance measures should I consider when sourcing affordable automatic products?

Quality assurance is crucial when sourcing products internationally. Start by requesting certifications relevant to your industry, such as ISO or CE marks, which indicate compliance with international standards. Implement a quality control process that includes pre-production samples, in-line inspections during manufacturing, and final product checks before shipment. Consider hiring a third-party inspection service to verify product quality and adherence to specifications. Establishing clear quality expectations in your purchase agreement can also help mitigate risks. -

What logistics considerations should I keep in mind when importing affordable automatic products?

When importing affordable automatic products, logistics plays a pivotal role in ensuring timely delivery. Evaluate shipping options such as air freight versus sea freight based on your budget and urgency. Understand the customs regulations and duties applicable in your country, as these can significantly impact your total landed cost. Partnering with a reliable freight forwarder can streamline the shipping process, helping you navigate documentation and compliance requirements. Additionally, consider the supplier’s location in relation to major shipping ports to optimize shipping times and costs. -

How can I mitigate risks when sourcing affordable automatic products from different regions?

Mitigating risks when sourcing from various regions involves thorough research and proactive measures. Diversify your supplier base to avoid over-reliance on a single source. Establish clear contracts that outline quality expectations, delivery timelines, and payment terms. Stay informed about political and economic conditions in the supplier’s region, as these can affect supply chain stability. Regular communication with suppliers and monitoring industry trends can also help you anticipate potential disruptions and adjust your sourcing strategy accordingly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for affordable automatic

In summary, the strategic sourcing of affordable automatic solutions is not merely a procurement process; it represents a crucial investment in operational efficiency and long-term profitability for businesses across Africa, South America, the Middle East, and Europe. By leveraging local suppliers and fostering strong partnerships, international B2B buyers can enhance their supply chain resilience while accessing innovative technologies tailored to their market needs.

What are the key benefits of strategic sourcing for international buyers? Emphasizing cost savings, quality assurance, and sustainability, strategic sourcing empowers businesses to make informed decisions that align with their growth objectives. It enables buyers to navigate the complexities of global markets while capitalizing on emerging opportunities, such as increased demand for automation in various sectors.

As we look to the future, the importance of adaptability in sourcing strategies cannot be overstated. International buyers are encouraged to stay abreast of market trends, technological advancements, and regulatory changes that may impact sourcing decisions. Engaging with local suppliers, attending industry trade events, and participating in cross-border collaborations can significantly enhance the sourcing experience.

Take action today: evaluate your current sourcing strategies and explore the vast network of suppliers available to you. Embrace the potential of affordable automatic solutions to drive your business forward in an increasingly competitive global landscape.