Maximize Efficiency: The Complete Thermo Couple Guide (2025)

Introduction: Navigating the Global Market for thermo couple

Navigating the global market for thermocouples can be a daunting task for B2B buyers, especially when sourcing reliable temperature measurement solutions that cater to diverse industrial applications. As industries across Africa, South America, the Middle East, and Europe increasingly rely on thermocouples for their efficiency and accuracy, understanding the various types and specifications becomes crucial. This comprehensive guide delves into the different types of thermocouples available, their applications in sectors like manufacturing, HVAC, and food processing, as well as strategies for supplier vetting and cost evaluation.

B2B buyers will benefit from insights into the nuances of thermocouple selection, including temperature tolerances, wire gauges, and accuracy requirements. We will also explore the importance of understanding local and international standards and certifications that can impact purchasing decisions. By equipping international buyers with knowledge of market trends and supplier landscapes, this guide aims to empower informed purchasing choices that align with specific operational needs and budget constraints. Whether you are sourcing thermocouples for high-temperature applications in metallurgy or for precise measurements in scientific research, this guide serves as your go-to resource for navigating the complexities of the global thermocouple market.

Understanding thermo couple Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type K | Nickel-chromium/nickel-aluminum; wide temperature range (-200°C to 1260°C) | Industrial ovens, kilns, and exhaust systems | Pros: Durable, versatile, and cost-effective. Cons: Sensitive to high humidity and oxidation. |

| Type J | Iron/constantan; suitable for lower temperature ranges (-40°C to 750°C) | Food processing, plastics, and HVAC systems | Pros: Low cost and good accuracy. Cons: Limited to lower temperatures, prone to rust. |

| Type T | Copper/constantan; excellent for cryogenic applications (-200°C to 350°C) | Refrigeration, cryogenic research, and food storage | Pros: High accuracy and stable in moist environments. Cons: Limited temperature range and less robust than other types. |

| Type R | Platinum/rhodium; high-temperature capability (0°C to 1600°C) | Metallurgy, ceramics, and high-end laboratories | Pros: Very stable and accurate at high temperatures. Cons: Expensive and can be less durable in harsh environments. |

| Type S | Platinum/rhodium; similar to Type R but with slightly different composition (0°C to 1600°C) | Aerospace, pharmaceuticals, and research labs | Pros: High accuracy and excellent stability. Cons: High cost and requires careful handling. |

What Are the Characteristics of Type K Thermocouples?

Type K thermocouples consist of nickel-chromium and nickel-aluminum alloys, making them suitable for a wide temperature range from -200°C to 1260°C. Their durability and cost-effectiveness make them a popular choice in various industrial applications, including ovens, kilns, and exhaust systems. When considering a Type K thermocouple, buyers should assess the operating environment, as they can be sensitive to high humidity and oxidation, which may affect their performance over time.

Why Choose Type J Thermocouples for Specific Applications?

Type J thermocouples are composed of iron and constantan, offering a temperature range of -40°C to 750°C. They are often used in food processing and HVAC systems due to their low cost and good accuracy. However, buyers should be cautious as Type J thermocouples are prone to rust and are only suitable for lower temperature applications. When selecting a Type J, consider the environmental conditions and potential exposure to moisture.

What Makes Type T Thermocouples Ideal for Cryogenic Applications?

Type T thermocouples utilize copper and constantan, making them particularly effective in cryogenic applications with a temperature range of -200°C to 350°C. Their high accuracy and stability in moist environments make them suitable for refrigeration and food storage. However, their limited temperature range and relative fragility compared to other types mean that buyers should evaluate their specific needs and consider the operational conditions before purchasing.

When to Use Type R Thermocouples in High-Temperature Environments?

Type R thermocouples, made from platinum and rhodium, can withstand high temperatures ranging from 0°C to 1600°C. They are ideal for applications in metallurgy, ceramics, and high-end laboratories due to their stability and accuracy at elevated temperatures. However, their high cost and potential lack of durability in harsh environments are critical considerations for B2B buyers. It’s essential to weigh the benefits against the investment required for Type R thermocouples.

How Do Type S Thermocouples Compare in Precision and Cost?

Type S thermocouples are similar to Type R but feature a slightly different composition of platinum and rhodium, also operating within a range of 0°C to 1600°C. They are favored in aerospace, pharmaceuticals, and research labs for their high accuracy and excellent stability. However, the cost is significantly higher compared to other types, and they require careful handling. Buyers should consider both the precision needed for their applications and the budget available when selecting Type S thermocouples.

Key Industrial Applications of thermo couple

| Industry/Sector | Specific Application of Thermocouple | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Temperature monitoring in kilns and furnaces | Ensures optimal firing temperatures, reducing waste | Temperature range, response time, and durability needed |

| Oil & Gas | Monitoring temperatures in drilling operations | Enhances safety by preventing overheating | High-temperature tolerance and resistance to corrosive environments |

| Food Processing | Temperature control in pasteurization processes | Ensures food safety and compliance with regulations | Compliance with food safety standards and accuracy |

| HVAC Systems | Monitoring and controlling air temperatures | Improves energy efficiency and comfort in buildings | Type selection based on environment and installation requirements |

| Automotive | Exhaust temperature measurement in engines | Optimizes engine performance and emissions control | Calibration type for specific applications and compatibility with existing systems |

How Are Thermocouples Used in Manufacturing?

In the manufacturing sector, thermocouples are essential for monitoring temperatures in kilns and furnaces. By providing real-time temperature data, they help maintain optimal firing temperatures, which is crucial for product quality and minimizing waste. B2B buyers in this industry must consider the temperature range and durability of the thermocouples, as extreme conditions can lead to failure if not properly sourced. Additionally, response time is critical; delays can result in costly production errors.

What Role Do Thermocouples Play in the Oil & Gas Industry?

In the oil and gas sector, thermocouples are used to monitor temperatures during drilling operations. This application is vital for preventing overheating, which can pose significant safety risks. For international buyers, particularly from regions with extreme conditions, sourcing thermocouples that can withstand high temperatures and corrosive environments is essential. Buyers should also ensure that the thermocouples are compatible with their existing systems to avoid integration issues.

How Are Thermocouples Essential in Food Processing?

Thermocouples are crucial in the food processing industry, particularly for temperature control during pasteurization. Accurate temperature readings ensure compliance with food safety regulations, thereby protecting consumers and avoiding costly recalls. B2B buyers need to prioritize thermocouples that meet food safety standards and provide high accuracy. Additionally, sourcing thermocouples that are easy to clean and maintain can significantly enhance operational efficiency.

How Do Thermocouples Improve HVAC Systems?

In HVAC systems, thermocouples are used to monitor and control air temperatures. This application is critical for improving energy efficiency and ensuring comfort in residential and commercial buildings. Buyers from diverse regions should select thermocouples based on their specific environmental conditions and installation requirements. Factors such as type selection (e.g., Type K, T, or J) and compatibility with existing HVAC controls are vital for optimal performance.

Why Are Thermocouples Important in the Automotive Sector?

In the automotive industry, thermocouples measure exhaust temperatures in engines to optimize performance and control emissions. This application is increasingly important as regulations become stricter globally. B2B buyers must consider the calibration type suitable for their specific applications and ensure compatibility with existing systems to facilitate smooth operations. Sourcing high-quality thermocouples can lead to better fuel efficiency and lower emissions, aligning with sustainability goals.

3 Common User Pain Points for ‘thermo couple’ & Their Solutions

Scenario 1: Selecting the Right Type of Thermocouple for Specific Applications

The Problem: B2B buyers often struggle with selecting the appropriate type of thermocouple for their unique applications. With various thermocouple types available—such as Type K, Type J, and Type T—each possessing distinct temperature ranges and characteristics, buyers can feel overwhelmed. This misalignment can lead to equipment malfunction, increased downtime, and ultimately, financial losses. For example, using a Type J thermocouple in a high-temperature metallurgical process where a Type K is required can result in inaccurate readings and potential damage to the sensor.

The Solution: To effectively choose the right thermocouple, buyers should first assess the specific temperature ranges and environmental conditions of their applications. Conduct thorough research on the different thermocouple types and their respective material compositions, as this directly affects their performance. Collaborate with manufacturers or distributors who can provide detailed specifications and recommendations based on industry standards. Furthermore, consider investing in a comprehensive thermocouple selection guide or training session for your technical team. This proactive approach ensures that the selected thermocouple aligns perfectly with operational requirements, thereby reducing the risk of equipment failure and optimizing process efficiency.

Scenario 2: Dealing with Inaccurate Temperature Readings

The Problem: Inaccurate temperature readings can be a significant pain point for B2B buyers utilizing thermocouples in critical processes. These inaccuracies may stem from various factors, including poor installation, incorrect calibration, or environmental interferences. For instance, a thermocouple installed near electrical equipment may pick up stray electromagnetic interference, resulting in false readings that could jeopardize product quality and safety.

The Solution: To mitigate inaccuracies, buyers should prioritize proper installation techniques. Ensure that thermocouples are installed in locations that minimize exposure to electromagnetic fields and thermal gradients. Conduct regular calibration checks to maintain accuracy over time. Utilizing high-quality thermocouples equipped with built-in noise-reduction features can also help. Additionally, consider implementing a robust maintenance schedule that includes periodic inspections and recalibrations. By establishing these practices, businesses can maintain reliable temperature measurements, which are crucial for quality control and operational efficiency.

Scenario 3: Managing Thermocouple Wear and Tear

The Problem: Thermocouples are subject to wear and tear over time, especially in demanding environments such as industrial furnaces, HVAC systems, and food processing plants. B2B buyers often face challenges when it comes to monitoring the lifespan of their thermocouples. A failure to replace worn-out thermocouples can lead to catastrophic equipment failures or production delays, ultimately affecting the bottom line.

The Solution: To effectively manage thermocouple longevity, buyers should implement a proactive monitoring strategy. This can include utilizing thermocouples with built-in diagnostics that provide real-time feedback on performance and wear levels. Establishing a routine inspection protocol will help identify signs of degradation early on. It’s also advisable to maintain an inventory of critical thermocouple types to enable quick replacements when necessary. Lastly, consider working closely with suppliers who can provide predictive maintenance services or alerts based on usage patterns. By taking these steps, businesses can ensure continuous operation and minimize downtime due to thermocouple failures.

Strategic Material Selection Guide for thermo couple

What Are the Common Materials Used in Thermocouples?

When selecting thermocouples for industrial applications, the choice of materials is crucial to ensure optimal performance, reliability, and compliance with local and international standards. Below, we analyze several common materials used in thermocouples, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Do Different Thermocouple Materials Perform?

1. Type K (Chromel-Alumel)

Key Properties:

Type K thermocouples are made from Chromel (nickel-chromium alloy) and Alumel (nickel-aluminum alloy). They can operate in a temperature range from -200°C to 1260°C (-328°F to 2300°F) and have good resistance to oxidation.

Pros & Cons:

The durability of Type K thermocouples makes them suitable for a wide range of applications, including gas turbine engines and industrial furnaces. However, they can suffer from drift in high-temperature environments, which may affect accuracy over time.

Impact on Application:

They are compatible with various media, including air and non-corrosive gases. However, they should not be used in environments with sulfur or other corrosive elements.

Considerations for International Buyers:

Type K thermocouples are recognized globally and comply with ASTM E230 standards. Buyers from regions like Europe and Australia should ensure compliance with local regulations regarding temperature measurement devices.

2. Type J (Iron-Constantan)

Key Properties:

Type J thermocouples consist of iron and constantan (copper-nickel alloy). They have a temperature range of -40°C to 750°C (-40°F to 1382°F) and are particularly effective in vacuum or inert gas environments.

Pros & Cons:

One of the main advantages is their cost-effectiveness and ease of use. However, they are not suitable for high-temperature applications due to the iron component’s susceptibility to oxidation, which can lead to rapid degradation.

Impact on Application:

Type J thermocouples are best suited for applications involving non-oxidizing atmospheres. They are not recommended for use in environments with moisture or corrosive chemicals.

Considerations for International Buyers:

When sourcing Type J thermocouples, buyers should verify compliance with JIS and DIN standards, especially in the Middle East and Europe, where strict adherence to quality and safety standards is mandatory.

3. Type T (Copper-Constantan)

Key Properties:

Type T thermocouples are made of copper and constantan, offering a temperature range from -200°C to 350°C (-328°F to 662°F). They are known for their excellent stability and accuracy in low-temperature applications.

Pros & Cons:

They are highly resistant to corrosion, making them ideal for use in moist environments. However, their limited temperature range may restrict their use in high-heat applications.

Impact on Application:

Type T thermocouples are particularly suitable for food processing and pharmaceutical applications due to their non-corrosive nature.

Considerations for International Buyers:

Type T thermocouples meet ASTM E230 standards, making them a reliable choice for buyers in Africa and South America, where compliance with international standards is often required.

4. Type R and S (Platinum-Rhodium)

Key Properties:

Type R and S thermocouples are made from platinum-rhodium alloys and can operate at temperatures up to 1600°C (2912°F). They offer high accuracy and stability, particularly in high-temperature applications.

Pros & Cons:

These thermocouples are extremely durable and provide excellent performance in harsh environments. However, they are significantly more expensive than other types, which may not be feasible for all applications.

Impact on Application:

Type R and S thermocouples are ideal for use in metallurgy and high-precision applications, such as laboratories and aerospace.

Considerations for International Buyers:

Due to their high cost, buyers should consider the total cost of ownership and ensure compliance with international standards like ASTM E230 and ISO 9001 to justify the investment.

Summary Table of Thermocouple Materials

| Material | Typical Use Case for Thermocouple | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Type K | Industrial furnaces, gas turbine engines | Wide temperature range | Drift in high temperatures | Medium |

| Type J | Non-oxidizing atmospheres, low-cost apps | Cost-effective | Not suitable for high temperatures | Low |

| Type T | Food processing, pharmaceuticals | Corrosion-resistant | Limited temperature range | Medium |

| Type R/S | Metallurgy, high-precision applications | High accuracy and durability | High cost | High |

Understanding the characteristics and applications of various thermocouple materials is essential for international B2B buyers to make informed purchasing decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for thermo couple

What Are the Key Stages in the Manufacturing Process of Thermocouples?

The manufacturing process of thermocouples involves several critical stages that ensure the final product meets the required performance standards. Understanding these stages is essential for B2B buyers to evaluate potential suppliers effectively.

1. Material Preparation

The first step in thermocouple manufacturing is the selection and preparation of materials. Typically, thermocouples are made from two dissimilar metals or alloys, such as nickel, iron, or platinum. Each material is chosen based on the required temperature range and application. The raw materials undergo a cleaning process to remove any contaminants that could affect conductivity and measurement accuracy.

2. Forming Techniques

After preparing the materials, the next stage involves forming the thermocouple wires. This is typically achieved through processes such as drawing, which reduces the diameter of the metal wire to the desired gauge. Precision in this step is critical since the wire gauge influences the thermocouple’s temperature tolerance and response time. Advanced techniques like cold working may also be employed to enhance the mechanical properties of the wires.

3. Assembly of Thermocouple Components

Once the wires are formed, they are joined to create the thermocouple junction. This is done by twisting, welding, or soldering the two wires together at their ends. The junction is the critical point where the temperature is measured, so the quality of this connection directly impacts the thermocouple’s accuracy. Different assembly methods are employed based on the thermocouple type, such as beaded, weld pad, or stick-on configurations.

4. Finishing Processes

The final stage in the manufacturing process involves finishing techniques that protect the thermocouple from environmental factors. This includes insulation, which can be made from materials like ceramic or mineral compounds, and protective sheaths that may be added for durability. The finishing process ensures that the thermocouple can withstand harsh operating conditions while maintaining measurement accuracy.

What Quality Assurance Measures Are Essential in Thermocouple Manufacturing?

Quality assurance (QA) is paramount in thermocouple manufacturing, ensuring that products meet international standards and customer specifications. B2B buyers should be aware of the QA measures implemented by suppliers.

International Standards for Quality Assurance in Thermocouples

Reputable thermocouple manufacturers adhere to international quality standards such as ISO 9001. This certification indicates that the company has a robust quality management system in place. Additionally, specific industry standards may apply, such as CE marking for products sold in Europe or API standards for thermocouples used in the oil and gas industry.

Key Quality Control Checkpoints

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards. This step is crucial as the quality of materials directly affects the final product.

-

In-Process Quality Control (IPQC): During manufacturing, continuous checks are performed to monitor the process and detect any deviations from the standard. This may include dimensional checks, electrical testing, and visual inspections.

-

Final Quality Control (FQC): Before dispatch, thermocouples undergo comprehensive testing to verify their performance. This may involve calibration against known temperature references and ensuring compliance with accuracy requirements.

What Testing Methods Are Commonly Used for Thermocouples?

Various testing methods are employed to ensure the functionality and reliability of thermocouples. Understanding these methods can help B2B buyers assess the capabilities of their suppliers.

-

Calibration Testing: This is performed to determine the accuracy of the thermocouple at different temperature points. Calibration is essential for ensuring that the thermocouple provides reliable readings in actual applications.

-

Response Time Testing: Thermocouples must respond quickly to temperature changes. Response time tests help determine how quickly a thermocouple can reach a stable reading after exposure to a temperature change.

-

Durability Testing: Manufacturers may conduct tests to simulate the thermocouple’s performance under extreme conditions, such as high temperatures or corrosive environments, to ensure it can withstand its intended application.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial in ensuring they receive high-quality thermocouples. Here are some actionable insights:

Conduct Supplier Audits

Regular audits of potential suppliers can help assess their manufacturing processes and quality assurance measures. Buyers should look for evidence of compliance with international standards and documentation of quality control procedures.

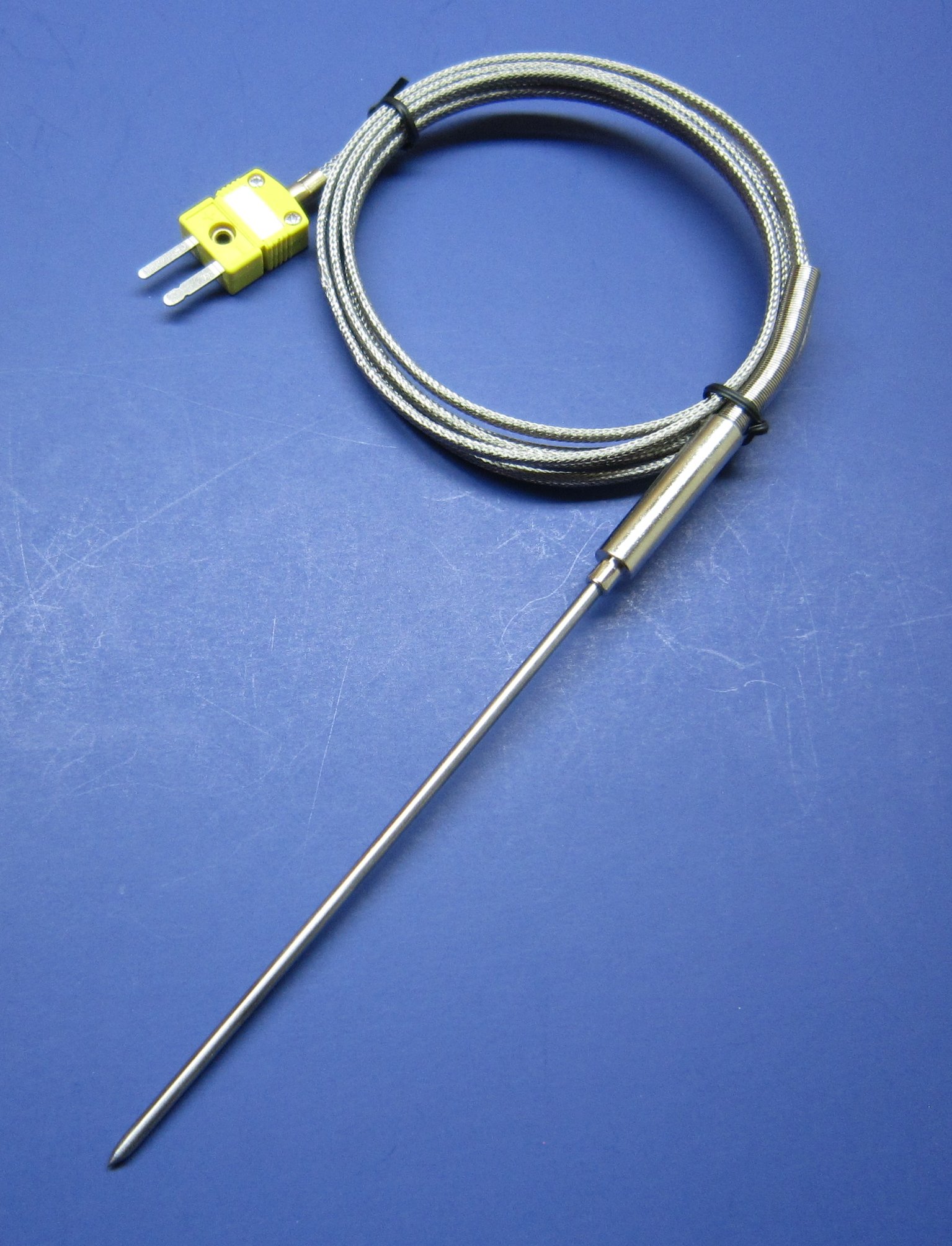

A stock image related to thermo couple.

Request Quality Control Reports

B2B buyers should ask suppliers for detailed quality control reports that outline their testing procedures, results, and any corrective actions taken. This documentation provides transparency and assurance regarding the quality of the products.

Utilize Third-Party Inspections

Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices. These services can verify compliance with industry standards and perform on-site inspections of manufacturing facilities.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When sourcing thermocouples from international suppliers, B2B buyers should be aware of specific nuances in quality control and certification:

-

Regional Standards Compliance: Different regions may have unique certification requirements. For instance, thermocouples sold in Europe must comply with CE marking, while those in North America may require UL certification. Understanding these regulations is essential for compliance.

-

Documentation for Customs: Proper documentation of quality certifications is vital for smooth customs clearance. Buyers should ensure that suppliers provide all necessary certificates and reports to avoid delays and additional costs.

-

Cultural Considerations: Quality assurance practices may vary across different countries. B2B buyers should consider cultural differences in manufacturing and quality control approaches, which may impact the overall quality of thermocouples.

By comprehensively understanding the manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when sourcing thermocouples, ensuring they receive reliable products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘thermo couple’

To ensure a successful procurement process for thermocouples, it’s essential to follow a structured approach. This guide provides a step-by-step checklist tailored for international B2B buyers from Africa, South America, the Middle East, and Europe. By adhering to these steps, you can mitigate risks and make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Before you start sourcing, clearly outline your technical requirements. This includes determining the type of thermocouple needed based on temperature range, accuracy, and application.

– Considerations: Identify if you need a Type K, J, or T thermocouple, as each serves different temperature tolerances and environments.

– Documentation: Prepare a detailed specification sheet that includes wire gauge, insulation type, and mounting options.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reputable suppliers. Utilize online directories, industry forums, and trade shows to gather a list of potential vendors.

– Key Resources: Websites like ThomasNet, Alibaba, and regional trade associations can provide valuable insights.

– Supplier Location: Consider suppliers with local representation or those experienced in your specific market to facilitate easier communication and support.

Step 3: Evaluate Supplier Capabilities and Certifications

Assess the technical capabilities and certifications of your shortlisted suppliers. Certification to international standards (such as ISO 9001) is a good indicator of quality assurance.

– Request Documentation: Ask for product certifications, quality control processes, and compliance with relevant industry standards.

– Case Studies: Review case studies or references from similar applications to gauge their experience and reliability.

Step 4: Verify Product Quality and Testing Procedures

Prioritize suppliers that have stringent testing procedures in place to ensure product reliability. This is crucial for thermocouples, where accuracy is paramount.

– Testing Methods: Inquire about their testing methods for accuracy, calibration, and durability.

– Samples: Request samples or prototypes to evaluate performance in your specific application before making bulk purchases.

Step 5: Assess Pricing and Payment Terms

Once you’ve narrowed down your options, compare pricing structures and payment terms across suppliers. Consider not just the unit price but also the total cost of ownership.

– Consider Hidden Costs: Factor in shipping, customs duties, and potential tariffs, especially if importing from overseas.

– Negotiation: Don’t hesitate to negotiate terms that fit your budget and cash flow needs.

Step 6: Understand Lead Times and Delivery Options

Clarify lead times and delivery options with your selected suppliers. This is vital for planning your operations effectively.

– Flexibility: Determine if the supplier can accommodate urgent orders or fluctuations in demand.

– Logistics: Evaluate the logistics capabilities, including shipping methods and tracking options, to ensure timely delivery.

Step 7: Establish a Communication Protocol

Effective communication is crucial throughout the sourcing process. Establish a clear communication protocol with your supplier to ensure transparency and quick resolution of any issues.

– Regular Updates: Set expectations for regular updates on order status, production timelines, and shipping information.

– Contact Points: Identify primary contacts on both sides to streamline communication and address any concerns promptly.

Following this practical sourcing guide will help international B2B buyers navigate the complexities of procuring thermocouples, ensuring they choose the right products from reliable suppliers while optimizing costs and efficiency.

Comprehensive Cost and Pricing Analysis for thermo couple Sourcing

What Are the Key Cost Components in Thermocouple Manufacturing?

When sourcing thermocouples, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of metals or alloys significantly impacts costs. Common thermocouples like Type K, J, and T use base metals, while higher-end types (e.g., R, S) use noble metals, which are more expensive.

-

Labor: Skilled labor is necessary for precision manufacturing, particularly for specialized thermocouples. Labor costs can vary by region; for example, sourcing from regions with lower labor costs could reduce overall expenses.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and maintenance. Efficient manufacturing processes can lower these overheads, but they may vary significantly between suppliers.

-

Tooling: Custom tooling for specialized thermocouples can be a substantial investment. Buyers should inquire about the tooling costs associated with their specific requirements.

-

Quality Control (QC): Rigorous QC processes ensure the accuracy and reliability of thermocouples. Suppliers with robust QC protocols may charge higher prices, but this can lead to long-term cost savings by reducing failures.

-

Logistics: Shipping costs, customs duties, and insurance can add to the total cost, especially for international transactions. Understanding Incoterms can help buyers manage these logistics expenses effectively.

-

Margin: Suppliers will typically include a profit margin in their pricing. This can vary widely based on market conditions, supplier reputation, and demand.

How Do Price Influencers Affect Thermocouple Costs?

Several factors influence thermocouple pricing, which buyers should consider:

-

Volume/MOQ: Purchasing in larger quantities often reduces the unit price. Buyers should negotiate minimum order quantities (MOQs) to achieve better pricing.

-

Specifications and Customization: Custom specifications can increase costs. Clear communication about requirements can help avoid unnecessary expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (like ISO) often lead to higher prices. However, these can ensure better performance and longevity, impacting the total cost of ownership.

-

Supplier Factors: The supplier’s reputation, production capabilities, and location can influence pricing. Established suppliers may charge more due to their reliability and service.

-

Incoterms: Understanding the terms of shipping and delivery can impact costs. For example, choosing DDP (Delivered Duty Paid) can simplify logistics but may come at a higher price.

What Tips Can Help Buyers Navigate Thermocouple Pricing?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, here are actionable tips to ensure cost-efficiency:

-

Negotiate Terms: Don’t hesitate to negotiate pricing, payment terms, and delivery schedules. Building a long-term relationship with suppliers can yield better terms over time.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the upfront cost, but also maintenance, replacement, and operational costs. A slightly higher initial investment in a quality thermocouple can result in lower TCO.

-

Research Local Suppliers: Investigating local suppliers can reduce shipping costs and lead times, benefiting your overall sourcing strategy.

-

Stay Informed on Market Trends: Keeping abreast of market trends and material costs can provide leverage during negotiations. Awareness of fluctuations in metal prices, for example, can inform your purchasing decisions.

-

Understand Pricing Nuances: Different regions may have varying pricing structures based on local demand, production capabilities, and logistics costs. Understanding these nuances can help buyers make informed decisions.

Disclaimer on Indicative Prices

Prices for thermocouples can vary widely based on the factors mentioned above. It is essential for buyers to obtain quotes from multiple suppliers and consider all aspects of the cost structure before making a decision.

Alternatives Analysis: Comparing thermo couple With Other Solutions

When considering temperature measurement solutions, it’s essential for B2B buyers to evaluate various alternatives to thermocouples. Each technology comes with unique advantages and limitations that can significantly impact operational efficiency and costs. This section delves into a comparative analysis of thermocouples against two viable alternatives: Resistance Temperature Detectors (RTDs) and Infrared Sensors.

Comparison Table of Temperature Measurement Solutions

| Comparison Aspect | Thermo Couple | Resistance Temperature Detector (RTD) | Infrared Sensor |

|---|---|---|---|

| Performance | Fast response, wide temperature range | High accuracy, stable over time | Non-contact, quick response |

| Cost | Generally low cost | Moderate to high cost | Moderate cost |

| Ease of Implementation | Simple installation | More complex wiring | Easy to set up, no contact needed |

| Maintenance | Minimal maintenance | Requires calibration | Low maintenance |

| Best Use Case | Industrial processes, exhaust systems | Laboratory settings, HVAC systems | Surface temperature measurements, moving targets |

What Are the Advantages and Disadvantages of Resistance Temperature Detectors (RTDs)?

RTDs are known for their high accuracy and stability over time, making them ideal for applications requiring precise temperature control. They operate on the principle that the resistance of a metal changes with temperature. However, RTDs tend to be more expensive than thermocouples, which can be a significant consideration for budget-conscious projects. Additionally, their installation can be more complex due to the need for proper wiring and calibration.

How Do Infrared Sensors Compare to Thermocouples?

Infrared sensors provide a non-contact method for measuring temperature, which is advantageous in situations where direct contact with the object is impractical or could alter the object’s temperature. They offer a quick response time and are easy to install, making them suitable for moving targets or hazardous environments. However, they may not provide the same level of accuracy as thermocouples or RTDs, especially at varying distances or when measuring shiny surfaces. Additionally, infrared sensors can be more costly depending on the sensitivity and range required.

Conclusion: How to Choose the Right Temperature Measurement Solution for Your Needs

A stock image related to thermo couple.

Selecting the appropriate temperature measurement solution involves assessing your specific application requirements, including budget, accuracy, and installation conditions. Thermocouples are an excellent choice for cost-effective, versatile applications, particularly in industrial settings. In contrast, if precision and stability are paramount, RTDs might be more suitable despite their higher cost and complexity. For applications where contact is impractical, infrared sensors offer an efficient alternative, although they may sacrifice some accuracy. By carefully evaluating these factors, B2B buyers can make informed decisions that align with their operational goals and budgetary constraints.

Essential Technical Properties and Trade Terminology for thermo couple

What Are the Essential Technical Properties of Thermocouples?

Understanding the critical specifications of thermocouples is vital for international B2B buyers, especially when making informed purchasing decisions. Here are some essential technical properties:

How Does Material Grade Affect Thermocouple Performance?

The material grade of a thermocouple refers to the specific metals or alloys used in its construction. Common types include Type K (Nickel-Chromium vs. Nickel-Alumel) and Type J (Iron vs. Constantan). The choice of material impacts the thermocouple’s temperature range, sensitivity, and durability. For example, Type K thermocouples are popular for their wide temperature range (from -200°C to +1260°C) and resistance to oxidation, making them suitable for various industrial applications. Selecting the appropriate material grade ensures optimal performance for specific temperature measurements.

Why Is Temperature Tolerance Important in Thermocouples?

Temperature tolerance indicates the range within which a thermocouple can accurately measure temperature without significant error. Different types of thermocouples have varying tolerances; for instance, Type T thermocouples are known for their stability at low temperatures. Understanding the temperature tolerance is crucial for applications in sectors like manufacturing, food processing, and energy, where precise temperature control is necessary for product quality and safety.

How Does Wire Gauge Impact Thermocouple Functionality?

Wire gauge relates to the thickness of the thermocouple wires, which affects their heat resistance and response time. Thicker wires can endure higher temperatures for extended periods without degradation, making them suitable for high-temperature environments like metallurgy. B2B buyers should consider wire gauge when selecting thermocouples for applications that demand reliability and longevity, ensuring they meet operational requirements.

What Is the Significance of Accuracy and Error Tolerance in Thermocouples?

Accuracy refers to how closely a thermocouple’s readings match the actual temperature, while error tolerance indicates the maximum allowable deviation from true temperature. High-precision applications, such as laboratory experiments or quality control in manufacturing, require thermocouples with error tolerances of less than 1°C. Understanding these specifications helps buyers select thermocouples that align with their quality assurance standards and operational requirements.

What Are Common Trade Terms Related to Thermocouples?

Navigating the thermocouple market involves familiarity with specific trade terminology. Here are some essential terms that every B2B buyer should understand:

What Does OEM Stand For in Thermocouple Manufacturing?

OEM stands for Original Equipment Manufacturer. In the thermocouple industry, it refers to companies that produce thermocouples for other brands or businesses. Understanding OEM relationships can help buyers identify reliable suppliers and assess the quality of products based on the manufacturer’s reputation.

Why Is MOQ Important for Purchasing Thermocouples?

MOQ, or Minimum Order Quantity, signifies the smallest quantity of thermocouples that a supplier is willing to sell. This term is crucial for B2B buyers, as it affects inventory management and cost efficiency. Knowing the MOQ allows buyers to plan their purchases effectively and avoid overstocking or underordering.

What Is an RFQ and How Does It Relate to Thermocouple Procurement?

An RFQ, or Request for Quotation, is a standard business process where buyers solicit price quotes from suppliers for specific thermocouple products. This process enables buyers to compare prices, terms, and conditions, ensuring they receive the best value for their investment.

How Do Incoterms Affect Thermocouple Shipping and Delivery?

Incoterms, or International Commercial Terms, define the responsibilities of buyers and sellers in international transactions, including shipping and delivery conditions. Understanding Incoterms is essential for B2B buyers to ensure clarity on shipping costs, risks, and responsibilities, ultimately facilitating smoother procurement processes.

Conclusion

Being well-versed in the technical properties and trade terminology related to thermocouples equips international B2B buyers with the knowledge needed to make informed purchasing decisions. By focusing on material grades, temperature tolerances, wire gauges, accuracy, and key industry terms, buyers can navigate the thermocouple market more effectively and ensure they select the right products for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the thermo couple Sector

What Are the Key Market Dynamics and Trends Influencing Thermocouple Sourcing?

The thermocouple market is experiencing significant growth driven by the increasing demand for temperature measurement across various industries, including manufacturing, automotive, and energy. The rise of Industry 4.0 and the Internet of Things (IoT) is pushing the adoption of smart sensors, including thermocouples, that can provide real-time data for better operational efficiencies. In regions like Africa and South America, burgeoning industrial sectors are creating opportunities for thermocouple suppliers, while buyers from Europe and the Middle East are increasingly looking for advanced technologies that can enhance precision and reliability.

Emerging trends such as miniaturization and the integration of thermocouples into more compact systems are reshaping product offerings. Suppliers are responding to these trends by developing specialized types of thermocouples, such as miniature and quick-disconnect models, which are essential for space-constrained applications. Additionally, advancements in materials and manufacturing processes are enhancing the durability and accuracy of thermocouples, making them suitable for extreme environments.

International B2B buyers must stay informed about these market dynamics to make strategic sourcing decisions. Engaging with suppliers who offer customized solutions tailored to specific industry needs can provide a competitive edge. Furthermore, understanding the local regulations and compliance requirements in each region is crucial for successful sourcing.

How Can International B2B Buyers Incorporate Sustainability and Ethical Sourcing in Thermocouple Procurement?

Sustainability and ethical sourcing are becoming increasingly important in the thermocouple sector. The environmental impact of manufacturing processes, including resource depletion and waste generation, necessitates a shift towards more sustainable practices. B2B buyers should prioritize suppliers who demonstrate commitment to environmentally friendly practices, such as using recycled materials and minimizing waste during production.

Green certifications and eco-labels, such as ISO 14001 for environmental management, can serve as indicators of a supplier’s commitment to sustainability. Buyers should also inquire about the sourcing of raw materials, opting for suppliers that ensure responsible mining and processing, particularly for metals used in thermocouples. This not only enhances corporate social responsibility but also aligns with the increasing consumer demand for sustainable products.

Incorporating sustainability into procurement strategies can also lead to cost savings. Suppliers that focus on reducing energy consumption and waste can pass these savings onto buyers, creating a win-win situation. Additionally, fostering long-term relationships with ethically responsible suppliers can lead to enhanced brand loyalty and market reputation.

A stock image related to thermo couple.

What Is the Historical Context of Thermocouples and Their Evolution in B2B Markets?

The history of thermocouples dates back to the early 19th century when Thomas Johann Seebeck discovered the thermoelectric effect, laying the groundwork for their development. Initially, thermocouples were primarily used in scientific applications, but their versatility has led to widespread adoption across various industries. Over the years, advancements in materials science and engineering have significantly improved the performance of thermocouples, making them more reliable and easier to integrate into modern systems.

Today, thermocouples are integral components in various applications, from industrial ovens to automotive exhaust systems. Their evolution reflects the broader trends in technology and manufacturing, emphasizing the importance of accurate temperature measurement in optimizing processes and ensuring safety. For B2B buyers, understanding this historical context can provide valuable insights into the ongoing innovations and future directions of the thermocouple market.

Frequently Asked Questions (FAQs) for B2B Buyers of thermo couple

-

How do I choose the right thermocouple for my application?

Choosing the right thermocouple involves understanding your specific temperature range, environment, and application requirements. For high-temperature applications, Type K thermocouples are ideal due to their durability and wide temperature range. If you’re working in a magnetic environment, consider Type J thermocouples, which are made of iron. Additionally, assess the wire gauge; thicker wires can withstand higher temperatures longer. Evaluate your accuracy needs as well, since achieving error tolerances of less than 1 degree can be challenging and costly. -

What are the common types of thermocouples used in industrial applications?

The most common types of thermocouples in industrial settings include Type K, Type J, Type T, and Type E. Type K is widely used due to its versatility and ability to measure a broad temperature range. Type J is suitable for lower temperatures and has magnetic properties, while Type T is often used in cryogenic applications. Type E thermocouples offer high accuracy and sensitivity, making them ideal for precise measurements. Each type has its specific application, so selecting one that aligns with your operational needs is crucial. -

What factors should I consider when sourcing thermocouples internationally?

When sourcing thermocouples internationally, consider the supplier’s reputation, product quality, and compliance with international standards. Verify their certifications and check for customer reviews or case studies. Additionally, assess their ability to provide customized solutions tailored to your requirements. Understanding the supplier’s logistics capabilities is essential, especially for timely delivery and cost management. Lastly, ensure clear communication regarding technical specifications and terms of sale to avoid misunderstandings. -

What is the minimum order quantity (MOQ) for thermocouples, and how does it vary by supplier?

Minimum order quantities (MOQ) for thermocouples can vary significantly by supplier and depend on the type and customization of the product. Some suppliers may have a low MOQ for standard types, while custom thermocouples might require larger orders. It’s advisable to discuss your needs directly with the supplier to understand their MOQ policy. Negotiating terms can sometimes yield flexibility, especially if you’re establishing a long-term partnership. -

What are common payment terms for international thermocouple purchases?

Payment terms for international purchases of thermocouples typically range from upfront payment to net 30 or net 60 days after delivery. Some suppliers may offer payment through letters of credit, especially for larger orders or new clients. It’s crucial to agree on payment terms before finalizing your order to ensure clarity and avoid potential disputes. Additionally, consider using secure payment methods to protect your transaction. -

How can I ensure quality assurance (QA) when sourcing thermocouples?

To ensure quality assurance when sourcing thermocouples, request documentation that verifies compliance with relevant industry standards, such as ISO 9001. Ask suppliers for their quality control processes, including testing methods for accuracy and durability. It’s beneficial to obtain samples for testing before placing a bulk order. Additionally, consider third-party inspections or audits of the manufacturing facility to gain insights into their production practices. -

What are the logistics considerations for importing thermocouples?

Logistics considerations for importing thermocouples include shipping options, customs duties, and delivery timelines. Evaluate the supplier’s ability to handle shipping logistics and choose a reliable freight forwarder to minimize delays. Understand the customs regulations in your country to anticipate any potential tariffs or fees. Clear communication with your supplier regarding shipping terms and tracking can help ensure smooth delivery and mitigate risks. -

How can I customize thermocouples for specific industrial applications?

Customizing thermocouples involves specifying the type, length, diameter, and connection method that suits your unique application. Discuss your requirements with the supplier, including any special materials or calibration needs. Many suppliers offer tailored solutions, such as different insulation materials or configurations like weld-on or stick-on thermocouples. Providing detailed specifications will help the supplier meet your expectations and deliver a product that fits your operational needs effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for thermo couple

What Are the Key Takeaways for B2B Buyers in Thermocouple Sourcing?

In conclusion, the strategic sourcing of thermocouples is paramount for businesses looking to enhance their operational efficiency and reliability. Understanding the specific types of thermocouples—such as Type K, J, and T—and their unique applications will enable buyers to select the most suitable products for their needs. By prioritizing factors like temperature range, accuracy, and wire gauge, businesses can make informed decisions that lead to improved performance and reduced downtime.

How Can International Buyers Leverage Strategic Sourcing?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, establishing strong supplier relationships is crucial. Engaging with reputable manufacturers and distributors can provide access to high-quality thermocouples and the latest technological advancements. Additionally, considering local sourcing options may reduce lead times and shipping costs, further enhancing competitiveness.

What Is the Future Outlook for Thermocouple Technology?

Looking ahead, the demand for advanced temperature measurement solutions is expected to grow, driven by innovations in industrial automation and process control. Buyers should stay informed about emerging trends, such as digital thermocouples and integrated sensor technologies, to ensure they remain at the forefront of their industries. By adopting a proactive approach to sourcing, businesses can not only meet current demands but also prepare for future challenges in temperature measurement.