Unlock Efficiency: The Complete CNC M Code List (2025)

Introduction: Navigating the Global Market for cnc m code list

Navigating the complexities of sourcing a CNC M Code list can be a daunting task for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Understanding the nuances of M Codes—critical commands used to control CNC machine operations—can significantly impact production efficiency and product quality. This guide aims to demystify the CNC M Code landscape, providing insights into various types of M Codes, their applications, and how they integrate with different CNC machines.

With a focus on actionable insights, this comprehensive resource will equip buyers with the knowledge needed to make informed purchasing decisions. We will explore key considerations for vetting suppliers, evaluating costs, and understanding the specific requirements of CNC machinery across different industries. By highlighting the variances in M Codes among manufacturers, particularly in regions like the UAE and Nigeria, buyers can better navigate their procurement strategies.

Whether you are a seasoned industry professional or new to CNC machining, this guide serves as a valuable tool for optimizing your operations. By understanding the intricacies of the CNC M Code list, international buyers can enhance their procurement processes, ensure compatibility with their existing systems, and ultimately drive business success.

Understanding cnc m code list Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard M-Codes | Commonly used across various CNC machines | General machining, prototyping | Pros: Familiarity across machines. Cons: Limited functionality for specialized tasks. |

| Manufacturer-Specific M-Codes | Unique codes tailored by manufacturers for specific machines | Custom machine operations, specialized tasks | Pros: Enhanced control features. Cons: Requires understanding of specific manuals. |

| Advanced M-Codes | Include commands for complex operations like probing and automation | High-precision machining, automated workflows | Pros: Increased efficiency and precision. Cons: Complexity may require additional training. |

| Custom M-Codes | Codes developed for specific applications or operations | Niche manufacturing processes | Pros: Tailored solutions for unique needs. Cons: May lack support or documentation. |

| Legacy M-Codes | Older codes that may still be in use in some industries | Maintenance of legacy systems | Pros: Compatibility with older equipment. Cons: Limited functionality and support. |

What Are Standard M-Codes and Their Applications?

Standard M-codes are the foundational set of miscellaneous codes used across various CNC machines. They enable basic functions such as starting and stopping the spindle, coolant control, and tool changes. These codes are essential for general machining and prototyping applications, making them widely familiar to operators. When considering purchasing equipment, buyers should note that while standard M-codes provide a solid base, they may not support specialized tasks, thus potentially limiting their operational scope.

How Do Manufacturer-Specific M-Codes Differ?

Manufacturer-specific M-codes are unique to particular brands or models of CNC machines, offering tailored functionalities that enhance the machine’s capabilities. These codes can control advanced features like high-pressure coolant systems or automated tool changers. For B2B buyers, understanding these codes is crucial, as they can significantly improve operational efficiency and precision in custom machine operations. However, reliance on these codes necessitates thorough knowledge of the specific machine’s manual, which can pose a challenge for some operators.

What Are Advanced M-Codes and Their Benefits?

Advanced M-codes incorporate commands for complex operations, including probing, threading, and automation tasks. These codes are particularly beneficial in high-precision machining environments where accuracy and efficiency are paramount. B2B buyers looking to automate workflows will find that investing in machines that support advanced M-codes can lead to substantial productivity gains. However, the complexity of these codes may require additional training for operators, which is an essential consideration for businesses aiming to maximize their investment.

Why Consider Custom M-Codes?

Custom M-codes are specifically developed to address unique operational needs within certain manufacturing processes. These codes can provide tailored solutions that enhance productivity and efficiency in niche applications. For B2B buyers, the ability to implement custom M-codes can be a significant advantage, allowing for greater flexibility in production. Nonetheless, the potential downside is the lack of support or documentation, which may complicate troubleshooting or operational training.

What Are Legacy M-Codes and Their Relevance Today?

Legacy M-codes refer to older codes that are still in use, particularly in industries that maintain legacy systems. While these codes ensure compatibility with older equipment, they may lack the functionality and support found in modern M-code systems. For B2B buyers, investing in machines that utilize legacy M-codes can be beneficial for maintaining existing systems, but they should be aware of the limitations and consider future scalability when making purchasing decisions.

Key Industrial Applications of cnc m code list

| Industry/Sector | Specific Application of CNC M Code List | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision Component Manufacturing | High accuracy and reliability in critical components | Certification standards and supplier reliability |

| Automotive | Tooling and Fixture Production | Enhanced production efficiency and reduced waste | Availability of advanced machining capabilities |

| Medical Devices | Custom Surgical Instrument Fabrication | Tailored solutions for specific medical needs | Compliance with health regulations and quality control |

| Electronics | PCB Manufacturing and Assembly | High-volume production with minimal defects | Sourcing for specialized CNC machines and tools |

| Oil and Gas | Component Production for Machinery | Durability and precision in harsh environments | Supplier experience in heavy-duty machining |

How is the CNC M Code List Utilized in Aerospace Component Manufacturing?

In the aerospace industry, the CNC M code list is crucial for precision component manufacturing, where tolerances are often within microns. M codes control various functions such as spindle speed, coolant flow, and tool changes, allowing manufacturers to produce complex parts with high accuracy. International buyers from regions like Europe and the Middle East must ensure that their CNC machines are compatible with specific M codes to meet stringent certification standards. This compatibility can significantly impact production reliability and safety in aviation applications.

What Role Does CNC M Code Play in Automotive Tooling and Fixture Production?

The automotive sector heavily relies on CNC machining for tooling and fixture production. The CNC M code list enables manufacturers to automate tool changes and coolant management, enhancing production efficiency and reducing material waste. For buyers in Africa and South America, sourcing CNC machines with robust M code capabilities can streamline operations and support high-volume production. Additionally, understanding the specific M codes for their machines can lead to better maintenance and operational efficiency.

How is CNC M Code Used in Custom Surgical Instrument Fabrication for Medical Devices?

CNC M codes are integral in the fabrication of custom surgical instruments, where precision and customization are paramount. By utilizing M codes, manufacturers can automate various machining processes, ensuring that instruments meet specific medical requirements. Buyers from the Middle East and Europe should prioritize suppliers who adhere to stringent health regulations and quality control measures, as the stakes in medical device manufacturing are exceptionally high. This focus on quality ensures patient safety and device efficacy.

In What Ways Does CNC M Code Enhance PCB Manufacturing and Assembly in Electronics?

In the electronics industry, the CNC M code list is vital for PCB manufacturing and assembly processes. The M codes facilitate precise control over drilling, routing, and finishing, which are essential for high-volume production with minimal defects. International B2B buyers, particularly from South America and Africa, should look for suppliers with advanced CNC capabilities that can handle the intricate designs typical in electronics. This focus on precision not only enhances product quality but also reduces the risk of costly rework.

Why is CNC M Code Important for Component Production in Oil and Gas Industries?

The oil and gas industry demands high precision and durability in component production, making the CNC M code list essential. M codes manage various operations such as tool changes and coolant application, crucial for maintaining the integrity of parts used in harsh environments. Buyers from Africa and the Middle East should consider suppliers with proven experience in heavy-duty machining to ensure that components can withstand extreme conditions. This experience is critical for maintaining operational reliability in oil and gas applications.

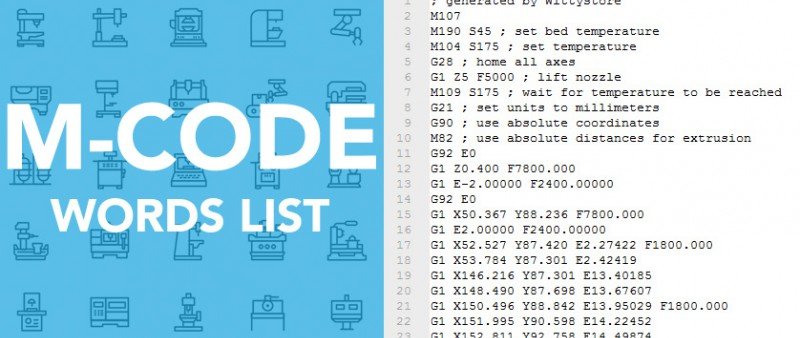

A stock image related to cnc m code list.

3 Common User Pain Points for ‘cnc m code list’ & Their Solutions

Scenario 1: Understanding Manufacturer-Specific M-Codes

The Problem:

One of the most significant challenges faced by B2B buyers, particularly in regions with diverse manufacturing capabilities like Africa and South America, is the variability of M-codes across different CNC machine manufacturers. Buyers may encounter a situation where they purchase a CNC machine but struggle to find a comprehensive M-code list that is specific to that machine. This lack of clarity can lead to operational inefficiencies, incorrect programming, and potential damage to the machine if the wrong commands are executed.

The Solution:

To mitigate this problem, buyers should prioritize sourcing CNC machines from reputable manufacturers who provide detailed documentation, including manufacturer-specific M-code lists. It is advisable to request these resources during the purchasing process. Additionally, buyers should utilize online platforms or forums dedicated to CNC machining where experienced operators share insights and resources. Creating a centralized repository of M-codes specific to the machines in use can also facilitate easier access for operators, reducing the chances of errors and enhancing productivity.

Scenario 2: Insufficient Training on M-Code Usage

The Problem:

Another prevalent issue arises from the insufficient training provided to operators regarding M-code usage. For B2B buyers, particularly those in emerging markets, the investment in advanced CNC machinery can be significant, yet the lack of proper training leads to underutilization of the machines’ capabilities. Operators may feel overwhelmed by the complexity of M-codes and might not fully understand how to implement them effectively, leading to decreased production quality and higher operational costs.

The Solution:

To address this challenge, B2B buyers should invest in comprehensive training programs for their operators. This can involve engaging with the CNC machine manufacturer for tailored training sessions or workshops that focus specifically on M-code usage. Additionally, creating a mentorship program where experienced operators can guide newcomers will foster a culture of learning. Supplementing these efforts with online courses or tutorials that cover M-code applications can further enhance the team’s competence and confidence in using the CNC machines effectively.

Scenario 3: Difficulty in Integrating M-Codes with CAD/CAM Systems

The Problem:

A common pain point for international B2B buyers is the difficulty in integrating M-codes with their CAD/CAM systems. This issue often arises when the software does not support the specific M-codes used by the CNC machines, leading to compatibility issues. This mismatch can result in delays in production schedules, increased costs, and frustration among the engineering teams who are tasked with programming the machines.

The Solution:

To solve this integration issue, buyers should thoroughly evaluate the compatibility of their CAD/CAM software with the CNC machines they plan to purchase. Engaging with software vendors to ensure that they provide updates that reflect the latest M-code standards is crucial. Additionally, establishing a communication channel between software developers and machine operators can facilitate quicker troubleshooting and adaptations. Regular software updates and training on new features can ensure that the integration remains smooth, minimizing downtime and enhancing overall productivity in the manufacturing process.

Strategic Material Selection Guide for cnc m code list

What Are the Key Properties of Common Materials Used in CNC Machining?

When selecting materials for CNC machining, particularly for applications involving M-codes, it is essential to consider their unique properties. Here, we analyze four common materials: Aluminum, Steel, Titanium, and Plastics. Each material offers distinct advantages and challenges that can affect the performance and suitability of the final product.

How Does Aluminum Perform in CNC Machining Applications?

Aluminum is widely favored for its lightweight nature and excellent machinability. It typically has a high strength-to-weight ratio and good corrosion resistance, making it suitable for various applications, including automotive and aerospace components. The temperature rating for aluminum is generally lower than that of steel, which may limit its use in high-temperature environments.

Pros:

– Lightweight and easy to machine, resulting in lower manufacturing costs.

– Good corrosion resistance, reducing the need for protective coatings.

Cons:

– Lower strength compared to steel, which can be a limitation in heavy-load applications.

– Can be more expensive than some steel grades, affecting overall project budgets.

Impact on Application:

Aluminum is compatible with various media, including water and oils, making it a versatile choice for many industries. However, it may not perform well in high-pressure environments.

What Are the Key Advantages of Using Steel in CNC Machining?

Steel is one of the most commonly used materials in CNC machining due to its durability and strength. With various grades available, such as stainless steel and tool steel, it offers excellent temperature and pressure ratings, making it ideal for heavy-duty applications.

Pros:

– Exceptional strength and durability, suitable for high-load applications.

– Versatile, with a wide range of grades available for specific requirements.

Cons:

– Heavier than aluminum, which may not be ideal for lightweight applications.

– More complex machining process, leading to higher manufacturing costs.

Impact on Application:

Steel is compatible with a wide range of media, including corrosive substances, but requires careful consideration of corrosion resistance based on the specific steel grade used.

Why Choose Titanium for CNC Machining Applications?

Titanium is renowned for its high strength-to-weight ratio and excellent corrosion resistance. It is often used in aerospace, medical, and military applications where performance is critical. However, titanium’s high cost and challenging machinability can be significant drawbacks.

Pros:

– Outstanding strength and corrosion resistance, ideal for harsh environments.

– Lightweight, making it suitable for applications where weight is a concern.

Cons:

– High cost compared to aluminum and steel, which can impact budget considerations.

– Difficult to machine, requiring specialized tools and techniques.

Impact on Application:

Titanium is compatible with various media, including seawater, making it an excellent choice for marine applications. However, its high cost may limit its use in less critical applications.

What Role Do Plastics Play in CNC Machining?

Plastics, such as polycarbonate and nylon, are increasingly used in CNC machining due to their lightweight nature and versatility. They offer good chemical resistance and can be easily molded into complex shapes, making them suitable for a variety of applications.

Pros:

– Lightweight and easy to machine, reducing manufacturing time and costs.

– Good chemical resistance, suitable for various environments.

Cons:

– Generally lower strength compared to metals, which may not be suitable for high-load applications.

– Can be sensitive to temperature changes, affecting performance in extreme conditions.

Impact on Application:

Plastics are compatible with a wide range of media, including acids and bases, making them ideal for chemical processing applications. However, their lower strength may limit their use in structural components.

Summary Table of Material Selection for CNC Machining

| Material | Typical Use Case for cnc m code list | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components | Lightweight and easy to machine | Lower strength than steel | Medium |

| Steel | Heavy machinery parts | Exceptional strength and durability | More complex machining | Medium |

| Titanium | Aerospace and medical applications | Outstanding strength and corrosion resistance | High cost and difficult to machine | High |

| Plastics | Consumer products and housings | Lightweight and good chemical resistance | Lower strength than metals | Low |

This analysis provides international B2B buyers with a strategic framework for selecting materials based on performance, cost, and application suitability, ensuring they make informed decisions in their CNC machining processes.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc m code list

What Are the Main Stages of Manufacturing Processes for CNC M Code Lists?

When it comes to manufacturing processes for CNC M code lists, several key stages are involved. Understanding these stages can help B2B buyers ensure that they are sourcing high-quality products that meet their specific needs.

1. Material Preparation: What Are the Key Considerations?

Material preparation is the foundational step in CNC machining. It involves selecting the appropriate raw materials based on the specifications of the final product. Common materials include metals like aluminum, steel, and titanium, as well as plastics. B2B buyers should ensure that suppliers are sourcing materials that comply with international standards, such as ASTM or ISO certifications.

Additionally, pre-processing techniques such as cutting, sawing, or shearing may be employed to create manageable sizes for the CNC machines. Buyers should inquire about the suppliers’ material traceability processes to ensure that all materials used are of the highest quality.

2. Forming: How Are CNC Components Shaped?

The forming stage involves the actual machining processes where the CNC machines, guided by G-code and M-code, cut, mill, or drill the raw material into the desired shape. Key techniques include:

- CNC Milling: Utilizes rotating tools to remove material, allowing for complex geometries.

- CNC Turning: Material is rotated against a cutting tool, ideal for cylindrical parts.

- 3D Printing: An increasingly popular method for creating complex shapes directly from digital models.

For B2B buyers, it’s essential to understand the types of CNC machines used by their suppliers and how these machines are calibrated. This will ensure precision and adherence to specifications.

3. Assembly: What Is the Role of Quality in Assembly Processes?

Once individual components are manufactured, they often require assembly. This may involve the integration of multiple parts into a final product. In this stage, suppliers should employ rigorous assembly techniques to ensure that all components fit and function together seamlessly.

Buyers should look for suppliers that utilize standard assembly practices and maintain documentation of assembly procedures. This transparency is crucial for establishing trust and ensuring that the end product meets all operational requirements.

4. Finishing: How Is the Surface Quality Achieved?

Finishing processes enhance the aesthetic and functional characteristics of the final product. Common finishing techniques include:

- Anodizing: For aluminum parts, this process enhances corrosion resistance and surface hardness.

- Painting and Coating: Provides additional protection and a polished appearance.

- Deburring: Removes sharp edges and improves safety.

B2B buyers should ask suppliers about their finishing capabilities and any post-processing inspections they perform to ensure that the final product meets industry standards.

What Quality Assurance Measures Are Essential for CNC Machining?

Quality assurance (QA) is a critical aspect of CNC machining that ensures the final products meet specified standards. It encompasses a variety of practices and checks throughout the manufacturing process.

1. What Are the Relevant International Standards for CNC Machining?

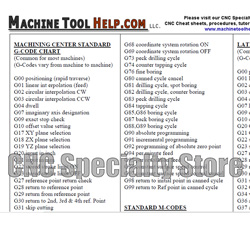

A stock image related to cnc m code list.

To guarantee quality, many CNC manufacturers adhere to international standards such as ISO 9001, which outlines the requirements for a quality management system. Other industry-specific standards include CE marking for safety in the European market and API standards for oil and gas components.

B2B buyers should prioritize suppliers with relevant certifications as they demonstrate a commitment to quality and continuous improvement.

2. What Are the Key QC Checkpoints in CNC Manufacturing?

Quality Control (QC) checkpoints are essential for identifying defects early in the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): Involves inspections of raw materials upon arrival at the manufacturing facility.

- In-Process Quality Control (IPQC): Continuous monitoring during the machining process to catch deviations from specifications.

- Final Quality Control (FQC): Comprehensive inspections after assembly and finishing to ensure the product meets all quality standards.

Understanding these checkpoints allows B2B buyers to assess the thoroughness of a supplier’s QC processes.

3. How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can adopt several strategies to verify the quality control practices of their suppliers:

- Audits: Conducting regular audits of the supplier’s manufacturing facilities can help assess their adherence to quality standards.

- Reports: Requesting detailed quality assurance reports can provide insights into past performance and areas of improvement.

- Third-Party Inspections: Engaging independent inspection agencies can offer an unbiased assessment of the supplier’s quality measures.

By implementing these practices, buyers can mitigate risks associated with poor quality and ensure a reliable supply chain.

What Are the QC and Certification Nuances for International B2B Buyers?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is vital.

1. What Should Buyers Know About Regional Standards and Compliance?

Different regions may have varying standards and compliance requirements. For example, European buyers may prioritize CE marking, while buyers in the Middle East may require compliance with local regulations. Understanding these regional standards is crucial for successful international transactions.

2. How Do Cultural Differences Impact Quality Expectations?

Cultural differences can influence quality expectations and communication styles. B2B buyers should be aware of these nuances to foster effective collaboration with suppliers. Establishing clear communication regarding quality expectations and standards can help bridge any gaps.

By focusing on these critical aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing CNC M code lists and ensure they partner with reliable suppliers that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc m code list’

To effectively source a comprehensive CNC M Code list for your manufacturing needs, follow this practical step-by-step checklist. This guide is tailored for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for identifying the right CNC M Code list. Consider the types of machines you operate and the specific functionalities you require.

– Identify Machine Types: Different CNC machines utilize varying M Codes. Knowing whether you are working with lathes, mills, or multi-axis machines will guide your search.

– Functionality Needs: List the specific functions you need, such as tool changes, spindle control, or coolant management.

Step 2: Research Reputable Suppliers

Conduct thorough research to find suppliers with a solid reputation in the CNC machining industry.

– Check Reviews and Testimonials: Look for feedback from other B2B buyers to gauge the reliability of the supplier.

– Industry Experience: Prioritize suppliers who have experience with your specific type of machinery and M Code applications.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Documentation and Certifications: Ensure that suppliers can provide proper documentation and certifications that validate their expertise in CNC operations.

– Support Services: Inquire about after-sales support, training, and resources they offer to help you understand and implement the M Codes effectively.

Step 4: Request Sample M Code Lists

Ask potential suppliers for sample CNC M Code lists to evaluate their comprehensiveness and relevance.

– Customization Options: Determine if the supplier can provide customized lists that cater to your specific machines and operations.

– Clarity and Usability: Review the format of the M Code list to ensure it’s user-friendly and easily interpretable by your team.

Step 5: Compare Pricing and Terms

Once you have gathered information from various suppliers, compare their pricing and terms.

– Value Over Cost: While cost is important, consider the overall value offered, including quality, support, and additional resources.

– Payment and Delivery Terms: Clarify payment terms, delivery schedules, and any potential penalties for late deliveries or changes in orders.

Step 6: Verify Compliance with Standards

Ensure that the M Code lists you are considering comply with international standards relevant to your industry.

– ISO Compliance: Check if the M Codes meet ISO standards, which can be crucial for maintaining quality and safety in manufacturing.

– Regulatory Requirements: Be aware of any local or regional regulations that may affect the compatibility of the M Codes with your operations.

Step 7: Finalize Your Supplier Selection

Make your final decision based on all gathered information and analysis.

– Long-term Relationship Potential: Consider the potential for a long-term partnership with the supplier, which can lead to better pricing and service in the future.

– Feedback Mechanisms: Establish a communication channel for ongoing feedback to address any issues or needs that may arise post-purchase.

Following this checklist will ensure that you select the best CNC M Code list tailored to your specific needs, ultimately enhancing your machining processes.

Comprehensive Cost and Pricing Analysis for cnc m code list Sourcing

What Are the Key Cost Components in CNC M Code List Sourcing?

When sourcing a CNC M code list, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The cost of software and hardware necessary for CNC operations can vary widely. High-quality materials will ensure better performance and longevity of the CNC machinery.

-

Labor: Skilled labor is essential for operating CNC machines and interpreting M codes. Labor costs can fluctuate based on region and expertise level, particularly in markets like Africa and South America where skilled technicians may be in short supply.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and equipment depreciation. Buyers should inquire about how these costs are allocated in supplier pricing.

-

Tooling: Specialized tooling required for CNC operations can significantly impact total costs. Custom tooling may be necessary for specific applications, which can increase initial expenses but may lower long-term operational costs.

-

Quality Control (QC): Ensuring the accuracy and reliability of CNC outputs necessitates investment in quality control measures. Suppliers who adhere to international quality standards may charge higher prices but can provide better assurance of product performance.

-

Logistics: Shipping costs, especially for international orders, can affect pricing. Factors such as distance, shipping method, and customs duties must be considered to avoid unexpected expenses.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding typical margins in your industry can help in assessing whether a quoted price is competitive.

How Do Price Influencers Affect CNC M Code List Costs?

Several factors influence the pricing of CNC M code lists, impacting the final cost for buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract discounts. Buyers should consider their demand forecast and negotiate bulk purchase agreements to reduce per-unit costs.

-

Specifications and Customization: Custom M code lists tailored to specific machine types or operational requirements may incur higher costs. Buyers should clearly communicate their needs to avoid unnecessary expenses.

-

Materials and Quality Certifications: Suppliers offering high-grade materials and recognized quality certifications may charge more. However, investing in quality can lead to reduced downtime and maintenance costs.

-

Supplier Factors: The reputation and location of the supplier can affect pricing. Established suppliers with proven track records might charge a premium, but they often offer better reliability and service.

-

Incoterms: The terms of shipping and delivery (Incoterms) can also influence costs. Buyers should negotiate terms that minimize their total landed costs, considering who bears shipping, insurance, and customs responsibilities.

What Are Effective Buyer Tips for Negotiating CNC M Code List Prices?

Navigating the complexities of pricing in international markets requires strategic approaches:

-

Negotiate Terms: Always seek to negotiate prices, especially if you are placing a large order. Leverage your position as a buyer to request discounts or favorable payment terms.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership (TCO), not just the purchase price. Consider long-term savings from higher-quality products versus cheaper alternatives that may require more frequent replacement or maintenance.

-

Understand Pricing Nuances: Be aware of regional pricing strategies and economic factors that may impact costs. In regions like the Middle East or Africa, fluctuations in currency and local economic conditions can significantly affect pricing.

-

Research and Compare Suppliers: Obtain multiple quotes and compare them not just on price but also on service, quality, and delivery times. A slightly higher price may be justified by superior service or faster delivery.

-

Be Cautious of Indicative Prices: Prices quoted by suppliers can often be indicative. Always confirm final prices before making commitments, considering all potential additional costs.

By understanding the intricacies of cost components, price influencers, and strategic negotiation tactics, international B2B buyers can make informed decisions when sourcing CNC M code lists, ultimately leading to more favorable outcomes in their procurement processes.

Alternatives Analysis: Comparing cnc m code list With Other Solutions

Understanding Alternatives to CNC M Code Lists

In the realm of CNC machining, while M code lists play a crucial role in controlling machine functions, there are alternative solutions that can enhance productivity, reduce costs, and streamline operations. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, it’s essential to understand these alternatives to make informed purchasing decisions.

Comparison Table of CNC M Code List with Alternative Solutions

| Comparison Aspect | Cnc M Code List | CAM Software | PLC (Programmable Logic Controller) |

|---|---|---|---|

| Performance | High precision in controlling CNC functions | Excellent for complex machining tasks | Reliable for automation in various industrial applications |

| Cost | Relatively low (software-based) | Higher initial investment | Moderate; costs vary based on complexity |

| Ease of Implementation | Requires familiarity with codes | User-friendly interfaces but requires training | Requires technical expertise for programming |

| Maintenance | Minimal updates needed | Regular updates and support required | Moderate; requires periodic checks and updates |

| Best Use Case | Standard CNC operations | Complex part designs requiring intricate machining | Automated processes across various manufacturing systems |

In-Depth Analysis of Alternatives

How Does CAM Software Compare to CNC M Code Lists?

Pros: CAM (Computer-Aided Manufacturing) software translates CAD designs into G-code and M-code, automating much of the programming process. This allows for more complex designs and faster production times, making it ideal for intricate parts that require precision.

Cons: The initial investment for high-quality CAM software can be substantial. Additionally, users need to undergo training to maximize the software’s capabilities, which may delay implementation in the short term.

What Advantages Does a PLC Offer Over CNC M Code Lists?

Pros: A PLC is a versatile solution for automating various industrial processes beyond just CNC operations. It can manage multiple machines and control entire production lines, enhancing efficiency across different manufacturing areas.

Cons: While PLCs are excellent for automation, they require a higher level of technical expertise for programming and maintenance. They are also more costly than a simple M code solution, which may not be justifiable for smaller operations focused solely on CNC machining.

Choosing the Right Solution for Your Needs

When considering alternatives to a CNC M code list, B2B buyers must assess their specific operational needs, budget constraints, and the complexity of the parts they intend to manufacture. For businesses focused on high-volume, intricate machining, investing in CAM software may offer the most significant benefits in the long run. Conversely, companies looking for a cost-effective solution for standard operations may find that a CNC M code list meets their needs adequately. For those with broader automation goals, a PLC could provide the versatility required to enhance overall production efficiency.

Ultimately, the choice hinges on aligning the selected solution with your operational goals, the skill level of your workforce, and your budgetary allowances.

Essential Technical Properties and Trade Terminology for cnc m code list

What Are the Essential Technical Properties of CNC M Codes?

Understanding the technical specifications of CNC M codes is crucial for international B2B buyers, especially when evaluating machinery and components for manufacturing processes. Here are some key properties to consider:

1. Precision Tolerance

Precision tolerance refers to the allowable deviation from a specified dimension in a machined part. For CNC machining, this is often expressed in micrometers or millimeters. High precision tolerance is essential for industries such as aerospace and automotive, where even minor inaccuracies can lead to significant operational issues. B2B buyers must ensure that the CNC machines they procure can meet the required tolerances for their specific applications.

2. Material Compatibility

Different CNC M codes may be used for various materials, including metals, plastics, and composites. Each material has unique properties affecting how it can be machined. Buyers should identify the materials they intend to work with and ensure that the CNC machines can handle those materials effectively. This compatibility is vital for optimizing production efficiency and reducing waste.

3. Axis Configuration

CNC machines operate on various axis configurations, typically ranging from three to five axes. The number of axes directly impacts the complexity of parts that can be machined. For example, 5-axis machines can create intricate geometries that 3-axis machines cannot. Buyers should assess their production needs to determine the appropriate axis configuration required for their operations.

4. Spindle Speed Range

The spindle speed range indicates the operational speed of the machine’s spindle, typically measured in RPM (revolutions per minute). Higher spindle speeds allow for faster machining processes but may require specific tooling and material considerations. Understanding spindle speed capabilities helps buyers select machines that optimize productivity while ensuring quality output.

5. Cooling System Type

Cooling systems in CNC machines, controlled by M codes, are crucial for maintaining optimal operating temperatures during machining. Different systems, such as flood or mist cooling, have varying efficiencies and applications. Buyers should evaluate the cooling requirements based on the materials and machining processes they plan to use to avoid overheating and ensure longer tool life.

6. Control Software Compatibility

Most CNC machines utilize specific control software that interprets M codes. Compatibility with popular software platforms can greatly enhance operational efficiency. Buyers should ensure that the CNC machines can integrate seamlessly with existing software solutions to facilitate smooth operations and reduce learning curves for operators.

What Are the Common Trade Terms Used in CNC Machining?

Familiarity with industry terminology can significantly streamline the procurement process. Here are some essential terms relevant to CNC M codes and machining:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the CNC industry, understanding OEM relationships is critical for buyers when sourcing machinery, as it affects warranty, support, and parts availability.

2. MOQ (Minimum Order Quantity)

MOQ signifies the smallest quantity of a product that a supplier is willing to sell. For CNC components, understanding MOQ is essential for budgeting and inventory management. It allows buyers to gauge the feasibility of their procurement plans based on production needs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price estimates for specific products or services. For B2B buyers in the CNC space, issuing an RFQ helps compare prices, lead times, and terms from multiple suppliers, enabling informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers to manage shipping, risk, and costs associated with the delivery of CNC machinery and parts.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. In the CNC industry, lead times can vary significantly based on machine specifications and supplier capabilities. Buyers should consider lead times in their planning to ensure timely project execution.

By grasping these essential properties and trade terms, international B2B buyers can make more informed decisions regarding CNC M codes and the machinery that employs them, ultimately enhancing their manufacturing processes.

Navigating Market Dynamics and Sourcing Trends in the cnc m code list Sector

What Are the Key Market Trends Affecting the CNC M Code List Sector?

The CNC machining industry is rapidly evolving, influenced by globalization, technological advancements, and shifting consumer demands. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must stay informed about these dynamics. One major trend is the increasing adoption of advanced CNC technologies, such as 5-axis machining and automation, which enhance precision and efficiency. As buyers seek to streamline operations and reduce costs, the integration of IoT (Internet of Things) in CNC machines is becoming a focal point. This technology allows for real-time monitoring and predictive maintenance, which can lead to significant operational improvements.

Another notable trend is the growing preference for customized solutions. Businesses are increasingly looking for CNC providers that can offer tailored services, including specific M-code implementations that suit their unique machining requirements. Additionally, the rise of e-commerce platforms for sourcing CNC components and services is reshaping the procurement landscape, allowing buyers to easily compare suppliers and access a broader range of products and services. Understanding these trends can help international buyers make informed decisions and gain a competitive edge in their respective markets.

How Is Sustainability Shaping Sourcing Practices in the CNC M Code List Sector?

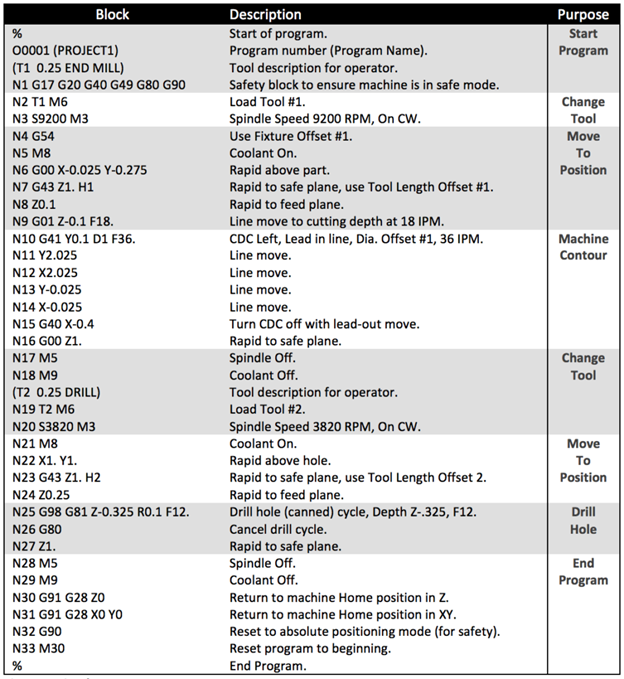

A stock image related to cnc m code list.

Sustainability has emerged as a crucial consideration for B2B buyers in the CNC machining sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt more sustainable practices. For international buyers, particularly in regions like Europe where regulatory frameworks are stringent, the need for ethical sourcing is paramount. This involves selecting suppliers who prioritize sustainable materials and processes.

Buyers should look for suppliers who hold recognized certifications, such as ISO 14001 for environmental management or those that utilize recycled materials in their CNC operations. Additionally, leveraging green technologies, such as energy-efficient CNC machines and waste reduction strategies, can significantly lower the carbon footprint of manufacturing activities. By integrating sustainability into their sourcing decisions, B2B buyers not only comply with regulations but also enhance their brand reputation and appeal to environmentally conscious customers.

What Is the Historical Context of CNC Machining Relevant to Today’s B2B Buyers?

The evolution of CNC machining dates back to the 1950s, with significant advancements occurring in the 1980s through the introduction of computerization. Initially, CNC systems relied heavily on manual programming, but the advent of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software revolutionized the industry. This shift allowed for the seamless translation of design into machine operations, enhancing precision and reducing lead times.

For today’s B2B buyers, understanding this historical context is essential. It highlights the progression towards more automated and efficient machining processes, underscoring the importance of staying current with technological advancements. As the industry continues to innovate, buyers must adapt by sourcing from suppliers who leverage the latest CNC technologies and practices to remain competitive in a fast-paced global market.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc m code list

-

How do I choose the right CNC M code list for my machinery?

When selecting a CNC M code list, it’s essential to consider the specific machine’s manufacturer and model, as M codes can vary significantly. Review the machine’s manual for the most accurate list tailored to your equipment. Additionally, consult with your supplier or manufacturer for any proprietary codes that may not be included in standard lists. This ensures compatibility and optimal performance in your manufacturing processes. -

What are the common M codes used in CNC machining?

Common M codes include M00 (Program Stop), M02 (End of Program), M03 (Spindle Start Clockwise), M05 (Spindle Stop), and M06 (Tool Change). These codes control essential machine functions, allowing for efficient operation. Familiarizing yourself with these codes can enhance your understanding of CNC programming and improve communication with suppliers and technicians. -

How can I verify the authenticity of a CNC M code supplier?

To verify a CNC M code supplier, check their industry reputation, client reviews, and certifications. Request references from previous clients and inquire about their experience with the supplier’s products. Additionally, assess their technical support and after-sales service. Engaging in direct conversations can also provide insights into their reliability and expertise in CNC machining. -

What are the payment terms typically offered by CNC M code suppliers?

Payment terms can vary widely among suppliers, but common options include net 30, net 60, or payment upon delivery. Some suppliers may offer discounts for early payments or larger orders. It’s advisable to negotiate terms that align with your cash flow needs and to ensure clarity in the agreement to avoid any future disputes. -

How do I handle logistics for sourcing CNC M code lists internationally?

When sourcing CNC M code lists from international suppliers, consider factors such as shipping costs, delivery times, and import regulations. Establish a reliable logistics partner familiar with customs procedures in your region. Additionally, utilize Incoterms to clarify responsibilities between buyers and suppliers regarding shipping and insurance. -

What should I consider regarding Minimum Order Quantity (MOQ) when sourcing CNC M codes?

MOQs can significantly impact your purchasing strategy, especially for small businesses. Discuss MOQs with potential suppliers to understand their requirements. If the MOQ is too high, negotiate for smaller batch orders or explore alternative suppliers who can accommodate your needs. This flexibility can help optimize inventory management and reduce upfront costs. -

What quality assurance measures should I expect from CNC M code suppliers?

Quality assurance measures can include comprehensive testing of M codes, adherence to industry standards, and certifications such as ISO 9001. Suppliers should provide documentation demonstrating their quality control processes. Requesting samples or trial orders can also help assess the quality of the M codes before committing to a larger purchase. -

How can I customize CNC M codes for specific machining operations?

Customization of CNC M codes often involves programming specific commands that cater to your unique machining operations. Collaborate closely with your CNC programmer or technician to develop tailored M codes that fit your production requirements. Many suppliers can also assist with custom programming solutions, ensuring the M codes integrate seamlessly with your existing systems.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cnc m code list

In the realm of CNC machining, understanding M-codes is pivotal for optimizing operational efficiency and precision. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate the complexities of sourcing CNC machinery and components, strategic sourcing becomes essential. Recognizing the variations in M-code applications across different manufacturers enables buyers to make informed decisions that align with their specific machining needs.

How Can Strategic Sourcing Enhance Your CNC Operations?

Implementing a robust strategic sourcing approach can lead to significant cost savings, improved supply chain resilience, and access to cutting-edge technology. By collaborating with trusted suppliers who understand regional market dynamics, buyers can leverage local insights to enhance their production capabilities. This not only facilitates the procurement of high-quality CNC equipment but also ensures compatibility with existing systems.

What’s Next for International B2B Buyers in CNC Machining?

Looking ahead, the integration of advanced technologies, such as Industry 4.0 and automation, will further revolutionize CNC machining processes. Buyers are encouraged to stay abreast of these developments and consider partnerships that foster innovation. Engage with suppliers who offer comprehensive support and training on M-codes to maximize the potential of your CNC investments. By doing so, you position your business for sustained growth and competitive advantage in the evolving manufacturing landscape.