Discover the Types of Electrical Plugs: A Complete Guide (2025)

Introduction: Navigating the Global Market for type of electrical plugs

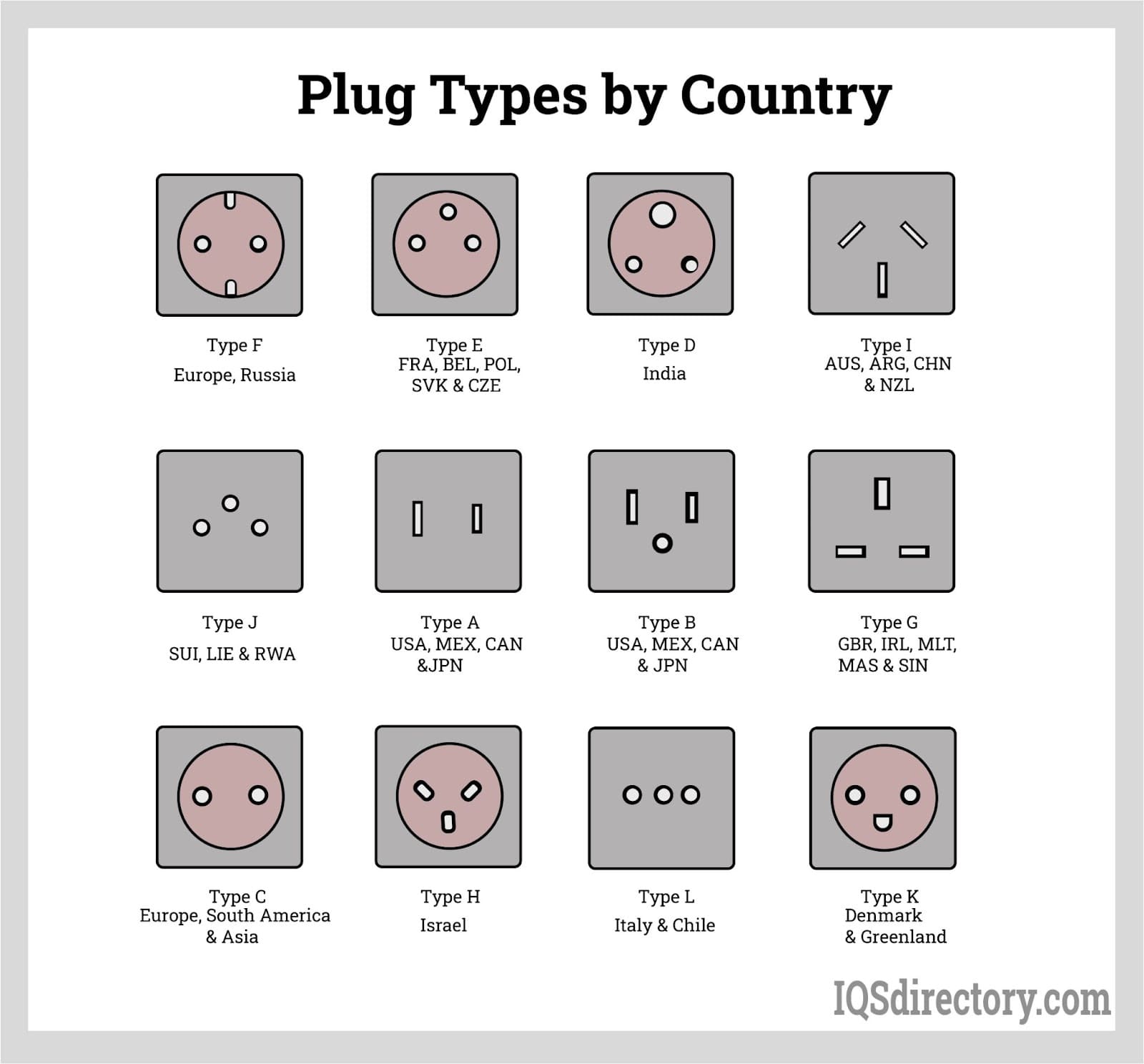

In today’s global marketplace, sourcing the right type of electrical plugs can pose significant challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With over 15 distinct plug types in use worldwide, understanding the compatibility, voltage requirements, and specific applications of each type is crucial for ensuring operational efficiency. This guide serves as a comprehensive resource, detailing the various types of electrical plugs, their applications across different industries, and critical considerations for supplier vetting and cost management.

International buyers, especially those from Nigeria, Indonesia, and other emerging markets, will benefit from insights on the nuances of plug types ranging from Type A, commonly found in North America, to Type C, prevalent in Europe and Africa. Each plug type has unique specifications that can affect equipment performance and safety standards. Additionally, the guide will explore sourcing strategies, enabling businesses to make informed decisions that align with local regulatory requirements and market needs.

By equipping buyers with the knowledge to navigate the complexities of electrical plug types, this resource empowers them to streamline procurement processes and avoid costly mistakes. Whether you’re looking to import electrical appliances or set up new facilities, understanding the global landscape of electrical plugs is essential for successful international operations.

Understanding type of electrical plugs Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type C | Two non-grounded pins, used in Europe, Africa, South America & Asia | General appliances, consumer electronics | Pros: Widely compatible; Cons: Not grounded, may pose safety risks. |

| Type G | Three rectangular pins, grounded, primarily in the UK and similar regions | Heavy-duty equipment, industrial applications | Pros: High safety; Cons: Limited compatibility outside UK. |

| Type E | Two round pins with a hole for grounding, used in France and surrounding countries | Domestic and commercial electrical devices | Pros: Grounded for safety; Cons: Not universally adopted. |

| Type I | Two or three pins, grounded options available, used in Australia, New Zealand, and China | Industrial machinery, consumer goods | Pros: Versatile; Cons: Limited compatibility in Europe. |

| Type N | Three pins, grounded, used in Brazil and South Africa | Commercial appliances, industrial equipment | Pros: High current capacity; Cons: Limited global availability. |

What Are the Key Characteristics of Type C Plugs?

Type C plugs, commonly known as the Europlug, feature two round pins and are predominantly used across Europe, Africa, South America, and Asia. Their non-grounded design makes them suitable for a variety of consumer electronics and household appliances. B2B buyers should consider the widespread compatibility of Type C plugs, which can facilitate easier cross-border transactions. However, the lack of grounding may present safety concerns, especially in environments where electrical surges are common.

Why Choose Type G Plugs for Heavy-Duty Applications?

Type G plugs are characterized by their three rectangular pins and are primarily used in the United Kingdom, Ireland, and some regions in Asia. Their grounded design makes them ideal for heavy-duty equipment and industrial applications, where safety is paramount. B2B buyers should appreciate the enhanced safety features, but they must also be aware that Type G plugs have limited compatibility outside the UK, potentially complicating international procurement.

How Does Type E Plug Suitability Vary Across Regions?

Type E plugs have two round pins and a grounding hole, making them a standard in France, Belgium, and several other European countries. Their grounded nature allows for safe use in both domestic and commercial electrical devices. B2B buyers should consider Type E plugs for applications in regions where they are standard, ensuring compliance with local safety regulations. However, their limited adoption outside of specific countries can be a drawback for international operations.

What Advantages Do Type I Plugs Offer for Industrial Use?

Type I plugs are versatile, featuring either two or three pins and are commonly used in Australia, New Zealand, and parts of China. Their adaptability makes them suitable for a range of applications, from industrial machinery to consumer goods. B2B buyers should focus on the plug’s grounding options, which enhance safety. However, buyers should note that Type I plugs may not be compatible with European standards, which could pose challenges in multinational operations.

What Are the Benefits of Using Type N Plugs in Commercial Settings?

Type N plugs, with three grounded pins, are primarily used in Brazil and South Africa. They are designed for high current capacity, making them suitable for commercial appliances and industrial equipment. B2B buyers should consider Type N plugs for their robust performance in demanding environments. However, the limited availability of Type N plugs on the global market could complicate sourcing, particularly for businesses operating in multiple regions.

Key Industrial Applications of type of electrical plugs

| Industry/Sector | Specific Application of type of electrical plugs | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering machinery and equipment with industrial plugs | Ensures reliable operation and reduces downtime | Compatibility with local voltage standards and plug types |

| Telecommunications | Connecting communication devices and network equipment | Facilitates uninterrupted service and connectivity | Durability and resistance to environmental factors |

| Construction | Powering tools and heavy machinery on-site | Enhances productivity and safety on construction sites | Compliance with safety regulations and local standards |

| Hospitality & Events | Providing power for appliances and entertainment equipment | Improves guest experience and operational efficiency | Flexibility in plug types to accommodate various devices |

| Renewable Energy | Integrating solar and wind energy systems with electrical grids | Supports sustainable energy solutions and reduces costs | Compatibility with different plug types and voltages |

How Are Electrical Plugs Utilized in Manufacturing?

In the manufacturing sector, type of electrical plugs are crucial for powering various machinery and equipment. Industrial plugs, often rated for higher amperages, ensure that machines operate smoothly without interruptions. This reliability is essential for minimizing downtime, which can be costly. For international buyers, understanding local voltage standards and ensuring compatibility with existing equipment is vital to avoid operational issues.

What Role Do Electrical Plugs Play in Telecommunications?

Telecommunications rely heavily on type of electrical plugs to connect communication devices and network equipment. The stability of these connections is paramount, as any disruption can lead to service outages, affecting both customers and revenue. Businesses in this sector must prioritize sourcing plugs that offer durability and resistance to environmental factors, particularly in regions with extreme weather conditions. Ensuring that the plugs meet local regulatory requirements is also critical.

Why Are Electrical Plugs Important in Construction?

In the construction industry, type of electrical plugs are used to power tools and heavy machinery on-site. This application is vital for enhancing productivity and ensuring safety during operations. Construction sites often require flexible power solutions, and sourcing plugs that comply with local safety regulations can mitigate risks. Buyers should consider the specific requirements of their tools and machinery, including voltage and amperage ratings, to ensure compatibility.

How Are Electrical Plugs Used in Hospitality & Events?

In the hospitality and events sector, type of electrical plugs facilitate the provision of power for various appliances and entertainment equipment. This application directly impacts guest experience and operational efficiency. To accommodate a range of devices, businesses must source plugs that offer flexibility in compatibility with different plug types. Additionally, ensuring that these plugs meet local electrical standards is essential for safety and compliance.

What Is the Role of Electrical Plugs in Renewable Energy?

Electrical plugs are integral to integrating renewable energy systems, such as solar and wind, with existing electrical grids. They enable the connection of energy-producing devices to power systems, supporting sustainable energy solutions. International B2B buyers should focus on sourcing plugs that are compatible with various voltages and plug types to facilitate seamless integration. Understanding the local infrastructure and regulations can also enhance project success.

3 Common User Pain Points for ‘type of electrical plugs’ & Their Solutions

Scenario 1: Navigating Voltage Compatibility Issues Across Regions

The Problem: As a B2B buyer sourcing electrical equipment for various international markets, you may encounter significant challenges regarding voltage compatibility. For instance, while Type C plugs are widely used in Europe and Africa (220-240V), Type A plugs operate at a much lower voltage (100-127V) in countries like the USA. This discrepancy can lead to equipment malfunction, safety hazards, and increased costs due to the need for voltage converters or replacements.

The Solution: To effectively navigate voltage compatibility, begin by conducting thorough research on the voltage specifications of the target market. Utilize resources like the IEC standards or databases that map plug types to their respective voltages. When sourcing electrical plugs, look for suppliers who offer dual-voltage appliances or devices designed for international use. Furthermore, consider investing in universal adapters that cater to multiple plug types and voltages, ensuring that your equipment can be utilized across various regions without the risk of damage. Establishing relationships with local distributors can also provide insights into the most suitable equipment for the specific voltage requirements in each market.

Scenario 2: Overcoming Plug Type Diversity in Global Supply Chains

The Problem: One of the most significant hurdles for B2B buyers is the vast diversity of plug types across different countries. For instance, while Type G plugs dominate in the UK, Type F is common in much of Europe. This inconsistency can complicate logistics, lead to increased shipping times, and create a mismatch between equipment and power sources in facilities.

The Solution: To address this issue, implement a standardized approach to sourcing plugs and sockets. Start by developing a comprehensive compatibility matrix that lists the electrical plugs used in your target regions alongside their specifications. Engage with manufacturers who can provide a variety of plug types or customizable options that align with your product needs. Additionally, consider working with a logistics partner specializing in international shipping to streamline the process of managing different plug types. This approach minimizes delays and ensures that your products arrive ready for immediate use in their respective markets.

Scenario 3: Ensuring Safety Compliance with Electrical Plugs

The Problem: Safety compliance is a critical concern when dealing with electrical plugs, particularly for B2B buyers in markets like Africa and South America, where regulations can vary significantly. Using non-compliant plugs can result in electrical hazards, leading to potential damage to equipment, liability issues, and even legal consequences.

The Solution: To ensure compliance with local safety standards, familiarize yourself with the regulations governing electrical equipment in each target market. This may include certifications such as CE marking in Europe or SANS in South Africa. Partnering with reputable suppliers who guarantee compliance with these standards is essential. Implement a rigorous vetting process that includes checking for safety certifications and conducting on-site inspections when possible. Additionally, consider incorporating safety features into your equipment design, such as surge protection and grounding, to further mitigate risks. Regular training for your purchasing team on compliance standards can also help in making informed decisions regarding electrical plugs and sockets.

Strategic Material Selection Guide for type of electrical plugs

When selecting materials for electrical plugs, international B2B buyers must consider various factors that affect performance, durability, and compliance with regional standards. Here, we analyze four common materials used in the manufacturing of electrical plugs, focusing on their properties, advantages, disadvantages, and implications for buyers in Africa, South America, the Middle East, and Europe.

What are the Key Properties of Polyvinyl Chloride (PVC) for Electrical Plugs?

Polyvinyl Chloride (PVC) is a widely used thermoplastic in electrical plug manufacturing. Its key properties include excellent electrical insulation, resistance to moisture, and a temperature rating of up to 70°C. PVC is also known for its good mechanical strength and flexibility, making it suitable for various applications.

Pros and Cons of PVC: The advantages of PVC include its low cost, ease of manufacturing, and good durability. However, it has limitations in high-temperature applications and can become brittle over time when exposed to UV light. Additionally, PVC may not be the best choice for environments with extreme temperatures or corrosive substances.

Impact on Application: PVC is compatible with a wide range of electrical appliances, making it a common choice for consumer electronics. However, buyers should be aware of its limitations in high-heat environments, which may affect the longevity of the plug.

Considerations for International Buyers: Buyers in regions like Nigeria and Brazil should ensure that PVC plugs comply with local standards such as the Brazilian NBR or Nigerian Standards Organization (NSO) regulations to avoid safety issues.

How Does Thermoplastic Elastomer (TPE) Enhance Electrical Plug Performance?

Thermoplastic Elastomer (TPE) is a flexible material that combines the properties of rubber and plastic. TPE offers excellent temperature resistance (up to 125°C) and is highly resistant to chemicals, making it suitable for demanding environments.

Pros and Cons of TPE: TPE’s advantages include superior flexibility, durability, and resistance to wear and tear. However, the manufacturing complexity is higher than that of PVC, leading to increased costs. Additionally, TPE may not be as widely available as other materials.

Impact on Application: TPE is ideal for plugs used in outdoor settings or industrial applications where exposure to harsh conditions is expected. Its chemical resistance makes it suitable for use with various media, including oils and solvents.

Considerations for International Buyers: Buyers in the Middle East and Europe should verify that TPE plugs meet compliance standards such as the European Union’s CE marking to ensure safety and reliability.

What Role Does Metal Play in Electrical Plug Construction?

Metals, particularly copper and brass, are commonly used for the conductive components of electrical plugs. Copper offers excellent conductivity, while brass provides good corrosion resistance and strength.

Pros and Cons of Metal: The primary advantage of using metals is their superior electrical conductivity, which enhances the performance of electrical plugs. However, metals can be prone to corrosion, especially in humid environments, and may increase the overall cost of the plug.

Impact on Application: The use of metal components is essential in high-current applications where conductivity is critical. However, buyers should consider the environmental conditions in which the plugs will be used, as moisture can lead to corrosion.

Considerations for International Buyers: Buyers in South America and Africa should ensure that metal components comply with local standards, such as ASTM for the U.S. or DIN for Germany, to avoid issues related to electrical safety and performance.

How Does Nylon Improve the Durability of Electrical Plugs?

Nylon is a strong, lightweight material often used in the housings of electrical plugs. It has a high melting point (around 220°C) and excellent resistance to impact and abrasion.

Pros and Cons of Nylon: The advantages of nylon include its durability and resistance to wear, making it suitable for high-use applications. However, nylon can be more expensive than other materials like PVC, and its processing can be more complex.

Impact on Application: Nylon is particularly beneficial in applications requiring robust and long-lasting plugs, such as industrial machinery or outdoor equipment.

Considerations for International Buyers: Buyers in Europe and the Middle East should ensure that nylon plugs meet relevant safety and performance standards, such as IEC standards, to ensure compliance and reliability.

Summary Table of Material Selection for Electrical Plugs

| Material | Typical Use Case for type of electrical plugs | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride (PVC) | Consumer electronics and household appliances | Low cost and good electrical insulation | Limited temperature resistance and UV sensitivity | Low |

| Thermoplastic Elastomer (TPE) | Outdoor and industrial applications | Superior flexibility and chemical resistance | Higher manufacturing complexity and cost | Medium |

| Metal (Copper/Brass) | High-current applications | Excellent electrical conductivity | Prone to corrosion in humid environments | Medium |

| Nylon | Industrial machinery and outdoor equipment | High durability and impact resistance | More expensive and complex processing | High |

This strategic material selection guide provides essential insights for B2B buyers in various regions, helping them make informed decisions that align with their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for type of electrical plugs

What Are the Key Manufacturing Processes for Electrical Plugs?

The manufacturing of electrical plugs involves several critical stages, each designed to ensure that the final product meets safety and performance standards. Understanding these processes can help B2B buyers assess potential suppliers effectively.

How Are Materials Prepared for Electrical Plug Manufacturing?

The first step in the manufacturing process is material preparation. Electrical plugs are typically made from a combination of metals and plastics. High-quality copper is often used for the conductive components due to its excellent electrical conductivity, while thermoplastic or thermosetting plastics are used for the casing, providing insulation and protection.

- Material Selection: Suppliers should prioritize materials that comply with international standards for electrical safety, such as UL (Underwriters Laboratories) or IEC (International Electrotechnical Commission).

- Material Testing: Before production, raw materials undergo testing to ensure they meet specific conductivity, temperature resistance, and mechanical strength requirements.

What Are the Main Forming Techniques in Electrical Plug Production?

Once materials are prepared, the next stage is forming. This involves shaping the metals and plastics into the desired configurations.

-

Metal Forming: Techniques such as stamping and forging are commonly employed to shape the metal components. Stamping involves cutting out shapes from metal sheets, while forging uses compressive forces to shape heated metal.

-

Plastic Molding: For the casing, injection molding is the prevalent technique. This process involves injecting molten plastic into a mold, where it cools and solidifies into the desired shape.

-

Quality Considerations: Each forming technique must adhere to strict tolerances to ensure that the plug fits securely into sockets.

How Is Assembly Conducted in Electrical Plug Manufacturing?

The assembly process brings together all the components of the electrical plug.

-

Component Assembly: This stage involves attaching the metal pins to the plastic casing. Automated assembly lines are often used to improve efficiency and consistency.

-

Soldering and Fastening: For plugs that require additional strength, components may be soldered or fastened with screws. The quality of this assembly is critical, as weak connections can lead to electrical failures.

-

Workforce Training: Ensuring that assembly line workers are well-trained in quality standards and techniques can significantly impact the final product’s reliability.

What Finishing Processes Are Used for Electrical Plugs?

The final stage of manufacturing involves finishing processes that enhance the appearance and functionality of the plugs.

-

Surface Treatment: Processes such as electroplating may be used to apply a thin layer of metal to the contacts for enhanced conductivity and corrosion resistance.

-

Final Inspection: Before packaging, plugs undergo a final inspection to check for defects in appearance, fit, and function.

-

Packaging: Proper packaging is essential to prevent damage during transit and to ensure that the plugs remain in compliance with international shipping standards.

What Quality Assurance Measures Are Essential for Electrical Plug Manufacturing?

Quality assurance is critical in ensuring that electrical plugs are safe and reliable for use. Various international standards govern the quality of electrical components.

Which International Standards Should B2B Buyers Be Aware Of?

-

ISO 9001: This standard outlines the requirements for a quality management system. Suppliers should be certified to demonstrate their commitment to quality.

-

CE Marking: In Europe, electrical plugs must have the CE mark, indicating compliance with health, safety, and environmental protection standards.

-

UL Certification: In North America, UL certification is essential for safety testing, especially for products that will be used in residential or commercial settings.

What Quality Control Checkpoints Should Be Implemented?

Quality control is integrated throughout the manufacturing process and includes several key checkpoints:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing checks ensure that processes remain within specified tolerances. This may include measuring dimensions, checking assembly integrity, and testing for electrical continuity.

-

Final Quality Control (FQC): After assembly, each plug should undergo final testing, including electrical testing for insulation resistance and operational testing to ensure proper functionality.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is crucial to ensure product reliability.

What Audits and Reports Should Buyers Request?

-

Supplier Audits: Regular audits can help assess a supplier’s adherence to quality standards. Buyers should request audit reports that detail compliance with ISO 9001 or other relevant certifications.

-

Quality Control Reports: Suppliers should provide documentation of their QC processes, including test results from IQC, IPQC, and FQC.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased review of a supplier’s manufacturing and quality assurance processes, ensuring that they meet international standards.

What Are the Common Testing Methods Used in Electrical Plug Quality Assurance?

Testing is an integral part of the quality assurance process for electrical plugs. Common testing methods include:

-

Electrical Testing: This includes measuring voltage and current ratings, insulation resistance tests, and dielectric strength tests to ensure safety and performance.

-

Mechanical Testing: Mechanical stress tests evaluate the durability of the plug, including pull tests to assess the strength of connections and impact tests to ensure robustness.

-

Environmental Testing: Plugs may also undergo environmental testing, simulating conditions such as humidity, temperature extremes, and exposure to chemicals to ensure reliability under various conditions.

Conclusion: Ensuring Quality in Your Supply Chain for Electrical Plugs

Understanding the manufacturing processes and quality assurance measures for electrical plugs is essential for international B2B buyers. By focusing on key manufacturing stages, international standards, and quality control practices, buyers can make informed decisions that ensure the reliability and safety of electrical products. This knowledge is particularly valuable for buyers from regions like Africa, South America, the Middle East, and Europe, where compliance with local and international standards is crucial for market acceptance and operational success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘type of electrical plugs’

The following practical sourcing guide provides international B2B buyers with a structured approach to procuring electrical plugs. This checklist focuses on essential steps to ensure compliance, quality, and compatibility with regional standards, particularly beneficial for businesses operating in Africa, South America, the Middle East, and Europe.

A stock image related to type of electrical plugs.

Step 1: Identify Your Regional Requirements

Understanding the specific electrical plug types and standards used in your target market is crucial. Each region has its own unique plug types (e.g., Type C in Europe, Type G in the UK), voltage, and frequency specifications. Familiarize yourself with the local electrical regulations and standards to ensure that the plugs you procure will be compatible with existing infrastructure.

Step 2: Define Your Technical Specifications

Clarifying the technical specifications of the electrical plugs you need will streamline your sourcing process. Consider factors such as:

– Current Rating: Determine whether you need plugs rated for 10A, 15A, or higher.

– Grounding Requirements: Decide if you require grounded or ungrounded plugs based on safety standards.

Step 3: Evaluate Supplier Certifications

Before engaging with potential suppliers, verify their certifications to ensure they comply with international safety and quality standards. Look for certifications such as ISO 9001 or IEC standards, which indicate a commitment to quality management. Suppliers with these certifications are more likely to provide reliable products that meet your specifications.

Step 4: Assess Supplier Reputation and Experience

Investigate the reputation and experience of the suppliers you are considering. A supplier with a solid track record in your specific region can offer valuable insights into local market dynamics. Request references or case studies from previous clients to gauge their reliability and service quality.

Step 5: Request Samples for Testing

Before making a bulk purchase, always request samples of the electrical plugs you intend to buy. This step allows you to assess the quality, durability, and compatibility of the products with your existing systems. Testing samples can prevent costly mistakes and ensure that the products meet your operational requirements.

Step 6: Negotiate Pricing and Terms

Once you are satisfied with the quality of the samples, enter into negotiations with your chosen supplier. Discuss pricing, payment terms, and delivery timelines. Be clear about your expectations regarding after-sales support and warranty policies, as these can significantly impact your overall satisfaction with the procurement.

Step 7: Plan for Logistics and Distribution

Consider the logistics involved in transporting the plugs from the supplier to your location. Evaluate shipping options, customs regulations, and potential tariffs that may apply. A well-planned logistics strategy will ensure timely delivery and minimize disruptions in your supply chain.

By following this comprehensive checklist, international B2B buyers can confidently navigate the complexities of sourcing electrical plugs, ensuring that they acquire products that are safe, compliant, and tailored to their specific market needs.

Comprehensive Cost and Pricing Analysis for type of electrical plugs Sourcing

What Are the Key Cost Components in Electrical Plug Manufacturing?

When sourcing electrical plugs, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials such as copper, plastic, and rubber vary in price depending on market conditions. For example, copper prices can fluctuate based on global demand and supply chains.

-

Labor: Labor costs can differ based on the manufacturing location. Countries with lower labor costs, such as those in Southeast Asia, may offer competitive pricing. However, it’s crucial to consider the quality of labor and any associated training costs.

-

Manufacturing Overhead: This encompasses costs related to facilities, equipment maintenance, and utilities. Efficient manufacturing processes can help minimize overhead, which is particularly important for high-volume orders.

-

Tooling: Custom molds and machinery setup for specific plug designs add to initial costs. For smaller orders, these expenses can be amortized over time, but they still represent a significant upfront investment.

-

Quality Control (QC): Ensuring compliance with international safety standards (such as CE or UL certifications) is vital. QC processes can add to costs but are necessary to prevent recalls and liability issues.

-

Logistics: Shipping costs can vary widely depending on the destination, volume, and shipping method. Understanding the Incoterms (International Commercial Terms) can help buyers anticipate additional costs related to shipping and customs.

-

Margin: Suppliers typically apply a markup on their costs to ensure profitability. This margin can vary based on the supplier’s market positioning and the competitive landscape.

How Do Price Influencers Affect the Cost of Electrical Plugs?

Several factors can influence pricing beyond the basic cost structure:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts. Buyers should negotiate MOQs to optimize pricing, particularly when dealing with manufacturers overseas.

-

Specifications and Customization: Customized plugs or those with specific certifications may incur additional costs. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: Higher quality materials and certifications come at a premium. Buyers should assess whether the enhanced quality justifies the cost, especially in regions with stringent safety regulations.

-

Supplier Factors: The reliability and reputation of suppliers can impact pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

What Negotiation Tips Can International Buyers Use to Secure Better Pricing?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation strategies are crucial:

-

Understand Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, durability, and compliance. A lower initial price may lead to higher costs in the long run if the product is subpar.

-

Leverage Multiple Quotes: Obtain quotes from multiple suppliers to understand the market rate. This will provide leverage during negotiations and help identify the best overall deal.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing, favorable terms, and priority service. Trust and reliability can often yield discounts not available to one-time buyers.

-

Be Aware of Pricing Nuances: Understand the local market conditions of the supplier’s country. Economic fluctuations, tariffs, and local regulations can all affect pricing and should be considered when negotiating.

Conclusion: Why Is It Important to Stay Informed About Electrical Plug Pricing?

Understanding the comprehensive cost structure and pricing influencers for electrical plugs is essential for international B2B buyers. By being informed and employing effective negotiation strategies, buyers can secure better deals, ensuring that their sourcing efforts align with both budgetary constraints and quality requirements. Always remember to ask for indicative prices and be mindful of the various factors that can impact final costs, particularly when dealing across international borders.

Alternatives Analysis: Comparing type of electrical plugs With Other Solutions

Understanding Alternatives to Traditional Electrical Plugs

In the realm of electrical connectivity, the traditional type of electrical plugs faces competition from various alternative solutions. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe evaluate their options, understanding these alternatives becomes essential. The focus should be on the performance, cost, implementation ease, maintenance, and best use cases for each solution.

Comparison of Electrical Plugs with Alternative Solutions

| Comparison Aspect | Type Of Electrical Plugs | Universal Power Adapters | Wireless Power Transfer |

|---|---|---|---|

| Performance | Reliable for most appliances; voltage compatibility varies by type | Versatile, accommodating multiple plug types; may reduce efficiency due to conversion | High efficiency for short distances; limited by device compatibility |

| Cost | Generally low; cost varies by plug type and material | Moderate; includes initial investment for the adapter | High; requires specialized devices and infrastructure |

| Ease of Implementation | Simple installation; requires appropriate socket type | User-friendly; plug and play for various regions | Complex; requires devices designed for wireless charging |

| Maintenance | Minimal; occasional replacement needed due to wear | Minimal; can last long if used properly | Higher; involves technology upgrades and device compatibility checks |

| Best Use Case | Ideal for fixed installations in homes and businesses | Excellent for travelers and businesses with diverse plug requirements | Suitable for modern devices that support wireless charging |

Detailed Breakdown of Alternatives

What are Universal Power Adapters?

Universal power adapters provide a flexible solution for users who travel or operate in multiple regions. They can accommodate various plug types and are designed to convert voltage, making them suitable for a wide range of devices. The primary advantage of universal adapters is their versatility; however, they may introduce slight inefficiencies during the conversion process. Additionally, they often require careful handling to ensure compatibility with specific devices.

How Does Wireless Power Transfer Work?

Wireless power transfer utilizes electromagnetic fields to charge devices without the need for physical connections. This technology is particularly beneficial for modern electronics, such as smartphones and tablets, that support wireless charging. While wireless power transfer offers a high level of convenience and reduces wear on physical connectors, it comes with higher initial costs and requires devices specifically designed to accept wireless charging. Furthermore, the effective range is typically limited, making it less suitable for larger appliances.

Making an Informed Choice for Your Needs

When considering the right solution for electrical connectivity, international B2B buyers should evaluate their specific needs against the features of traditional plugs and their alternatives. Factors such as the type of devices being used, the frequency of travel, and the overall cost of ownership should guide the decision-making process. For instance, businesses operating in multiple countries may benefit from universal power adapters, while those focused on modern electronic devices may find wireless power transfer more suitable. Ultimately, the right choice will depend on a thorough assessment of operational requirements, budget constraints, and long-term maintenance considerations.

Essential Technical Properties and Trade Terminology for type of electrical plugs

What Are the Key Technical Properties of Electrical Plugs?

Understanding the technical specifications of electrical plugs is essential for B2B buyers, especially when sourcing products from diverse markets. Here are some critical specifications to consider:

-

Material Grade

– Electrical plugs are typically made from various materials, including thermoplastics and metals. The choice of material affects durability, conductivity, and resistance to environmental factors. For instance, plugs made from high-grade polycarbonate are more resistant to heat and impact, which is vital for industrial applications. Buyers should prioritize materials that meet international safety standards to ensure reliability. -

Current Rating (Amperage)

– The current rating indicates the maximum amount of electrical current a plug can safely carry. Common ratings include 10A, 16A, and 20A. Selecting the appropriate current rating is crucial to prevent overheating and potential fire hazards. B2B buyers need to match the plug’s rating with their equipment’s requirements to ensure operational safety and efficiency. -

Voltage Rating

– Voltage ratings indicate the maximum voltage that a plug can handle, commonly ranging from 100V to 250V, depending on the region. Understanding voltage compatibility is essential for international trade, as mismatched voltage levels can lead to equipment damage. Buyers should verify that the plugs sourced meet the voltage specifications of their target markets. -

Pin Configuration

– The configuration and size of the pins are critical for compatibility with sockets. Different regions use varying pin designs, such as Type C, Type G, and Type I. Ensuring that plugs fit standard sockets in target markets is vital for seamless integration. Buyers should familiarize themselves with local plug types to avoid sourcing errors. -

Temperature Tolerance

– This specification defines the range of temperatures within which the plug can operate safely. High-temperature tolerance is particularly important in industrial settings where equipment may be exposed to extreme conditions. Buyers should assess the operational environment of their products to choose plugs that can withstand the necessary temperature ranges. -

Durability and Lifecycle

– The lifecycle of a plug refers to its expected lifespan under normal usage conditions. Factors such as resistance to wear, corrosion, and exposure to chemicals impact durability. B2B buyers should consider sourcing plugs that offer warranties or certifications for durability, ensuring long-term performance and cost-effectiveness.

What Are Common Trade Terms Related to Electrical Plugs?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are several common terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that manufacture products that are then sold under another company’s brand name. Understanding OEM relationships can help buyers identify reliable suppliers who can provide high-quality plugs tailored to specific requirements. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Buyers should be aware of MOQs to manage inventory effectively and ensure that they can meet demand without overcommitting financially. -

RFQ (Request for Quotation)

– An RFQ is a document that a buyer submits to suppliers to solicit price quotes for specific products. Crafting a detailed RFQ can facilitate better pricing and terms from suppliers, making it an essential tool for B2B procurement. -

Incoterms (International Commercial Terms)

– These are standardized terms that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms helps buyers assess shipping costs, insurance responsibilities, and risk management strategies when sourcing plugs from overseas. -

Certification Standards

– Certification standards, such as IEC, UL, or CE, indicate that a product meets specific safety and performance criteria. Buyers should prioritize certified plugs to ensure compliance with local regulations and safety norms in their respective markets. -

Lead Time

– This term refers to the time it takes from placing an order until the product is delivered. Understanding lead times helps buyers plan their inventory and production schedules effectively, ensuring they can meet customer demands without delays.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing electrical plugs, ensuring safety, compatibility, and reliability in their operations.

Navigating Market Dynamics and Sourcing Trends in the type of electrical plugs Sector

What Are the Key Market Dynamics and Trends in the Electrical Plugs Sector?

The electrical plugs sector is experiencing significant transformation driven by globalization, technological advancements, and changing consumer preferences. International B2B buyers from regions like Africa, South America, the Middle East, and Europe should note that the demand for standardized electrical plugs is increasing as global trade expands. The need for compatibility across diverse electrical systems is pushing manufacturers to design versatile products that can accommodate multiple plug types. Additionally, the rise of smart technologies in homes and businesses is creating a demand for intelligent plugs that can integrate with IoT devices, enhancing energy efficiency and convenience.

Emerging trends in sourcing include an increased focus on local manufacturing to reduce lead times and shipping costs. Buyers are leveraging regional suppliers to fulfill their needs, especially in regions like Africa and South America, where local production can lead to significant cost savings. Furthermore, the COVID-19 pandemic has accelerated the shift toward e-commerce, prompting buyers to seek online platforms for sourcing electrical plugs. As international trade regulations evolve, understanding the compliance requirements for importing different plug types becomes crucial for B2B buyers.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in Electrical Plugs?

The environmental impact of electrical plug production is becoming a critical consideration for B2B buyers. Manufacturers are increasingly held accountable for their carbon footprints, prompting a shift towards sustainable practices. Buyers should look for suppliers who prioritize eco-friendly materials and processes. Certifications such as ISO 14001 can help identify manufacturers that adhere to stringent environmental management standards.

Ethical sourcing is also gaining prominence. B2B buyers must ensure that their supply chains are transparent and that materials are sourced responsibly. This includes verifying that suppliers comply with labor laws and maintain fair working conditions. Buyers should consider engaging with suppliers who use recycled materials or offer products designed for end-of-life recyclability. By prioritizing sustainability and ethics, businesses not only mitigate risks but also enhance their brand reputation in an increasingly eco-conscious market.

What Is the Brief History of Electrical Plugs and Their Evolution?

The evolution of electrical plugs can be traced back to the late 19th century, coinciding with the widespread adoption of electricity. Initially, plugs were developed for specific uses, leading to a plethora of designs and types worldwide. The lack of standardization created compatibility issues, prompting various countries to develop their unique plug types, as seen with the 15 recognized types today.

Over the years, technological advancements have influenced plug design, leading to the introduction of grounding features and improved safety measures. The advent of global trade has further pushed the need for compatibility, resulting in ongoing discussions about standardizing electrical plugs. Understanding this historical context allows B2B buyers to appreciate the complexities of sourcing electrical plugs and the importance of considering both historical significance and modern advancements when making purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of type of electrical plugs

-

How do I solve compatibility issues with different electrical plug types?

To address compatibility issues, first identify the plug type needed for your devices based on the destination country. Utilize adapters or converters to facilitate the connection between incompatible plug types. Additionally, consider sourcing multi-standard plugs that can accommodate various types, such as Type C or Type G. Engaging with suppliers who specialize in international standards can ensure you receive products that meet your needs across different regions. -

What is the best electrical plug type for my business in Africa?

For businesses operating in Africa, Type C and Type D plugs are commonly used. Type C is prevalent across many African nations and is compatible with various appliances. If your operations extend to countries like South Africa, Type M plugs are also essential. Assess your equipment requirements and regional standards to select the most suitable plug type for seamless operations. -

What are the typical minimum order quantities (MOQs) for electrical plugs?

MOQs for electrical plugs can vary significantly depending on the supplier and the type of plug. Generally, MOQs range from 500 to 5,000 units for standard plugs. However, specialized or customized plugs may have higher MOQs. It’s advisable to negotiate terms with suppliers based on your projected demand, ensuring that you balance cost-effectiveness with supply chain reliability. -

How can I ensure quality assurance (QA) when sourcing electrical plugs?

To ensure QA, select suppliers who are ISO certified and adhere to international safety standards. Request product samples for testing before placing bulk orders. Additionally, inquire about their QA processes, such as regular inspections and certifications. Establish clear quality expectations in your contracts, and consider third-party inspections for larger shipments to mitigate risks of non-compliance. -

What payment terms should I expect when sourcing electrical plugs internationally?

Payment terms can vary widely based on the supplier and the nature of the transaction. Common terms include a 30% deposit upon order confirmation and the balance before shipment. Some suppliers may offer letters of credit or payment upon delivery for established relationships. Always clarify payment expectations early in negotiations to avoid misunderstandings and ensure smooth transactions. -

How do I evaluate suppliers for electrical plugs?

Evaluating suppliers involves several steps. Start by checking their experience in the industry and their reputation through reviews or testimonials. Verify their certifications and compliance with international standards. Request a portfolio of previous projects and inquire about their production capacity and lead times. Building a relationship based on transparency and mutual trust is crucial for long-term partnerships. -

What logistics considerations should I keep in mind when importing electrical plugs?

When importing electrical plugs, consider shipping methods, costs, and lead times. Ensure compliance with customs regulations in your destination country, which may involve specific documentation or certifications. Factor in potential delays and plan for contingencies. Collaborating with logistics experts can streamline the process, ensuring timely delivery while adhering to all regulatory requirements.

A stock image related to type of electrical plugs.

- Can I customize electrical plugs for my specific needs?

Yes, many suppliers offer customization options for electrical plugs. You can request specific features such as color, size, or branding. Discuss your requirements early in the sourcing process to understand the feasibility and associated costs. Keep in mind that customized products may have higher MOQs and longer lead times, so plan accordingly to meet your business needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for type of electrical plugs

In the evolving landscape of global commerce, understanding the diverse types of electrical plugs and their compatibility is crucial for international B2B buyers. Each region, from Africa to Europe, utilizes specific plug types that cater to local electrical standards and safety requirements. Strategic sourcing of electrical plugs not only ensures compliance with these standards but also enhances operational efficiency and product reliability.

A stock image related to type of electrical plugs.

How Can Strategic Sourcing Enhance Your Supply Chain?

By engaging in strategic sourcing, businesses can mitigate risks associated with supply chain disruptions and capitalize on emerging market opportunities. This involves evaluating suppliers based on their ability to meet international standards and local regulations. Buyers should prioritize partnerships that offer a diverse range of plug types, ensuring they can cater to various markets efficiently.

What’s Next for International B2B Buyers?

As global demand for electrical appliances continues to rise, the importance of selecting the right electrical plugs cannot be overstated. Buyers from regions like Africa, South America, the Middle East, and Europe should remain vigilant about trends in plug technology and regional compliance requirements. Investing in quality sourcing strategies today will pave the way for sustainable growth and competitive advantage in the future.

Explore partnerships that align with your business goals and embrace the opportunities that come with understanding the global electrical plug landscape.