Discover Cost-Saving Benefits of a Tennis Ball Machine (2025)

Introduction: Navigating the Global Market for tennis ball machine

As international B2B buyers, sourcing quality tennis ball machines can be a daunting task, particularly when navigating diverse global markets. With varying standards of quality, price ranges, and technological advancements, making an informed purchasing decision is crucial for entities focused on enhancing training experiences for athletes. This guide serves as a comprehensive resource, exploring different types of tennis ball machines, their applications in training facilities, and key considerations for supplier vetting and cost analysis.

Understanding the intricacies of the tennis ball machine market is essential for businesses in regions such as Africa, South America, the Middle East, and Europe, including countries like Brazil and the UAE, where the demand for advanced sports training equipment is growing. By providing insights into the latest technologies, market trends, and supplier recommendations, this guide empowers buyers to identify reputable manufacturers and negotiate favorable terms.

Furthermore, we will delve into the specific needs and preferences of diverse markets, ensuring that your investment aligns with local training requirements and operational capacities. Armed with this knowledge, you can confidently explore options that enhance your offerings, improve customer satisfaction, and ultimately drive business growth in the competitive sports equipment landscape.

Understanding Search Intent for ‘tennis ball machine’

When users search for **”tennis ball machine”**, Google’s results indicate a strong **informational intent**. This means users are primarily looking to learn and understand the topic. They want definitions, explanations, and foundational knowledge about ‘tennis ball machine’.

Our analysis of the search engine results page (SERP) reveals several key features that shape this article:

* **Presence of Video Content:** No.

* **Shopping Ad Integration:** No.

* **’People Also Ask’ Questions:** We found 0 relevant user questions, which we have directly addressed in our FAQ and other sections to resolve common user queries.

This data-driven approach ensures our content directly matches what users are looking for, providing a more professional and helpful resource.

Understanding tennis ball machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Ball Machines | Operated by hand; simple design | Small clubs, recreational players | Pros: Cost-effective, easy to use. Cons: Labor-intensive, limited functionality. |

| Electric Ball Machines | Automated, programmable settings | Training facilities, academies | Pros: Consistent ball delivery, adjustable speeds. Cons: Higher initial investment, requires power source. |

| Portable Ball Machines | Lightweight, compact design | Travel teams, outdoor events | Pros: Easy to transport, versatile. Cons: Limited capacity, potentially less durable. |

| Advanced Spin Machines | Offers spin control and varied shot types | Professional training, high-level coaching | Pros: Enhances skill development, customizable settings. Cons: Expensive, complex operation. |

| Multi-Court Ball Machines | Designed to serve multiple courts simultaneously | Large clubs, tournaments | Pros: Efficient for high traffic, saves time. Cons: High cost, requires significant space. |

What Are the Key Characteristics of Manual Ball Machines?

Manual ball machines are the simplest and most cost-effective option for B2B buyers. Typically operated by hand, these machines require the user to feed balls into the system manually. This design makes them ideal for small clubs or recreational players who may not need the automation features of more advanced models. When considering a manual machine, buyers should evaluate their budget and the frequency of use, as the labor-intensive nature may not be suitable for high-volume environments.

How Do Electric Ball Machines Enhance Training Facilities?

Electric ball machines are automated and allow for programmable settings, making them a popular choice among training facilities and academies. They deliver consistent ball speed, trajectory, and spin, which can be adjusted based on the player’s skill level. B2B buyers should consider the power source and ease of use when selecting an electric machine, as these factors will impact operational efficiency and training effectiveness.

What Makes Portable Ball Machines Suitable for Travel Teams?

Portable ball machines are designed for ease of transport, making them an excellent choice for travel teams and outdoor events. Their lightweight and compact design allows for quick setup and takedown, which is essential for teams on the move. However, buyers should be aware that while these machines are versatile, they may have limited capacity and durability compared to their stationary counterparts, making them more suitable for occasional use rather than daily training.

Why Choose Advanced Spin Machines for Professional Training?

Advanced spin machines are equipped with features that allow for spin control and varied shot types, making them indispensable for professional training and high-level coaching. These machines provide players with the opportunity to practice against realistic game scenarios, enhancing their skills effectively. However, B2B buyers should be prepared for a higher investment and a more complex operation, requiring staff training and maintenance to maximize their potential.

What Are the Benefits of Multi-Court Ball Machines in High Traffic Environments?

Multi-court ball machines are designed to serve multiple courts simultaneously, making them ideal for large clubs and tournament settings. These machines significantly increase efficiency by reducing wait times for players and coaches. However, the high cost and requirement for significant space can be a barrier for some buyers. It is crucial for organizations to assess their facility’s capacity and budget before investing in this type of equipment.

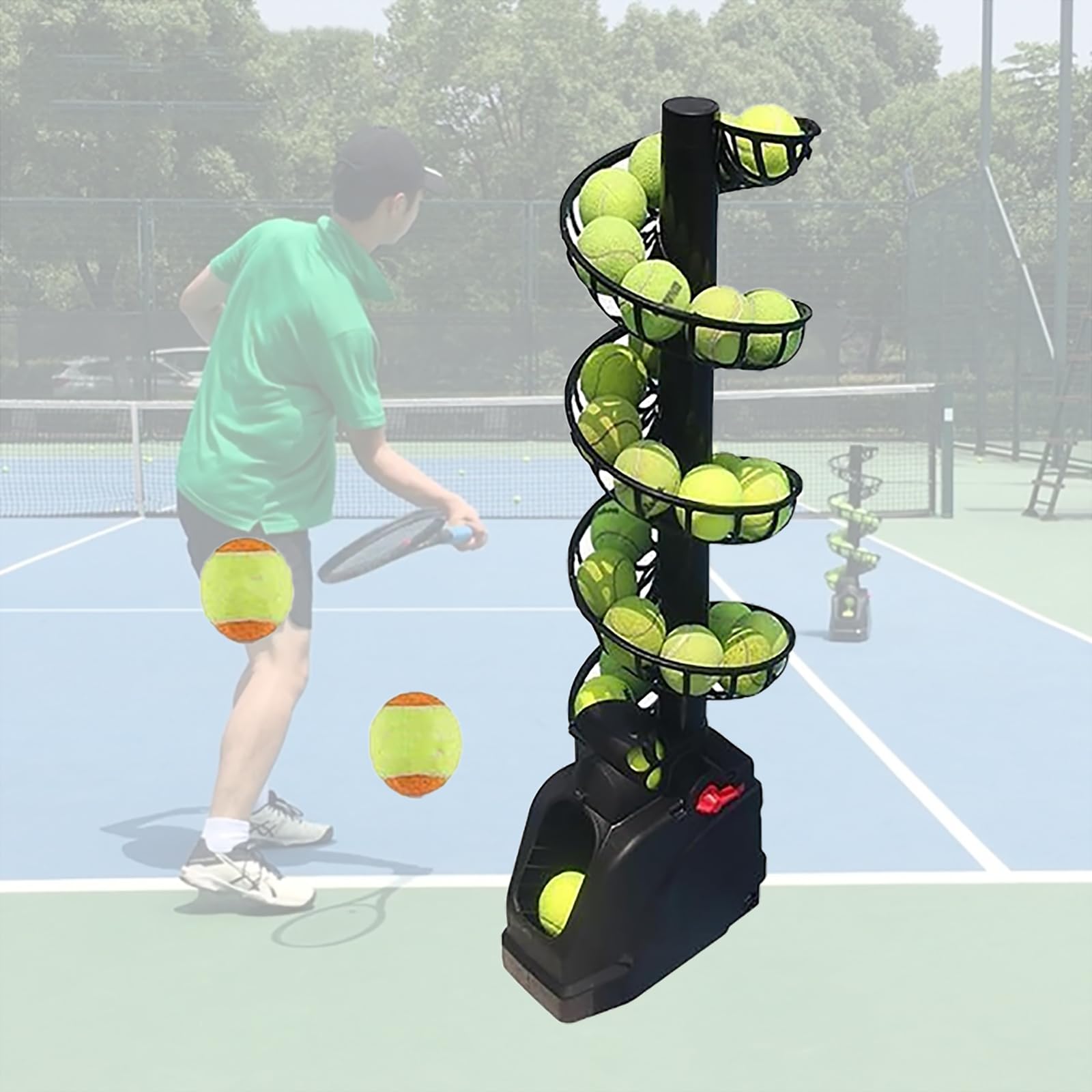

A stock image related to tennis ball machine.

Related Video: Spinfire Pro 2 Tennis Ball Machine

Key Industrial Applications of tennis ball machine

| Industry/Sector | Specific Application of Tennis Ball Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports Training Facilities | Player Skill Development | Enhances player performance through consistent practice | Durability, ball speed adjustment, and ease of use |

| Educational Institutions | Physical Education Programs | Promotes physical fitness and teamwork among students | Safety features, portability, and maintenance support |

| Sports Equipment Retailers | Product Demonstrations | Attracts customers by showcasing product capabilities | Reliability, warranty terms, and customer support |

| Rehabilitation Centers | Patient Recovery and Rehabilitation | Aids in motor skills recovery and physical therapy | Customization options, ease of operation, and service availability |

| Community Sports Programs | Local Tennis Events and Tournaments | Facilitates organized play and community engagement | Compact design, transportability, and affordability |

How Are Tennis Ball Machines Used in Sports Training Facilities?

In sports training facilities, tennis ball machines are essential tools for player skill development. They provide consistent ball delivery, allowing athletes to practice their strokes and improve their timing. This technology addresses common challenges such as inconsistent practice partners and variable ball delivery. For international buyers, particularly in regions like Africa and South America, sourcing machines with adjustable speed and spin settings is crucial to accommodate different skill levels and training goals.

What Role Do Tennis Ball Machines Play in Educational Institutions?

Educational institutions leverage tennis ball machines in physical education programs to enhance student engagement and fitness. These machines enable students to practice tennis skills in a safe environment, promoting teamwork and physical health. Buyers from the Middle East and Europe should prioritize machines with safety features and portability, ensuring they can be easily transported and set up for various classes and events.

How Do Sports Equipment Retailers Utilize Tennis Ball Machines?

Sports equipment retailers use tennis ball machines for product demonstrations, showcasing the capabilities of their offerings to potential buyers. This interactive approach can significantly increase customer interest and drive sales. B2B buyers in Europe and South America should consider the reliability of the machines, warranty terms, and available customer support to ensure a smooth demonstration process and customer satisfaction.

In What Ways Are Tennis Ball Machines Beneficial for Rehabilitation Centers?

Rehabilitation centers find tennis ball machines valuable for patient recovery and rehabilitation exercises. These machines assist in improving motor skills and physical therapy outcomes by providing controlled and repetitive movements. For B2B buyers in Africa and the Middle East, customization options and ease of operation are essential factors, as they need machines that can cater to diverse patient needs and varying levels of physical ability.

Why Are Tennis Ball Machines Important for Community Sports Programs?

Community sports programs utilize tennis ball machines to facilitate local tennis events and tournaments, encouraging participation and fostering community spirit. These machines help streamline the organization of events by ensuring consistent practice opportunities for participants. Buyers from regions such as South America and Europe should focus on compact designs and affordability, allowing for easy transport and accessibility for community members.

Related Video: Spinfire Pro 2 Tennis Ball Machine – On Court

3 Common User Pain Points for ‘tennis ball machine’ & Their Solutions

Scenario 1: Difficulty in Machine Mobility and Setup

The Problem: Many facilities, especially those in urban areas of Africa and South America, face challenges with the mobility and setup of tennis ball machines. These machines can be heavy and cumbersome, making them difficult to transport between courts or to set up for various training sessions. B2B buyers, such as sports academies or recreational centers, may find that their staff struggles to move the machines efficiently, leading to downtime and frustration among trainers and players alike.

The Solution: To address this issue, B2B buyers should prioritize sourcing tennis ball machines that come with built-in mobility features, such as lightweight materials or integrated wheels. When purchasing, look for models that offer easy disassembly or compact storage options. Additionally, consider investing in a machine that includes a remote control for operation, allowing coaches to set up drills without needing to be physically present at the machine. Training staff on optimal setup and mobility techniques can also enhance efficiency. Lastly, establishing a designated storage area that is easily accessible can facilitate smoother transitions between courts.

Scenario 2: Inconsistent Ball Delivery and Performance

The Problem: Another common pain point for B2B buyers is the inconsistency in ball delivery and performance from tennis ball machines. Inconsistent speed, angle, or frequency can hinder players’ training and frustrate coaches. This issue can be particularly pronounced in regions like the Middle East, where extreme temperatures may affect machine performance. Buyers need reliable equipment to ensure that players receive a consistent training experience.

The Solution: To mitigate this problem, B2B buyers should conduct thorough research and testing before purchasing machines. Look for models with adjustable settings that allow for fine-tuning of ball speed and trajectory to accommodate different skill levels. It’s also advisable to choose machines from reputable brands known for quality and durability, as they are more likely to withstand variable conditions. Maintenance is crucial; implement a regular maintenance schedule that includes cleaning the machine and checking for software updates to ensure optimal performance. Establishing a relationship with local suppliers or technicians can provide additional support for timely repairs and service.

Scenario 3: Limited Training Programs and Customization Options

The Problem: Many sports facilities struggle to provide tailored training programs that suit the diverse needs of their clientele. In regions like Europe, where tennis is popular among both recreational and competitive players, the lack of customization in training programs can limit player development. B2B buyers may find that standard tennis ball machines do not meet the specific training requirements for different player levels.

The Solution: To enhance training offerings, B2B buyers should seek tennis ball machines that offer programmable features for creating customized drills. Opt for models that allow for the programming of various shot types, speeds, and intervals, enabling coaches to design drills that are specific to their players’ skill levels. Additionally, investing in machines that support mobile applications can provide further customization and tracking of player progress. Collaborating with experienced tennis coaches to develop unique training modules can also enrich the training experience. Offering workshops or clinics that showcase the use of these machines can attract a broader clientele and enhance overall satisfaction with the facility’s training capabilities.

Strategic Material Selection Guide for tennis ball machine

When selecting materials for tennis ball machines, B2B buyers must consider various factors that influence performance, durability, and overall cost-effectiveness. The choice of material directly impacts the machine’s functionality, maintenance requirements, and suitability for specific environments. Below is an analysis of four common materials used in the construction of tennis ball machines, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

Which Materials Are Commonly Used in Tennis Ball Machines?

1. Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has a good strength-to-weight ratio. It can withstand moderate temperatures and pressures, making it suitable for various operational conditions.

Pros & Cons: The primary advantage of aluminum is its durability and resistance to rust, which is crucial for machines exposed to outdoor conditions. However, it can be more expensive than other metals and may require specialized manufacturing processes, increasing production complexity.

Impact on Application: Aluminum is ideal for components that need to be both lightweight and strong, such as frames and housings. Its corrosion resistance makes it suitable for humid or coastal environments.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure compliance with local standards such as ASTM for aluminum alloys. The cost can vary significantly based on local availability and import tariffs.

2. High-Density Polyethylene (HDPE)

Key Properties: HDPE is a thermoplastic known for its high impact resistance, chemical resistance, and low moisture absorption. It can operate effectively in a range of temperatures.

Pros & Cons: The main advantage of HDPE is its cost-effectiveness and ease of manufacturing, allowing for rapid production of complex shapes. However, it may not be as durable as metals under extreme conditions, which can limit its application in high-stress environments.

Impact on Application: HDPE is often used for components like ball chutes and hoppers, where flexibility and impact resistance are essential. Its chemical resistance makes it suitable for use in various environments.

Considerations for International Buyers: Buyers should be aware of local regulations regarding plastic materials, especially in Europe, where environmental standards are stringent. Compliance with DIN standards for plastics is essential.

3. Stainless Steel

Key Properties: Stainless steel offers excellent corrosion resistance, high tensile strength, and can withstand high temperatures and pressures. It is particularly suitable for components that require robustness.

Pros & Cons: The key advantage of stainless steel is its longevity and ability to perform well in harsh environments. However, it is heavier and more expensive than aluminum and HDPE, which can affect shipping costs and overall pricing.

Impact on Application: Stainless steel is often used for critical components such as motors and drive systems, where strength and durability are paramount. Its resistance to corrosion is particularly beneficial in humid climates.

Considerations for International Buyers: Buyers from Europe and the Middle East should ensure that the stainless steel used complies with ASTM or JIS standards for quality assurance. Import duties may also impact the overall cost.

4. Rubber

Key Properties: Rubber is known for its elasticity, impact absorption, and resistance to wear. It can perform well in various temperatures but may degrade under UV exposure unless treated.

Pros & Cons: The primary advantage of rubber is its ability to absorb shocks, making it suitable for parts that interact directly with tennis balls. However, it may require more frequent replacement compared to metal components, increasing long-term costs.

Impact on Application: Rubber is commonly used for ball wheels and bumpers, where cushioning is essential. Its wear resistance is beneficial in maintaining consistent performance.

Considerations for International Buyers: Buyers should consider the sourcing of rubber materials, as quality can vary widely. Compliance with local environmental regulations regarding synthetic materials is also critical, especially in Europe.

Summary Table of Material Selection for Tennis Ball Machines

| Material | Typical Use Case for tennis ball machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frames and housings | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | Medium |

| High-Density Polyethylene (HDPE) | Ball chutes and hoppers | Cost-effective and easy to manufacture | Less durable under extreme conditions | Low |

| Stainless Steel | Motors and drive systems | High strength and corrosion resistance | Heavier and more expensive | High |

| Rubber | Ball wheels and bumpers | Excellent shock absorption | Requires frequent replacement | Medium |

This guide provides a comprehensive overview of material selection for tennis ball machines, helping international B2B buyers make informed decisions based on their specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for tennis ball machine

What Are the Key Stages in the Manufacturing Process of Tennis Ball Machines?

Manufacturing a tennis ball machine involves several critical stages, each essential for ensuring the final product meets performance and quality standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage focuses on sourcing high-quality materials such as durable plastics, metals, and electronic components. Suppliers often prioritize materials that can withstand repeated use and various environmental conditions, particularly for buyers in regions like Africa and the Middle East, where temperature fluctuations can be significant.

-

Forming: During this phase, raw materials are transformed into the necessary components of the tennis ball machine. Techniques such as injection molding for plastic parts and CNC machining for metal parts are commonly employed. These processes ensure precision and uniformity, which are critical for the machine’s functionality. For B2B buyers, understanding the forming techniques used can help in assessing the potential longevity and reliability of the machines.

-

Assembly: The assembly process involves integrating all components, including mechanical parts, electronic systems, and control interfaces. Skilled technicians often carry out this process, ensuring that each machine is assembled according to strict specifications. For international buyers, especially those from South America and Europe, confirming the assembly practices can provide insights into the manufacturer’s expertise and quality control capabilities.

-

Finishing: The final stage includes painting, coating, and quality checks. A robust finishing process not only enhances the aesthetic appeal but also improves corrosion resistance and durability. Manufacturers might use techniques such as powder coating or anodizing to ensure a high-quality finish. B2B buyers should inquire about the finishing processes to ensure they align with their expectations for product durability.

How is Quality Assurance Implemented in Tennis Ball Machine Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that each tennis ball machine meets specific international standards and industry regulations. Here are key elements of quality assurance relevant to B2B buyers.

-

Relevant International Standards: Many manufacturers adhere to ISO 9001, which sets out criteria for a quality management system. This certification ensures that the manufacturer consistently provides products that meet customer and regulatory requirements. Additionally, compliance with CE marking is crucial for products sold in Europe, indicating conformity with health, safety, and environmental protection standards.

-

Industry-Specific Certifications: Depending on the target market, manufacturers may also pursue additional certifications such as API (American Petroleum Institute) for specialized machinery. These certifications can provide assurances about the machine’s performance and reliability, particularly in demanding environments.

What Are the Quality Control Checkpoints in Tennis Ball Machine Production?

In the production of tennis ball machines, several quality control (QC) checkpoints are implemented to ensure that each unit meets established standards.

-

Incoming Quality Control (IQC): This initial checkpoint occurs when raw materials and components arrive at the manufacturing facility. IQC involves inspecting shipments for defects, verifying specifications, and ensuring compliance with quality standards before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC involves monitoring various stages to identify and rectify issues in real-time. This may include testing components for precision and functionality as they are being assembled. Regular checks during this phase help reduce waste and rework costs.

-

Final Quality Control (FQC): The FQC stage occurs after assembly and includes comprehensive testing of the completed tennis ball machine. This may involve functional tests, performance evaluations, and safety checks to ensure the machine operates as intended. B2B buyers should request detailed FQC reports to gain confidence in the product’s reliability.

What Common Testing Methods Are Used in Quality Assurance for Tennis Ball Machines?

Various testing methods are employed to ensure that tennis ball machines meet quality and performance standards.

-

Functional Testing: This involves running the machine under various conditions to ensure it operates correctly. Functional testing simulates real-world usage, evaluating features such as ball speed, trajectory, and operational consistency.

-

Durability Testing: Manufacturers might conduct stress tests to assess how well the machine withstands prolonged use. This is particularly important for buyers in regions with high usage rates, ensuring that the machine can handle the demands of frequent play.

-

Safety Testing: Compliance with safety regulations is crucial. Testing may include evaluating electrical safety, mechanical integrity, and user safety to prevent accidents during operation.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially in international markets, verifying a supplier’s quality control processes is essential for making informed purchasing decisions.

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing practices and quality assurance procedures. Buyers can assess whether suppliers adhere to international standards and have robust QC measures in place.

-

Quality Reports: Requesting detailed quality reports, including IQC, IPQC, and FQC data, can help buyers gauge the effectiveness of a supplier’s QC processes. These documents should outline testing methods, results, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent entities can evaluate the manufacturing processes and quality controls, providing unbiased assessments of a supplier’s capabilities.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must navigate various quality control nuances when sourcing tennis ball machines.

-

Cultural Considerations: Different regions may have varying expectations regarding quality and compliance. Understanding these cultural nuances can aid in establishing clear communication with suppliers.

-

Regulatory Requirements: Buyers should be aware of specific regulations and standards applicable in their region. For example, products sold in the EU must comply with CE marking, while those in other regions may have different requirements.

-

Logistics and Supply Chain: Quality can also be affected by the logistics and supply chain management of a supplier. Buyers should consider how suppliers manage their supply chain to minimize risks related to quality and delivery times.

By understanding the manufacturing processes and quality assurance practices associated with tennis ball machines, B2B buyers can make better-informed decisions, ensuring they select reliable suppliers that meet their operational needs.

Related Video: Tennis ball machine DIY – part 1

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tennis ball machine’

To successfully procure a tennis ball machine that meets your business needs, it’s essential to follow a structured approach. This guide provides a step-by-step checklist that will help international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Clarifying your technical specifications is the first step in the sourcing process. Consider factors such as machine capacity, speed settings, oscillation features, and whether you need manual or remote controls. Clearly defined specifications will streamline your search and ensure that you communicate your needs effectively to potential suppliers.

Step 2: Research Market Trends and Innovations

Understanding current market trends and innovations in tennis ball machines is critical. Look for the latest technologies, such as automated features, mobile app controls, and energy efficiency options. This knowledge will enable you to compare products effectively and choose a machine that not only meets your requirements but also offers a competitive advantage.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it is crucial to vet potential suppliers thoroughly. Request detailed company profiles, case studies, and references from existing buyers in similar markets. It’s advisable to assess their experience in international shipping and compliance with local regulations, especially for buyers in diverse regions like the Middle East and Africa.

- Check for Reviews and Testimonials: Look for feedback from other businesses that have purchased from the supplier.

- Assess Response Times: Gauge how quickly potential suppliers respond to inquiries, as this reflects their customer service.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers hold the necessary certifications and standards. This may include ISO certifications or compliance with international safety and quality standards. Certification verification protects your investment and ensures that the machines meet safety and operational standards.

- Request Documentation: Don’t hesitate to ask suppliers to provide copies of their certifications.

- Check Compliance with Export Regulations: Make sure they comply with export regulations relevant to your region, especially if you are sourcing from overseas.

Step 5: Request Samples or Demonstrations

Whenever possible, request samples or demonstrations of the tennis ball machines. This hands-on experience allows you to evaluate performance, usability, and build quality. It’s also an opportunity to assess whether the machine meets your operational expectations.

- Assess User Experience: Pay attention to how intuitive the controls are and how easy it is to set up.

- Evaluate Performance: Test the machine under conditions that replicate your intended use.

Step 6: Negotiate Terms and Pricing

Once you’ve narrowed down your options, it’s time to negotiate terms and pricing. Be clear about your budget and any additional costs that may arise, such as shipping or warranty fees. Effective negotiation can lead to better pricing, favorable payment terms, and added value services.

- Consider Volume Discounts: Inquire about bulk purchase discounts if you plan to buy multiple machines.

- Discuss Warranty and Support: Ensure that you understand warranty terms and the kind of after-sales support offered.

Step 7: Finalize Contract and Payment Terms

After reaching an agreement, draft a formal contract outlining all terms discussed. Pay close attention to payment terms, delivery schedules, and return policies. A well-structured contract protects both parties and ensures that expectations are clearly set.

- Include Performance Clauses: Specify performance expectations and remedies for non-compliance.

- Review Legal Considerations: Consult with a legal expert to ensure all contractual obligations are enforceable in your jurisdiction.

By following this structured checklist, B2B buyers can navigate the procurement process of tennis ball machines more effectively, ensuring that they make informed decisions that align with their business goals.

Comprehensive Cost and Pricing Analysis for tennis ball machine Sourcing

What Are the Key Cost Components in Sourcing Tennis Ball Machines?

When sourcing tennis ball machines, understanding the cost structure is critical for international B2B buyers. The main cost components typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The choice of materials directly impacts the durability and performance of the tennis ball machine. High-quality components, such as durable plastics and metals, lead to higher costs but improve longevity and customer satisfaction.

-

Labor: Labor costs can vary significantly depending on the country of manufacture. Countries with lower labor costs may offer competitive pricing, but it’s essential to assess the skill level and expertise of the workforce to ensure product quality.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, including utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead, thereby lowering the overall cost.

-

Tooling: Initial tooling for custom designs adds to upfront costs. Reusable tooling can amortize these costs over larger production runs, making high-volume orders more cost-effective.

-

Quality Control: Implementing strict QC measures ensures product reliability and compliance with international standards, which can add to the initial costs but reduces the risk of returns and warranty claims.

-

Logistics: Shipping costs, tariffs, and handling fees must be factored into the total cost. The choice of Incoterms can significantly influence logistics expenses and delivery timelines.

-

Margin: Supplier profit margins vary widely. Understanding the margin expectations can help buyers negotiate better pricing structures.

How Do Price Influencers Affect Tennis Ball Machine Costs?

Several factors influence the pricing of tennis ball machines, which buyers should consider when sourcing.

-

Volume/MOQ: Manufacturers often provide discounts for larger orders. Understanding the Minimum Order Quantity (MOQ) can help buyers negotiate better prices, particularly for high-demand regions like Africa and South America.

-

Specifications and Customization: Customized machines, tailored to specific needs, tend to be more expensive. Buyers should weigh the benefits of customization against the additional costs.

-

Materials and Quality Certifications: Machines that meet international quality standards or certifications (such as ISO) may come at a premium. However, these certifications can enhance the product’s credibility in the market.

-

Supplier Factors: Supplier reliability, reputation, and location can greatly influence pricing. Engaging with reputable suppliers who demonstrate consistent quality can often justify higher prices due to reduced risk.

-

Incoterms: The chosen Incoterm (e.g., FOB, CIF) can affect the total landed cost. Understanding these terms helps buyers mitigate unexpected costs in international transactions.

What Are the Best Negotiation Strategies for B2B Buyers?

Negotiation is a crucial aspect of securing favorable pricing for tennis ball machines. Here are some tips tailored for international buyers:

-

Research and Preparation: Conduct thorough market research on pricing benchmarks in your region. Knowledge of competitors and alternative suppliers can strengthen your negotiation position.

-

Build Relationships: Establishing a rapport with suppliers can lead to better pricing and terms. Long-term partnerships often yield more favorable conditions.

-

Leverage Volume: If possible, commit to larger order quantities to negotiate bulk discounts. This can be particularly effective in markets like Europe and the Middle East, where suppliers may be more amenable to volume-based pricing.

-

Consider Total Cost of Ownership (TCO): Focus on the long-term costs associated with the product, including maintenance, warranty, and operational efficiency. A slightly higher initial investment may lead to lower TCO.

-

Be Aware of Pricing Nuances: International buyers must consider currency fluctuations, payment terms, and regional economic conditions that can affect final pricing.

Disclaimer

Prices mentioned in this analysis are indicative and will vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct due diligence to obtain accurate quotes and ensure comprehensive cost assessments.

Alternatives Analysis: Comparing tennis ball machine With Other Solutions

Understanding Alternatives to Tennis Ball Machines

When considering the best training tools for tennis, it’s essential to evaluate various options that can meet the specific needs of players and coaches. While tennis ball machines are popular for their ability to simulate match conditions and provide consistent practice, there are alternative solutions that may also serve your training objectives effectively. Below is a detailed comparison of tennis ball machines with two viable alternatives: on-court ball feeders and human ball throwers.

Comparison Table of Tennis Ball Machines and Alternatives

| Comparison Aspect | Tennis Ball Machine | On-Court Ball Feeder | Human Ball Thrower |

|---|---|---|---|

| Performance | High consistency, adjustable speed, and angles | Variable consistency, depends on user skill | High variability, can mimic game scenarios |

| Cost | Moderate to high initial investment | Low to moderate cost | Low cost (requires no equipment) |

| Ease of Implementation | Requires setup and power source | Simple to set up, manual operation | No setup, requires only a player |

| Maintenance | Regular maintenance needed, parts can wear out | Minimal maintenance, durable | No maintenance required |

| Best Use Case | Individual practice, drills, and repetitive training | Group practice sessions, skill drills | Realistic match practice, varying shot types |

Analyzing On-Court Ball Feeders: What Are Their Strengths and Weaknesses?

On-court ball feeders are a practical alternative for tennis training, especially for group sessions. They allow players to practice their skills without requiring a constant human presence. The key advantages include lower costs compared to tennis ball machines and the ability to easily adjust the number of balls fed for varying practice intensity. However, the performance can be inconsistent based on the skill level of the feeder, and they may not provide the same level of precision in ball placement as a machine.

Evaluating Human Ball Throwers: Are They Worth Considering?

Human ball throwers represent a traditional approach to tennis practice and can be highly effective for simulating real match conditions. The primary advantages of this method include high variability in shot types, allowing players to adapt to different scenarios dynamically. Additionally, there are no upfront costs for equipment, making it accessible for all budgets. However, this method relies heavily on the thrower’s skill and stamina, which can lead to inconsistency in practice sessions. Moreover, as the session progresses, fatigue can impact performance quality.

How Should B2B Buyers Choose the Right Solution for Tennis Training?

Selecting the right training solution for tennis largely depends on your objectives, budget, and the specific needs of your players or facility. If consistency and precision are paramount—such as for individual training or repetitive drills—a tennis ball machine might be the best choice despite its higher cost and maintenance requirements. Conversely, if your focus is on group training or if budget constraints are a significant consideration, exploring on-court ball feeders or utilizing human ball throwers could provide effective alternatives. Ultimately, understanding the unique strengths and limitations of each option will empower B2B buyers to make informed decisions that align with their training goals and operational capabilities.

Essential Technical Properties and Trade Terminology for tennis ball machine

What Are the Key Technical Properties of a Tennis Ball Machine?

When evaluating tennis ball machines for international trade, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are the key specifications to consider:

1. Material Grade

The construction material of a tennis ball machine significantly impacts its durability and performance. Common materials include high-grade aluminum and reinforced plastics, which are lightweight yet robust. Buyers must prioritize machines made from corrosion-resistant materials, especially in humid or coastal environments found in regions like Africa and South America.

2. Ball Capacity

This refers to the number of tennis balls the machine can hold at one time, which affects the duration of practice sessions. Machines with higher capacities reduce the need for frequent reloading, making them more suitable for clubs and training academies. A larger ball capacity can also enhance training efficiency, particularly in busier facilities.

3. Speed Range

The speed range indicates how fast the machine can launch tennis balls, typically measured in miles per hour (mph) or kilometers per hour (km/h). A broader speed range allows for varied training intensity, catering to players of different skill levels. For international buyers, understanding the speed capabilities is essential to match local training standards and player expectations.

4. Spin Control

Spin control features enable the machine to impart topspin, backspin, or no spin on the ball. This property is vital for replicating real match conditions and providing comprehensive training. Machines with adjustable spin settings can accommodate different training needs, making them more appealing to diverse customer bases across regions.

5. Power Source

Tennis ball machines may operate on electricity or battery power. Electric machines are often more powerful and consistent, but battery-operated models offer portability and convenience. For buyers in regions with unstable electricity supply, battery-powered options may be preferable, allowing for training sessions in various locations without reliance on power sources.

What Are Common Trade Terms Related to Tennis Ball Machines?

Understanding industry terminology is essential for navigating the procurement process effectively. Here are some common trade terms that B2B buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of tennis ball machines, buyers should consider whether they are purchasing directly from OEMs or distributors, as this can impact pricing, warranties, and after-sales support.

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units a supplier is willing to sell. For international buyers, understanding MOQs is crucial for budgeting and inventory management. High MOQs may require buyers to commit to larger orders, which could be a barrier for smaller clubs or organizations.

3. RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to suppliers inviting them to submit price offers for specific products. For buyers in the B2B space, crafting a clear RFQ for tennis ball machines can streamline the purchasing process and ensure they receive competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight) is essential for buyers to understand shipping costs and risk management during transportation.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. For international buyers, understanding lead times can help in planning inventory and training schedules. It’s important to factor in potential delays, especially when sourcing from overseas suppliers.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when purchasing tennis ball machines, ensuring they meet their operational needs and budget constraints effectively.

Navigating Market Dynamics and Sourcing Trends in the tennis ball machine Sector

What Are the Current Market Dynamics and Key Trends in the Tennis Ball Machine Sector?

The tennis ball machine market is experiencing significant growth due to several global drivers. The increasing popularity of tennis as a recreational and competitive sport, particularly in regions like Africa, South America, the Middle East, and Europe, is a primary factor. Emerging economies, such as Brazil and the UAE, are investing in sports infrastructure and facilities, which is driving demand for advanced training equipment, including tennis ball machines.

Technology is at the forefront of this sector. Innovations such as automated ball feeders, programmable settings, and connectivity features that allow users to control machines via smartphones are becoming standard. Additionally, the rise of data analytics in sports training is influencing the design of tennis ball machines, enabling players to improve their skills through performance tracking. B2B buyers should be aware that sourcing partners who offer these advanced technological features can provide a competitive edge.

Another noteworthy trend is the growth of online retail channels, which is reshaping the traditional distribution model. International buyers can benefit from sourcing directly from manufacturers or authorized distributors via e-commerce platforms, ensuring access to the latest products while also potentially reducing costs. As the market evolves, B2B buyers must keep an eye on these dynamics to make informed sourcing decisions.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in Tennis Ball Machines?

Sustainability is becoming a critical consideration in the tennis ball machine sector. The environmental impact of manufacturing processes and materials is under scrutiny, and B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes the use of eco-friendly materials, energy-efficient manufacturing processes, and reduced carbon footprints.

A stock image related to tennis ball machine.

Ethical sourcing is equally important. Buyers should assess the supply chain practices of potential suppliers to ensure they uphold fair labor standards and responsible sourcing of materials. Certifications such as ISO 14001 (Environmental Management) or Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Furthermore, integrating sustainability into sourcing strategies can enhance brand reputation and attract environmentally-conscious customers. By choosing suppliers who prioritize green certifications and sustainable materials, B2B buyers not only contribute to environmental preservation but also position themselves as leaders in responsible business practices within the sports equipment sector.

How Has the Tennis Ball Machine Sector Evolved Over Time?

The tennis ball machine sector has evolved significantly over the past few decades. Initially, these machines were simple devices designed mainly for repetitive ball delivery. However, advancements in technology have transformed them into sophisticated training tools equipped with features like variable speed settings, oscillation, and remote control capabilities.

The introduction of digital technology has allowed for enhanced user interaction, enabling players to customize their training sessions according to their needs. This evolution reflects broader trends in the sports equipment industry, where technology plays a critical role in enhancing performance and training efficacy. As a result, international B2B buyers must consider not only the functionality of tennis ball machines but also the technological innovations that can impact training outcomes for their clients.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of tennis ball machine

-

How do I choose the right tennis ball machine for my business needs?

Selecting the right tennis ball machine involves assessing your specific requirements, including the level of play, training objectives, and budget. For commercial use, consider machines with advanced features such as programmable drills, oscillation, and remote control. Additionally, evaluate the machine’s durability and warranty options, especially in regions with diverse climate conditions. Engaging with suppliers to discuss your needs can also lead to customized solutions that fit your business model. -

What are the key features to look for in a tennis ball machine for training purposes?

When sourcing a tennis ball machine for training, prioritize features like adjustable speed settings, spin options, and trajectory control. Machines that offer programmable drills can enhance training efficiency by simulating various game scenarios. It’s also beneficial to look for portability if you need to move the equipment frequently. Advanced technologies, such as app connectivity for remote control, can further streamline training sessions. -

What is the minimum order quantity (MOQ) for tennis ball machines from international suppliers?

The minimum order quantity (MOQ) for tennis ball machines can vary significantly based on the manufacturer and your location. Typically, MOQs range from 5 to 20 units for bulk purchases. It’s essential to negotiate with suppliers, particularly if you’re looking to start with a smaller inventory. Some manufacturers may also offer flexibility or discounts for larger orders, which can be advantageous for businesses aiming to expand their product range. -

How can I ensure the quality of tennis ball machines when sourcing internationally?

To ensure quality when sourcing tennis ball machines from international suppliers, conduct thorough research on the manufacturer’s reputation. Request certifications, quality assurance processes, and product samples for evaluation. Engaging a third-party inspection service can provide additional assurance of product standards before shipment. Additionally, reading reviews and seeking testimonials from other buyers can help gauge reliability and performance. -

What payment terms are commonly offered for international purchases of tennis ball machines?

Payment terms can vary among suppliers, but common options for international purchases include letters of credit, wire transfers, and payment upon delivery. For larger orders, suppliers may offer payment plans or installment options. It’s crucial to clarify terms and conditions before finalizing purchases, including any potential currency exchange implications. Establishing a good relationship with your supplier can also lead to more favorable terms over time. -

What logistics considerations should I keep in mind when importing tennis ball machines?

When importing tennis ball machines, consider shipping methods, customs duties, and regional regulations. Shipping via sea freight can be cost-effective for bulk orders, while air freight may be necessary for urgent deliveries. Ensure that you understand the import regulations in your country, especially in Africa, South America, the Middle East, and Europe, to avoid unexpected delays. Collaborating with a reliable logistics partner can streamline the process and ensure compliance. -

How do I vet potential suppliers of tennis ball machines?

Vetting suppliers is critical for ensuring a successful purchase. Start by reviewing their business credentials, including years in operation, certifications, and industry reputation. Request references from previous clients to understand their experiences. Additionally, assess their responsiveness, communication style, and willingness to provide detailed product information. Attending trade shows or industry events can also facilitate direct interactions with potential suppliers. -

What customization options are typically available for tennis ball machines?

Many manufacturers offer customization options for tennis ball machines to meet specific training needs. This can include adjustments to features such as ball speed, spin, and oscillation patterns. Some suppliers may also provide branding opportunities, allowing you to incorporate your company logo. Discussing your requirements upfront with suppliers can lead to tailored solutions that enhance your business offering and cater to your target market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for tennis ball machine

In today’s competitive market, strategic sourcing of tennis ball machines is paramount for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. By understanding the diverse functionalities and technological advancements of these machines, businesses can enhance training programs and improve player performance. Key takeaways include the importance of assessing local market demands, evaluating supplier reliability, and considering total cost of ownership over time.

Investing in high-quality tennis ball machines not only elevates training standards but also fosters long-term partnerships with suppliers who can provide ongoing support and innovation. As the demand for sports training equipment continues to rise globally, navigating the complexities of international procurement will be essential.

Looking ahead, it is crucial for buyers to remain agile and informed about emerging trends in sports technology. Engaging with reputable suppliers and leveraging digital platforms will provide a competitive edge in sourcing decisions. Now is the time to capitalize on the opportunities presented by the evolving sports market. Connect with trusted manufacturers and explore the latest innovations to elevate your offerings and meet the growing needs of tennis enthusiasts worldwide.