Discover Cost-Saving Benefits of Grating Steel (2025)

Introduction: Navigating the Global Market for grating steel

Navigating the global market for grating steel can present numerous challenges for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With the increasing demand for durable and versatile flooring solutions in various industrial applications, sourcing the right type of grating steel becomes crucial. This guide is designed to provide a comprehensive overview of the diverse types of grating steel available, their specific applications, and critical factors to consider when selecting a supplier.

In this guide, we will delve into various aspects of grating steel, including standard and heavy-duty options, materials such as galvanized and stainless steel, and essential features like slip resistance and load capacity. Additionally, we will offer actionable insights on supplier vetting processes, pricing strategies, and the impact of regional regulations on purchasing decisions.

By equipping B2B buyers with the knowledge needed to make informed choices, this resource empowers you to navigate the complexities of the grating steel market effectively. Whether you are looking to enhance safety in industrial environments or meet architectural requirements, understanding the nuances of grating steel will help you secure the best solutions for your projects.

Understanding grating steel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard-Duty Welded | Lightweight, cost-effective, suitable for pedestrian loads | Catwalks, platforms, and walkways | Pros: Affordable, easy installation; Cons: Limited load capacity compared to heavy-duty options. |

| Heavy-Duty Welded | Robust design for high load-bearing applications | Industrial flooring, docks, ramps | Pros: High strength and durability; Cons: Higher cost, heavier weight may require more support. |

| Swage-Locked | Strong joints with a clean appearance | Mezzanines, stair treads, and grating systems | Pros: Aesthetic appeal, excellent load distribution; Cons: More complex manufacturing may lead to longer lead times. |

| Press-Locked | Versatile construction with a smooth finish | Fencing, ventilation covers, and shelving | Pros: Lightweight, easy to handle; Cons: May not support as much weight as welded types. |

| Clinched (HEXMESH™) | Hexagonal design for unique applications | Concrete liners, industrial flooring | Pros: Prevents cracking in concrete, unique design; Cons: Limited availability and higher customization costs. |

What are the Characteristics of Standard-Duty Welded Grating?

Standard-duty welded grating is characterized by its lightweight construction, making it an economical choice for applications that do not require heavy load support. Typically made from carbon steel or aluminum, it is commonly used in pedestrian areas such as catwalks and platforms. When purchasing this type, buyers should consider the specific load requirements of their application, as it is not suitable for heavy vehicular traffic.

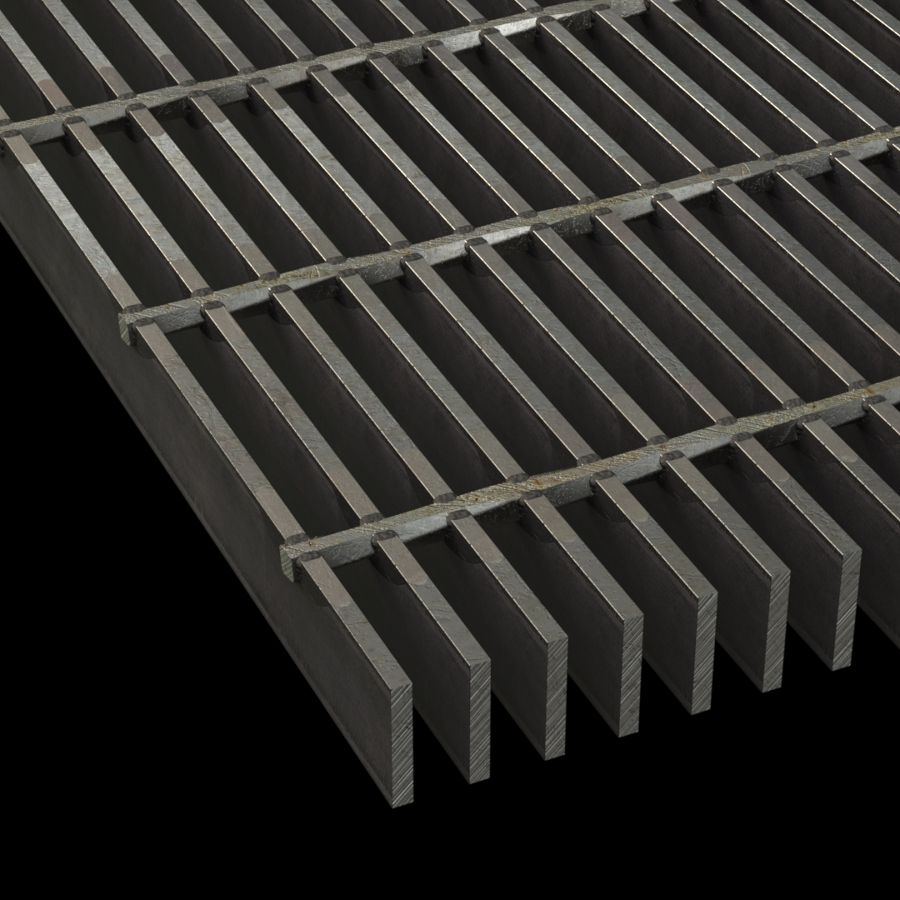

A stock image related to grating steel.

How Does Heavy-Duty Welded Grating Differ from Standard-Duty?

A stock image related to grating steel.

Heavy-duty welded grating is designed to withstand significant loads, making it ideal for industrial applications such as flooring in warehouses, docks, and ramps. Its robust construction involves resistance welding, which ensures a strong and durable product. Buyers should evaluate their load-bearing needs and the potential for wear and tear in demanding environments, as this type offers the durability necessary for heavy-duty applications, albeit at a higher cost.

What are the Benefits of Swage-Locked Grating?

Swage-locked grating is recognized for its strong joints and clean, aesthetic finish. This type is ideal for applications requiring both strength and visual appeal, such as mezzanines and stair treads. When considering swage-locked grating, B2B buyers should account for its excellent load distribution capabilities and the potential for longer lead times due to its more complex manufacturing process.

Why Choose Press-Locked Grating for Your Projects?

Press-locked grating is versatile and features a smooth finish, making it suitable for a variety of applications, including fencing and ventilation covers. Its lightweight nature allows for easier handling and installation. However, buyers should be mindful that while it is easier to manage, it may not support heavy loads as effectively as welded options, so assessing the specific requirements of the project is essential.

What Makes Clinched Grating Unique?

Clinched grating, often referred to as HEXMESH™, features a unique hexagonal design that is particularly effective in applications requiring concrete reinforcement. It is commonly used as a liner in concrete structures to prevent cracking. Buyers interested in this type should consider its specialized application and the potential for higher customization costs, as it may not be as readily available as other grating types.

Key Industrial Applications of grating steel

| Industry/Sector | Specific Application of grating steel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Platforms and walkways for drilling sites | Enhanced safety and durability in harsh environments | Ensure compliance with local safety regulations and standards |

| Construction & Infrastructure | Mezzanines and stair treads in commercial buildings | Optimized space utilization and safety for workers | Consider load-bearing capacity and corrosion resistance |

| Waste Management | Grates for drainage and filtration systems | Improved efficiency in waste processing and management | Evaluate ease of maintenance and material longevity |

| Mining & Quarrying | Heavy-duty grating for access roads and ramps | Increased operational safety and reduced equipment wear | Look for high load capacity and custom fabrication options |

| Food & Beverage | Flooring in processing plants | Hygiene and slip resistance for compliance with health standards | Assess material certifications and anti-slip surface options |

How is Grating Steel Used in the Oil & Gas Industry?

In the oil and gas sector, grating steel is primarily utilized for platforms and walkways at drilling sites. These applications are crucial for ensuring safe access to equipment and operations in often hazardous environments. Grating allows for the easy drainage of liquids, reducing slip hazards. International buyers must prioritize compliance with local safety standards and consider the environmental impact of materials used, particularly in sensitive regions like Africa and the Middle East.

What are the Applications of Grating Steel in Construction & Infrastructure?

Grating steel serves a vital role in construction and infrastructure, particularly in the creation of mezzanines and stair treads within commercial buildings. It helps optimize space while ensuring the safety of workers who traverse these areas. Buyers need to assess the load-bearing capacity of grating products and their corrosion resistance, especially in regions with high humidity or exposure to chemicals, as seen in parts of Europe and South America.

How is Grating Steel Beneficial in Waste Management?

In waste management, grating steel is employed in drainage and filtration systems. This application enhances the efficiency of waste processing by allowing for effective liquid flow while minimizing clogging. For international B2B buyers, it is essential to evaluate the ease of maintenance and the longevity of materials, as well as ensuring that the grating meets local environmental regulations, particularly in developing regions.

What Role Does Grating Steel Play in Mining & Quarrying?

In the mining and quarrying industries, heavy-duty grating is essential for constructing access roads and ramps. These applications are designed to handle significant loads and ensure safe passage for heavy equipment. Buyers should seek grating solutions that offer high load capacity and the option for custom fabrication to meet specific operational needs, particularly in remote locations across Africa and South America.

Why is Grating Steel Important in the Food & Beverage Sector?

Grating steel is also widely used in food and beverage processing plants, where flooring must meet stringent hygiene and safety standards. The slip-resistant surface of grating helps prevent accidents while also facilitating easy cleaning and maintenance. Buyers should consider material certifications and the availability of anti-slip surface options to ensure compliance with health regulations, especially in European markets where standards are rigorous.

3 Common User Pain Points for ‘grating steel’ & Their Solutions

Scenario 1: Sourcing Quality Grating Steel for Diverse Applications

The Problem:

B2B buyers often face challenges in sourcing grating steel that meets specific application requirements. For instance, a construction firm in South America may need grating for both industrial flooring and architectural designs. The difficulty arises when the buyer struggles to identify suppliers that offer a range of grating types—like standard-duty, heavy-duty, or ADA-compliant options. This can lead to delays in project timelines and increased costs due to the need for multiple suppliers.

The Solution:

To effectively source quality grating steel, B2B buyers should conduct thorough market research to identify suppliers with a comprehensive product range. Start by creating a checklist of required specifications, including load capacity, material type (carbon steel, stainless steel, etc.), and surface finish (smooth or serrated). Utilize online resources and supplier directories to compare offerings from multiple manufacturers. Engage with suppliers that provide customization options and have a track record of delivering to your region. Consider requesting samples or visiting the supplier’s facility to ensure their products meet your standards. By establishing strong relationships with versatile suppliers, buyers can streamline their procurement process and avoid delays.

Scenario 2: Understanding Technical Specifications for Grating Steel

The Problem:

Another common pain point is the technical complexity associated with grating steel specifications. Buyers from Africa or the Middle East may encounter difficulties in understanding the various nomenclature and standards used in the industry. For example, terms like “bearing bar spacing,” “cross bar configurations,” and “percent open area” can be confusing, leading to miscalculations that compromise safety and functionality in their applications.

The Solution:

To navigate the technical specifications of grating steel effectively, buyers should invest time in education and training. This could involve attending industry workshops or webinars that focus on grating applications and specifications. Additionally, buyers should leverage resources like online design tools provided by manufacturers, which can simplify the selection process by calculating load requirements based on project specifications. Collaborating with engineers or technical consultants can also provide valuable insights into selecting the right type of grating for specific applications. Buyers should prioritize suppliers that offer detailed product catalogs and technical support, ensuring they have access to expert advice when needed.

Scenario 3: Managing Cost Efficiency and Budget Constraints

The Problem:

Cost efficiency is a critical concern for B2B buyers, especially in competitive markets like Europe. A manufacturing company may find that the initial quotes for grating steel are higher than expected, leading to budget constraints that could jeopardize the overall project. This situation becomes even more complicated when considering long-term costs related to maintenance and replacement.

The Solution:

To manage cost efficiency effectively, buyers should adopt a holistic approach to procurement. Begin by comparing quotes from multiple suppliers while considering not just the upfront costs, but also the total lifecycle costs associated with the grating steel. Buyers should inquire about warranties, maintenance requirements, and the expected lifespan of the products. Opting for galvanized or powder-coated options can provide long-term durability at a reasonable price. Additionally, consider bulk purchasing or establishing long-term contracts with suppliers to negotiate better pricing. Collaborating with financial advisors to analyze cost-benefit scenarios can also help in making informed decisions. By strategically managing procurement processes, buyers can maximize their budget while ensuring the quality and durability of their grating steel solutions.

Strategic Material Selection Guide for grating steel

What Are the Key Properties of Carbon Steel for Grating Applications?

Carbon steel is one of the most commonly used materials for grating due to its excellent strength and affordability. It typically exhibits high tensile strength and is suitable for a range of applications, including industrial flooring and walkways. Carbon steel grating can withstand significant loads, making it ideal for heavy-duty applications. However, it has limited corrosion resistance, which can be a concern in humid or corrosive environments. Buyers should consider protective coatings or galvanization to enhance its durability.

What Are the Advantages and Disadvantages of Stainless Steel Grating?

Stainless steel grating is renowned for its superior corrosion resistance, making it an excellent choice for environments exposed to moisture or chemicals. It is highly durable and maintains its structural integrity over time, even under harsh conditions. However, stainless steel is generally more expensive than carbon steel, which can impact budget considerations. Its manufacturing process can also be more complex, potentially leading to longer lead times. For international buyers, compliance with standards such as ASTM and DIN is crucial, especially in sectors like food processing and pharmaceuticals where hygiene is paramount.

A stock image related to grating steel.

How Does Aluminum Grating Compare in Terms of Performance?

Aluminum grating is lightweight yet strong, making it a popular choice for applications where weight is a critical factor, such as in portable structures or elevated walkways. It offers excellent corrosion resistance and is often used in marine environments. However, it may not support as heavy loads as carbon or stainless steel, limiting its application in heavy-duty scenarios. Additionally, the cost of aluminum can be higher than carbon steel, which may deter some buyers. For international procurement, understanding local standards and certifications is essential, especially in regions with specific environmental regulations.

What Are the Specific Considerations for Galvanized Steel Grating?

Galvanized steel grating combines the strength of carbon steel with a protective zinc coating, enhancing its corrosion resistance. This makes it suitable for outdoor applications and environments where moisture is prevalent. The galvanization process adds to the manufacturing complexity and cost, but it significantly extends the lifespan of the grating. Buyers from regions with high humidity or corrosive conditions, such as parts of Africa and South America, should consider galvanized options. Compliance with local standards, such as JIS in Japan or EN in Europe, is vital for ensuring product quality and safety.

Summary Table of Material Selection for Grating Steel

| Material | Typical Use Case for grating steel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Industrial flooring, walkways | High strength and affordability | Limited corrosion resistance | Low |

| Stainless Steel | Food processing, chemical plants | Superior corrosion resistance | Higher cost and complex mfg | High |

| Aluminum | Portable structures, marine use | Lightweight and corrosion resistant | Lower load capacity | Medium |

| Galvanized Steel | Outdoor applications, humid areas | Enhanced corrosion resistance | Increased cost due to galvanization | Medium |

This strategic material selection guide provides international B2B buyers with essential insights into the properties, advantages, and considerations of various grating steel materials. Understanding these factors will aid in making informed purchasing decisions that align with specific application requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for grating steel

What Are the Main Stages of Manufacturing Grating Steel?

The manufacturing of grating steel involves several key stages that ensure the final product meets the necessary performance and safety standards. Understanding these stages is crucial for B2B buyers who need reliable and high-quality grating solutions.

Material Preparation: What Goes into Grating Steel?

The first stage in the manufacturing process is material preparation, which typically involves selecting high-quality steel—most commonly carbon steel, stainless steel, or galvanized steel. The choice of material impacts durability, corrosion resistance, and overall performance. Steel is often sourced from reputable suppliers who adhere to international quality standards.

Once sourced, the steel undergoes cutting into specified lengths for the bearing bars and cross bars. This step is vital as the dimensions will directly affect the load-bearing capacity and fit of the grating in its intended application.

Forming: How Is Grating Steel Shaped?

The next stage is forming, where the prepared steel bars are shaped into the desired configurations. This can be achieved through various methods, including:

- Welding: This is the most common technique for creating grating. The bearing bars and cross bars are welded together using resistance welding or automated electric hydraulic welding. This ensures strong, permanent joints capable of withstanding significant loads.

- Swage-Locking and Press-Locking: These methods are used to create grating that requires a different structural integrity or load-bearing capability. Swage-locking is particularly beneficial for lightweight applications, while press-locking offers a smooth finish suitable for architectural applications.

Assembly: What Is Involved in the Assembly Process?

Once the bars are formed, they are assembled into panels. This step involves arranging the bearing bars and cross bars in a grid pattern, followed by welding or locking them together. The assembly stage is crucial for ensuring the stability and strength of the grating.

During assembly, additional features such as kick plates or banding may be added to enhance safety and performance. Kick plates provide a barrier to prevent items from falling off the edges, while banding closes open ends for a finished appearance.

Finishing: What Are the Final Touches for Grating Steel?

The finishing process includes surface treatments to enhance the grating’s durability and aesthetic appeal. Common finishing techniques include:

- Galvanization: A coating of zinc is applied to prevent rust and corrosion, making the grating suitable for outdoor or harsh environments.

- Powder Coating: This provides a protective layer that can be colored to meet specific design requirements.

These finishes not only improve longevity but also ensure compliance with safety standards, especially in industrial and commercial settings.

How Is Quality Assurance Implemented in Grating Steel Manufacturing?

Quality assurance (QA) is essential throughout the manufacturing process to ensure that the final product meets industry standards and customer expectations. For international B2B buyers, understanding the QA protocols in place can significantly influence purchasing decisions.

What Are the Relevant International Standards for Grating Steel?

Grating steel manufacturers often adhere to various international quality standards, including:

- ISO 9001: This standard focuses on quality management systems and ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: Particularly important in Europe, CE marking indicates that the product complies with EU safety, health, and environmental protection standards.

- API Standards: For applications in the oil and gas industry, manufacturers may follow American Petroleum Institute standards, which focus on safety and performance.

These certifications can serve as a baseline for evaluating potential suppliers.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure that any issues are identified and rectified promptly. Key checkpoints include:

- Incoming Quality Control (IQC): At this stage, raw materials are inspected for compliance with specifications before they enter production.

- In-Process Quality Control (IPQC): This involves monitoring the manufacturing processes to ensure that standards are maintained throughout production. Techniques such as visual inspections, dimensional checks, and weld quality assessments are common.

- Final Quality Control (FQC): After assembly and finishing, the final product undergoes rigorous testing to verify its strength, load capacity, and overall quality. This may include load testing and corrosion resistance assessments.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is critical. Here are some actionable steps:

What Steps Can Buyers Take to Ensure Supplier Quality?

-

Request Documentation: Ask suppliers for their quality assurance documentation, including certifications and quality management system details.

-

Conduct Audits: Regular audits of suppliers can provide insight into their manufacturing processes and quality control practices. Buyers should consider performing both announced and unannounced audits to get an accurate picture.

-

Third-Party Inspection: Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s quality control systems. These agencies can conduct various tests and provide detailed reports on product quality.

-

Review Test Reports: Request test reports from previous batches or similar products to ensure that the supplier meets the necessary specifications and quality standards.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control in the international context is crucial for buyers.

-

Regional Standards: Different regions may have varying standards and regulations. Buyers should be aware of local compliance requirements and ensure that their suppliers can meet them.

-

Cultural Differences: The approach to quality assurance may differ based on cultural practices in manufacturing. Buyers should be prepared to navigate these differences when working with suppliers from diverse regions.

-

Language Barriers: Clear communication is vital in ensuring quality expectations are met. Buyers should consider working with suppliers who provide documentation and support in their preferred language to minimize misunderstandings.

By gaining a comprehensive understanding of the manufacturing processes and quality assurance protocols for grating steel, international B2B buyers can make informed decisions that lead to successful partnerships and high-quality outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘grating steel’

Introduction: How to Effectively Source Grating Steel

Sourcing grating steel requires a strategic approach to ensure that your procurement meets quality standards, budget constraints, and project specifications. This guide provides a practical checklist that international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—can follow to streamline their sourcing process and make informed decisions.

Step 1: Define Your Technical Specifications

Before you start sourcing, it’s essential to outline your technical requirements. This includes specifying the type of grating (e.g., standard-duty, heavy-duty, or custom), material (e.g., carbon steel, galvanized steel, or stainless steel), and any specific dimensions or load-bearing capacities needed.

- Why it matters: Clear specifications help suppliers provide accurate quotes and ensure that the grating will meet the performance requirements of your project.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in grating steel. Look for companies with a solid reputation, positive customer reviews, and a track record of reliability.

- What to consider: Examine the supplier’s experience in your industry, geographic location, and their ability to fulfill large orders or custom requests.

Step 3: Evaluate Supplier Certifications

✅ Verify Supplier Certifications. Check if the suppliers hold relevant certifications such as ISO 9001 or other industry-specific quality standards. This verification is crucial for ensuring that the products meet international quality benchmarks.

- Why it’s important: Certified suppliers are more likely to adhere to quality control processes, which can significantly reduce the risk of defects in your grating steel.

Step 4: Request Samples and Specifications

Before making a final decision, request samples of the grating steel. This allows you to assess the quality, surface finish, and dimensions firsthand.

- What to look for: Ensure that the samples meet your specified requirements, such as load capacity and slip resistance. Pay attention to the finish as well; for instance, galvanized surfaces should exhibit a consistent coating.

Step 5: Compare Pricing and Terms

Collect quotes from multiple suppliers and compare not only the prices but also the terms of sale. Look for hidden costs such as shipping, handling, and installation fees that could affect your overall budget.

- Important considerations: Understand each supplier’s payment terms, delivery timelines, and return policies. This information can help you avoid unexpected expenses down the line.

Step 6: Check References and Past Projects

Request references from previous clients, particularly those in similar industries or projects. Understanding their experiences can provide insights into the supplier’s reliability and product quality.

- Why it’s essential: Feedback from past clients can reveal potential issues you may encounter and help you gauge the supplier’s responsiveness and customer service quality.

Step 7: Finalize Your Order and Confirm Delivery

Once you have selected a supplier, finalize your order by confirming all specifications, quantities, and delivery schedules. Document everything in a contract to avoid any miscommunication.

- What to ensure: Make sure that the delivery terms are clearly stated, including the expected delivery date and logistics involved. This step is crucial for maintaining your project timeline.

By following these steps, you can navigate the complexities of sourcing grating steel effectively, ensuring that your procurement process is efficient and aligned with your project needs.

Comprehensive Cost and Pricing Analysis for grating steel Sourcing

When sourcing grating steel, understanding the comprehensive cost structure and pricing analysis is crucial for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. This section delves into the various components that influence the pricing of grating steel and provides actionable insights for making informed purchasing decisions.

What Are the Key Cost Components in Grating Steel Sourcing?

The cost structure of grating steel can be broken down into several key components:

-

Materials: The type of steel used—carbon steel, stainless steel, or galvanized steel—significantly affects the cost. Premium materials like stainless steel typically command higher prices due to their durability and corrosion resistance.

-

Labor: Labor costs depend on the complexity of the manufacturing process. For instance, welded grating involves more labor than pressed or swage-locked options, which can elevate overall costs.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, equipment depreciation, and maintenance. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Initial tooling costs can be significant, especially for custom orders. Buyers should consider whether the supplier can absorb these costs through larger orders or if they will be passed on to the buyer.

-

Quality Control (QC): Rigorous quality control ensures that products meet required specifications, which can add to the cost. Certifications like ISO can also influence pricing, as they reflect a commitment to quality.

-

Logistics: Shipping and handling are critical, particularly for international buyers. Factors such as distance, shipping method, and freight rates can impact the total cost.

-

Margin: Suppliers will add their profit margin to cover operational costs and ensure profitability. This margin varies based on market conditions and competitive landscape.

How Do Pricing Influencers Impact Grating Steel Costs?

Several factors can influence the final pricing of grating steel:

-

Volume/MOQ: Buying in bulk can lead to significant discounts. Suppliers often have minimum order quantities (MOQ), and exceeding these thresholds can yield better pricing.

-

Specifications and Customization: Custom specifications, such as size, load-bearing capacity, and surface finish, can increase costs. Standardized products generally offer more competitive pricing.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., ASTM, EN) justify increased prices. Buyers should assess their specific needs against the costs associated with premium materials.

-

Supplier Factors: Established suppliers may offer better pricing due to economies of scale. It’s beneficial to research supplier reputation and reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international buyers, as they dictate who bears shipping costs, insurance, and liability during transportation.

What Buyer Tips Can Enhance Cost Efficiency in Grating Steel Sourcing?

-

Negotiate Effectively: Engaging in negotiations can lead to better terms. Leverage factors like bulk purchasing or long-term contracts to obtain discounts.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, durability, and replacement costs over the product’s lifecycle. This holistic view can lead to smarter purchasing decisions.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations, tariffs, and local taxes can impact pricing. Buyers should factor these into their budgets and be aware of any potential trade barriers.

-

Seek Multiple Quotes: Comparing quotes from different suppliers can reveal competitive pricing and help buyers identify the best value for their needs.

-

Plan for Logistics: Effective logistics planning can minimize shipping costs. Consider local suppliers to reduce freight expenses and delivery times.

Disclaimer on Indicative Prices

Pricing for grating steel can fluctuate based on market conditions, supply chain issues, and demand. Therefore, the prices mentioned in discussions or quoted by suppliers should be seen as indicative and subject to change. Buyers are encouraged to conduct thorough market research and engage in direct discussions with suppliers to secure the most accurate pricing information.

Alternatives Analysis: Comparing grating steel With Other Solutions

When considering flooring and support solutions in industrial settings, it is essential for B2B buyers to evaluate various options to ensure they meet specific operational requirements. Grating steel is a popular choice due to its strength and versatility, but alternative solutions may offer distinct advantages depending on the context and application. This section provides a comparative analysis of grating steel against two viable alternatives: fiberglass reinforced plastic (FRP) grating and aluminum grating.

Comparison Table of Grating Steel and Alternatives

| Comparison Aspect | Grating Steel | Fiberglass Reinforced Plastic (FRP) Grating | Aluminum Grating |

|---|---|---|---|

| Performance | High load capacity, durable | Good load capacity, corrosion-resistant | Lightweight, corrosion-resistant |

| Cost | Moderate initial investment | Higher initial cost, lower lifecycle cost | Higher initial cost |

| Ease of Implementation | Requires welding and cutting | Easy to install with minimal tools | Easy to install, lightweight |

| Maintenance | Regular inspections needed | Low maintenance, resistant to chemicals | Low maintenance, resistant to corrosion |

| Best Use Case | Heavy-duty applications | Chemical processing, marine environments | Architectural features, platforms |

Pros and Cons of Fiberglass Reinforced Plastic (FRP) Grating

FRP grating is known for its excellent resistance to corrosion and chemicals, making it ideal for industries such as chemical processing, oil and gas, and marine applications. Its lightweight nature allows for easy installation, often without the need for heavy machinery. However, while FRP grating offers lower maintenance costs over time, it typically comes with a higher initial investment compared to grating steel. Additionally, it may not support as heavy a load as steel options, limiting its use in some heavy-duty applications.

Pros and Cons of Aluminum Grating

Aluminum grating is another alternative that provides several benefits. Its lightweight structure makes it easy to handle and install, reducing labor costs. Aluminum is also highly resistant to corrosion, making it a suitable choice for outdoor and marine applications. Despite these advantages, aluminum grating can be more expensive upfront than steel options, which may deter budget-conscious buyers. Additionally, while it performs well in various environments, it may not offer the same load-bearing capacity as heavy-duty steel grating.

Conclusion: How to Choose the Right Grating Solution for Your Needs

Choosing the right grating solution involves assessing the specific requirements of your project, including load capacities, environmental conditions, and budget constraints. Grating steel remains a strong contender for heavy-duty applications due to its durability and strength. However, if corrosion resistance and lightweight properties are critical, alternatives like FRP or aluminum grating may be more appropriate. Buyers should weigh the pros and cons of each option and consider the long-term implications of their choice, including maintenance costs and performance longevity, to ensure they select the best solution for their operational needs.

Essential Technical Properties and Trade Terminology for grating steel

What Are the Key Technical Properties of Grating Steel?

Understanding the technical properties of grating steel is essential for B2B buyers in industries ranging from construction to manufacturing. Here are some critical specifications that influence purchasing decisions:

1. Material Grade: Why Is It Important?

Grating steel is typically available in various material grades, such as carbon steel, stainless steel, and galvanized steel. The material grade affects the grating’s strength, corrosion resistance, and suitability for specific applications. For example, stainless steel is ideal for environments exposed to moisture or chemicals, while carbon steel is often used for general-purpose applications. Choosing the right material grade can significantly impact the longevity and maintenance costs of the grating.

2. Load Capacity: What Does It Mean?

Load capacity refers to the maximum weight the grating can support without deformation or failure. This specification is crucial for B2B buyers, especially in heavy-duty applications such as industrial flooring and vehicular access points. Understanding the load capacity ensures that the selected grating will meet the specific demands of the application, preventing costly failures and safety hazards.

3. Tolerance: How Does It Affect Fit?

Tolerance specifies the allowable deviation in dimensions and shape during the manufacturing process. Tight tolerances are essential for applications requiring precise fits, such as in modular construction or when integrating with existing structures. For international buyers, understanding tolerance can help ensure that the grating will seamlessly fit into their projects, reducing the need for additional adjustments or modifications.

4. Percent Open Area: What Is Its Significance?

The percent open area is a measure of the grating’s ventilation or drainage capability. A higher open area percentage allows for better airflow and water drainage, making it suitable for applications in wet environments. B2B buyers should consider this property to enhance safety and performance in their projects, especially in sectors like wastewater treatment and food processing.

5. Finish: How Does It Impact Durability?

The finish of grating steel can include options like painted, galvanized, or powder-coated. The finish plays a crucial role in the grating’s resistance to corrosion and wear. For buyers in regions with high humidity or corrosive environments, selecting the appropriate finish can extend the lifespan of the grating and reduce maintenance costs.

What Are Common Trade Terms Related to Grating Steel?

Familiarizing yourself with industry terminology can facilitate smoother transactions and better communication with suppliers. Here are several essential trade terms:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of grating steel, buyers might engage with OEMs to procure customized solutions tailored to their specific requirements, ensuring product compatibility with existing systems.

2. MOQ (Minimum Order Quantity): Why Is It Relevant?

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for buyers to manage inventory and costs effectively. For international buyers, knowing the MOQ can help in planning shipments and reducing excess inventory.

3. RFQ (Request for Quotation): What Is Its Purpose?

An RFQ is a document sent to suppliers to request pricing and other pertinent details about products. This process allows buyers to compare offers and negotiate terms before making a purchasing decision. For B2B buyers, a well-structured RFQ can lead to better pricing and terms.

4. Incoterms: How Do They Affect Shipping?

Incoterms (International Commercial Terms) are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for buyers to clarify shipping costs, risks, and responsibilities, which can vary significantly depending on the chosen terms.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring they acquire the right grating steel products for their specific applications while optimizing their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the grating steel Sector

What are the Current Market Dynamics and Key Trends in the Grating Steel Sector?

The grating steel market is witnessing a significant transformation driven by global economic recovery and industrial growth, particularly in emerging markets across Africa, South America, the Middle East, and Europe. The construction and infrastructure sectors are major consumers of grating steel, with increased investments in urban development and industrial projects. A notable trend is the rise of advanced manufacturing technologies such as automated welding and laser cutting, which enhance production efficiency and reduce costs. Additionally, the integration of Industry 4.0 technologies, including IoT and data analytics, is enabling manufacturers to optimize their supply chains and respond quickly to market demands.

International B2B buyers should also consider the growing focus on customization. Suppliers are increasingly offering tailored solutions to meet specific project requirements, which can lead to improved operational efficiency and cost-effectiveness. Furthermore, sustainability is becoming a key consideration, with buyers prioritizing suppliers who demonstrate environmental responsibility in their operations. This shift is particularly evident in Europe, where stringent regulations are driving the adoption of eco-friendly practices in the production and sourcing of grating steel.

How is Sustainability Shaping the Grating Steel Industry?

Sustainability is a critical factor influencing sourcing decisions in the grating steel sector. The environmental impact of steel production is significant, contributing to greenhouse gas emissions and resource depletion. As a result, international B2B buyers are increasingly seeking suppliers who adhere to sustainable practices and ethical sourcing standards. This includes the use of recycled materials and the implementation of energy-efficient manufacturing processes.

Ethical supply chains are also gaining importance, with buyers demanding transparency regarding the sourcing of raw materials and labor practices. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming essential for suppliers aiming to attract environmentally conscious clients. Moreover, the availability of ‘green’ materials, such as galvanized or powder-coated steel, which offer enhanced durability and lower maintenance requirements, is also influencing purchasing decisions. By prioritizing sustainability, B2B buyers can not only reduce their environmental footprint but also enhance their brand reputation in an increasingly eco-conscious market.

What is the Historical Context of the Grating Steel Sector?

The grating steel sector has evolved significantly since its inception in the early 20th century, when it was primarily used for industrial flooring and safety applications. The introduction of new manufacturing techniques, such as welding and press-locking, expanded its applications beyond traditional uses to include architectural elements and infrastructure projects. Over the decades, advancements in material science have led to the development of various types of grating, including aluminum and stainless steel options, catering to diverse market needs.

In recent years, the focus has shifted towards customization and sustainability, reflecting broader trends in the construction industry. As B2B buyers increasingly prioritize safety, durability, and environmental responsibility, the grating steel sector continues to adapt, ensuring it meets the demands of modern infrastructure and design. This historical context underscores the importance of innovation and responsiveness in a competitive global market, positioning grating steel as a vital component in contemporary construction and industrial applications.

Frequently Asked Questions (FAQs) for B2B Buyers of grating steel

-

How do I determine the right type of grating steel for my project?

To select the appropriate grating steel, consider factors like load capacity, environment, and application type. For heavy-duty applications, heavy-duty welded grating is ideal due to its robust construction. In contrast, standard-duty grating is suitable for pedestrian areas. Additionally, assess the material—galvanized steel offers corrosion resistance, while stainless steel is best for highly corrosive environments. Consult with suppliers for product specifications and load tables to ensure compliance with safety regulations. -

What is the best grating steel for industrial flooring applications?

Heavy-duty welded steel grating is often the best choice for industrial flooring due to its strength and durability. It can support high loads and withstand heavy traffic, making it ideal for environments like warehouses, factories, and loading docks. Look for options with a serrated surface for added slip resistance. It’s also essential to consider the environment; galvanized or stainless steel may be required for humid or corrosive settings to ensure longevity. -

How can I verify the credibility of a grating steel supplier?

To vet a grating steel supplier, start by checking their reputation in the industry. Look for customer reviews, testimonials, and case studies. Verify certifications such as ISO 9001, which indicates quality management standards. Request references from previous clients, especially those in your region, to gauge reliability. Additionally, assess their capacity for timely delivery and responsiveness to inquiries, which reflects their commitment to customer service. -

What customization options are available for grating steel?

Many suppliers offer customization options, including specific dimensions, shapes, and finishes. Common requests include custom spacing between bars, varying thicknesses, and specialized coatings for enhanced corrosion resistance. When discussing your project needs with suppliers, provide detailed specifications to ensure they can meet your requirements. Be sure to ask about lead times for custom orders, as they can vary significantly. -

What are the typical minimum order quantities (MOQs) for grating steel?

Minimum order quantities for grating steel can vary by supplier and product type. Generally, MOQs range from a few panels to several tons, depending on the material and customization requirements. For international buyers, it’s essential to inquire about MOQs during the sourcing process, as smaller quantities may incur higher per-unit costs. Some suppliers may also offer flexibility on MOQs for repeat customers or large projects. -

What payment terms should I expect when purchasing grating steel internationally?

Payment terms can vary widely among suppliers but typically include options like upfront payment, partial payment upon order confirmation, and balance payment prior to shipping. International transactions may also require letters of credit or bank guarantees to mitigate risk. Always clarify payment terms before finalizing the order to avoid misunderstandings. Additionally, consider the impact of currency fluctuations on pricing and payment. -

How can I ensure quality assurance (QA) for my grating steel order?

To ensure quality assurance, request product certifications and material test reports from your supplier. This documentation should confirm compliance with industry standards like ASTM or EN. Additionally, consider establishing a quality inspection process, which may include third-party inspections before shipment. Discussing QA protocols with your supplier upfront can help prevent issues and ensure that the final product meets your expectations. -

What logistics considerations should I keep in mind when importing grating steel?

When importing grating steel, consider factors such as shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder familiar with your destination country’s regulations to facilitate smooth customs processes. Understand the incoterms being used, such as FOB or CIF, to clarify responsibilities for shipping costs and risks. Additionally, factor in lead times for production and transportation to align with your project schedules.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for grating steel

In the competitive landscape of industrial solutions, strategic sourcing of grating steel is pivotal for international B2B buyers, especially in emerging markets such as Africa, South America, the Middle East, and established regions like Europe. By understanding the diverse applications and specifications of grating steel—ranging from standard-duty to heavy-duty options—buyers can make informed decisions that enhance safety, durability, and cost-effectiveness in their projects.

Investing in quality steel grating not only ensures compliance with local regulations but also contributes to the longevity and performance of infrastructure. As buyers evaluate suppliers, it is essential to consider factors such as material type, load capacity, and customization capabilities. Building strong relationships with reputable manufacturers can lead to better pricing, timely deliveries, and superior customer support.

Looking ahead, the demand for innovative grating solutions is set to rise, driven by infrastructure development and sustainability initiatives. B2B buyers are encouraged to explore new partnerships and technologies that enhance their sourcing strategies. Embrace this opportunity to secure a competitive edge and ensure your projects benefit from the best grating steel solutions available in the market.