Top 6 Brass Plumbing Fittings Manufacturers List and Guide: How T…

Introduction: Navigating the Global Market for Brass Plumbing Fittings Manufacturers

In today’s competitive landscape, sourcing high-quality brass plumbing fittings can be a daunting task for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying reliable manufacturers but also in navigating the complexities of compliance, material specifications, and pricing structures. This guide aims to equip procurement professionals with the necessary insights to make informed purchasing decisions by exploring various types of brass fittings, their applications, and essential supplier vetting criteria.

Throughout this comprehensive resource, we will delve into the intricacies of brass plumbing fittings, covering everything from industrial valves and compression fittings to specialized applications in HVAC and gas systems. Additionally, we will provide actionable strategies for assessing suppliers, including quality certifications and compliance with international standards. Understanding the cost factors associated with brass fittings will also be a focal point, enabling buyers to negotiate effectively and optimize their procurement budgets.

By utilizing this guide, B2B buyers can streamline their sourcing process, mitigate risks, and ensure they partner with reputable manufacturers that meet their specific needs. Whether you’re looking to enhance your supply chain or expand your product offerings, this resource serves as a pivotal tool in navigating the global market for brass plumbing fittings, ultimately driving success in your business endeavors.

Top 10 Brass Plumbing Fittings Manufacturers Manufacturers & Suppliers List

1. American Copper & Brass – Brass Fittings

Domain: acandb.com

Registered: 2001 (24 years)

Introduction: American Copper & Brass offers a variety of brass fittings including couplings, adapters, elbows, nipples, tees, plugs, and hex bushings. These products are sourced from top manufacturers such as Brass Craft and Everflow Supplies. The inventory is regularly restocked, and customers are encouraged to set up accounts for easy reordering. For assistance, customers can fill out a contact form or call …

2. Mid-America Fittings – Lead Free Brass Valves

Domain: midamericafittings.com

Registered: 2002 (23 years)

Introduction: Mid-America Fittings is a leading manufacturer of made in the USA lead free/low lead brass fittings. The product categories include:

1. **Industrial Valves**:

– 100 & 200 Series Valves

– 350 Series Miniature Ball Valves

– Barrel Faucets & Selector Valves

– Drain & Shutoff Cocks & Misc. Valves

– “O” Ring Sealed Valves (Solid Bottom)

– 4100-4200-5200 Series Instrumentation …

3. BrassCraft – Solid Brass Fittings

Domain: brasscraft.com

Registered: 1995 (30 years)

Introduction: BrassCraft® fittings are shaped from a single piece of brass rod through 22 different machining operations, resulting in a one-piece, solid brass part without seams or brazed joints. The product range includes common brass fittings such as compression, flare, pipe, and hose barb, as well as specialty engineered products.

4. Merit Brass – Comprehensive Piping Solutions

Domain: meritbrass.com

Registered: 1997 (28 years)

Introduction: Merit Brass offers a comprehensive range of piping solutions, including:

– Pipe

– Pipe Fittings (Malleable Iron Pipe Fittings)

– Pipe Flanges

– Pipe Nipples (including custom fabrications)

– Press Fittings & Valves (CarbonPress®, CopperPress®, StainlessPress®)

– Valves

– Stainless Steel Tubing

– PTFE Thread Tape

The company provides diverse alloys for PVF inventory and project needs, inc…

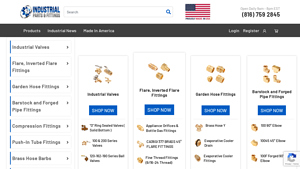

5. Industrial Parts Fittings – American Made Brass Valves & Fittings

Domain: industrialpartsfittings.com

Registered: 2019 (6 years)

Introduction: American Made Brass Fittings, Adapters, Valves, Compression. Product categories include: Industrial Valves (“O” Ring Sealed Valves, 100 & 200 Series Valves, 120-162-190 Series Ball Valves), Flare and Inverted Flare Fittings, Appliance Orifices & Bottle Gas Fittings, CA360/377 Brass 45° Flare Fittings, Fine Thread Fittings (9/16-24 Thread), Garden Hose Fittings, Brass Hose Y, Evaporative Cooler Dra…

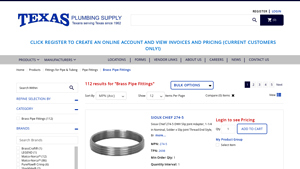

6. Texas Plumbing Supply – Brass Pipe Fittings

Domain: texasplumbingsupplyinc.com

Registered: 2010 (15 years)

Introduction: Brass Pipe Fittings available from various manufacturers including BrassCraft Manufacturing, Matco-Norca, PureFlow, Sharkbite, and Sioux Chief. The fittings are made of brass and come in various nominal sizes ranging from 1/8 in to 6 in. Types of fittings include 45 deg Elbow, 90 deg Elbow, Adapter, Bushing, Cap, Coupling, Cross, Extender, Flange, Plug, Tee, and Union. The products are categorized…

Understanding Brass Plumbing Fittings Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Forged Brass Fittings | Made from solid brass, offering high strength and durability | Industrial piping, HVAC systems | Pros: High pressure tolerance, long lifespan. Cons: Higher cost compared to standard fittings. |

| Lead-Free Brass Fittings | Compliant with health standards, eliminating lead content | Residential plumbing, food and beverage | Pros: Safe for drinking water, regulatory compliance. Cons: May have limited availability. |

| Compression Brass Fittings | Utilizes compression technology for secure connections | Plumbing repairs, HVAC systems | Pros: Easy installation, reliable sealing. Cons: Requires specific tools for installation. |

| Push-In Brass Fittings | Designed for quick, tool-free installation | HVAC, irrigation systems | Pros: Fast assembly, reduced labor costs. Cons: May not suit high-pressure applications. |

| Specialty Brass Fittings | Custom fittings tailored for specific applications | Niche industrial uses, specialized plumbing | Pros: Tailored solutions for unique needs. Cons: Longer lead times, potentially higher costs. |

What Are the Characteristics of Forged Brass Fittings?

Forged brass fittings are renowned for their exceptional strength and durability, making them ideal for high-pressure applications. Their construction from solid brass ensures a robust design that can withstand extreme conditions. In B2B contexts, these fittings are commonly used in industrial piping and HVAC systems, where reliability is paramount. Buyers should consider the higher initial investment, but the long-term performance and reduced maintenance needs often justify the cost.

Why Choose Lead-Free Brass Fittings for Plumbing?

Lead-free brass fittings are specifically designed to meet health and safety regulations, ensuring that no harmful lead leaches into drinking water. This makes them highly suitable for residential plumbing and food and beverage applications. B2B buyers must prioritize these fittings to comply with local regulations and to guarantee the safety of their end-users. While they may be slightly more expensive or less readily available than traditional fittings, the health benefits and compliance advantages are significant.

How Do Compression Brass Fittings Work?

Compression brass fittings use a mechanical compression method to create a secure seal, making them a popular choice for plumbing repairs and HVAC systems. Their straightforward installation process allows for quick assembly, which can save time and labor costs in commercial settings. However, buyers should be aware that specialized tools are often required for installation, which can add to upfront costs. Overall, their reliability and ease of use make them a favored option in various B2B applications.

What Are the Benefits of Push-In Brass Fittings?

Push-in brass fittings are designed for quick and easy installation without the need for tools, which significantly reduces assembly time. This feature makes them particularly advantageous for HVAC and irrigation systems, where efficiency is critical. While they offer fast installation and lower labor costs, buyers should consider their suitability for high-pressure applications, as they may not perform as well under extreme conditions compared to traditional fittings.

When Should You Consider Specialty Brass Fittings?

Specialty brass fittings are custom-designed to meet unique application requirements in niche markets, such as specialized plumbing systems or industrial processes. These fittings provide tailored solutions that standard options may not fulfill, making them invaluable for specific projects. However, buyers should be prepared for potentially longer lead times and higher costs associated with custom orders. The benefits of achieving precise specifications often outweigh these drawbacks in specialized industries.

Key Industrial Applications of Brass Plumbing Fittings Manufacturers

| Industry/Sector | Specific Application of Brass Plumbing Fittings Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Infrastructure | Use in plumbing systems for residential and commercial buildings | Ensures durability and reliability in water supply systems | Compliance with local building codes and regulations |

| Oil & Gas | Brass fittings in pipeline systems for fluid transfer | Provides resistance to corrosion and high pressure applications | Certification for high-pressure applications and safety standards |

| HVAC (Heating, Ventilation, Air Conditioning) | Brass fittings in HVAC systems for fluid and gas transport | Enhances system efficiency and reduces maintenance costs | Consideration for temperature and pressure ratings |

| Agriculture | Use in irrigation systems and agricultural machinery | Promotes efficient water management and resource conservation | Availability of fittings compatible with various irrigation systems |

| Automotive | Brass fittings in fuel and hydraulic systems | Improves performance and safety in vehicle operations | Assurance of compatibility with specific vehicle models |

How Are Brass Plumbing Fittings Used in Construction & Infrastructure?

In the construction and infrastructure sector, brass plumbing fittings are integral to both residential and commercial plumbing systems. They are utilized in water supply lines, drainage systems, and HVAC installations. The durability and corrosion resistance of brass make it an ideal choice for long-term applications, ensuring that systems remain leak-free and efficient. For international buyers, it is crucial to ensure that these fittings comply with local building codes and standards to avoid costly reworks and ensure safety.

What Role Do Brass Plumbing Fittings Play in the Oil & Gas Industry?

Brass fittings are commonly employed in the oil and gas sector, particularly in pipeline systems for fluid transfer. Their resistance to corrosion and ability to withstand high pressure make them suitable for transporting various liquids and gases safely. Buyers in this industry must prioritize sourcing fittings that meet stringent certification requirements for safety and performance, ensuring reliability in critical applications where failure is not an option.

Why Are Brass Fittings Essential for HVAC Systems?

In HVAC systems, brass plumbing fittings are essential for the transportation of fluids and gases. They help maintain system efficiency and reduce the likelihood of leaks, which can lead to costly energy losses. For businesses in this sector, sourcing high-quality brass fittings that can withstand specific temperature and pressure ratings is vital. International buyers should also consider the compatibility of these fittings with various HVAC designs to optimize performance.

How Do Brass Plumbing Fittings Benefit Agricultural Applications?

Brass fittings find significant application in irrigation systems and agricultural machinery, where they facilitate efficient water management. Their durability ensures that irrigation systems operate effectively, promoting better crop yield and resource conservation. Buyers in Africa and South America should look for fittings that are compatible with different irrigation technologies and that can withstand varying environmental conditions, ensuring longevity and reliability.

In What Ways Are Brass Fittings Used in Automotive Systems?

In the automotive industry, brass fittings are utilized in fuel and hydraulic systems, playing a critical role in vehicle performance and safety. Their ability to withstand high pressures and resist corrosion ensures that vehicles operate efficiently under various conditions. Buyers must ensure compatibility with specific vehicle models and consider sourcing from manufacturers that provide robust testing and certification to guarantee reliability in automotive applications.

3 Common User Pain Points for ‘Brass Plumbing Fittings Manufacturers’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Brass Fittings

The Problem: B2B buyers often struggle with identifying reliable brass plumbing fittings manufacturers that can consistently provide high-quality products. In many cases, they receive subpar fittings that do not meet industry standards, leading to potential leaks, failures, and costly repairs. This issue is especially pronounced for international buyers who may not be familiar with local suppliers’ reputations or product quality. Additionally, factors such as varying compliance standards and inconsistent manufacturing practices can create uncertainty in product sourcing.

The Solution: To effectively source quality brass fittings, buyers should prioritize manufacturers that demonstrate compliance with international standards, such as ISO certifications and specific regional regulations like the Buy American Act. Conducting thorough due diligence, including reviewing product specifications and obtaining samples for testing, can help ensure quality. Additionally, leveraging online platforms that feature verified supplier ratings and customer reviews can aid in identifying reputable manufacturers. Collaborating with local distributors who have established relationships with trusted manufacturers can also streamline the sourcing process and provide valuable insights into product performance and reliability.

Scenario 2: Inconsistent Availability of Specific Fitting Types

The Problem: Many B2B buyers encounter challenges with the inconsistent availability of specific brass fittings, which can disrupt their supply chains and project timelines. For instance, a plumbing contractor may require unique fittings for a custom installation, but find that the necessary components are out of stock or backordered from their supplier. This situation not only delays projects but can also lead to increased costs due to rushed orders or the need to source from multiple vendors.

The Solution: To mitigate the risk of stockouts, buyers should establish strategic partnerships with multiple brass fittings manufacturers to create a diverse supply chain. Utilizing forecasting tools can help predict demand and inform manufacturers about upcoming projects that may require specific fittings. Additionally, buyers should inquire about manufacturers’ inventory management practices and lead times. Setting up a system for regular communication with suppliers can also provide updates on stock levels and upcoming restocks, allowing buyers to plan orders more effectively. Implementing just-in-time inventory practices can further reduce the risk of disruptions in the supply chain.

Scenario 3: Navigating Complex Technical Specifications

The Problem: Understanding the technical specifications of brass plumbing fittings can be daunting for B2B buyers, particularly those who are new to the industry. Buyers may find themselves overwhelmed by terms such as ‘lead-free compliance,’ ‘thread types,’ and ‘pressure ratings,’ leading to potential mistakes in ordering the wrong fittings for their projects. This lack of technical knowledge can result in costly errors and project delays.

The Solution: To navigate the complexities of technical specifications, B2B buyers should invest in training and resources to enhance their understanding of brass fittings. Manufacturers often provide detailed catalogs and specification sheets that outline the features and applications of their products. Buyers should take advantage of these resources and consider attending workshops or webinars hosted by manufacturers or industry associations. Additionally, engaging with technical support teams from suppliers can provide clarity on specific requirements and ensure that the correct fittings are selected for each application. Building a relationship with knowledgeable sales representatives can also facilitate a better understanding of product specifications and their implications for various plumbing systems.

Strategic Material Selection Guide for Brass Plumbing Fittings Manufacturers

What Are the Key Materials Used in Brass Plumbing Fittings?

Brass plumbing fittings are primarily made from a variety of materials, each offering distinct properties and advantages. Understanding these materials is crucial for international B2B buyers looking to select the most suitable options for their applications.

How Does the Composition of Brass Affect Performance?

1. CA360 Brass (Common Brass Alloy)

CA360 is a widely used brass alloy known for its excellent machinability and corrosion resistance. It typically contains around 61% copper, 35% zinc, and small amounts of lead.

– Key Properties: Good temperature and pressure ratings, withstanding up to 150°C and 2000 psi.

– Pros: High durability and ease of machining make it suitable for mass production.

– Cons: Lead content may limit its use in potable water applications due to health regulations.

– Impact on Application: Compatible with water, gas, and various chemicals, but not suitable for drinking water in regions with stringent regulations.

– Considerations for International Buyers: Compliance with local regulations such as the U.S. Safe Drinking Water Act or European Union directives is essential. Buyers from regions like Germany and Brazil should ensure lead-free options are available.

2. CA377 Brass (Lead-Free Brass Alloy)

CA377 is an alternative to CA360, designed to be lead-free while maintaining similar mechanical properties.

– Key Properties: Comparable temperature ratings and pressure resistance as CA360.

– Pros: Safe for drinking water applications, making it suitable for a broader range of uses.

– Cons: Slightly higher manufacturing costs due to the absence of lead.

– Impact on Application: Ideal for potable water systems, HVAC, and plumbing applications.

– Considerations for International Buyers: Increasingly important in regions with strict health regulations, such as the EU and North America. Buyers should look for certifications like NSF/ANSI 61.

3. Brass with Nickel Coating

Nickel-coated brass fittings provide enhanced corrosion resistance and aesthetic appeal.

– Key Properties: Maintains the mechanical properties of brass while offering improved resistance to tarnishing and corrosion.

– Pros: Aesthetic finish and extended lifespan in harsh environments.

– Cons: Higher manufacturing complexity and cost due to the additional coating process.

– Impact on Application: Suitable for both decorative and functional applications in plumbing and HVAC systems.

– Considerations for International Buyers: Buyers in humid or coastal regions, such as parts of South America and the Middle East, should consider nickel-coated options for enhanced durability.

4. Forged Brass

Forged brass fittings are produced through a forging process, resulting in a denser and stronger product.

– Key Properties: High strength and impact resistance, suitable for high-pressure applications.

– Pros: Exceptional durability and reliability, making them ideal for critical applications.

– Cons: Higher production costs and more complex manufacturing processes.

– Impact on Application: Often used in industrial applications requiring high-pressure resistance.

– Considerations for International Buyers: Buyers should ensure compliance with relevant standards such as ASTM or DIN, particularly in Europe.

Summary of Material Selection for Brass Plumbing Fittings

| Material | Typical Use Case for Brass Plumbing Fittings Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| CA360 Brass | General plumbing, gas fittings, HVAC systems | Excellent machinability and durability | Lead content limits potable water use | Medium |

| CA377 Brass | Potable water systems, HVAC applications | Safe for drinking water applications | Higher cost due to lead-free composition | Medium |

| Brass with Nickel Coating | Decorative plumbing, harsh environments | Enhanced corrosion resistance and aesthetics | Increased manufacturing complexity | High |

| Forged Brass | High-pressure industrial applications | Exceptional strength and reliability | Higher production costs | High |

This strategic material selection guide provides valuable insights for B2B buyers in diverse regions. By understanding the properties, advantages, and limitations of each material, buyers can make informed decisions that align with their operational needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for Brass Plumbing Fittings Manufacturers

What Are the Main Stages in the Manufacturing Process of Brass Plumbing Fittings?

The manufacturing of brass plumbing fittings involves several critical stages, each designed to ensure the final product meets industry standards and customer expectations.

-

Material Preparation: The process begins with sourcing high-quality brass alloys, typically composed of copper and zinc. Manufacturers must ensure that the raw materials comply with international standards, such as ASTM or ISO specifications. This stage often involves material testing to confirm the chemical composition and mechanical properties of the brass.

-

Forming: The next step is forming, which can include processes like forging, casting, or machining. Forging is commonly used for high-stress applications, while casting allows for more intricate designs. Machining, including turning and milling, is employed to achieve precise dimensions and tolerances. Advanced techniques such as CNC machining enhance accuracy and consistency.

-

Assembly: In this stage, various components are assembled to create the final fittings. This may involve processes like soldering or welding, particularly for fittings that require a hermetic seal. Attention to detail is crucial here, as improper assembly can lead to leaks or structural failures.

-

Finishing: The final stage involves surface treatments to improve durability and aesthetics. Common finishing processes include electroplating, polishing, and applying protective coatings. These treatments not only enhance the appearance but also provide corrosion resistance, which is vital for plumbing applications.

How Is Quality Assurance Integrated into Brass Fittings Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that every product meets specified standards before it reaches the market.

What International Standards Govern Brass Plumbing Fittings?

Brass plumbing fittings manufacturers typically adhere to several international standards, with ISO 9001 being the most widely recognized for quality management systems. Compliance with these standards ensures systematic processes for continuous improvement and customer satisfaction. Additionally, other certifications such as CE marking and API standards can be critical, especially for products intended for specific markets or applications.

What Are the Key Quality Control Checkpoints in Brass Fittings Production?

Quality control is established through multiple checkpoints during the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves the inspection of raw materials upon delivery. Suppliers must provide certificates of compliance, and materials are tested for quality before they enter the production line.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, various inspections are conducted to verify that production is proceeding according to specifications. This includes monitoring the forming and assembly stages to catch any deviations early.

-

Final Quality Control (FQC): After production, each finished product undergoes thorough inspections and testing to ensure it meets dimensional and performance standards. This may involve pressure testing, leak testing, and dimensional verification.

Which Testing Methods Are Commonly Used for Quality Assurance in Brass Fittings?

Several testing methods are employed to assess the quality and safety of brass plumbing fittings:

-

Hydrostatic Testing: This method involves filling the fittings with water and subjecting them to high pressure to check for leaks. It is a crucial step for ensuring the integrity of plumbing systems.

-

Dimensional Inspection: Using calipers and gauges, manufacturers measure the fittings to ensure they meet specified tolerances. This inspection is essential for ensuring compatibility with other plumbing components.

-

Material Testing: Techniques such as spectroscopy can be used to verify the chemical composition of the brass, ensuring it meets regulatory requirements.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for mitigating risks.

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and compliance with international standards firsthand. This can be critical for establishing trust.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality assurance reports that outline their testing methods, results, and any certifications obtained. This transparency helps buyers make informed decisions.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. These inspections can be arranged at various stages, from material sourcing to final product delivery.

What Are the Nuances of Quality Control Certifications for International B2B Buyers?

Understanding the nuances of quality control certifications is vital for international buyers. Different regions may have varying standards and requirements. For example, European buyers may prioritize CE marking, which indicates compliance with EU safety, health, and environmental protection legislation. In contrast, buyers in the Middle East might focus on local standards that comply with GCC regulations.

Additionally, manufacturers seeking to export products often need to navigate complex compliance landscapes. Buyers should be proactive in asking suppliers about their certifications and how they align with the specific requirements of their target markets.

In conclusion, a thorough understanding of manufacturing processes and quality assurance practices is essential for B2B buyers in the brass plumbing fittings industry. By focusing on the main stages of production, quality control checkpoints, and testing methods, buyers can ensure they select reliable suppliers that deliver high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Brass Plumbing Fittings Manufacturers’

To successfully source brass plumbing fittings from international manufacturers, it is essential to follow a structured approach. This guide outlines the critical steps to ensure that you select the right suppliers while meeting your specific needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the brass fittings you need, including dimensions, pressure ratings, and any specific industry standards. This step is crucial because it ensures that you communicate precisely what you require, reducing the risk of receiving unsuitable products. Consider factors such as corrosion resistance, lead-free options, and compatibility with existing systems.

Step 2: Conduct Market Research

Investigate potential manufacturers and suppliers to understand the market landscape. Look for companies with a solid reputation in the industry and a proven track record of quality. Utilize resources such as trade shows, industry publications, and online directories to compile a list of potential candidates. Pay attention to their product range and certifications relevant to your region.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet your shortlisted suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. This step is vital to assess their reliability and capacity to meet your needs. Look for reviews or testimonials that highlight their service, product quality, and delivery reliability.

Step 4: Verify Supplier Certifications

Ensure that the suppliers possess necessary certifications, such as ISO 9001 or compliance with local regulations like the Buy American Act or similar standards relevant to your market. These certifications indicate that the manufacturer adheres to quality management practices and regulatory requirements. Additionally, inquire about their production processes and quality control measures.

Step 5: Request Samples and Specifications

Always request product samples before placing bulk orders. This allows you to evaluate the quality of the fittings firsthand and ensure they meet your specifications. Additionally, ask for detailed specifications sheets that include material composition, testing results, and installation guidelines. This transparency is crucial for your quality assurance process.

Step 6: Discuss Pricing and Payment Terms

Engage in discussions regarding pricing structures and payment terms to ensure they fit within your budget. Consider factors such as bulk order discounts, shipping costs, and payment methods. A clear understanding of these financial elements will help avoid misunderstandings later and facilitate smoother transactions.

Step 7: Establish Communication and Support Channels

Ensure that the supplier has robust communication channels and customer support in place. This is essential for addressing any issues that may arise during the ordering process or after delivery. A responsive supplier can significantly enhance your procurement experience, making it easier to resolve concerns and maintain a good business relationship.

By following these steps, B2B buyers can effectively source brass plumbing fittings that meet their technical and commercial requirements, leading to successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for Brass Plumbing Fittings Manufacturers Sourcing

What Are the Key Cost Components in Brass Plumbing Fittings Manufacturing?

Understanding the cost structure of brass plumbing fittings manufacturing is crucial for B2B buyers aiming to source competitively priced products. The primary cost components include:

-

Materials: The primary material, brass, varies in cost based on market fluctuations, alloy composition, and sourcing location. For example, high-quality brass that meets specific standards can command a premium price.

-

Labor: Labor costs can differ significantly depending on the region and the skill level required. In countries with higher labor costs, manufacturers may need to balance wages with productivity to maintain competitiveness.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and maintenance. Manufacturers in regions with higher operational costs may pass these expenses onto buyers.

-

Tooling: The cost of tooling can be substantial, particularly for custom fittings. Advanced machinery and molds are essential for precision manufacturing and can significantly affect the overall price.

-

Quality Control (QC): Implementing robust QC measures ensures product reliability and compliance with industry standards, which can increase costs but is vital for maintaining a reputable product line.

-

Logistics: Shipping costs are influenced by distance, shipping method, and freight terms. Buyers should consider these costs, especially when importing from overseas.

-

Margin: Manufacturers typically add a profit margin based on the total costs incurred and market demand, which can vary by supplier and product category.

How Do Price Influencers Affect Brass Fittings Costs?

Several factors can influence the pricing of brass plumbing fittings, including:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer better rates for larger orders. Understanding the MOQ can help buyers negotiate more favorable terms.

-

Specifications and Customization: Customized fittings with specific dimensions or features typically incur higher costs. Buyers should weigh the need for customization against budget constraints.

-

Material Quality and Certifications: Products that comply with strict industry standards or certifications (e.g., lead-free, NSF certified) often come at a premium. Buyers should consider these factors when evaluating suppliers.

-

Supplier Factors: The supplier’s reputation, location, and production capacity can influence pricing. Established manufacturers with a track record of quality may charge more but offer reliability.

-

Incoterms: Understanding shipping terms is essential for calculating the total landed cost. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the shipping costs and risks, which can significantly affect pricing.

What Tips Can Help Buyers Negotiate Better Prices for Brass Plumbing Fittings?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, can employ several strategies to optimize their sourcing:

-

Negotiate Smartly: Always negotiate pricing based on volume, payment terms, and delivery schedules. Suppliers may be more flexible with prices for larger or recurring orders.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not just the purchase price but also shipping, duties, and potential maintenance costs over the product’s lifespan.

-

Understand Pricing Nuances: Be aware that prices can vary widely based on geographic location and economic factors. For instance, European suppliers might offer higher quality but at a premium compared to manufacturers in other regions.

-

Establish Long-Term Relationships: Building a relationship with suppliers can lead to better pricing and priority service. Long-term partnerships often result in more favorable terms and reduced costs.

What Should Buyers Keep in Mind Regarding Indicative Prices?

When considering brass plumbing fittings, it’s essential to remember that prices are often indicative and can fluctuate based on market conditions, exchange rates, and supplier pricing strategies. Always request up-to-date quotes and be prepared for negotiations based on current market insights. Understanding these dynamics will empower buyers to make informed decisions and optimize their sourcing strategies.

Alternatives Analysis: Comparing Brass Plumbing Fittings Manufacturers With Other Solutions

Introduction to Alternatives in Plumbing Fittings

In the plumbing industry, selecting the right fittings is crucial for ensuring system efficiency and longevity. While brass plumbing fittings have long been a standard choice due to their durability and corrosion resistance, various alternatives are available that may better suit specific applications or budget constraints. This analysis will compare brass plumbing fittings manufacturers with alternative solutions, providing B2B buyers with essential insights to inform their purchasing decisions.

Comparison Table

| Comparison Aspect | Brass Plumbing Fittings Manufacturers | Plastic Plumbing Fittings | Stainless Steel Plumbing Fittings |

|---|---|---|---|

| Performance | High durability, excellent corrosion resistance | Moderate durability, susceptible to UV degradation | Very high durability, excellent corrosion resistance |

| Cost | Generally higher initial cost | Lower initial cost | Higher initial cost |

| Ease of Implementation | Standard installation processes | Lightweight, easy to handle | Heavier, may require specialized tools |

| Maintenance | Low maintenance, but requires periodic checks | Very low maintenance | Low maintenance, but may require periodic inspections |

| Best Use Case | Industrial and commercial applications | Residential plumbing, irrigation | High-pressure systems, food and beverage industries |

Detailed Breakdown of Alternatives

Plastic Plumbing Fittings

Plastic fittings, made from materials like PVC or CPVC, are often favored for their cost-effectiveness and lightweight nature. They are particularly useful in residential plumbing applications and irrigation systems due to their resistance to corrosion and rust. However, plastic fittings may not withstand high temperatures or pressures as effectively as brass, and prolonged exposure to UV light can degrade their integrity. Therefore, while they offer a lower upfront cost, their long-term performance in demanding environments may be a concern.

Stainless Steel Plumbing Fittings

Stainless steel fittings are another viable alternative that offers exceptional durability and resistance to corrosion, making them suitable for high-pressure applications. They can handle a wider temperature range compared to brass and plastic. However, stainless steel fittings typically come with a higher initial cost and may require specialized tools for installation due to their weight. They are best suited for applications in industries such as food and beverage, pharmaceuticals, and other sectors where hygiene and strength are paramount.

Conclusion: How to Choose the Right Plumbing Fitting Solution

When selecting the right plumbing fitting solution, B2B buyers must consider various factors such as performance requirements, budget constraints, and specific application needs. Brass plumbing fittings are ideal for commercial and industrial uses where durability and longevity are critical. In contrast, plastic fittings may serve well in residential settings where cost and ease of installation are more important. Stainless steel fittings are best suited for high-pressure or hygienic applications. By carefully evaluating these factors, buyers can make informed decisions that align with their operational goals and financial considerations.

Essential Technical Properties and Trade Terminology for Brass Plumbing Fittings Manufacturers

What Are the Key Technical Specifications for Brass Plumbing Fittings?

Understanding the technical specifications of brass plumbing fittings is crucial for international B2B buyers. Here are some essential properties to consider:

-

Material Grade

The grade of brass used (such as CA360 or CA377) indicates its composition and properties, including corrosion resistance and strength. Higher-grade materials often translate to enhanced durability and longevity in various applications, making them a vital consideration for manufacturers and installers alike. -

Pressure Rating

This specification denotes the maximum pressure that a fitting can withstand without failure. It is critical for buyers to ensure that the fittings meet the pressure requirements of their specific plumbing systems. A mismatch can lead to leaks or catastrophic failures, impacting both safety and operational efficiency. -

Temperature Tolerance

Brass fittings must perform effectively within a specific temperature range. Understanding the thermal limits of a fitting is essential, especially in applications involving hot water or steam. Buyers should verify that the products can handle the temperature extremes they will encounter. -

Thread Type and Size

The compatibility of threads (e.g., NPT, BSP) is fundamental for ensuring a proper seal and preventing leaks. Buyers should confirm the correct thread size and type to avoid installation issues and potential system failures. -

Dimensional Tolerance

This refers to the allowable variation in the dimensions of the fittings, ensuring they fit correctly with other components. Tight tolerances are particularly important in high-precision applications, where even minor discrepancies can lead to operational problems. -

Lead Content Compliance

With increasing regulations regarding lead content in plumbing materials, it’s essential for buyers to verify that fittings are compliant with local and international standards (e.g., AB1953 in the U.S.). This is not only a legal requirement but also critical for ensuring safe drinking water.

What Are Common Trade Terms in the Brass Fittings Industry?

Navigating the terminology in the brass plumbing fittings industry can be challenging. Here are some commonly used terms that every buyer should understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand. For buyers, sourcing from OEMs can ensure high-quality components that meet specific design standards. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory costs and ensure they meet supplier requirements without overcommitting. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products. This is a critical step in the procurement process, enabling buyers to compare prices and terms from multiple suppliers. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international shipping. They clarify who is responsible for shipping, insurance, and tariffs, which is crucial for effective logistics planning. -

Lead Time

This term refers to the time it takes for a supplier to fulfill an order from the moment it is placed until it is delivered. Understanding lead times helps buyers plan their projects and manage inventory effectively. -

Certification Standards

Various certifications (like ISO, ASTM) validate the quality and safety of plumbing fittings. Buyers should ensure that suppliers provide products that meet relevant certification standards to guarantee compliance and quality assurance.

Incorporating this knowledge into your procurement strategy can significantly enhance decision-making and ensure that you select the right brass plumbing fittings for your projects.

Navigating Market Dynamics and Sourcing Trends in the Brass Plumbing Fittings Manufacturers Sector

What Are the Current Market Dynamics and Key Trends in the Brass Plumbing Fittings Sector?

The brass plumbing fittings market is experiencing significant growth driven by several global factors. Increasing urbanization, particularly in developing regions such as Africa and South America, is enhancing infrastructure development, thereby boosting demand for plumbing fittings. In Europe and the Middle East, stringent regulations regarding water quality and efficiency are pushing manufacturers to innovate. As a result, there is a notable shift towards smart plumbing solutions that integrate IoT technology, enabling better monitoring and management of plumbing systems.

Emerging trends include the adoption of digital sourcing platforms that facilitate real-time procurement and supply chain transparency. B2B buyers are increasingly relying on online marketplaces to streamline their sourcing processes, thus reducing lead times and enhancing inventory management. Additionally, the integration of artificial intelligence in inventory forecasting is becoming more prevalent, allowing manufacturers to respond swiftly to market fluctuations. Buyers from regions like Germany and Brazil are particularly focused on these technological advancements to optimize their purchasing strategies.

How Is Sustainability Influencing Sourcing in the Brass Plumbing Fittings Industry?

Sustainability and ethical sourcing are increasingly becoming pivotal in the brass plumbing fittings sector. The environmental impact of brass production, particularly concerning energy consumption and emissions, has led to a growing emphasis on greener manufacturing processes. Manufacturers are now exploring lead-free brass alloys and eco-friendly production techniques to meet the demands of environmentally conscious buyers.

Ethical supply chains are also gaining traction, with B2B buyers seeking suppliers who adhere to fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 for environmental management and the use of recycled materials are becoming essential criteria for procurement decisions. Buyers are encouraged to engage with manufacturers who can demonstrate compliance with these standards, thus ensuring that their sourcing practices align with global sustainability goals.

What Is the Historical Context of Brass Plumbing Fittings Manufacturing?

The history of brass plumbing fittings manufacturing can be traced back to ancient civilizations, where brass was prized for its durability and resistance to corrosion. Over the centuries, advancements in metallurgy and manufacturing techniques have transformed the industry. The Industrial Revolution marked a significant turning point, introducing mass production methods that made brass fittings more accessible and affordable.

In recent decades, the industry has witnessed a shift towards automation and precision engineering, enhancing product quality and consistency. As the demand for plumbing solutions continues to evolve, manufacturers are focusing on innovation and sustainability, ensuring that brass fittings remain integral to modern plumbing systems.

Conclusion

Navigating the brass plumbing fittings market requires a keen understanding of current trends, sustainability imperatives, and historical context. By leveraging technological advancements and prioritizing ethical sourcing, B2B buyers can make informed decisions that align with both their operational needs and broader environmental goals. This strategic approach not only enhances procurement efficiency but also fosters long-term partnerships within the industry.

Frequently Asked Questions (FAQs) for B2B Buyers of Brass Plumbing Fittings Manufacturers

-

How do I choose the right brass plumbing fittings manufacturer for my needs?

When selecting a brass plumbing fittings manufacturer, consider factors such as their industry experience, product range, compliance with international standards, and customer reviews. Evaluate their capabilities for customization, lead times, and minimum order quantities (MOQs). It’s also beneficial to inquire about their quality assurance processes and certifications, such as ISO or ASTM compliance, to ensure product reliability. Establishing clear communication and support options can further enhance your partnership. -

What are the key quality assurance practices for brass fittings?

Quality assurance for brass fittings should include rigorous testing and inspection at various production stages. Manufacturers typically conduct dimensional checks, pressure testing, and corrosion resistance evaluations to ensure durability and performance. It’s essential to verify that the manufacturer adheres to recognized quality standards, such as ISO 9001, and utilizes certified raw materials. Requesting documentation of their QA practices can provide additional assurance of product quality. -

What customization options are available for brass plumbing fittings?

Many brass fittings manufacturers offer customization options to meet specific project requirements. Customization may include alterations in size, shape, threading, and finishes. Some manufacturers can also produce unique designs based on your specifications. It’s advisable to discuss your needs upfront and request samples to evaluate the quality of customized fittings before placing a bulk order. -

What are typical minimum order quantities (MOQs) for brass fittings?

Minimum order quantities for brass fittings can vary significantly between manufacturers, often depending on the type of fitting and production capabilities. MOQs can range from a few dozen to several hundred units. When negotiating with suppliers, clarify their MOQs and explore potential flexibility for initial orders. Additionally, consider the implications of MOQ on your inventory management and cash flow. -

What payment terms should I expect when sourcing brass fittings internationally?

Payment terms for international brass fittings transactions typically include options such as advance payment, letters of credit, or net payment terms (e.g., net 30, net 60). The terms may vary based on the manufacturer’s policies, your relationship with them, and the transaction size. Always clarify payment terms in the contract to avoid misunderstandings, and consider using secure payment methods that provide protection against fraud. -

How can I ensure timely delivery of my brass fittings order?

To ensure timely delivery, it is crucial to establish clear timelines with your manufacturer from the outset. Discuss production lead times, shipping options, and any potential delays due to customs or logistics. Employing reliable logistics partners and considering incoterms (like FOB or CIF) can also influence delivery efficiency. Regular communication with your manufacturer throughout the process can help address any issues that may arise. -

What are the main regulations I need to be aware of when importing brass fittings?

When importing brass fittings, familiarize yourself with relevant regulations that may apply in your region. This includes compliance with material safety standards, lead content restrictions, and customs duties. Each country may have specific requirements for plumbing materials, so it’s essential to research and verify that your supplier adheres to these regulations. Engaging a customs broker can also facilitate the import process. -

How do I vet potential brass plumbing fittings suppliers?

To vet brass plumbing fittings suppliers, start by reviewing their company background, industry reputation, and customer testimonials. Request references and samples of their products to assess quality firsthand. Additionally, inquire about their manufacturing processes, certifications, and ability to meet your specific needs. Conducting on-site visits, if possible, can also provide valuable insights into their operations and quality control measures.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Brass Plumbing Fittings Manufacturers

Strategic sourcing in the brass plumbing fittings sector presents a unique opportunity for international B2B buyers to enhance their supply chain efficiency while ensuring compliance with regional standards. By focusing on suppliers that adhere to rigorous manufacturing guidelines, such as the Buy American Act, buyers can mitigate risks associated with quality and reliability. The diverse range of products available, from industrial valves to specialized fittings, underscores the importance of aligning sourcing strategies with specific project requirements.

As the demand for high-quality brass fittings continues to rise in markets across Africa, South America, the Middle East, and Europe, strategic sourcing becomes essential. Buyers should prioritize partnerships with manufacturers who not only offer a wide array of products but also demonstrate a commitment to sustainability and innovation. This approach will not only secure a competitive advantage but also foster long-term relationships that can adapt to changing market dynamics.

Looking ahead, we encourage B2B buyers to actively engage with manufacturers, explore new product lines, and stay informed about industry trends. By doing so, they can ensure they are well-positioned to meet their plumbing needs while maximizing value and efficiency in their operations.