Discover Cost-Saving Solutions with Braided Type Cables (2025)

Introduction: Navigating the Global Market for braided type

In today’s fast-paced global market, sourcing high-quality braided type cables can be a daunting challenge for international B2B buyers. Whether you are in Egypt, Brazil, or any part of Europe, navigating the myriad of options available while ensuring compliance with local standards and expectations can be overwhelming. This guide aims to simplify your purchasing journey by providing comprehensive insights into the various types of braided type cables, their applications, and essential factors to consider when selecting suppliers.

Understanding the differences between cables—such as USB-C to USB-C or USB-A to Micro B—is crucial for making informed decisions that align with your business needs. Additionally, the guide will cover critical aspects of supplier vetting, enabling you to identify trustworthy partners who can deliver quality products at competitive prices. With an emphasis on cost considerations and performance metrics, you will gain clarity on how to optimize your procurement strategy effectively.

By empowering you with the knowledge to evaluate products and suppliers critically, this guide will help you minimize risks and enhance your procurement efficiency. Whether you are looking to source cables for consumer electronics, industrial applications, or corporate environments, the insights provided here will equip you to make strategic purchasing decisions that drive value for your organization.

Understanding braided type Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| USB-C to USB-C Braided Cable | High power delivery (up to 240W), durable materials | Electronics, IT equipment | Pros: High-speed data transfer, versatile compatibility. Cons: May be more expensive than standard cables. |

| USB 4.0 Braided Type-C Cable | Supports high-speed data transfer (up to 40Gbps) | Data centers, tech companies | Pros: Future-proof technology, excellent performance. Cons: Limited availability in some regions. |

| Braided USB-C to Micro-B Cable | Dual compatibility with Type-C and Micro-B | Mobile devices, peripherals | Pros: Versatile for various devices, generally lower cost. Cons: Slower charging capabilities compared to USB-C only. |

| Heavy-Duty Braided Type-C Cable | Enhanced strain relief, rugged design | Industrial, construction applications | Pros: Durable for harsh environments, long lifespan. Cons: Bulkier design may not suit all applications. |

| Cotton Braided USB-C Cable | Eco-friendly materials, tangle-free design | Retail, consumer electronics | Pros: Aesthetic appeal, sustainable choice. Cons: May not offer the same durability as synthetic options. |

What Are the Characteristics of USB-C to USB-C Braided Cables?

USB-C to USB-C braided cables are characterized by their ability to deliver high power (up to 240W) and support data transfer speeds of 480 Mbps. These cables are widely used in B2B environments for connecting various electronic devices such as laptops, tablets, and smartphones. When purchasing, businesses should consider the cable’s durability and compatibility with their existing devices to ensure seamless integration.

Why Choose USB 4.0 Braided Type-C Cables for Your Business?

USB 4.0 braided Type-C cables support incredibly fast data transfer rates, reaching up to 40Gbps, making them ideal for data centers and tech companies that require efficient data handling. Their future-proof nature is a significant advantage for businesses looking to invest in long-term solutions. However, buyers should be aware of potential regional availability issues, which can affect procurement.

How Do Braided USB-C to Micro-B Cables Benefit Various Industries?

Braided USB-C to Micro-B cables provide dual compatibility, making them suitable for a variety of mobile devices and peripherals. This versatility can be advantageous for businesses that manage multiple device types. While these cables are generally more affordable, buyers should note that they may not support the same fast charging capabilities as dedicated USB-C cables.

What Makes Heavy-Duty Braided Type-C Cables Ideal for Industrial Use?

Heavy-duty braided Type-C cables are designed with enhanced strain relief and rugged materials, making them suitable for industrial and construction applications. Their durability ensures a long lifespan, even in harsh conditions. However, businesses should consider the bulkier design, which may limit their use in more compact setups.

What Are the Advantages of Using Cotton Braided USB-C Cables?

Cotton braided USB-C cables are made from eco-friendly materials and feature a tangle-free design, appealing to businesses focused on sustainability. Their aesthetic appeal can also enhance product presentation in retail settings. However, buyers should evaluate the durability of cotton against synthetic options to ensure they meet their operational needs.

Key Industrial Applications of braided type

| Industry/Sector | Specific Application of Braided Type | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | High-speed charging and data transfer cables | Enhanced device performance and customer satisfaction | Compatibility with various devices and durability |

| Automotive | Durable USB-C cables for vehicle infotainment systems | Reliable connectivity for navigation and entertainment | Resistance to extreme temperatures and vibrations |

| Industrial Automation | Braided cables for robotic systems | Improved safety and efficiency in operations | Compliance with industry standards and certifications |

| Telecommunications | High-performance cables for data centers | Increased data transmission speeds | Bulk purchasing options and long-term reliability |

| Healthcare | Medical device connectivity cables | Ensured device functionality and patient safety | Sterilization capabilities and biocompatibility |

How is Braided Type Used in Consumer Electronics?

In the consumer electronics sector, braided type cables are essential for high-speed charging and data transfer. These cables are designed to support rapid charging, which is crucial for smartphones, tablets, and laptops, especially in markets like Africa and South America where rapid tech adoption is evident. The durable braided material prevents wear and tear, addressing common issues like fraying and tangling. International B2B buyers should prioritize compatibility with various devices and ensure the cables meet local safety standards.

What Role Does Braided Type Play in the Automotive Industry?

In the automotive industry, braided USB-C cables are utilized for infotainment systems, enabling seamless connectivity for navigation, media playback, and communication. The reliability of these cables is paramount, as they must withstand vibrations and temperature fluctuations. For buyers in regions like the Middle East and Europe, sourcing cables that comply with automotive standards and are resistant to harsh conditions is critical for maintaining performance and safety in vehicles.

How is Braided Type Essential for Industrial Automation?

Braided type cables are integral to industrial automation, particularly in robotic systems where reliable data transmission is crucial for operational efficiency. These cables are designed to endure the rigors of industrial environments, reducing the risk of downtime due to cable failure. B2B buyers should focus on sourcing cables that comply with industry standards, ensuring safety and reliability in their automation processes, especially in emerging markets in Africa and South America.

Why are Braided Type Cables Important in Telecommunications?

In telecommunications, high-performance braided cables are vital for data centers, facilitating increased data transmission speeds and reliability. As demand for faster internet and data services grows, these cables play a significant role in maintaining service quality. International buyers should consider bulk purchasing options to ensure a steady supply and focus on long-term reliability to meet the demands of their customers.

How is Braided Type Used in Healthcare Applications?

In the healthcare sector, braided type cables are critical for connecting medical devices, ensuring they operate efficiently and safely. These cables must be biocompatible and capable of withstanding sterilization processes to prevent contamination. B2B buyers in this sector should prioritize sourcing cables that meet stringent health regulations, ensuring patient safety and device functionality in hospitals and clinics across various regions, including Europe and South America.

3 Common User Pain Points for ‘braided type’ & Their Solutions

Scenario 1: Compatibility Confusion with Braided Type Cables

The Problem: One of the most significant challenges B2B buyers face is ensuring compatibility across a diverse range of devices. For instance, a company in Egypt may procure braided Type-C cables for smartphones, laptops, and tablets, only to discover that some devices do not support the fast-charging or data transfer capabilities of the chosen cables. This mismatch leads to frustration, wasted resources, and ultimately impacts operational efficiency.

The Solution: To mitigate compatibility issues, it is essential for B2B buyers to conduct thorough research before procurement. Buyers should create a comprehensive inventory of devices that will use the cables, including specifications such as charging capacity and data transfer rates. When sourcing braided Type-C cables, prioritize options that explicitly state compatibility with a wide range of devices and support features like Power Delivery (PD) and USB 4.0. Consider working with suppliers that provide detailed compatibility charts and technical support. Furthermore, establishing a direct line of communication with manufacturers can facilitate better understanding and resolution of compatibility concerns.

Scenario 2: Durability and Longevity of Braided Cables

The Problem: Companies in South America often encounter the issue of cables wearing out quickly due to frequent use in demanding environments. For example, a logistics firm may find that its braided Type-C cables fray or break after only a few months of use, leading to increased costs and interruptions in daily operations.

The Solution: To ensure durability and longevity, B2B buyers should invest in high-quality braided Type-C cables specifically designed for heavy-duty use. Look for cables that feature reinforced connectors, strain relief, and durable materials such as nylon braiding or aluminum alloy. When selecting suppliers, consider those who provide warranties or guarantees on their products, as this often indicates confidence in durability. It may also be beneficial to conduct small-scale trials of different brands and types before committing to large orders. Additionally, implementing a regular maintenance check on cables, including storing them properly and avoiding excessive bending, can significantly extend their lifespan.

Scenario 3: Slow Charging and Data Transfer Rates

The Problem: In the Middle East, businesses often find themselves frustrated with slow charging and data transfer speeds from their braided Type-C cables. This is particularly problematic for tech companies that rely on quick data synchronization between devices and rapid charging capabilities to keep their operations running smoothly.

The Solution: To address issues related to slow charging and data transfer, B2B buyers should focus on sourcing braided Type-C cables that support higher power outputs and faster data rates. Look for cables that offer specifications such as 240W power delivery and 480 Mbps data transfer rates, as seen in some high-performance cables. Buyers should also assess the quality of the connectors, as inferior materials can lead to significant losses in charging speed and data integrity. When negotiating with suppliers, request samples to test performance under actual working conditions before making bulk purchases. Furthermore, consider investing in charging hubs or power adapters that can fully utilize the capabilities of high-speed cables, ensuring that all devices benefit from the enhanced performance.

Strategic Material Selection Guide for braided type

What Are the Key Materials Used in Braided Type Products?

When selecting materials for braided type products, several common options are available, each with unique properties and implications for performance and application. This section will analyze four prevalent materials: nylon, cotton, polyester, and PVC.

How Does Nylon Impact Performance in Braided Type Applications?

Nylon is a popular choice for braided cables due to its excellent tensile strength and flexibility. It typically has a temperature rating of up to 120°C, making it suitable for high-temperature applications. Furthermore, nylon exhibits good abrasion resistance and is resistant to many chemicals, which enhances its durability in various environments.

Pros: Nylon’s flexibility allows for easy handling and installation, making it ideal for consumer electronics and industrial applications. Its durability ensures a long lifespan, reducing replacement costs.

Cons: However, nylon can be more expensive than other materials, and its production process may involve complex manufacturing techniques. Additionally, it can absorb moisture, which may affect performance in humid environments.

For international B2B buyers, especially in regions like Africa and South America, compliance with local standards is crucial. Buyers should ensure that the nylon used meets ASTM or DIN standards to ensure reliability and safety.

What Benefits Does Cotton Offer for Braided Type Products?

Cotton is another material often used in braided applications, particularly for its eco-friendliness and aesthetic appeal. It has a lower temperature rating compared to nylon, typically around 80°C, but it is biodegradable, making it a sustainable choice.

Pros: The primary advantage of cotton is its natural fibers, which provide a soft touch and are comfortable to handle. It is also less expensive than synthetic alternatives, making it an attractive option for budget-conscious buyers.

Cons: Cotton lacks the durability and abrasion resistance of synthetic materials, which can lead to a shorter lifespan in demanding applications. It is also less resistant to moisture and chemicals, which may limit its use in certain environments.

Buyers from Europe may prefer cotton for its sustainability credentials, but they should ensure that the cotton meets relevant environmental standards, such as those set by the Global Organic Textile Standard (GOTS).

How Does Polyester Compare in Terms of Durability and Cost?

Polyester is favored for its excellent resistance to UV light and moisture, making it suitable for outdoor applications. It can withstand temperatures up to 120°C and is less prone to stretching compared to nylon.

Pros: Polyester’s durability and resistance to fading make it ideal for products exposed to sunlight and moisture, such as outdoor cables. It is also relatively inexpensive, offering a good balance between cost and performance.

Cons: While polyester is strong, it may not provide the same level of flexibility as nylon, which can be a drawback in applications requiring tight bends. Additionally, it can be less comfortable to handle compared to natural fibers.

International buyers should consider the specific environmental conditions of their regions, such as high UV exposure in the Middle East, when selecting polyester products. Compliance with ISO standards can also be beneficial for ensuring product quality.

What Role Does PVC Play in Braided Type Products?

PVC (Polyvinyl Chloride) is commonly used for its excellent chemical resistance and low cost. It can operate effectively in a temperature range of -10°C to 60°C, making it suitable for various indoor applications.

Pros: PVC is highly durable and resistant to abrasion, making it an excellent choice for industrial applications. Its low cost makes it accessible for bulk purchases, appealing to budget-oriented businesses.

Cons: However, PVC is less flexible than nylon or polyester, which can limit its application in scenarios requiring tight bends. Additionally, it is not biodegradable, raising concerns for environmentally conscious buyers.

For B2B buyers in Europe and other regions with strict environmental regulations, it is essential to ensure that PVC products comply with REACH regulations to avoid potential legal issues.

Summary Table of Material Properties for Braided Type Products

| Material | Typical Use Case for braided type | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | High-performance electronics | Excellent flexibility and durability | Higher cost and moisture absorption | Medium |

| Cotton | Eco-friendly consumer products | Biodegradable and comfortable | Less durable and moisture resistant | Low |

| Polyester | Outdoor cables and textiles | UV and moisture resistant | Less flexible than nylon | Medium |

| PVC | Industrial applications | Cost-effective and durable | Less flexible and not biodegradable | Low |

This guide provides international B2B buyers with a comprehensive overview of material options for braided type products, aiding in informed decision-making based on specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for braided type

What Are the Main Stages of Manufacturing Braided Type Products?

Manufacturing braided type products, such as cables and connectors, involves several key stages that ensure quality and performance. Here’s a breakdown of the typical manufacturing process:

-

Material Preparation

The process begins with sourcing high-quality raw materials, which may include braided textiles, copper wiring, and connectors. The choice of materials significantly impacts the durability and performance of the final product. For instance, nylon or polyester is often used for braiding due to their strength and flexibility. Manufacturers should ensure that materials comply with international standards, such as RoHS (Restriction of Hazardous Substances), to guarantee safety and environmental compliance. -

Forming

Once materials are prepared, they are cut to the required lengths. The braiding process involves intertwining multiple strands of fiber or wire, which can be done using automatic braiding machines. This stage is crucial as it determines the cable’s flexibility and resistance to wear and tear. Automated machinery is preferred for consistency and efficiency, reducing the risk of human error. -

Assembly

After braiding, the next step is to assemble the components. This includes attaching the connectors to both ends of the cable. High-quality connectors, typically made from aluminum alloy or other conductive materials, are essential for efficient power delivery and data transfer. The assembly process often involves precision techniques to ensure a secure fit, which is vital for maintaining performance and safety. -

Finishing

The final stage involves applying protective coatings and performing aesthetic enhancements, such as printing logos or branding. Quality finishing protects the product from environmental factors and enhances its appearance. Additionally, products may undergo a curing process to improve durability.

How Is Quality Assurance Implemented in the Manufacturing of Braided Type Products?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that the products meet established standards. Here are key aspects of QA for braided type products:

-

International Standards Compliance

Adherence to international standards like ISO 9001 is essential for maintaining quality management systems. ISO 9001 outlines a framework for consistent product quality and customer satisfaction. Other industry-specific certifications, such as CE for European markets or API for oil and gas applications, may also be relevant depending on the end-use of the braided products. -

Quality Control Checkpoints

Quality control is typically segmented into various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specifications.

- In-Process Quality Control (IPQC): Regular checks during manufacturing help identify any defects early. This may include monitoring the braiding process for consistency and testing electrical connections.

- Final Quality Control (FQC): After assembly, the finished products undergo thorough testing, including performance tests for power delivery and data transfer rates.

- Common Testing Methods

Manufacturers may employ various testing methods to ensure product reliability, including:

- Electrical Testing: Verifying the integrity of electrical connections and performance under load.

- Mechanical Testing: Assessing the physical durability of the braided materials, including tensile strength and flexibility.

- Environmental Testing: Evaluating the product’s performance under extreme conditions (temperature, humidity, etc.) to simulate real-world use.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are actionable steps:

-

Supplier Audits

Conducting on-site audits allows buyers to assess manufacturing facilities firsthand. This includes reviewing quality management systems, machinery, and adherence to safety standards. Buyers should prepare a checklist based on international standards and specific industry needs. -

Requesting Quality Reports

Suppliers should provide detailed quality reports, including results from IQC, IPQC, and FQC. These documents should outline any defects found during testing and how they were addressed. Buyers can evaluate these reports to gauge supplier reliability. -

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality assurance practices. These inspections can be scheduled at various stages of the manufacturing process, offering additional peace of mind. -

Understanding QC Nuances for Different Regions

Buyers should be aware of the specific quality standards and regulations in their region. For instance, European buyers might emphasize CE marking and compliance with EU regulations, while buyers from the Middle East may focus on local standards such as the GCC conformity mark. Understanding these nuances can help buyers ensure that products meet the necessary legal and quality requirements.

What Challenges Do International B2B Buyers Face in Quality Assurance?

International buyers often encounter challenges related to quality assurance, particularly in sourcing braided type products. Some common issues include:

-

Communication Barriers: Differences in language and cultural understanding can lead to misinterpretations of quality expectations. Clear communication and documented agreements are essential to mitigate this risk.

-

Supply Chain Complexity: Sourcing materials from different countries can introduce variability in quality. Buyers should establish strong relationships with reliable suppliers who can consistently meet quality standards.

-

Regulatory Differences: Navigating the varying regulations across regions can be daunting. Buyers should stay informed about local standards and ensure their suppliers are compliant to avoid potential legal complications.

By understanding the manufacturing processes and quality assurance measures in place for braided type products, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers that meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘braided type’

In the evolving landscape of international business, sourcing braided type products, especially cables, requires a strategic approach. This guide offers a practical checklist for B2B buyers from Africa, South America, the Middle East, and Europe, ensuring you make informed procurement decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential before initiating the sourcing process. Determine the required cable type (e.g., USB-C), length, power delivery capacity, and data transfer speeds. This clarity will help in narrowing down potential suppliers who can meet your specific needs.

- Considerations:

- Power requirements (e.g., 240W for fast charging).

- Compatibility with existing devices (smartphones, tablets, laptops).

Step 2: Research Reputable Suppliers

Identifying reliable suppliers is a critical step in the sourcing process. Utilize online platforms, industry directories, and trade shows to compile a list of potential vendors. Look for suppliers with positive reviews and a strong track record in delivering quality braided type products.

- Key Resources:

- B2B marketplaces like Alibaba or Global Sources.

- Industry-specific trade associations for vetted suppliers.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers to ensure they meet your business standards. Request company profiles, case studies, and references from buyers in similar industries or regions. This step is crucial to avoid potential pitfalls associated with subpar suppliers.

- What to Check:

- Supplier certifications and compliance with international standards.

- Reviews from previous clients to assess reliability and product quality.

Step 4: Request Product Samples

Obtaining product samples is a vital step that allows you to evaluate the quality of braided type cables firsthand. This not only helps in assessing material durability but also ensures the product meets your technical specifications.

- Testing Criteria:

- Check for tangle-free design and durability of the braided material.

- Verify performance under actual usage conditions (charging speed, data transfer).

Step 5: Negotiate Pricing and Terms

Once you are satisfied with the product samples, proceed to negotiate pricing and terms. Discuss bulk purchase discounts, payment terms, and delivery schedules. This is particularly important for international buyers to ensure that all logistical aspects are covered.

- Important Aspects:

- Understand the pricing structure, including any hidden costs (shipping, tariffs).

- Ensure clear communication regarding lead times for production and delivery.

Step 6: Verify Warranty and Support Services

Before finalizing your purchase, confirm the warranty and after-sales support offered by the supplier. A solid warranty can safeguard your investment, while responsive customer service can help resolve any issues that may arise post-purchase.

- What to Look For:

- Length of warranty coverage and what it entails.

- Availability of technical support in your region.

Step 7: Establish a Long-term Relationship

Building a long-term relationship with a reliable supplier can lead to better pricing, improved service, and priority support in the future. After your initial purchase, maintain open lines of communication to discuss future needs and potential improvements.

- Strategies for Relationship Building:

- Regularly provide feedback on product performance.

- Engage in discussions about upcoming product lines or innovations.

By following these steps, B2B buyers can confidently navigate the sourcing process for braided type products, ensuring quality, reliability, and value for their businesses.

Comprehensive Cost and Pricing Analysis for braided type Sourcing

What Are the Key Cost Components in Braided Type Sourcing?

When considering the sourcing of braided type products, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials, such as high-quality braided nylon or aluminum connectors, significantly impacts the cost. Premium materials enhance durability and performance, which may justify a higher price point.

-

Labor: Labor costs vary based on geographical location and the complexity of the manufacturing process. Countries with lower labor costs may offer competitive pricing but could compromise on quality.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient production processes can help mitigate these costs.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. However, these costs are typically amortized over larger production runs, making them less impactful per unit when ordered in bulk.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to overall costs. Buyers should weigh the benefits of enhanced quality against these additional expenses.

-

Logistics: Shipping and handling costs can fluctuate based on distance, mode of transport, and current market conditions. For international buyers, understanding Incoterms is essential to determine who bears these costs.

-

Margin: Suppliers typically add a profit margin, which can vary based on their business model and market positioning. Negotiating this margin is often possible, particularly for bulk purchases.

How Do Price Influencers Affect Braided Type Sourcing?

Several factors can influence the pricing of braided type products, including:

-

Volume/MOQ: Minimum order quantities (MOQs) can greatly affect pricing. Larger orders often result in discounted rates, making it advantageous for buyers to consolidate purchases.

-

Specifications/Customization: Custom designs or specifications may incur additional costs. Buyers should clarify their requirements upfront to avoid unexpected expenses.

-

Materials: The choice of materials can lead to significant price variations. Buyers should consider the trade-off between cost and quality, especially for high-performance applications.

-

Quality and Certifications: Products that meet international quality standards or possess certifications may come at a premium. However, these certifications can enhance product credibility in competitive markets.

-

Supplier Factors: The supplier’s reputation, experience, and reliability can influence pricing. A well-established supplier may charge more, but they can also offer better service and quality assurance.

-

Incoterms: Understanding the shipping terms is vital for calculating total costs. Incoterms dictate responsibilities for shipping, insurance, and tariffs, impacting overall pricing.

What Are Effective Buyer Tips for Cost Efficiency?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are actionable tips for cost efficiency:

-

Negotiation: Leverage your purchasing power by negotiating pricing, especially when committing to larger orders. Suppliers may be more willing to offer discounts to secure bulk contracts.

-

Total Cost of Ownership (TCO): Consider the total cost of ownership beyond the purchase price. This includes maintenance, potential downtime, and replacement costs, which can vary based on the quality of the product.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that can affect overall costs. It’s advisable to work with suppliers who have experience dealing with international shipments to navigate these complexities.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and terms. Trust and reliability can often lead to improved service and reduced costs over time.

-

Market Research: Conduct thorough market research to compare prices and quality across suppliers. This not only helps in finding the best deal but also provides leverage during negotiations.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier policies, and specific buyer requirements. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing braided type With Other Solutions

When considering the best cable solutions for your business needs, it’s crucial to evaluate various options available in the market. This section explores the braided type cables and compares them against alternative solutions such as traditional rubber cables and reinforced cables. Understanding the differences can help international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, make informed decisions.

Comparison Table: Braided Type vs. Alternatives

| Comparison Aspect | Braided Type | Traditional Rubber Cable | Reinforced Cable |

|---|---|---|---|

| Performance | High durability and flexibility | Moderate durability; less flexible | Very high durability; less flexible |

| Cost | Moderate to high | Low to moderate | High |

| Ease of Implementation | Easy to install and use | Very easy to install | Moderate; may require specialized knowledge |

| Maintenance | Low maintenance; resistant to wear | Moderate maintenance | Low maintenance; resistant to damage |

| Best Use Case | Ideal for mobile devices and laptops | Suitable for basic charging needs | Best for industrial environments |

What Are the Advantages of Braided Type Cables?

Braided type cables, such as the Green Lion Braided Type-C to Type-C Cable, are known for their high durability due to the use of braided materials. This construction not only enhances their lifespan but also provides flexibility, making them ideal for environments where cables may be frequently moved or bent. Their moderate cost is justified by their performance, particularly in fast charging and data transfer scenarios, making them perfect for businesses that rely on technology.

How Do Traditional Rubber Cables Compare?

Traditional rubber cables are a cost-effective solution that many businesses have used for years. They are easy to implement and typically have a low upfront cost. However, they fall short in terms of durability and flexibility when compared to braided types. Over time, rubber cables may wear out, leading to increased maintenance needs and potential failures during critical operations. For businesses with minimal usage or budget constraints, rubber cables might suffice, but they may not be the best choice for high-performance needs.

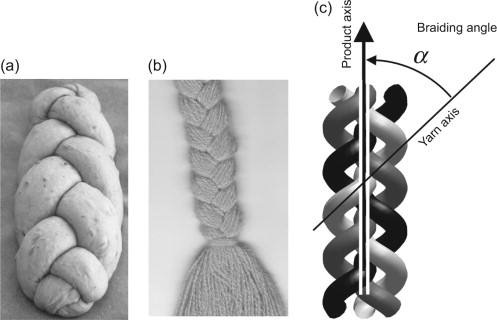

A stock image related to braided type.

What Are the Benefits of Reinforced Cables?

Reinforced cables are designed for extreme durability and are suitable for industrial applications where cables may face harsh conditions. They typically have a higher cost due to their robust construction and specialized materials. While they offer excellent resistance to wear and tear, their rigidity can be a disadvantage in environments where flexibility is required. For companies operating in challenging environments, such as manufacturing or construction, reinforced cables may be the best option, though they may not be necessary for standard office use.

How Can B2B Buyers Choose the Right Solution?

When selecting the right cable solution, B2B buyers should consider their specific needs, including the environment in which the cables will be used, budget constraints, and performance requirements. For businesses requiring flexibility and durability, braided type cables are a solid choice. However, for those on a tighter budget or with less demanding applications, traditional rubber cables may be adequate. Conversely, industries that face extreme conditions might benefit from investing in reinforced cables despite their higher cost. Evaluating these factors will help buyers make an informed decision that aligns with their operational needs and financial considerations.

Essential Technical Properties and Trade Terminology for braided type

What Are the Essential Technical Properties of Braided Type Cables?

When evaluating braided type cables, several technical properties are critical to ensure performance, durability, and compatibility with various devices. Understanding these specifications can significantly influence purchasing decisions for international B2B buyers.

1. Material Composition: Why Does It Matter?

Braided type cables are typically made from materials such as nylon, cotton, or polyester combined with copper wiring. The choice of material affects durability, flexibility, and resistance to wear and tear. For B2B buyers, selecting cables with high-quality materials ensures longevity and reduced replacement costs, particularly in high-demand environments like manufacturing or logistics.

2. Current Rating: What Is the Importance of Amperage?

The current rating, measured in Amperes (A), indicates the maximum amount of electrical current the cable can safely carry without overheating. For example, a cable rated for 3A is suitable for devices requiring up to 15W of power. B2B buyers must consider the current rating to ensure compatibility with their devices, particularly in industries that rely on high-power equipment.

3. Data Transfer Rate: How Fast Can Your Data Move?

Data transfer rates, expressed in Megabits per second (Mbps), determine how quickly data can be transmitted between devices. A cable with a 480 Mbps transfer rate is ideal for tasks like syncing large files or streaming high-definition video. Buyers should choose cables that meet or exceed their data transfer needs to avoid bottlenecks in operations.

4. Length and Flexibility: What Fits Your Business Needs?

A stock image related to braided type.

Cable length can significantly impact usability, especially in settings where devices are spaced apart. Common lengths range from 1 meter to 6 feet or more. Additionally, flexibility provided by the braiding material allows for easier handling and reduces the risk of damage. B2B buyers should assess their workspace layout to select the appropriate length and flexibility for their applications.

5. Strain Relief: How Does It Enhance Durability?

Strain relief refers to features at the ends of the cable that reduce stress on the connectors. This property is crucial for preventing breakage, especially in environments where cables are frequently plugged and unplugged. Investing in cables with robust strain relief can lower maintenance costs and improve operational efficiency.

What Are Common Trade Terms Related to Braided Type Cables?

Familiarity with industry-specific terminology is essential for B2B buyers to navigate the procurement process effectively. Here are some common terms that buyers should know:

1. OEM (Original Equipment Manufacturer): What Does It Signify?

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of braided cables, this term is important as it indicates the source of the cable and its compatibility with specific devices. Buyers often seek OEM products for assurance of quality and performance.

A stock image related to braided type.

2. MOQ (Minimum Order Quantity): Why Is It Critical?

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for budget planning and inventory management. Buyers should negotiate MOQs to align with their purchasing capacity while ensuring they meet supplier requirements.

3. RFQ (Request for Quotation): How to Use It Effectively?

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, submitting an RFQ can streamline the purchasing process and facilitate comparisons among different suppliers, leading to better decision-making.

4. Incoterms: What Are They and Why Are They Important?

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms can help buyers in Africa, South America, the Middle East, and Europe clarify their obligations and manage risks during international transactions.

5. Lead Time: How Does It Affect Your Supply Chain?

Lead time refers to the time taken from placing an order to receiving the product. For B2B buyers, understanding lead times is crucial for inventory management and ensuring that operations run smoothly without interruptions.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed purchasing decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the braided type Sector

What Are the Current Market Dynamics and Key Trends in the Braided Type Sector?

The global market for braided type products, particularly in the tech accessories sector, is experiencing significant growth driven by the increasing demand for reliable and efficient charging solutions. Key trends include the rise of USB-C connectivity, which is becoming the standard across various devices, including smartphones, laptops, and tablets. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should note that the demand for high-performance braided cables is surging as businesses seek durable, high-speed charging options.

Moreover, the ongoing digital transformation across industries is amplifying the need for robust tech accessories that can support fast data transfer and charging capabilities. In addition to performance, buyers are increasingly prioritizing compatibility with multiple devices, as seen with products like the Green Lion Braided Type-C to Type-C Cable, which offers a universal solution for various tech products. B2B buyers should also consider the growing trend of custom branding and packaging, which can enhance their product offerings and align with customer expectations.

How Is Sustainability and Ethical Sourcing Shaping the Braided Type Market?

As environmental concerns become more pressing, sustainability is emerging as a critical factor for B2B buyers in the braided type sector. The environmental impact of manufacturing processes and materials used in cables is under scrutiny, prompting companies to adopt sustainable practices. Buyers should look for suppliers that utilize eco-friendly materials and processes, such as recycled plastics and biodegradable packaging.

Ethical sourcing is equally important, as consumers increasingly demand transparency in supply chains. Certifications like RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) can assure buyers of compliance with environmental standards. Additionally, the use of ‘green’ materials not only aligns with corporate social responsibility goals but can also enhance brand reputation. B2B buyers should engage with manufacturers who demonstrate a commitment to sustainability, as this can be a significant differentiator in a competitive market.

What Is the Brief Evolution of the Braided Type Sector?

The braided type sector has evolved significantly over the past two decades, transitioning from traditional plastic-coated cables to advanced braided designs. Initially, cables were primarily focused on functionality, with little regard for aesthetics or durability. However, as technology advanced, manufacturers began incorporating braided materials, which offer enhanced durability and flexibility. This shift was driven by consumer demand for products that not only perform well but also withstand everyday wear and tear.

The introduction of USB-C technology marked a pivotal moment in the sector, leading to a standardization of connectors and charging capabilities across devices. This evolution has opened new markets and opportunities for B2B buyers, as they can now source cables that cater to a wide range of devices and applications. As the market continues to innovate, staying informed about the latest trends and technological advancements will be essential for buyers looking to make strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of braided type

-

How do I select the right braided type cables for my business needs?

When selecting braided type cables, consider factors such as compatibility with your devices, power delivery capacity, and data transfer speeds. Evaluate the materials used in the cable’s construction, such as aluminum alloy connectors and durable braiding, which enhance longevity and reduce tangling. Additionally, assess the length required for your applications, whether for home, office, or travel use. Lastly, ensure the cables meet safety certifications and have a warranty for added assurance. -

What is the best braided type cable for high-speed data transfer?

For high-speed data transfer, look for braided type cables that support USB 3.1 or higher standards, as they can offer transfer speeds up to 10 Gbps or more. Cables like the USB 4.0 Type-C cables are excellent choices due to their advanced technology and compatibility with a range of devices. Ensure the cable also supports fast charging capabilities, which can be beneficial for businesses needing quick power delivery alongside data transmission. -

What are the advantages of using braided type cables in a business environment?

Braided type cables provide several advantages, including enhanced durability due to their protective outer layer that resists fraying and wear. Their flexible design helps prevent tangling, making them easier to manage in busy workspaces. Additionally, the aesthetic appeal of braided cables can contribute to a more professional appearance in office settings. The availability of various lengths and power capacities also makes them suitable for diverse applications, from charging devices to connecting peripherals. -

How do I verify the credibility of a supplier for braided type cables?

To verify a supplier’s credibility, start by reviewing their business history and customer testimonials. Request samples to assess product quality before committing to larger orders. Check for certifications and compliance with international standards relevant to your region, such as ISO certifications. Engage in direct communication to evaluate their responsiveness and willingness to accommodate your specific needs, such as customization options or bulk pricing. -

What is the typical minimum order quantity (MOQ) for braided type cables?

The minimum order quantity (MOQ) for braided type cables can vary significantly between suppliers. Generally, MOQs can range from 100 to 1,000 units, depending on the manufacturer and the complexity of the product. Discuss your needs with potential suppliers to negotiate favorable terms, especially if you are looking to test the market with a smaller initial order. Consider the supplier’s flexibility in accommodating lower MOQs for first-time buyers. -

What payment terms should I expect when sourcing braided type cables internationally?

Payment terms for international purchases of braided type cables typically involve options like advance payment, Letter of Credit, or payment on delivery. Common practice is to negotiate a 30% upfront payment with the remaining balance due upon shipment or delivery. Ensure that you understand any additional fees related to international transactions, such as currency conversion or bank transfer charges. Always prioritize suppliers who offer secure payment methods to safeguard your investment. -

What quality assurance measures should I look for in braided type cables?

When sourcing braided type cables, look for suppliers who implement strict quality assurance (QA) protocols, including testing for durability, performance, and safety standards. Request documentation of compliance with relevant certifications, such as CE, RoHS, or UL listings. Additionally, inquire about their return policy and warranty options, which can provide insight into their confidence in product quality. Establishing a clear QA agreement can help ensure the cables meet your specifications consistently. -

How can I streamline logistics for importing braided type cables?

To streamline logistics for importing braided type cables, partner with suppliers who have experience in international shipping and can provide efficient freight forwarding services. Utilize Incoterms to clarify responsibilities for shipping, customs clearance, and delivery. Establish a reliable communication channel with your supplier to track shipment progress and resolve issues promptly. Consider consolidating shipments to reduce costs and improve delivery times, especially when sourcing from multiple suppliers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for braided type

In conclusion, effective strategic sourcing of braided type cables offers a significant competitive edge for international B2B buyers. By focusing on high-quality products such as the Green Lion Braided Type-C cable or the ToughTested 6 ft USB-C cable, businesses can ensure reliable performance and compatibility across various devices. The durability and enhanced features of braided cables—like tangle-free designs and robust connectors—make them ideal for high-demand environments, especially in regions like Africa, South America, the Middle East, and Europe.

How Can International Buyers Leverage Strategic Sourcing for Braided Cables?

Investing in strategic sourcing not only reduces costs through bulk purchasing but also enhances supply chain efficiency. Buyers should prioritize suppliers with proven track records in quality and customer service to mitigate risks associated with sourcing. By establishing strong partnerships with manufacturers, businesses can secure favorable terms and ensure a steady supply of top-tier products.

What is the Future Outlook for Braided Type Cables?

As technology continues to evolve, the demand for high-performance, durable cables will only increase. International B2B buyers are encouraged to stay ahead of market trends and invest in innovative solutions that meet their operational needs. Embrace the future of connectivity by making informed sourcing decisions today, ensuring your business remains competitive and well-equipped for tomorrow’s challenges.