The Ultimate Guide to 55 Gallon Barrel Dimensions (2025)

Introduction: Navigating the Global Market for 55 gallon barrel dimensions

Navigating the complexities of 55 gallon barrel dimensions can be a significant challenge for international B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. Whether you’re sourcing barrels for chemicals, food products, or industrial applications, understanding the specific dimensions and types of 55-gallon drums is crucial. This guide delves into the intricacies of various barrel materials—steel, plastic, and fiber—while also exploring their applications and compliance with international standards.

As you embark on your purchasing journey, this comprehensive resource will equip you with essential insights into the dimensions, weight, and capacity of different drum types, ensuring you make informed decisions. You’ll learn about the advantages and limitations of open-head versus closed-head configurations, as well as the implications for shipping and storage logistics. Moreover, we will provide guidance on supplier vetting, pricing strategies, and tips for negotiating favorable contracts.

By leveraging this guide, B2B buyers can enhance their procurement strategies, reduce costs, and ensure that their operations run smoothly. Understanding the nuances of 55-gallon barrel dimensions not only facilitates efficient logistics but also aligns with compliance regulations, ultimately contributing to a more sustainable supply chain.

Understanding 55 gallon barrel dimensions Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

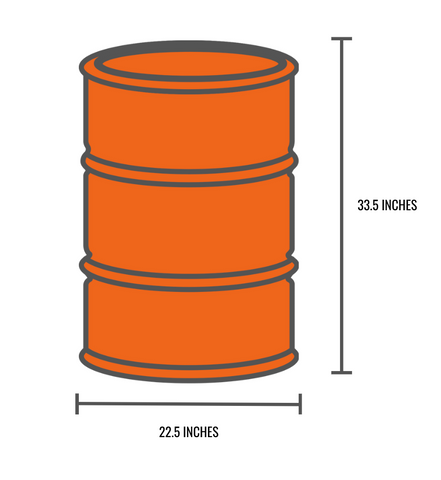

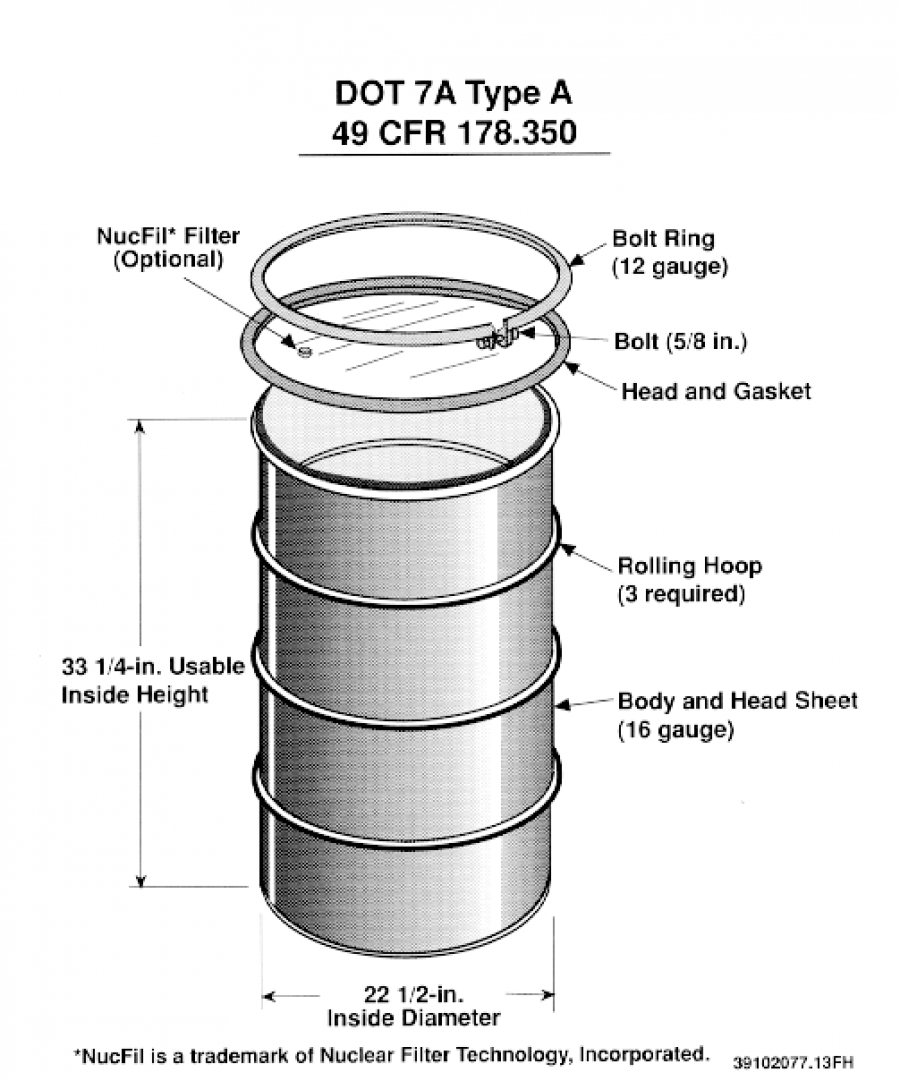

| Steel Drum | Durable, typically 33-36.75 inches tall, 22.38-24.5 inches wide | Chemicals, oils, hazardous materials | Pros: High strength, reusable; Cons: Heavier, may rust. |

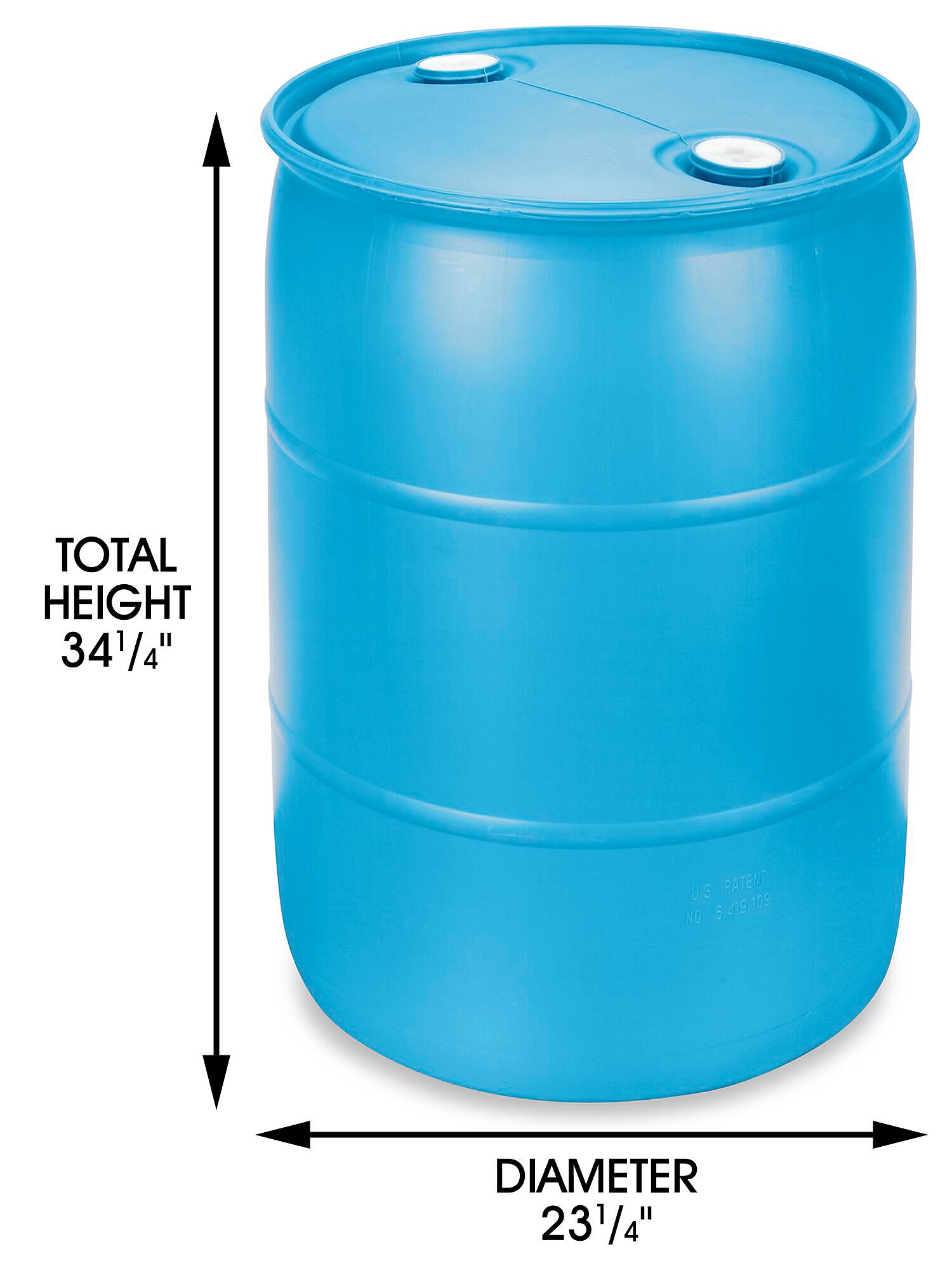

| Plastic Drum | Lightweight, made from HDPE, typically 33-35 inches tall | Food, pharmaceuticals, chemicals | Pros: Corrosion-resistant, versatile; Cons: Not as durable as steel. |

| Fiber Drum | Made from kraft paper, often lighter, dimensions vary | Dry goods, powders | Pros: Lightweight, eco-friendly; Cons: Less durable, not for liquids. |

| Open-Head Drum | Removable top, suitable for thick substances, standard height | Adhesives, paints, granulated products | Pros: Easy access, versatile; Cons: Less secure for transport. |

| Closed-Head Drum | Permanently sealed top, designed for low-viscosity liquids | Solvents, chemicals | Pros: Secure, minimizes spillage; Cons: Limited access for filling. |

What are the Key Characteristics of Steel Drums?

Steel drums are renowned for their durability and strength, making them ideal for transporting hazardous materials and chemicals. With standard dimensions of 33 to 36.75 inches in height and 22.38 to 24.5 inches in diameter, they can easily withstand the rigors of shipping and storage. B2B buyers should consider the weight of filled steel drums, which can exceed 500 pounds, as this may impact handling and shipping costs. Additionally, while steel drums are reusable, they can be prone to rust if not properly maintained, which is a crucial consideration for long-term use.

How Do Plastic Drums Differ in Use and Application?

Plastic drums, typically made from high-density polyethylene (HDPE), offer a lighter alternative to steel drums, measuring around 33 to 35 inches in height. These drums are often used for food, pharmaceuticals, and chemicals due to their corrosion-resistant properties. However, buyers should be cautious as they may not be suitable for all hazardous materials. The versatility of plastic drums makes them appealing, but it is essential to ensure that the drum’s material is compatible with the contents to prevent chemical reactions or degradation.

What Are the Advantages of Fiber Drums?

Fiber drums are constructed from multiple layers of kraft paper, making them lightweight and eco-friendly. Their dimensions can vary, but they are generally used for dry goods and powders. While fiber drums are less durable than their steel or plastic counterparts, they can be an excellent choice for companies focused on sustainability. B2B buyers should consider the type of product being stored, as fiber drums are not suitable for liquids. Additionally, they are often more cost-effective for bulk shipping of non-perishable items.

Why Choose Open-Head Drums for Certain Applications?

Open-head drums are characterized by their removable tops, making them suitable for thick or viscous substances such as adhesives and paints. With standard dimensions similar to closed-head drums, they offer easy access for filling and dispensing. However, this design can pose challenges during transportation, as the open nature may lead to spillage if not properly secured. B2B buyers should evaluate their specific needs for accessibility versus security when choosing this type of drum.

What Makes Closed-Head Drums Ideal for Liquids?

Closed-head drums are designed with a permanently sealed top, ideal for transporting low-viscosity liquids like solvents and chemicals. They typically feature a bunghole for filling and dispensing, ensuring minimal risk of spillage. The secure design is a significant advantage for companies dealing with hazardous materials, as it meets UN standards for safety. However, buyers should be aware that access is limited, which may complicate filling processes for certain products. Understanding the balance between security and accessibility is vital when selecting closed-head drums for specific applications.

Key Industrial Applications of 55 gallon barrel dimensions

| Industry/Sector | Specific Application of 55 Gallon Barrel Dimensions | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Chemical Manufacturing | Storage and transport of chemicals in bulk | Efficient handling of hazardous materials and compliance with safety standards | Ensure UN-rated drums for hazardous materials; verify compatibility with chemicals. |

| Food and Beverage | Bulk storage of liquids such as oils, sauces, and beverages | Cost-effective and space-efficient storage solution | Check for FDA compliance and food-grade materials; consider open or closed-head options based on product viscosity. |

| Agriculture | Transporting fertilizers and pesticides | Reliable and durable packaging for sensitive agricultural products | Source drums that can withstand outdoor conditions; consider color-coding for easy identification. |

| Oil and Gas | Storage and transportation of crude oil and lubricants | Maximizes storage capacity while ensuring safety and compliance | Select drums with appropriate material for oil compatibility; assess the need for temperature control measures. |

| Pharmaceuticals | Transport and storage of active ingredients and chemicals | Maintains product integrity and meets regulatory standards | Look for stainless steel or specially lined drums for purity; ensure proper documentation for international shipping. |

How Are 55 Gallon Barrel Dimensions Used in Chemical Manufacturing?

In the chemical manufacturing sector, 55-gallon barrels are essential for storing and transporting bulk chemicals, including solvents and reagents. The dimensions of these barrels facilitate the efficient handling of hazardous materials, ensuring compliance with safety standards. International buyers, particularly from Africa and the Middle East, must prioritize sourcing UN-rated drums that meet the specific performance standards for hazardous materials to mitigate risks during transportation.

What Role Do 55 Gallon Barrels Play in Food and Beverage Storage?

For the food and beverage industry, 55-gallon barrels serve as a practical solution for bulk storage of oils, sauces, and other liquids. Their dimensions allow for optimal space utilization in warehouses and during transport, reducing costs. Buyers from South America, such as Colombia, should ensure that the barrels are FDA-compliant and made from food-grade materials. Depending on the product viscosity, they may choose between open-head and closed-head options for ease of access.

Why Are 55 Gallon Barrels Important in Agriculture?

In agriculture, 55-gallon drums are commonly used for transporting fertilizers and pesticides, providing a reliable packaging solution for sensitive products. The dimensions of these barrels allow for efficient stacking and storage in various environments. Buyers need to consider sourcing drums that can withstand outdoor conditions, and they may opt for color-coded barrels to facilitate easy identification of contents, particularly in diverse agricultural settings across Africa.

How Are 55 Gallon Barrels Utilized in the Oil and Gas Industry?

The oil and gas sector relies on 55-gallon barrels for the storage and transportation of crude oil, lubricants, and other petroleum products. The dimensions of these barrels maximize storage capacity while ensuring compliance with safety regulations. International buyers should select drums made from materials compatible with oil and consider temperature control measures to maintain product integrity, especially in regions with extreme climates.

A stock image related to 55 gallon barrel dimensions.

What Are the Applications of 55 Gallon Barrels in Pharmaceuticals?

In pharmaceuticals, 55-gallon drums are critical for the transport and storage of active ingredients and chemicals. Their dimensions ensure that they can accommodate large volumes while maintaining product integrity during shipping. Buyers, particularly in Europe, should look for stainless steel or specially lined drums to ensure purity and compliance with stringent regulatory standards. Proper documentation is also essential for international shipping, ensuring that all materials meet local and international regulations.

3 Common User Pain Points for ’55 gallon barrel dimensions’ & Their Solutions

Scenario 1: Sizing Confusion in International Shipping

The Problem: International B2B buyers often face challenges when sourcing 55-gallon barrels due to varying dimensions across manufacturers and materials. For instance, a buyer in South America might order steel drums expecting them to match standard dimensions, only to find that the supplier’s drums are slightly larger or smaller. This discrepancy can lead to difficulties in transportation, storage, and compatibility with existing packaging systems. Such confusion not only disrupts supply chains but also increases costs due to potential returns or additional handling.

The Solution: To mitigate sizing confusion, it’s essential to establish clear specifications before placing orders. Buyers should request detailed dimension sheets that include height, diameter, and weight for each drum type—steel, plastic, or fiber. Consider creating a standardized specification document that outlines the exact dimensions required for your operations. Additionally, leveraging local suppliers who understand regional standards can help ensure compatibility with local shipping and storage practices. When selecting a supplier, ask for samples or detailed photographs to verify dimensions and quality before making bulk purchases.

Scenario 2: Regulatory Compliance Issues with UN-Rated Drums

The Problem: In the Middle East, businesses often deal with hazardous materials that require UN-rated 55-gallon drums. However, the challenge arises when buyers mistakenly assume that all drums labeled as “55-gallon” meet these regulatory requirements. Non-compliance can lead to legal issues, costly fines, and even accidents during transportation. Buyers may find themselves in a difficult position if they discover that their drums do not meet the necessary UN specifications after they have already been filled and shipped.

The Solution: To avoid regulatory compliance issues, it is crucial to conduct thorough research on the UN rating of the drums being sourced. Buyers should familiarize themselves with the specific UN standards applicable to their products, including packaging groups and performance tests. When engaging with suppliers, directly ask for documentation that proves the drums meet UN standards. Consider establishing a relationship with suppliers who specialize in hazardous materials, as they will be more knowledgeable about compliance requirements. Furthermore, ensure that all employees involved in the procurement process are trained to recognize compliance labels and specifications.

Scenario 3: Challenges with Temperature Sensitivity During Storage

The Problem: Companies in Europe often need to store temperature-sensitive products in 55-gallon drums. However, they may encounter issues if the dimensions of the drums are not optimized for temperature control. For example, if drums are too tall or wide, they may not fit into existing temperature control systems, leading to inefficient heating or cooling and potential spoilage of goods. This misalignment can result in significant financial losses and impact product quality.

The Solution: To address temperature sensitivity issues, buyers should consider the specific storage solutions available and how drum dimensions will affect them. Prior to purchasing, assess the compatibility of the drum dimensions with existing temperature control equipment. It may also be beneficial to invest in temperature monitoring systems that can provide real-time data on the conditions within the drums. When selecting drums, prioritize those that are designed for temperature stability, such as insulated drums or those specifically manufactured to accommodate heating or cooling systems. Finally, establish regular maintenance schedules for temperature control equipment to ensure optimal performance and mitigate risks associated with temperature fluctuations.

Strategic Material Selection Guide for 55 gallon barrel dimensions

What Are the Key Properties of Steel 55 Gallon Drums?

Steel drums are the most common type of 55-gallon barrel, known for their strength and durability. They typically have a temperature rating of up to 200°F (93°C) and can withstand high pressure, making them suitable for a wide range of liquids, including hazardous materials. Their corrosion resistance is enhanced through coatings or linings, which are essential for storing chemicals.

Pros: Steel drums are robust and provide excellent protection against physical damage. They are also recyclable, making them environmentally friendly. Their standardization means they are widely available across international markets.

Cons: The primary disadvantage is their weight, which can increase shipping costs. Additionally, they may require additional treatment to prevent rusting, particularly in humid climates.

Impact on Application: Steel drums are ideal for storing and transporting chemicals, oils, and other liquids. However, compatibility with corrosive substances must be assessed to ensure safety.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as UN regulations for hazardous materials. In regions like Africa and South America, where logistics can be challenging, the durability of steel drums can be a significant advantage.

How Do Plastic 55 Gallon Drums Compare in Performance?

Plastic drums, often made from high-density polyethylene (HDPE), are lightweight and resistant to corrosion. They can handle temperatures up to 120°F (49°C) and are suitable for storing a variety of chemicals, including corrosive substances.

Pros: Their lightweight nature reduces shipping costs, and they are often less expensive than steel drums. Plastic drums are also resistant to UV light, making them suitable for outdoor storage.

Cons: They have lower durability compared to steel drums and can be prone to cracking under extreme temperatures. Additionally, they may not be suitable for high-pressure applications.

Impact on Application: Plastic drums are excellent for storing liquids such as chemicals, food products, and pharmaceuticals. However, they should not be used for high-viscosity or heavy materials.

Considerations for International Buyers: Compliance with local food safety regulations is crucial for buyers in the food and beverage industry. In regions like Europe, adherence to EU standards for plastic materials is essential.

What Are the Advantages of Fiber 55 Gallon Drums?

Fiber drums are constructed from layers of kraft paper and are designed for lightweight applications. They are typically used for dry goods and can handle moderate temperatures.

Pros: Fiber drums are lightweight and cost-effective, making them a popular choice for shipping dry materials. They are also recyclable and biodegradable.

Cons: Their primary limitation is that they are not suitable for liquids, especially those that are corrosive or require airtight storage. They also have a lower strength compared to steel and plastic drums.

Impact on Application: Fiber drums are ideal for packaging powders, granules, and other dry goods. Their design allows for easy stacking, which is beneficial for storage.

Considerations for International Buyers: Buyers should be aware of local recycling regulations, especially in Europe, where sustainability is a key focus. Additionally, they should check for compliance with ASTM standards for fiberboard packaging.

Summary Table of 55 Gallon Barrel Materials

| Material | Typical Use Case for 55 gallon barrel dimensions | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Storing and transporting chemicals and oils | High durability and strength | Heavier, higher shipping costs | Medium |

| Plastic | Storing chemicals, food products, and pharmaceuticals | Lightweight and corrosion-resistant | Lower durability, not for high-pressure | Low |

| Fiber | Packaging dry goods like powders and granules | Cost-effective and recyclable | Not suitable for liquids, lower strength | Low |

This strategic material selection guide provides international B2B buyers with essential insights into the various types of 55-gallon barrels, enabling informed decisions based on specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 55 gallon barrel dimensions

What Are the Key Stages in the Manufacturing Process of 55 Gallon Barrels?

Understanding the manufacturing process for 55-gallon barrels is crucial for international B2B buyers. The production involves several stages, each requiring precision and adherence to standards to ensure the final product meets safety and functionality criteria.

Material Preparation: What Materials Are Used in Barrel Manufacturing?

The primary materials for 55-gallon barrels include steel, plastic, and fiberboard. For steel drums, manufacturers typically use cold-rolled carbon steel or stainless steel, which undergoes rigorous testing for quality and strength. Plastic drums are made from high-density polyethylene (HDPE) through blow-molding techniques, while fiber drums are produced from multiple layers of kraft paper.

A stock image related to 55 gallon barrel dimensions.

Before production, materials are sourced from verified suppliers to ensure compliance with international standards. This initial stage is critical, as the quality of raw materials directly affects the durability and safety of the barrels.

How Are 55 Gallon Barrels Formed and Assembled?

The forming process varies by material:

- Steel Drums: Steel sheets are cut to size and electrically welded into cylindrical shapes. The drums are then expanded using reinforcing hoops for added strength. The tops and bottoms are mechanically seamed to the body, ensuring a secure fit.

- Plastic Drums: These are created by placing melted plastic into molds and using compressed air to form the shape. The process allows for various colors and UV resistance, which is beneficial for specific applications.

- Fiber Drums: Fiber drums start as rolled cylinders of layered paper and are assembled with metal or fiberboard bottoms. The tops can be either multi-layer fiberboard or metal, secured with clips or locking rings.

In all cases, the assembly process must ensure that the barrels are leak-proof and can withstand the intended load.

What Finishing Techniques Are Employed in Barrel Production?

Finishing techniques include painting, coating, and lining. Steel drums often receive a protective paint finish to prevent corrosion, while stainless steel barrels may be polished to enhance cleanliness. For plastic drums, the color is molded into the material, which can provide additional UV protection.

Lining is particularly important for drums intended for hazardous materials. A proper lining ensures that the contents do not react with the barrel material, maintaining product integrity.

What Are the Key Quality Assurance Standards for 55 Gallon Barrels?

Quality assurance is essential to guarantee that 55-gallon barrels meet international standards. Notably, ISO 9001 is a widely recognized standard that outlines the requirements for quality management systems. Compliance with this standard ensures that manufacturers consistently produce high-quality products.

Which Industry-Specific Certifications Should Buyers Be Aware Of?

In addition to ISO standards, specific industry certifications are crucial:

- UN Certification: For barrels containing hazardous materials, the UN provides certification to ensure compliance with international shipping regulations.

- API Certification: For barrels used in the oil and gas industry, API standards ensure that the drums can safely contain various petroleum products.

- CE Marking: This certification indicates compliance with European health, safety, and environmental protection standards.

B2B buyers should inquire about these certifications when sourcing barrels to ensure compliance with local and international regulations.

How Is Quality Control Implemented Throughout the Manufacturing Process?

Quality control (QC) is integrated at multiple stages of the manufacturing process. Here are the common checkpoints:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During production, regular checks are performed to monitor dimensions, weight, and material integrity. This includes testing welds and seals for steel drums and ensuring proper molding for plastic drums.

- Final Quality Control (FQC): After production, each barrel undergoes a comprehensive inspection, including testing for leaks and structural integrity. This step is crucial to prevent defects from reaching the customer.

What Common Testing Methods Are Used to Verify Barrel Quality?

Several testing methods are employed to verify the quality of 55-gallon barrels:

- Hydrostatic Testing: This method involves filling the barrel with water to check for leaks. It’s particularly important for closed-head drums used for liquids.

- Pressure Testing: For barrels designed to hold pressurized contents, pressure testing ensures that the drum can withstand the required pressure levels without failure.

- Impact Testing: This assesses the durability of the barrel under physical stress, simulating real-world handling conditions.

B2B buyers should request documentation of these tests to verify that the products meet safety and quality standards.

How Can International Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential to ensure product reliability. Here are some strategies:

- Supplier Audits: Conducting onsite audits allows buyers to assess the manufacturing process, quality control measures, and compliance with international standards. This is particularly important when sourcing from regions with different regulatory environments.

- Requesting Quality Reports: Suppliers should provide documentation detailing their quality control processes, including test results and certifications.

- Third-Party Inspections: Engaging independent inspection services can provide an unbiased assessment of the supplier’s quality control practices and product compliance.

What QC and Certification Nuances Should Buyers Consider in Different Regions?

When dealing with suppliers from Africa, South America, the Middle East, and Europe, B2B buyers should consider regional nuances:

- Africa: Regulatory standards may vary significantly; therefore, buyers should ensure that suppliers comply with both local and international standards.

- South America: Buyers should be aware of local certifications and may need to navigate complex customs regulations when importing barrels.

- Middle East: The demand for specific certifications, such as those related to hazardous materials, is often stricter, particularly in oil-rich nations.

- Europe: Compliance with EU standards is mandatory, and buyers should verify that suppliers have CE marking for their products.

By understanding these nuances, international B2B buyers can better navigate the complexities of sourcing 55-gallon barrels from various regions.

Practical Sourcing Guide: A Step-by-Step Checklist for ’55 gallon barrel dimensions’

In today’s global marketplace, understanding the dimensions and specifications of 55-gallon barrels is essential for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. This practical sourcing guide provides a step-by-step checklist to help you procure the right barrels for your business needs efficiently and effectively.

Step 1: Define Your Technical Specifications

Start by clearly identifying the dimensions and material requirements for the 55-gallon barrels you need. Understanding the variations in height (typically between 33 to 36.75 inches) and diameter (ranging from 22.375 to 24.5 inches) based on the barrel type—steel, plastic, or fiber—is crucial. This will ensure compatibility with your storage and transportation systems.

Step 2: Research Barrel Types and Their Applications

Different types of 55-gallon barrels serve various purposes, so it’s important to know which type aligns with your products.

– Steel Drums: Best for hazardous materials and long-term storage due to their durability.

– Plastic Drums: Suitable for chemicals and food products, offering versatility in handling.

– Fiber Drums: Ideal for lightweight, dry goods, providing a cost-effective solution.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure reliability and quality. Request documentation such as company profiles, product certifications, and customer testimonials from businesses within your industry. This step is vital to mitigate risks associated with subpar products or unreliable service.

Step 4: Check Compliance with International Standards

Ensure that the barrels comply with international standards, especially if you are shipping hazardous materials. Look for UN ratings that indicate the barrel has been tested for safety and performance under specific conditions. This not only safeguards your products but also protects your company from potential legal issues.

Step 5: Request Samples for Quality Assessment

Prior to placing a bulk order, request samples of the barrels to evaluate their quality and suitability for your needs. Inspect the structural integrity, seals, and overall design, which can impact the functionality and safety of your products. Pay attention to the weight capacity, especially if you intend to store heavy materials.

Step 6: Understand Shipping and Handling Considerations

Shipping costs can significantly affect your procurement budget, so consider the logistics involved in transporting the barrels. Evaluate how many barrels can fit on standard pallets and whether the supplier can deliver to your location efficiently. This is particularly important for buyers in regions with varying infrastructure capabilities.

Step 7: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations regarding pricing, delivery timelines, and payment terms. Ensure that you understand the total cost of ownership, including any potential additional fees for shipping or handling. Establishing a clear agreement will help maintain a positive business relationship and prevent misunderstandings down the line.

By following this checklist, B2B buyers can effectively navigate the complexities of procuring 55-gallon barrels, ensuring they select the right product for their specific needs while minimizing risks and maximizing value.

Comprehensive Cost and Pricing Analysis for 55 gallon barrel dimensions Sourcing

A stock image related to 55 gallon barrel dimensions.

What Are the Key Cost Components in Sourcing 55 Gallon Barrels?

When sourcing 55-gallon barrels, understanding the cost structure is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The type of barrel—steel, plastic, or fiber—significantly influences material costs. Steel barrels are typically more expensive due to the price of raw materials and the production process, while plastic drums are generally lower in cost but may not provide the same durability.

-

Labor and Manufacturing Overhead: Labor costs can vary greatly depending on the region and the complexity of the manufacturing process. Overhead costs, which include utilities, rent, and administrative expenses, should also be factored in, particularly for manufacturers in countries with higher operational costs.

-

Tooling and Quality Control: Initial tooling costs can be substantial, especially for custom dimensions or features. Quality control measures are crucial, particularly for industries handling hazardous materials, as they ensure compliance with international standards.

-

Logistics: The transportation of barrels can incur significant costs, particularly for international shipping. Factors such as distance, shipping method, and the chosen Incoterms (International Commercial Terms) can greatly impact logistics expenses.

-

Margin: Supplier margins can vary based on market demand, competition, and the supplier’s reputation. Understanding these factors can help buyers negotiate better deals.

How Do Price Influencers Affect 55 Gallon Barrel Sourcing?

Several price influencers come into play when sourcing 55-gallon barrels, impacting the final pricing structure.

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing typically lowers unit costs. Buyers should negotiate favorable terms based on anticipated usage, as suppliers often provide discounts for larger orders.

-

Specifications and Customization: Custom features, such as specific dimensions or additional certifications (like UN-rated for hazardous materials), can increase costs. Buyers should assess whether the added features are necessary for their operations.

-

Material Quality and Certifications: Higher quality materials may lead to increased costs but can ensure longevity and safety, particularly for sensitive or hazardous products. Certifications can also drive up the price but are often necessary for regulatory compliance.

-

Supplier Factors: The supplier’s location, reliability, and production capacity can influence pricing. Establishing a relationship with a reputable supplier can yield better pricing and terms.

What Are the Best Buyer Tips for Cost-Efficiency?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, here are actionable tips for achieving cost-efficiency in sourcing 55-gallon barrels:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially for larger orders. Highlighting long-term relationships and consistent orders can incentivize suppliers to offer better rates.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. TCO includes shipping, storage, handling, and potential reusability of the barrels. Evaluating the total cost helps in making informed purchasing decisions.

-

Understand Pricing Nuances for International Buyers: Currency fluctuations, import duties, and local regulations can affect pricing. Buyers should stay informed about these factors and work with suppliers who are experienced in international transactions.

-

Assess Incoterms Carefully: Different Incoterms can shift costs and responsibilities between buyers and sellers. Understanding terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) can help in budgeting accurately for total acquisition costs.

Disclaimer for Indicative Prices

Please note that prices for 55-gallon barrels can vary widely based on the aforementioned factors. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing aligned with their specific needs and circumstances.

Alternatives Analysis: Comparing 55 gallon barrel dimensions With Other Solutions

Introduction: Understanding Alternatives to 55 Gallon Barrels

When considering storage and transportation solutions for bulk liquids and solids, the 55-gallon barrel is a popular choice due to its robust design and versatility. However, international B2B buyers should explore alternative options that may better suit specific operational needs, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis compares the dimensions and functionalities of 55-gallon barrels against other viable solutions, helping buyers make informed decisions.

Comparison Table of 55 Gallon Barrel Dimensions and Alternatives

| Comparison Aspect | 55 Gallon Barrel Dimensions | Intermediate Bulk Container (IBC) | Plastic Tote (Bulk Container) |

|---|---|---|---|

| Performance | Strong, durable, versatile | High capacity, good for liquids | Lightweight, reusable |

| Cost | Moderate | Higher initial cost | Lower cost per unit |

| Ease of Implementation | Easily handled by one person | Requires forklift for transport | Requires forklift for transport |

| Maintenance | Low (can be reused) | Moderate (depends on material) | Low (easier to clean) |

| Best Use Case | Transporting various products | Ideal for bulk liquids and chemicals | Suitable for food-grade materials |

Detailed Breakdown of Alternatives

What Are Intermediate Bulk Containers (IBCs)?

Intermediate Bulk Containers (IBCs) provide a higher capacity solution for transporting liquids. Typically holding between 275 to 330 gallons, IBCs are designed for bulk liquids and can handle a range of chemicals and substances. While they come at a higher initial cost than 55-gallon barrels, their larger capacity can reduce the frequency of transport, ultimately saving costs in logistics. However, their requirement for specialized equipment, such as forklifts, can complicate handling in facilities without the necessary machinery.

How Do Plastic Totes Compare to 55 Gallon Barrels?

Plastic totes, or bulk containers, are another alternative worth considering. These lightweight options are typically used for food-grade materials and other non-hazardous products. Their lower cost and ease of cleaning make them attractive for many industries. However, their inability to handle hazardous materials and the need for forklift transport may limit their use in specific applications. Additionally, while they are reusable, the longevity may not match that of steel or fiber drums.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate storage and transport solution involves evaluating your specific operational requirements, including the type of materials being transported, cost constraints, and available handling equipment. While 55-gallon barrels are versatile and robust, alternatives like IBCs and plastic totes may offer benefits in capacity, cost-efficiency, or ease of cleaning. B2B buyers should assess these factors carefully to determine which solution aligns best with their logistical needs, ensuring efficient and safe transport of goods across international markets.

Essential Technical Properties and Trade Terminology for 55 gallon barrel dimensions

What Are the Key Technical Properties of 55-Gallon Barrels?

Understanding the technical properties of 55-gallon barrels is essential for international B2B buyers, especially when selecting the right container for shipping and storing various materials. Here are some critical specifications to consider:

-

Material Grade

– Definition: The material grade refers to the type of material used to manufacture the drum—commonly steel, plastic, or fiber.

– B2B Importance: The material impacts durability, compatibility with contents, and overall shipping costs. For example, steel drums offer high strength and are suitable for hazardous materials, while plastic drums are lighter and ideal for corrosive substances. -

Dimensions

– Definition: Standard dimensions for 55-gallon barrels typically range from 33 to 36.75 inches in height and 22.375 to 24.5 inches in diameter.

– B2B Importance: Accurate dimensions ensure that the drums fit properly on pallets and in storage spaces. Knowing these specifications helps prevent logistical issues and reduces transportation costs. -

Weight Capacity

– Definition: This refers to the maximum weight a barrel can hold, which includes both the weight of the barrel and its contents.

– B2B Importance: Understanding weight capacity is crucial for compliance with shipping regulations and for determining freight costs. For instance, a filled 55-gallon drum can weigh around 500 pounds depending on the contents. -

Head Type

– Definition: Barrels can be classified as either open-head (removable lid) or closed-head (permanently attached top).

– B2B Importance: The head type affects the ease of access to the contents. Open-head barrels are ideal for thick liquids and solids, while closed-head barrels are suited for low-viscosity liquids. This distinction influences product handling and storage decisions. -

UN Rating

– Definition: A UN rating indicates whether a drum meets international standards for transporting hazardous materials.

– B2B Importance: For companies shipping hazardous goods, selecting UN-rated barrels is crucial for compliance with global regulations, ensuring safety and avoiding legal issues.

What Are Common Trade Terms Related to 55-Gallon Barrels?

Familiarity with trade terminology is vital for effective communication and negotiation in the B2B landscape. Here are some common terms related to 55-gallon barrels:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Knowing whether a barrel is OEM can help buyers assess quality and compatibility with existing equipment. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding MOQ helps buyers plan their purchases and manage inventory effectively, especially when sourcing from different regions like Africa or Europe. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price quotes from suppliers.

– Importance: An RFQ allows buyers to compare prices and terms from multiple suppliers, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms published by the International Chamber of Commerce (ICC).

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risk management, and cost allocation, particularly when dealing with international suppliers. -

Lead Time

– Definition: The time between placing an order and receiving it.

– Importance: Knowing lead times helps buyers plan their operations and manage supply chain expectations, which is especially critical in regions with variable shipping conditions.

By understanding these technical properties and trade terminologies, international B2B buyers can make better-informed decisions regarding their use of 55-gallon barrels in various applications.

Navigating Market Dynamics and Sourcing Trends in the 55 gallon barrel dimensions Sector

What Are the Key Market Dynamics and Trends in the 55 Gallon Barrel Dimensions Sector?

The global market for 55-gallon barrels is primarily driven by industries such as chemicals, food and beverage, pharmaceuticals, and logistics. As businesses increasingly prioritize efficiency and safety in their supply chains, the demand for standardized packaging solutions like the 55-gallon drum is on the rise. Key trends include the integration of smart technology in barrel manufacturing, allowing for real-time tracking and monitoring of contents, which is particularly valuable for international B2B buyers from regions like Africa and South America, where logistics can be challenging.

Moreover, the emergence of e-commerce has accelerated the need for versatile and lightweight packaging solutions. Buyers are now looking for drums that not only meet their storage needs but also enhance operational efficiency. For instance, open-head drums are favored for their ease of access, while tight-head drums are preferred for hazardous materials due to their secure design. Understanding these dynamics can help B2B buyers make informed purchasing decisions, ensuring compliance with international shipping regulations and safety standards.

How Is Sustainability Influencing Sourcing Trends for 55 Gallon Barrels?

Sustainability has become a cornerstone of modern B2B procurement practices. The environmental impact of packaging materials is under scrutiny, prompting companies to seek out eco-friendly solutions. For the 55-gallon barrel dimensions sector, this means an increased focus on sustainable materials such as recycled steel and high-density polyethylene (HDPE) that can be reused or repurposed.

Ethical sourcing is also gaining traction, with businesses looking to partner with suppliers that adhere to responsible manufacturing practices. Certifications such as ISO 14001 for environmental management and the use of ‘green’ materials can enhance a company’s reputation and appeal to eco-conscious consumers. For buyers in regions like the Middle East and Europe, where regulatory frameworks around sustainability are becoming more stringent, aligning with suppliers that prioritize ethical practices is not just beneficial; it is becoming a necessity.

What Is the Historical Context of 55 Gallon Barrels for B2B Buyers?

The 55-gallon drum has a rich history that dates back to the early 20th century when the need for efficient bulk storage and transportation emerged. Originally standardized by Standard Oil in the early 1900s, these drums revolutionized the way goods were shipped, particularly petroleum products. Over the decades, the design has evolved to accommodate various materials, including steel, plastic, and fiber, each serving different industrial needs.

Understanding this historical context is vital for B2B buyers, as it highlights the evolution of materials and manufacturing processes. This awareness can guide purchasing decisions, ensuring that buyers select the most appropriate drum type based on their specific application, whether it be for chemicals, food products, or hazardous materials. The ongoing adaptation of the 55-gallon drum to meet contemporary market demands showcases its enduring relevance in the global supply chain.

Frequently Asked Questions (FAQs) for B2B Buyers of 55 gallon barrel dimensions

-

How do I choose the right 55-gallon drum for my specific needs?

Selecting the appropriate 55-gallon drum depends on the material compatibility with your products. Steel drums are ideal for hazardous liquids, while plastic drums suit chemicals and food products. Fiber drums are lightweight and excellent for dry goods. Consider whether you need an open-head for easy access or a closed-head for secure storage. Additionally, assess the density of the contents to avoid overloading, and ensure compliance with international standards, especially if shipping hazardous materials. -

What are the standard dimensions of a 55-gallon drum?

A standard 55-gallon drum typically measures between 33 to 36.75 inches in height and 22.375 to 24.5 inches in diameter. Steel drums usually fall within the range of 33 to 34.75 inches tall, while plastic drums may vary slightly. Always confirm the specific dimensions with your supplier, as variations can occur based on the manufacturer and whether the drum is open or closed-head. Accurate measurements are critical for storage and shipping efficiency. -

What should I consider regarding the weight of a filled 55-gallon drum?

The weight of a filled 55-gallon drum varies significantly based on the contents. For example, a drum filled with water weighs approximately 459 pounds. It’s crucial to account for the total weight when planning transportation and storage, as this can impact shipping costs and handling requirements. Always confirm the density of your product to ensure the selected drum meets the weight capacity and safety standards for your logistics needs. -

How do I ensure my 55-gallon drums meet international shipping standards?

To comply with international shipping standards, ensure your drums are UN-rated if they will contain hazardous materials. These ratings indicate that the drums have passed specific performance tests. Additionally, verify that your supplier adheres to local and international regulations, including labeling and documentation requirements. Engaging with experienced logistics partners familiar with the regulations in your target markets can streamline the process and reduce risks. -

What customization options are available for 55-gallon drums?

Many suppliers offer customization options for 55-gallon drums, including color, interior lining, and additional fittings. You can also request specific dimensions if your application requires non-standard sizes. When ordering customized drums, inquire about minimum order quantities (MOQs) and lead times, as these can vary significantly. Customization can enhance product safety and compatibility, particularly for specialized applications in industries like pharmaceuticals or food and beverage. -

What payment terms should I negotiate with my 55-gallon drum supplier?

When sourcing 55-gallon drums, negotiate payment terms that align with your cash flow and financial strategy. Common options include net 30 or net 60 terms, which allow time to pay after delivery. Additionally, consider discussing early payment discounts or bulk purchase incentives. It’s also advisable to evaluate the supplier’s creditworthiness and reputation to mitigate risks associated with upfront payments, especially for large orders. -

How can I vet suppliers for 55-gallon drums effectively?

Vetting suppliers involves assessing their manufacturing capabilities, compliance with safety standards, and past performance. Request certifications, such as ISO or UN ratings, to ensure quality and safety. Consider visiting the supplier’s facility if possible, or ask for references from previous clients. Additionally, evaluate their ability to meet your specific needs regarding customization, lead times, and after-sales support, which are crucial for establishing a reliable long-term partnership. -

What logistics considerations should I keep in mind when shipping 55-gallon drums?

When planning the logistics of shipping 55-gallon drums, consider factors such as transport modes, stacking capabilities, and regional regulations. Ensure that the drums are properly packed to prevent damage during transit and comply with shipping regulations for hazardous materials if applicable. Analyze shipping costs based on weight and volume, and work with logistics providers experienced in handling bulk shipments to optimize your supply chain efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 55 gallon barrel dimensions

As international B2B buyers continue to navigate the complexities of sourcing, understanding the dimensions and specifications of 55-gallon barrels is crucial. The standard dimensions—typically ranging from 33 to 36.75 inches in height and 22.375 to 24.5 inches in diameter—vary by material type, whether steel, plastic, or fiber. This knowledge not only aids in optimizing storage and transportation logistics but also ensures compliance with international shipping standards, particularly for hazardous materials.

Strategic sourcing of 55-gallon barrels can lead to significant cost savings and operational efficiencies. By selecting the right drum type for specific applications—be it open-head for solids or closed-head for liquids—businesses can enhance their supply chain effectiveness. Furthermore, engaging with reliable suppliers who understand regional regulations and quality standards can mitigate risks and ensure product integrity.

Looking ahead, it is essential for buyers in Africa, South America, the Middle East, and Europe to prioritize strategic partnerships and leverage technology for better sourcing decisions. By staying informed about market trends and drum specifications, organizations can streamline their procurement processes and drive sustainable growth. Embrace the opportunity to enhance your operations—make informed sourcing decisions today.