Optimize Performance: The Complete Guide to Torquing Springs (2025)

Introduction: Navigating the Global Market for torquing springs

Navigating the complexities of sourcing torquing springs in the global market can be a daunting task for B2B buyers, especially when considering the diverse needs of orthodontic practices across continents such as Africa, South America, the Middle East, and Europe. These essential components, designed to apply precise torque to anterior teeth, play a critical role in achieving optimal orthodontic outcomes. However, buyers often face challenges like identifying reliable suppliers, understanding product specifications, and evaluating cost-effectiveness.

This comprehensive guide serves as a valuable resource for international B2B buyers by delving into the various types of torquing springs available, their specific applications, and how to effectively vet suppliers. We will explore key considerations such as material quality, design variations, and compliance with regional standards, ensuring that buyers can make informed decisions that align with their operational needs. Additionally, we will provide insights into pricing structures and potential volume discounts, particularly relevant for buyers in emerging markets like Brazil and Egypt, where cost management is crucial.

By the end of this guide, B2B buyers will be equipped with the knowledge and tools necessary to navigate the global market for torquing springs confidently, ensuring they select the right products that meet their clinical requirements and budget constraints. This empowerment will lead to enhanced patient care and satisfaction, driving success in their orthodontic practices.

Understanding torquing springs Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Warren Torquing Springs | Heat-treated Elgiloy® material; automatic activation on arch wire; available in various sizes. | Orthodontic practices for anterior tooth adjustments. | Pros: Consistent force application; easy activation. Cons: Limited to specific wire dimensions. |

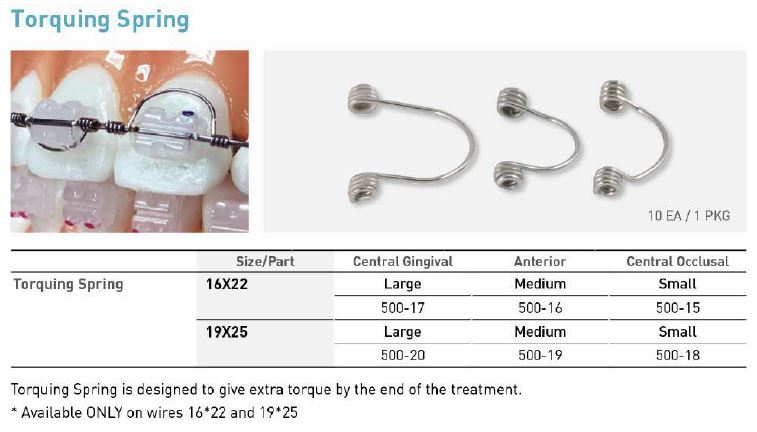

| Goodman Torquing Springs | Crimps to rectangular wires; delivers 125-150 grams of torque; available in small and large sizes. | Versatile for different tooth types; suitable for relapse prevention. | Pros: Effective for a wide range of teeth; prevents relapse. Cons: Requires specific crimping tools. |

| ART® Spring | Pre-formed; universal design; no adjustments needed; suitable for maxillary and mandibular teeth. | Efficient for finishing and stabilizing occlusion in orthodontics. | Pros: Simple to use; stays active throughout treatment. Cons: May not be adaptable for all bracket systems. |

| Torquing Springs (CX) | Controlled torque forces; available in multiple heights and wire sizes; bulk purchasing options. | General orthodontic supply for precise tooth movements. | Pros: Cost-effective in bulk; high-quality assurance. Cons: Limited to specific wire sizes and heights. |

| Bioprogressive Torquing Springs | Designed for bioprogressive treatment methods; various force levels; compatible with different arch wires. | Specialized orthodontic applications focusing on progressive treatment. | Pros: Tailored for specific treatment philosophies; adjustable force levels. Cons: May require additional training for effective use. |

What Are Warren Torquing Springs and How Are They Used?

Warren Torquing Springs are crafted from heat-treated Elgiloy®, providing consistent force application to anterior teeth. They automatically activate when the arch wire is placed, making them user-friendly for orthodontic practices. Buyers should consider the specific wire dimensions as these springs are not compatible with all sizes, which could limit their application in diverse treatment scenarios.

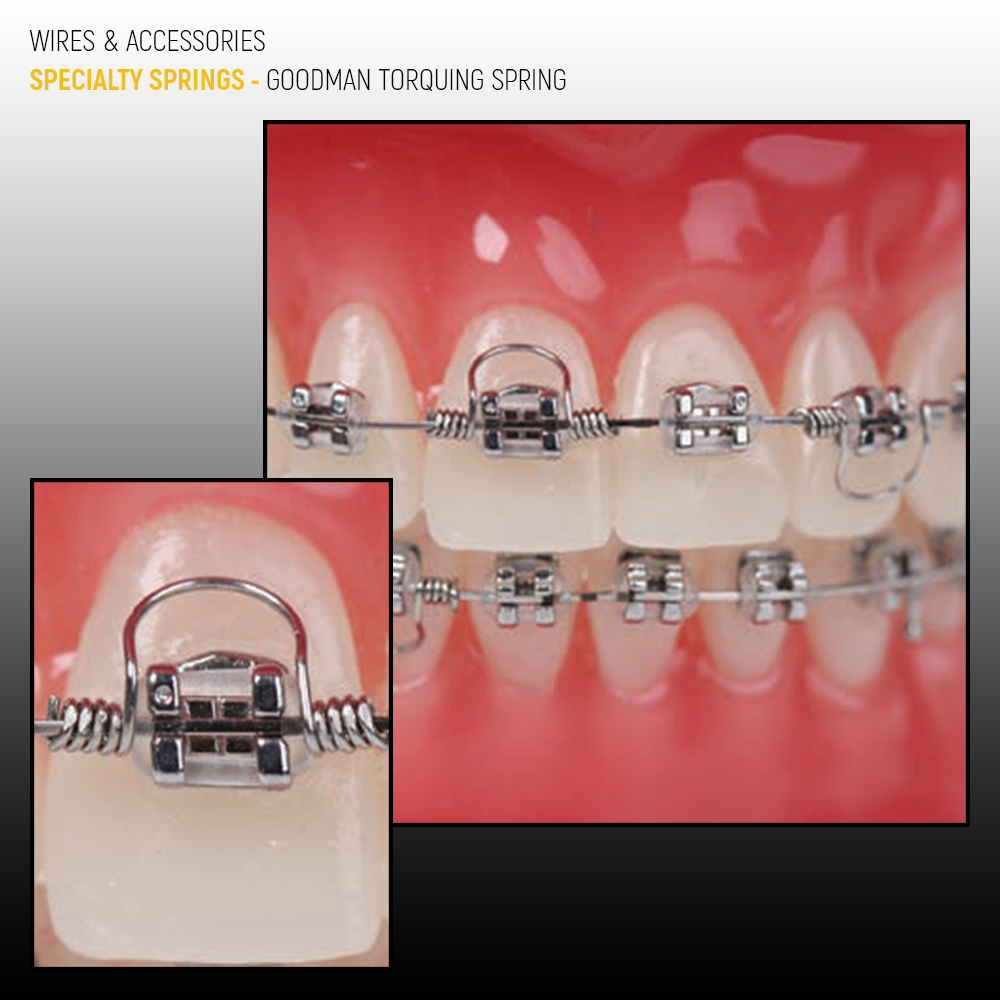

How Do Goodman Torquing Springs Prevent Relapse?

Goodman Torquing Springs are versatile and can apply torque to various teeth, including centrals and bicuspids. They can crimp onto rectangular wires, delivering significant torque levels to align roots effectively. B2B buyers should note the necessity of specialized crimping tools for optimal use, which may add to the initial investment but ultimately enhances treatment efficiency.

What Are the Benefits of Using ART® Springs?

The ART® Spring offers a pre-formed solution that simplifies the application of torque to anterior teeth without the need for adjustments. Its universal design ensures compatibility with any bracket system, making it a reliable choice for orthodontic practices. Buyers should appreciate its ease of use, although they should confirm its compatibility with their existing systems to avoid potential limitations.

Why Choose CX Torquing Springs for Orthodontic Needs?

CX Torquing Springs provide controlled torque forces essential for precise tooth movements. Available in various heights and wire sizes, they are a cost-effective option for practices looking to buy in bulk. However, buyers should consider the specific dimensions required for their treatments, as these springs may not fit all wire types, potentially limiting their versatility.

What Makes Bioprogressive Torquing Springs Unique?

Bioprogressive Torquing Springs are specially designed for orthodontic methods that focus on progressive treatment approaches. They offer adjustable force levels, making them suitable for various treatment philosophies. B2B buyers should be aware that using these springs may necessitate additional training for staff to maximize their effectiveness in specific clinical scenarios.

Key Industrial Applications of torquing springs

| Industry/Sector | Specific Application of Torquing Springs | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Orthodontics | Application in tooth alignment and movement | Enables precise torque application for effective treatments | Material quality, compliance with dental standards, and pricing |

| Automotive Manufacturing | Use in tensioning mechanisms for suspension systems | Improves vehicle stability and handling | Sourcing from reputable suppliers, durability, and customization |

| Aerospace | Integration in control systems for aircraft components | Enhances safety and operational efficiency | Compliance with aerospace regulations and testing certifications |

| Robotics | Utilization in robotic arms for precise torque control | Increases precision and efficiency in automation processes | Compatibility with existing systems and performance specifications |

| Medical Devices | Application in devices requiring consistent pressure control | Ensures reliability in critical medical equipment | Regulatory compliance, material specifications, and supply chain reliability |

How Are Torquing Springs Used in Orthodontics?

In orthodontics, torquing springs are crucial for applying targeted forces to align teeth effectively. They are often utilized in conjunction with archwires to achieve precise tooth movements, particularly for correcting anterior teeth positioning. For international buyers, particularly in regions like Africa and South America, sourcing high-quality, compliant springs is vital to ensure patient safety and treatment efficacy. Understanding the specific wire sizes and configurations needed for different orthodontic cases is also essential.

A stock image related to torquing springs.

What Role Do Torquing Springs Play in Automotive Manufacturing?

In the automotive sector, torquing springs are employed in suspension systems to maintain tension and stability. They help in managing the vehicle’s alignment and improve handling during operation. For B2B buyers in the Middle East and Europe, it is important to consider the durability and material quality of these springs, as they must withstand harsh driving conditions. Suppliers should also provide customization options to fit various vehicle models.

How Are Torquing Springs Integrated into Aerospace Applications?

Torquing springs find their application in aerospace, particularly in control systems where precise torque is necessary for component adjustments. They enhance the safety and efficiency of aircraft systems. Buyers from Europe and other regions must ensure that the springs comply with rigorous aerospace standards and have undergone necessary testing. This guarantees that the components will perform reliably under extreme conditions.

How Do Robotics Benefit from Torquing Springs?

In robotics, torquing springs are utilized to provide precise torque control in robotic arms, which is essential for tasks requiring high accuracy. This application increases the overall efficiency and effectiveness of automation processes. International B2B buyers, especially in technologically advancing regions, should focus on sourcing springs that are compatible with their existing systems and meet performance specifications.

What Importance Do Torquing Springs Hold in Medical Devices?

Torquing springs are also critical in medical devices where consistent pressure control is required, such as in surgical instruments or dental devices. They ensure reliability in equipment that could impact patient outcomes. Buyers in Africa and South America should prioritize sourcing from suppliers who adhere to medical device regulations and offer robust material specifications to ensure safety and performance in critical applications.

3 Common User Pain Points for ‘torquing springs’ & Their Solutions

Scenario 1: Difficulty in Achieving Precise Tooth Movement with Torquing Springs

The Problem: Many B2B buyers in orthodontics face challenges when it comes to achieving the desired precision in tooth movement using torquing springs. This can lead to prolonged treatment times and patient dissatisfaction, especially when specific teeth do not respond to torque as expected. Buyers may struggle with selecting the right spring size or type, leading to ineffective torque application. This issue is particularly pronounced in diverse markets like Africa and South America, where access to product information and training may be limited.

The Solution: To overcome this challenge, buyers should invest time in understanding the specifications of various torquing springs available in the market. For instance, manufacturers like RMO and Goodman provide detailed product specifications on their websites. Buyers should familiarize themselves with the different sizes and types of springs, such as the Warren and Goodman torquing springs, which are designed for various wire dimensions. Furthermore, utilizing a product like the ART® Spring, which does not require forming or bending, can simplify the process and enhance precision. Implementing a training program for orthodontic staff on the effective use of these springs can also significantly improve treatment outcomes, ensuring that the right torque is consistently applied for optimal tooth movement.

Scenario 2: Challenges in Sourcing Quality Torquing Springs

The Problem: B2B buyers often encounter difficulties in sourcing high-quality torquing springs that meet their clinical needs. In regions like the Middle East and Europe, where there is a diverse range of suppliers, buyers may find it challenging to assess the quality and reliability of products. This can lead to inconsistent treatment results and increased costs associated with returns or replacements. Additionally, language barriers and varying standards can complicate the sourcing process for international buyers.

The Solution: To mitigate sourcing challenges, buyers should establish relationships with reputable suppliers who provide detailed product information, including materials, manufacturing processes, and compliance with international standards. For example, suppliers like CX Orthodontic Supply offer a money-back guarantee, which can instill confidence in their product quality. Conducting thorough research, including reading reviews and testimonials from other orthodontic professionals, can also aid in selecting trustworthy sources. Buyers should consider bulk purchasing options to not only save costs but also ensure a consistent supply of quality products. Engaging in local dental trade shows can also provide direct access to suppliers and facilitate better understanding of product offerings.

Scenario 3: Inefficient Use of Torquing Springs Leading to Treatment Delays

The Problem: A common pain point among B2B buyers is the inefficient use of torquing springs during orthodontic treatments, which can lead to delays in achieving desired outcomes. In practices where multiple treatments are handled simultaneously, staff may not always apply the springs correctly or may forget to activate them, resulting in ineffective torque application. This inefficiency is especially concerning in fast-paced environments across European orthodontic practices, where patient turnover is high.

The Solution: To enhance efficiency, practices should implement standardized protocols for using torquing springs. This includes providing detailed instructions on the correct application process, emphasizing the importance of activating the springs when placing arch wires. Consider creating a checklist for orthodontic staff to ensure that all necessary steps are followed during each patient visit. Additionally, investing in training sessions focused on the practical use of torquing springs can empower staff to use these tools more effectively. Incorporating visual aids or instructional videos into training can further reinforce proper techniques. By streamlining processes and ensuring that all staff are well-trained, practices can reduce treatment delays and improve overall patient satisfaction.

Strategic Material Selection Guide for torquing springs

When selecting materials for torquing springs, it is essential to consider various factors that impact performance, durability, and suitability for specific applications. Below, we analyze four common materials used in the manufacturing of torquing springs, providing actionable insights for international B2B buyers.

What Are the Key Properties of Stainless Steel for Torquing Springs?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high tensile strength, and ability to withstand elevated temperatures. It typically has a temperature rating of up to 600°F (315°C) and a pressure rating that varies based on the specific grade used.

Pros & Cons: The durability of stainless steel makes it an ideal choice for long-lasting applications. However, the manufacturing complexity can lead to higher costs compared to other materials. While it is suitable for many environments, it may not be the best option for applications requiring extreme flexibility.

Impact on Application: Stainless steel is compatible with various media, making it versatile for different orthodontic applications. However, buyers should consider the specific grade of stainless steel to ensure it meets their operational requirements.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Africa and South America should verify local suppliers’ certifications to ensure quality and safety.

How Does Elgiloy® Compare as a Material for Torquing Springs?

Key Properties: Elgiloy® is a cobalt-chromium alloy known for its superior fatigue resistance and spring properties. It can handle high-stress applications and has a temperature rating of up to 600°F (315°C).

Pros & Cons: The primary advantage of Elgiloy® is its exceptional resilience and ability to maintain performance under repeated stress. However, it comes at a higher cost, making it less suitable for budget-sensitive projects.

Impact on Application: Elgiloy® is particularly effective in orthodontic applications where consistent force is required over time. Its unique properties allow for precise control of torque, essential for effective tooth movement.

Considerations for International Buyers: Buyers should be aware of the limited availability of Elgiloy® in some regions. Ensuring compliance with local regulations and standards is vital, especially in Europe, where stringent guidelines exist.

What Are the Benefits of Using Titanium in Torquing Springs?

Key Properties: Titanium is known for its lightweight, high strength-to-weight ratio, and excellent corrosion resistance. It can withstand temperatures up to 800°F (427°C) and is inert to many chemicals.

Pros & Cons: The lightweight nature of titanium makes it an attractive option for applications requiring minimal mass. However, the manufacturing process can be complex and costly, which may deter some buyers.

Impact on Application: Titanium’s compatibility with various media makes it suitable for diverse orthodontic applications. Its strength allows for effective torque delivery without adding unnecessary weight.

Considerations for International Buyers: Buyers in the Middle East and Europe should consider the availability of titanium and its compliance with international standards. Understanding local market dynamics can help in sourcing titanium springs effectively.

Why Is Music Wire a Common Choice for Torquing Springs?

Key Properties: Music wire is a high-carbon steel known for its high tensile strength and elasticity. It has a temperature rating of up to 500°F (260°C) and is relatively inexpensive compared to other materials.

Pros & Cons: Music wire is cost-effective and readily available, making it a popular choice for many applications. However, it has lower corrosion resistance compared to stainless steel and may require additional coatings for specific environments.

Impact on Application: Music wire is suitable for applications where cost is a significant factor, but it may not perform as well in high-corrosion environments. Buyers should assess the specific application requirements before selection.

Considerations for International Buyers: Buyers from Africa and South America should ensure that music wire meets local quality standards and is sourced from reputable suppliers to avoid quality issues.

Summary Table of Material Selection for Torquing Springs

| Material | Typical Use Case for torquing springs | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | General orthodontic applications | Excellent corrosion resistance | Higher manufacturing complexity | Medium |

| Elgiloy® | High-stress orthodontic applications | Exceptional fatigue resistance | Higher cost | High |

| Titanium | Lightweight orthodontic applications | High strength-to-weight ratio | Complex manufacturing process | High |

| Music Wire | Cost-sensitive orthodontic solutions | Cost-effective and readily available | Lower corrosion resistance | Low |

This comprehensive analysis provides international B2B buyers with essential insights into material selection for torquing springs, enabling informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for torquing springs

What Are the Key Stages in the Manufacturing Process of Torquing Springs?

The manufacturing of torquing springs involves several critical stages that ensure the final product meets the specific requirements of orthodontic applications. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation:

The first step in the production of torquing springs is the selection of high-quality materials. Commonly used materials include heat-treated alloys such as Elgiloy® and stainless steel. These materials are chosen for their strength, elasticity, and resistance to deformation. The raw materials undergo a thorough inspection to ensure they meet the required specifications before moving to the next stage. -

Forming:

The forming process involves shaping the raw materials into the desired spring configuration. Advanced techniques such as precision wire forming and CNC machining are employed to create consistent and accurate shapes. The use of computer-aided design (CAD) software in this phase allows for the precise engineering of spring dimensions tailored to specific orthodontic needs, such as varying wire sizes and torque requirements. -

Assembly:

In the assembly stage, the formed springs are integrated with other components if necessary. This may involve crimping the springs onto arch wires or integrating them with brackets. Specialized tools, such as crimping pliers, ensure that the assembly is performed accurately, maintaining the integrity of the spring’s design and functionality. -

Finishing:

The finishing process includes surface treatments that enhance the durability and performance of the springs. This may involve polishing to remove any burrs or rough edges, applying coatings for corrosion resistance, or heat treatment to improve mechanical properties. Each finishing step is crucial for ensuring the spring can withstand the forces applied during orthodontic treatments.

How Is Quality Assurance Implemented in the Production of Torquing Springs?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for torquing springs. It ensures that the products meet international standards and the specific needs of B2B buyers.

-

Relevant International Standards:

Manufacturers typically adhere to international standards such as ISO 9001, which outlines the requirements for a quality management system. Compliance with ISO standards not only signifies a commitment to quality but also instills confidence among B2B buyers in various regions, including Africa, South America, the Middle East, and Europe. -

Industry-Specific Certifications:

In addition to ISO certifications, manufacturers may also pursue industry-specific certifications such as CE marking in Europe and API certification for medical devices. These certifications indicate that the products have been tested and verified for safety and efficacy, which is particularly important for orthodontic applications. -

Quality Control Checkpoints:

Effective quality control involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Inspecting raw materials before production to ensure they meet specifications.

– In-Process Quality Control (IPQC): Monitoring processes during manufacturing to catch defects early.

– Final Quality Control (FQC): Conducting thorough inspections and tests on the finished products to ensure they meet all quality standards.

What Common Testing Methods Are Used to Ensure Product Quality?

Manufacturers employ various testing methods to verify the quality and performance of torquing springs:

- Mechanical Testing: This includes tensile strength tests, fatigue tests, and elasticity measurements to ensure that the springs can withstand the forces they will encounter during use.

- Dimensional Inspection: Precision measuring tools are used to verify that the springs adhere to specified dimensions, ensuring they fit the intended orthodontic applications.

- Corrosion Resistance Testing: Springs may undergo salt spray tests or other corrosion tests to ensure they can withstand environmental factors without degrading.

How Can B2B Buyers Verify Supplier Quality Assurance Processes?

B2B buyers must take proactive steps to verify the quality assurance processes of their suppliers:

-

Supplier Audits: Conducting on-site audits of the manufacturing facilities can provide insights into the production processes, quality control measures, and adherence to international standards. This is crucial for buyers looking to establish long-term partnerships.

-

Requesting Quality Reports: Suppliers should be willing to provide documentation of their quality assurance processes, including test results, certifications, and compliance with standards. Regular updates on quality metrics can also be beneficial.

-

Third-Party Inspections: Engaging independent third-party inspection services can add an extra layer of assurance. These services can validate that the products meet specified standards and that the supplier adheres to their stated quality assurance processes.

What Are the Specific Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, must navigate specific nuances in quality control:

-

Cultural and Regulatory Differences: Different regions may have varying expectations regarding product quality and regulatory compliance. Understanding these differences can help buyers make informed decisions.

-

Logistical Considerations: International shipping and customs can affect product integrity. Buyers should ensure that suppliers have robust packaging and shipping processes to prevent damage during transit.

-

Supplier Relationships: Building strong relationships with suppliers can facilitate better communication regarding quality issues and improvements. This is especially important in regions where personal relationships play a crucial role in business dealings.

By focusing on these manufacturing processes and quality assurance protocols, international B2B buyers can make informed decisions when sourcing torquing springs, ultimately leading to successful orthodontic treatment outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘torquing springs’

To effectively procure torquing springs for orthodontic applications, international B2B buyers must navigate a complex landscape of options and considerations. This checklist serves as a practical guide to streamline the sourcing process and ensure you make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the torquing springs meet your needs. Consider factors such as the wire dimensions (e.g., 0.016 x 0.022 or 0.019 x 0.025) and the type of materials used (like heat-treated Elgiloy®). This step will help you avoid compatibility issues and ensure optimal performance in your orthodontic treatments.

Step 2: Research Reputable Suppliers

Finding reliable suppliers is essential for sourcing high-quality torquing springs. Look for manufacturers with a strong reputation in the orthodontic industry, particularly those recognized in your region. Consider checking online reviews, industry forums, and supplier directories to gather insights on potential partners.

- Tip: Focus on suppliers that offer detailed product descriptions and specifications, as this reflects their commitment to transparency.

Step 3: Evaluate Supplier Certifications and Standards

Ensure that your potential suppliers adhere to international quality standards and possess relevant certifications. Certifications such as ISO 13485 (for medical devices) and CE marking (for European compliance) indicate that the products meet stringent quality requirements.

- Why it matters: Compliance with these standards not only assures product quality but also mitigates risks associated with dental and orthodontic applications.

Step 4: Request Samples for Testing

Before placing a bulk order, request samples of the torquing springs you are considering. Testing these samples in your practice allows you to evaluate their performance, compatibility, and effectiveness in real-world scenarios.

- What to look for: Pay attention to how well the springs maintain consistent torque and how easily they integrate with your existing archwires.

Step 5: Negotiate Pricing and Terms

Engage in negotiations with your selected suppliers to secure favorable pricing and payment terms. Consider bulk purchase discounts, shipping costs, and payment flexibility, particularly if you are planning a large order.

- Consideration: Many suppliers offer volume discounts, which can significantly reduce costs, especially for B2B buyers in regions like Africa and South America.

Step 6: Review Shipping and Handling Policies

Understanding the shipping and handling policies of your suppliers is vital to avoid unexpected delays or costs. Verify lead times, shipping methods, and any additional fees that may apply, particularly for international orders.

- Pro Tip: Ensure that the supplier has experience shipping to your region, as this can reduce the likelihood of customs complications.

Step 7: Establish a Long-term Relationship

Once you have successfully sourced your torquing springs, consider fostering a long-term relationship with your supplier. This can lead to better pricing, priority service, and access to new products as they become available.

- Why it’s beneficial: A strong partnership can enhance supply chain stability and improve your ability to respond to changing market demands.

A stock image related to torquing springs.

By following this step-by-step checklist, you can effectively navigate the sourcing process for torquing springs, ensuring that you select the right products for your orthodontic needs while fostering valuable supplier relationships.

Comprehensive Cost and Pricing Analysis for torquing springs Sourcing

What Are the Key Cost Components for Torquing Springs?

When sourcing torquing springs, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The choice of material significantly impacts the cost. High-quality alloys like heat-treated Elgiloy® or nickel-titanium are commonly used, providing durability and consistent performance. Expect a price premium for materials that offer better mechanical properties and longevity.

-

Labor: Skilled labor is necessary for the precision manufacturing of torquing springs. Labor costs can vary by region, with higher wages in developed countries compared to emerging markets in Africa and South America.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these overheads.

-

Tooling: Initial tooling costs can be substantial, particularly for custom designs or specifications. This is a one-time investment that can be amortized over large production runs.

-

Quality Control (QC): Rigorous QC processes ensure that the springs meet required specifications and certifications. This adds to the overall cost but is crucial for maintaining product reliability and safety.

-

Logistics: Shipping costs can vary widely based on the origin and destination. Factors such as distance, shipping method, and import duties play a role in determining logistics expenses.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can be negotiated, especially for large orders or long-term contracts.

How Do Pricing Influencers Impact the Cost of Torquing Springs?

Several factors influence the pricing of torquing springs, making it essential for buyers to consider them during negotiations:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to discounts. Suppliers are more willing to negotiate on price for larger orders, which can significantly reduce the per-unit cost.

-

Specifications/Customization: Custom designs or specific requirements may incur additional costs. Standard products are generally less expensive than tailored solutions.

-

Material Quality and Certifications: Springs made from premium materials with certifications (e.g., ISO, CE) can command higher prices. Buyers should weigh the benefits of quality against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may offer better quality assurance, while newer entrants might provide lower prices to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. These terms define responsibilities for shipping, insurance, and tariffs, which can impact total costs.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing Torquing Springs?

For B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, here are some actionable tips to achieve cost efficiency:

-

Negotiate Terms: Leverage your purchasing power by negotiating payment terms, delivery schedules, and prices. Establishing a long-term relationship can lead to better deals.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, factor in shipping, customs duties, and potential replacement costs. Sometimes, a higher upfront cost can result in lower TCO due to better quality and durability.

-

Evaluate Local Suppliers: Sourcing from local suppliers can reduce shipping costs and lead times. Investigate the availability of quality products within your region.

-

Stay Informed About Market Trends: Understanding market dynamics, such as fluctuating raw material prices or changes in international trade policies, can provide leverage in negotiations.

-

Request Samples: Before committing to a large order, request samples to assess quality. This can prevent costly mistakes and ensure the products meet your specifications.

Disclaimer on Indicative Prices

Prices for torquing springs can vary widely based on specifications, order volume, and supplier factors. The prices mentioned in various sources (e.g., $10.50 to $69.95 per pack) are indicative and subject to change. Always confirm current pricing with suppliers before placing an order to ensure accurate budgeting.

Alternatives Analysis: Comparing torquing springs With Other Solutions

When evaluating the best orthodontic solutions for applying torque to teeth, it’s essential to consider alternatives to torquing springs. While torquing springs offer unique benefits in terms of force application, other methods can also effectively achieve desired tooth movements. Below, we compare torquing springs against two viable alternatives: the Anterior Root Torquing Spring (ART®) and the use of temporary anchorage devices (TADs).

| Comparison Aspect | Torquing Springs | Anterior Root Torquing Spring (ART®) | Temporary Anchorage Devices (TADs) |

|---|---|---|---|

| Performance | Delivers consistent, targeted torque to individual teeth. | Provides efficient torque control with no adjustments needed. | Allows for significant control over tooth movement and stability. |

| Cost | Generally low to moderate cost (approx. $10-$70 per pack). | Moderate cost, typically around $50-$100 per package. | Higher initial investment (ranging from $200 to $500+ depending on the system). |

| Ease of Implementation | Easy to use; simply crimp onto archwire. | User-friendly; requires no forming or bending. | Requires surgical placement and training, which can complicate the process. |

| Maintenance | Minimal; springs can be replaced as needed. | None; remains active throughout treatment. | Requires periodic checks and adjustments to ensure proper placement. |

| Best Use Case | Ideal for specific tooth movements in various orthodontic treatments. | Best for finishing and stabilizing occlusion in complex cases. | Most effective in cases requiring significant movement or anchorage. |

What Are the Advantages and Disadvantages of Anterior Root Torquing Springs (ART®)?

The Anterior Root Torquing Spring (ART®) is a pre-formed device that simplifies the application of torque to anterior teeth. Its primary advantage is ease of use; it requires no adjustments or bending and can be integrated with any bracket system. This makes it an excellent choice for orthodontists looking to streamline their processes. However, it may not provide the same level of individualized force control that torquing springs offer, as it is designed for more general applications.

How Do Temporary Anchorage Devices (TADs) Compare?

Temporary Anchorage Devices (TADs) are a more advanced alternative that allows for precise control over tooth movement. They can be particularly beneficial in complex cases where significant anchorage is required. TADs can achieve greater stability and are adaptable to various treatment plans. However, their implementation is more invasive, requiring surgical placement and ongoing maintenance, which can deter some practitioners from utilizing them, especially in regions with limited access to specialized orthodontic care.

How Can B2B Buyers Choose the Right Solution for Their Needs?

For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, selecting the right orthodontic solution involves evaluating specific clinical needs, budget constraints, and the complexity of cases they typically handle. Torquing springs may be ideal for practices focusing on routine orthodontic adjustments due to their cost-effectiveness and ease of use. Conversely, practices dealing with more complex cases might benefit from investing in ART® or TAD systems despite the higher costs and implementation challenges. Ultimately, understanding the unique requirements of their patient base and operational capabilities will guide buyers toward the most suitable option.

Essential Technical Properties and Trade Terminology for torquing springs

What Are the Essential Technical Properties of Torquing Springs?

When sourcing torquing springs for orthodontic applications, understanding their technical properties is crucial for making informed purchasing decisions. Here are some key specifications to consider:

1. Material Grade: What is the Significance of Material Selection?

Torquing springs are typically made from specialized materials such as Elgiloy®, a heat-treated cobalt-chromium alloy known for its excellent elasticity and strength. The choice of material directly affects the spring’s durability and performance, ensuring it maintains its shape and function under stress. For B2B buyers, selecting springs made from high-grade materials can lead to reduced replacement costs and improved treatment outcomes.

2. Force Range: How Does Torque Force Impact Performance?

The torque force exerted by a spring, usually measured in grams, is critical for effective tooth movement. For example, some torquing springs deliver between 125 to 150 grams of force. Understanding the required torque force for specific orthodontic cases allows practitioners to select the right spring, improving treatment efficiency and patient satisfaction.

3. Dimensions and Compatibility: Why Are Size Specifications Important?

Torquing springs come in various dimensions, such as .016 x .022 or .019 x .025, and must be compatible with the arch wires they are used with. Each spring is designed for specific wire sizes, and using the correct dimensions is essential for ensuring optimal performance and avoiding complications during orthodontic procedures. B2B buyers should verify size specifications before placing orders to prevent delays and additional costs.

4. Activation Mechanism: What Role Does Automatic Activation Play?

Many torquing springs feature an automatic activation mechanism that engages once the arch wire is placed in the bracket. This design enhances ease of use by eliminating the need for additional adjustments, which can save time in clinical settings. For international buyers, understanding this feature can streamline procurement processes and improve operational efficiency.

5. Spring Height and Configuration: How Do Variations Affect Treatment?

Torquing springs are available in various heights (e.g., 3mm, 4mm, 5mm) and configurations, allowing orthodontists to select the most appropriate option based on individual patient needs. The height affects how the spring applies force to specific teeth, which is crucial for targeted treatment. Buyers should assess the treatment philosophy of their practice to determine the best configurations to order.

What Are Common Trade Terms in the Torquing Springs Industry?

Familiarizing yourself with industry-specific terminology is vital for effective communication and negotiation. Here are some common trade terms relevant to torquing springs:

1. OEM (Original Equipment Manufacturer): What Does OEM Mean in the Context of Torquing Springs?

OEM refers to companies that manufacture products that may be marketed under another company’s brand. In the torquing springs market, understanding OEM relationships can help buyers identify quality products and ensure they are sourcing from reputable manufacturers.

2. MOQ (Minimum Order Quantity): Why Is MOQ Important for Bulk Purchasing?

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory management. It can also influence purchasing strategies, especially for international buyers looking to optimize shipping costs.

3. RFQ (Request for Quotation): How Can RFQ Streamline Procurement Processes?

An RFQ is a document used to solicit price quotes from suppliers. By issuing an RFQ for torquing springs, buyers can compare prices and terms from multiple vendors, ensuring they receive the best value for their purchases.

4. Incoterms: What Are Incoterms and How Do They Affect International Shipping?

A stock image related to torquing springs.

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping transactions. Familiarity with Incoterms is crucial for international buyers to understand their obligations regarding shipping costs, insurance, and risk transfer, ultimately facilitating smoother transactions.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they procure the right torquing springs for their orthodontic needs while optimizing costs and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the torquing springs Sector

What Are the Current Market Dynamics and Key Trends in the Torquing Springs Sector?

The global market for torquing springs is witnessing significant growth driven by advancements in orthodontic technology and increased demand for dental care. Factors such as rising awareness of oral health, the proliferation of cosmetic dentistry, and the growing prevalence of malocclusion are propelling market expansion. In particular, regions like Africa and South America are experiencing a surge in orthodontic procedures, creating opportunities for B2B buyers to source high-quality torquing springs.

Emerging technologies such as 3D printing and digital orthodontics are reshaping the sourcing landscape. These innovations enable manufacturers to create customized torquing springs that meet specific clinical needs, thereby enhancing treatment outcomes. Furthermore, the shift towards e-commerce platforms facilitates easier access to a wider range of products, allowing international buyers to compare prices and quality from various suppliers.

In Europe and the Middle East, regulatory compliance and product certifications play a crucial role in sourcing decisions. Buyers are increasingly prioritizing suppliers who adhere to international quality standards, such as ISO certifications, which assures them of product reliability and performance. As competition intensifies, B2B buyers are advised to stay informed about market trends and emerging suppliers to optimize their sourcing strategies effectively.

How Can Sustainability and Ethical Sourcing Impact Your B2B Purchases of Torquing Springs?

Sustainability has become a critical consideration for B2B buyers in the torquing springs sector. The environmental impact of manufacturing processes, including resource consumption and waste generation, is under scrutiny. Companies that prioritize sustainable practices can enhance their brand reputation and appeal to environmentally conscious consumers.

Ethical sourcing is equally important, especially in regions like Africa and South America, where supply chain transparency can be lacking. Buyers should seek suppliers who demonstrate commitment to ethical labor practices and environmental stewardship. Certifications such as FSC (Forest Stewardship Council) and ISO 14001 (Environmental Management) can provide assurance of a supplier’s dedication to sustainable practices.

Moreover, the use of ‘green’ materials, such as recyclable or biodegradable components in the production of torquing springs, is gaining traction. By opting for suppliers that utilize environmentally friendly materials, buyers can reduce their ecological footprint while also addressing consumer demand for sustainable products.

What Is the Evolution of Torquing Springs and Its Relevance to Current B2B Trends?

The evolution of torquing springs can be traced back to the early developments in orthodontic appliances, where the need for precise tooth movement became apparent. Initially, these devices were rudimentary, but advancements in materials science have led to the introduction of high-performance alloys such as Elgiloy, which provide superior strength and durability.

Today, torquing springs are designed for specific applications, allowing orthodontists to apply targeted forces to individual teeth, thus improving treatment efficiency. The growing trend towards personalized orthodontic solutions underscores the importance of this evolution. For B2B buyers, understanding the historical context and technological advancements in torquing springs can inform better sourcing decisions, ensuring they select products that align with modern treatment methodologies and patient needs.

In summary, international B2B buyers in the torquing springs sector must navigate a dynamic market characterized by innovation, sustainability, and ethical sourcing. By leveraging these insights, they can enhance their procurement strategies and contribute to better orthodontic outcomes.

Frequently Asked Questions (FAQs) for B2B Buyers of torquing springs

-

How do I choose the right torquing spring for my orthodontic practice?

Choosing the right torquing spring involves assessing the specific needs of your orthodontic treatment plan. Consider the size and type of the archwire you will be using, as torquing springs are designed to fit specific dimensions. Evaluate the force required for each case, as different springs provide varying levels of torque. Additionally, consult with your orthodontic supplier for guidance on the best options available that align with your treatment philosophy. -

What is the best torquing spring for anterior tooth alignment?

For anterior tooth alignment, the Warren Torquing Spring is highly recommended due to its ability to apply consistent torque to individual teeth. Its design allows for automatic activation upon placement in the archwire, ensuring ease of use and effective force application. Evaluate options like the Goodman Torquing Springs as well, which can deliver targeted torque for a range of anterior teeth, making them suitable for diverse treatment scenarios. -

How can I verify the quality of torquing springs from suppliers?

To verify the quality of torquing springs, request certifications and quality assurance documentation from suppliers. Look for products that comply with international standards, such as ISO certifications. Additionally, consider suppliers that offer product guarantees or warranties, as this indicates confidence in their manufacturing processes. It’s also beneficial to read customer reviews and seek references from other orthodontic practices that have sourced from the same supplier. -

What are the minimum order quantities (MOQ) for torquing springs?

Minimum order quantities for torquing springs can vary significantly by supplier and region. Typically, MOQs may range from 10 to 100 units, depending on the specific product and supplier policies. For bulk orders, some suppliers might offer volume discounts, which can be advantageous for larger practices or distributors. Always inquire about MOQs upfront to ensure they align with your purchasing capabilities and inventory management. -

What payment terms should I expect when purchasing torquing springs internationally?

International payment terms can vary widely among suppliers. Common terms include upfront payment, net 30, or even net 60 days, depending on your relationship with the supplier. Additionally, consider payment methods such as wire transfers, credit cards, or letters of credit to mitigate risk. Always clarify terms before placing an order to avoid misunderstandings and ensure smooth transactions. -

How do I handle customs and logistics when importing torquing springs?

When importing torquing springs, familiarize yourself with the customs regulations of your country. Ensure that all necessary documentation, such as invoices and certificates of origin, is prepared. Engage with a reliable freight forwarder who understands the logistics of medical supplies, as they can streamline the shipping process and help navigate potential tariffs or duties. Planning for delays in customs clearance is also essential to manage inventory effectively. -

Can I customize torquing springs to fit specific treatment needs?

Many suppliers offer customization options for torquing springs, allowing you to specify dimensions, materials, and torque levels. Discuss your requirements with the supplier, as they may have the capability to produce springs tailored to your treatment protocols. However, be aware that custom orders may come with longer lead times and higher costs, so factor these into your planning. -

What should I do if I receive defective torquing springs?

If you receive defective torquing springs, promptly contact the supplier with detailed information about the issue, including batch numbers and photographs if applicable. Most reputable suppliers have return policies in place for defective items, which may include replacements or refunds. Ensure you understand the return process and any associated timelines to resolve the issue efficiently, minimizing disruptions to your practice.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for torquing springs

As the global demand for orthodontic solutions continues to grow, strategic sourcing of torquing springs presents a unique opportunity for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. By leveraging high-quality products like Warren and Goodman torquing springs, businesses can enhance treatment efficacy and patient satisfaction while optimizing operational efficiencies.

How can strategic sourcing benefit your business? It allows for better price negotiations, access to superior product quality, and improved supply chain reliability. Additionally, understanding the specific needs of regional markets, such as compliance with local regulations and preferences, can further enhance the effectiveness of sourcing strategies.

Looking ahead, the orthodontic industry is poised for innovation, with advancements in materials and design offering new possibilities for treatment. International buyers should remain proactive in their sourcing efforts, exploring partnerships with reputable suppliers to secure competitive advantages. By investing in quality torquing springs, businesses can ensure they meet the evolving needs of their clientele, driving growth and success in a dynamic marketplace. Engage with suppliers today to fortify your supply chain and elevate your orthodontic offerings.