Cut Costs with Automation Systems: The Ultimate Guide (2025)

Introduction: Navigating the Global Market for automation systems

In an increasingly competitive global landscape, sourcing automation systems that enhance operational efficiency and reduce costs can be a daunting challenge for international B2B buyers. As businesses in Africa, South America, the Middle East, and Europe (including key markets like Germany and Egypt) seek to modernize their operations, understanding the nuances of automation technologies becomes crucial. This guide provides a comprehensive overview of various automation systems, including industrial robots, automated guided vehicles, and collaborative robots, while also addressing their applications across diverse sectors such as manufacturing, logistics, and energy management.

Buyers will gain actionable insights on supplier vetting processes, enabling them to identify reliable partners who can deliver tailored solutions that meet their specific needs. Additionally, this resource outlines cost considerations and the latest trends in automation technology, helping businesses make informed purchasing decisions. By equipping B2B buyers with the knowledge required to navigate the complexities of the global market, this guide empowers them to leverage automation systems effectively, driving innovation and operational excellence within their organizations.

With the right tools and information at hand, international buyers can transform their operational capabilities, enhance productivity, and ultimately achieve a competitive edge in their respective markets.

Understanding automation systems Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Industrial Robots | Autonomous systems performing repetitive tasks with precision. | Manufacturing, assembly lines, quality control. | Pros: High efficiency, reduced labor costs. Cons: High initial investment, maintenance complexity. |

| Collaborative Robots (Cobots) | Designed to work alongside human workers safely and efficiently. | Assembly, packaging, and logistics operations. | Pros: Flexible integration, enhanced worker safety. Cons: Limited payload capacity, specialized training needed. |

| Automated Guided Vehicles (AGVs) | Mobile robots for material transport within facilities. | Warehousing, manufacturing, and distribution. | Pros: Reduced labor costs, increased operational efficiency. Cons: Infrastructure modifications may be needed. |

| Building Management Systems | Integrates various building operations like HVAC, security, and lighting. | Commercial buildings, hotels, and hospitals. | Pros: Energy savings, improved occupant comfort. Cons: Complexity in integration, potential data privacy issues. |

| Warehouse Automation Systems | Automates inventory management and order fulfillment processes. | E-commerce, retail, and logistics sectors. | Pros: Increased throughput, reduced human error. Cons: High upfront costs, ongoing operational costs. |

What Are the Key Characteristics of Industrial Robots for B2B Buyers?

Industrial robots are designed for high-volume, repetitive tasks in manufacturing environments. These systems utilize advanced sensors and control algorithms to execute precise movements, making them ideal for assembly, welding, and quality assurance applications. B2B buyers should consider their specific operational needs, compatibility with existing systems, and the potential return on investment when evaluating industrial robots. While they offer significant efficiency improvements, the initial cost and maintenance requirements can be substantial.

How Do Collaborative Robots (Cobots) Enhance Workplace Safety and Efficiency?

Collaborative robots, or cobots, are engineered to work alongside human operators, enhancing productivity without compromising safety. These robots are equipped with advanced sensors that allow them to detect human presence and adjust their operations accordingly. Suitable for assembly lines and packaging, cobots are particularly beneficial for small to medium-sized enterprises looking to automate without extensive infrastructure changes. Buyers should assess the specific tasks they wish to automate, the required payload capacity, and the training necessary for staff to operate these systems effectively.

Why Choose Automated Guided Vehicles (AGVs) for Material Transport?

Automated Guided Vehicles (AGVs) are mobile robots that transport materials within a facility, enhancing logistics and operational efficiency. They are particularly effective in warehouses and manufacturing plants where they can move goods from one point to another without human intervention. B2B buyers should evaluate the layout of their facilities, the types of loads to be moved, and the level of automation desired. Although AGVs can significantly reduce labor costs, they may require modifications to existing infrastructure to accommodate their operation.

What Are the Benefits of Building Management Systems for Commercial Properties?

Building Management Systems (BMS) integrate various operational aspects of a building, such as HVAC, lighting, and security, into a single platform for easier management. These systems improve energy efficiency and enhance occupant comfort, making them vital for commercial properties like hotels and hospitals. Buyers should consider the scalability of the BMS, its ability to integrate with existing systems, and the potential for energy savings. While the complexity of these systems can pose challenges during installation, the long-term benefits often outweigh the initial hurdles.

How Do Warehouse Automation Systems Improve Order Fulfillment?

Warehouse automation systems streamline inventory management and order fulfillment processes, significantly increasing throughput and reducing errors. These systems can include automated storage and retrieval systems, conveyor belts, and robotic picking solutions, making them essential for e-commerce and retail sectors. When considering warehouse automation, B2B buyers should analyze their current operational workflows, the potential for increased efficiency, and the costs associated with implementation and maintenance. Although the upfront investment can be high, the long-term gains in productivity and accuracy can be substantial.

Key Industrial Applications of automation systems

| Industry/Sector | Specific Application of Automation Systems | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Industrial Robots | Increased efficiency and reduced labor costs | Compatibility with existing systems and ease of integration |

| Logistics and Warehousing | Automated Guided Vehicles (AGVs) | Streamlined operations and improved inventory accuracy | Navigation technology and load capacity |

| Food and Beverage Production | Automated Quality Control Systems | Consistent product quality and reduced waste | Regulatory compliance and adaptability to different products |

| Energy Management | Building Automation Systems | Enhanced energy efficiency and cost savings | Scalability and integration with renewable energy sources |

| Healthcare | Robotic Surgery Systems | Improved precision and reduced recovery time | Regulatory approval and training requirements |

How Are Automation Systems Used in Manufacturing?

In the manufacturing sector, industrial robots are employed to automate repetitive tasks such as assembly, welding, and painting. This application significantly boosts production efficiency while minimizing labor costs. For international buyers, particularly in regions like Africa and South America, sourcing robots that can easily integrate with existing machinery is crucial. Additionally, buyers should consider the availability of local support and maintenance services to ensure minimal downtime.

What Role Do Automated Guided Vehicles Play in Logistics?

Automated Guided Vehicles (AGVs) are transforming logistics and warehousing by automating the transport of goods within facilities. These self-driving vehicles enhance operational efficiency and inventory accuracy by reducing human error and labor costs. For buyers in the Middle East and Europe, key considerations include the AGVs’ navigation technology and load capacity, ensuring they meet the specific needs of their facilities and operations.

How Do Automated Quality Control Systems Benefit Food Production?

In the food and beverage industry, automated quality control systems are vital for maintaining product consistency and safety. These systems utilize sensors and AI to monitor production processes, identifying deviations that could lead to defects or safety issues. International buyers, especially in regions with strict food regulations like Europe, must ensure that the systems they procure comply with local standards and can adapt to various product types.

What Are the Advantages of Building Automation Systems in Energy Management?

Building automation systems are crucial for energy management, enabling businesses to monitor and control energy consumption effectively. These systems can lead to substantial cost savings and enhanced energy efficiency, especially in commercial buildings. Buyers from Africa and the Middle East should focus on the scalability of these systems, ensuring they can incorporate renewable energy sources and adapt to future technological advancements.

How Do Robotic Surgery Systems Enhance Healthcare Delivery?

In healthcare, robotic surgery systems provide enhanced precision in surgical procedures, leading to quicker recovery times and fewer complications. This application is particularly relevant for hospitals looking to improve patient outcomes while managing costs. Buyers in Europe and emerging markets should prioritize sourcing systems that have received regulatory approval and consider the necessary training for medical staff to operate these advanced technologies effectively.

3 Common User Pain Points for ‘automation systems’ & Their Solutions

Scenario 1: Difficulty in Integration with Existing Systems

The Problem: Many B2B buyers face significant hurdles when trying to integrate new automation systems with their existing infrastructure. Companies may have legacy systems that are not designed to communicate with modern automation solutions, leading to operational silos. This integration challenge can result in increased downtime, inefficiencies, and higher costs, as businesses may have to invest heavily in custom solutions or face disruptions in their workflow.

The Solution: To overcome integration issues, buyers should prioritize automation systems that support open standards and interoperability. When sourcing automation solutions, inquire about the system’s compatibility with existing technologies, including the protocols they utilize (like MQTT, OPC UA, or REST APIs). Additionally, consider engaging with system integrators who specialize in customizing solutions for specific operational needs. Conducting a thorough compatibility assessment during the procurement process can help identify potential integration challenges early on. Ensure that the vendor provides robust technical support and documentation to facilitate a smoother transition.

Scenario 2: Lack of Skilled Workforce for Automation Management

The Problem: As automation systems become more sophisticated, the skills required to operate and manage these systems are evolving. B2B buyers often find that their current workforce lacks the necessary expertise to effectively manage automation systems, which can lead to underutilization of these technologies. This skills gap can hinder the expected return on investment and prevent businesses from maximizing the benefits of automation.

The Solution: To address this skills gap, companies should invest in training programs tailored to their automation systems. Collaborating with vendors who offer comprehensive training and certification can empower employees to manage and maintain new technologies effectively. Additionally, companies may consider hiring specialized personnel or consultants during the initial implementation phase to guide their teams. Establishing a continuous learning culture within the organization can further enhance workforce capabilities, ensuring that staff remains up-to-date with the latest automation trends and tools.

Scenario 3: High Initial Costs and Unclear ROI

The Problem: One of the most significant barriers to adopting automation systems for many B2B buyers is the high initial investment required. This upfront cost can be daunting, especially for businesses operating on tight budgets or in regions where financial resources are limited. Furthermore, the uncertainty regarding the return on investment (ROI) complicates the decision-making process, as buyers may struggle to quantify the long-term benefits of automation.

The Solution: To alleviate concerns about high upfront costs and ROI, buyers should conduct a comprehensive cost-benefit analysis before making a purchase. This analysis should include not only the initial investment but also long-term savings from increased efficiency, reduced labor costs, and improved productivity. Engaging with vendors who offer flexible financing options or pilot programs can mitigate initial costs and allow businesses to test the system’s effectiveness before full implementation. Additionally, establishing clear KPIs (Key Performance Indicators) to measure the impact of automation on business processes can provide tangible evidence of ROI over time, helping to justify the investment to stakeholders.

Strategic Material Selection Guide for automation systems

What Are the Key Materials Used in Automation Systems?

When selecting materials for automation systems, international B2B buyers must consider the properties, advantages, and limitations of various materials. This analysis focuses on four common materials: aluminum, stainless steel, plastic, and copper. Each material has unique characteristics that influence its suitability for specific applications in automation systems.

How Does Aluminum Benefit Automation Systems?

Aluminum is widely used in automation systems due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 150°C and can withstand moderate pressure levels.

Pros: Aluminum is durable, easy to machine, and cost-effective compared to other metals. It is also highly recyclable, making it an environmentally friendly choice.

Cons: However, aluminum may not be suitable for applications that require high strength or resistance to extreme temperatures. Its lower tensile strength compared to steel can be a limitation in heavy-duty applications.

Impact on Application: Aluminum is ideal for components like frames, enclosures, and housings in automation systems, particularly where weight reduction is critical.

Considerations for Buyers: International buyers should ensure compliance with local standards such as ASTM or DIN. In regions like Africa and South America, sourcing aluminum from local suppliers can reduce costs and lead times.

Why Choose Stainless Steel for Automation Systems?

Stainless steel is another popular choice for automation systems, particularly in environments that require high corrosion resistance and strength. It can handle temperatures up to 300°C and high-pressure applications.

Pros: The durability and strength of stainless steel make it suitable for heavy-duty applications. It is also resistant to rust and staining, ensuring a longer lifespan in harsh environments.

Cons: The main drawback is its higher cost compared to aluminum and plastics. Additionally, stainless steel can be more challenging to machine, increasing manufacturing complexity.

Impact on Application: Stainless steel is commonly used in food processing automation systems and pharmaceutical applications where hygiene is paramount.

Considerations for Buyers: Buyers in Europe, particularly Germany, should pay attention to compliance with EU regulations on food safety and materials. Understanding local standards is crucial for successful implementation.

What Role Does Plastic Play in Automation Systems?

Plastic materials, including polycarbonate and polypropylene, are frequently used in automation systems due to their versatility and lightweight properties. They typically have a temperature resistance of up to 100°C and are not suitable for high-pressure applications.

Pros: Plastics are cost-effective, easy to mold, and can be engineered for specific applications. They also offer good electrical insulation properties.

Cons: However, plastics may not provide the same level of durability or temperature resistance as metals. They are also more susceptible to wear and tear over time.

Impact on Application: Plastic is often used in non-structural components like housings, covers, and insulation in automation systems.

Considerations for Buyers: Buyers should be aware of the specific types of plastics used and their compatibility with the media they will encounter. In regions like the Middle East, where temperatures can soar, careful selection of high-temperature resistant plastics is essential.

How Is Copper Utilized in Automation Systems?

Copper is primarily used in automation systems for electrical applications due to its excellent conductivity. It can withstand temperatures up to 200°C and is suitable for various pressure ratings.

Pros: Copper’s high electrical conductivity makes it ideal for wiring and connections in automation systems. It is also resistant to corrosion, especially when coated.

Cons: The main disadvantage is its susceptibility to oxidation, which can lead to reduced conductivity over time. Copper is also more expensive than aluminum.

Impact on Application: Copper is crucial in electrical components, including sensors and control systems, where reliable conductivity is essential.

Considerations for Buyers: Buyers in Africa and South America should consider the availability of copper and potential tariffs or import duties. Compliance with international standards for electrical components is also critical.

Summary Table of Material Selection for Automation Systems

| Material | Typical Use Case for automation systems | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frames, enclosures, housings | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Stainless Steel | Food processing, pharmaceutical systems | High strength and corrosion-resistant | Higher cost and machining complexity | High |

| Plastic | Non-structural components | Cost-effective and easy to mold | Limited durability and temperature resistance | Low |

| Copper | Electrical connections | Excellent conductivity | Susceptible to oxidation | Medium |

This guide provides a comprehensive overview of material selection for automation systems, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for automation systems

What Are the Main Stages in Manufacturing Automation Systems?

The manufacturing process for automation systems typically encompasses several critical stages, each vital for ensuring high-quality output. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Is It Done?

Material preparation involves sourcing and processing raw materials required for automation systems. This stage is crucial as the quality of materials directly influences the final product’s performance. Common practices include:

- Sourcing Quality Materials: Engage suppliers with proven track records in providing high-grade materials, such as metals for sensors and plastics for casings.

- Pre-processing Techniques: Techniques like cutting, molding, and machining are employed to prepare materials for the next stages. It’s essential to ensure that materials meet specific industry standards to avoid future issues in assembly.

What Are the Key Techniques in Forming Automation Systems?

The forming stage transforms raw materials into components through various methods, depending on the complexity and requirements of the automation system. Key techniques include:

- Casting and Molding: Commonly used for creating intricate shapes in plastics and metals. Ensure that the molds are precision-engineered to minimize defects.

- Machining: Processes like milling and turning refine components to exact specifications. Advanced CNC (Computer Numerical Control) machines are widely used for their precision and efficiency.

- Additive Manufacturing: Increasingly popular, especially for prototyping and small batch productions, 3D printing allows for rapid iteration and design flexibility.

How Does the Assembly Process Work for Automation Systems?

Assembly is where individual components come together to form a complete automation system. This stage is critical for functionality and reliability. Key aspects include:

- Manual vs. Automated Assembly: A combination of both methods is often employed. While automated assembly lines improve speed and consistency, manual assembly is sometimes necessary for complex tasks requiring skilled labor.

- Integration of Components: This involves integrating sensors, controllers, and actuators to ensure that the system operates seamlessly. Ensure that each component is thoroughly tested for compatibility.

- Documentation and Traceability: Keeping detailed records of assembly processes, including component batch numbers, is vital for quality control and future troubleshooting.

What Finishing Techniques Are Used in Automation Systems Manufacturing?

Finishing techniques enhance the durability and appearance of automation systems. They include:

- Surface Treatments: Processes like anodizing, painting, or coating improve resistance to wear and corrosion. Selecting the right finish is critical based on the operational environment.

- Final Inspection: Before packaging, systems undergo a final inspection to ensure they meet design specifications and quality standards.

How Is Quality Control Implemented in Automation Systems Manufacturing?

Quality Control (QC) is essential in the manufacturing of automation systems to ensure that products meet international and industry-specific standards. Key components of QC include:

What Are the Relevant International Standards for Automation Systems?

B2B buyers should be familiar with several international standards that govern the quality of automation systems:

- ISO 9001: This standard outlines requirements for a quality management system (QMS) and is applicable across industries. Suppliers should have ISO 9001 certification to demonstrate their commitment to quality.

- CE Marking: For products sold in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards.

- API Standards: Relevant for automation systems in the oil and gas sector, API standards ensure safety and reliability.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are integrated throughout the manufacturing process, including:

- Incoming Quality Control (IQC): Inspection of raw materials upon receipt to ensure they meet predefined specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify and rectify defects early.

- Final Quality Control (FQC): A comprehensive evaluation of the finished product to confirm it meets all quality and performance standards.

Which Testing Methods Are Commonly Used in Automation Systems Manufacturing?

Various testing methods are employed to verify the functionality and reliability of automation systems:

- Functional Testing: Ensures that all components operate as intended under simulated conditions.

- Stress Testing: Evaluates how systems perform under extreme conditions, helping to identify potential failure points.

- Environmental Testing: Assesses how systems perform in various environmental conditions, crucial for products used in diverse climates.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers:

- Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes and QC measures. This can help identify risks and ensure compliance with quality standards.

- Requesting Quality Reports: Suppliers should provide detailed QC reports, including data from testing phases and records of any non-conformities.

- Third-Party Inspections: Engage third-party inspection services to perform unbiased evaluations of suppliers’ manufacturing processes and product quality.

What Are the QC and Certification Nuances for International B2B Buyers?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is essential:

- Regional Compliance Standards: Be aware of local regulations and standards that may differ from international norms. For example, certain countries may require specific certifications for products used in critical industries.

- Cultural Considerations: Different regions may have varying attitudes toward quality and compliance. Building strong relationships with suppliers can facilitate better communication and adherence to standards.

- Documentation for Export: Ensure that all necessary documentation is in place for exporting goods, including certificates of conformity and test reports, to avoid delays at customs.

By understanding the manufacturing processes and quality assurance practices specific to automation systems, international B2B buyers can make informed purchasing decisions, mitigate risks, and establish long-term partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automation systems’

In the rapidly evolving landscape of automation systems, international B2B buyers must navigate a complex array of options and considerations. This checklist serves as a practical guide to streamline the sourcing process, ensuring that you make informed decisions tailored to your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. Identify the specific functionalities and performance metrics you require, such as energy management, safety protocols, or remote monitoring capabilities. Be sure to consider integration with existing systems and compliance with local regulations, as these will significantly influence your overall system effectiveness.

Step 2: Conduct Market Research

Before engaging suppliers, conduct thorough market research to understand the current trends and technologies in automation systems. Look for industry reports, case studies, and reviews that highlight the performance of various systems. This knowledge will empower you to ask informed questions and identify potential suppliers that align with your requirements.

Step 3: Evaluate Potential Suppliers

Vetting suppliers is crucial to ensure you partner with reputable providers. Request detailed company profiles, including their experience, client testimonials, and case studies relevant to your industry. Assess their financial stability and technical expertise to mitigate risks associated with supplier reliability.

- Tip: Consider suppliers that have successfully implemented systems in similar markets or regions, as they will have a better understanding of your specific needs.

Step 4: Verify Certifications and Compliance

Ensure that potential suppliers possess the necessary certifications and comply with international standards. This is especially important in regions like Europe and the Middle East, where regulatory compliance is stringent. Certifications such as ISO 9001 for quality management and ISO 14001 for environmental management demonstrate a supplier’s commitment to quality and sustainability.

Step 5: Request Demonstrations and Trials

Before finalizing your decision, request live demonstrations or trial periods of the automation systems. This allows you to evaluate the system’s performance in real-world conditions and assess user-friendliness. Pay attention to the system’s adaptability, as well as the quality of customer support offered during the trial.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations regarding pricing, delivery timelines, and service agreements. Be clear about your expectations concerning maintenance, training, and support services. Ensure that the contract includes provisions for scalability, allowing for future upgrades as your needs evolve.

Step 7: Plan for Implementation and Training

Effective implementation is critical to the success of your automation system. Develop a comprehensive implementation plan that includes timelines, resource allocation, and risk management strategies. Additionally, ensure that adequate training is provided for your staff to maximize the system’s benefits and minimize operational disruptions.

By following this structured checklist, B2B buyers from Africa, South America, the Middle East, and Europe can confidently navigate the complexities of sourcing automation systems, ultimately leading to enhanced operational efficiency and competitive advantage.

Comprehensive Cost and Pricing Analysis for automation systems Sourcing

What Are the Key Cost Components in Automation Systems Sourcing?

When sourcing automation systems, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: This forms the bulk of the costs and includes components like sensors, controllers, actuators, and other hardware. The quality and source of these materials significantly affect the final price.

-

Labor: Labor costs encompass both direct labor (workers involved in assembly and installation) and indirect labor (supervisors and quality assurance personnel). In regions with higher wage standards, labor costs can substantially inflate the overall price.

-

Manufacturing Overhead: This includes utilities, rent, equipment depreciation, and other operational expenses incurred during the production process. Efficient manufacturing practices can help minimize these costs.

-

Tooling: Specific tooling may be required for custom automation solutions. The cost of these tools can be a significant factor, especially for bespoke projects.

-

Quality Control (QC): Ensuring that systems meet quality standards involves additional costs for testing and certification. This is particularly relevant for international buyers who may require compliance with specific industry standards.

-

Logistics: Shipping and handling costs can vary widely based on the geographic location of both the supplier and the buyer. Factors such as distance, mode of transport, and import/export regulations play a crucial role.

-

Margin: Suppliers will apply a markup to cover their costs and profit. This margin can vary based on the supplier’s pricing strategy and competitive landscape.

How Do Price Influencers Impact Automation Systems Costs?

Several factors can influence the pricing of automation systems. Understanding these can help buyers make informed decisions:

-

Volume/MOQ (Minimum Order Quantity): Generally, larger orders can lead to reduced per-unit costs due to economies of scale. Buyers should assess their needs carefully to avoid overcommitting.

-

Specifications and Customization: Custom solutions tailored to specific operational needs often come at a premium. Buyers should weigh the benefits of customization against standard solutions that may offer cost savings.

-

Materials and Quality Certifications: The choice of materials (e.g., high-grade vs. standard components) and the presence of certifications (like ISO or CE) can significantly affect pricing. Buyers should consider the long-term benefits of investing in higher-quality systems.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their track record, but they may also offer better service and product quality.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) can influence the total cost. Buyers should clarify responsibilities for shipping, insurance, and customs duties to avoid unexpected expenses.

What Are the Best Practices for Negotiating Automation Systems Pricing?

To secure the best pricing on automation systems, international buyers should consider the following strategies:

-

Research and Compare: Conduct thorough market research to understand standard pricing structures and identify competitive suppliers. This will provide leverage during negotiations.

-

Focus on Total Cost of Ownership (TCO): Buyers should look beyond the initial purchase price and consider long-term costs, including maintenance, operation, and potential downtime. This perspective can justify a higher upfront investment if it leads to lower operational costs.

-

Be Transparent About Needs: Clearly communicate your requirements and constraints to suppliers. This can foster collaboration and may lead to more favorable pricing options.

-

Leverage Volume Discounts: If feasible, consolidate purchases to maximize volume discounts. Suppliers are often willing to negotiate better rates for larger orders.

-

Negotiate Terms and Conditions: Be open to discussing payment terms, delivery schedules, and warranties. Flexible terms can sometimes offset higher initial costs.

What Should International Buyers Consider Regarding Pricing Nuances?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rate variations can impact costs significantly. Buyers should consider locking in rates or negotiating in a stable currency.

-

Import Tariffs and Duties: Understand the local regulations regarding tariffs and duties, as these can add substantial costs to imported systems.

-

Cultural Differences in Negotiation: Different regions may have varying negotiation styles. Familiarity with local customs and practices can facilitate smoother discussions.

-

Disclaimer on Indicative Prices: Pricing for automation systems can vary widely based on the factors discussed. Buyers should approach indicative prices as a starting point and expect variations based on specific project requirements and supplier negotiations.

By considering these insights, international B2B buyers can navigate the complexities of sourcing automation systems more effectively, leading to better decision-making and cost management.

Alternatives Analysis: Comparing automation systems With Other Solutions

Understanding Alternatives to Automation Systems

In the ever-evolving landscape of technology, international B2B buyers must weigh various solutions that can enhance operational efficiency and reduce costs. While automation systems are a popular choice for streamlining processes, there are other viable alternatives that may better suit specific needs or contexts. This section provides a comparative analysis of automation systems against collaborative robots (cobots) and manual processes, highlighting their distinct advantages and limitations.

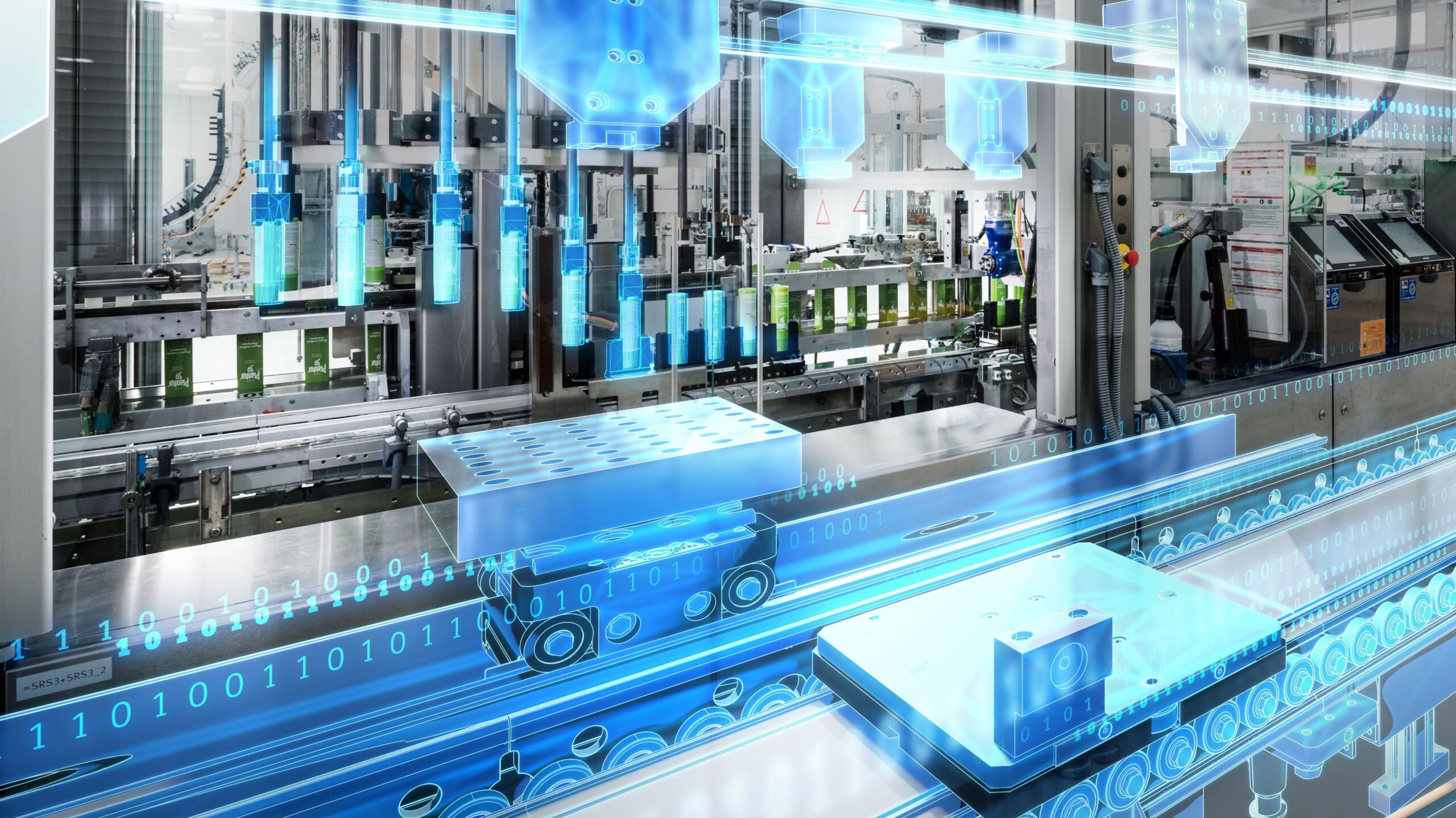

A stock image related to automation systems.

Comparison Table of Automation Systems and Alternatives

| Comparison Aspect | Automation Systems | Collaborative Robots (Cobots) | Manual Processes |

|---|---|---|---|

| Performance | High efficiency in repetitive tasks | Moderate efficiency, human assistance | Variable efficiency, dependent on skill |

| Cost | Higher initial investment | Moderate cost, lower than full automation | Low initial cost, but high ongoing labor costs |

| Ease of Implementation | Complex setup, requires expertise | Easier integration, user-friendly | Simple to implement, no technology needed |

| Maintenance | Requires specialized service | Low maintenance, user-managed | Minimal, but labor-intensive |

| Best Use Case | Large-scale production environments | Small to medium tasks alongside humans | Low-tech, personalized service settings |

Exploring Collaborative Robots (Cobots): What Are Their Benefits and Drawbacks?

A stock image related to automation systems.

Collaborative robots, or cobots, are designed to work alongside human operators, enhancing productivity without fully replacing human labor. These robots are particularly effective in environments where tasks require both precision and human touch. The benefits of cobots include their lower cost compared to full automation systems and their ease of implementation, which allows for quick integration into existing workflows. However, their performance may not match that of fully automated systems in high-volume production scenarios, and they may still require skilled human oversight for optimal results.

A stock image related to automation systems.

Evaluating Manual Processes: When Are They Appropriate?

Manual processes involve human labor for tasks traditionally handled by machines or automation systems. These methods boast low initial costs and can be implemented with minimal training or technology. They are particularly effective in settings that require customization and a personal touch, such as artisanal production or customer service. However, the downsides include variable efficiency and higher long-term labor costs, as reliance on human labor can lead to inconsistencies in output and increased risk of errors.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting between automation systems and their alternatives, B2B buyers must consider their specific operational needs, budget constraints, and the complexity of implementation. For organizations requiring high efficiency and consistency in large-scale operations, automation systems may be the best fit. Conversely, businesses looking for flexibility and lower upfront costs might find collaborative robots or manual processes more suitable. Ultimately, a thorough analysis of operational requirements and cost-benefit scenarios will guide buyers toward the most effective solution for their unique context.

Essential Technical Properties and Trade Terminology for automation systems

What Are the Essential Technical Properties of Automation Systems?

When purchasing automation systems, international B2B buyers should be well-acquainted with several critical technical properties that can significantly influence system performance and reliability. Here are some essential specifications to consider:

-

Material Grade

– Definition: The material grade refers to the composition and quality of materials used in the construction of automation components, such as sensors, actuators, and controllers.

– B2B Importance: High-quality materials enhance durability and performance, minimizing downtime and maintenance costs. Buyers should ensure that the materials meet industry standards, especially in harsh operational environments. -

Tolerance Levels

– Definition: Tolerance levels specify the permissible limits of variation in a physical dimension or measured value of a component.

– B2B Importance: Tight tolerance levels are crucial for ensuring precision in automated processes. For industries like manufacturing and pharmaceuticals, even minor deviations can lead to significant inefficiencies or product defects. -

Power Consumption

– Definition: Power consumption indicates the amount of electrical energy required for the operation of an automation system.

– B2B Importance: Understanding power requirements helps buyers assess operational costs and energy efficiency. Systems with lower power consumption not only reduce costs but also contribute to sustainability goals, which are increasingly important for global businesses. -

Response Time

– Definition: Response time measures how quickly an automation system can react to changes in input or environmental conditions.

– B2B Importance: Faster response times are essential in high-speed manufacturing environments where delays can lead to bottlenecks. Buyers should prioritize systems that can provide rapid adjustments to maintain productivity. -

Connectivity Options

– Definition: This refers to the types of communication protocols and interfaces supported by the automation system, such as Ethernet, Wi-Fi, or proprietary protocols.

– B2B Importance: A diverse range of connectivity options allows seamless integration with existing systems and future upgrades. Buyers should evaluate compatibility with Industry 4.0 standards to enhance interoperability.

What Are the Common Trade Terms in Automation Systems?

Understanding industry-specific jargon can facilitate smoother negotiations and transactions. Here are several key trade terms that B2B buyers should familiarize themselves with:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Engaging with OEMs can offer buyers access to high-quality components and systems tailored to specific needs, often at competitive prices. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding MOQ helps buyers plan their purchases effectively. Larger orders may lead to better pricing but require careful inventory management. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document that a buyer submits to suppliers to solicit price quotes for specific products or services.

– Importance: Issuing an RFQ allows buyers to compare prices and terms from multiple suppliers, ensuring they get the best deal. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that define responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risks, and costs, which is crucial for international transactions. -

Lead Time

– Definition: Lead time refers to the amount of time it takes from placing an order until the product is delivered.

– Importance: Knowing the lead time is essential for planning production schedules and inventory management. Buyers should account for lead times when sourcing automation systems to avoid production delays.

By understanding these essential technical properties and trade terminology, B2B buyers can make informed decisions that align with their operational needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the automation systems Sector

What Are the Key Trends Shaping the Automation Systems Market?

The automation systems sector is witnessing significant transformation driven by advancements in technology and changing market demands. Key global drivers include the need for operational efficiency, reduced labor costs, and increased productivity. In regions such as Africa, South America, the Middle East, and Europe, businesses are adopting automation to remain competitive in the global market. For instance, in Europe, industries are increasingly leveraging advanced robotics and Artificial Intelligence (AI) to enhance manufacturing processes, while in Africa, there is a growing trend towards using automation to improve agricultural productivity.

Current B2B tech trends include the rise of smart automation, which integrates IoT (Internet of Things) devices for real-time monitoring and control. This is particularly relevant for international buyers looking to enhance their operational capabilities. Furthermore, the shift towards cloud-based automation solutions allows businesses to scale their operations without significant upfront investments. Emerging sourcing trends highlight the importance of selecting suppliers who offer integrated solutions, which can streamline procurement processes and reduce lead times.

How Can Sustainability and Ethical Sourcing Impact Your Procurement Decisions?

As global attention shifts towards sustainability, B2B buyers in the automation systems sector must consider the environmental impact of their sourcing decisions. Automation systems often utilize materials and components that can contribute to waste and pollution if not sourced responsibly. Therefore, prioritizing suppliers with sustainable practices is crucial. This includes evaluating the lifecycle of products, from raw material extraction to end-of-life disposal.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers should seek suppliers who adhere to fair labor practices and have transparent sourcing policies. Certifications such as ISO 14001 for environmental management systems and others focused on ethical production can serve as indicators of a supplier’s commitment to sustainability. By aligning with suppliers who prioritize ‘green’ materials and practices, businesses not only enhance their brand reputation but also contribute to global sustainability efforts.

How Has the Automation Systems Sector Evolved Over Time?

The evolution of automation systems can be traced back to the industrial revolution, where mechanization first transformed manufacturing processes. Over the decades, advancements in technology have led to the introduction of programmable logic controllers (PLCs) and robotics, which significantly increased efficiency and precision in production. In recent years, the integration of AI and machine learning has further revolutionized the sector, allowing for predictive maintenance and enhanced data analytics.

For international B2B buyers, understanding this historical context is essential as it underscores the rapid pace of innovation within the sector. Today’s automation solutions are not merely tools for efficiency; they represent a strategic investment in a company’s future resilience and competitiveness. As such, buyers should stay informed about ongoing technological advancements and their implications for sourcing decisions in the automation systems market.

Frequently Asked Questions (FAQs) for B2B Buyers of automation systems

-

How do I solve issues related to the integration of automation systems in my existing infrastructure?

To address integration challenges, start by conducting a thorough assessment of your current systems and identifying compatibility requirements. Collaborate with your automation supplier to ensure they provide support for integration with legacy systems. Additionally, consider modular automation solutions that allow gradual implementation, which can ease the transition. Comprehensive training for your team will also enhance the integration process, enabling smoother operations and minimizing downtime. -

What is the best automation system for small to medium-sized enterprises (SMEs)?

The best automation system for SMEs often depends on specific operational needs and budget constraints. Cloud-based automation solutions are highly recommended as they offer scalability, lower upfront costs, and remote access. Look for systems that provide essential features such as inventory management, process automation, and data analytics. Additionally, ensure that the chosen system can grow with your business, allowing for future upgrades without significant investment. -

How can I ensure the quality of automation systems when sourcing from international suppliers?

To ensure quality, start by vetting suppliers through certifications such as ISO 9001 or industry-specific standards. Request product samples and conduct on-site inspections if possible. Establish clear quality assurance (QA) protocols, including testing procedures and performance benchmarks. Additionally, leverage third-party quality assessment services to provide an unbiased evaluation before making a bulk purchase. -

What are the typical minimum order quantities (MOQs) for automation systems?

Minimum order quantities for automation systems can vary widely based on the supplier and product type. Generally, MOQs for custom automation solutions tend to be higher, ranging from 50 to 100 units, while standardized components may have lower MOQs. Always inquire directly with suppliers about their MOQs to understand pricing implications and negotiate terms that suit your purchasing needs. -

What payment terms should I consider when purchasing automation systems internationally?

Common payment terms in international B2B transactions include letters of credit, wire transfers, and payment upon delivery. Negotiate terms that provide both parties with security; for instance, consider using escrow services for larger orders. Ensure you understand the payment schedule, currency fluctuations, and any additional fees that may arise from international transactions to avoid unexpected costs. -

How do I manage logistics and shipping for automation systems sourced from different countries?

Effective logistics management involves selecting reliable freight forwarders with experience in handling automation systems. Consider factors such as shipping routes, customs regulations, and potential tariffs specific to your country. Additionally, keep open lines of communication with suppliers to coordinate shipping timelines and track shipments. Utilizing technology such as logistics management software can further streamline the process and provide real-time updates. -

What customization options should I look for in automation systems?

When considering automation systems, look for suppliers that offer flexible customization options tailored to your specific operational needs. Key areas for customization may include software configurations, hardware specifications, and interface designs. Ensure that the supplier can accommodate changes in response to evolving business requirements, and inquire about the lead times and costs associated with these customizations. -

How can I assess the long-term support and service capabilities of automation system suppliers?

Evaluating a supplier’s long-term support capabilities involves investigating their customer service reputation, warranty policies, and availability of technical support. Request references from existing clients to gauge their satisfaction with post-purchase support. Additionally, inquire about training programs, maintenance services, and upgrade options, ensuring the supplier is committed to providing ongoing assistance to maximize your automation investment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for automation systems

What Are the Key Takeaways for B2B Buyers in Automation Systems?

In an era where efficiency and innovation drive competitiveness, strategic sourcing of automation systems is paramount for international B2B buyers. Understanding the diverse range of automation technologies—from collaborative robots to advanced sensor systems—enables companies to select solutions tailored to their unique operational needs. The convergence of affordability and technological advancement allows businesses in Africa, South America, the Middle East, and Europe to leverage automation for enhanced productivity and cost savings.

How Can Strategic Sourcing Enhance Your Business Operations?

Investing in automation systems not only streamlines processes but also mitigates risks associated with human error and labor shortages. By adopting a strategic sourcing approach, buyers can identify reputable suppliers, negotiate favorable terms, and ensure the integration of cutting-edge technologies that align with their goals.

What Is the Future Outlook for Automation Systems?

Looking ahead, the automation landscape will continue to evolve, driven by advancements in artificial intelligence and data analytics. International B2B buyers are encouraged to stay informed and agile, embracing these innovations to maintain a competitive edge. Take the next step in your automation journey—evaluate your current systems and consider how strategic sourcing can transform your operations for the future.