Cut Costs with High Pressure Boiler Insights (2025)

Introduction: Navigating the Global Market for high pressure boiler

Navigating the complexities of sourcing high-pressure boilers can be a daunting task for international B2B buyers, especially when considering the unique industrial requirements across diverse regions like Africa, South America, the Middle East, and Europe. High-pressure boilers play a crucial role in various applications, from food processing to power generation, making it essential for businesses to understand the nuances of their specifications, performance, and operational safety. This comprehensive guide delves into the different types of high-pressure boilers, their applications, and the latest technologies that enhance efficiency and sustainability.

In this guide, you will find detailed insights on how to vet suppliers effectively, understand the cost implications, and assess the regulatory compliance specific to your region. By addressing critical questions such as “What are the key features to look for in a high-pressure boiler?” and “How do different types of boilers impact operational efficiency?”, we empower you to make informed purchasing decisions that align with your business goals.

Whether you are seeking to enhance production capabilities or comply with stringent environmental standards, this guide serves as an invaluable resource for international B2B buyers. Equip yourself with the knowledge to navigate the global market for high-pressure boilers, ensuring that your investment not only meets immediate operational needs but also contributes to long-term sustainability and profitability.

Understanding high pressure boiler Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fire-Tube Boiler | Hot gases pass through tubes surrounded by water. | Power generation, manufacturing, food processing. | Pros: Lower initial cost, easier maintenance. Cons: Lower efficiency compared to water-tube boilers. |

| Water-Tube Boiler | Water circulates through tubes heated by combustion. | Chemical processing, textile manufacturing. | Pros: Higher efficiency, suitable for high pressures. Cons: Higher initial cost, more complex maintenance. |

| Electric Steam Boiler | Uses electric heating elements instead of fuel. | Hospitals, laboratories, and small-scale industries. | Pros: No emissions, compact design. Cons: Higher operating costs, limited steam output. |

| Biomass Boiler | Burns organic materials for steam generation. | Renewable energy applications, agricultural sectors. | Pros: Eco-friendly, reduces waste. Cons: Requires fuel supply management, potential for higher maintenance. |

| Modular Boiler | Comprises multiple smaller boilers for scalability. | Large facilities needing flexible steam solutions. | Pros: Easy to scale, quick installation. Cons: Potentially higher upfront costs, requires more space. |

What Are the Characteristics of Fire-Tube Boilers?

Fire-tube boilers are characterized by their design where hot gases from combustion flow through tubes that are surrounded by water. This design is typically favored in applications requiring moderate steam pressures and is widely used in industries such as power generation and food processing. When considering a fire-tube boiler, buyers should evaluate the initial cost and ease of maintenance, as they are generally less complex but may not offer the same efficiency as other types.

How Do Water-Tube Boilers Differ in Performance?

Water-tube boilers circulate water through tubes that are heated by external combustion gases, allowing for higher pressures and steam generation efficiency. They are particularly suitable for industries like chemical processing and textiles, where high-pressure steam is necessary. Buyers should consider the higher initial investment and complexity in maintenance but can benefit from improved performance and efficiency, especially in demanding applications.

What Advantages Do Electric Steam Boilers Offer?

Electric steam boilers utilize electric heating elements, providing a clean and compact solution for steam generation. They are ideal for settings like hospitals and laboratories where emissions are a concern. While they have the advantage of being environmentally friendly and easier to install, buyers should weigh the higher operating costs and limited output capacity when making purchasing decisions.

Why Choose Biomass Boilers for Sustainable Operations?

Biomass boilers leverage organic materials to generate steam, making them a sustainable choice for industries focused on reducing their carbon footprint. They are commonly used in renewable energy applications and agricultural sectors. Buyers should consider the benefits of waste reduction and eco-friendliness, but also keep in mind the need for effective fuel supply management and potential maintenance challenges.

What Are the Key Benefits of Modular Boilers?

Modular boilers consist of multiple smaller units, allowing for flexible steam generation that can be easily scaled to meet varying demands. This design is particularly advantageous for large facilities that require adaptability. While they can offer quick installation and scalability, buyers should be prepared for potentially higher upfront costs and the need for additional space to accommodate multiple units.

Key Industrial Applications of high pressure boiler

| Industry/Sector | Specific Application of High Pressure Boiler | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Steam generation for cooking, sterilization, and cleaning | Ensures food safety and quality, reduces processing time | Compliance with food safety standards, energy efficiency, and reliability |

| Chemical Manufacturing | Providing heat for chemical reactions and distillation processes | Enhances reaction rates and yields, reduces production costs | Material compatibility, pressure ratings, and safety features |

| Pharmaceuticals | Sterilization of equipment and production processes | Guarantees product integrity and compliance with regulations | Quality certifications, low emissions, and operational efficiency |

| Textiles | Dyeing and finishing processes requiring high steam pressure | Improves dyeing quality and reduces water usage | Flexibility in capacity, energy source options, and maintenance support |

| Power Generation | Steam generation for turbines in power plants | Increases energy output and operational efficiency | Boiler size, fuel type compatibility, and environmental impact |

How is High Pressure Boiler Used in the Food and Beverage Industry?

In the food and beverage sector, high pressure boilers are crucial for steam generation used in cooking, sterilization, and cleaning processes. These boilers provide the necessary high-temperature steam required to effectively sterilize equipment and ensure food safety, which is paramount in this industry. For international buyers, particularly from regions like Africa and South America, sourcing boilers that comply with local food safety regulations is essential. Additionally, energy efficiency becomes a key consideration, as it can significantly impact operational costs.

What Role Does High Pressure Boiler Play in Chemical Manufacturing?

High pressure boilers are integral to chemical manufacturing, where they supply heat for various processes, including chemical reactions and distillation. The ability to operate at high pressures enhances reaction rates and improves product yields, making operations more cost-effective. Buyers in the Middle East and Europe should focus on sourcing boilers that are compatible with the specific chemicals being processed, ensuring material durability and safety. Moreover, compliance with international safety standards is critical to avoid costly disruptions.

Why are High Pressure Boilers Important in Pharmaceuticals?

In the pharmaceutical industry, high pressure boilers are essential for sterilizing equipment and ensuring the integrity of production processes. The high-temperature steam produced is vital for meeting stringent health regulations and maintaining product quality. International B2B buyers should prioritize sourcing boilers with certifications that meet global pharmaceutical standards, as well as those that offer low emissions and high operational efficiency to align with environmental regulations prevalent in Europe and the UAE.

How Do High Pressure Boilers Benefit the Textile Industry?

High pressure boilers are utilized in the textile industry for dyeing and finishing processes that require high steam pressure. This application not only improves the quality of dyeing but also helps in reducing water consumption, which is increasingly important in water-scarce regions. Buyers from Africa and South America should consider boilers that offer flexible capacity options and can accommodate different fuel types, as this can enhance operational efficiency and sustainability.

What is the Role of High Pressure Boilers in Power Generation?

In power generation, high pressure boilers are vital for producing steam that drives turbines. This application increases energy output and enhances the overall efficiency of power plants. For international buyers, particularly in regions with rapidly growing energy demands, sourcing appropriately sized boilers that can handle various fuel types while minimizing environmental impact is critical. Additionally, considering the boiler’s design for easy maintenance can lead to significant long-term operational savings.

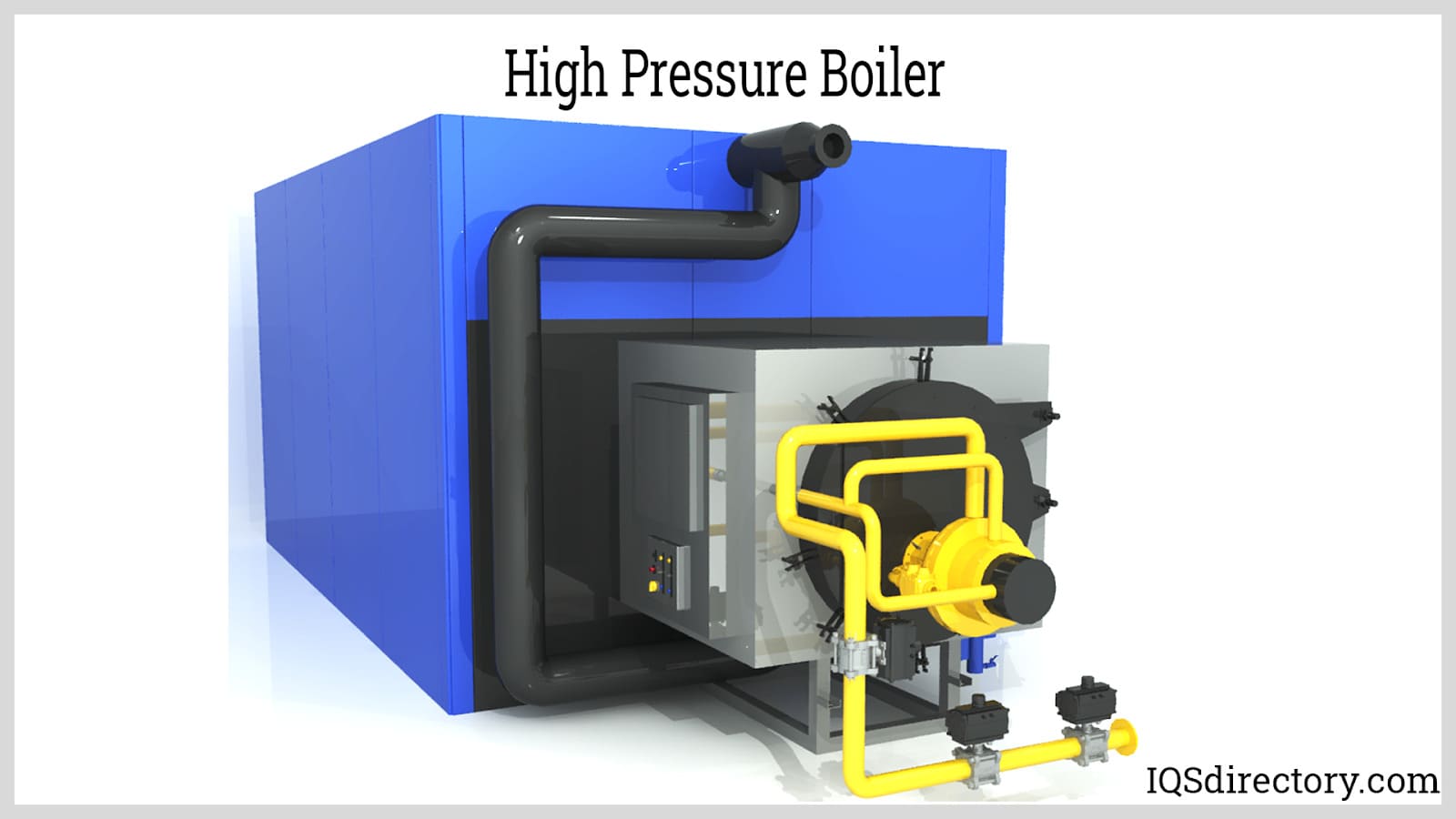

A stock image related to high pressure boiler.

3 Common User Pain Points for ‘high pressure boiler’ & Their Solutions

Scenario 1: Navigating Compliance with Local Boiler Regulations

The Problem: B2B buyers in regions like Africa, South America, and the Middle East often face the challenge of ensuring their high-pressure boilers comply with local regulations. Each country has its own set of boiler operation standards, which can vary significantly. Failing to comply can lead to hefty fines, operational shutdowns, or even legal action. Buyers may feel overwhelmed by the complexity of these regulations and the potential implications for their business.

The Solution: To navigate compliance effectively, it is crucial to engage with local boiler manufacturers or suppliers who are well-versed in regional regulations. Buyers should conduct thorough research on the specific requirements in their country and industry. This includes understanding the maximum allowable working pressure (MAWP) standards, safety valve requirements, and inspection intervals. Additionally, consider partnering with a compliance consultant who specializes in boiler operations to ensure that all aspects of the boiler installation and operation meet local standards. Regular training for staff on compliance requirements will also mitigate risks and enhance operational safety.

Scenario 2: Managing Operational Efficiency and Downtime

The Problem: High-pressure boilers are often critical to industrial operations, and unexpected downtime can lead to significant production losses. B2B buyers may experience challenges related to the efficiency of their boiler systems, such as slow start-up times or frequent maintenance needs. This not only affects productivity but can also inflate operational costs, especially in industries like food processing or manufacturing where steam is essential.

The Solution: To manage operational efficiency, buyers should invest in modern high-pressure boiler technology that emphasizes quick start-up capabilities and low water volume designs. When selecting a boiler, look for models that offer rapid steam generation—ideally capable of going from cold to full steam in under ten minutes. Additionally, implementing a predictive maintenance strategy can help identify potential issues before they lead to downtime. This includes regular monitoring of pressure levels, temperature, and water quality. Investing in smart monitoring systems can provide real-time data to help detect anomalies, allowing for timely intervention.

Scenario 3: Reducing Environmental Impact and Energy Costs

The Problem: With increasing pressure to reduce carbon footprints, many B2B buyers are concerned about the environmental impact of their high-pressure boilers. Traditional boiler systems can be inefficient, leading to excessive fuel consumption and higher emissions. Buyers are often caught between the need for efficiency and the desire to meet environmental regulations, which can create tension in procurement decisions.

The Solution: To address these environmental concerns, buyers should prioritize high-efficiency boiler models that are designed with sustainability in mind. Look for boilers that have low NOx emissions and high fuel efficiency ratings. Additionally, consider integrating renewable energy sources, such as biomass or solar thermal systems, into your steam generation process. Conducting a life cycle assessment (LCA) can help buyers understand the environmental impact of different boiler options and guide them towards more sustainable choices. Engaging with suppliers who offer energy audits can also uncover opportunities for improving energy efficiency and reducing overall operational costs. By adopting a holistic approach to boiler selection and operation, businesses can meet both their efficiency goals and environmental obligations.

Strategic Material Selection Guide for high pressure boiler

What Are the Common Materials Used in High Pressure Boilers?

When selecting materials for high-pressure boilers, it is essential to consider various factors, including mechanical properties, corrosion resistance, and compatibility with the intended application. Here, we analyze four common materials used in high-pressure boiler construction, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Carbon Steel Perform in High Pressure Boilers?

Key Properties:

Carbon steel is a widely used material in high-pressure boiler construction due to its excellent tensile strength and ability to withstand high temperatures and pressures. It typically has a maximum allowable working pressure (MAWP) above 15 PSI, making it suitable for various industrial applications.

Pros & Cons:

Carbon steel offers a good balance of durability and cost-effectiveness. It is relatively inexpensive compared to other materials like stainless steel. However, it is prone to corrosion and requires protective coatings or treatments to enhance its longevity, especially in humid or corrosive environments.

Impact on Application:

Carbon steel is compatible with water and steam but may not perform well in environments with aggressive chemicals. Its susceptibility to corrosion can lead to failures, making regular maintenance crucial.

Considerations for International Buyers:

Buyers from regions like Africa and the Middle East should ensure compliance with local standards such as ASTM A106 or DIN 17175. In Europe, the EN 10028 standard is often referenced. Understanding local regulations can help mitigate risks associated with material selection.

What Role Does Stainless Steel Play in High Pressure Boilers?

Key Properties:

Stainless steel is known for its exceptional corrosion resistance and ability to maintain structural integrity at high temperatures. It can withstand pressures significantly above 15 PSI, making it ideal for high-pressure applications.

Pros & Cons:

The key advantage of stainless steel is its durability and resistance to rust and corrosion, which reduces maintenance costs over time. However, it is more expensive than carbon steel and may require specialized welding techniques, increasing manufacturing complexity.

Impact on Application:

Stainless steel is suitable for applications involving steam and water, as well as more aggressive media like chemicals. Its corrosion resistance makes it a preferred choice in industries such as food processing and pharmaceuticals.

Considerations for International Buyers:

Buyers should look for compliance with standards such as ASTM A312 or JIS G3463. In regions like South America, understanding the local supply chain for stainless steel can help reduce lead times and costs.

Why Is Alloy Steel Important for High Pressure Boiler Applications?

Key Properties:

Alloy steel combines carbon steel with other elements like chromium, molybdenum, and nickel to enhance its mechanical properties. It is designed to withstand high temperatures and pressures, making it suitable for high-pressure boiler applications.

Pros & Cons:

The primary advantage of alloy steel is its enhanced strength and resistance to thermal fatigue. However, the cost of alloy steel is generally higher than that of carbon steel, and it may require specific fabrication methods, which can complicate manufacturing.

Impact on Application:

Alloy steel is ideal for applications that involve high-pressure steam and require resistance to thermal shock. It is commonly used in power generation and petrochemical industries.

Considerations for International Buyers:

Understanding compliance with ASTM A335 or DIN 17175 standards is crucial for buyers in Europe and the Middle East. Additionally, buyers should consider the availability of alloy steel in their region to ensure timely procurement.

How Does Copper Contribute to High Pressure Boiler Efficiency?

Key Properties:

Copper is known for its excellent thermal conductivity and resistance to corrosion. While not typically used for the entire boiler structure, it is often employed in components like heat exchangers and piping.

Pros & Cons:

The key advantage of copper is its high thermal efficiency, which can improve the overall performance of a high-pressure boiler. However, copper is more expensive than steel and may not be suitable for high-pressure applications alone.

Impact on Application:

Copper is particularly effective in applications requiring rapid heat transfer. It is compatible with water and steam but may not perform well in environments with high levels of sulfur or chlorine.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM B280 or JIS H3300. In regions like Europe, understanding the local market for copper can help in sourcing high-quality materials.

Summary Table of Material Selection for High Pressure Boilers

| Material | Typical Use Case for High Pressure Boiler | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General industrial applications | Cost-effective and durable | Prone to corrosion | Low |

| Stainless Steel | Food processing, pharmaceuticals | Exceptional corrosion resistance | Higher cost and complex fabrication | High |

| Alloy Steel | Power generation, petrochemical industries | Enhanced strength and thermal resistance | Higher cost and specific manufacturing | Medium |

| Copper | Heat exchangers, piping | High thermal conductivity | Expensive and limited high-pressure use | High |

A stock image related to high pressure boiler.

This strategic material selection guide provides international B2B buyers with a comprehensive understanding of the materials used in high-pressure boilers, enabling informed decision-making tailored to their specific operational needs and regulatory environments.

In-depth Look: Manufacturing Processes and Quality Assurance for high pressure boiler

What are the Main Stages of Manufacturing High Pressure Boilers?

The manufacturing of high pressure boilers involves several critical stages, each designed to ensure that the final product meets stringent performance and safety standards. The primary stages of manufacturing include material preparation, forming, assembly, and finishing.

How is Material Prepared for High Pressure Boiler Manufacturing?

Material preparation begins with the selection of high-quality steel, typically carbon or alloy steel, which is essential for the strength and durability of the boiler. The selected materials undergo rigorous testing for chemical composition and mechanical properties to ensure they meet international standards such as ASTM (American Society for Testing and Materials).

Once the materials are certified, they are cut and shaped into components using advanced techniques such as laser cutting and plasma cutting. This precision in material preparation is crucial for minimizing waste and ensuring that each piece fits perfectly during assembly.

What Forming Techniques Are Used in High Pressure Boiler Production?

The forming stage involves shaping the prepared materials into their final configurations. Common techniques include:

- Rolling: Steel plates are rolled into cylindrical shapes, which are fundamental for the boiler shell.

- Welding: Automated and manual welding processes are employed to join components. Techniques such as TIG (Tungsten Inert Gas) welding are favored for their precision and ability to produce strong, leak-proof joints.

- Bending and Pressing: For specific parts, bending and pressing techniques are utilized to achieve the necessary angles and contours.

These forming techniques ensure that the boiler can withstand high pressures and temperatures during operation.

What is the Assembly Process for High Pressure Boilers?

The assembly stage is where all individual components come together. Key steps in this process include:

- Component Assembly: Major components such as the boiler shell, tubes, and headers are aligned and secured.

- Installation of Safety Features: Safety valves and control systems are integrated to ensure that the boiler operates within safe parameters.

- Insulation Application: Insulation materials are added to enhance energy efficiency and maintain optimal operating temperatures.

Attention to detail during assembly is crucial, as any misalignment can lead to operational inefficiencies or safety hazards.

How is the Finishing Process Conducted for High Pressure Boilers?

The finishing stage involves several steps aimed at enhancing the boiler’s performance and longevity. This includes:

- Surface Treatment: Techniques such as shot blasting or sandblasting are used to remove impurities and prepare the surface for coating.

- Coating Application: High-quality paints or anti-corrosive coatings are applied to protect the boiler from environmental factors.

- Final Inspection: A thorough inspection is conducted to ensure that all components meet quality standards and specifications.

This finishing process not only improves the boiler’s aesthetics but also extends its service life.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance in the manufacturing of high pressure boilers is paramount, especially for international B2B buyers. Adhering to recognized standards ensures that the product will operate safely and efficiently.

Which International Standards Are Relevant for High Pressure Boilers?

- ISO 9001: This standard focuses on quality management systems and emphasizes customer satisfaction, process efficiency, and continual improvement.

- CE Marking: For buyers in Europe, the CE mark indicates compliance with EU safety, health, and environmental requirements.

- API Standards: The American Petroleum Institute (API) provides guidelines specifically for boilers used in the oil and gas industry, ensuring that they meet rigorous safety and performance criteria.

Understanding these standards is essential for ensuring that the boilers purchased will meet local and international regulations.

What are the Key Quality Control Checkpoints in High Pressure Boiler Manufacturing?

Quality control (QC) checkpoints play a critical role in maintaining the integrity of high pressure boilers throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified standards before processing begins.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is conducted to identify any deviations from quality standards. This includes inspection of welds, dimensions, and assembly accuracy.

- Final Quality Control (FQC): Once the boiler is fully assembled, a final inspection is performed. This includes pressure testing to ensure that the boiler can withstand its rated pressure without leaks.

These QC checkpoints help identify issues early, preventing costly rework and ensuring compliance with safety standards.

What Testing Methods Are Commonly Used for High Pressure Boilers?

Testing is an integral part of quality assurance in high pressure boiler manufacturing. Common testing methods include:

- Hydrostatic Testing: This method involves filling the boiler with water and pressurizing it to check for leaks and structural integrity.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and radiography are employed to inspect welds and materials without damaging them.

- Performance Testing: Boilers are tested under operational conditions to ensure they meet efficiency and performance specifications.

These testing methods provide assurance to B2B buyers that the boilers are safe and reliable.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is crucial. Here are actionable steps:

- Supplier Audits: Conduct regular audits of the manufacturer’s facilities to assess their quality control processes and compliance with international standards.

- Request Documentation: Ask for quality assurance reports, including IQC, IPQC, and FQC records, to understand their quality management practices.

- Third-Party Inspection: Engage independent third-party inspection services to verify compliance with relevant standards and conduct additional testing if necessary.

These steps ensure that buyers can trust their suppliers to deliver high-quality, safe, and efficient high pressure boilers.

What Are the QC and Certification Nuances for International B2B Buyers?

When navigating the international market for high pressure boilers, buyers should be aware of specific nuances related to quality control and certification:

- Regional Regulations: Different regions may have unique regulations that affect boiler specifications, such as emissions standards in Europe (EN standards) and safety regulations in the Middle East (GSO standards).

- Documentation Requirements: Ensure that all certifications and quality assurance documentation are readily available and translated if necessary, to facilitate compliance checks in your region.

- Cultural Considerations: Understanding local business practices and communication styles can enhance negotiations and ensure a smoother procurement process.

By being informed about these nuances, international B2B buyers can make better purchasing decisions and foster successful supplier relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘high pressure boiler’

In the competitive landscape of industrial operations, sourcing a high-pressure boiler requires careful consideration and strategic planning. This guide provides a practical checklist to assist international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, in making informed decisions when procuring high-pressure boilers.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial before engaging with suppliers. Determine the maximum allowable working pressure (MAWP) that your operations will require, as well as the steam output capacity and efficiency ratings. Understanding these parameters will help you narrow down your options and ensure that the selected boiler meets your operational demands.

Step 2: Research Compliance and Regulatory Standards

Different regions have specific regulations governing boiler operations. Research local compliance requirements in your country or region, including safety standards and emissions regulations. Ensure that any potential boiler meets these standards, as non-compliance can lead to costly fines and operational disruptions.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their reputation in the market by looking for reviews and testimonials, and verify their experience with high-pressure boilers to ensure reliability.

Step 4: Verify Supplier Certifications and Quality Assurance

Ensure that your chosen supplier holds relevant certifications, such as ISO 9001 or ASME certifications. These certifications indicate adherence to quality management standards and industry best practices. Additionally, inquire about their quality assurance processes to confirm that they employ rigorous testing and inspection methods during manufacturing.

Step 5: Analyze Energy Efficiency and Environmental Impact

High-pressure boilers can significantly impact operational costs and environmental footprint. Evaluate the energy efficiency ratings of potential models and inquire about advanced features that enhance sustainability, such as low NOx emissions. Consider suppliers that offer boilers designed to minimize energy consumption while maximizing output.

Step 6: Request Quotes and Compare Pricing

Once you have narrowed down your options, request detailed quotes from multiple suppliers. Ensure that quotes include all associated costs, such as installation, shipping, and maintenance. Compare not only the prices but also the value offered, such as warranty terms, after-sales support, and additional services.

Step 7: Plan for Installation and Maintenance Support

Installation and ongoing maintenance are critical components of boiler operation. Confirm that your supplier provides comprehensive installation services and training for your team. Additionally, discuss the availability of maintenance contracts and the supplier’s capacity to provide timely support and spare parts as needed.

By following this step-by-step checklist, international B2B buyers can ensure that they make informed, strategic decisions when sourcing high-pressure boilers, ultimately leading to enhanced operational efficiency and compliance.

Comprehensive Cost and Pricing Analysis for high pressure boiler Sourcing

What Are the Key Cost Components in Sourcing High Pressure Boilers?

When sourcing high pressure boilers, understanding the comprehensive cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials such as steel, insulation, and various components can significantly influence the overall price. High-quality materials may incur a higher upfront cost but can lead to increased durability and lower maintenance expenses.

-

Labor: Skilled labor is necessary for the manufacturing process, and labor costs can vary widely depending on the region. For buyers in Africa and South America, it is crucial to consider local labor rates and expertise when evaluating potential suppliers.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and administrative expenses. Suppliers with efficient manufacturing processes may offer more competitive pricing.

-

Tooling: Specialized tooling for the production of high pressure boilers can be a considerable investment. Buyers should inquire about the tooling costs as they may be incorporated into the overall price.

-

Quality Control (QC): Rigorous quality control processes are vital in ensuring that boilers meet safety and performance standards. Suppliers that invest in comprehensive QC may have higher prices, but this can lead to long-term savings by reducing the likelihood of defects and failures.

-

Logistics: Shipping costs, including freight and insurance, are significant for international buyers. Understanding the logistics involved in transporting heavy equipment like high pressure boilers can help in negotiating better terms.

-

Margin: Finally, the supplier’s profit margin will affect the final price. Different suppliers may have varying margins based on their market positioning and operational efficiencies.

What Influences Pricing for High Pressure Boilers?

Several factors can influence the pricing of high pressure boilers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders may qualify for bulk pricing discounts. Buyers should assess their needs and consider negotiating for better rates based on projected usage.

-

Specifications and Customization: Custom features or specifications will typically result in higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Boilers that meet specific industry standards or certifications (such as ASME) may carry a premium price. However, this investment can lead to enhanced reliability and compliance with regulatory requirements.

-

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers may charge more but offer better service and support.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) involved in the transaction is crucial. Different terms can affect pricing by determining who bears the cost of shipping, insurance, and customs duties.

What Buyer Tips Can Enhance Cost-Efficiency in High Pressure Boiler Sourcing?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Engaging in open negotiations with suppliers can lead to better pricing. Buyers should be prepared to discuss terms and express their needs clearly.

-

Total Cost of Ownership (TCO): Assessing the TCO rather than just the upfront cost can provide a clearer picture of the financial implications of a purchase. This includes maintenance, operational efficiency, and potential downtime costs.

-

Understanding Pricing Nuances: Each region may have unique pricing structures based on local market conditions, currency fluctuations, and regulatory environments. Buyers should conduct thorough market research to understand these nuances.

-

Supplier Diversification: Relying on multiple suppliers can create competitive pressure, leading to better pricing and terms. This strategy also mitigates risks associated with supply chain disruptions.

Conclusion: What Should Buyers Consider Regarding Indicative Prices?

While indicative prices for high pressure boilers can provide a baseline for budgeting, they should be treated as starting points. Factors such as market demand, material availability, and geopolitical influences can lead to fluctuations in pricing. Buyers should remain flexible and engage in continuous dialogue with suppliers to secure the best possible terms for their high pressure boiler sourcing needs.

Alternatives Analysis: Comparing high pressure boiler With Other Solutions

When considering the optimal solution for steam generation in industrial applications, it’s crucial to evaluate high-pressure boilers against other viable technologies. Each solution has its own set of advantages and disadvantages that can affect operational efficiency, cost, and suitability for specific applications. Below, we compare high-pressure boilers with two alternatives: low-pressure boilers and electric steam generators.

| Comparison Aspect | High Pressure Boiler | Low Pressure Boiler | Electric Steam Generator |

|---|---|---|---|

| Performance | High efficiency, rapid steam generation | Suitable for heating and limited processes | Instant steam generation, no emissions |

| Cost | Higher initial investment, long-term savings | Lower initial cost, higher operating cost | Moderate initial cost, low operating cost |

| Ease of Implementation | Requires skilled operators and regulatory compliance | Easier installation, fewer regulations | Simple installation, minimal training required |

| Maintenance | Higher maintenance needs due to pressure | Generally lower maintenance requirements | Minimal maintenance, fewer components |

| Best Use Case | Heavy industrial applications, high demand | Commercial heating, small-scale processes | Situations with limited space, low demand |

What Are the Pros and Cons of Low Pressure Boilers Compared to High Pressure Boilers?

Low-pressure boilers operate below 15 psi, making them a more economical choice for certain applications. They are particularly beneficial for heating large buildings or providing hot water to facilities such as hospitals and schools. The lower operational pressure means reduced wear and tear on components, which can lead to lower maintenance costs. However, they may not be suitable for high-demand industrial processes that require quick and significant steam output, limiting their versatility.

How Do Electric Steam Generators Compare to High Pressure Boilers?

Electric steam generators are an increasingly popular alternative due to their ability to produce steam on demand without the need for fuel combustion. They are especially advantageous in environments with strict emissions regulations. The installation process is typically straightforward, and they require minimal maintenance. However, electric steam generators may not be as cost-effective for larger operations due to higher electricity costs compared to conventional fuels. They are best suited for applications with lower steam requirements and space constraints.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Choosing the right steam generation solution depends on several factors including operational needs, budget constraints, and environmental considerations. High-pressure boilers are ideal for industries requiring high efficiency and rapid steam generation, making them suitable for manufacturing and heavy industries. In contrast, low-pressure boilers offer a cost-effective solution for commercial heating needs, while electric steam generators present an environmentally friendly option for smaller operations with limited space. By thoroughly assessing these factors, international B2B buyers from regions like Africa, South America, the Middle East, and Europe can make informed decisions that align with their operational goals and sustainability objectives.

Essential Technical Properties and Trade Terminology for high pressure boiler

What Are the Essential Technical Properties of High Pressure Boilers?

When evaluating high pressure boilers for industrial applications, understanding specific technical properties is crucial. Here are some key specifications that international B2B buyers should consider:

-

Maximum Allowable Working Pressure (MAWP)

– Definition: This is the maximum pressure at which a boiler can safely operate. For high pressure boilers, MAWP typically exceeds 15 psi.

– B2B Importance: Knowing the MAWP helps ensure compliance with safety regulations and informs operational capacities. For industries in sectors like manufacturing and energy, a higher MAWP can translate into greater efficiency and productivity. -

Material Grade

– Definition: High pressure boilers are often constructed from materials such as carbon steel or alloy steel, which can withstand elevated temperatures and pressures.

– B2B Importance: The choice of material affects durability, maintenance requirements, and overall lifecycle costs. Buyers should prioritize materials that meet or exceed industry standards to mitigate risks associated with boiler failure. -

Efficiency Rating

– Definition: This refers to the boiler’s ability to convert fuel into usable energy, often expressed as a percentage.

– B2B Importance: Higher efficiency ratings mean lower operational costs and reduced environmental impact. For companies in regions with strict emissions regulations, investing in high-efficiency boilers can lead to significant savings and compliance advantages. -

Heat Transfer Surface Area

– Definition: The total area available for heat exchange between the combustion gases and the water/steam in the boiler.

– B2B Importance: A larger heat transfer surface area generally allows for more effective heating, leading to improved steam output and operational efficiency. This is particularly important for industries requiring rapid steam generation for processes. -

Safety Features

– Definition: These include pressure relief valves, low-water cutoffs, and automatic controls designed to prevent accidents.

– B2B Importance: Safety features are critical in protecting personnel and assets. B2B buyers must ensure that the boilers they invest in have robust safety mechanisms to comply with local regulations and enhance operational safety.

What Are Common Trade Terms Associated with High Pressure Boilers?

Understanding industry jargon can streamline negotiations and ensure clear communication. Here are several common terms that buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Engaging with OEMs can ensure high-quality components and reliable support, which is essential for maintenance and parts replacement. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding MOQ is crucial for budgeting and inventory management. It helps buyers negotiate better terms or make informed decisions about purchasing frequency. -

RFQ (Request for Quotation)

– Definition: A document used to solicit price quotes from suppliers for specific products or services.

– Importance: An RFQ enables buyers to compare prices and terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international rules that clarify the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risks, and costs, which is vital for accurate budgeting and logistical planning. -

Lead Time

– Definition: The time taken from placing an order to receiving the product.

– Importance: Knowing lead times is essential for project planning and ensuring that operations are not disrupted due to delays in equipment availability.

By understanding these technical properties and trade terms, international B2B buyers can make more informed decisions regarding high pressure boilers, ultimately leading to better operational efficiency and compliance with industry standards.

Navigating Market Dynamics and Sourcing Trends in the high pressure boiler Sector

What Are the Current Market Dynamics and Key Trends in the High Pressure Boiler Sector?

The global high pressure boiler market is experiencing significant growth, driven by increasing industrialization and the rising demand for energy-efficient solutions. In regions such as Africa and South America, rapid urbanization and infrastructure development are primary catalysts for market expansion. In the Middle East and Europe, stringent environmental regulations and a shift towards renewable energy sources are influencing purchasing decisions.

Emerging technologies such as IoT-enabled monitoring systems and advanced control mechanisms are transforming boiler operations, enhancing efficiency, and minimizing downtime. International B2B buyers are increasingly prioritizing suppliers that offer smart boiler solutions, which facilitate real-time performance tracking and predictive maintenance. This trend not only boosts operational efficiency but also leads to significant cost savings over time.

Additionally, the shift towards modular boiler designs is gaining traction, providing companies with flexibility in scaling their operations. Modular systems can be installed quickly and require less space, making them ideal for facilities with limited real estate. Furthermore, the growing emphasis on safety and compliance with international standards is prompting manufacturers to innovate and improve the safety features of high pressure boilers. Buyers from diverse regions, especially those in developing markets, should focus on suppliers that emphasize both technological advancement and compliance with local regulations to ensure a seamless integration into their operations.

A stock image related to high pressure boiler.

How Can Sustainability and Ethical Sourcing Impact Your High Pressure Boiler Procurement?

In today’s business environment, sustainability and ethical sourcing are critical factors influencing procurement decisions in the high pressure boiler sector. The environmental impact of boiler operations, particularly concerning emissions and energy consumption, is under scrutiny. International B2B buyers are increasingly seeking high pressure boilers that are not only efficient but also environmentally friendly, adhering to global standards for emissions reduction.

Utilizing ‘green’ certifications and materials is becoming a necessity. Manufacturers that prioritize eco-friendly practices, such as using low NOx burners and incorporating energy recovery systems, are more appealing to buyers focused on sustainability. Moreover, the importance of an ethical supply chain cannot be overstated. Buyers should conduct thorough due diligence on suppliers to ensure they adhere to ethical labor practices and sustainable sourcing of materials. This approach not only mitigates risks but also enhances brand reputation in a market where consumers are increasingly aware of corporate responsibility.

Adopting these sustainable practices can also lead to long-term financial benefits, including reduced operational costs and potential tax incentives in certain regions. By prioritizing sustainability and ethical sourcing, B2B buyers can align their procurement strategies with broader corporate social responsibility goals, enhancing their competitive advantage.

What Is the Historical Context Behind High Pressure Boiler Development?

The development of high pressure boilers can be traced back to the Industrial Revolution, where the need for efficient energy sources became paramount. Initially, steam boilers operated at low pressures, limiting their efficiency and application. However, as industries grew and the demand for high-capacity steam generation increased, the definition of “high pressure” evolved, establishing a threshold of 15 psi in the early 1900s.

Over the decades, technological advancements have significantly transformed high pressure boiler designs, leading to improved safety features, fuel efficiency, and environmental compliance. The introduction of materials such as stainless steel and advancements in combustion technology have enabled boilers to operate at higher pressures and temperatures safely. This evolution reflects a broader trend in the industrial sector, where efficiency and sustainability are increasingly prioritized, shaping the future of high pressure boilers and their role in global energy production.

Understanding this historical context allows B2B buyers to appreciate the technological advancements that have led to today’s high performance, energy-efficient systems, providing a solid foundation for making informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of high pressure boiler

-

How do I choose the right high pressure boiler for my industrial application?

Selecting the appropriate high pressure boiler requires a thorough understanding of your specific operational needs. Consider factors such as the required steam pressure and temperature, the type of fuel available, and the efficiency ratings of different models. It’s also essential to evaluate the boiler’s capacity to meet peak demand and its compatibility with your existing infrastructure. Collaborating with manufacturers who can provide tailored solutions and conducting site assessments can further ensure you make an informed choice. -

What are the key advantages of high pressure boilers over low pressure boilers?

High pressure boilers offer several benefits, including increased energy efficiency, higher steam output, and faster heating capabilities. They are particularly suited for industrial applications that require rapid steam generation, such as in food processing, chemical manufacturing, and power generation. The ability to operate at higher temperatures and pressures also allows for better energy transfer to downstream equipment, ultimately enhancing overall productivity and reducing operational costs. -

What should I consider when vetting suppliers for high pressure boilers?

When vetting suppliers, assess their reputation, experience, and certifications in the industry. Look for suppliers who have a proven track record of providing high-quality products and excellent customer service. Request references and case studies from previous clients, and check for compliance with international safety standards. Additionally, consider their ability to provide customization options and after-sales support, which can be crucial for long-term operational success. -

What are the typical payment terms for purchasing high pressure boilers internationally?

Payment terms can vary significantly between suppliers and regions. Commonly, suppliers may require an upfront deposit (20-30%) upon order confirmation, with the balance due before shipment or upon delivery. For larger purchases, consider negotiating terms such as letters of credit or installment payments to manage cash flow. Always ensure that the payment terms are clearly outlined in the contract to avoid any misunderstandings. -

What is the minimum order quantity (MOQ) for high pressure boilers?

The MOQ for high pressure boilers typically depends on the manufacturer and the specific model you are interested in. Some manufacturers may offer single-unit purchases, while others might have a minimum order requirement to ensure cost-effectiveness in production. It is advisable to discuss your needs with potential suppliers to find out their MOQ and explore options for bulk purchasing if necessary. -

How can I ensure the quality and reliability of high pressure boilers?

To ensure quality and reliability, look for boilers that meet international standards such as ASME (American Society of Mechanical Engineers) and ISO certifications. Request documentation regarding the manufacturing process, materials used, and testing protocols. Additionally, consider suppliers that offer warranties and after-sales support, as this can be indicative of their confidence in the product’s quality and reliability. -

What logistics considerations should I keep in mind when sourcing high pressure boilers?

Logistics play a crucial role in the procurement of high pressure boilers. Consider factors such as shipping methods, customs clearance, and local regulations that may affect delivery. Working with suppliers who have experience in international shipping can streamline the process. Additionally, factor in lead times for production and delivery to ensure your operational timelines are met. -

Are there any specific regulations I need to be aware of when importing high pressure boilers?

Yes, importing high pressure boilers often requires compliance with local and international regulations. Familiarize yourself with safety standards, environmental regulations, and import tariffs specific to your country or region. Consult with legal experts or regulatory bodies to ensure adherence to all necessary guidelines. This proactive approach will help avoid delays and potential penalties during the importation process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for high pressure boiler

How Can Strategic Sourcing Enhance Your High Pressure Boiler Procurement?

In conclusion, the strategic sourcing of high pressure boilers presents a significant opportunity for international B2B buyers to enhance operational efficiency and reduce costs. Understanding the nuances between high and low pressure systems is crucial, as it allows businesses to select the right boiler type tailored to their specific industrial applications. For instance, high pressure boilers are indispensable in sectors such as manufacturing and food processing, where consistent steam supply is critical.

Moreover, investing in modern, efficient boiler systems not only drives down energy consumption but also aligns with increasing regulatory demands for environmental sustainability. Buyers should prioritize suppliers that offer advanced designs with low NOx emissions and rapid response capabilities to optimize fuel usage and minimize waste.

As you navigate the procurement landscape, consider engaging with reputable manufacturers and industry experts who can provide insights into the latest technological advancements. The future of high pressure boiler systems is promising, with innovations paving the way for enhanced performance and sustainability. Now is the time to act—evaluate your options, establish strong supplier relationships, and ensure your business is equipped for the demands of tomorrow’s industrial environment.