Cut Costs with the Ultimate Air Dryer Buying Guide (2025)

Introduction: Navigating the Global Market for air dryer

The global market for air dryers presents a unique challenge for B2B buyers, particularly when it comes to sourcing reliable and efficient solutions for their industrial operations. As businesses in Africa, South America, the Middle East, and Europe seek to optimize their compressed air systems, understanding the intricacies of air dryer technology becomes paramount. This guide serves as a comprehensive resource, covering various types of air dryers—including refrigerated, desiccant, and regenerative options—alongside their specific applications in diverse industries.

International buyers often face hurdles in supplier vetting, cost assessment, and understanding local regulations that impact procurement decisions. This guide not only demystifies these aspects but also provides insights into best practices for evaluating suppliers and negotiating contracts. By exploring factors such as energy efficiency, maintenance requirements, and potential operational savings, B2B buyers can make informed purchasing decisions that align with their business objectives.

Whether you’re in Poland looking for high-performance air dryers or in Nigeria seeking cost-effective solutions, this guide equips you with the knowledge to navigate the complexities of the global air dryer market. With a focus on actionable insights and practical considerations, international buyers will be empowered to enhance their operations and ensure their compressed air systems are free from moisture-related issues that can hinder productivity.

Understanding air dryer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Refrigerated Air Dryers | Utilizes cooling to condense moisture; typically has a dew point of 35°F to 50°F. | Manufacturing, automotive, food processing | Pros: Cost-effective, low maintenance. Cons: Limited dew point. |

| Desiccant Air Dryers | Uses desiccant materials to absorb moisture; achieves very low dew points (< -100°F). | Pharmaceutical, electronics, and aerospace industries | Pros: Excellent moisture removal, suitable for sensitive applications. Cons: Higher operational costs. |

| Membrane Air Dryers | Employs selective permeation; ideal for small-scale applications and portable solutions. | Oil & gas, remote locations, and small workshops | Pros: Compact, energy-efficient. Cons: Limited capacity and dew point. |

| Heatless Regenerative Dryers | Uses a two-tower system with one tower drying while the other regenerates; no external heat. | Heavy-duty industrial applications, oil fields | Pros: Energy-efficient, low maintenance. Cons: Larger footprint. |

| Cycling Refrigerated Dryers | Adjusts cooling capacity based on demand; provides better energy efficiency. | Automotive, painting, and manufacturing | Pros: Energy savings, consistent performance. Cons: Higher initial cost. |

What are the Characteristics of Refrigerated Air Dryers?

Refrigerated air dryers are widely used in industrial settings due to their straightforward design and operation. They work by cooling the compressed air, which causes moisture to condense and be removed. These dryers are suitable for applications where the air quality does not require extremely low dew points, making them ideal for manufacturing processes, automotive assembly, and food processing. When considering a refrigerated air dryer, buyers should evaluate their specific moisture removal needs and operational costs, as these units generally have lower initial costs but limited dew point capabilities.

How Do Desiccant Air Dryers Stand Out?

Desiccant air dryers excel in applications requiring ultra-dry air, achieving dew points below -100°F. They utilize desiccant materials to absorb moisture, making them indispensable in industries like pharmaceuticals, electronics, and aerospace, where moisture can compromise product integrity. When purchasing desiccant dryers, businesses should consider their capacity requirements and the total cost of ownership, as these systems may have higher operational costs due to energy consumption and desiccant replacement.

What are the Advantages of Membrane Air Dryers?

Membrane air dryers are compact and energy-efficient, making them suitable for small-scale applications or remote locations. They operate using selective permeation, allowing moisture to pass through the membrane while retaining dry air. These dryers are particularly effective in oil and gas applications and small workshops. Buyers should assess their air quality requirements and space limitations, as membrane dryers typically have a lower capacity and dew point compared to other types.

What Makes Heatless Regenerative Dryers Unique?

Heatless regenerative dryers employ a dual-tower system where one tower dries the air while the other regenerates. This technology is particularly beneficial in heavy-duty industrial applications, including oil fields, where consistent and reliable moisture removal is critical. While they are energy-efficient and require minimal maintenance, buyers should be aware of their larger footprint and ensure they have the space to accommodate these systems.

Why Choose Cycling Refrigerated Dryers?

Cycling refrigerated dryers adjust their cooling capacity based on the demand for dry air, offering improved energy efficiency. They are suitable for diverse applications such as automotive painting and manufacturing, where consistent air quality is essential. While these dryers can result in significant energy savings, buyers should consider the higher initial investment compared to standard refrigerated dryers, weighing long-term savings against upfront costs.

Key Industrial Applications of air dryer

| Industry/Sector | Specific Application of Air Dryer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Preventing corrosion in pneumatic tools | Reduces maintenance costs and downtime | Ensure compatibility with existing equipment and airflow |

| Food and Beverage | Drying compressed air for packaging processes | Maintains product quality and safety standards | Look for dryers that meet food safety regulations |

| Automotive | Ensuring clean air for paint spray booths | Enhances finish quality and reduces rework | Consider dryers with low dew point specifications |

| Pharmaceuticals | Providing ultra-dry air for tablet coating | Ensures product efficacy and compliance | Focus on energy efficiency and low maintenance needs |

| Oil and Gas | Drying air for instrumentation and control systems | Prevents equipment failure and operational risks | Evaluate durability for harsh environments |

How is Air Dryer Used in Manufacturing to Prevent Corrosion?

In manufacturing, air dryers are crucial for preventing corrosion in pneumatic tools and systems. Excess moisture in compressed air can lead to rust and operational failures, significantly increasing maintenance costs and downtime. By integrating air dryers into their compressed air systems, manufacturers ensure that the air supplied to tools is dry, extending equipment life and maintaining operational efficiency. Buyers from regions like Africa and South America should prioritize compatibility with existing machinery and airflow requirements when sourcing air dryers.

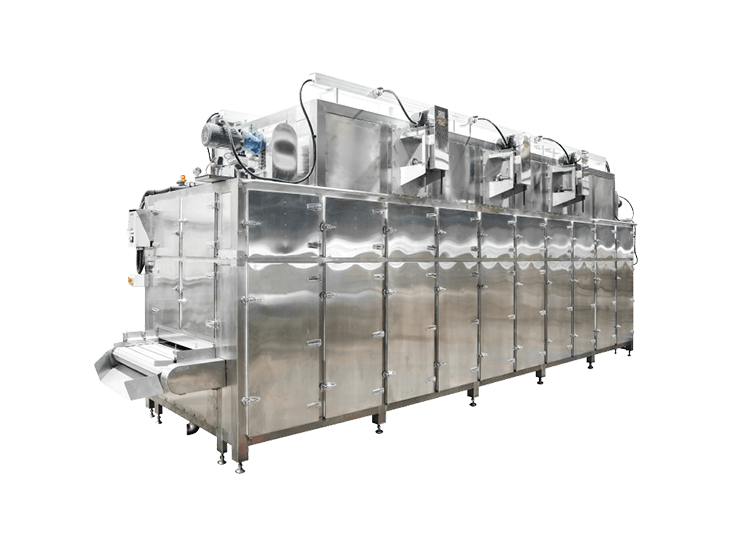

A stock image related to air dryer.

What Role Do Air Dryers Play in Food and Beverage Packaging?

In the food and beverage sector, air dryers are employed to dry compressed air used in packaging processes. Moisture in the air can compromise product quality and introduce safety hazards. By utilizing air dryers, companies can achieve the necessary dryness levels, ensuring that packaging is secure and hygienic. B2B buyers in Europe and the Middle East must consider sourcing air dryers that comply with food safety regulations to maintain industry standards.

How Do Air Dryers Improve Paint Quality in Automotive Applications?

Air dryers are essential in automotive painting processes, particularly in spray booths where clean air is critical. Moisture-laden air can negatively impact the finish quality, leading to defects and increased rework. By using air dryers to provide dry, clean air, automotive manufacturers enhance paint adherence and appearance. Buyers in regions like Poland should seek air dryers with specific low dew point capabilities to ensure optimal performance in their painting processes.

Why Are Air Dryers Important in Pharmaceuticals?

In the pharmaceutical industry, air dryers are vital for providing ultra-dry air in processes such as tablet coating. Moisture can affect the efficacy of pharmaceutical products and compliance with industry standards. Air dryers help maintain the required humidity levels, ensuring product quality and safety. International buyers, especially from Africa and South America, should focus on energy-efficient models that require minimal maintenance to optimize operational costs.

How Do Air Dryers Support Operations in Oil and Gas?

In the oil and gas industry, air dryers are used to provide dry air for instrumentation and control systems. Moisture can lead to equipment failures, which can be costly and dangerous. By using air dryers, companies prevent operational risks and ensure the reliability of their systems. Buyers from the Middle East should evaluate the durability and robustness of air dryers to withstand harsh environmental conditions typical in this sector.

3 Common User Pain Points for ‘air dryer’ & Their Solutions

Scenario 1: Insufficient Dew Point Control Leading to Product Quality Issues

The Problem: Many B2B buyers, especially in industries like food processing and pharmaceuticals, rely on precise moisture control in their compressed air systems. A common challenge arises when the air dryer fails to maintain the necessary dew point, leading to excessive moisture in the compressed air. This can result in product spoilage, equipment corrosion, and compromised quality standards, which are particularly critical in regulated environments. Buyers may find themselves facing costly downtime and potential regulatory penalties due to moisture-related failures.

The Solution: To address this issue, buyers should invest in high-quality desiccant air dryers, which can achieve lower dew points compared to traditional refrigerated dryers. When sourcing an air dryer, it’s essential to specify the required dew point based on the application. For instance, in pharmaceutical manufacturing, a dew point of -40°F or lower may be required. Buyers should also consider using a combination of a refrigerated dryer followed by a desiccant dryer for optimal results. Regular maintenance and monitoring of the dryer’s performance through pressure dew point sensors can ensure it operates within the specified limits, thereby safeguarding product quality.

Scenario 2: High Operating Costs Due to Inefficient Air Dryer Systems

The Problem: Many businesses experience high operating costs linked to inefficient air dryer systems. This can be exacerbated in regions like Africa and South America, where energy costs can be significant. An outdated or improperly sized air dryer can lead to excessive energy consumption, increased maintenance needs, and frequent breakdowns, all of which contribute to soaring operational costs. Buyers may struggle to justify these expenses, especially in competitive markets where margins are thin.

The Solution: To mitigate these costs, buyers should evaluate their current air dryer systems and consider investing in energy-efficient models. Products equipped with variable speed drives (VSD) can adjust their energy consumption based on the demand, significantly reducing electricity costs. Moreover, conducting an air audit can help identify leaks and inefficiencies in the entire compressed air system, allowing for targeted improvements. Sourcing dryers that feature advanced control systems for monitoring and optimizing energy usage can also provide actionable insights into operation, enabling better decision-making and cost management.

Scenario 3: Frequent Maintenance and Downtime from Aging Equipment

The Problem: Businesses using aging air dryer equipment often face frequent maintenance issues, resulting in unplanned downtime. This scenario is especially prevalent in industries that depend on continuous operations, such as manufacturing and construction. Buyers may find that older models require more frequent repairs and replacements, which can disrupt production schedules and lead to financial losses. Additionally, sourcing spare parts for older units can become increasingly difficult and costly.

The Solution: To resolve this pain point, it’s advisable for buyers to conduct a comprehensive review of their existing air dryer systems. If equipment is more than 10 years old, it may be time to consider an upgrade. Investing in modern, reliable air dryers that come with warranties and robust service agreements can reduce the frequency of breakdowns. Additionally, establishing a preventive maintenance schedule can help extend the lifespan of new equipment and minimize unscheduled downtime. Buyers should also explore manufacturers that offer remote monitoring solutions, enabling real-time diagnostics and predictive maintenance, which can drastically reduce maintenance-related disruptions.

Strategic Material Selection Guide for air dryer

What Are the Key Materials Used in Air Dryers?

When selecting an air dryer for industrial applications, the choice of material is critical to ensure optimal performance, durability, and cost-effectiveness. Below, we analyze four common materials used in the construction of air dryers: Aluminum, Stainless Steel, Carbon Steel, and Plastic. Each material has unique properties, advantages, and limitations that are essential for international B2B buyers to consider.

How Does Aluminum Impact Air Dryer Performance?

Key Properties: Aluminum is lightweight and has excellent thermal conductivity, making it effective for heat exchange in refrigerated air dryers. It typically withstands pressure ratings up to 150 psi, depending on the design.

Pros & Cons: The primary advantage of aluminum is its resistance to corrosion, which is crucial in humid environments. However, it can be more expensive than other materials like carbon steel and may not be suitable for high-pressure applications due to its lower strength.

Impact on Application: Aluminum is ideal for applications requiring lightweight components and efficient heat transfer. It is compatible with various media, including compressed air and gases.

Considerations for International Buyers: Buyers from regions with high humidity, such as parts of Africa and South America, will appreciate aluminum’s corrosion resistance. Compliance with ASTM standards is often necessary, particularly in Europe.

What Role Does Stainless Steel Play in Air Dryers?

Key Properties: Stainless steel is known for its high strength and excellent corrosion resistance, withstanding temperatures up to 800°F and pressures exceeding 300 psi.

Pros & Cons: The durability of stainless steel makes it suitable for harsh environments, and it is often the preferred choice for food-grade applications. However, its high cost and manufacturing complexity can be drawbacks for budget-sensitive projects.

Impact on Application: Stainless steel is particularly effective in applications that require stringent hygiene standards, such as pharmaceutical and food processing industries. It is compatible with a wide range of media, including corrosive gases.

Considerations for International Buyers: Compliance with international standards, such as DIN and JIS, is crucial for buyers in Europe and the Middle East. The initial investment may be higher, but the long-term benefits often justify the cost.

How Does Carbon Steel Compare in Air Dryer Construction?

Key Properties: Carbon steel offers good strength and can handle pressures up to 200 psi. However, it is less resistant to corrosion compared to aluminum and stainless steel.

Pros & Cons: The main advantage of carbon steel is its cost-effectiveness, making it a popular choice for budget-conscious buyers. However, it requires protective coatings to prevent rust, especially in humid environments.

Impact on Application: Carbon steel is suitable for general industrial applications but may not be ideal for environments with high moisture levels. It is compatible with non-corrosive media.

Considerations for International Buyers: Buyers in regions like Nigeria and Poland should consider the local climate when choosing carbon steel. Compliance with ASTM standards is essential, especially for industries requiring specific material certifications.

What Advantages Does Plastic Offer for Air Dryers?

Key Properties: Plastic materials, such as polycarbonate and polypropylene, are lightweight and resistant to corrosion, with pressure ratings typically around 100 psi.

Pros & Cons: The primary advantage of plastic is its low cost and ease of manufacturing. However, it may not withstand high temperatures and pressures as effectively as metals.

Impact on Application: Plastic is suitable for low-pressure applications and environments where corrosion is a concern. It is often used in smaller, portable air dryer units.

Considerations for International Buyers: For buyers in the Middle East and Africa, the lightweight nature of plastic can be advantageous for transport. However, they should ensure that the selected plastic meets relevant industry standards.

Summary Table of Material Selection for Air Dryers

| Material | Typical Use Case for air dryer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Refrigerated air dryers | Excellent corrosion resistance | Higher cost compared to carbon steel | Medium |

| Stainless Steel | Food and pharmaceutical applications | High strength and durability | Expensive and complex to manufacture | High |

| Carbon Steel | General industrial applications | Cost-effective | Requires protective coatings | Low |

| Plastic | Portable and low-pressure units | Lightweight and corrosion-resistant | Limited temperature and pressure tolerance | Low |

This strategic material selection guide aims to equip international B2B buyers with the knowledge necessary to make informed decisions when purchasing air dryers, ensuring they choose the right material for their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for air dryer

What Are the Main Stages of Air Dryer Manufacturing?

The manufacturing process of air dryers involves several critical stages, each contributing to the final product’s performance and reliability. Understanding these stages can help B2B buyers make informed decisions when sourcing air dryers for their operations.

Material Preparation: What Materials Are Used in Air Dryer Production?

The first stage in manufacturing air dryers involves selecting high-quality materials to ensure durability and efficiency. Common materials include:

- Aluminum: Lightweight and resistant to corrosion, making it ideal for components that require thermal conductivity.

- Stainless Steel: Used for structural parts that need to withstand high pressure and prevent rust.

- Copper: Often used in heat exchangers due to its excellent thermal properties.

Purchasing agents should prioritize suppliers that source materials compliant with international standards, which can affect the longevity and performance of the air dryer.

Forming: How Are Air Dryer Components Shaped?

The forming stage involves various techniques that shape the raw materials into components of the air dryer. Key techniques include:

- CNC Machining: Provides precision in creating components such as housing and internal fittings, ensuring they meet strict tolerances.

- Metal Stamping: Used for producing parts like brackets and frames quickly and efficiently.

- Injection Molding: Commonly used for producing plastic components, such as control panels and housing covers.

Understanding these techniques allows buyers to gauge the quality and reliability of the products they are sourcing.

Assembly: What Processes Are Involved in Air Dryer Assembly?

Once the components are formed, they undergo assembly, where various parts are integrated into a complete air dryer. This stage typically involves:

- Component Inspection: Each part is checked for defects before assembly to ensure quality.

- Welding and Fastening: Components are joined using welding techniques or fasteners, depending on the design requirements.

- Integration of Control Systems: Modern air dryers may feature automated control systems that require careful installation and calibration.

Buyers should inquire about the assembly processes used by suppliers to ensure they adhere to best practices and quality standards.

Finishing: How Is the Final Product Prepared for Market?

The finishing stage includes processes that enhance the air dryer’s appearance and functionality. Key activities include:

- Surface Treatment: Techniques such as anodizing or powder coating are employed to improve corrosion resistance and aesthetic appeal.

- Quality Checks: Final inspections are conducted to ensure that the air dryer meets performance specifications and is free from defects.

B2B buyers should look for suppliers that provide detailed finishing processes and quality assurances.

What Quality Assurance Measures Are Implemented During Air Dryer Production?

Quality assurance (QA) is vital in air dryer manufacturing to ensure that products meet international standards and customer expectations. The following quality assurance practices are commonly adopted:

What International Standards Should B2B Buyers Look For?

Air dryers should comply with relevant international quality standards, which can include:

- ISO 9001: This standard focuses on quality management systems and is critical for ensuring consistent quality across manufacturing processes.

- CE Marking: Indicates that the product meets European safety, health, and environmental protection standards.

- API Standards: Relevant for air dryers used in oil and gas applications, ensuring they meet industry-specific requirements.

When sourcing air dryers, B2B buyers should verify that suppliers hold these certifications, as they reflect a commitment to quality.

What Are the Key Quality Control Checkpoints in Air Dryer Manufacturing?

Quality control (QC) checkpoints are integral to maintaining product quality throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival at the manufacturing facility.

- In-Process Quality Control (IPQC): Ongoing checks during the production process to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished air dryer to ensure it meets all performance and safety standards.

Understanding these checkpoints can help buyers assess the reliability of a supplier’s QC processes.

What Testing Methods Are Commonly Used in Air Dryer Quality Assurance?

Several testing methods are employed to evaluate the performance and safety of air dryers:

- Leak Testing: Ensures that the air dryer maintains pressure without leaks, which is crucial for operational efficiency.

- Performance Testing: Measures the dryer’s ability to meet specified dew point and flow rate requirements.

- Durability Testing: Simulates operational conditions to test the longevity and reliability of the air dryer over time.

B2B buyers should ask suppliers for detailed reports on these tests to ensure product reliability.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must perform due diligence when selecting suppliers for air dryers. Here are actionable insights for verifying supplier quality control:

What Are the Best Practices for Conducting Supplier Audits?

- On-Site Audits: Conducting on-site inspections allows buyers to assess the manufacturing environment, equipment, and processes in real-time.

- Documentation Review: Requesting access to quality control documentation, including test reports and compliance certificates, helps validate a supplier’s claims.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality practices.

These steps are crucial for mitigating risks associated with sourcing from international suppliers.

What Nuances Should International Buyers Consider Regarding Quality Control?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of the following nuances:

- Cultural Differences: Different regions may have varying standards for quality and compliance. It’s essential to understand local regulations and practices.

- Logistical Challenges: Shipping and customs regulations can affect product delivery and compliance. Buyers should ensure that suppliers can navigate these challenges.

- Communication Barriers: Language differences may lead to misunderstandings regarding specifications and quality expectations. Clear communication is vital.

By considering these factors, buyers can better navigate the complexities of sourcing air dryers from global suppliers.

Conclusion

Understanding the manufacturing processes and quality assurance measures for air dryers is essential for international B2B buyers. By focusing on material selection, manufacturing techniques, and robust quality control practices, buyers can ensure they procure reliable and efficient air dryers that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘air dryer’

In this section, we provide an actionable sourcing guide specifically designed for international B2B buyers looking to procure air dryers. This checklist will help streamline your decision-making process and ensure that you select the most suitable air dryer for your operational needs.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your application is crucial. Determine the necessary airflow capacity (measured in CFM), dew point requirements, and the type of air dryer that best suits your needs, whether it’s refrigerated, desiccant, or membrane-based. This foundational knowledge will guide your selection process and help you avoid costly mistakes.

Step 2: Conduct Market Research on Air Dryer Types

Familiarize yourself with the different types of air dryers available in the market. Each type serves unique applications:

– Refrigerated Air Dryers: Ideal for general industrial applications.

– Desiccant Air Dryers: Best for environments requiring ultra-dry air.

– Membrane Dryers: Useful for portable applications.

Understanding these differences will enable you to match the right technology with your specific operational needs.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Look for manufacturers and distributors with a strong reputation in your region:

– Request company profiles, case studies, and references from buyers in similar industries.

– Check for certifications such as ISO or industry-specific standards to ensure quality and reliability.

This step helps mitigate risks associated with supplier reliability and product quality.

Step 4: Compare Pricing and Total Cost of Ownership (TCO)

While initial pricing is important, consider the total cost of ownership, which includes maintenance, energy consumption, and potential downtime costs. Request quotes from multiple suppliers and ask about warranties and service agreements. A lower upfront cost may lead to higher operational expenses over time, so be sure to calculate the TCO for a more informed decision.

Step 5: Verify Compliance with Local Regulations

Ensure that the air dryer you are considering complies with local regulations in your target market. Different regions may have specific standards regarding emissions, safety, and energy efficiency. Non-compliance can lead to fines and operational delays, so it’s essential to confirm that your supplier meets these requirements.

Step 6: Request a Demo or Trial Period

Whenever possible, request a demonstration or trial period for the air dryer you intend to purchase. This hands-on experience allows you to assess performance, ease of use, and maintenance requirements firsthand. It also provides an opportunity to identify any potential issues before committing to a purchase.

Step 7: Establish Clear Communication and Support Channels

Finally, ensure that your supplier offers robust customer support and clear communication channels. This includes availability for technical support, spare parts, and maintenance services. Establishing a good relationship with your supplier can lead to better service and responsiveness, which is vital for minimizing downtime in your operations.

By following this checklist, B2B buyers can make informed decisions when sourcing air dryers, ensuring they meet both operational needs and budget constraints effectively.

Comprehensive Cost and Pricing Analysis for air dryer Sourcing

What Are the Key Cost Components in Air Dryer Sourcing?

When sourcing air dryers, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost of air dryers. High-quality metals, desiccants, and insulation materials typically increase the price but improve performance and durability. For example, a refrigerated air dryer might utilize stainless steel for its longevity, while desiccant dryers may rely on specialized adsorption materials.

-

Labor: Labor costs can vary based on the region of production. Manufacturers in regions with higher labor costs, such as Europe, may have different pricing compared to those in Africa or South America. It is essential to consider these variations when evaluating quotes.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. These costs are often factored into the final pricing of the air dryers.

-

Tooling: Custom tooling for specific air dryer designs can be a significant upfront investment. Buyers requiring unique specifications should be prepared for increased initial costs, which may be amortized over larger order volumes.

-

Quality Control (QC): Ensuring the reliability and efficiency of air dryers necessitates rigorous QC processes, which can add to the overall cost. Certifications, such as ISO compliance, can also influence pricing.

-

Logistics: Shipping costs, including transportation and handling, are critical, particularly for international buyers. Factors such as distance, shipping method, and packaging impact these costs.

-

Margin: Suppliers will typically add a margin to cover their operational costs and profit. Understanding the typical margins in your industry can help in negotiations.

How Do Price Influencers Impact Air Dryer Costs?

Several factors can influence the pricing of air dryers, especially for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Ordering in bulk can lead to significant discounts. Suppliers often provide lower unit prices for larger orders, which can be beneficial for businesses planning long-term usage.

-

Specifications and Customization: Customized air dryers that meet specific operational needs often come at a premium. Buyers should clearly define their requirements to avoid unnecessary costs.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like CE or UL) can raise prices but also ensure better performance and compliance with safety standards. Investing in certified products may lead to long-term savings by reducing maintenance and downtime.

-

Supplier Factors: Reputation, reliability, and location of suppliers can affect pricing. Established suppliers with a proven track record may charge more due to their reliability and the quality of their products.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international transactions. They dictate the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk. For instance, an EXW (Ex Works) agreement may leave the buyer responsible for all logistics costs, increasing the total cost.

What Are the Best Buyer Tips for Cost-Efficiency?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, consider these actionable insights for cost-efficient sourcing of air dryers:

-

Negotiate Effectively: Always be prepared to negotiate pricing, especially when dealing with larger orders. Leverage your purchasing power and explore multiple quotes to find the best deal.

-

Total Cost of Ownership (TCO): When assessing prices, consider the TCO, which includes initial purchase price, installation, maintenance, and operational costs over the product’s lifespan. Sometimes, a higher upfront cost may lead to lower long-term costs.

-

Understand Pricing Nuances: Prices can vary significantly across regions due to local market conditions, currency fluctuations, and tariffs. Conduct thorough market research to understand these nuances before committing to a supplier.

-

Stay Informed on Market Trends: Regularly monitor industry trends, new technologies, and supplier developments. This knowledge can empower you to make informed purchasing decisions and potentially negotiate better terms.

Disclaimer on Indicative Prices

It is important to note that the prices mentioned in various sources may fluctuate based on market conditions, supplier agreements, and currency exchange rates. Always seek updated quotes and conduct thorough due diligence before finalizing any purchases.

Alternatives Analysis: Comparing air dryer With Other Solutions

When considering solutions for drying compressed air, it’s essential to evaluate various alternatives to air dryers. Each method can impact operational efficiency, cost, and maintenance requirements differently. This analysis focuses on comparing air dryers with two viable alternatives: desiccant air dryers and membrane air dryers.

Comparison Table of Air Drying Solutions

| Comparison Aspect | Air Dryer | Desiccant Air Dryer | Membrane Air Dryer |

|---|---|---|---|

| Performance | Effective for moderate humidity | Superior for low humidity | Good for low volume applications |

| Cost | Moderate initial investment | Higher upfront and operational costs | Lower initial cost but may need replacement |

| Ease of Implementation | Relatively easy to install | More complex setup required | Simple installation |

| Maintenance | Low maintenance | Moderate, requires regular replacement of desiccants | Low maintenance, but membranes can degrade |

| Best Use Case | General industrial applications | Applications needing ultra-dry air | Portable and low-volume drying needs |

What Are the Benefits of Desiccant Air Dryers?

Desiccant air dryers utilize materials that absorb moisture from the air. They excel in environments where extremely low dew points are necessary, making them ideal for industries such as pharmaceuticals, food processing, and electronics manufacturing. The primary advantage is their ability to maintain a dew point below -40°F, which can be critical for sensitive applications. However, the initial investment and ongoing costs for replacing desiccant materials can be significant. Additionally, their operational complexity may require specialized training for personnel.

How Do Membrane Air Dryers Work and What Are Their Pros and Cons?

A stock image related to air dryer.

Membrane air dryers operate using selective permeation, where moisture passes through a membrane while dry air remains. These dryers are particularly advantageous for applications requiring low volumes of dry air, such as in automotive or small-scale manufacturing processes. They are easy to install and typically have lower initial costs compared to desiccant systems. However, the membranes can degrade over time, necessitating replacement, which can lead to increased long-term costs. Their performance is also less effective in highly humid environments, which may limit their applicability in certain sectors.

Conclusion: How Can B2B Buyers Choose the Right Drying Solution?

Selecting the right air drying solution depends on specific operational needs, budget constraints, and the environmental conditions of the application. For industries requiring ultra-dry air, desiccant dryers may be the best fit despite their higher costs. Conversely, businesses looking for a balance between performance and cost-effectiveness might opt for refrigerated air dryers. Membrane air dryers are suitable for low-volume applications where space and simplicity are paramount. Ultimately, understanding the unique requirements of your operation will guide you in choosing the most appropriate air drying technology.

Essential Technical Properties and Trade Terminology for air dryer

What Are the Essential Technical Properties of Air Dryers?

When selecting an air dryer, understanding its technical properties is crucial for B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe. Here are some key specifications to consider:

1. Flow Rate (CFM)

The flow rate, measured in cubic feet per minute (CFM), indicates the volume of air the dryer can process. It is essential to match the flow rate to the requirements of your compressed air system to ensure efficient operation. An insufficient flow rate may lead to moisture build-up, while an oversized dryer can result in wasted energy and increased costs.

2. Dew Point

The dew point is the temperature at which moisture begins to condense out of the air. For industrial applications, a lower dew point (e.g., -40°F or lower) is often necessary to prevent moisture-related issues like corrosion and freezing. Understanding the dew point helps buyers select an air dryer that maintains the necessary air quality for their operations.

3. Type of Dryer

Air dryers come in various types, including refrigerated, desiccant, and membrane dryers. Each type has its advantages and is suited for different applications. For instance, refrigerated dryers are cost-effective and require minimal maintenance, making them ideal for general use, while desiccant dryers are better for applications requiring ultra-dry air.

4. Energy Efficiency

Energy consumption is a significant cost factor for businesses. Energy-efficient models can reduce operational costs and minimize environmental impact. Look for dryers with low power consumption ratings and those that meet or exceed energy efficiency standards.

5. Operating Pressure

The operating pressure indicates the pressure level at which the air dryer functions effectively. This specification is crucial for ensuring compatibility with existing compressed air systems. Different applications may require varying operating pressures, and understanding this helps avoid system failures.

6. Material Grade

The construction material of the air dryer affects its durability and resistance to corrosion. Common materials include aluminum, stainless steel, and carbon steel. Selecting the right material ensures longevity and reliability, especially in harsh industrial environments.

What Are Common Trade Terms Associated with Air Dryers?

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms related to air dryers:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the air dryer industry, knowing if a product is OEM can assure buyers of its quality and compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This is particularly important for B2B buyers to understand as it can affect purchasing strategies and inventory management, especially for businesses operating in regions with limited suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting price quotes for specific products or services. For air dryers, issuing an RFQ can help buyers compare costs and negotiate better terms, ensuring they receive competitive pricing.

4. Incoterms

International Commercial Terms (Incoterms) are a series of predefined commercial terms published by the International Chamber of Commerce. They are critical in defining the responsibilities of buyers and sellers in international shipping. Understanding Incoterms can help buyers manage shipping costs and risks effectively.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For air dryers, understanding lead times is essential for planning and maintaining operational efficiency, particularly for businesses that rely on continuous air supply.

6. Service Level Agreement (SLA)

An SLA outlines the expected service levels between a supplier and a customer. It typically includes performance metrics, such as maintenance response times and uptime guarantees, which are crucial for ensuring that air dryers operate effectively without unexpected downtimes.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions when purchasing air dryers, ensuring that they select the right equipment for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the air dryer Sector

What Are the Current Market Dynamics and Key Trends in the Air Dryer Sector?

The air dryer market is experiencing notable growth driven by several global factors. Rising industrialization, particularly in developing regions like Africa and South America, is increasing the demand for efficient compressed air systems. Technological advancements are also shaping the landscape; for instance, the adoption of smart air dryers equipped with IoT capabilities allows for better monitoring and predictive maintenance, which is crucial for minimizing downtime. Furthermore, energy efficiency has become a priority for many businesses, leading to a surge in demand for energy-efficient air dryers, such as non-cycling refrigerated air dryers, which consume less energy while providing high performance.

In addition, international B2B buyers are increasingly prioritizing suppliers that offer comprehensive service packages, including installation and maintenance, which enhances the overall value proposition. Buyers from regions like Europe and the Middle East are particularly focused on obtaining products that comply with stringent regulatory standards, ensuring both quality and reliability. Additionally, the rise of e-commerce platforms has transformed sourcing strategies, allowing buyers to easily compare products and prices, thus enhancing their purchasing decisions.

How Does Sustainability and Ethical Sourcing Impact B2B Buyers in the Air Dryer Sector?

Sustainability is becoming an essential criterion for B2B buyers in the air dryer sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. As a result, companies are increasingly looking for air dryers that utilize ‘green’ technologies, such as energy-efficient designs and materials that reduce carbon footprints.

Moreover, ethical sourcing practices are gaining traction, with buyers demanding transparency in supply chains. This includes ensuring that the materials used in air dryers are sourced responsibly and that manufacturers adhere to fair labor practices. Certifications like ISO 14001 (Environmental Management) and Energy Star ratings are becoming critical in the decision-making process, as they signify a commitment to sustainable practices. By choosing suppliers that prioritize sustainability, buyers not only enhance their corporate social responsibility (CSR) profiles but also improve their operational efficiencies through lower energy costs and reduced waste.

What Is the Brief Evolution of Air Dryer Technology?

The evolution of air dryer technology can be traced back to the early 20th century when the need for moisture-free compressed air became apparent in industrial applications. Initially, simple mechanical systems were used to remove moisture; however, these were often inefficient and cumbersome.

With advancements in technology, the introduction of refrigerated air dryers revolutionized the sector by providing a more effective means of moisture removal. By the late 20th century, desiccant air dryers emerged, utilizing materials that absorb moisture, allowing for even lower dew points. Today, the market has advanced further with the integration of smart technologies and IoT capabilities, enabling real-time monitoring and enhanced operational efficiencies. This historical progression highlights the increasing sophistication of air dryer systems, reflecting the growing demands of international B2B buyers for reliable, efficient, and environmentally friendly solutions.

In conclusion, the air dryer sector is evolving rapidly, presenting numerous opportunities for B2B buyers who are keen to leverage market dynamics, sustainability trends, and technological advancements to enhance their operations and supply chain efficiency.

Frequently Asked Questions (FAQs) for B2B Buyers of air dryer

-

How do I solve moisture issues in my compressed air system?

To effectively solve moisture issues in your compressed air system, consider investing in a high-quality air dryer. Options include refrigerated dryers, which cool air to condense moisture, or desiccant dryers, which absorb water vapor. Regular maintenance and monitoring of the system are crucial to ensure optimal performance. Additionally, installing filters and separators can help remove moisture before it enters the dryer. Always evaluate the specific needs of your application, such as flow rate and dew point requirements, to choose the right type of dryer. -

What is the best air dryer for industrial applications?

The best air dryer for industrial applications largely depends on your specific operational requirements. Refrigerated air dryers are ideal for general use, as they efficiently remove moisture and are easy to maintain. For applications requiring ultra-dry air, desiccant dryers are preferable, achieving dew points as low as -100°F. Evaluate factors such as airflow capacity, installation space, and energy consumption when selecting a dryer. Consulting with manufacturers or suppliers can provide insights into the most suitable options for your unique needs. -

What should I consider when sourcing air dryers from international suppliers?

When sourcing air dryers from international suppliers, consider factors such as the supplier’s reputation, product quality, and compliance with international standards. Conduct thorough research, including reviewing certifications and customer testimonials. Additionally, assess the supplier’s ability to provide after-sales support and spare parts. Language barriers can also be an issue, so ensure clear communication. Lastly, consider the logistics of shipping and customs regulations in your country to avoid delays in receiving your equipment. -

How can I verify the credibility of an air dryer supplier?

Verifying the credibility of an air dryer supplier involves several steps. Start by checking their business credentials, such as registration and industry certifications. Look for customer reviews and case studies that showcase their reliability and product performance. Engaging in direct communication can also help gauge their responsiveness and customer service quality. If possible, visit their facility or request references from previous clients. Platforms like Alibaba and Global Sources can provide additional insights into supplier ratings and feedback. -

What are typical payment terms for international B2B transactions?

Typical payment terms for international B2B transactions often include options like advance payment, letter of credit, or net payment terms (e.g., 30, 60, or 90 days). Advanced payments can secure your order but may carry risks if the supplier is unverified. A letter of credit offers protection by ensuring payment only occurs upon meeting specified conditions. Discuss and negotiate payment terms upfront to ensure mutual understanding and reduce the risk of disputes. Always consider currency fluctuations and transaction fees when making international payments.

A stock image related to air dryer.

-

What is the minimum order quantity (MOQ) for air dryers?

The minimum order quantity (MOQ) for air dryers can vary significantly based on the supplier and the specific model. Some suppliers may have an MOQ as low as one unit, while others might require bulk orders to meet production costs. When negotiating with suppliers, clarify the MOQ and explore options for customization or bundling with other products. Understanding the MOQ can help you assess overall costs and make informed purchasing decisions, especially when planning for future scalability. -

How can I ensure quality assurance for air dryers purchased internationally?

To ensure quality assurance for air dryers purchased internationally, request certifications and compliance documentation from the supplier. Quality standards such as ISO 9001 can indicate a commitment to maintaining high production standards. It’s also advisable to request samples or conduct factory inspections, if feasible. Additionally, consider third-party inspection services to verify the quality of the products before shipment. Establishing a clear agreement on quality expectations and warranty terms will also safeguard your investment. -

What logistics considerations should I keep in mind when importing air dryers?

When importing air dryers, logistics considerations include shipping methods, customs clearance, and delivery timelines. Choose between air freight for speed or ocean freight for cost-effectiveness, depending on your urgency and budget. Ensure that you understand the customs regulations in your country, including any duties or taxes applicable to imported goods. Collaborating with a reliable freight forwarder can help navigate these complexities and ensure timely delivery. Properly packaging and labeling the equipment is essential to avoid damage during transit and facilitate smooth customs processing.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for air dryer

In today’s competitive landscape, strategic sourcing of air dryers is essential for international B2B buyers looking to enhance operational efficiency and reduce costs. By leveraging a diverse range of products—from refrigerated to desiccant air dryers—businesses can tailor their solutions to meet specific requirements, ensuring optimal performance in diverse environments, whether in Europe, Africa, South America, or the Middle East.

Key takeaways include the importance of understanding the nuances between different dryer types and the benefits of sourcing locally to minimize shipping costs and lead times. Additionally, investing in high-quality air dryers can significantly mitigate risks associated with moisture in compressed air systems, such as equipment corrosion and production downtime.

As we look toward the future, international B2B buyers should prioritize partnerships with reliable suppliers who offer comprehensive product support and innovative solutions. This approach will not only streamline procurement processes but also foster long-term relationships that can adapt to evolving market demands. Engage with suppliers today to explore customized air dryer solutions that will drive your business forward in an ever-changing global market.