Cut Costs with the Ultimate Pipe Flange Sourcing Guide (2025)

Introduction: Navigating the Global Market for pipe flange

Navigating the complexities of sourcing high-quality pipe flanges can be a significant challenge for international B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe. With a diverse range of flange types, materials, and applications available in the global market, making informed purchasing decisions is critical to ensuring the integrity and efficiency of piping systems. This guide serves as a comprehensive resource, covering essential topics including the various types of flanges, their specific applications, and crucial considerations for supplier vetting.

Understanding the nuances of flange specifications, such as face types and material compatibility, can directly impact project costs and operational reliability. Furthermore, we delve into strategies for identifying reputable suppliers and negotiating favorable pricing, tailored specifically for international buyers. By equipping yourself with the knowledge presented in this guide, you will enhance your ability to navigate the global market effectively, ensuring that your business secures the right flanges for your unique needs.

Whether you are based in Kenya, the UK, or elsewhere, the insights provided will empower you to make well-informed decisions that not only meet your technical requirements but also align with your budgetary constraints. Embrace the opportunity to streamline your sourcing process and optimize your supply chain efficiency with our expert guidance on pipe flanges.

Understanding pipe flange Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Threaded Flanges | Internal threads for easy connection without welding | Low-pressure piping systems | Pros: Easy installation; no welding required. Cons: Limited to lower pressure applications. |

| Socket-Weld Flanges | Pipe fits into the flange; secured with a weld | Small diameter piping in low-temp scenarios | Pros: Simple installation; strong connection. Cons: Not suitable for larger pipes. |

| Slip-on Flanges | Flange slips over the pipe; requires welding on both sides | High flow-rate systems | Pros: Versatile size options; good for high flow. Cons: Requires more technical installation. |

| Weld Neck Flanges | Designed for butt welding; excellent for high-pressure systems | Critical process piping | Pros: High integrity and durability; ideal for heavy-duty applications. Cons: More expensive; complex installation. |

| Blind Flanges | Solid disc used to seal off ends of piping | Maintenance and isolation applications | Pros: Easy to install; effective sealing. Cons: Cannot be used for flow applications. |

What Are the Characteristics of Threaded Flanges?

Threaded flanges, also known as screwed flanges, are characterized by their internal threads that allow for easy attachment to corresponding male threads on pipes or fittings. This design is particularly advantageous in low-pressure applications where welding is not feasible. For B2B buyers, the key consideration is the pressure rating; while they simplify installation and maintenance, they are limited to lower pressure environments. Additionally, ensure compatibility with the materials used in your piping system to avoid corrosion issues.

How Do Socket-Weld Flanges Differ from Other Flanges?

Socket-weld flanges feature a design where the pipe is inserted into the flange and then secured with a weld. They are best suited for smaller diameter pipes and applications involving low temperatures and pressures. B2B buyers should consider the installation ease and the strength of the weld when selecting this type. However, their use is limited to smaller pipes, which may not meet the needs of larger industrial systems.

Why Choose Slip-on Flanges for High Flow-Rate Systems?

Slip-on flanges are popular due to their versatility and availability in a wide range of sizes, making them ideal for high flow-rate applications. They are designed to slip over the pipe, requiring welding on both sides for a secure connection. Buyers should weigh the benefits of their adaptability against the need for more technical installation skills. While they are advantageous for systems requiring high throughput, the welding process can add to installation time and complexity.

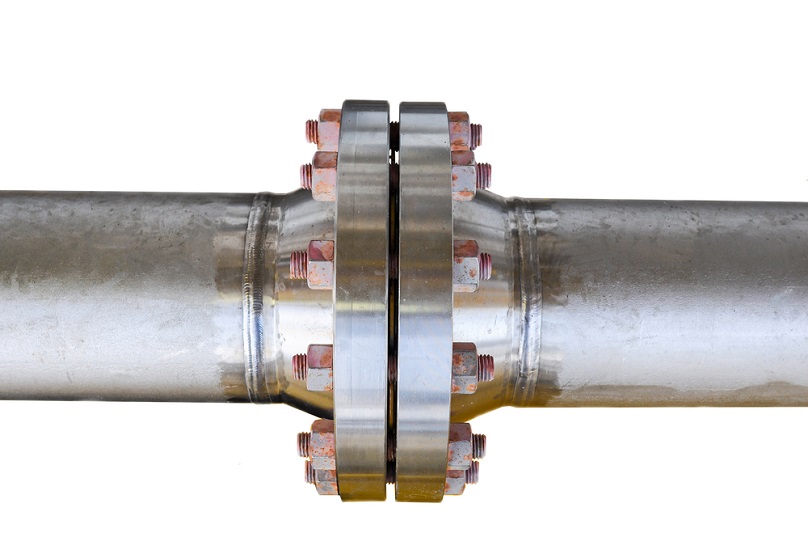

A stock image related to pipe flange.

What Makes Weld Neck Flanges Ideal for Critical Applications?

Weld neck flanges are designed for butt welding, providing a strong and reliable connection suitable for high-pressure and high-temperature applications. They are often used in critical process piping where safety and integrity are paramount. B2B buyers should consider their durability and performance under stress, but also take into account the higher cost and complexity of installation compared to other flange types. Their robust design makes them a preferred choice for industries like oil and gas.

When Should You Use Blind Flanges?

Blind flanges are solid discs used to terminate or isolate piping systems, effectively sealing off flow. They are particularly useful in maintenance scenarios where a section of the pipeline needs to be closed off for repairs or inspections. Buyers should consider their ease of installation and effectiveness in creating a tight seal; however, they cannot be utilized in applications where flow is required. Their cost-effectiveness in maintenance situations makes them a practical choice for many B2B buyers.

Key Industrial Applications of pipe flange

| Industry/Sector | Specific Application of Pipe Flange | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Connection of pipelines and equipment | Ensures secure and leak-proof connections in high-pressure systems | Material compatibility (e.g., stainless steel, carbon steel), pressure ratings, and temperature tolerances |

| Water Treatment | Flanged connections in treatment plants | Facilitates easy maintenance and replacement of components | Corrosion resistance, gasket material compatibility, and international certifications |

| Chemical Processing | Integration of piping systems | Provides flexibility for system modifications and repairs | Compliance with industry standards, chemical compatibility, and flange type (e.g., weld neck, blind) |

| Construction | Plumbing and HVAC systems | Enables efficient installation and maintenance of piping systems | Availability of various sizes, materials, and compatibility with existing systems |

| Manufacturing | Connecting machinery and piping systems | Enhances operational efficiency by ensuring easy access for repairs | Sourcing from reliable suppliers with quality assurance and appropriate certifications |

How Are Pipe Flanges Used in the Oil and Gas Industry?

In the oil and gas sector, pipe flanges are critical for connecting pipelines to various equipment, such as pumps and compressors. These connections must withstand high pressures and harsh environmental conditions. For international buyers, especially in regions like Africa and the Middle East, sourcing flanges made from durable materials like stainless steel or carbon steel is crucial. Additionally, understanding the pressure ratings and temperature tolerances is essential to ensure safety and compliance with industry regulations.

What Role Do Pipe Flanges Play in Water Treatment Facilities?

Pipe flanges are extensively used in water treatment plants to connect various piping components, including valves and filters. They facilitate quick disassembly for maintenance, which is vital in ensuring continuous operation. Buyers from South America and Europe should prioritize corrosion-resistant materials and compatible gasket types to maintain system integrity. Compliance with local and international standards is also necessary to guarantee quality and safety in water treatment processes.

How Are Pipe Flanges Integrated into Chemical Processing?

In chemical processing, flanges are used to connect pipes that transport various chemicals. These connections need to be robust enough to handle corrosive substances and high pressures. International buyers must consider the chemical compatibility of flange materials and the specific flange type that suits their application, such as weld neck or blind flanges. Additionally, ensuring compliance with industry standards is vital for operational safety and efficiency.

Why Are Pipe Flanges Important in Construction Projects?

In construction, pipe flanges are essential for plumbing and HVAC systems. They allow for easy installation and maintenance of piping systems, which is crucial for project timelines and budgets. Buyers should focus on sourcing flanges that come in various sizes and materials to match existing systems. Furthermore, ensuring that suppliers can provide timely deliveries and quality assurance is vital for successful project execution.

What Benefits Do Pipe Flanges Provide in Manufacturing?

In manufacturing, pipe flanges are used to connect machinery and piping systems, enhancing operational efficiency. They allow for quick access to equipment for repairs and maintenance. Buyers should look for suppliers who offer flanges with robust quality assurance processes and relevant certifications. Additionally, understanding the specific requirements of their manufacturing processes, such as size and material compatibility, is essential for optimizing performance and minimizing downtime.

3 Common User Pain Points for ‘pipe flange’ & Their Solutions

Scenario 1: Sourcing Quality Pipe Flanges in Diverse Markets

The Problem: International B2B buyers often face challenges when sourcing pipe flanges that meet their specific requirements for quality and compliance. For example, a manufacturer in Kenya may struggle to find suppliers who provide flanges made from the right materials, such as stainless steel or carbon steel, that conform to local and international standards. This not only affects the integrity of their piping systems but can also lead to project delays and increased costs if they have to re-order or replace substandard products.

The Solution: To overcome sourcing challenges, B2B buyers should establish relationships with reputable suppliers that specialize in international trade. Conducting thorough research on suppliers’ certifications, such as ISO or ASME compliance, can ensure that the flanges meet quality standards. Additionally, utilizing platforms that provide detailed product specifications and customer reviews can aid in making informed purchasing decisions. It’s advisable to request samples or conduct site visits if feasible, to verify the quality of the flanges before placing bulk orders. Lastly, consider leveraging local distributors who understand the regional market nuances and can provide guidance on compliance with local regulations.

Scenario 2: Ensuring Proper Flange Installation and Maintenance

The Problem: Many B2B buyers underestimate the importance of proper installation and maintenance of pipe flanges, which can lead to leaks, costly repairs, and even safety hazards. For instance, a construction company in Brazil may experience frequent pipeline failures due to improper bolting techniques or the wrong gasket selection, resulting in downtime and financial loss.

The Solution: To ensure proper installation, it is crucial to follow a standardized procedure. Buyers should invest in training for their installation teams, focusing on best practices for bolting and gasket installation. Utilizing torque wrenches and adhering to manufacturer specifications for bolt tightening can prevent over-tightening or under-tightening, which is a common cause of flange failure. Additionally, maintaining a regular inspection schedule is vital. Establish a routine check-up system to examine flange connections for signs of wear, corrosion, or leaks. Implementing a preventive maintenance strategy can significantly enhance the longevity of the piping systems and reduce the risk of unexpected failures.

Scenario 3: Selecting the Right Flange Type for Specific Applications

The Problem: B2B buyers often struggle with selecting the appropriate flange type for their specific applications, leading to inefficiencies and increased costs. For example, an oil and gas company operating in the Middle East might need to choose between various flange types such as slip-on, weld neck, or blind flanges for different segments of their pipeline, and making the wrong choice can compromise system performance.

The Solution: Buyers should begin by conducting a thorough analysis of their application requirements, including pressure, temperature, and fluid types. Understanding the characteristics of each flange type is critical; for instance, weld neck flanges are ideal for high-pressure applications, while slip-on flanges are easier to install but may not handle the same pressure levels. Consulting with engineering experts or using simulation software can help visualize how different flange types will perform under specific conditions. Additionally, it’s beneficial to involve the supplier in the decision-making process; many suppliers have technical support teams that can provide insights based on their experience with similar applications. Ultimately, investing time in proper selection will save costs and enhance the reliability of the piping system.

Strategic Material Selection Guide for pipe flange

What Are the Key Properties of Common Pipe Flange Materials?

When selecting pipe flanges for international applications, understanding the properties of various materials is essential. Here are analyses of four common materials used for pipe flanges: stainless steel, carbon steel, brass, and PVC.

How Does Stainless Steel Perform in Pipe Flange Applications?

Stainless steel is known for its excellent corrosion resistance and high-temperature tolerance, making it suitable for a variety of applications, including chemical processing and oil and gas industries. Its temperature rating can exceed 1000°F (537°C), and it can handle pressures up to 1500 psi, depending on the specific grade.

Pros: Stainless steel flanges are durable, resistant to rust, and require minimal maintenance. They can be used in both high-pressure and high-temperature environments, making them versatile.

Cons: The primary disadvantage is cost; stainless steel flanges are generally more expensive than other materials. Additionally, they can be more complex to manufacture, which may lead to longer lead times.

Impact on Application: Stainless steel flanges are compatible with a wide range of media, including corrosive substances. However, buyers should ensure that the specific grade of stainless steel meets the requirements of their application.

Considerations for International Buyers: Compliance with standards such as ASTM A182 or DIN 17440 is critical. Buyers from regions like Europe or the Middle East should verify the specific grade used, as local regulations may dictate material specifications.

What Are the Advantages of Using Carbon Steel for Pipe Flanges?

Carbon steel is a popular choice for flanges due to its strength and affordability. It typically has a temperature rating of up to 800°F (427°C) and can handle pressures around 1500 psi.

Pros: Carbon steel flanges are cost-effective and offer good mechanical properties. They are widely available and suitable for various applications, including water and steam systems.

Cons: However, carbon steel is prone to corrosion, especially in humid or acidic environments, which may necessitate additional protective coatings. This can increase overall maintenance costs.

Impact on Application: Carbon steel flanges are generally compatible with water, oil, and gas. However, they may not be suitable for corrosive media without proper treatment.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A105 or JIS B2220. In regions like Africa or South America, where the climate may be more humid, additional corrosion protection may be necessary.

Why Choose Brass for Pipe Flanges in Specific Applications?

Brass is often used for flanges in plumbing and HVAC applications due to its good corrosion resistance and aesthetic appeal. It can typically handle temperatures up to 400°F (204°C) and pressures around 300 psi.

Pros: Brass flanges are easy to machine and provide a good seal, making them ideal for low-pressure applications. They also resist corrosion from water and are often used in potable water systems.

Cons: The downside is that brass is more expensive than carbon steel and can be less durable in high-pressure applications. Additionally, it may not be suitable for high-temperature environments.

Impact on Application: Brass flanges are excellent for water and gas applications but should be avoided in high-pressure or high-temperature scenarios.

Considerations for International Buyers: Compliance with standards like ASTM B16.24 is essential. Buyers in Europe may prefer brass flanges for plumbing systems due to their aesthetic qualities.

When Is PVC the Right Choice for Pipe Flanges?

PVC flanges are commonly used in non-pressure applications, particularly in drainage and wastewater systems. They can typically withstand temperatures up to 140°F (60°C) and pressures up to 150 psi.

Pros: PVC flanges are lightweight, resistant to corrosion, and easy to install. They are also cost-effective, making them a popular choice for budget-conscious projects.

Cons: However, PVC flanges are not suitable for high-temperature or high-pressure applications, which limits their usability. They can also become brittle over time when exposed to UV light.

Impact on Application: PVC flanges are ideal for non-potable water systems but should not be used in applications involving hot water or steam.

Considerations for International Buyers: Buyers should check for compliance with standards such as ASTM D2466. In regions like Africa, where PVC is commonly used for plumbing, ensuring the right specifications is crucial.

Summary Table of Pipe Flange Materials

| Material | Typical Use Case for pipe flange | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Chemical processing, oil & gas | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Carbon Steel | Water and steam systems | Cost-effective and strong | Prone to corrosion | Medium |

| Brass | Plumbing, HVAC | Good corrosion resistance | Less durable in high-pressure scenarios | Medium |

| PVC | Drainage, wastewater systems | Lightweight and easy to install | Not suitable for high temperatures | Low |

This strategic material selection guide provides international B2B buyers with essential insights into the properties, advantages, and limitations of various pipe flange materials, enabling informed purchasing decisions tailored to specific applications and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for pipe flange

What Are the Main Stages of Pipe Flange Manufacturing?

The manufacturing of pipe flanges involves several critical stages, each contributing to the overall quality and functionality of the final product. Understanding these processes can help international B2B buyers make informed decisions when sourcing flanges for their projects.

1. Material Preparation: What Materials Are Commonly Used?

The first step in the manufacturing process is material preparation. Pipe flanges are typically made from a variety of metals, including:

- Stainless Steel: Known for its corrosion resistance, making it ideal for various applications.

- Carbon Steel: Offers strength and durability, often used in industrial settings.

- Alloys: Such as Monel and Inconel, used in specialized applications requiring high strength and corrosion resistance.

Before the fabrication begins, the raw materials must be sourced from reputable suppliers and undergo inspections to ensure they meet the required specifications. B2B buyers should inquire about the material certification from suppliers to verify compliance with international standards.

2. Forming: How Are Flanges Shaped?

Once the materials are prepared, the next stage is forming. This can be achieved through various techniques:

- Forging: A common method where the metal is shaped under high pressure, enhancing its strength.

- Casting: Involves pouring molten metal into a mold to create the desired flange shape.

- Machining: For precision, flanges may be further machined to meet exact specifications, ensuring proper fit and finish.

These methods can affect the mechanical properties of the flanges, so it is essential for buyers to understand the techniques used by their suppliers.

3. Assembly: What Components Are Included?

After forming, flanges may require assembly, which typically involves the integration of several components:

- Flange Body: The main structure that connects to pipes.

- Gaskets: Essential for creating a seal between flanges, preventing leaks.

- Bolting: Used to secure the flanges together, ensuring a tight connection.

Buyers should pay attention to the types of gaskets and bolts used, as these components significantly affect the overall performance and reliability of the flange in their specific applications.

4. Finishing: How Is Quality Enhanced?

The final stage is finishing, which may include:

- Surface Treatments: Such as galvanizing or coating to improve corrosion resistance.

- Polishing: For aesthetic purposes or to meet specific industry standards.

- Heat Treatment: Enhances mechanical properties, making flanges more durable.

Understanding the finishing processes can help buyers determine whether the flanges will perform adequately in their intended environments.

What International Quality Standards Should B2B Buyers Consider?

Quality assurance is paramount in the manufacturing of pipe flanges. Various international standards guide the quality processes that manufacturers must follow.

ISO 9001: What Does It Mean for Quality Management?

ISO 9001 is a widely recognized quality management standard that outlines the criteria for a quality management system (QMS). Manufacturers that comply with this standard demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Buyers should check if their suppliers are ISO 9001 certified, as this can be an indicator of a commitment to quality.

CE Marking: What Is Its Importance in Europe?

For products sold in the European market, CE marking signifies compliance with health, safety, and environmental protection standards. This is particularly important for B2B buyers in Europe, as it ensures that the products meet stringent regulatory requirements.

API Standards: How Do They Relate to Flange Quality?

The American Petroleum Institute (API) provides specific standards for flanges used in the oil and gas industry. These standards cover material specifications, manufacturing processes, and testing requirements. Buyers in industries such as oil and gas should ensure that their suppliers adhere to API standards.

What Are the Key Quality Control Checkpoints in Flange Manufacturing?

Quality control (QC) checkpoints are crucial to maintaining the integrity of the manufacturing process. Here are the typical QC stages:

Incoming Quality Control (IQC)

During the IQC stage, raw materials are inspected upon arrival to verify their quality and compliance with specifications. This step is essential for preventing defects in the final product.

In-Process Quality Control (IPQC)

IPQC occurs at various stages of the manufacturing process. This involves continuous monitoring and testing to ensure that each step meets the established quality standards. Techniques such as visual inspections and dimensional checks are commonly employed.

Final Quality Control (FQC)

The FQC stage involves a comprehensive inspection of the finished flanges. This includes testing for dimensions, surface finish, and mechanical properties. Common testing methods include:

- Hydrostatic Testing: To check for leaks.

- Ultrasonic Testing: For detecting internal defects.

- Visual Inspection: To identify surface irregularities.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is vital for international buyers. Here are practical steps to ensure your suppliers meet your quality expectations:

Supplier Audits: What Should They Include?

Conducting supplier audits can provide insights into the manufacturing processes and QC measures in place. These audits should include:

- Facility Inspections: Evaluating the manufacturing environment and equipment.

- Process Evaluations: Reviewing the production methods and QC checkpoints.

- Documentation Review: Ensuring that proper records of inspections and tests are maintained.

Quality Reports: How Can They Be Utilized?

Requesting quality reports from suppliers can help buyers understand the QC measures implemented during production. These reports should detail the testing methods used, results obtained, and any corrective actions taken.

Third-Party Inspections: Are They Necessary?

Engaging third-party inspection services can provide an unbiased assessment of the quality of the flanges being produced. This is particularly important for buyers in regions such as Africa and South America, where local regulations and standards may vary.

What Quality Control Nuances Should International Buyers Be Aware Of?

For international B2B buyers, understanding the nuances of quality control across different regions is essential. Buyers should be aware of:

- Regional Standards: Different regions may have varying standards and regulations governing flange manufacturing.

- Cultural Differences: Approaches to quality assurance may differ based on local practices and expectations.

- Supply Chain Risks: Political and economic instability in certain regions can affect the reliability of supply chains, making it crucial to have contingency plans in place.

A stock image related to pipe flange.

By being informed about manufacturing processes and quality assurance standards, B2B buyers can make well-informed sourcing decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pipe flange’

In the global marketplace, sourcing pipe flanges requires a strategic approach to ensure quality, compatibility, and cost-effectiveness. This guide offers a step-by-step checklist for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, to streamline the procurement process.

Step 1: Define Your Technical Specifications

Before starting the procurement process, it’s vital to clearly outline the technical specifications for the pipe flanges you need. This includes determining the type of flange (e.g., threaded, slip-on, blind), material (e.g., stainless steel, carbon steel), pressure ratings, and sizes that match your piping system. Accurate specifications help avoid mismatches that can lead to operational inefficiencies and increased costs.

Step 2: Research Applicable Standards and Regulations

Understanding the relevant industry standards and regulations in your region is crucial. Different countries have varying requirements for pressure ratings, materials, and safety standards for piping systems. Ensure that the flanges you are considering meet these standards to avoid legal complications and ensure safety compliance.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who have a proven track record in delivering quality products and can provide certifications that validate their compliance with international standards.

- Supplier certifications to consider:

- ISO 9001: Quality Management

- ASME: American Society of Mechanical Engineers

- API: American Petroleum Institute

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the flanges you intend to procure. Testing samples allows you to verify the quality, compatibility, and performance of the flanges under your operational conditions. This step is crucial to ensure that the flanges will meet your application requirements before making a bulk purchase.

Step 5: Analyze Pricing Structures

Pricing is a critical factor in procurement decisions. Analyze the pricing structures provided by different suppliers, taking into account not just the unit price but also shipping costs, tariffs, and any potential hidden fees. A lower initial price may not always translate to overall savings if additional costs arise later in the supply chain.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations to establish favorable terms and conditions. Discuss payment terms, delivery timelines, and warranty provisions. Ensure that all agreements are documented to protect your interests and ensure clarity for both parties.

Step 7: Plan for Logistics and Delivery

Finally, develop a logistics plan to ensure that your flanges are delivered on time and in good condition. Consider factors such as shipping methods, customs clearance, and storage upon arrival. Effective logistics planning can help mitigate delays and additional costs, ensuring a smooth procurement process.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing pipe flanges, ensuring they make informed decisions that align with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for pipe flange Sourcing

What Are the Key Cost Components in Pipe Flange Sourcing?

When evaluating the costs associated with sourcing pipe flanges, several components come into play. Understanding these can help B2B buyers make informed decisions.

-

Materials: The choice of materials significantly affects the cost. Common materials for pipe flanges include stainless steel, carbon steel, brass, and PVC. Stainless steel flanges, while more durable, are generally pricier than their carbon steel counterparts. Buyers should assess the required material based on the application to avoid overspending.

-

Labor: Labor costs are incurred during the manufacturing process and can vary by region. Countries with higher labor rates, such as those in Europe, may see increased flange prices compared to manufacturers in regions like Africa or South America where labor costs are typically lower.

-

Manufacturing Overhead: This includes costs related to factory operations, maintenance, and utilities. Manufacturers often pass these costs onto buyers. Understanding the manufacturer’s operational efficiency can provide insight into potential pricing variations.

-

Tooling: The initial investment in tooling for production can be significant, particularly for custom or specialized flanges. Buyers should inquire whether tooling costs are included in the quoted price or charged separately.

-

Quality Control (QC): Rigorous QC processes ensure that flanges meet industry standards and specifications. While this may increase initial costs, it can prevent costly failures and replacements later on, making it a worthwhile investment.

-

Logistics: Shipping costs, including freight, tariffs, and handling, can dramatically affect the total cost of acquisition. Buyers should consider both the distance from suppliers and the chosen shipping method, as these factors can lead to substantial price differences.

-

Margin: Supplier margins vary widely based on market conditions and competition. Understanding the supplier’s pricing strategy can aid in negotiations.

How Do Price Influencers Affect Pipe Flange Costs?

Several factors can influence the pricing of pipe flanges:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to discounts. Buyers should negotiate MOQs to optimize their purchasing strategy.

-

Specifications and Customization: Customized flanges or those with specific certifications will typically incur higher costs. Buyers should carefully assess whether customization is necessary for their application.

-

Material Quality and Certifications: Flanges that comply with industry standards or possess certifications (e.g., ISO, ASTM) may be priced higher. However, these certifications often ensure reliability, which is critical for many applications.

-

Supplier Factors: Supplier reputation, reliability, and service can influence pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can affect logistics costs and responsibilities. Buyers should select terms that minimize their total cost while ensuring a smooth delivery process.

What Are Effective Buyer Tips for Cost-Efficiency?

To maximize cost-efficiency in sourcing pipe flanges, consider the following strategies:

-

Negotiate with Suppliers: Engage in open discussions with suppliers about pricing, especially if you can commit to larger orders. Building a relationship can lead to better terms.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial price. Consider maintenance, replacement, and operational costs associated with the flanges. A lower upfront cost may lead to higher long-term expenses if quality is compromised.

-

Understand Pricing Nuances for International Buyers: International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of currency fluctuations, local tariffs, and import duties that can affect the final cost. Researching local regulations can prevent unforeseen expenses.

-

Request Quotes from Multiple Suppliers: Obtaining quotes from various suppliers allows for better comparison and negotiation opportunities.

Disclaimer on Indicative Prices

Please note that the prices for pipe flanges can fluctuate based on market conditions and regional factors. It is advisable to conduct thorough market research and obtain current quotes from suppliers to ensure accurate budgeting.

Alternatives Analysis: Comparing pipe flange With Other Solutions

When considering piping solutions, it’s vital for B2B buyers to evaluate not just the primary option—pipe flanges—but also alternative methods that may provide similar functionalities. This analysis seeks to compare pipe flanges with two viable alternatives: welded connections and threaded fittings. Each method has unique characteristics that can cater to specific operational needs and environments.

Comparison Table of Pipe Flanges and Alternatives

| Comparison Aspect | Pipe Flange | Welded Connections | Threaded Fittings |

|---|---|---|---|

| Performance | High integrity, suitable for high pressure and temperature | Excellent for permanent joints | Good for low-pressure systems |

| Cost | Moderate initial cost; ongoing maintenance may incur extra costs | Higher upfront costs due to labor and equipment | Generally low cost, but may require additional fittings |

| Ease of Implementation | Requires specialized tools and skilled labor | Complex installation; requires welding expertise | Simple installation; can be done with basic tools |

| Maintenance | Requires regular inspection and potential replacement of gaskets | Minimal maintenance once installed | Frequent checks needed for wear and tear |

| Best Use Case | Ideal for dynamic systems needing frequent access | Best for fixed installations in high-demand environments | Suitable for low-pressure applications or where disassembly is infrequent |

What Are the Advantages and Disadvantages of Welded Connections?

Welded connections are a traditional method of joining pipes that offer high structural integrity. Their primary advantage is their ability to handle high pressures and temperatures, making them ideal for industrial applications such as petrochemical plants. However, they require skilled labor and specialized equipment, which can lead to higher initial costs. Moreover, once a welded joint is made, it is challenging to disassemble, which may be a drawback in systems requiring frequent access.

How Do Threaded Fittings Compare to Pipe Flanges?

Threaded fittings provide a simpler and more cost-effective alternative to pipe flanges, particularly for low-pressure systems. They are easy to install with minimal tools and can be quickly disassembled if necessary. However, they may not provide the same level of sealing integrity and can be prone to leaks under high pressure or temperature conditions. As such, they are best used in applications where ease of installation and maintenance outweigh the need for high-pressure performance.

Conclusion: How to Choose the Right Piping Solution for Your Needs

For international B2B buyers, selecting the right piping solution hinges on understanding the specific operational requirements of your systems. Pipe flanges offer flexibility and strength, making them suitable for complex or dynamic environments. Welded connections excel in permanent, high-demand applications but come with higher installation costs. Threaded fittings serve well in low-pressure scenarios where simplicity and cost are paramount. By carefully evaluating the performance, cost, implementation ease, maintenance needs, and best use cases, buyers can make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for pipe flange

A stock image related to pipe flange.

What Are the Essential Technical Properties of Pipe Flanges?

Understanding the technical properties of pipe flanges is crucial for international B2B buyers, especially those involved in construction, manufacturing, and infrastructure projects. Here are several key specifications that should be prioritized:

1. Material Grade: Why Does It Matter?

Flanges are available in various materials, including stainless steel, carbon steel, and PVC. The material grade determines the flange’s strength, corrosion resistance, and suitability for specific applications. For instance, stainless steel flanges are often preferred for high-pressure and high-temperature applications due to their durability and resistance to corrosion. Buyers should consider the environmental conditions and fluid types involved in their systems to select the appropriate material.

2. Pressure Rating: How to Choose the Right One?

Flanges come with different pressure ratings, often classified under ANSI (American National Standards Institute) or ASME (American Society of Mechanical Engineers) standards. Common ratings include 150, 300, and 600 pounds per square inch (PSI). Understanding the pressure requirements of your piping system ensures that the selected flange can withstand the operational demands, thus preventing potential failures or leaks.

3. Tolerance: What Should You Know?

Tolerance refers to the allowable variation in the dimensions of the flange, such as thickness and diameter. This specification is vital for ensuring a proper fit within the piping system. Tight tolerances are essential in high-precision applications, while looser tolerances may suffice in less critical environments. Buyers should confirm tolerance levels with manufacturers to ensure compatibility with existing systems.

4. Face Type: Which One is Right for Your Application?

Flange face types, such as flat face (FF), raised face (RF), and ring joint (RTJ), influence how the flange seals against the gasket. The choice of face type affects the sealing effectiveness, especially in high-pressure applications. Understanding the specific needs of your system will guide you in selecting the appropriate face type, thus improving overall system reliability.

5. Size and Compatibility: How to Ensure a Proper Fit?

Flanges come in various sizes, and it’s essential to select a flange that matches the diameter of the pipe it will connect to. Compatibility with existing piping systems is crucial for ensuring a seamless installation and optimal performance. Buyers should refer to standard size charts and consult with suppliers to determine the correct flange dimensions.

What Are Common Trade Terms Related to Pipe Flanges?

Familiarity with industry jargon can streamline the purchasing process and enhance communication between buyers and suppliers. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer): What Does This Mean?

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of pipe flanges, working with OEMs ensures that the components meet specific standards and quality requirements, which is critical for maintaining system integrity.

2. MOQ (Minimum Order Quantity): Why Is It Important?

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for budgeting and inventory management. Buyers should negotiate MOQ terms that align with their project needs to avoid excess inventory or supply shortages.

3. RFQ (Request for Quotation): How to Use It Effectively?

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. Crafting a detailed RFQ for pipe flanges can lead to competitive pricing and better service terms. Be sure to include specifications, quantities, and delivery timelines to receive accurate quotes.

4. Incoterms (International Commercial Terms): What Should You Know?

Incoterms are standardized terms used in international trade to define the responsibilities of buyers and sellers. Understanding these terms helps clarify shipping responsibilities, risk management, and cost allocation. Familiarity with Incoterms is essential for international B2B buyers to avoid misunderstandings during transactions.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing pipe flanges, ensuring compatibility, reliability, and cost-effectiveness in their projects.

Navigating Market Dynamics and Sourcing Trends in the pipe flange Sector

What Are the Current Market Dynamics and Key Trends in the Pipe Flange Sector?

The global pipe flange market is witnessing a robust transformation driven by several factors. Increasing industrial activities, particularly in sectors such as oil and gas, water management, and construction, are propelling demand for reliable and durable piping solutions. Moreover, the rise of smart technologies, including IoT and automation, is influencing B2B sourcing trends, as companies seek flanges that are compatible with advanced monitoring systems.

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding local market dynamics is crucial. In Africa, for instance, the growing investment in infrastructure projects creates a steady demand for various flange types, including stainless steel and carbon steel options. In South America, economic recovery post-pandemic has sparked a resurgence in the manufacturing sector, leading to increased flange requirements. Meanwhile, in the Middle East, the shift towards renewable energy sources is driving innovation in flange design, particularly for applications in solar and wind energy systems.

European buyers are also focusing on product quality and compliance with stringent regulations, which has led to a surge in demand for specialty flanges that meet high-performance standards. Additionally, the rise of e-commerce platforms and digital marketplaces is simplifying the procurement process, enabling international buyers to access a broader range of suppliers and products efficiently.

How Can Sustainability and Ethical Sourcing Impact the Pipe Flange Sector?

Sustainability is becoming a central theme in the pipe flange sector, with an increasing emphasis on minimizing environmental impact and fostering ethical supply chains. The production of flanges often involves significant energy consumption and resource extraction, leading to concerns about carbon footprints and waste management. B2B buyers are increasingly prioritizing suppliers that demonstrate commitment to sustainable practices, such as using recycled materials and adopting energy-efficient manufacturing processes.

Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming essential considerations for buyers seeking to ensure that their supply chains align with environmental standards. Furthermore, the use of “green” materials, like bio-based plastics or low-carbon steel, is gaining traction. These materials not only reduce environmental impact but also appeal to a growing consumer base that values sustainability.

For buyers in regions like Europe and the Middle East, where regulatory pressures for environmental compliance are more pronounced, sourcing from suppliers who are transparent about their sustainability practices is not just a preference but a necessity. Companies that proactively address these concerns will likely enhance their market competitiveness and brand reputation.

What is the Brief Evolution and History of Pipe Flanges?

The history of pipe flanges dates back to the early days of industrialization when the need for reliable piping connections became apparent. Initially, flanges were simple metal discs used to connect two pipes, and their designs were rudimentary. As the industrial landscape evolved, so did flange technology, leading to the development of various types such as slip-on, weld neck, and blind flanges, each tailored to specific applications and performance requirements.

The introduction of standardized flange dimensions in the early 20th century greatly facilitated global trade and manufacturing, allowing for interoperability across different regions and industries. Over the years, advancements in materials science and engineering have led to the creation of high-performance flanges capable of withstanding extreme pressures and temperatures. Today, the ongoing integration of smart technologies and sustainability practices is shaping the future of flanges, making them more versatile and environmentally friendly.

In summary, the pipe flange market is evolving rapidly, influenced by technological advancements and shifting buyer preferences. International B2B buyers must stay informed about these dynamics to make strategic sourcing decisions that align with their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of pipe flange

-

How do I choose the right pipe flange for my project?

Choosing the right pipe flange involves considering several factors, including the material compatibility with your piping system, the pressure and temperature ratings, and the specific application requirements. For instance, stainless steel flanges are excellent for high-pressure systems, while PVC flanges are suitable for lower-pressure applications. Additionally, the flange type (e.g., slip-on, weld neck, or blind) should align with your installation process and maintenance needs. Always consult with your supplier to ensure that the selected flange meets industry standards and your specific project demands. -

What is the best material for pipe flanges in high-temperature applications?

For high-temperature applications, materials like Inconel, Monel, or carbon steel with high-temperature ratings are ideal. These materials withstand thermal expansion and maintain integrity under extreme conditions. When selecting a flange, ensure it matches the piping material to avoid galvanic corrosion. Additionally, verify that the flange is rated for the specific temperature range of your application. Consulting with your supplier or a materials engineer can help in making the best choice for your needs. -

What factors should I consider when sourcing pipe flanges internationally?

When sourcing pipe flanges internationally, consider factors like the supplier’s reputation, compliance with international standards, and material certifications. Verify the supplier’s ability to provide documentation for quality assurance, such as ISO certifications or material test reports. Additionally, assess the logistics involved, including shipping times, customs regulations, and import duties for your country. Establishing a clear communication channel with the supplier will facilitate a smoother procurement process. -

What is the minimum order quantity (MOQ) for pipe flanges?

Minimum order quantities for pipe flanges vary by supplier and can depend on the type and material of the flanges. Generally, MOQs range from 50 to 100 pieces, but some manufacturers may accommodate smaller orders, especially for custom flanges. It’s crucial to discuss your requirements with potential suppliers to negotiate terms that suit your project needs without incurring excess costs. -

How can I ensure the quality of pipe flanges when buying from a supplier?

To ensure quality, request detailed specifications and certifications from your supplier. Look for flanges that meet international standards, such as ASTM or ASME. Additionally, consider third-party inspections or audits to verify manufacturing processes and material integrity. Establishing a quality assurance agreement with your supplier can also help maintain consistent quality throughout your order. -

What payment terms are common for international B2B purchases of pipe flanges?

Common payment terms for international B2B purchases include letters of credit, advance payments, or net payment terms (e.g., net 30, net 60). Letters of credit provide security for both parties, while advance payments may be required for custom or large orders. Discussing and agreeing on payment terms upfront with your supplier is essential to avoid misunderstandings and ensure a smooth transaction process. -

What are the logistics considerations for importing pipe flanges?

Logistics considerations include shipping methods, transit times, customs clearance, and handling fees. Choose a reliable freight forwarder familiar with importing industrial materials to streamline the process. Additionally, be aware of local regulations regarding material imports to avoid delays. It’s also beneficial to have a clear understanding of the incoterms (e.g., FOB, CIF) to determine responsibilities for shipping costs and risks. -

Can I customize pipe flanges for specific applications?

Yes, many suppliers offer customization options for pipe flanges, including size, material, and design modifications to suit specific applications. When discussing your needs, provide detailed specifications and any relevant standards that must be met. Custom flanges can enhance performance and compatibility in specialized systems, but be mindful of potential lead times and costs associated with custom orders.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for pipe flange

In the ever-evolving landscape of industrial procurement, strategic sourcing for pipe flanges presents a crucial opportunity for international B2B buyers. Understanding the various flange types—such as threaded, socket-weld, slip-on, and blind flanges—enables organizations to select the most suitable options for their specific applications. Key takeaways include the importance of matching flange materials with operational requirements, as well as considering factors like pressure ratings and compatibility with existing piping systems.

Strategic sourcing not only enhances supply chain efficiency but also drives cost savings and improves product quality. By leveraging local suppliers in regions like Africa, South America, the Middle East, and Europe, businesses can foster partnerships that ensure timely deliveries and compliance with regional standards.

Looking ahead, the demand for sustainable and high-performance piping solutions will continue to rise. International B2B buyers are encouraged to embrace innovative sourcing strategies, explore new market trends, and prioritize suppliers who demonstrate a commitment to quality and sustainability. Engaging proactively in these practices will not only secure competitive advantages but also contribute to long-term operational success.