Discover 12 Different Kinds of Bolts to Boost Your Projects (2025)

Introduction: Navigating the Global Market for different kinds of bolts

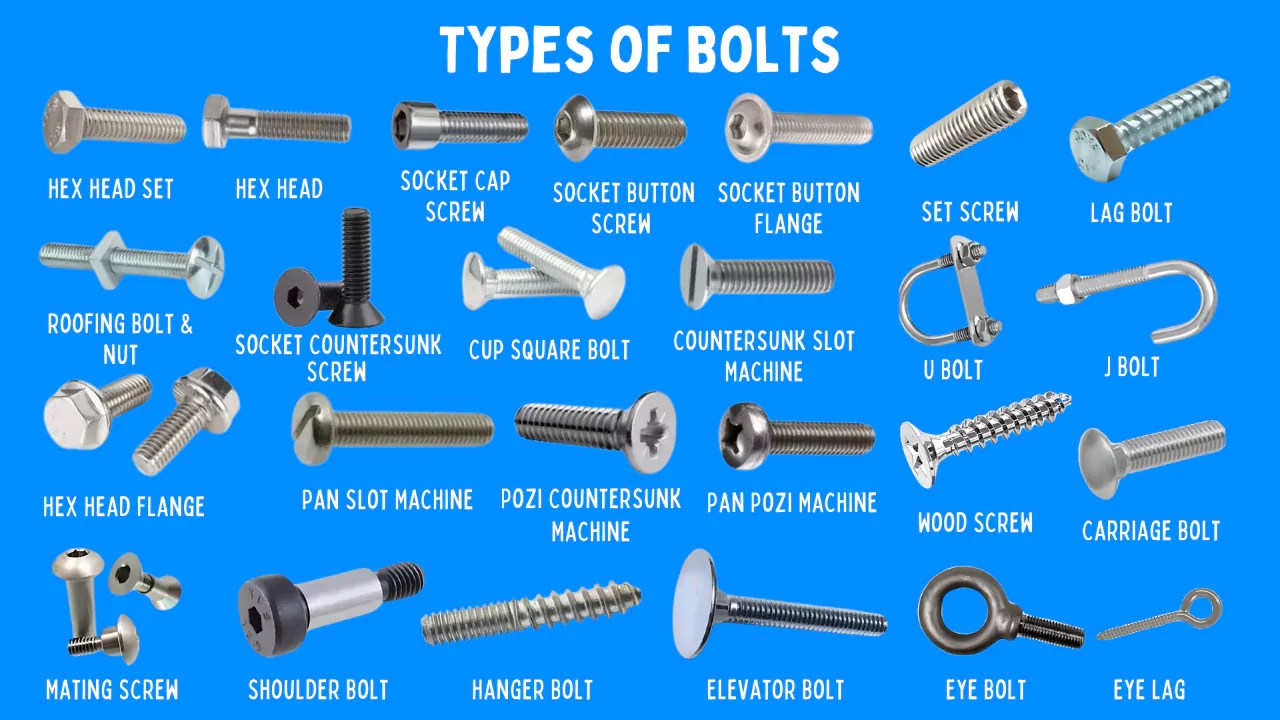

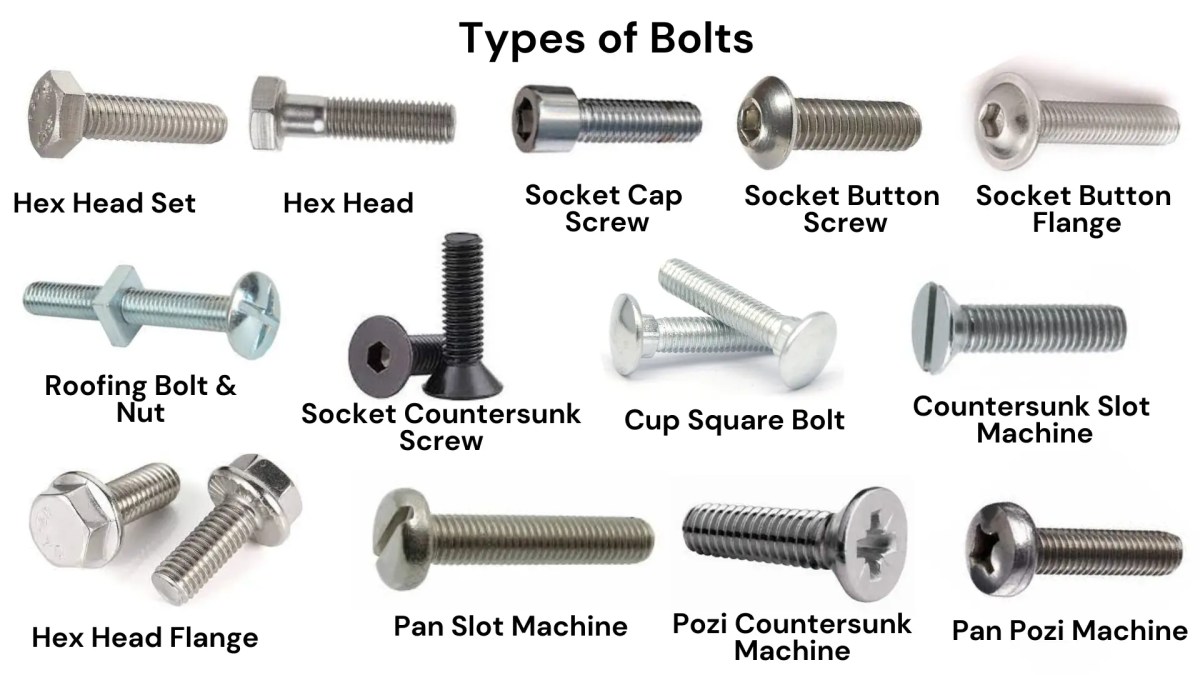

Navigating the global market for different kinds of bolts can be a daunting challenge for international B2B buyers, especially when sourcing materials that meet specific industry standards and applications. With a diverse array of bolt types available, from hex bolts to carriage bolts and beyond, understanding which fastener is best suited for your project is crucial. This comprehensive guide delves into the various types of bolts, their applications, and how to effectively vet suppliers to ensure quality and reliability.

For businesses in Africa, South America, the Middle East, and Europe, making informed purchasing decisions is essential to optimize supply chains and reduce costs. This guide will provide actionable insights into bolt specifications, usage scenarios, and pricing strategies that cater to the unique needs of diverse markets. Additionally, we will explore the intricacies of supplier relationships, including how to assess their capabilities and compliance with international standards.

As you navigate this complex landscape, our goal is to empower you with the knowledge necessary to streamline your procurement process. By understanding the nuances of different bolt types and their respective applications, you can enhance your operational efficiency, mitigate risks, and ultimately drive greater value for your business. Whether you are in the automotive, construction, or manufacturing sectors, this guide is designed to be your trusted resource for navigating the global market of bolts.

Understanding different kinds of bolts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hex Bolts | Hexagonal head, available in various grades | Construction, machinery assembly | Pros: High strength; Cons: Requires a wrench for installation. |

| Carriage Bolts | Smooth, rounded head with a square neck | Wood and metal connections | Pros: Prevents spinning; Cons: Limited to specific applications. |

| Lag Bolts | Wood-threaded with a pointed tip | Wood construction, heavy-duty tasks | Pros: Excellent grip in wood; Cons: Not suitable for metal. |

| Eye Bolts | Circular ring on the head for rope or chain | Lifting, rigging applications | Pros: Versatile for lifting; Cons: Limited load capacity. |

| U-Bolts | U-shaped for attaching to round surfaces | Pipe mounting, structural support | Pros: Easy installation; Cons: Requires specific sizing. |

What are Hex Bolts and Their B2B Relevance?

Hex bolts are one of the most common types of fasteners used in various industries. Their hexagonal head allows for easy gripping with a wrench, providing a secure fastening option. Hex bolts are typically made from high-strength materials, making them ideal for construction and machinery assembly. When purchasing hex bolts, buyers should consider the material grade, as it impacts strength and corrosion resistance. Ensuring compatibility with existing tools and assembly methods is also crucial.

How Do Carriage Bolts Function in B2B Applications?

Carriage bolts are characterized by their smooth, rounded head and square neck, which prevents them from turning when tightened. They are predominantly used in wood and metal connections, making them a staple in construction and furniture assembly. B2B buyers should evaluate the length and diameter of carriage bolts to ensure they meet specific application requirements. Their ease of use in installations requiring a flush finish makes them a preferred choice, though their application is somewhat limited compared to other bolt types.

Why Choose Lag Bolts for Wood Construction?

Lag bolts are specifically designed for heavy-duty applications in wood. Their wood-threaded design and pointed tip enable them to penetrate wooden materials effectively, providing a strong grip. They are commonly used in construction and heavy-duty tasks where traditional screws may not suffice. Buyers should be cautious about using lag bolts in metal applications, as they are not designed for such use. It is essential to select the appropriate size and length to achieve optimal performance in wood applications.

What Makes Eye Bolts Suitable for Lifting Applications?

Eye bolts feature a circular ring on the head, allowing for easy attachment of ropes or chains. They are widely used in lifting and rigging applications, making them essential for industries such as construction and shipping. When purchasing eye bolts, buyers should pay attention to the load capacity and material, as these factors determine their suitability for specific tasks. While versatile, eye bolts may have limitations in terms of load capacity, making it important to assess the specific requirements of the application.

How Do U-Bolts Serve in Structural Support?

U-bolts are designed in a U-shape, making them ideal for attaching to round surfaces such as pipes. They are commonly used in pipe mounting and structural support applications across various industries. When sourcing U-bolts, buyers should consider the diameter and length to ensure proper fit and functionality. Their ease of installation is a significant advantage; however, selecting the right size is crucial to avoid issues during assembly. U-bolts are effective in providing secure connections in a wide range of applications.

Key Industrial Applications of different kinds of bolts

| Industry/Sector | Specific Application of different kinds of bolts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Use of hex bolts in vehicle assembly for securing engine components. | Ensures structural integrity and safety of vehicles. | Sourcing high-strength materials and corrosion resistance. |

| Construction | Lag bolts for securing wooden beams in residential and commercial projects. | Provides durability and load-bearing capacity in structures. | Compliance with local building codes and environmental conditions. |

| Aerospace | Use of shoulder bolts in aircraft assembly for pivot points. | Enhances safety and reliability in critical applications. | Certification of materials and adherence to strict aviation standards. |

| Renewable Energy | Elevator bolts in wind turbine assembly for securing blades. | Optimizes energy production and operational efficiency. | Availability of specialized sizes and resistance to harsh environmental conditions. |

| Heavy Machinery | U-bolts for securing pipes and frames in industrial equipment. | Reduces maintenance costs and improves operational reliability. | Consideration of load capacity and compatibility with existing machinery. |

How Are Different Kinds of Bolts Used in Automotive Manufacturing?

In the automotive manufacturing sector, hex bolts are extensively used to secure engine components and other critical parts. These bolts provide the necessary tensile strength to withstand the vibrations and stresses encountered during vehicle operation. For international buyers, particularly in regions like Africa and South America, sourcing high-strength hex bolts that comply with local automotive safety standards is crucial. Additionally, considering corrosion resistance is vital to ensure longevity in various climates.

What Role Do Lag Bolts Play in Construction Projects?

Lag bolts are essential in the construction industry, particularly for securing wooden beams in both residential and commercial structures. They offer superior load-bearing capacity, making them ideal for heavy-duty applications. Buyers in the Middle East and Europe should focus on sourcing lag bolts that comply with local building codes to ensure structural integrity. Additionally, understanding the environmental conditions, such as humidity and temperature fluctuations, can influence the choice of materials used for these bolts.

Why Are Shoulder Bolts Important in Aerospace Applications?

In aerospace applications, shoulder bolts serve a critical function by providing pivot points for various moving components within aircraft. Their design allows for smooth rotational movement, which is essential for safety and reliability in flight operations. International B2B buyers in the aerospace sector must prioritize sourcing certified materials that meet stringent aviation standards. This includes ensuring that the shoulder bolts can withstand high-stress conditions and are resistant to fatigue over time.

How Do Elevator Bolts Contribute to Renewable Energy Solutions?

Elevator bolts are commonly used in the assembly of wind turbines, where they secure the blades to the hub. This application is crucial for optimizing energy production and ensuring the operational efficiency of the turbines. Buyers in the renewable energy sector, particularly in Europe, should consider sourcing specialized elevator bolts that can withstand harsh environmental conditions, including high winds and corrosion. Ensuring the availability of the right sizes and specifications is also essential for seamless assembly.

What Benefits Do U-Bolts Provide in Heavy Machinery?

U-bolts are widely utilized in heavy machinery for securing pipes and frames, playing a significant role in maintaining the structural integrity of industrial equipment. By reducing maintenance costs and enhancing operational reliability, these bolts contribute to overall productivity. B2B buyers from regions with heavy industrial activities, such as South Africa, should focus on sourcing U-bolts that meet specific load capacity requirements and are compatible with existing machinery to ensure optimal performance.

3 Common User Pain Points for ‘different kinds of bolts’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Bolt Type for Specific Applications

The Problem: B2B buyers often struggle to identify the appropriate type of bolt for specific applications. For instance, a manufacturer in South Africa may require bolts that withstand high tensile strength for heavy machinery but is unsure whether to choose hex bolts, carriage bolts, or flange bolts. This confusion can lead to costly mistakes, such as selecting the wrong fastener that fails under pressure, causing production delays and increased operational costs.

The Solution: To address this challenge, it’s essential to develop a clear understanding of the application requirements. Start by gathering detailed specifications regarding load, environmental conditions, and material compatibility. For example, if you need bolts for outdoor equipment exposed to moisture, consider using stainless steel or galvanized bolts to prevent corrosion. Engage with suppliers who can provide comprehensive technical data sheets for each bolt type, including tensile strength, material properties, and recommended applications. Additionally, consider leveraging a fastener type chart to compare characteristics and select the most suitable option efficiently.

Scenario 2: Inconsistent Quality and Sourcing Issues in Bolt Procurement

The Problem: International buyers, especially from regions like the Middle East and Africa, often face challenges related to inconsistent quality when sourcing bolts from multiple suppliers. Variations in manufacturing standards can lead to discrepancies in strength and reliability. This inconsistency not only affects project timelines but also raises safety concerns, especially in critical applications such as construction or automotive industries.

The Solution: To mitigate sourcing issues, establish strong relationships with reputable manufacturers and suppliers who adhere to international quality standards, such as ISO 9001. Conduct thorough supplier audits and request samples for testing before placing bulk orders. Implement a quality assurance process that includes regular inspections and testing of bolts upon delivery. Additionally, consider consolidating your suppliers to a select few who consistently meet your quality expectations. This strategic approach not only simplifies procurement but also enhances accountability and reduces risks associated with poor-quality fasteners.

Scenario 3: Challenges in Installation and Maintenance of Bolts

The Problem: Many B2B buyers encounter difficulties during the installation and maintenance of bolts, which can result in improper fastening and subsequent equipment failures. For example, a construction firm in Europe might struggle with the installation of self-drilling screws due to insufficient knowledge about the correct torque specifications or the need for pre-drilled pilot holes, leading to stripped heads or broken screws.

The Solution: To improve installation practices, invest in training for your team on proper fastening techniques, including torque specifications and the importance of using the correct tools. Provide detailed installation guides for different bolt types, emphasizing the significance of using compatible nuts and washers. For self-drilling screws, ensure that your team understands the specific applications and material thicknesses they are designed for. Additionally, consider using torque wrenches to achieve the right tightness without over-torquing, which can lead to fastener failure. Regular maintenance checks should also be scheduled to ensure that bolts remain secure and to identify any signs of wear or corrosion early on.

Strategic Material Selection Guide for different kinds of bolts

What Are the Key Properties of Steel Bolts for International B2B Buyers?

Steel is one of the most commonly used materials for bolts due to its excellent mechanical properties. It typically exhibits high tensile strength, making it suitable for heavy-duty applications. Steel bolts can withstand high temperatures and pressures, which is critical in industries such as construction and manufacturing. Additionally, they can be treated or coated to enhance corrosion resistance, particularly important in humid or saline environments prevalent in parts of Africa and South America.

However, steel bolts can be susceptible to corrosion if not properly treated. This can lead to premature failure in environments with high moisture or exposure to chemicals. The cost of steel bolts varies based on the type of steel and any additional treatments, but they generally fall into the medium cost range. International buyers should consider compliance with standards such as ASTM for the U.S. and DIN for Europe to ensure quality and performance.

How Do Stainless Steel Bolts Compare in Terms of Performance?

Stainless steel bolts are known for their exceptional corrosion resistance, making them ideal for applications in marine environments or industries that involve exposure to chemicals. They maintain their strength at high temperatures, which is beneficial for applications in the oil and gas sector.

Despite their advantages, stainless steel bolts are typically more expensive than standard steel bolts. They also have lower tensile strength compared to carbon steel, which may limit their use in certain high-load applications. Buyers in regions such as the Middle East, where high temperatures and humidity can affect material performance, should ensure that the stainless steel grades used meet specific standards like AISI or ASTM to guarantee durability.

What Are the Benefits of Using Alloy Steel Bolts?

Alloy steel bolts are manufactured using a combination of steel and other elements like chromium, molybdenum, or nickel, which enhance their mechanical properties. These bolts exhibit improved strength and toughness, making them suitable for high-stress applications such as automotive and aerospace industries. They also offer better wear resistance, which is crucial for applications involving friction.

A stock image related to different kinds of bolts.

On the downside, alloy steel bolts can be more expensive to produce and may require specialized manufacturing processes. They also may not offer the same level of corrosion resistance as stainless steel unless treated. For international buyers, especially in Europe and South America, compliance with specific industry standards, such as ISO or JIS, is essential to ensure the bolts meet the required safety and performance criteria.

Why Choose Plastic or Composite Bolts for Certain Applications?

A stock image related to different kinds of bolts.

Plastic or composite bolts are increasingly being used in applications where weight reduction and corrosion resistance are critical. They are non-conductive, making them suitable for electrical applications, and they resist chemicals, which is advantageous in the chemical processing industry. Their lightweight nature also allows for easier handling and installation.

However, plastic bolts generally have lower tensile strength compared to metal counterparts, limiting their use to lighter applications. They can also be more expensive than standard steel bolts, depending on the type of plastic used. Buyers in regions with specific environmental regulations, such as Europe, should ensure that the materials comply with relevant standards for safety and environmental impact.

Summary Table of Material Selection for Different Kinds of Bolts

| Material | Typical Use Case for different kinds of bolts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Construction, manufacturing | High tensile strength | Susceptible to corrosion | Medium |

| Stainless Steel | Marine, chemical processing | Excellent corrosion resistance | Higher cost, lower tensile strength | High |

| Alloy Steel | Automotive, aerospace | Improved strength and toughness | Higher manufacturing cost, corrosion issues | Medium to High |

| Plastic/Composite | Electrical applications, lightweight needs | Lightweight, chemical resistance | Lower tensile strength, limited applications | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for different kinds of bolts

What Are the Main Stages of Manufacturing Different Types of Bolts?

Manufacturing bolts involves a series of precise and methodical stages to ensure the final product meets the required specifications. Here’s a breakdown of the main stages:

-

Material Preparation

The process begins with selecting the appropriate raw materials, typically high-grade steel, stainless steel, or other alloys. The chosen material is then cut into blanks, which are the initial shapes from which bolts will be formed. For specific applications, additional treatments such as heat treatment may be applied to enhance material properties like strength and corrosion resistance. -

Forming Techniques

Various forming techniques are employed to shape the bolts. Common methods include:

– Cold Heading: This process involves deforming metal wire into the desired shape without heating. It is efficient and helps maintain the material’s strength.

– Die Stamping: A cold forming process that uses dies to cut and shape the metal into precise profiles.

– Thread Rolling: This technique creates threads by rolling metal stock through dies, ensuring accurate and durable thread profiles. -

Assembly

Depending on the type of bolt, assembly may involve adding components such as washers, nuts, or special fittings. For example, self-drilling screws may require additional features like a drill point for ease of installation. -

Finishing Processes

The finishing stage often includes surface treatments such as galvanization, coating, or painting to improve corrosion resistance and aesthetic appeal. These processes are crucial for ensuring the longevity of the bolts in various environments.

How Is Quality Assurance Implemented in Bolt Manufacturing?

Quality assurance (QA) is a critical aspect of bolt manufacturing, ensuring that products meet international and industry-specific standards. Here are key elements of the QA process:

-

International Standards Compliance

Many manufacturers adhere to ISO 9001, which sets out criteria for quality management systems. Compliance with this standard ensures that products are consistently manufactured to meet customer and regulatory requirements. -

Industry-Specific Certifications

Depending on the application, bolts may need to comply with other certifications such as CE marking for products sold in Europe or API standards for oil and gas applications. Understanding these certifications is vital for international buyers to ensure product reliability.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process to detect any defects early on. These checkpoints typically include:

-

Incoming Quality Control (IQC)

This initial checkpoint assesses the quality of raw materials before they enter the production line. Suppliers should provide material certificates to ensure compliance with specified standards. -

In-Process Quality Control (IPQC)

IPQC takes place during the manufacturing process. Operators monitor critical parameters such as dimensions and mechanical properties to ensure that the production remains within specified tolerances. -

Final Quality Control (FQC)

At the end of the manufacturing process, FQC involves comprehensive testing of the finished bolts. Common tests include tensile strength tests, dimensional checks, and surface inspections. Any non-conforming products are identified and addressed before shipment.

What Common Testing Methods Are Used to Ensure Bolt Quality?

Manufacturers employ various testing methods to ensure that bolts meet the necessary specifications. These may include:

- Tensile Tests: To determine the strength and ductility of the material.

- Hardness Tests: To assess the hardness of the bolts, which is crucial for their performance.

- Corrosion Resistance Tests: Particularly important for bolts used in harsh environments, such as marine applications.

- Dimensional Inspections: Using precise measuring tools to confirm that the bolts meet specified dimensions.

How Can B2B Buyers Verify Supplier Quality Control Measures?

International B2B buyers should take proactive steps to verify the quality control measures of their suppliers. Here are some actionable strategies:

-

Supplier Audits

Conducting regular audits of suppliers can help buyers assess compliance with quality standards. An audit should evaluate the supplier’s manufacturing processes, quality control systems, and adherence to international standards. -

Requesting Quality Reports

Buyers should request detailed quality reports from suppliers, including results from IQC, IPQC, and FQC stages. These reports provide insights into the consistency and reliability of the manufacturing process. -

Utilizing Third-Party Inspections

Engaging third-party inspection services can provide an independent assessment of a supplier’s quality control processes. These inspections can occur at various stages of production and can help validate compliance with required standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When sourcing bolts internationally, buyers must be aware of specific nuances related to quality control and certifications:

-

Understanding Regional Standards: Different regions may have varying standards and certifications. For example, European buyers should be familiar with CE marking requirements, while buyers in the Middle East may need to comply with specific local standards.

-

Language Barriers: Communication regarding quality specifications may be hindered by language differences. It’s advisable to have clear, documented specifications and requirements in both parties’ languages.

-

Cultural Differences: Attitudes towards quality control and certifications can vary by region. Buyers should be culturally sensitive and understand the local market practices to ensure smooth transactions.

By focusing on these aspects, international B2B buyers can make informed decisions when sourcing bolts, ensuring they receive high-quality products that meet their specific requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘different kinds of bolts’

To successfully navigate the procurement of various types of bolts, international B2B buyers must follow a structured approach that ensures quality, compliance, and cost-effectiveness. This checklist is designed to guide you through the essential steps in sourcing bolts for your business needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the bolts you need. This includes dimensions, material type (e.g., stainless steel, carbon steel), and specific standards (such as ISO or ASTM). Having precise specifications helps in communicating your needs to suppliers and ensures you receive suitable products.

- Consider application needs: Are the bolts meant for heavy-duty machinery or light fixtures?

- Identify environmental factors: Will they be exposed to moisture, heat, or corrosive substances?

Step 2: Conduct Market Research on Suppliers

Investigate potential suppliers by researching their reputation in the market. Look for companies that specialize in the type of bolts you need and have a proven track record in your region.

- Utilize online platforms: Websites like Alibaba or industry-specific directories can help identify suppliers.

- Check reviews and ratings: Seek out feedback from previous customers to gauge reliability and quality.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- Assess certifications: Verify that suppliers hold relevant certifications (e.g., ISO 9001) that demonstrate their commitment to quality standards.

- Inquire about production capabilities: Ensure they can meet your volume and delivery timelines.

Step 4: Request Samples for Quality Assurance

Once you have shortlisted suppliers, request samples of the bolts. Testing samples ensures they meet your specifications and quality standards before placing a larger order.

- Conduct material tests: Check for tensile strength, corrosion resistance, and any other relevant performance metrics.

- Evaluate finish and dimensions: Ensure the bolts match your specified tolerances and surface finishes.

Step 5: Negotiate Pricing and Terms

After selecting a supplier based on quality and reliability, move on to discussing pricing and terms. Understanding the total cost of ownership, including shipping and duties, is essential.

- Discuss bulk discounts: Inquire about price breaks for larger orders, which can significantly reduce overall costs.

- Clarify payment terms: Establish clear terms regarding deposits, payment methods, and timelines to avoid any misunderstandings.

Step 6: Ensure Compliance with Local Regulations

Verify that the bolts comply with local regulations and standards in your market. This is particularly important for buyers in regions like Africa and the Middle East, where compliance can vary significantly.

- Review import regulations: Understand any tariffs, duties, or specific requirements for importing fasteners into your country.

- Check for safety standards: Ensure that the bolts meet any relevant safety and environmental regulations.

Step 7: Establish a Long-term Relationship

Building a long-term relationship with reliable suppliers can lead to better pricing, improved service, and priority during supply shortages.

- Maintain open communication: Regularly discuss your needs and any changes in specifications.

- Provide feedback: Share your experiences with the supplier to foster a partnership that benefits both parties.

By following this checklist, international B2B buyers can effectively source the right types of bolts, ensuring both quality and cost efficiency in their procurement process.

Comprehensive Cost and Pricing Analysis for different kinds of bolts Sourcing

What Are the Key Cost Components in Bolt Manufacturing?

Understanding the cost structure of bolts is essential for international B2B buyers. The primary components include:

-

Materials: The choice of raw materials significantly impacts pricing. Common materials for bolts include carbon steel, stainless steel, and alloy steel. Each has varying costs based on market prices, which can fluctuate due to global supply chain issues.

-

Labor: Labor costs vary by region. For instance, manufacturing in countries with lower labor costs can yield cheaper bolts, but this might affect quality. It’s crucial to balance labor cost savings with the required quality standards.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these costs, allowing for more competitive pricing.

-

Tooling: Specialized tooling can be expensive, especially for custom bolts. The initial investment in tooling can be offset by higher volume orders, making it important to consider economies of scale.

-

Quality Control (QC): Ensuring that bolts meet international standards requires investment in QC processes. Quality certifications such as ISO can add to the cost but are often necessary for international trade.

-

Logistics: Shipping costs can vary significantly based on the destination, shipping method, and current freight rates. Additionally, duties and tariffs can influence the final cost of imported bolts.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the standard margins in different regions can help buyers negotiate better deals.

How Do Price Influencers Affect Bolt Costs?

Several factors can influence the pricing of bolts, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk purchases. Understanding the MOQ can help buyers negotiate better pricing, especially when sourcing from regions like Africa or South America.

-

Specifications and Customization: Customized bolts that meet specific engineering needs often come at a premium. Buyers should assess whether standard products can fulfill their requirements to avoid unnecessary costs.

-

Materials: The choice of materials not only affects the price but also the performance characteristics of the bolts. Stainless steel bolts, for example, are more expensive but offer better corrosion resistance.

-

Quality and Certifications: Higher quality bolts with recognized certifications are typically more expensive. Buyers must weigh the benefits of quality against cost, particularly in industries where safety is paramount.

-

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers may charge more due to their proven quality and service, while newer suppliers may offer lower prices to attract customers.

-

Incoterms: Understanding the terms of shipment (such as FOB, CIF) is critical for international buyers. These terms dictate who is responsible for shipping costs and risks, which can affect the total landed cost of bolts.

What Are the Best Negotiation Strategies for International Bolt Buyers?

To maximize cost-efficiency, B2B buyers should consider the following strategies:

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQ and gain leverage for better pricing. Long-term contracts can also secure more favorable terms.

-

Evaluate Total Cost of Ownership: Beyond the initial purchase price, consider maintenance, replacement, and operational costs associated with the bolts. Selecting higher-quality bolts may lead to lower overall costs in the long run.

-

Understand Regional Market Dynamics: Buyers from Africa, South America, the Middle East, and Europe should be aware of local market conditions and pricing trends. This knowledge can help in negotiating fair prices.

-

Communicate Specifications Clearly: Providing detailed specifications can reduce misunderstandings and ensure that quotes are accurate, which helps in avoiding unexpected costs later in the procurement process.

Conclusion

While the cost of bolts can vary significantly based on numerous factors, international B2B buyers can navigate these complexities by understanding the cost components, recognizing price influencers, and employing effective negotiation strategies. It’s essential to maintain a comprehensive view of the total cost of ownership and to choose suppliers that align with both quality and budgetary requirements.

Disclaimer: Prices and costs mentioned are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements.

Alternatives Analysis: Comparing different kinds of bolts With Other Solutions

The need for reliable fastening solutions is critical in various industries, and while different kinds of bolts are commonly used, there are several alternative methods and technologies that can also serve similar purposes. This section explores the comparative advantages and disadvantages of bolts against a few noteworthy alternatives, helping international B2B buyers make informed decisions.

| Comparison Aspect | Different Kinds Of Bolts | Alternative 1: Rivets | Alternative 2: Adhesives |

|---|---|---|---|

| Performance | High strength; ideal for heavy loads and structural applications. | Excellent for permanent connections; can handle shear loads well. | Good for lightweight applications; can provide a seal against moisture. |

| Cost | Moderate initial investment; costs can vary based on type and material. | Generally lower cost; installation tools may increase overall expense. | Often cheaper than bolts and rivets; minimal tooling required. |

| Ease of Implementation | Requires tools for installation; may need additional components like nuts and washers. | Installation requires specialized tools (e.g., rivet guns), which can complicate the process. | Simple application; no special tools required; quick drying options available. |

| Maintenance | Moderate; may require periodic checks for loosening. | Very low; once installed, rivets are permanent and require no maintenance. | Varies; some adhesives can degrade over time and may need reapplication. |

| Best Use Case | Best suited for structural, automotive, and machinery applications. | Ideal for aircraft, automotive, and construction where permanent joints are necessary. | Best for lightweight materials, electronics, and applications where sealing is crucial. |

What Are the Advantages and Disadvantages of Using Rivets as an Alternative to Bolts?

Rivets are permanent fasteners that provide strong and durable connections, often used in applications where vibration or dynamic loads are present. They are particularly effective in structural applications, such as bridges and aircraft, where long-term stability is paramount. However, the main drawback of rivets is that they require specialized installation tools, which can add to the overall project costs and complexity. Additionally, once installed, rivets cannot be easily removed, making them less versatile in applications where future disassembly is anticipated.

How Do Adhesives Compare to Different Kinds of Bolts?

Adhesives offer a unique fastening solution, particularly in applications involving dissimilar materials or when a seal against moisture is essential. They are often less expensive than mechanical fasteners and require minimal equipment for application, making them a cost-effective choice for many manufacturers. However, adhesives may not provide the same level of structural integrity as bolts or rivets, especially in load-bearing applications. Their performance can also degrade over time due to environmental factors, which may necessitate reapplication or replacement.

Conclusion: How Can B2B Buyers Choose the Right Fastening Solution?

When selecting the appropriate fastening solution, B2B buyers should consider the specific requirements of their projects, including load-bearing capacity, environmental factors, and the need for future maintenance or disassembly. Different kinds of bolts remain a robust choice for heavy-duty applications, while rivets and adhesives can offer viable alternatives depending on the context. By assessing the unique characteristics of each option, buyers can make informed decisions that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for different kinds of bolts

What Are the Essential Technical Properties of Different Kinds of Bolts?

When sourcing bolts for various industrial applications, understanding their technical properties is crucial. Here are some key specifications that B2B buyers should consider:

-

Material Grade

The material grade of a bolt indicates its strength and durability. Common materials include carbon steel, stainless steel, and alloy steel. For instance, Grade 8 bolts are made from medium carbon steel and are heat-treated for increased strength, making them ideal for high-stress applications. For B2B buyers, selecting the right material grade ensures that the bolts can withstand the operational environment, thus preventing premature failure and reducing downtime. -

Thread Tolerance

Thread tolerance refers to the precision with which the threads of a bolt are manufactured. It is typically categorized into classes, such as Class 2A for external threads and Class 2B for internal threads. Higher tolerances lead to a better fit and reduced wear. Understanding thread tolerance is essential for ensuring compatibility with nuts and other fasteners, which is vital in maintaining structural integrity in assemblies. -

Coating and Corrosion Resistance

Many bolts come with coatings such as zinc plating, galvanization, or powder coating to enhance their resistance to corrosion. This property is particularly important for applications in harsh environments, like coastal areas or industries with high moisture levels. B2B buyers must consider the environmental conditions where the bolts will be used to select the right coating, as this can significantly affect the lifespan of the fastener. -

Load Capacity

Load capacity, often measured in pounds or kilograms, indicates how much weight a bolt can support before failure. This property is critical for ensuring safety in construction and manufacturing applications. Buyers should assess the load requirements of their specific projects to choose bolts that can safely handle the anticipated stresses. -

Length and Diameter

The length and diameter of a bolt are fundamental specifications that determine its application. Longer bolts are necessary for thicker materials, while diameter impacts the strength and load capacity. Buyers should ensure they select the appropriate size to fit their specific assembly requirements, as incorrect dimensions can lead to structural failures.

What Are Common Trade Terms Relevant to Bolt Sourcing?

Understanding industry jargon is essential for effective communication and negotiation in the B2B space. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, sourcing bolts from OEMs ensures that they receive high-quality, reliable components that meet industry standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers when negotiating purchases, as it can impact inventory costs and supply chain management. Understanding MOQ helps buyers plan their orders more effectively. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. B2B buyers should use RFQs to ensure they receive competitive pricing and to streamline the procurement process. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in a transaction. They specify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers understand their obligations and costs involved in importing bolts from international suppliers. -

Lead Time

Lead time is the period between placing an order and receiving the product. For B2B buyers, understanding lead times is essential for project planning and inventory management, as delays can disrupt operations. -

Certification Standards

Certification standards, such as ISO or ASTM, indicate that a product meets specific quality and safety criteria. B2B buyers should look for certified bolts to ensure compliance with industry regulations and to enhance reliability in their applications.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement processes and ensure the reliability of their projects.

Navigating Market Dynamics and Sourcing Trends in the different kinds of bolts Sector

What Are the Current Market Dynamics and Key Trends in the Bolts Sector?

The global bolts market is experiencing notable growth, driven by the increasing demand across various industries, including construction, automotive, and manufacturing. The proliferation of advanced manufacturing technologies, such as die stamping and cold forming, is reshaping the sourcing landscape for international B2B buyers. Buyers from regions like Africa, South America, the Middle East, and Europe are increasingly looking for suppliers who can provide high-quality products with shorter lead times. Additionally, the rise of e-commerce platforms is enabling buyers to access a broader range of suppliers, facilitating competitive pricing and streamlined procurement processes.

Emerging trends include the integration of smart technologies in manufacturing, such as IoT-enabled machinery that enhances precision and reduces waste. As global supply chains become more complex, buyers are seeking suppliers who employ data analytics to forecast demand and manage inventory effectively. Moreover, as countries strive for economic recovery post-pandemic, there is an increased focus on local sourcing to mitigate risks associated with global supply chains. This shift is particularly relevant for buyers in Africa and South America, where local manufacturing capabilities are being developed to foster self-sufficiency.

How Important Is Sustainability and Ethical Sourcing in the Bolts Sector?

Sustainability is becoming a critical consideration for B2B buyers in the bolts sector. The environmental impact of bolt production, which can involve significant energy consumption and waste generation, is prompting companies to seek suppliers that adhere to sustainable practices. This includes the use of recycled materials and energy-efficient manufacturing processes. Buyers are increasingly looking for suppliers who can provide certifications, such as ISO 14001, which demonstrate a commitment to environmental management.

Ethical sourcing is equally important, particularly as businesses face growing pressure from consumers and stakeholders to ensure that their supply chains are free from human rights abuses and environmental degradation. Buyers should prioritize suppliers who can demonstrate transparency in their sourcing practices, such as those who are certified by organizations like the Responsible Business Alliance (RBA). Additionally, sourcing from suppliers that utilize ‘green’ materials—like eco-friendly coatings and finishes—can enhance a company’s reputation and appeal to environmentally conscious consumers.

How Has the Bolts Sector Evolved Over Time?

The bolts sector has evolved significantly since its inception, driven by technological advancements and changing market demands. Initially, bolts were produced using rudimentary hand-forging techniques. However, the industrial revolution marked a turning point, introducing mechanized manufacturing processes such as metal stamping and cold heading. These innovations not only increased production efficiency but also improved the quality and precision of bolts.

As industries grew, so did the complexity and variety of bolts. Today, the market includes a diverse range of bolt types, each designed for specific applications, from hex bolts used in construction to specialized fasteners for automotive applications. The evolution of materials, including high-strength alloys and corrosion-resistant coatings, has also played a crucial role in meeting the demands of various industries, ensuring that bolts can withstand harsh environments while providing reliable performance.

In conclusion, international B2B buyers navigating the bolts market must stay informed about market dynamics, prioritize sustainable sourcing, and understand the historical context of bolt production to make informed purchasing decisions. By doing so, they can leverage the evolving landscape to enhance their supply chain strategies and foster long-term partnerships with suppliers.

Frequently Asked Questions (FAQs) for B2B Buyers of different kinds of bolts

-

How do I choose the right bolts for my application?

Selecting the appropriate bolts involves understanding your specific requirements, including load capacity, environmental factors, and material compatibility. For instance, stainless steel bolts are ideal for corrosive environments, while high-strength bolts are better suited for heavy-load applications. Review the specifications provided by manufacturers and consider conducting tests to ensure the chosen bolts meet your operational needs. Additionally, consult with suppliers who can provide insights into the most suitable bolt types for your projects. -

What is the best bolt type for outdoor construction projects?

For outdoor construction, galvanized or stainless steel bolts are highly recommended due to their resistance to rust and corrosion. Galvanized bolts offer a protective zinc coating, making them suitable for humid or wet environments. If your project involves exposure to extreme weather conditions, consider using bolts specifically designed for outdoor use, such as those with additional coatings or made from weather-resistant materials. Always consult with your supplier about the best options for your specific climate and project requirements. -

How can I ensure the quality of bolts from international suppliers?

To ensure quality, conduct thorough vetting of potential suppliers by checking their certifications, quality control processes, and customer reviews. Request samples before placing bulk orders to assess the quality firsthand. It’s also beneficial to engage suppliers who adhere to international standards, such as ISO certifications, which can indicate a commitment to quality. Establishing clear communication regarding quality expectations and inspection processes can further mitigate risks associated with international sourcing. -

What are the typical minimum order quantities (MOQ) for bolts?

Minimum order quantities can vary significantly based on the supplier, bolt type, and material. Generally, MOQs for bolts range from 100 to 1,000 units. For customized bolts, MOQs may be higher due to production setup costs. It’s advisable to discuss your specific needs with suppliers to negotiate favorable terms, especially if you are a small or medium-sized enterprise. Some suppliers may offer flexibility on MOQs for long-term partnerships or bulk orders. -

What payment terms should I expect when buying bolts internationally?

Payment terms for international bolt purchases typically range from 30% upfront deposit to 70% upon delivery, but this can vary by supplier and region. Common payment methods include bank transfers, letters of credit, and PayPal. Ensure you understand the terms clearly before finalizing any agreements, and consider using escrow services for added security in transactions. Establishing a good relationship with suppliers can also lead to more favorable payment conditions over time. -

How does logistics impact the sourcing of bolts from different regions?

Logistics play a critical role in sourcing bolts internationally, affecting lead times and overall costs. Factors such as shipping methods, customs regulations, and local infrastructure can significantly influence delivery schedules. To mitigate delays, work with suppliers who have reliable logistics partners and can provide transparent shipping timelines. It’s also wise to factor in potential tariffs or duties when calculating total costs, especially when importing from regions with varying trade agreements. -

Can bolts be customized for specific applications?

Yes, many suppliers offer customization options for bolts, including variations in size, material, thread type, and finishes. Customization allows you to tailor bolts to meet specific performance requirements or aesthetic preferences. When seeking customized bolts, provide detailed specifications to your supplier and inquire about the associated costs and lead times. Engaging in a collaborative design process can also ensure that the final product meets your exact needs. -

What quality assurance processes should I look for when sourcing bolts?

When sourcing bolts, look for suppliers that implement rigorous quality assurance (QA) processes, such as material testing, dimensional inspections, and performance evaluations. Certifications from recognized organizations (like ISO 9001) can indicate adherence to quality standards. It’s beneficial to request documentation of QA processes and results, as well as to discuss any warranties or guarantees offered on the bolts. Regular audits and inspections throughout the production process can further enhance confidence in the quality of your purchased bolts.

A stock image related to different kinds of bolts.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for different kinds of bolts

In the realm of fasteners, particularly bolts, strategic sourcing is essential for international B2B buyers aiming to optimize their supply chains. By understanding the diverse types of bolts—such as hex bolts, carriage bolts, and eye bolts—buyers can make informed choices that align with their specific applications and industry requirements. The ability to source high-quality fasteners can significantly influence product durability and performance, ultimately impacting customer satisfaction and operational efficiency.

How Can Strategic Sourcing Enhance Your Bolt Procurement?

Investing in strategic sourcing not only facilitates cost savings but also strengthens supplier relationships, ensuring consistent quality and availability of products. As markets evolve, particularly in regions like Africa, South America, the Middle East, and Europe, leveraging local suppliers while maintaining global standards can provide a competitive edge.

What’s Next for International Buyers?

Looking ahead, international B2B buyers should focus on building resilient supply chains that can adapt to changing market demands and economic fluctuations. Engaging with suppliers who prioritize innovation and sustainability will be crucial. Embrace the opportunity to explore new bolt technologies and materials that can enhance your product offerings.

In conclusion, the future of bolt sourcing holds great promise for those who strategically navigate the landscape. Take action now to optimize your procurement processes and establish partnerships that will drive growth and efficiency in your operations.