Discover 5 Essential Plug Types for Global Sourcing (2025)

Introduction: Navigating the Global Market for plug types

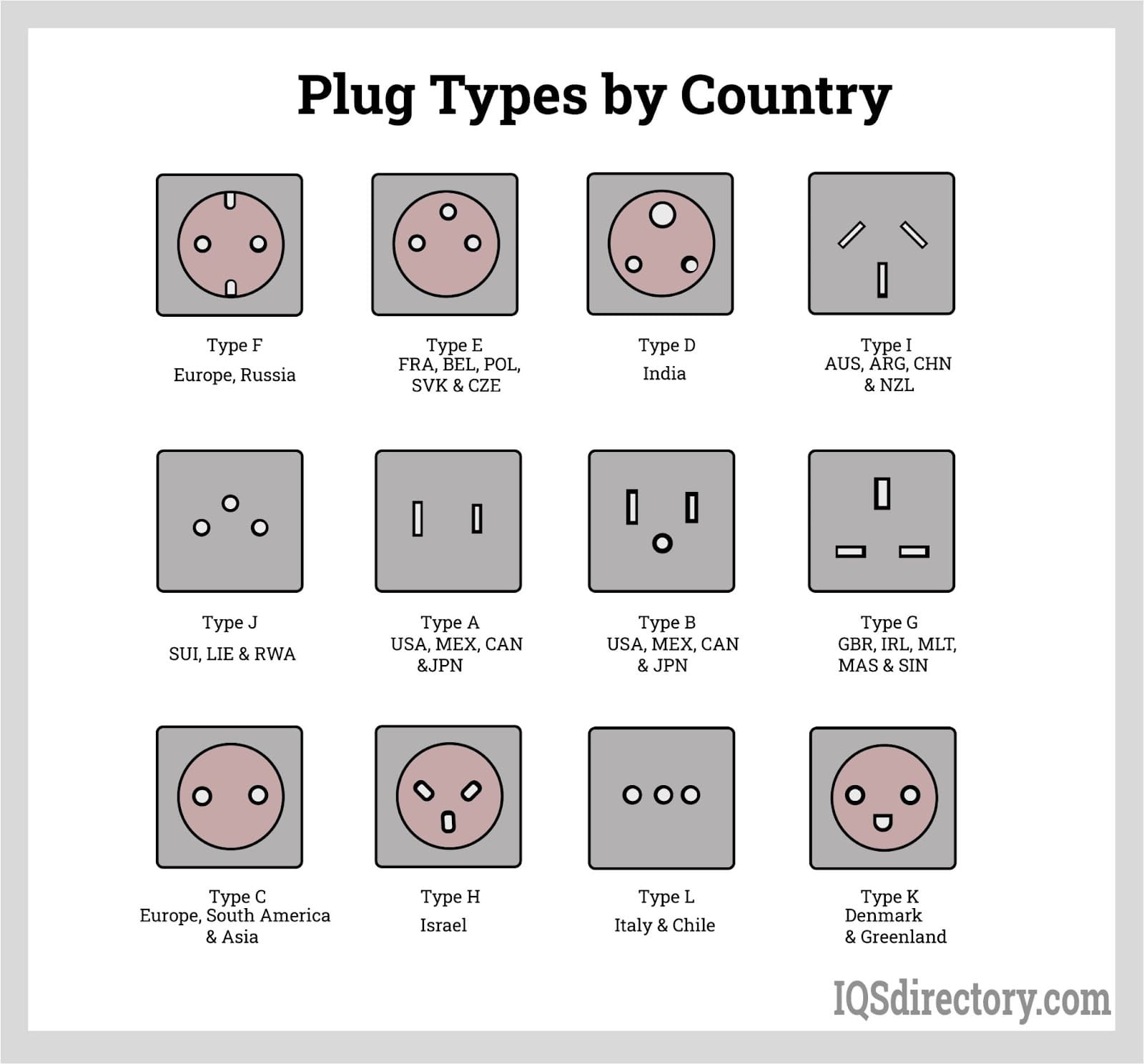

Navigating the complex landscape of plug types is a significant challenge for international B2B buyers, particularly those sourcing electrical equipment across diverse markets in Africa, South America, the Middle East, and Europe, including countries like Argentina and Turkey. With over 15 distinct plug types utilized worldwide, understanding which plug type is compatible with specific devices can prevent costly errors and operational delays. This comprehensive guide delves into the various plug types, their applications, voltage specifications, and the importance of proper supplier vetting.

In this guide, B2B buyers will find detailed insights into the characteristics of each plug type, including their respective advantages and limitations. Additionally, we cover vital factors such as cost considerations, sourcing strategies, and tips for ensuring compliance with local electrical standards. By providing actionable insights and best practices, this resource empowers buyers to make informed purchasing decisions that align with their operational needs.

Whether you are an importer, distributor, or retailer, understanding the nuances of plug types can enhance your supply chain efficiency and customer satisfaction. This guide serves as an essential tool for navigating the global market, ensuring that your business remains competitive and compliant in an increasingly interconnected world.

Understanding plug types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type C | 2 pins, non-grounded, 2.5 A to 16 A | Common in Europe, Africa, and South America for appliances | Pros: Widely compatible, versatile. Cons: Not grounded, limited to lower power devices. |

| Type G | 3 pins, grounded, 13 A | Predominantly used in the UK, Ireland, and parts of the Middle East | Pros: Safe for high-power devices, robust. Cons: Bulkier design may not fit all sockets. |

| Type I | 2 or 3 pins, grounded, 10 A to 16 A | Used in Australia, New Zealand, and Argentina for various electronics | Pros: Flexible pin configuration, strong grounding. Cons: Limited compatibility outside its regions. |

| Type E | 2 pins, grounded, 16 A | Common in France, Belgium, and Poland for household and industrial appliances | Pros: Grounding enhances safety, widely used. Cons: Requires specific socket types, less common elsewhere. |

| Type N | 3 pins, grounded, 10 A to 20 A | Found in Brazil and South Africa for larger appliances | Pros: Supports higher amperage, safe grounding. Cons: Limited to specific regions, potential for confusion with other types. |

What are the Characteristics of Type C Plugs and Their Suitability for B2B Buyers?

Type C plugs, characterized by their two non-grounded pins, are widely used across Europe, Africa, and South America. They are rated for 2.5 A to 16 A, making them suitable for a variety of household and light industrial applications. B2B buyers should consider Type C plugs for low-power devices, such as chargers and small appliances, due to their high compatibility. However, the lack of grounding may pose risks for sensitive equipment, making it essential to evaluate the power requirements of devices before purchasing.

How Do Type G Plugs Differ and What Are Their Key Applications?

Type G plugs feature three grounded pins and are primarily used in the UK, Ireland, and some Middle Eastern countries. With a rating of 13 A, they are ideal for high-power devices, including industrial machinery and large appliances. For B2B buyers, the robust design of Type G plugs offers enhanced safety and reliability. However, their bulkiness can be a drawback, especially in tight spaces, and compatibility with non-G sockets can limit their use in international trade.

What Makes Type I Plugs a Good Choice for International Buyers?

Type I plugs are distinguished by their flexible pin configuration, which can be either two or three pins, and are primarily found in Australia, New Zealand, and Argentina. Rated for 10 A to 16 A, they are suitable for a range of electronics, from consumer appliances to industrial equipment. B2B buyers should appreciate the strong grounding feature that enhances safety during operation. However, Type I plugs may not be compatible with sockets in regions outside their primary use, which could complicate international procurement.

Why Are Type E Plugs Popular Among B2B Buyers in Europe?

Type E plugs, with their two grounded pins and a rating of 16 A, are commonly used in countries like France, Belgium, and Poland. Their grounding feature provides an added layer of safety, making them suitable for both household and industrial applications. B2B buyers should consider Type E plugs for devices that require stable and safe power supply. The primary downside is their specific socket requirements, which may limit their use in global markets.

What Are the Key Considerations for Type N Plugs in B2B Transactions?

Type N plugs, which feature three grounded pins and can handle 10 A to 20 A, are primarily used in Brazil and South Africa. They are well-suited for larger appliances and industrial applications due to their higher amperage capacity. B2B buyers should take note of their safe grounding, which minimizes electrical hazards. However, Type N plugs are less common outside their regions, which may lead to challenges in sourcing compatible devices for international operations.

Key Industrial Applications of plug types

| Industry/Sector | Specific Application of plug types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Machinery and Equipment Power Supply | Ensures operational efficiency and safety | Compatibility with local voltage and plug types |

| Construction | Site Power Distribution | Reliable energy supply for tools and machinery | Durability and weather resistance of plug types |

| Telecommunications | Network Infrastructure | Supports uninterrupted service and connectivity | Compliance with international standards |

| Hospitality | Electrical Appliances in Hotels and Restaurants | Enhances guest experience with versatile plugs | Variety of plug types for different equipment |

| Renewable Energy | Solar Power Systems | Facilitates energy conversion and use | Adaptability to local grid and regulations |

How Are Plug Types Used in Manufacturing?

In the manufacturing sector, plug types are crucial for powering various machinery and equipment. Different regions utilize specific plug configurations, making it essential for international buyers to understand local standards. For example, Type C plugs are widely used in Europe and Africa, while Type I is common in Australia and Argentina. Ensuring compatibility with local voltage (typically 220-240V) is vital to prevent equipment damage and ensure operational efficiency. Buyers should also consider sourcing plugs that meet safety regulations to minimize risks.

What Are the Applications of Plug Types in Construction?

Construction sites often require robust power distribution systems to operate tools and machinery. Plug types play a significant role in ensuring a reliable energy supply. The use of durable, weather-resistant plugs is essential to withstand the harsh conditions commonly found on construction sites. For instance, Type G plugs, prevalent in the UK and the Middle East, provide a grounded connection that enhances safety. International buyers must ensure that the plugs they source can handle the power requirements of their specific equipment and comply with local electrical codes.

How Do Plug Types Support Telecommunications Infrastructure?

In the telecommunications industry, plug types are essential for network infrastructure, including routers, switches, and servers. A reliable power supply is critical to maintaining uninterrupted service and connectivity. International B2B buyers should focus on sourcing plugs that comply with international standards to ensure compatibility with various equipment. For instance, Type E and F plugs are commonly used in Europe and can support devices operating at 230V. Buyers must also consider the sourcing of power strips and adapters that can accommodate multiple plug types for greater flexibility.

What Role Do Plug Types Play in the Hospitality Industry?

In the hospitality sector, the versatility of plug types enhances the guest experience by accommodating various electrical appliances, such as chargers, hairdryers, and kitchen equipment. Hotels and restaurants often face the challenge of catering to international guests who may have different plug requirements. For example, Type C plugs are widely used in many countries, making them a practical choice for European and African establishments. International buyers should consider sourcing a variety of plug types and universal adapters to meet the diverse needs of their clientele.

How Are Plug Types Utilized in Renewable Energy Applications?

Plug types are increasingly important in renewable energy applications, particularly in solar power systems. These systems often require specific plug configurations to connect solar panels to inverters and the local grid. For example, Type N plugs are used in Brazil and South Africa, where solar energy is gaining traction. Buyers in this sector must ensure that the plugs sourced are adaptable to local grid specifications and comply with regulatory standards. This adaptability facilitates energy conversion and enhances the overall efficiency of renewable energy systems.

3 Common User Pain Points for ‘plug types’ & Their Solutions

Scenario 1: Navigating Diverse Plug Types Across Regions

The Problem: International B2B buyers often face the challenge of understanding the diverse plug types used in different regions, particularly when sourcing equipment for markets in Africa, South America, the Middle East, and Europe. For instance, a company based in Turkey planning to expand operations into Brazil may not realize that Brazil uses plug types C and N, which differ significantly from the Type F plugs commonly found in Turkey. This lack of awareness can lead to costly delays in project timelines and increased shipping costs due to the need for adapters or replacements.

The Solution: To effectively manage the diversity of plug types, buyers should invest in comprehensive market research prior to sourcing equipment. This involves creating a detailed list of the plug types used in target markets and verifying compatibility with the equipment being procured. Utilizing a reliable resource, such as the International Electrotechnical Commission (IEC) website or local electrical standards, can provide accurate information about plug types and their specifications. Additionally, establishing partnerships with local suppliers can facilitate smoother operations, as these suppliers often have insights into the specific needs and standards of their respective markets.

Scenario 2: Ensuring Electrical Safety Compliance

The Problem: Another common issue arises when B2B buyers inadvertently procure equipment with incompatible plug types that do not meet local electrical safety standards. For example, equipment designed for Type G sockets may pose safety risks when used with Type C or E sockets, which could lead to electrical failures or even hazards like fires. This scenario is particularly concerning for businesses in regions like South Africa or Turkey, where adherence to strict electrical codes is mandatory.

The Solution: To avoid safety compliance issues, buyers must thoroughly assess the electrical standards of the regions where their equipment will be used. This includes understanding voltage levels, amperage requirements, and grounding standards associated with different plug types. It’s advisable to consult with local electrical authorities or hire a compliance consultant to ensure that all equipment meets regional regulations. Additionally, sourcing equipment from reputable manufacturers who provide detailed product specifications can help mitigate risks. Implementing a standardized checklist for compliance can also streamline this process, ensuring that all products are vetted before purchase.

Scenario 3: Overcoming Supply Chain Disruptions

The Problem: Supply chain disruptions can significantly impact the availability of specific plug types, especially for businesses operating in remote areas or regions with limited access to electrical components. For instance, a company in Argentina may find it challenging to procure Type I plugs due to local shortages or import restrictions, leading to project delays and increased operational costs.

The Solution: To combat supply chain issues, B2B buyers should diversify their sourcing strategies. This can involve establishing relationships with multiple suppliers across different regions, thus reducing reliance on a single source. Additionally, buyers can consider investing in universal adapters or multi-type sockets that accommodate various plug types, which can provide flexibility during shortages. Furthermore, maintaining a buffer stock of essential components can help mitigate the impact of unforeseen supply chain disruptions. Engaging with local manufacturers or distributors who understand the regional market dynamics can also provide valuable insights and help secure a steady supply of plug types.

Strategic Material Selection Guide for plug types

When selecting materials for plug types, international B2B buyers must consider factors such as performance, durability, and compliance with regional standards. Here, we analyze four common materials used in plug manufacturing, focusing on their properties, advantages, disadvantages, and implications for specific applications.

A stock image related to plug types.

What are the Key Properties of Thermoplastic Materials for Plug Types?

Thermoplastic materials, such as polyvinyl chloride (PVC) and nylon, are widely used in plug manufacturing due to their excellent electrical insulation properties and versatility. They typically have a temperature rating of up to 85°C and can withstand moderate mechanical stress. Their corrosion resistance makes them suitable for various environments, but they may not perform well under extreme temperatures or prolonged exposure to UV light.

Pros: Thermoplastics are generally cost-effective, lightweight, and easy to mold into complex shapes. They offer good electrical insulation and can be produced in various colors for branding purposes.

Cons: While thermoplastics are durable, they may not be suitable for high-temperature applications or environments with significant mechanical wear. Additionally, they can degrade over time when exposed to certain chemicals or UV radiation.

Impact on Application: Thermoplastics are ideal for indoor use and applications where moisture exposure is limited. However, they may not be suitable for outdoor applications in regions with high UV exposure.

How Do Metal Components Enhance Plug Performance?

Metal components, such as brass or copper, are often used in the conductive parts of plugs. Brass, for instance, has excellent electrical conductivity and corrosion resistance, with a temperature rating that can exceed 200°C. This makes it suitable for high-performance applications where reliability is critical.

Pros: Metal components enhance electrical performance and durability. They can handle higher currents and are less likely to deform under mechanical stress compared to plastics.

Cons: Metals are typically heavier and more expensive than thermoplastics. They can also be prone to corrosion if not properly coated or treated, particularly in humid environments.

Impact on Application: Metal components are essential for plugs used in high-power applications or in environments where mechanical durability is crucial. Buyers must ensure that the metals used comply with local regulations regarding electrical safety.

What are the Benefits of Using Rubber in Plug Manufacturing?

Rubber is another common material, particularly for the outer casing of plugs. It offers excellent flexibility and can withstand a wide range of temperatures, typically from -40°C to 100°C. Rubber is also highly resistant to abrasion and impact, making it suitable for rugged environments.

Pros: The flexibility of rubber provides a robust protective layer, reducing the risk of damage during handling. It also offers good electrical insulation and can be produced in various colors.

Cons: Rubber can be more expensive than thermoplastics and may degrade over time when exposed to certain chemicals or extreme temperatures. Additionally, it may not provide the same level of structural integrity as metal components.

Impact on Application: Rubber is ideal for plugs that will be frequently moved or used in harsh environments, such as construction sites. Buyers should consider the specific type of rubber used to ensure compatibility with local climate conditions.

How Does Composite Material Offer Versatility in Plug Types?

Composite materials, which combine plastics with fibers or other materials, are increasingly popular in plug manufacturing. These materials can provide enhanced strength and temperature resistance, with some composites rated for temperatures up to 150°C.

Pros: Composites can be tailored to meet specific performance requirements, offering a balance between weight and strength. They are also resistant to corrosion and can be designed to meet various aesthetic preferences.

Cons: The manufacturing process for composites can be more complex and costly, which may increase the final product price. Additionally, not all composites are suitable for high-load applications.

Impact on Application: Composites are suitable for specialized applications where traditional materials may fall short. Buyers should evaluate the specific composite used to ensure it meets the required performance standards.

| Material | Typical Use Case for plug types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic | Indoor plugs | Cost-effective and lightweight | Limited high-temperature performance | Low |

| Metal (Brass) | High-power applications | Excellent conductivity and durability | Heavier and more expensive | Medium |

| Rubber | Rugged outdoor plugs | Flexible and impact-resistant | Degrades in extreme conditions | Medium |

| Composite | Specialized applications | Tailored performance and aesthetics | Complex manufacturing process | High |

This strategic material selection guide provides B2B buyers with essential insights to make informed decisions based on their specific needs and regional standards. Understanding the properties and applications of each material will help in selecting the most suitable plug types for various environments and requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for plug types

What Are the Key Stages in the Manufacturing Process of Plug Types?

The manufacturing of plug types involves several critical stages that ensure the final product meets safety and performance standards. Understanding these stages is essential for international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe.

Material Preparation: What Materials Are Used?

The first step in the manufacturing process is material preparation. Typically, plugs are made from various materials, including:

- Plastics: High-grade thermoplastics are commonly used for insulation and housing due to their durability and electrical resistance.

- Metals: Copper is the most prevalent choice for pins due to its excellent conductivity. Some manufacturers may also use alloys that provide increased strength and resistance to corrosion.

- Rubber or Silicone: These materials are often used for flexible parts or seals to ensure water resistance and durability.

Suppliers should ensure that all materials used comply with relevant international standards, which can significantly affect the quality of the final product.

Forming: How Are Plugs Shaped?

The forming stage involves shaping the prepared materials into the desired plug configuration. This can include:

- Injection Molding: This technique is frequently used for producing plastic components. It allows for high precision and can produce complex shapes efficiently.

- Stamping: Metal pins are often manufactured through stamping, which involves pressing a sheet of metal into the desired shape using a die.

- Die Casting: For more intricate metal components, die casting is employed, ensuring high accuracy and a smooth finish.

These techniques must be closely monitored to avoid defects that could compromise safety or performance.

Assembly: What Does the Assembly Process Entail?

Once the components are formed, the assembly stage begins. This typically involves:

- Pin Insertion: Metal pins are inserted into the plastic housing. This may involve automated machinery to ensure consistency.

- Wiring Connections: If the plug design includes integrated electronics, wiring must be correctly connected and insulated to prevent short circuits.

- Final Assembly: The final assembly involves securing all components together, ensuring no loose parts remain that could affect usability.

Efficient assembly processes are crucial for maintaining production speed while ensuring quality.

Finishing: How Are Plugs Made Safe and Aesthetic?

The finishing stage focuses on the final touches that enhance both safety and aesthetics:

- Surface Treatment: Components are often treated with coatings to improve resistance to wear and corrosion.

- Quality Checks: This stage includes visual inspections to ensure no defects are present before the plugs are packaged for shipment.

Attention to detail in the finishing stage can significantly influence customer satisfaction and product longevity.

What Quality Assurance Measures Are Essential for Plug Types?

Quality assurance (QA) is critical in the manufacturing process of plug types. B2B buyers must understand the QA protocols that suppliers implement to guarantee product reliability and safety.

Which International Standards Should Buyers Be Aware Of?

International standards play a vital role in ensuring the quality and safety of electrical products. Key standards for plug types include:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently meet customer requirements and enhance satisfaction.

- CE Marking: Essential for products sold in the European Economic Area, this marking indicates compliance with health, safety, and environmental protection standards.

- UL Certification: Particularly important in North America, this certification signifies that the product meets specific safety standards.

Buyers should prioritize suppliers who adhere to these standards, as they reflect a commitment to quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are critical throughout the manufacturing process. The primary checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early, allowing for immediate corrective actions.

- Final Quality Control (FQC): This final stage checks the completed products against the established specifications before they are shipped.

Implementing a robust QC system helps prevent defects from reaching the market.

What Common Testing Methods Are Used for Plug Types?

Testing methods are crucial for validating the performance and safety of plug types. Common methods include:

- Electrical Testing: This involves checking for proper conductivity, insulation resistance, and grounding.

- Mechanical Testing: Tests assess the durability of the plug under various stresses, including pull tests and drop tests.

- Environmental Testing: Products may undergo tests to simulate extreme temperatures, humidity, and corrosion to ensure they can withstand real-world conditions.

These tests not only ensure safety but also enhance the product’s reliability over its lifespan.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of potential suppliers is crucial. Here are effective strategies:

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess quality control practices. Buyers should:

- Request Documentation: Ask for quality management system documentation, including certifications and test results.

- Conduct On-Site Audits: Whenever possible, visit manufacturing facilities to observe processes firsthand and evaluate compliance with international standards.

- Review Past Audit Reports: Analyzing previous audits can provide insights into the supplier’s track record in maintaining quality.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control measures. These inspections typically include:

- Random Sampling: Inspectors assess a random sample of products to determine if they meet specified standards.

- Compliance Verification: They check whether the supplier adheres to relevant standards and regulations.

Utilizing third-party inspections can help mitigate risks associated with sourcing products from different regions.

What Nuances Should International Buyers Consider?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of several nuances when sourcing plug types:

- Regulatory Differences: Different regions may have varying regulations regarding electrical products. Buyers should familiarize themselves with these regulations to avoid compliance issues.

- Cultural Considerations: Understanding the cultural context of suppliers can enhance communication and lead to better partnerships.

- Logistical Challenges: International shipping may pose challenges, including customs regulations and tariffs. Buyers should plan accordingly to ensure smooth transactions.

By paying attention to these factors and employing rigorous quality assurance measures, international B2B buyers can ensure they source reliable and safe plug types that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plug types’

A stock image related to plug types.

To assist international B2B buyers in effectively sourcing plug types, this guide provides a structured checklist that outlines essential steps for procurement. By following these steps, buyers can ensure they make informed decisions that align with their technical and regional requirements.

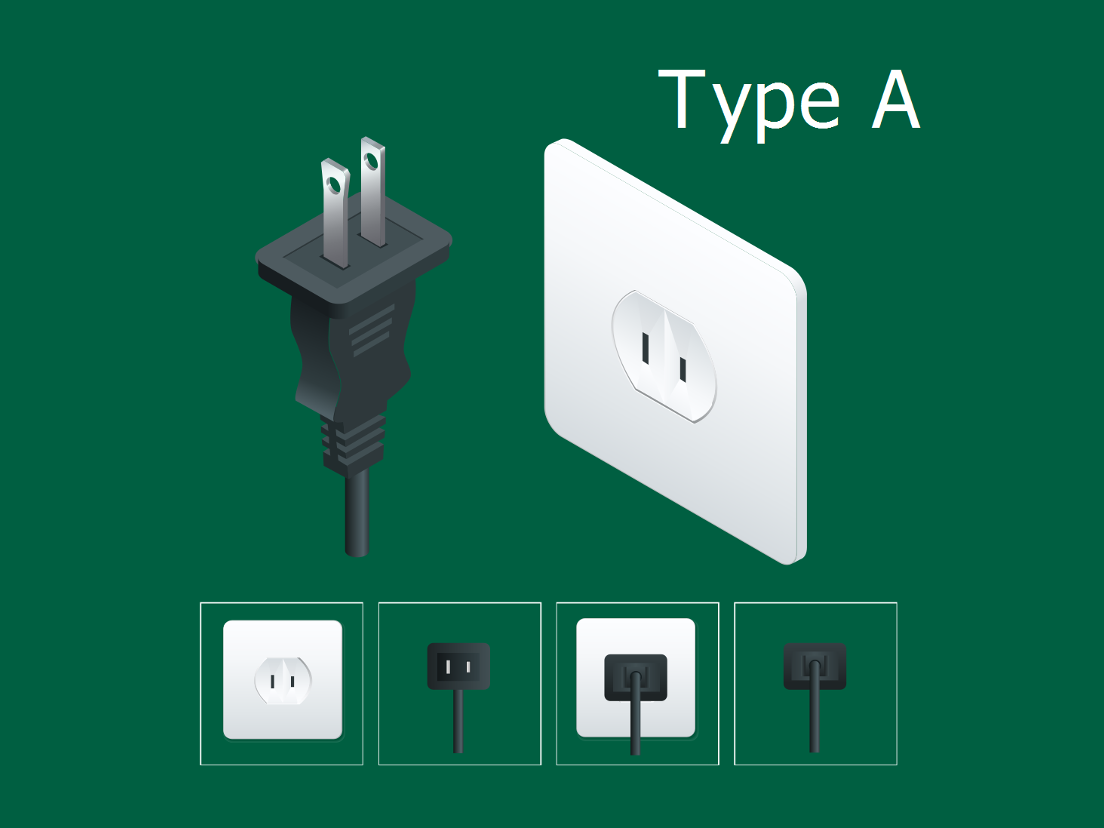

Step 1: Identify Your Regional Requirements

Understanding the specific plug types used in your target market is crucial. Different countries utilize various plug configurations, voltages, and frequencies. For instance, Type C plugs are common in Europe and Africa, while Type I is prevalent in Australia and Argentina. Ensuring compatibility with local standards will prevent operational issues and safety hazards.

Step 2: Define Your Technical Specifications

Clearly outline the technical requirements of the plugs you intend to procure. This includes voltage ratings, amperage, and grounding needs. Consider factors such as:

– Power requirements: Ensure the plugs can handle the necessary voltage and current.

– Safety standards: Verify that the plugs meet international safety regulations and certifications, such as IEC standards.

Step 3: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers who specialize in the required plug types. Look for suppliers with a proven track record in your industry. Consider:

– Supplier reputation: Read reviews and testimonials from other B2B buyers.

– Product range: Ensure they offer a variety of plug types and customization options if necessary.

Step 4: Request Samples and Specifications

Before making a bulk purchase, request samples of the plugs to evaluate their quality and compatibility. Analyze the samples based on:

– Material quality: Assess whether the materials used are durable and meet your specifications.

– Design and functionality: Check if the plugs fit securely into sockets and perform as expected under load.

Step 5: Verify Supplier Certifications

Ensure that your selected suppliers possess the necessary certifications for the plugs they offer. Certifications may include ISO, CE, or specific regional standards. This step is vital as it:

– Guarantees compliance: Validates that the plugs meet safety and performance standards.

– Reduces risk: Minimizes the likelihood of defects or failures that could disrupt operations.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate terms that suit both parties. Discuss pricing, delivery timelines, and payment terms. Consider:

– Bulk discounts: Inquire about price breaks for larger orders.

– Warranty and support: Ensure there is a clear understanding of warranty provisions and after-sales support.

Step 7: Establish a Quality Control Process

Implement a quality control process to monitor the received plugs. This could involve:

– Inspections: Conducting thorough inspections upon arrival to ensure they meet your specifications.

– Feedback loops: Establishing communication with your supplier for continuous improvement based on your quality assessments.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing plug types, ensuring they procure products that meet both technical requirements and regional standards, ultimately facilitating smoother operations in their markets.

Comprehensive Cost and Pricing Analysis for plug types Sourcing

What are the Key Cost Components in Plug Types Sourcing?

When sourcing plug types, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. For instance, plastic housings are less expensive than metal, while higher-quality materials can increase durability and safety, thereby justifying a higher price.

-

Labor: Labor costs vary by region. In countries with lower labor costs, such as certain regions in Africa and South America, manufacturing may be cheaper. However, this can come at the cost of quality assurance.

-

Manufacturing Overhead: This includes costs related to utilities, factory maintenance, and administrative expenses. A well-optimized manufacturing process can help reduce these overheads.

-

Tooling: Initial tooling costs can be high, especially for custom plug types. However, these costs can be amortized over larger production runs, making them more manageable for high-volume orders.

-

Quality Control (QC): Ensuring that products meet international standards is essential. Investing in QC processes can prevent costly recalls or failures, particularly in markets like Europe, where safety regulations are stringent.

-

Logistics: Transportation costs can vary greatly depending on the shipping method and distance. International shipping, especially from Asia to Africa or South America, can significantly impact the final cost.

-

Margin: Suppliers typically mark up their costs to maintain profitability. Understanding the typical margins in your industry can aid in negotiations.

How Do Price Influencers Affect Plug Types Sourcing?

Several factors influence the pricing of plug types in international markets:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Buyers should negotiate MOQs to benefit from economies of scale.

-

Specifications and Customization: Customized plugs that meet specific regional standards may incur higher costs due to additional design and manufacturing processes. Buyers should consider the necessity of customization against the potential price increase.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., CE marking in Europe) can raise costs but may also provide long-term savings through increased durability and compliance with regulations.

-

Supplier Factors: Supplier reliability, reputation, and location can all influence pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer lower prices to gain market share.

-

Incoterms: The terms of shipping and delivery can affect the overall cost. Understanding Incoterms (e.g., FOB, CIF) will help buyers calculate total landed costs, including duties and taxes.

What Tips Can Help B2B Buyers Negotiate Better Prices?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation and strategic sourcing can lead to significant savings:

-

Conduct Market Research: Understanding market rates and competitor pricing can empower buyers during negotiations. Being informed about typical costs in different regions can also help identify fair pricing.

-

Focus on Total Cost of Ownership (TCO): While initial costs are important, consider the TCO, which includes maintenance, durability, and potential repair costs. Higher upfront costs for better quality products can lead to lower long-term expenses.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing and service. Suppliers may offer discounts or better terms for repeat business or larger orders.

-

Leverage Technology: Utilize e-procurement platforms that can provide real-time pricing and availability, allowing for more informed purchasing decisions.

-

Be Open to Multiple Suppliers: Diversifying suppliers can mitigate risks and create competitive pricing pressure. This strategy also allows buyers to compare quality and service levels.

Are There Pricing Nuances for International B2B Buyers?

International B2B buyers must be aware of specific pricing nuances that can affect sourcing:

-

Currency Fluctuations: Exchange rate volatility can impact pricing, especially when dealing with suppliers in different currencies. Locking in prices through forward contracts may be beneficial.

-

Tariffs and Trade Regulations: Import duties and trade agreements can significantly alter costs. Understanding these can help buyers make more informed decisions about where to source plugs.

-

Local Market Conditions: Economic conditions and demand in the supplier’s country can influence pricing. For instance, high demand in Europe may lead to increased prices compared to other regions.

Disclaimer

The prices and cost structures discussed in this analysis are indicative and may vary based on specific agreements, market conditions, and supplier negotiations. Always conduct thorough due diligence before making sourcing decisions.

Alternatives Analysis: Comparing plug types With Other Solutions

Understanding Alternatives to Plug Types: What Are the Options?

In the global marketplace, the diversity of plug types can pose challenges for B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. While plug types serve as a fundamental means of connecting devices to power sources, alternative solutions exist that may offer enhanced performance, cost savings, or ease of use. This analysis explores how plug types compare to two viable alternatives: universal adapters and wireless power transfer technologies.

Comparison Table of Plug Types and Alternatives

| Comparison Aspect | Plug Types | Universal Adapters | Wireless Power Transfer |

|---|---|---|---|

| Performance | Varies by type; generally reliable | Moderate; depends on quality | High for compatible devices; range limitations |

| Cost | Low to moderate; one-time investment | Moderate; recurring purchases may apply | High initial investment; ongoing costs for infrastructure |

| Ease of Implementation | Straightforward; plug and play | Easy; requires selection based on device compatibility | Complex; installation and device compatibility considerations |

| Maintenance | Low; minimal upkeep | Moderate; can wear out | Low; minimal maintenance required |

| Best Use Case | Standardized environments | Traveling, diverse device needs | Smart homes, charging mobile devices |

What Are the Pros and Cons of Universal Adapters?

Universal adapters provide a flexible solution for businesses that need to connect devices across different plug types. These adapters are designed to accommodate multiple plug configurations, making them ideal for international travel or in environments where various electrical standards exist.

Pros:

– Versatility: Can support numerous plug types, making them suitable for various regions.

– Convenience: Simplifies the process of connecting devices without needing multiple plug types.

Cons:

– Dependence on Quality: Cheaper adapters may not provide reliable connections or could be unsafe.

– Wear and Tear: Adapters can degrade over time, necessitating replacements, which can lead to recurring costs.

How Does Wireless Power Transfer Compare?

Wireless power transfer is an emerging technology that enables devices to charge without physical connections. This method employs electromagnetic fields to transfer energy, making it a futuristic solution for powering devices.

Pros:

– Convenience: Eliminates the need for plugs and adapters, reducing clutter and potential compatibility issues.

– Innovative: Aligns with trends toward smart homes and IoT devices.

Cons:

– Cost: High initial setup costs and infrastructure investments are required.

– Range Limitations: Effective only within a limited range, which may not be suitable for all applications.

A stock image related to plug types.

How Can B2B Buyers Choose the Right Solution?

When selecting the appropriate solution for their electrical connectivity needs, B2B buyers should consider several factors, including the specific requirements of their devices, the environments in which they operate, and their budget constraints. Plug types may be the most straightforward option for consistent environments, while universal adapters offer flexibility for diverse needs. On the other hand, wireless power transfer presents an innovative, albeit costly, alternative for future-focused businesses. By evaluating these aspects carefully, buyers can make informed decisions that align with their operational goals and enhance efficiency in their operations.

Essential Technical Properties and Trade Terminology for plug types

What Are the Essential Technical Properties of Plug Types?

Understanding the technical specifications of plug types is crucial for international B2B buyers, especially when sourcing electrical components for diverse markets. Here are some critical properties to consider:

1. Material Grade

The material used in plugs can significantly affect their durability and safety. Common materials include polycarbonate, thermoplastic, and metals like copper for the pins. High-quality materials ensure better conductivity and resistance to heat, which is vital for reducing the risk of electrical failures. For B2B buyers, sourcing plugs made from superior materials can translate to long-term reliability and reduced maintenance costs.

2. Electrical Rating

Each plug type comes with specific electrical ratings, typically measured in amperes (A) and volts (V). For example, Type C plugs usually support up to 2.5 A and are designed for 220-240 V systems. Understanding these ratings helps buyers ensure compatibility with local electrical standards, which is essential for preventing equipment damage and ensuring safety in operations.

3. Pin Configuration and Size

The design and dimensions of the pins are critical for compatibility with sockets. Different regions have varying requirements; for instance, Type G plugs have three rectangular pins, while Type I plugs feature two flat pins with an optional grounding pin. Buyers must pay attention to pin size and shape to avoid compatibility issues, especially when exporting or importing electrical products.

4. Grounding Mechanism

Grounding is a safety feature that prevents electric shock and equipment damage. Plugs may be ungrounded (e.g., Type A) or grounded (e.g., Type E). Understanding the grounding requirements of the equipment and the regions where the plugs will be used is vital for compliance with safety standards, especially in regions with strict electrical regulations.

5. Tolerance Levels

Tolerance refers to the allowable deviation in dimensions and electrical performance parameters. For plugs, ensuring they meet specified tolerances is essential to guarantee consistent performance across different operating conditions. Buyers should inquire about tolerance levels during procurement to avoid issues related to fit and function.

What Are Common Trade Terminology and Jargon Related to Plug Types?

Navigating the world of electrical components involves understanding specific trade terms that can impact purchasing decisions. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of plug types, OEMs may produce plugs according to specified designs for different brands. B2B buyers should consider OEM partnerships for high-quality, customized solutions.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it can affect inventory costs and the ability to test new products in the market. Buyers should negotiate MOQ terms that align with their purchasing strategy.

3. RFQ (Request for Quotation)

An RFQ is a document sent by buyers to suppliers requesting pricing for specific products or services. For plugs, an RFQ helps buyers compare costs and specifications from multiple suppliers, aiding in informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping transactions. Familiarity with these terms—such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight)—is essential for B2B buyers to understand shipping costs, risks, and delivery responsibilities.

5. Certification Standards

Certification standards refer to the regulations and approvals that electrical products must meet to ensure safety and performance. Different regions may have specific certifications, such as CE marking in Europe or UL certification in the USA. Buyers should prioritize products that meet relevant certification standards to ensure compliance and safety.

By understanding these essential technical properties and trade terminologies, B2B buyers can make informed decisions, streamline procurement processes, and enhance the reliability of their electrical systems across different markets.

Navigating Market Dynamics and Sourcing Trends in the plug types Sector

What Are the Current Market Dynamics and Key Trends in the Plug Types Sector?

The global plug types market is experiencing significant transformation driven by technological advancements, regulatory changes, and shifting consumer preferences. As international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe (e.g., Argentina, Turkey), navigate these dynamics, it is crucial to stay informed about key trends. One major driver is the increasing demand for standardized plug types to facilitate international trade and travel. The International Electrotechnical Commission (IEC) is advocating for more universal standards, which could simplify sourcing and reduce compatibility issues.

Emerging technologies, such as smart plugs, are also reshaping the market. These devices not only enhance energy efficiency but also allow for remote control and monitoring, appealing to both consumers and businesses looking to optimize energy consumption. Additionally, the rise of e-commerce platforms is making it easier for buyers in remote regions to access a diverse range of plug types, fostering competition and innovation among manufacturers.

International buyers should also be aware of the regional variations in plug types and electrical standards. Understanding the specific requirements for countries within the target markets can streamline the sourcing process and minimize compliance risks. Engaging with local suppliers who are familiar with regional regulations can facilitate smoother transactions and enhance supply chain resilience.

How Important Is Sustainability and Ethical Sourcing in the Plug Types Sector?

Sustainability is becoming increasingly critical in the plug types sector, with environmental impacts influencing purchasing decisions among B2B buyers. The production and disposal of electronic components, including plugs and sockets, can lead to significant environmental degradation if not managed responsibly. Buyers are now prioritizing suppliers who adhere to sustainable practices and demonstrate a commitment to reducing their carbon footprint.

Ethical sourcing is equally important, as businesses aim to ensure that their supply chains are free from exploitative labor practices and environmentally harmful materials. Certifications such as ISO 14001 for environmental management and Fair Trade can provide assurance that suppliers are committed to ethical practices. Buyers should actively seek out manufacturers that provide transparent information about their sourcing processes and materials used in production.

Moreover, the integration of eco-friendly materials in plug design, such as biodegradable plastics or recycled metals, is gaining traction. By choosing suppliers who prioritize these materials, B2B buyers can contribute to a more sustainable future while also meeting the growing consumer demand for greener products.

How Has the Plug Types Market Evolved Over Time?

The plug types market has evolved significantly since the introduction of electric power, with the standardization of plugs and sockets becoming essential for the widespread adoption of electricity. Initially, various plug designs emerged without any regulation, leading to compatibility issues. The establishment of international standards by organizations like the IEC has been pivotal in addressing these challenges.

In recent years, the focus has shifted towards enhancing safety and efficiency. Innovations in plug technology, such as the introduction of grounded plugs and surge protection features, have improved user safety. Furthermore, the rise of smart technology integration has transformed traditional plug designs into multifunctional devices that cater to modern energy needs.

As international B2B buyers engage with the plug types sector, understanding this historical context can provide valuable insights into current trends and future opportunities. Adapting to these changes will be crucial for businesses looking to thrive in an increasingly interconnected global market.

Frequently Asked Questions (FAQs) for B2B Buyers of plug types

-

How do I choose the right plug type for my country?

To select the appropriate plug type for your operations, first, identify the plug types used in your target market. Each country has specific standards, often denoted by letters such as Type C for many European and African nations or Type I for Argentina. Utilize resources like the WorldStandards or IEC websites to access comprehensive lists of plug types by country. Understanding local voltage and frequency is also crucial, as mismatches can lead to equipment damage or safety hazards. -

What is the best plug type for my electrical equipment?

The best plug type for your electrical equipment depends on the device’s specifications and the region where it will be used. For instance, if your equipment is designed for European markets, Type C or Type F plugs are commonly recommended due to their grounding features and compatibility. Always verify the voltage requirements (e.g., 220-240V in Europe) and ensure that the plug can handle the necessary amperage to avoid overheating or failure. -

How can I ensure the quality of plugs from international suppliers?

To ensure quality when sourcing plugs internationally, consider suppliers who comply with international standards such as IEC or ISO. Request samples before placing bulk orders and check for certifications that validate product safety and performance. Additionally, read reviews and testimonials from other businesses, and consider third-party inspections to assess product integrity and adherence to your specifications. -

What are the common payment terms in international B2B transactions for plugs?

Payment terms in international B2B transactions can vary but often include options like letters of credit, advance payments, or net payment terms (e.g., net 30 days). It’s essential to negotiate terms that protect your financial interests while remaining favorable to the supplier. Be clear about currency exchange rates and any additional fees that may apply to international transactions to avoid unexpected costs. -

What is the minimum order quantity (MOQ) for plugs when sourcing internationally?

Minimum order quantities (MOQs) for plugs can vary significantly based on the supplier, the type of plug, and the complexity of customization. Generally, MOQs can range from a few hundred to several thousand units. Before committing, discuss your needs with potential suppliers to understand their MOQ policies, as some may be flexible, especially for new business relationships. -

How do I handle logistics and shipping for imported plugs?

When importing plugs, work with a reliable logistics partner experienced in international shipping. Ensure they understand the regulations regarding electrical components in your target market, including customs documentation and import tariffs. Consider air freight for urgent needs and sea freight for larger, cost-effective shipments. Tracking shipments and understanding lead times will help you manage inventory and production schedules effectively. -

What should I know about plug customization options for my business?

Customization options for plugs can include design changes, branding, and specific electrical specifications to meet local regulations. Discuss your requirements with suppliers upfront, as many manufacturers offer customizable solutions. Be mindful of additional costs and lead times associated with custom orders, and ensure that any changes comply with safety standards in your target market to avoid compliance issues. -

How can I verify the compatibility of plugs with my existing systems?

To verify plug compatibility with your existing systems, check the specifications of both the plugs and the equipment they will connect to. Ensure that the voltage, amperage, and pin configuration match. Additionally, consider using adapters for temporary solutions, but for long-term use, sourcing the correct plug type is essential. Consult with technical experts if unsure, to prevent operational disruptions and ensure safety.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for plug types

How Can Strategic Sourcing Enhance Your Plug Type Procurement?

In today’s global marketplace, understanding the diverse plug types and their compatibility is crucial for international B2B buyers. The landscape of electrical plugs, with its 15 distinct types, highlights the importance of strategic sourcing. Buyers from Africa, South America, the Middle East, and Europe must navigate these variations to ensure seamless operations and compliance with local regulations.

Effective strategic sourcing not only reduces procurement costs but also mitigates risks associated with product compatibility and safety. By leveraging local suppliers who are knowledgeable about regional standards, businesses can enhance their supply chain resilience. This approach allows for more timely deliveries and the opportunity to adapt to changing market demands swiftly.

As we look to the future, the push for universal standards in plug types may gain momentum, but until then, maintaining an agile sourcing strategy is essential. B2B buyers should actively engage with suppliers, share insights, and stay informed about emerging trends. This proactive stance will empower businesses to optimize their electrical equipment procurement, leading to increased efficiency and innovation. Embrace the complexities of plug types and position your business for success in the evolving global market.