Discover 5 Key Electrical Socket Types for Your Business (2025)

Introduction: Navigating the Global Market for electrical socket types

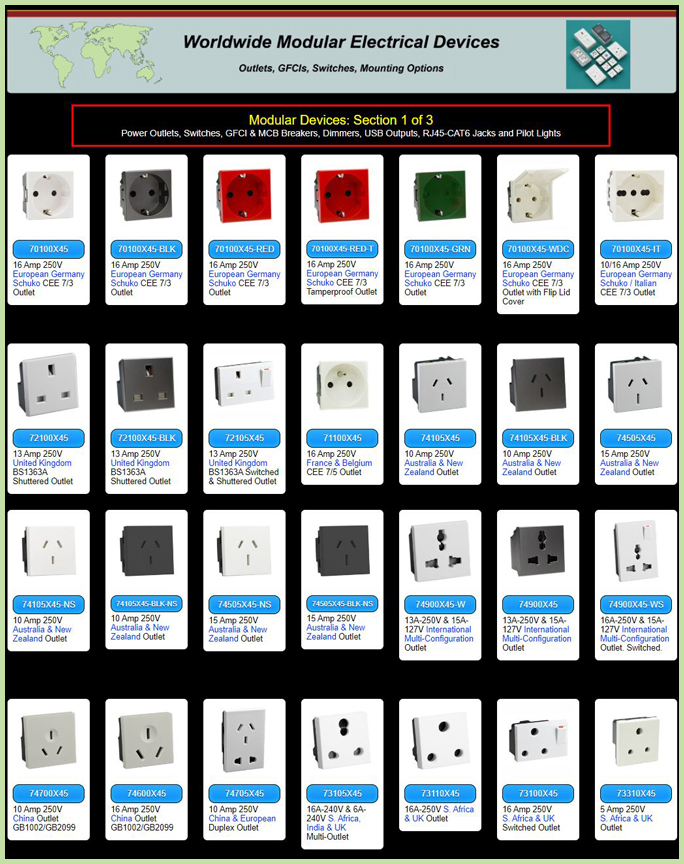

Navigating the global market for electrical socket types poses a significant challenge for international B2B buyers, particularly those sourcing products for diverse regions like Africa, South America, the Middle East, and Europe. With over 15 distinct electrical socket types in use worldwide, understanding these variations is crucial for ensuring compatibility and safety in electrical installations. This comprehensive guide delves into the different types of electrical sockets, their applications, and essential considerations for sourcing the right products.

We will explore how each socket type is utilized across various industries and geographical regions, helping you identify the best options for your needs. Additionally, this guide will provide insights on supplier vetting processes, cost analysis, and regulatory compliance, empowering you to make informed purchasing decisions.

By addressing common pain points—such as ensuring product compatibility, navigating local regulations, and managing supply chain logistics—this resource aims to streamline your procurement process. Whether you are operating in Brazil, Colombia, or any other region, understanding the intricacies of electrical socket types will enhance your operational efficiency and reduce the risk of costly errors. Equip yourself with the knowledge needed to thrive in the global market and ensure that your electrical systems function seamlessly across borders.

Understanding electrical socket types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type C | 2 pins, not grounded, widely used in Europe, Africa, and South America | General appliances, lighting | Pros: Commonly available, versatile; Cons: Not grounded, limited to lower power devices. |

| Type G | 3 pins, grounded, used in UK and some Middle Eastern countries | Heavy-duty appliances, commercial use | Pros: High safety with grounding; Cons: Less common globally, may require adapters. |

| Type N | 3 pins, grounded, used in Brazil and South Africa | Industrial equipment, residential use | Pros: High current capacity; Cons: Limited compatibility with other types. |

| Type E/F | 2 pins, grounded, compatible with various European devices | European machinery, home appliances | Pros: Versatile compatibility; Cons: May require specific adapters for non-European devices. |

| Type I | 2 or 3 pins, grounded, prevalent in Australia and New Zealand | Consumer electronics, power tools | Pros: Dual pin options for flexibility; Cons: Can be bulky, limiting outlet placement. |

What Are the Characteristics of Type C Sockets?

Type C sockets are characterized by their two round pins and lack of grounding. They are predominantly used across Europe, Africa, and South America. This makes them a versatile choice for B2B buyers looking to source electrical components for general appliances and lighting fixtures. When considering Type C sockets, it’s crucial to assess the power requirements of the devices being used, as these sockets are not grounded and are suitable primarily for lower power applications.

Why Choose Type G Sockets for Heavy-Duty Applications?

Type G sockets are known for their three rectangular pins and grounding capability, primarily utilized in the UK and some Middle Eastern countries. These sockets are ideal for heavy-duty appliances and commercial use, providing enhanced safety through grounding. B2B buyers should consider the availability of Type G sockets in their region and factor in the need for adapters when importing equipment from other regions that utilize different socket types.

How Does Type N Benefit Industrial Applications?

Type N sockets feature three pins and are grounded, making them suitable for high-current applications. They are primarily used in Brazil and South Africa, catering to both industrial equipment and residential use. When purchasing Type N sockets, B2B buyers should evaluate the compatibility with existing devices and the overall electrical infrastructure, as these sockets may not be compatible with other global standards.

What Makes Type E/F Popular in Europe?

Type E and F sockets are widely used across Europe and are distinguished by their two round pins and grounding capabilities. They offer excellent compatibility with various European devices, making them a preferred choice for machinery and home appliances. B2B buyers should ensure that their electrical equipment is compatible with these sockets and consider the potential need for adapters when working with non-European devices.

Why Consider Type I Sockets for Flexibility in Use?

Type I sockets come with either two or three pins and are commonly found in Australia and New Zealand. They are suitable for consumer electronics and power tools, providing flexibility with dual pin options. B2B buyers should consider the space limitations for Type I sockets, as their bulkiness may restrict outlet placement in tight areas. Ensuring compatibility with various devices is also essential when integrating Type I sockets into electrical systems.

Key Industrial Applications of electrical socket types

| Industry/Sector | Specific Application of Electrical Socket Types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Use of industrial sockets for machinery and equipment | Ensures operational efficiency and safety | Voltage compatibility, durability, and load capacity |

| Hospitality | Installation of various socket types in guest rooms and public areas | Enhances guest experience with diverse charging options | Aesthetic design, safety standards, and local regulations |

| Construction | Temporary power setups at construction sites | Provides flexible power solutions for tools and lighting | Weather resistance, portability, and compliance with codes |

| Healthcare | Medical equipment requiring specific socket types | Ensures safety and reliability of critical devices | Compatibility with medical standards and regulations |

| Retail | Point of sale systems and electronic displays | Facilitates efficient operations and customer service | Ease of access, type of socket, and energy efficiency |

How Are Electrical Socket Types Used in Manufacturing?

In the manufacturing sector, electrical socket types play a crucial role in powering machinery and equipment. Industrial sockets must accommodate high-voltage requirements and withstand rigorous conditions. For international buyers in Africa and South America, ensuring that sockets are compatible with local voltage standards (typically 220-240V) is essential. Additionally, these sockets must be durable to handle heavy machinery loads, reducing downtime and maintenance costs.

What Are the Applications of Electrical Sockets in Hospitality?

In the hospitality industry, electrical sockets are integral to enhancing guest experiences. Hotels often install a variety of socket types in guest rooms and public areas to accommodate different devices, from laptops to mobile phones. International buyers should consider the aesthetic design of sockets, as they must blend with the interior decor. Compliance with safety standards is also paramount, especially in regions like the Middle East, where electrical safety regulations are strictly enforced.

How Are Electrical Socket Types Utilized in Construction?

Construction sites require temporary power setups, making the choice of electrical socket types critical. Sockets must be weather-resistant to ensure safety and functionality in outdoor environments. Buyers in Europe and Africa should prioritize portability and compliance with local electrical codes. The ability to quickly set up and dismantle power sources can significantly enhance operational efficiency, allowing for seamless work processes.

Why Are Specific Socket Types Important in Healthcare?

In healthcare settings, the reliability of electrical socket types is vital for medical equipment. Specific sockets, such as those designed for high-frequency devices, must meet stringent medical standards. International buyers, particularly in regions with varying healthcare regulations, need to ensure that sockets are compatible with local medical equipment and safety requirements. This ensures that critical devices remain operational, safeguarding patient health.

How Do Electrical Sockets Support Retail Operations?

In the retail sector, electrical sockets are essential for powering point-of-sale systems and electronic displays. The right socket types facilitate efficient operations, allowing businesses to serve customers quickly and effectively. Buyers should consider the ease of access to sockets and their energy efficiency, especially in regions like Brazil, where energy costs can be significant. Selecting the appropriate sockets can enhance customer service and operational performance.

3 Common User Pain Points for ‘electrical socket types’ & Their Solutions

Scenario 1: Incompatibility with Local Electrical Standards

The Problem:

B2B buyers often face significant challenges when attempting to source electrical sockets that are compatible with local electrical standards. For example, a company based in Brazil may want to import equipment from Europe that utilizes Type C or Type L plugs. The mismatch in plug types can lead to operational inefficiencies, delays in project timelines, and increased costs due to the need for adapters or re-engineering. This issue is particularly pressing in sectors such as construction, manufacturing, and technology, where precise electrical specifications are critical for operational safety and efficiency.

The Solution:

To mitigate this issue, B2B buyers should conduct thorough market research to understand the specific electrical standards, including plug types and voltage requirements, in their respective regions. Utilizing databases such as the International Electrotechnical Commission (IEC) or region-specific standards organizations can provide invaluable insights. When procuring equipment, buyers should specify the required socket types and voltage ratings in their purchase agreements to ensure compatibility. Additionally, investing in universal sockets or adapters can provide a flexible solution, enabling the use of multiple plug types without the need for extensive rewiring. Establishing relationships with reliable local suppliers who understand these standards can also streamline the sourcing process.

Scenario 2: Safety Compliance and Electrical Fires

The Problem:

Safety compliance is a critical concern for B2B buyers, particularly in industries where electrical installations are prevalent. The use of outdated or inappropriate electrical sockets can lead to risks such as electrical fires, equipment failure, or even personal injury. For instance, companies in construction or manufacturing often use heavy machinery that requires high-amperage sockets. Without proper grounding and circuit protection, the risk of short circuits increases significantly, endangering both personnel and equipment.

The Solution:

To address safety compliance, buyers must prioritize sourcing high-quality electrical sockets that meet local safety regulations, such as the National Electrical Code (NEC) or European Union standards. It is essential to choose sockets with built-in safety features, such as Ground Fault Circuit Interrupters (GFCIs) or Arc Fault Circuit Interrupters (AFCIs), which provide additional protection against electrical faults. Collaborating with certified electrical engineers to conduct risk assessments and ensure proper installation can further enhance safety. Regular audits of existing electrical systems can help identify and replace outdated sockets, thus maintaining a safe working environment. Additionally, training staff on the proper use of electrical outlets and the importance of compliance can foster a culture of safety within the organization.

Scenario 3: Limited Availability of Specialized Sockets

The Problem:

International B2B buyers may encounter difficulties in finding specialized electrical sockets that cater to unique operational needs. For example, a tech firm in South Africa may require sockets designed for high-performance computing equipment, which often necessitate specific amperage and grounding configurations. The limited availability of such specialized sockets can lead to project delays and increased costs, as companies may need to source from multiple vendors or resort to suboptimal solutions.

The Solution:

To overcome this challenge, B2B buyers should develop a robust sourcing strategy that includes reaching out to manufacturers specializing in electrical components. Building relationships with suppliers who offer customizable solutions can ensure access to the required socket types tailored to specific operational demands. Conducting a needs assessment to identify the precise electrical requirements of the equipment in use can help streamline the procurement process. Additionally, leveraging online platforms and industry networks can facilitate the discovery of niche suppliers that cater to specialized needs. Regularly reviewing the electrical infrastructure and anticipating future requirements can also help companies preemptively secure the necessary socket types, minimizing disruptions and ensuring smooth operations.

Strategic Material Selection Guide for electrical socket types

What Are the Key Materials Used in Electrical Socket Types?

When selecting materials for electrical sockets, it is crucial to consider their properties, performance, and suitability for specific applications. Below are four common materials used in the manufacturing of electrical sockets, analyzed from a B2B perspective.

How Do Thermoplastics Perform in Electrical Socket Applications?

Key Properties: Thermoplastics, such as polycarbonate and nylon, are known for their excellent electrical insulation properties, temperature resistance (up to 120°C), and impact strength. They also exhibit good chemical resistance, making them suitable for various environments.

Pros & Cons: The durability of thermoplastics is a significant advantage, as they can withstand repeated mechanical stress. They are relatively low-cost and easy to mold, which simplifies manufacturing processes. However, their performance can be compromised under high temperatures or exposure to UV light, leading to potential degradation over time.

Impact on Application: Thermoplastics are ideal for residential and light commercial applications where electrical insulation and safety are paramount. They are compatible with various media, including standard household voltages.

Considerations for International Buyers: Compliance with international standards such as IEC 60670 is essential. Buyers from Africa and South America should also consider local certifications for electrical safety.

What Advantages Do Metal Components Offer in Electrical Socket Manufacturing?

Key Properties: Metals like copper and brass are often used for contacts and terminals due to their excellent electrical conductivity and thermal properties. They can handle high current loads and have a temperature rating that can exceed 200°C.

Pros & Cons: The primary advantage of metal components is their durability and reliability in conducting electricity, which is crucial for high-performance sockets. However, they are more expensive than thermoplastics and can corrode if not properly treated, which may lead to reduced performance and safety risks.

Impact on Application: Metal components are essential in heavy-duty electrical sockets used in industrial settings or for high-power appliances. They ensure a stable connection and minimize energy losses.

Considerations for International Buyers: Buyers should ensure that metal components meet standards such as ASTM B16 for copper and brass alloys. Corrosion resistance is particularly important in humid or coastal regions, common in parts of Africa and South America.

Why Are Ceramics Used in Specific Electrical Socket Types?

Key Properties: Ceramics are known for their high-temperature resistance (up to 200°C) and excellent dielectric properties. They are non-conductive and can withstand harsh environmental conditions.

Pros & Cons: The high durability and heat resistance of ceramics make them suitable for specialized applications, such as high-voltage sockets. However, they are more brittle than other materials and can break under mechanical stress, making them less suitable for general use.

Impact on Application: Ceramics are often used in industrial applications where high temperatures and electrical insulation are critical. They are compatible with various media, especially in high-voltage settings.

Considerations for International Buyers: Compliance with international standards for high-voltage applications is crucial. Buyers must also consider the specific environmental conditions of their region, particularly in the Middle East, where high temperatures are prevalent.

What Role Does Rubber Play in Electrical Socket Design?

Key Properties: Rubber is highly flexible and offers excellent insulation properties. It is resistant to moisture and can operate effectively in temperatures ranging from -40°C to 90°C.

Pros & Cons: The flexibility and moisture resistance of rubber make it ideal for outdoor and portable applications. However, it may not withstand high temperatures as well as other materials, leading to potential degradation over time.

Impact on Application: Rubber is commonly used in weather-resistant sockets and outdoor applications, providing safety and reliability in various conditions. Its compatibility with a wide range of electrical devices makes it versatile.

Considerations for International Buyers: Buyers should look for rubber materials that meet specific international standards for outdoor use, such as IEC 60529 for ingress protection (IP ratings). This is especially relevant in regions like South America, where weather conditions can vary significantly.

Summary Table of Material Selection for Electrical Socket Types

| Material | Typical Use Case for electrical socket types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastics | Residential and light commercial sockets | Excellent insulation and impact resistance | Degrades under UV exposure | Low |

| Metals | Heavy-duty and industrial sockets | High conductivity and durability | Prone to corrosion if untreated | High |

| Ceramics | High-voltage industrial applications | High-temperature resistance | Brittle and can break under stress | Medium |

| Rubber | Weather-resistant and outdoor sockets | Flexible and moisture-resistant | Limited high-temperature performance | Medium |

This comprehensive analysis of materials will assist international B2B buyers in making informed decisions regarding electrical socket types, ensuring compliance with local standards and suitability for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for electrical socket types

What Are the Main Stages in the Manufacturing Process of Electrical Sockets?

The manufacturing of electrical sockets involves several critical stages that ensure high-quality products capable of meeting international standards. Understanding these stages can help B2B buyers make informed decisions when sourcing electrical sockets.

A stock image related to electrical socket types.

Material Preparation: What Materials Are Used in Electrical Socket Manufacturing?

The manufacturing process begins with the selection and preparation of raw materials. Common materials include:

- Plastics: High-quality thermoplastics such as polycarbonate and nylon are used for the outer casing due to their durability and insulation properties.

- Metal Components: Copper and brass are typically used for internal contacts and pins due to their excellent electrical conductivity.

- Insulation Materials: Materials like PVC and rubber are employed for insulation to ensure safety and compliance with electrical standards.

Once materials are selected, they undergo quality checks to ensure they meet the required specifications for strength and electrical safety.

How Are Electrical Sockets Formed?

The forming stage involves shaping the raw materials into the desired socket configuration. This can include various techniques such as:

- Injection Molding: This is the primary method for creating plastic housings. Molten plastic is injected into a mold to form the socket’s body.

- Stamping and Die-Cutting: For metal components, stamping techniques are used to create the necessary shapes and sizes of contacts and pins.

- Assembly of Components: After forming, components are assembled. This may involve inserting metal contacts into the plastic housing and securing them through various fastening techniques.

What Finishing Techniques Are Used to Ensure Quality?

The finishing stage focuses on enhancing the product’s appearance and functionality. Key techniques include:

- Surface Treatment: Metal components may undergo plating (e.g., nickel or gold plating) to prevent corrosion and improve conductivity.

- Final Assembly: The sockets are fully assembled, ensuring that all components fit correctly and function as intended.

- Quality Testing: Each finished product is subject to rigorous testing to ensure it meets safety and performance standards.

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance is vital in the production of electrical sockets. International and industry-specific standards play a crucial role in ensuring that products are safe and reliable.

Which International Standards Apply to Electrical Socket Manufacturing?

B2B buyers should look for suppliers that comply with relevant international standards, including:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring that manufacturers maintain consistent quality in their processes.

- IEC 60884: This standard specifies requirements for general requirements for socket-outlets for household and similar purposes.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

What Are the Common Quality Control Checkpoints in Electrical Socket Manufacturing?

Quality control checkpoints are essential to ensure that each stage of the manufacturing process adheres to established standards. Key checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Ongoing inspections are performed during production to catch defects early.

- Final Quality Control (FQC): Finished products undergo thorough testing to ensure they meet all relevant standards before shipment.

What Testing Methods Are Commonly Used for Electrical Sockets?

To ensure safety and reliability, various testing methods are employed during the manufacturing process:

- Electrical Testing: This includes insulation resistance tests, dielectric strength tests, and current carrying capacity tests.

- Mechanical Testing: Tests for mechanical strength, such as impact resistance and durability testing, are performed to ensure the socket can withstand physical stress.

- Environmental Testing: Sockets may undergo exposure to extreme temperatures, humidity, and other environmental factors to evaluate their performance under various conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is crucial for international B2B buyers. Here are several methods to ensure compliance:

- Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturer’s production processes and quality assurance practices firsthand.

- Requesting Quality Reports: Buyers should request documentation on quality control processes, including test results and compliance certificates.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality standards and practices.

What Nuances Should International B2B Buyers Consider When Sourcing Electrical Sockets?

When sourcing electrical sockets from regions such as Africa, South America, the Middle East, and Europe, buyers should be aware of specific nuances:

- Regulatory Differences: Different countries may have varying safety regulations and standards that affect the approval and certification of electrical sockets. Ensure that the supplier is familiar with local regulations.

- Cultural Considerations: Understanding the cultural and business practices of suppliers in these regions can facilitate smoother negotiations and partnerships.

- Logistical Challenges: Consider the implications of shipping and customs regulations when sourcing from different continents. Ensure that the supplier is equipped to handle international shipping requirements.

By understanding the manufacturing processes, quality assurance practices, and the nuances of international sourcing, B2B buyers can make informed decisions when purchasing electrical sockets. This not only ensures compliance with relevant standards but also enhances the reliability and safety of the products they provide to their customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electrical socket types’

To assist international B2B buyers in effectively sourcing electrical socket types, this guide outlines essential steps to ensure informed procurement decisions. By following this checklist, you can align your purchasing strategy with technical requirements, compliance standards, and market expectations.

Step 1: Identify Your Electrical Requirements

Understanding your specific electrical needs is the first step in sourcing electrical sockets. Consider the voltage, amperage, and type of devices you plan to connect. Different regions have distinct standards, so it’s crucial to identify whether you require sockets for 100-127V (e.g., Type A and B) or 220-240V (e.g., Type C, F, or G) applications.

- Voltage and Amperage Needs: Match the socket type to the voltage and current specifications of your equipment.

- Device Compatibility: Ensure that the sockets you choose are compatible with the plugs of the devices you intend to use.

Step 2: Research Regional Standards and Compliance

Each region has its own electrical standards, which can affect your sourcing decisions. Familiarize yourself with the local regulations for electrical installations in your target market, particularly in Africa, South America, the Middle East, and Europe.

- Safety Standards: Look for compliance with international standards such as IEC or local certification marks.

- Voltage Regulations: Ensure that the sockets conform to the voltage requirements of your target region to prevent electrical hazards.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is crucial. Review their capabilities, certifications, and past performance in the industry.

- Request Documentation: Ask for company profiles, quality certifications, and product testing results.

- Check References: Seek testimonials or case studies from other businesses in your industry to assess reliability.

Step 4: Assess Quality and Durability

Quality is paramount when sourcing electrical sockets to ensure long-term reliability and safety. Evaluate the materials used and the manufacturing processes employed by your suppliers.

- Material Specifications: Look for sockets made from high-quality, heat-resistant materials.

- Testing Standards: Confirm that the products have undergone rigorous testing for durability and safety.

Step 5: Compare Pricing and Terms of Purchase

Price is a significant factor in procurement, but it should not compromise quality. Collect quotes from multiple suppliers to compare pricing while considering the total cost of ownership.

- Bulk Discounts: Inquire about volume discounts or loyalty programs that can reduce your overall costs.

- Payment Terms: Understand the payment options available, including credit terms, deposits, and shipping costs.

Step 6: Plan for Logistics and Delivery

Effective logistics planning is essential to ensure timely delivery and minimize disruptions to your operations. Discuss shipping options with your suppliers.

- Shipping Methods: Evaluate the reliability of the shipping methods proposed by suppliers.

- Lead Times: Confirm production and delivery timelines to align with your project schedules.

Step 7: Implement a Quality Control Process

Once you have sourced your electrical sockets, establishing a quality control process will help maintain standards throughout your supply chain.

- Inspection Protocols: Develop inspection criteria upon receipt of goods to ensure they meet the agreed specifications.

- Feedback Loop: Create a system for providing feedback to suppliers based on product performance and customer satisfaction.

By following this structured approach, B2B buyers can navigate the complexities of sourcing electrical socket types effectively, ensuring they meet their technical and operational requirements while also aligning with regional standards and market conditions.

Comprehensive Cost and Pricing Analysis for electrical socket types Sourcing

What Are the Key Cost Components in Electrical Socket Manufacturing?

When sourcing electrical sockets, understanding the cost structure is crucial for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Common materials include thermoplastics for housing and copper for contacts. High-quality materials may incur a higher initial cost but can lead to long-term savings through durability and safety.

-

Labor: Labor costs vary by region. Countries with lower labor costs can offer competitive pricing, but this may affect quality and compliance with international standards.

-

Manufacturing Overhead: This includes expenses related to production facilities, utilities, and administrative costs. Efficient manufacturing processes can reduce overhead, thereby lowering costs.

-

Tooling: Initial tooling costs for molds and specialized equipment can be substantial, particularly for custom socket types. Buyers should consider whether they can meet minimum order quantities (MOQs) to spread these costs across larger production runs.

-

Quality Control (QC): Ensuring product safety and compliance with standards (like IEC or UL certifications) requires investment in quality control processes. This is essential for maintaining reliability, especially in markets with stringent regulations.

-

Logistics: Shipping costs can vary significantly based on distance, transportation modes, and freight terms. Buyers should consider logistics when calculating the total cost of ownership.

-

Margin: Suppliers’ profit margins will vary based on market conditions, competition, and the perceived value of their products.

How Do Price Influencers Affect Electrical Socket Sourcing?

Several factors influence the pricing of electrical sockets, which B2B buyers should consider:

-

Volume/MOQ: Higher order volumes generally lead to lower per-unit costs. Suppliers often offer discounts for bulk orders, making it essential for buyers to align their purchasing strategies accordingly.

-

Specifications and Customization: Customized sockets (for instance, specific plug types or unique colors) can increase costs due to additional tooling and production complexities. Buyers should weigh the need for customization against potential cost increases.

-

Materials Quality and Certifications: Sockets made from higher-grade materials or those that meet international safety certifications will command higher prices. However, investing in quality can prevent future issues related to safety and compliance.

-

Supplier Factors: The reputation, reliability, and location of suppliers can influence pricing. Established suppliers with a track record of quality may charge more but can offer better assurance of product performance.

-

Incoterms: Understanding shipping terms (such as FOB, CIF, or DDP) is essential, as they determine who bears the cost and risk at various points in the shipping process. This knowledge can help buyers negotiate better terms and avoid unexpected costs.

What Negotiation Tips Can Improve Cost-Efficiency for International Buyers?

To ensure cost-efficiency when sourcing electrical sockets, international B2B buyers can implement several strategies:

-

Leverage Volume Discounts: Consolidate orders across multiple projects to meet MOQs, thus unlocking bulk pricing.

-

Engage in Transparent Negotiations: Build relationships with suppliers to foster open discussions about pricing structures and potential discounts.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the product, including maintenance, potential failures, and energy efficiency, rather than focusing solely on upfront costs.

-

Evaluate Different Suppliers: Obtain quotes from multiple suppliers to compare not just prices but also quality and service levels.

-

Understand Local Market Conditions: Be aware of regional economic conditions, tariffs, and regulations that could affect pricing and availability.

What Should Buyers Know About Pricing Nuances in Different Regions?

Buyers from Africa, South America, the Middle East, and Europe face unique pricing nuances. Economic conditions, currency fluctuations, and local regulations can impact costs. For instance, buyers in Brazil may encounter import tariffs that significantly affect the final price of imported electrical sockets. Similarly, buyers in Africa should be aware of potential logistics challenges that could inflate costs. Understanding these regional dynamics can provide a competitive edge in negotiations and sourcing strategies.

Disclaimer

Prices for electrical sockets can vary widely based on the factors discussed. The figures mentioned are indicative and should be validated through direct engagement with suppliers for accurate and current pricing.

Alternatives Analysis: Comparing electrical socket types With Other Solutions

Exploring Alternatives to Electrical Socket Types: What Are the Options?

In today’s global market, electrical infrastructure plays a crucial role in ensuring smooth business operations. While electrical socket types are the standard method for delivering power to devices, various alternative solutions can offer unique advantages. This section compares traditional electrical socket types with other emerging technologies, providing international B2B buyers with actionable insights to make informed decisions.

Comparison Table of Electrical Socket Types and Alternatives

| Comparison Aspect | Electrical Socket Types | Wireless Power Transfer | Smart Plugs |

|---|---|---|---|

| Performance | Reliable for fixed installations; requires physical connection | Limited range; efficiency decreases with distance | Offers remote control; performance depends on Wi-Fi stability |

| Cost | Generally low initial cost; installation may vary based on infrastructure | Higher initial investment; ongoing costs may be lower | Moderate cost; can add up with multiple units |

| Ease of Implementation | Requires electrical installation; must comply with local regulations | Needs specialized infrastructure; installation can be complex | Easy to install; often plug-and-play |

| Maintenance | Low maintenance; occasional checks needed | Requires regular updates and maintenance for optimal efficiency | Minimal maintenance; firmware updates may be necessary |

| Best Use Case | Ideal for permanent installations in homes and businesses | Useful for temporary setups or in areas without wiring | Great for smart homes; allows for automation and monitoring |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Wireless Power Transfer?

Wireless power transfer utilizes electromagnetic fields to deliver energy to devices without physical connections. This method offers the benefit of eliminating the need for traditional wiring, making it ideal for portable devices or environments where cabling is impractical. However, its performance can be hampered by distance and obstructions, leading to energy loss. Moreover, the initial setup can be costly and complex, requiring specialized equipment and installation expertise.

How Do Smart Plugs Enhance Electrical Systems?

Smart plugs are devices that enable users to control their electrical outlets remotely through a smartphone or voice assistant. These plugs can be easily installed into existing sockets, allowing for quick integration into any electrical system. The primary advantage of smart plugs is their ability to automate and monitor energy usage, providing insights into consumption patterns. On the downside, their reliance on stable Wi-Fi can pose challenges in areas with connectivity issues. Additionally, while the upfront costs are reasonable, the expense can accumulate if multiple units are needed for various appliances.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate electrical solution, B2B buyers must consider the specific needs of their operations, including installation capabilities, budget constraints, and the intended use case. Traditional electrical socket types remain the most reliable option for permanent installations, particularly in environments with high energy demands. However, alternatives like wireless power transfer and smart plugs can offer flexibility and enhanced control, especially in dynamic or evolving workspaces. Ultimately, understanding the strengths and limitations of each option will empower buyers to make informed decisions that align with their business objectives.

Essential Technical Properties and Trade Terminology for electrical socket types

What Are the Key Technical Properties of Electrical Socket Types?

Understanding the technical specifications of electrical sockets is essential for B2B buyers, especially when sourcing components for international markets. Here are some critical properties to consider:

-

Material Grade

– Definition: The material used in manufacturing electrical sockets, commonly thermoplastics or thermosetting plastics, which impact durability and heat resistance.

– B2B Importance: High-grade materials ensure longevity and safety, reducing the risk of product failure. For buyers, this translates to lower warranty claims and enhanced customer satisfaction. -

Current Rating (Amperage)

– Definition: The maximum current a socket can safely carry, typically ranging from 10A to 20A for most residential and commercial applications.

– B2B Importance: Selecting the right amperage is crucial for compatibility with appliances. Underestimating this can lead to overheating and potential fire hazards, which can affect a company’s reputation and compliance with safety standards. -

Voltage Compatibility

– Definition: The range of voltage the socket is designed to handle, with most types accommodating either 100-127V or 220-240V.

– B2B Importance: Buyers need to ensure that the sockets they source match the voltage requirements of their target markets. Mismatched voltage can lead to equipment malfunction or damage, resulting in costly replacements. -

Grounding Type

– Definition: Refers to whether the socket includes a grounding pin, which is essential for safety in preventing electrical shocks.

– B2B Importance: Grounded sockets are often required by electrical codes in many regions. Buyers must be aware of local regulations to ensure compliance, thereby avoiding legal complications and enhancing safety. -

Temperature Rating

– Definition: The maximum operating temperature the socket can withstand without degradation, often rated between -20°C to 60°C.

– B2B Importance: Understanding temperature ratings helps buyers select products suitable for different climates, especially in regions like Africa or South America, where temperatures can vary significantly.

What Are Common Trade Terms Related to Electrical Sockets?

Familiarity with industry jargon is vital for effective communication in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Buyers often work with OEMs to ensure they receive high-quality components that meet specific standards, facilitating better integration into their products. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding MOQ is crucial for budgeting and inventory management. Buyers should negotiate these terms to align with their production schedules and cash flow. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products.

– Importance: An RFQ helps streamline the procurement process, allowing buyers to compare prices and terms from multiple suppliers, facilitating better purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of sellers and buyers in shipping goods.

– Importance: Knowing Incoterms is essential for managing risks and costs associated with international trade. They clarify who is responsible for shipping, insurance, and tariffs, helping buyers avoid unexpected expenses. -

Certification Standards

– Definition: Compliance marks (e.g., CE, UL) indicating that products meet specific safety and quality standards.

– Importance: Certifications reassure buyers about the quality and safety of the electrical sockets they purchase, which is particularly important in regulated markets.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring compliance, safety, and compatibility in their sourcing strategies.

Navigating Market Dynamics and Sourcing Trends in the electrical socket types Sector

What are the Key Market Dynamics and Trends in the Electrical Socket Types Sector?

The global market for electrical socket types is shaped by various factors including technological advancements, regulatory changes, and shifting consumer preferences. As of 2023, there are 15 distinct plug and socket types used worldwide, each catering to specific regional electrical standards. For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding these standards is critical for ensuring compatibility and compliance.

Emerging trends highlight a growing demand for multifunctional and innovative socket designs, such as smart sockets that integrate with home automation systems. Additionally, the rise of e-commerce platforms has transformed sourcing practices, enabling buyers to access a broader range of products directly from manufacturers. In regions like Brazil and Colombia, the push for modernization in infrastructure is increasing the demand for compliant and safe electrical installations, while in Africa, the focus is on cost-effective solutions to meet rapid urbanization needs.

A stock image related to electrical socket types.

Moreover, the COVID-19 pandemic has accelerated digital transformation in procurement, with many businesses adopting online sourcing strategies. Buyers are increasingly seeking suppliers that offer flexibility in their product offerings, alongside robust logistics capabilities to navigate the complexities of international shipping and regulations.

How Does Sustainability and Ethical Sourcing Impact Electrical Socket Types?

In the context of electrical sockets, sustainability and ethical sourcing have become paramount for B2B buyers. The manufacturing processes of electrical sockets can have significant environmental impacts, from raw material extraction to waste generation. Consequently, buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials and minimizing carbon footprints.

Green certifications, such as Energy Star or RoHS compliance, are essential indicators of a product’s environmental impact. These certifications not only ensure that products meet international safety and efficiency standards but also resonate with eco-conscious consumers and businesses. Buyers in regions like Europe are particularly attuned to these standards due to stringent environmental regulations.

Ethical supply chains are equally important, as they ensure that labor practices meet international human rights standards. This is particularly relevant for buyers sourcing from developing regions in Africa and South America, where transparency and social responsibility in the supply chain are increasingly scrutinized. By choosing suppliers that uphold ethical practices, businesses can enhance their brand reputation and foster customer loyalty.

What is the Brief Evolution of Electrical Socket Types and Its Relevance to B2B?

The evolution of electrical socket types reflects advancements in electrical engineering and changing safety regulations. Initially, sockets were designed without standardized shapes or voltages, leading to compatibility issues. The introduction of national standards in the mid-20th century helped to streamline socket designs, ensuring safety and efficiency across different regions.

Today, the ongoing development of smart technology has introduced new challenges and opportunities in the electrical socket market. As smart homes become more prevalent, B2B buyers must consider the compatibility of traditional sockets with smart appliances. This evolution necessitates a more informed approach to sourcing, as buyers navigate an increasingly complex landscape of electrical standards and technologies. Understanding the historical context of electrical sockets can provide valuable insights into current trends and future developments, enabling businesses to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of electrical socket types

-

How do I choose the right electrical socket type for my products?

Choosing the right electrical socket type involves understanding the specific needs of your target market. Evaluate the voltage and amperage requirements of your products and the socket compatibility in your target regions. For example, in Europe, Type C and Type F sockets are common, while in South Africa, Type M is prevalent. Conduct market research to identify the most widely used socket types in your target countries, ensuring compliance with local standards to avoid compatibility issues. -

What are the most common electrical socket types used in Africa and South America?

In Africa, the Type C and Type M sockets are widely utilized, while Type N is common in Brazil. In South America, countries like Colombia primarily use Type A and C sockets. Understanding the regional preferences will help you source appropriate sockets for your products, facilitating smoother operations and reducing returns due to incompatibility. -

How do I verify the quality of electrical sockets from international suppliers?

To verify the quality of electrical sockets, request certifications such as ISO, CE, or UL, which indicate compliance with international safety standards. Conduct supplier audits or assessments, checking their production processes and quality control measures. Additionally, consider ordering samples for testing before committing to larger orders to ensure that the sockets meet your specifications and quality expectations. -

What is the minimum order quantity (MOQ) for electrical sockets when sourcing internationally?

MOQs for electrical sockets can vary significantly based on the supplier and the type of socket. Typically, it ranges from 500 to 10,000 units. When negotiating with suppliers, inquire about their flexibility on MOQs, especially if you’re a smaller business. Some suppliers may offer lower MOQs for custom orders, allowing you to test the market without overcommitting. -

What payment terms should I expect when sourcing electrical sockets internationally?

Payment terms can vary by supplier but typically include options like 30% upfront and 70% upon delivery or a letter of credit for larger orders. It’s essential to negotiate terms that protect your interests while ensuring the supplier feels secure. Consider using secure payment methods such as PayPal or escrow services for added protection against fraud. -

How do I handle logistics when importing electrical sockets?

Handling logistics involves selecting a reliable freight forwarder familiar with importing electrical goods. Ensure they understand the import regulations in your destination country, including customs clearance, tariffs, and any specific documentation required. Planning for logistics should include estimated shipping times and costs, as well as options for tracking shipments to avoid delays. -

What customization options should I consider for electrical sockets?

Customization options can include specific voltage ratings, color variations, branding, or special features like child safety mechanisms. Discuss these options with your supplier early in the negotiation process, as they can impact lead times and costs. Custom sockets can differentiate your products in the market, making them more appealing to buyers in your target regions. -

How can I ensure compliance with local regulations for electrical sockets?

To ensure compliance with local regulations, familiarize yourself with the electrical standards in your target countries. Each region may have specific safety and performance requirements for electrical sockets. Collaborate with local experts or consultants who can provide insights into necessary certifications, testing, and labeling requirements, ensuring that your products are market-ready and legally compliant.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for electrical socket types

A stock image related to electrical socket types.

How Can Strategic Sourcing Enhance Your Electrical Socket Procurement?

In conclusion, understanding the diverse types of electrical sockets and their global applications is crucial for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. By strategically sourcing electrical sockets tailored to specific regional standards, businesses can ensure compliance with local regulations, enhance safety, and optimize operational efficiency.

Buyers should prioritize partnerships with manufacturers that offer a variety of socket types, including Type C, Type G, and Type N, which are prevalent across multiple regions. Additionally, considering the demand for specialized outlets such as GFCI and AFCI can provide added safety and functionality, catering to modern electrical needs.

As the global market continues to evolve, staying informed about emerging trends and innovations in electrical socket technology will be vital. By leveraging strategic sourcing practices, companies can not only secure high-quality products but also foster sustainable relationships with suppliers.

We encourage international buyers to assess their current electrical needs and explore sourcing options that align with their operational goals. This proactive approach will position your business for future success in an increasingly interconnected marketplace.