Discover 5 Outlet Types: The Ultimate Sourcing Guide (2025)

Introduction: Navigating the Global Market for outlet types

As international B2B buyers navigate the complex landscape of sourcing electrical outlets, understanding the various types of outlet options available becomes crucial. From selecting the right type for specific applications to ensuring compliance with local regulations, the process can be daunting. This guide aims to demystify the world of outlet types, providing a comprehensive overview that covers essential aspects such as applications, supplier vetting, and cost considerations.

In this resource, we will explore different outlet types, including standard receptacles, GFCI outlets, AFCI outlets, and specialty options designed for specific markets. Each type serves distinct functions, catering to diverse electrical needs across various industries. Buyers will also gain insights into how to effectively vet suppliers, ensuring that they partner with reliable manufacturers who adhere to quality and safety standards.

Our guide is tailored for international B2B buyers from regions like Africa, South America, the Middle East, and Europe, including key markets such as the UAE and the UK. By equipping buyers with the knowledge and tools to make informed purchasing decisions, we aim to empower businesses to optimize their electrical installations, enhance safety, and improve operational efficiency. Whether you are upgrading your facilities or sourcing for new projects, this guide will serve as an invaluable resource in your decision-making process.

Understanding outlet types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ground Fault Circuit Interrupter (GFCI) | Monitors electrical flow, shuts off power if leakage is detected. | Restaurants, hotels, healthcare facilities | Pros: Enhances safety in wet areas. Cons: May require regular testing and maintenance. |

| Arc Fault Circuit Interrupter (AFCI) | Detects arc faults, reducing the risk of electrical fires. | Offices, residential buildings, schools | Pros: Prevents fire hazards. Cons: Higher initial cost compared to standard outlets. |

| Tamper-Resistant Receptacles (TRR) | Built-in shutters prevent foreign objects from being inserted. | Childcare centers, schools, residential areas | Pros: Increased safety for children. Cons: Slightly higher cost than traditional outlets. |

| USB Charging Outlets | Integrated USB ports for direct device charging. | Hotels, conference centers, public spaces | Pros: Convenient for users, reduces clutter. Cons: Limited to USB-compatible devices. |

| Weather-Resistant Receptacles | Designed to withstand moisture and harsh outdoor conditions. | Outdoor venues, pools, construction sites | Pros: Durable and safe for outdoor use. Cons: Higher installation costs due to specialized materials. |

What Are the Key Characteristics of GFCI Outlets for B2B Buyers?

Ground Fault Circuit Interrupter (GFCI) outlets are essential for environments where water and electricity may interact, such as kitchens and bathrooms. They continuously monitor the electrical current and can shut off power almost instantaneously if they detect a fault, significantly reducing the risk of electric shock. For B2B buyers, investing in GFCI outlets is crucial for compliance with safety regulations and enhancing the safety profile of facilities, especially in hospitality and healthcare sectors. Regular testing and maintenance are recommended to ensure reliability.

How Do AFCI Outlets Enhance Safety in Commercial Settings?

Arc Fault Circuit Interrupters (AFCIs) are designed to protect against electrical fires caused by arcing faults. These outlets are particularly beneficial in office environments and residential buildings where electrical loads can fluctuate. AFCIs not only detect faults in wiring but also in plugged-in devices, offering a comprehensive safety solution. While they may come with a higher upfront cost, the long-term benefits in fire prevention and compliance with safety codes make them a valuable investment for B2B buyers.

Why Choose Tamper-Resistant Receptacles for Child Safety?

Tamper-Resistant Receptacles (TRRs) feature a unique shutter system that prevents children from inserting foreign objects into the outlet, making them ideal for schools, childcare facilities, and homes with young children. While TRRs may cost slightly more than traditional outlets, the enhanced safety they provide justifies the investment. B2B buyers should consider TRRs as a proactive measure to prevent accidents and ensure compliance with safety standards, especially in environments frequented by children.

What Are the Benefits of USB Charging Outlets in Public Spaces?

USB charging outlets offer a modern solution for charging devices directly without the need for adapters. They are increasingly found in hotels, conference centers, and public spaces, catering to the growing demand for convenient charging options. For B2B buyers, integrating USB outlets can enhance customer experience and convenience, making spaces more attractive. However, it is essential to note that these outlets are limited to USB-compatible devices, which may restrict their utility in some scenarios.

How Do Weather-Resistant Receptacles Improve Outdoor Safety?

Weather-Resistant Receptacles are specifically designed to withstand moisture, making them ideal for outdoor venues, construction sites, and areas prone to environmental exposure. These outlets are built with durable materials to prevent electrical hazards associated with rain, snow, and humidity. B2B buyers should prioritize weather-resistant options to ensure safety and compliance in outdoor installations, despite the higher installation costs associated with these specialized outlets.

Key Industrial Applications of outlet types

| Industry/Sector | Specific Application of outlet types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Use of GFCI outlets in production areas | Enhances worker safety by preventing electrical shocks | Ensure compliance with local safety regulations and standards |

| Healthcare | Installation of tamper-resistant receptacles in clinics | Protects patients, especially children, from electrical hazards | Consider outlet durability and ease of cleaning |

| Hospitality | USB receptacles in hotel rooms | Provides convenience for guests and improves customer satisfaction | Assess compatibility with international plug standards |

| Construction | Weather-resistant outlets on construction sites | Safeguards electrical connections in harsh weather conditions | Evaluate weatherproofing features and reliability |

| Retail | Combination outlets for point-of-sale systems | Allows simultaneous charging of devices, improving efficiency | Focus on high-traffic durability and ease of installation |

How Are GFCI Outlets Applied in Manufacturing Facilities?

In manufacturing settings, GFCI outlets are critical for ensuring worker safety, especially in areas where machinery may be exposed to moisture. These outlets monitor electrical flow and quickly shut off power if a ground fault is detected, significantly reducing the risk of electrical shocks. International B2B buyers in this sector must consider the local electrical codes, ensuring that their outlet choices meet safety standards specific to their region, particularly in countries like the UAE and South Africa, where industrial safety regulations are stringent.

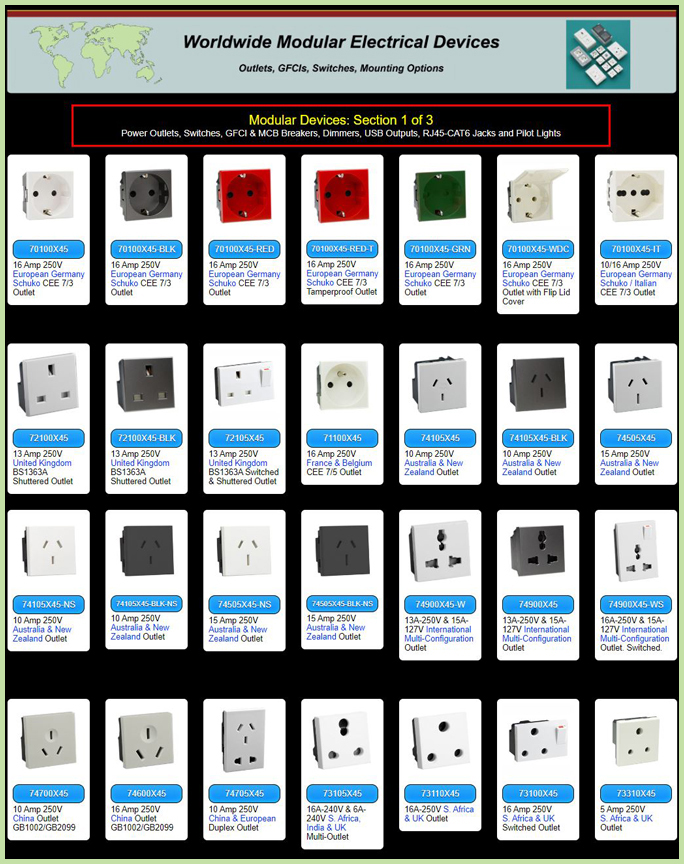

A stock image related to outlet types.

What Role Do Tamper-Resistant Receptacles Play in Healthcare?

Tamper-resistant receptacles are essential in healthcare environments, such as clinics and hospitals, where patient safety is paramount. These outlets feature built-in shutters that prevent accidental insertion of foreign objects, making them ideal for areas frequented by children or vulnerable patients. Buyers in the healthcare sector should prioritize sourcing high-quality tamper-resistant outlets that comply with health regulations and are easy to clean, especially in regions like Europe where hygiene standards are high.

How Do USB Receptacles Enhance Guest Experience in Hospitality?

In the hospitality industry, the integration of USB receptacles in hotel rooms has become a standard expectation. These outlets provide guests with a convenient way to charge multiple devices without the need for additional adapters. For B2B buyers in this sector, it is crucial to ensure that the USB outlets are compatible with various international plug types, catering to a diverse clientele from regions such as South America and the Middle East.

Why Are Weather-Resistant Outlets Important in Construction?

Weather-resistant outlets are vital on construction sites where electrical equipment is often exposed to the elements. These outlets are designed to protect against moisture and debris, ensuring reliable operation in challenging conditions. B2B buyers should focus on sourcing outlets that are certified for outdoor use and can withstand harsh weather, particularly in regions that experience extreme climates, such as parts of Africa and Europe.

How Do Combination Outlets Benefit Retail Environments?

Combination outlets are increasingly utilized in retail environments, particularly at point-of-sale systems, where multiple devices need to be powered simultaneously. By allowing for both standard plugs and USB connections, these outlets enhance operational efficiency and customer experience. Buyers in the retail sector should consider the durability and ease of installation of these outlets, especially in high-traffic areas, to ensure they can withstand regular use while meeting international electrical standards.

3 Common User Pain Points for ‘outlet types’ & Their Solutions

Scenario 1: Insufficient Power Supply for Commercial Equipment

The Problem: Many B2B buyers in sectors like manufacturing and hospitality face the issue of inadequate electrical outlets to support their heavy machinery or multiple devices. This often leads to equipment downtime, as workers scramble to find alternative power sources or use unsafe extension cords that could lead to fire hazards or equipment damage. The frustration of constantly managing power supply limitations can hinder productivity and ultimately affect the bottom line.

The Solution: To mitigate this challenge, B2B buyers should invest in specialized electrical outlets that cater to high-demand equipment. For instance, implementing 20-amp outlets in strategic locations can provide the necessary power for machinery like commercial mixers or industrial equipment. Buyers should conduct a thorough assessment of their power needs and consult with an electrical engineer to specify the appropriate outlet types. Additionally, using combination outlets that incorporate multiple functions can allow for simultaneous connections without overloading circuits. Ensure that all installations adhere to local electrical codes to enhance safety and efficiency.

Scenario 2: Safety Hazards with Outdated Outlet Types

The Problem: In regions with older infrastructure, such as parts of Africa and South America, businesses often rely on outdated two-pronged receptacles that do not provide adequate protection against electrical faults. This can expose employees to electrical shocks and increase the risk of fires. The lack of grounding and safety features in older outlet types presents a significant safety concern for businesses that cannot afford downtime or accidents.

The Solution: Upgrading to modern, safer outlet types is essential for mitigating these risks. B2B buyers should prioritize the installation of Ground Fault Circuit Interrupter (GFCI) and Arc Fault Circuit Interrupter (AFCI) outlets in high-risk areas, such as kitchens and workshops. These outlets not only protect against shocks but also minimize the chances of electrical fires caused by arcing faults. When sourcing these outlets, work with reputable suppliers that understand local regulations and can provide products that meet safety standards. Additionally, regular safety audits of electrical systems can help identify outdated outlets that require replacement, ensuring a safer workplace environment.

Scenario 3: Compatibility Issues with International Equipment

The Problem: As businesses expand internationally, they often encounter compatibility issues with different outlet types and voltage standards. For example, a company in Europe that imports machinery from the Middle East may find that the equipment uses a different plug type or voltage, resulting in costly delays and disruptions to operations. This issue can complicate logistics and increase overall project costs.

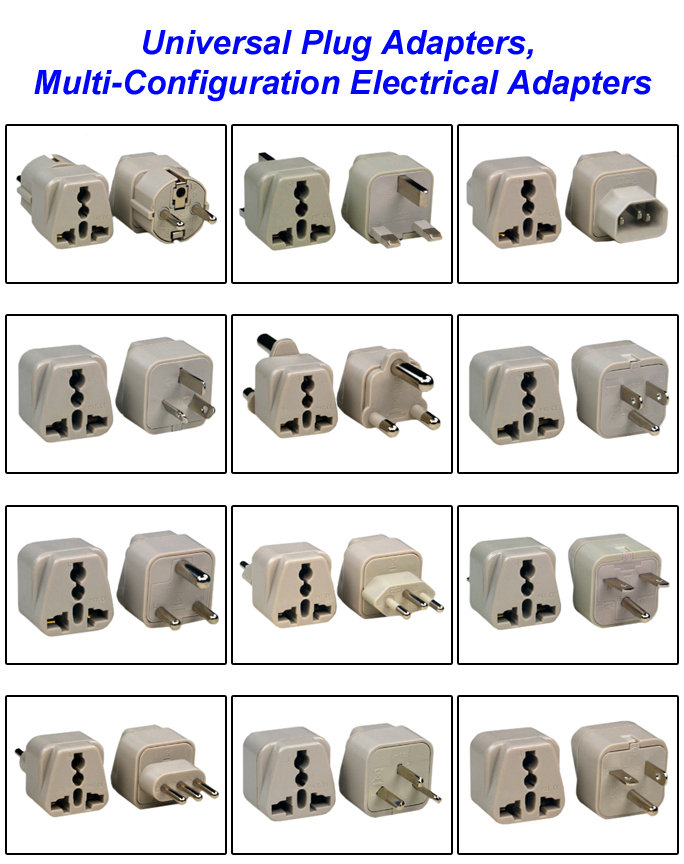

The Solution: To navigate these compatibility challenges, it’s vital for B2B buyers to conduct thorough research on the electrical standards of the countries they are operating in. Utilizing multi-voltage or universal power supplies can significantly ease the transition between different outlet types. Additionally, buyers should consider sourcing equipment that includes adaptable plug types or provide plug adapters as a solution. Engaging with local electrical contractors who understand regional standards can also streamline the process of setting up appropriate outlets and ensuring compliance with local regulations. This proactive approach not only saves time but also fosters smoother international operations, enhancing overall business efficiency.

Strategic Material Selection Guide for outlet types

What Are the Key Materials Used in Electrical Outlet Types?

When selecting materials for electrical outlets, understanding their properties, advantages, and limitations is crucial for ensuring optimal performance and compliance with international standards. Here we analyze four common materials used in outlet types: thermoplastic, thermoset, metal, and rubber.

How Do Thermoplastic Materials Perform in Electrical Outlets?

Key Properties: Thermoplastics, such as polycarbonate and nylon, exhibit excellent electrical insulation properties and can withstand high temperatures, typically rated up to 120°C. They are also resistant to corrosion and moisture, making them suitable for various environments.

Pros & Cons: The durability of thermoplastics is a significant advantage, as they can endure impacts and resist wear over time. However, they may not be as heat resistant as thermoset materials, which could limit their use in high-temperature applications. Additionally, while thermoplastics are generally cost-effective, their manufacturing complexity can vary based on the design requirements.

Impact on Application: Thermoplastic outlets are ideal for residential and commercial applications, particularly in environments where moisture is a concern, such as kitchens and bathrooms.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local electrical safety standards, such as IEC standards, which often specify the use of thermoplastics in residential outlets.

What Are the Advantages of Thermoset Materials in Outlet Manufacturing?

Key Properties: Thermoset materials, such as phenolic resin, are characterized by their high heat resistance, typically rated above 150°C, and excellent mechanical strength. They are less prone to deformation under stress compared to thermoplastics.

Pros & Cons: The primary advantage of thermosets is their ability to withstand high temperatures and resist chemical degradation. However, they are more brittle than thermoplastics, which can lead to cracking under impact. Additionally, thermosets can be more expensive to manufacture due to the curing process required.

Impact on Application: Thermoset outlets are particularly suitable for industrial applications where high heat and chemical exposure are prevalent, such as in manufacturing plants.

Considerations for International Buyers: Buyers in Europe should look for compliance with EN standards, which often recommend thermoset materials for heavy-duty applications due to their superior durability.

How Do Metal Components Enhance Electrical Outlet Performance?

Key Properties: Metal components, typically made from brass or stainless steel, provide excellent conductivity and strength. They are often used in the grounding and contact points of outlets.

Pros & Cons: The conductivity of metal enhances the performance of electrical outlets, ensuring efficient power delivery. However, metal can corrode over time, especially in humid environments, which can lead to electrical failures. Additionally, the cost of metal components is generally higher compared to plastics.

Impact on Application: Metal components are crucial in commercial and industrial settings, where reliability and performance are paramount.

Considerations for International Buyers: Buyers from South America should be aware of local corrosion risks and consider coatings or treatments to enhance metal durability in humid climates.

What Role Does Rubber Play in Electrical Outlet Design?

Key Properties: Rubber materials, especially those that are weather-resistant, offer excellent insulation and flexibility. They can withstand a range of temperatures and provide a degree of moisture resistance.

Pros & Cons: The flexibility and insulation properties of rubber make it an excellent choice for protective covers and seals in electrical outlets. However, rubber can degrade over time when exposed to UV light, which can limit its lifespan in outdoor applications.

Impact on Application: Rubber is particularly beneficial in outdoor electrical outlets, where moisture and environmental exposure are significant concerns.

Considerations for International Buyers: Buyers in regions with extreme weather conditions, such as the UAE, should prioritize rubber materials that are specifically designed for UV resistance and weatherproofing.

Summary Table of Material Selection for Outlet Types

| Material | Typical Use Case for outlet types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic | Residential and commercial outlets | Excellent insulation and moisture resistance | Lower heat resistance than thermosets | Low |

| Thermoset | Industrial applications | High heat resistance and mechanical strength | Brittle and higher manufacturing costs | High |

| Metal | Commercial and industrial outlets | Superior conductivity and strength | Prone to corrosion | Medium |

| Rubber | Outdoor electrical outlets | Flexibility and excellent insulation | Degrades under UV exposure | Medium |

By understanding these materials and their implications, international B2B buyers can make informed decisions that align with their specific application needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for outlet types

What Are the Key Stages in the Manufacturing Process for Electrical Outlets?

The manufacturing process for electrical outlets involves several critical stages, each designed to ensure the final product meets safety and quality standards. Below are the main stages:

-

Material Preparation:

– Selection of Raw Materials: High-quality plastics, metals, and insulating materials are selected based on their electrical properties and durability. Common plastics include polycarbonate and nylon, while copper and brass are often used for contacts.

– Material Testing: Raw materials undergo testing for conductivity, insulation resistance, and fire retardance. This is essential to prevent electrical hazards and ensure long-term performance. -

Forming:

– Injection Molding: The selected plastic materials are heated and injected into molds to create the outlet casing. This process allows for precise shapes and dimensions, crucial for fitting standardized electrical components.

– Metal Stamping: Metal parts, such as terminals and screws, are produced through stamping techniques that ensure accuracy and consistency in size. -

Assembly:

– Component Integration: The molded plastic casings are combined with metal components, including terminals, screws, and safety features like shutters for tamper-resistant outlets.

– Soldering and Fastening: Electrical connections are soldered, and parts are fastened securely to ensure mechanical stability and electrical conductivity. -

Finishing:

– Surface Treatment: The outlets undergo surface treatments to enhance aesthetics and durability, including coating and polishing.

– Labeling and Packaging: Final products are labeled according to international standards and packaged for distribution, ensuring they are protected during transport.

How Is Quality Assurance Implemented in Electrical Outlet Manufacturing?

Quality assurance (QA) is critical in the manufacturing of electrical outlets to ensure compliance with international safety standards and customer expectations. Below are the key elements involved in QA:

-

Adherence to International Standards:

– ISO 9001 Certification: This standard focuses on quality management systems and is essential for manufacturers aiming to produce high-quality electrical outlets. It ensures consistency in production and customer satisfaction.

– CE Marking: For European markets, CE marking indicates compliance with safety and health standards. Manufacturers must ensure their products meet the necessary directives to be marketed in Europe. -

Industry-Specific Standards:

– NEMA Standards: In North America, the National Electrical Manufacturers Association provides guidelines for electrical outlet safety and performance.

– UL Certification: Underwriters Laboratories (UL) certification is often sought by manufacturers to demonstrate that their products meet rigorous safety standards. -

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. Materials must meet specified criteria before they are used in production.

– In-Process Quality Control (IPQC): During manufacturing, processes are monitored to catch any deviations from quality standards early. This can include visual inspections and measurements.

– Final Quality Control (FQC): Before packaging, each outlet undergoes rigorous testing, including electrical performance tests and safety checks, to ensure they meet all specifications.

What Common Testing Methods Are Used in Electrical Outlet Manufacturing?

Manufacturers use various testing methods to ensure the safety and reliability of electrical outlets. Some common tests include:

-

Dielectric Strength Testing: This test checks the insulation strength by applying high voltage to the outlet to ensure it can withstand electrical surges without breaking down.

-

Mechanical Endurance Testing: Outlets are subjected to repeated plugging and unplugging to simulate real-world use. This tests the durability of the mechanical components.

-

Temperature Rise Testing: This assesses the outlet’s ability to dissipate heat during operation. Excessive heat can indicate potential failure, so this test is crucial for safety.

-

Environmental Testing: Outlets are tested for performance in various environmental conditions, including extreme temperatures and humidity, to ensure they perform reliably in different climates.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, ensuring supplier quality is vital. Here are strategies for verifying quality control:

-

Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes, quality control measures, and compliance with international standards. This can be done through on-site visits or third-party inspection services.

-

Request Quality Reports: Ask suppliers for detailed quality assurance reports, including results from IQC, IPQC, and FQC processes. This documentation provides insight into their commitment to quality.

-

Third-Party Certifications: Verify that suppliers hold relevant certifications, such as ISO 9001 or CE marking. This can often be confirmed through the issuing body or their official website.

-

Product Samples: Request samples of the products for independent testing. This allows buyers to assess the quality firsthand before committing to larger orders.

What Quality Control Nuances Should International B2B Buyers Be Aware Of?

International buyers should be mindful of several nuances related to quality control:

-

Regional Regulations: Different regions have varying safety standards and regulations. For example, CE marking is mandatory in Europe, while UL certification is essential in the U.S. Buyers should familiarize themselves with local requirements to avoid compliance issues.

-

Cultural Differences in Quality Expectations: Quality perceptions can vary by region. Buyers should communicate their quality expectations clearly and ensure that suppliers understand these requirements.

-

Shipping and Handling: Ensure that suppliers have robust packaging and handling procedures to prevent damage during transportation. This is especially important for electrical components, which can be sensitive to physical shocks.

-

After-Sales Support: Establish clear agreements regarding after-sales support and warranty terms. This is crucial for addressing any potential issues that may arise post-purchase.

By understanding these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when sourcing electrical outlets, ensuring they select reliable and compliant suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘outlet types’

In the ever-evolving landscape of electrical components, international B2B buyers must navigate a myriad of outlet types to ensure safety, efficiency, and compliance with local regulations. This guide serves as a practical checklist for sourcing the right electrical outlets for your business needs, whether you are operating in Africa, South America, the Middle East, or Europe.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is the foundation of any successful sourcing strategy. Identify the voltage, amperage, and type of appliances you will be using with the outlets. This ensures compatibility and safety.

– Consider local standards: Different regions have distinct electrical standards; for example, European outlets often require different specifications than those in the Middle East.

– Assess your load requirements: Determine whether you need standard 15-amp outlets or higher-capacity 20-amp outlets for heavy-duty equipment.

Step 2: Research Outlet Types and Their Applications

Familiarize yourself with the various outlet types available, such as GFCI, AFCI, and tamper-resistant receptacles. Each type has specific applications and safety features.

– GFCI outlets are essential in wet areas to prevent electrical shocks.

– AFCI outlets help mitigate fire risks from arc faults, especially in residential and commercial settings.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. This includes checking their certifications, product quality, and customer reviews.

– Request documentation: Ask for relevant certifications, such as ISO 9001 or IEC standards, to ensure compliance with international safety regulations.

– Check references: Speak with previous clients in your region or industry to gauge their experience with the supplier.

Step 4: Assess Pricing and Payment Terms

Obtaining competitive pricing is crucial, but it should not compromise quality. Compare prices among multiple suppliers while considering their payment terms.

– Evaluate bulk discounts: Many suppliers offer reduced rates for larger orders, which can significantly impact your procurement budget.

– Consider payment flexibility: Look for suppliers that provide favorable payment terms, such as net 30 or net 60, to manage cash flow effectively.

Step 5: Verify After-Sales Support and Warranty Options

Strong after-sales support can be a game-changer in your sourcing strategy. Inquire about warranty options and customer service availability.

– Understand warranty terms: Ensure that the warranty covers defects and provides adequate time for product replacement if necessary.

– Assess support services: Look for suppliers that offer installation guidance, troubleshooting, and prompt customer support.

Step 6: Plan for Logistics and Delivery

Consider the logistics involved in shipping and delivery. This step is vital for ensuring timely procurement and minimizing downtime.

– Evaluate shipping options: Compare costs and delivery times from different suppliers to find the most efficient route.

– Consider local regulations: Be aware of import duties and taxes that may apply when sourcing from international suppliers.

Step 7: Conduct a Trial Order

Before placing a large order, conduct a trial with a smaller batch to assess quality and supplier reliability.

– Test for compliance: Ensure the trial products meet your initial specifications and safety standards.

– Gather feedback: Use the trial period to collect feedback from your team regarding functionality and ease of use.

By following these steps, B2B buyers can confidently source the right outlet types that meet their operational needs while adhering to safety standards and local regulations.

Comprehensive Cost and Pricing Analysis for outlet types Sourcing

What Are the Key Cost Components in Outlet Types Sourcing?

When sourcing electrical outlets, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality plastics, metals, and components like circuit interrupters (GFCI and AFCI) can increase the price but are essential for safety and compliance with international standards.

-

Labor: Labor costs vary by region. Countries with lower labor costs may offer cheaper outlets, but it’s important to consider the potential trade-offs in quality and compliance with safety standards.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can lower these costs, benefiting buyers looking for competitive pricing.

-

Tooling: Initial tooling costs for custom designs can be significant. For large orders, these costs can be amortized over the volume, lowering the per-unit price.

-

Quality Control (QC): Investing in robust QC processes ensures that products meet safety and performance standards, which can prevent costly recalls or legal issues down the line.

-

Logistics: Transportation costs can fluctuate based on the distance from the supplier to the buyer, shipping method, and current fuel prices. Understanding these variables is essential for accurate budgeting.

-

Margin: Suppliers will add their margin to the cost, which varies based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect Outlet Types Sourcing?

Several factors influence the pricing of electrical outlets, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often result in lower per-unit costs. Negotiating MOQs with suppliers can lead to significant savings.

-

Specifications and Customization: Outlets designed for specific applications (e.g., tamper-resistant, weather-resistant) may carry a premium. Customization requests can also increase costs, so it’s beneficial to align requirements with standard offerings when possible.

-

Materials and Quality Certifications: Outlets that meet international safety standards (such as CE or UL certifications) may be priced higher. Buyers should weigh the long-term benefits of quality against initial costs.

-

Supplier Factors: Reputation, reliability, and service levels of suppliers can influence pricing. Established suppliers may charge more but offer better support and quality assurance.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) affect pricing by determining who bears shipping and insurance costs. Understanding these terms can help buyers minimize unexpected expenses.

What Are Some Negotiation Tips for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront price. This includes potential maintenance costs, energy efficiency, and lifespan of the product, which can impact overall value.

-

Leverage Competitive Quotes: Gather multiple quotes to understand the market landscape. Use this information as leverage in negotiations to secure better pricing or terms.

-

Build Relationships: Developing strong relationships with suppliers can lead to better pricing, priority service, and improved communication, which is vital for international transactions.

-

Consider Local Regulations: Be aware of local regulations that may affect pricing, such as import tariffs or compliance costs. This knowledge can help in negotiations and planning.

-

Be Clear on Payment Terms: Clearly outline payment terms to avoid misunderstandings. Consider using letters of credit for international transactions to protect against risks.

Disclaimer on Indicative Prices

Prices for electrical outlets can vary widely based on the factors discussed above. Buyers should conduct thorough market research and consult with suppliers for current pricing tailored to their specific needs.

Alternatives Analysis: Comparing outlet types With Other Solutions

When considering electrical outlet types, it’s essential to explore alternatives that may provide similar functionalities or meet specific operational needs. With the growing demand for efficient energy solutions, international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should evaluate various options to determine the best fit for their projects. Below is a comparative analysis of outlet types against two viable alternatives: Power Distribution Units (PDUs) and Smart Plugs.

| Comparison Aspect | Outlet Types | Power Distribution Units (PDUs) | Smart Plugs |

|---|---|---|---|

| Performance | Reliable for standard use cases; offers various configurations (GFCI, AFCI, etc.) | High performance with multiple outputs; suitable for data centers and industrial applications | Convenient for remote control and monitoring of devices; limited to lower power devices |

| Cost | Generally low to moderate cost depending on type and installation | Higher initial investment but cost-effective for large installations | Low-cost option, especially for individual units |

| Ease of Implementation | Requires standard electrical installation; may need professional help | Requires professional installation; more complex setup | Very easy to set up; often plug-and-play |

| Maintenance | Low maintenance; occasional checks needed for safety | Moderate maintenance; needs regular monitoring for load management | Minimal maintenance; software updates may be required |

| Best Use Case | Ideal for residential and commercial environments needing reliable power | Best for data centers, server rooms, or large-scale electrical setups | Excellent for home automation or small business applications needing device control |

What are Power Distribution Units (PDUs) and Their Advantages?

Power Distribution Units (PDUs) are designed to distribute power to multiple devices in a single location, particularly in data centers and industrial settings. They offer various configurations, including surge protection and monitoring capabilities.

Pros:

– High-capacity power management.

– Multiple outlets for diverse devices.

– Monitoring features for real-time load management.

Cons:

– Higher initial costs and complexity in installation.

– Overkill for simple residential setups.

How Do Smart Plugs Enhance Electrical Efficiency?

Smart plugs provide a modern approach to controlling electrical devices remotely via smartphone applications or voice-activated systems. They are particularly useful for automating energy usage in homes and small businesses.

Pros:

– Cost-effective and easy to implement.

– Allows for remote control and scheduling of devices.

– Energy monitoring features help optimize consumption.

Cons:

– Limited to lower power devices; not suitable for heavy machinery.

– Reliance on Wi-Fi or network connectivity can lead to vulnerabilities.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When evaluating outlet types against alternatives, B2B buyers should consider their specific operational requirements, such as the scale of the installation, the types of devices being used, and budget constraints. For projects requiring reliable, safe power for heavy-duty equipment, traditional outlet types or PDUs may be more appropriate. Conversely, for businesses focused on energy efficiency and automation, integrating smart plugs could provide a versatile and cost-effective solution.

Ultimately, understanding the unique needs of your operations and aligning them with the right electrical solution is crucial for enhancing productivity and ensuring safety. Prioritize options that not only meet current requirements but also allow for scalability and future innovations.

Essential Technical Properties and Trade Terminology for outlet types

What Are the Key Technical Properties of Electrical Outlets?

Understanding the technical properties of electrical outlets is crucial for B2B buyers, especially when ensuring compatibility with various appliances and compliance with local regulations. Here are some critical specifications to consider:

-

Amperage Rating

The amperage rating (measured in amps) indicates the maximum current the outlet can handle. Common ratings include 15-amp and 20-amp outlets. For B2B buyers, selecting the right amperage is essential to prevent overloads and ensure the safe operation of equipment. Incorrect amperage can lead to equipment damage or fire hazards. -

Voltage Rating

Voltage rating (measured in volts) specifies the electrical potential difference the outlet can accommodate. In regions like Europe, outlets typically operate at 230 volts, while in North America, the standard is 120 volts. Understanding voltage ratings helps buyers choose outlets that match their equipment specifications, reducing the risk of electrical failures. -

Material Composition

The materials used in electrical outlets, such as thermoplastic or metal, can impact durability and safety. High-quality materials resist wear and environmental factors, making them essential for long-term use in industrial applications. Buyers should prioritize outlets made from materials that meet local safety standards to ensure reliability. -

Grounding Mechanism

Outlets can either be grounded or ungrounded. Grounding mechanisms reduce the risk of electric shock by providing a safe path for excess current. For businesses, selecting grounded outlets is crucial in environments where safety is paramount, such as in laboratories or industrial settings. -

Tamper-Resistance

Tamper-resistant outlets feature built-in shutters that prevent foreign objects from being inserted. This is particularly important in settings with children or high foot traffic. Choosing tamper-resistant options can enhance safety and compliance with local regulations.

What Trade Terminology Should B2B Buyers Know About Electrical Outlets?

Familiarity with industry jargon can streamline the purchasing process and enhance communication with suppliers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for buyers looking for specific outlet types that are compatible with their existing equipment. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of an item that a supplier is willing to sell. For B2B buyers, being aware of MOQs helps in budgeting and inventory management, ensuring that purchasing decisions align with operational needs. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and availability for specific products. Utilizing RFQs can help B2B buyers obtain competitive pricing for electrical outlets, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms is essential for B2B transactions, particularly for international buyers, to clarify cost, risk, and delivery obligations. -

UL Listed

“UL Listed” signifies that a product has been tested and meets specific safety standards set by Underwriters Laboratories. For B2B buyers, ensuring that electrical outlets are UL Listed is crucial for compliance with safety regulations and for safeguarding against liability issues.

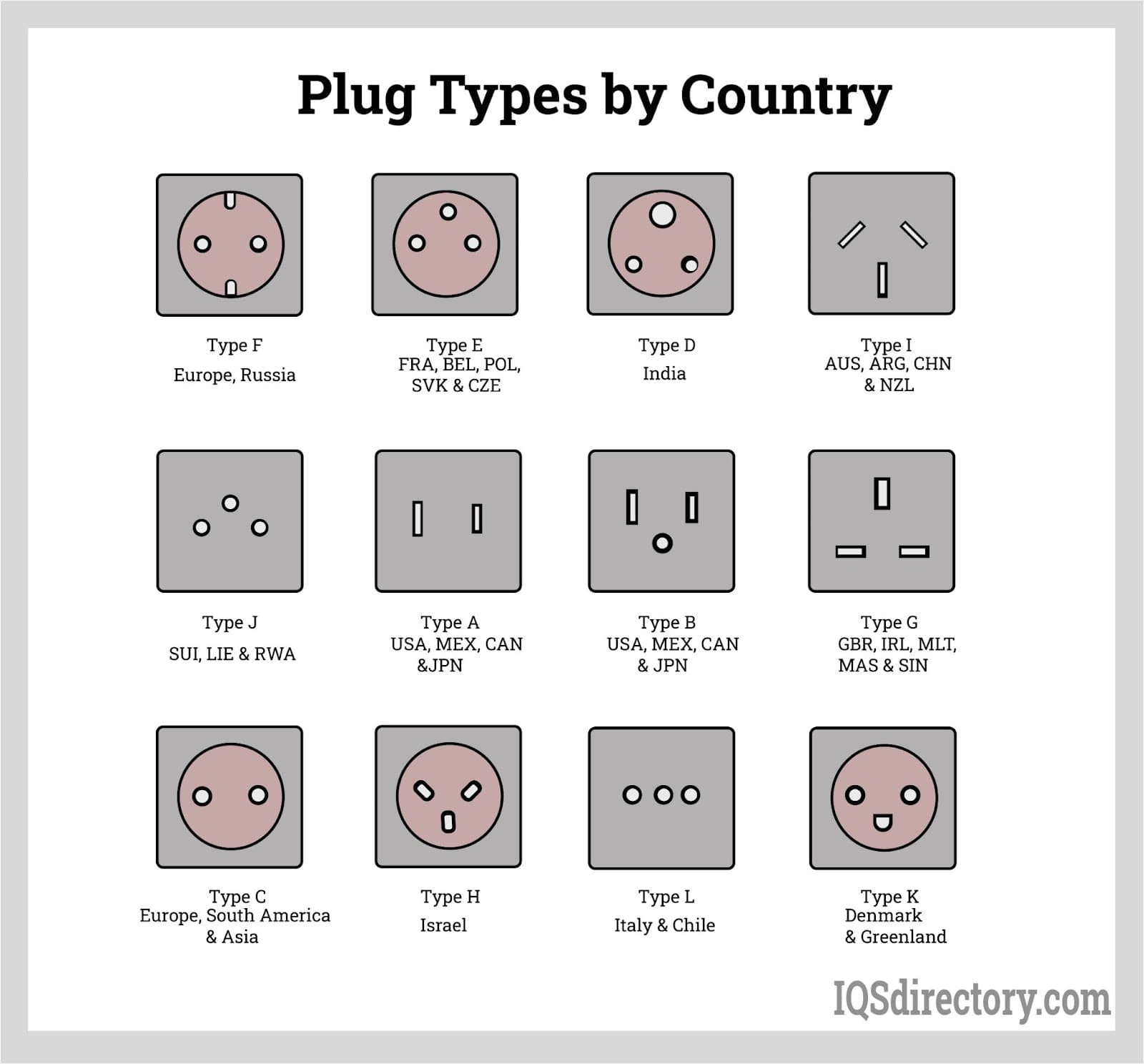

A stock image related to outlet types.

- Surge Protection

This term refers to the ability of an outlet to protect connected devices from voltage spikes. Outlets with built-in surge protection are essential for businesses that rely on sensitive electronic equipment, helping to prevent costly damage and downtime.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions when selecting electrical outlets that meet their specific operational and safety requirements.

Navigating Market Dynamics and Sourcing Trends in the outlet types Sector

What Are the Current Market Dynamics and Sourcing Trends in the Outlet Types Sector?

The outlet types sector is experiencing significant growth driven by technological advancements and changing consumer needs. Globally, the demand for smart home solutions is reshaping the market, with international buyers increasingly seeking outlets that integrate technology such as USB ports and smart features. In regions like Africa and South America, the expansion of urbanization and the increasing penetration of electrical devices are propelling the demand for diverse outlet types. In the Middle East and Europe, regulatory standards are becoming stricter, especially concerning safety features like GFCI and AFCI outlets, prompting buyers to prioritize compliance when sourcing products.

Emerging trends include the adoption of smart outlets that allow for remote control and energy monitoring, appealing to both environmentally conscious consumers and businesses looking to optimize energy usage. Additionally, the rise of e-commerce platforms is transforming the sourcing landscape, enabling international buyers to access a wider range of products and suppliers. For instance, B2B buyers can now easily compare prices, features, and certifications from various vendors online, streamlining the procurement process.

Furthermore, the shift towards sustainability is influencing purchasing decisions. Buyers are increasingly inclined to source products that demonstrate eco-friendly practices, such as energy-efficient designs and materials sourced from sustainable suppliers. This trend is particularly pronounced in Europe and the Middle East, where consumers are more attuned to environmental impacts and corporate social responsibility.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in the Outlet Types Sector?

Sustainability is becoming a crucial factor in the sourcing of outlet types. B2B buyers are more aware of the environmental impacts associated with electrical products, including energy consumption and waste management. Companies are now prioritizing suppliers who offer eco-friendly products, such as outlets made from recycled materials or those designed to minimize energy usage.

Ethical sourcing is also gaining traction, as businesses recognize the importance of transparent supply chains. Buyers should seek suppliers with certifications that indicate responsible manufacturing practices, such as ISO 14001 for environmental management or certifications for fair labor practices. These certifications not only enhance brand reputation but also align with the values of increasingly conscious consumers.

Moreover, the demand for “green” products is influencing market dynamics. Outlets that feature energy-efficient technologies, such as automatic shut-off systems and smart energy management capabilities, are gaining popularity. By sourcing these innovative products, businesses can reduce their carbon footprint and appeal to a broader customer base that values sustainability.

How Has the Outlet Types Sector Evolved Over Time?

The evolution of outlet types has been marked by significant technological advancements and safety improvements. Initially, electrical outlets were simple two-pronged designs that lacked grounding, posing potential risks of electric shock. As safety standards were introduced, grounded receptacles became mandatory in many regions, reducing the risk of electrical hazards.

In recent decades, the advent of smart technology has transformed the landscape further. Outlets are now equipped with features such as USB ports and surge protection, catering to the growing number of electronic devices in homes and businesses. This evolution reflects not only advancements in technology but also a heightened awareness of safety and energy efficiency among consumers.

Today, as the outlet types sector continues to innovate, B2B buyers must stay informed about the latest trends and technologies to make well-informed sourcing decisions. By understanding market dynamics and embracing sustainability, businesses can position themselves competitively in an ever-evolving landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of outlet types

-

How do I solve compatibility issues with different outlet types for my imported appliances?

To solve compatibility issues with different outlet types, first identify the electrical standards in your target market. Most countries have unique plug and socket configurations, voltage, and frequency specifications. Invest in universal adapters or ensure that your appliances are compatible with local standards by sourcing from suppliers who offer products that meet international certifications. Collaborating with manufacturers who can customize outlet types to match your requirements can also mitigate compatibility challenges. -

What is the best outlet type for industrial applications?

For industrial applications, the best outlet types are typically heavy-duty receptacles, such as 20-amp or 30-amp outlets, designed for high-power machines. Look for outlets that feature weather-resistant and tamper-proof properties, especially if used in outdoor or high-traffic environments. Additionally, GFCI and AFCI outlets are recommended to enhance safety by preventing electrical shocks and fires. Always consult local electrical codes to ensure compliance and safety. -

How can I verify the quality of electrical outlets before purchasing?

Verifying the quality of electrical outlets involves checking for certifications such as CE, UL, or IEC compliance, which indicate adherence to safety and performance standards. Request samples from potential suppliers to test for durability and functionality. Additionally, consider supplier reputation; seek reviews or testimonials from previous buyers. Conducting factory visits or third-party inspections can also provide assurance regarding product quality. -

What customization options are available for electrical outlets?

Many manufacturers offer customization options for electrical outlets, including specific voltage ratings, colors, and designs tailored to your branding. You can also request features such as integrated USB ports or additional safety mechanisms like tamper-resistant designs. When approaching suppliers, communicate your specific needs and inquire about their ability to accommodate these custom requests, including any associated costs or minimum order quantities. -

What are the minimum order quantities (MOQs) for bulk outlet purchases?

Minimum order quantities (MOQs) for bulk outlet purchases vary by supplier and product type. Generally, MOQs can range from 100 to several thousand units depending on the manufacturer’s production capabilities and the complexity of the product. Always clarify MOQs upfront when engaging with suppliers to ensure that your purchasing needs align with their production policies. Negotiation may be possible for larger or ongoing orders. -

What payment terms should I expect when sourcing electrical outlets internationally?

Payment terms for international sourcing can vary significantly. Common terms include advance payment, letter of credit, or payment upon delivery. Many suppliers require a deposit (usually 30-50%) to start production, with the balance due before shipping. Ensure that payment terms are clearly defined in your contract to avoid misunderstandings. Using secure payment methods that offer buyer protection can also safeguard your investment.

A stock image related to outlet types.

-

How can I ensure timely delivery of electrical outlets from international suppliers?

To ensure timely delivery from international suppliers, establish clear communication regarding shipping timelines and logistics. Utilize freight forwarders who are experienced in handling electrical components to navigate customs and ensure compliance with local regulations. Additionally, consider suppliers with a proven track record of reliable shipping and those who offer real-time tracking systems. Building a good relationship with your suppliers can also facilitate smoother logistics. -

What should I know about warranty and return policies for electrical outlets?

Understanding warranty and return policies is crucial when sourcing electrical outlets. Check if the supplier offers a warranty covering manufacturing defects and for how long it lasts. Familiarize yourself with the return process, including any restocking fees or conditions for returns. It’s advisable to include warranty terms in your contract to protect against defective products. Always clarify these policies before finalizing your purchase to avoid complications later on.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for outlet types

What Are the Key Takeaways for International B2B Buyers Regarding Outlet Types?

As international B2B buyers navigate the diverse landscape of electrical outlets, understanding the specific needs and regulatory requirements of their target markets is crucial. Each outlet type—whether it be GFCI, AFCI, or USB receptacles—serves distinct functions that cater to safety, efficiency, and technological advancements. Buyers should prioritize sourcing outlets that align with local electrical codes and standards, particularly when operating in regions like Africa, South America, the Middle East, and Europe.

How Does Strategic Sourcing Enhance Supply Chain Efficiency?

Strategic sourcing is vital for optimizing supply chains and ensuring that businesses obtain the most suitable electrical outlets at competitive prices. By building strong relationships with reputable suppliers and manufacturers, companies can enhance their procurement processes, reduce costs, and improve the quality of their electrical installations. Furthermore, this proactive approach allows businesses to anticipate market trends and adapt to evolving customer demands.

What Should B2B Buyers Focus on Moving Forward?

Looking ahead, international buyers must stay informed about technological innovations and emerging trends in outlet types. As the demand for smart home solutions and energy-efficient products continues to rise, aligning sourcing strategies with these trends will be essential. Engage with trusted suppliers, participate in industry forums, and invest in training to ensure your business remains competitive in an ever-evolving marketplace. The future of electrical outlets is promising, and with the right sourcing strategies, your business can lead the charge.