Discover 5 Types of Electrical Outlets for Global Sourcing (2025)

Introduction: Navigating the Global Market for type of electrical outlets

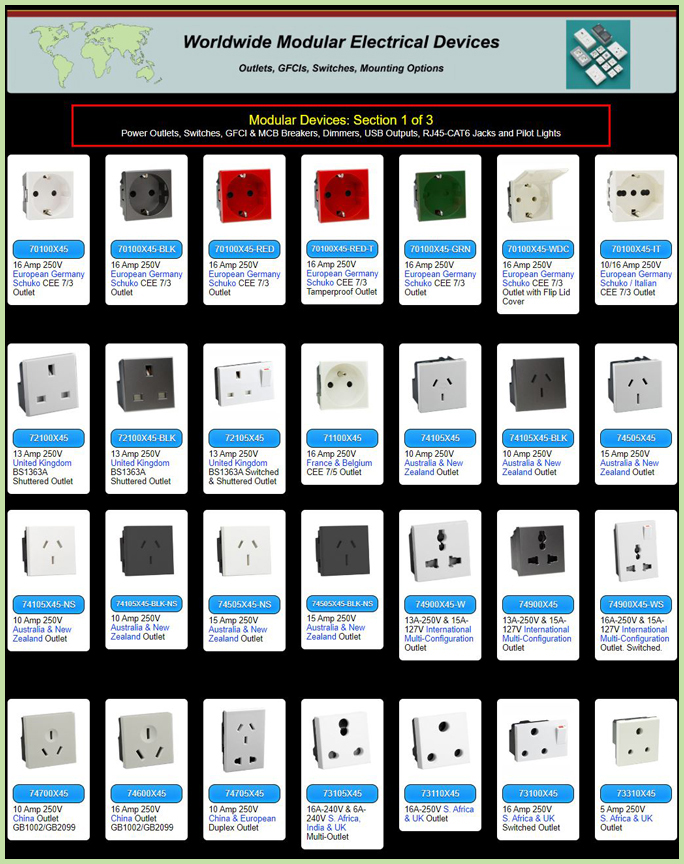

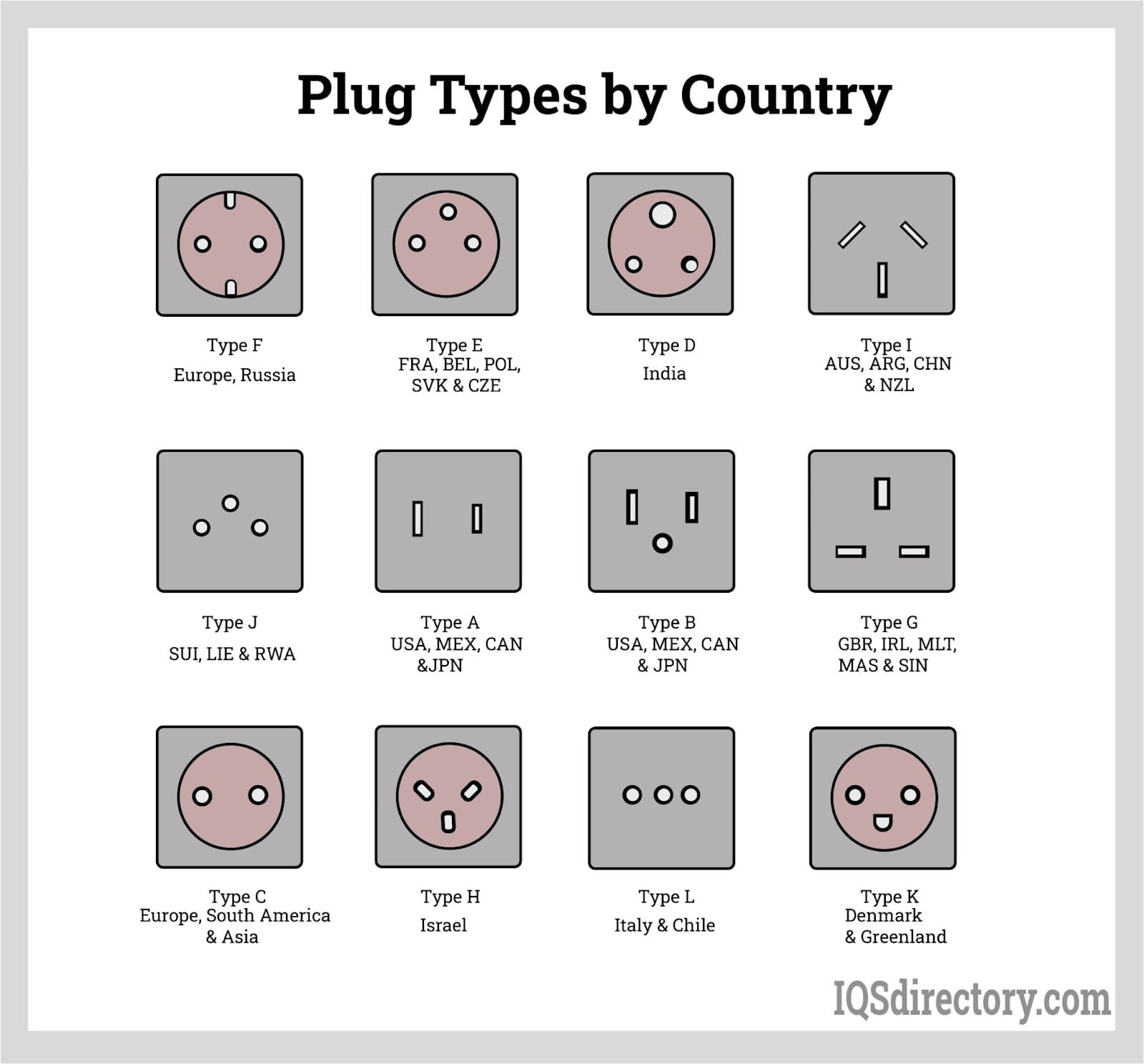

Navigating the complex landscape of electrical outlets is a significant challenge for international B2B buyers, especially those sourcing equipment and appliances across diverse markets in Africa, South America, the Middle East, and Europe. With over 15 different types of electrical sockets globally, understanding the specifications, compatibility, and applications of these outlets is essential for ensuring seamless operations and reducing the risk of equipment malfunction. This comprehensive guide delves into the various types of electrical outlets, including their unique features and intended uses, while providing insights on supplier vetting, cost considerations, and compliance with local regulations.

By equipping B2B buyers with the knowledge to identify and select the appropriate electrical outlets for their specific needs, this guide empowers informed purchasing decisions. It addresses common pain points, such as the potential for electrical hazards, compatibility issues, and the challenges of sourcing reliable suppliers in different regions. Whether you’re based in Spain looking for Type F sockets, or in the UAE needing Type G outlets, this guide will serve as a valuable resource for navigating the global market for electrical outlets. By understanding the intricacies of electrical socket types, buyers can optimize their procurement strategies, ensuring that their investments are safe, efficient, and compliant with international standards.

Understanding type of electrical outlets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type C | Two round pins, ungrounded, compatible with multiple types | General appliances in Europe, Africa, South America | Pros: Widely used, versatile. Cons: Not grounded, lower safety. |

| Type G | Three rectangular pins, grounded, higher voltage capacity | UK, UAE, and other countries requiring high power | Pros: Grounded for safety, robust. Cons: Limited compatibility with other types. |

| Type E | Two round pins with a female grounding pin | France, Belgium, and other European nations | Pros: Grounded, compatible with Type C. Cons: May require adapters in non-compatible regions. |

| Type M | Three large round pins, grounded, high amperage | South Africa, industrial applications | Pros: High power capacity, durable. Cons: Bulky, limited global use. |

| GFCI Outlets | Ground Fault Circuit Interrupter for shock protection | Bathrooms, kitchens, and outdoor areas | Pros: Enhances safety in wet areas. Cons: May be more expensive than standard outlets. |

What Are the Characteristics of Type C Electrical Outlets?

Type C outlets are characterized by their two round pins and lack of grounding, making them common in many regions, especially in Europe, Africa, and South America. These outlets are suitable for a wide range of general appliances, such as lamps and small electronics. B2B buyers should consider that while Type C outlets are versatile, their lack of grounding may present safety risks for high-powered devices. Additionally, compatibility with multiple plug types can reduce the need for multiple outlet types in a facility.

How Does Type G Electrical Outlet Differ from Others?

Type G outlets feature three rectangular pins and are primarily used in the UK, UAE, and several other countries. They are grounded, providing enhanced safety for high-voltage applications. B2B buyers should prioritize Type G outlets for environments requiring reliable power for heavy machinery or sensitive equipment. While they offer robust safety features, buyers must be aware of their limited compatibility with other outlet types, which may necessitate additional adapters or specialized plugs.

Why Choose Type E Electrical Outlets for Your Business?

Type E outlets are equipped with two round pins and a female grounding pin, primarily found in France and several neighboring countries. These outlets are grounded, ensuring a safer connection for electrical devices. For B2B buyers, Type E outlets are suitable for various commercial applications, including offices and retail spaces. However, compatibility with Type C plugs can be an advantage, though buyers should consider the need for adapters when operating in regions with differing outlet types.

What Makes Type M Electrical Outlets Ideal for Industrial Use?

Type M outlets are distinguished by their three large round pins and are predominantly used in South Africa, especially in industrial settings. These outlets support higher amperage, making them suitable for heavy-duty machinery and tools. B2B buyers should evaluate Type M outlets for their durability and power capacity, but also note their bulkiness and limited global application. Ensuring that your equipment is compatible with Type M outlets is crucial for smooth operations.

How Do GFCI Outlets Enhance Safety in Electrical Installations?

GFCI (Ground Fault Circuit Interrupter) outlets are specialized safety devices designed to prevent electrical shocks, particularly in wet areas like bathrooms and kitchens. They continuously monitor the flow of electricity and automatically shut off power when a fault is detected. For B2B buyers, incorporating GFCI outlets into commercial facilities can significantly enhance safety standards. While they may be more expensive than standard outlets, the investment is justified by the added protection they provide against electrical hazards.

Key Industrial Applications of type of electrical outlets

| Industry/Sector | Specific Application of type of electrical outlets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Heavy machinery and equipment power supply | Ensures reliable operation of machinery, reducing downtime | Compatibility with voltage and amperage requirements |

| Hospitality | Guest room electrical systems | Enhances guest experience with versatile charging options | Compliance with local electrical standards and safety regulations |

| Healthcare | Medical equipment connectivity | Critical for patient safety and operational efficiency | Need for GFCI and AFCI outlets in wet or sensitive areas |

| Construction | Temporary power solutions at job sites | Increases productivity by providing power for tools and lighting | Durability and weather resistance for outdoor usage |

| Retail | Point of Sale (POS) systems | Streamlines transactions and improves customer service | Accessibility and ease of installation for rapid deployment |

How Are Different Types of Electrical Outlets Used in Manufacturing?

In the manufacturing sector, heavy machinery and equipment often require specific types of electrical outlets to ensure proper power supply. For instance, 20-amp outlets are necessary for high-demand machines, while standard 15-amp outlets suffice for smaller tools. By sourcing the correct type of outlet, manufacturers can minimize downtime due to electrical failures, thus enhancing productivity. International buyers must consider local voltage standards and compatibility with existing electrical infrastructure when sourcing these outlets.

What Role Do Electrical Outlets Play in the Hospitality Industry?

In the hospitality industry, the versatility of electrical outlets significantly contributes to guest satisfaction. Hotels typically install a mix of standard and USB charging outlets in guest rooms to accommodate various devices. This not only enhances the guest experience but also reduces the need for additional charging equipment. For B2B buyers in this sector, compliance with local electrical standards and safety regulations is crucial to prevent liability issues and ensure guest safety.

Why Are Specialized Outlets Essential in Healthcare Settings?

Healthcare facilities require specialized electrical outlets to ensure the safe operation of medical equipment. GFCI (Ground Fault Circuit Interrupter) and AFCI (Arc Fault Circuit Interrupter) outlets are particularly important in areas such as operating rooms and patient care areas, where electrical safety is paramount. These outlets prevent electrical shocks and reduce fire risks, making them essential for patient safety. B2B buyers must focus on sourcing outlets that meet stringent healthcare regulations and standards.

How Do Electrical Outlets Support Construction Projects?

In the construction industry, temporary power solutions are vital for site operations. Construction sites often use heavy-duty outlets that can withstand harsh conditions and provide reliable power for tools and lighting. Weather-resistant outlets are particularly important for outdoor applications to prevent electrical hazards. Buyers in this sector should prioritize sourcing durable, weather-resistant outlets that comply with local electrical codes to ensure safety and efficiency on job sites.

A stock image related to type of electrical outlets.

What Benefits Do Retail Electrical Outlets Offer for Business Operations?

In retail environments, the type of electrical outlets used can impact the efficiency of Point of Sale (POS) systems. Retailers benefit from outlets that provide easy access to power for multiple devices, including registers, scanners, and charging stations. This streamlining of operations enhances customer service and transaction speed. For international B2B buyers, considerations should include the installation ease and accessibility of these outlets to facilitate rapid deployment in retail spaces.

3 Common User Pain Points for ‘type of electrical outlets’ & Their Solutions

Scenario 1: Compatibility Confusion with International Electrical Outlets

The Problem:

International B2B buyers often face significant challenges when sourcing electrical outlets due to the lack of standardization across countries. For example, a buyer in South Africa may import machinery designed for European markets, only to discover that the plugs do not fit into local sockets. This not only leads to delays in operations but also increases costs as they scramble to find compatible adapters or to rewire equipment. The frustration grows when they realize that different regions use various types of outlets—Type C in Europe versus Type M in South Africa—making it difficult to streamline procurement processes.

The Solution:

To mitigate compatibility issues, B2B buyers should conduct thorough research on the specific types of electrical outlets used in their target markets before making purchases. This involves creating a comprehensive checklist that includes outlet types, voltage requirements, and amperage specifications for each country of interest. Additionally, sourcing suppliers who can provide equipment with interchangeable plugs or offering adapters as part of the purchase can save time and costs. By collaborating with local electrical experts or consultants, buyers can also ensure that their installations comply with local safety regulations, thereby preventing future operational disruptions.

Scenario 2: Safety Concerns with Electrical Outlets in Commercial Spaces

The Problem:

When outfitting commercial spaces, B2B buyers must address safety concerns related to electrical outlets, particularly in environments where water exposure is a risk, such as kitchens or outdoor areas. For instance, a buyer in the UAE looking to equip a restaurant may find that standard outlets are insufficient for preventing electrical shocks or fires. The lack of Ground Fault Circuit Interrupter (GFCI) outlets can lead to hazardous situations, risking both employee safety and compliance with local electrical codes.

The Solution:

Buyers should prioritize the installation of GFCI outlets in any areas prone to moisture. This entails sourcing GFCI-compliant electrical outlets from reputable suppliers who specialize in commercial-grade electrical components. Additionally, conducting regular safety audits and inspections can help identify potential risks before they lead to accidents. Implementing a training program for staff on the importance of using these safety features, including how to reset GFCI outlets, will enhance workplace safety. Such proactive measures not only protect employees but also safeguard the business against costly liabilities.

Scenario 3: Difficulty in Sourcing Specialty Electrical Outlets for Specific Equipment

The Problem:

B2B buyers often encounter challenges when sourcing specialty electrical outlets that meet the unique requirements of specific equipment. For example, a manufacturing company in Brazil may need to install outlets for heavy machinery that requires high amperage (Type N outlets) but struggles to find suppliers who can provide these specialized components in a timely manner. The result can be extended downtime and lost productivity, impacting overall business operations.

The Solution:

To effectively source specialty electrical outlets, buyers should establish relationships with multiple suppliers who specialize in industrial electrical components. Creating a detailed inventory of the machinery and their specific electrical requirements can streamline the procurement process. Furthermore, buyers should consider investing in modular electrical outlet systems that can adapt to various machinery needs, providing flexibility for future upgrades. Engaging with local electrical engineers to ensure proper installation and compliance with local regulations can also enhance operational efficiency, reducing downtime and ensuring that all equipment runs smoothly.

Strategic Material Selection Guide for type of electrical outlets

What Are the Key Materials Used in Electrical Outlets?

When selecting electrical outlets for international markets, understanding the materials used in their construction is crucial. Different materials offer varied properties that can significantly impact performance, durability, and compliance with local regulations. Here, we analyze four common materials used in electrical outlets: thermoplastics, thermosetting plastics, metal, and rubber.

How Do Thermoplastics Perform in Electrical Outlet Applications?

Thermoplastics, such as polyvinyl chloride (PVC) and acrylonitrile butadiene styrene (ABS), are widely used for electrical outlets due to their excellent electrical insulation properties and moldability. These materials can withstand temperatures up to 85°C and are resistant to moisture and chemicals, making them suitable for various environments.

Pros:

– Cost-effective and lightweight, reducing shipping expenses.

– High durability and resistance to impact, which is beneficial in high-traffic areas.

Cons:

– Limited temperature resistance compared to thermosetting plastics.

– May not be suitable for heavy-duty applications where higher heat resistance is required.

For international buyers, thermoplastics comply with various standards such as IEC 60947 and ASTM D256, making them a reliable choice for general applications in Africa, South America, and Europe.

What Advantages Do Thermosetting Plastics Offer?

Thermosetting plastics, like phenolic resins, are known for their superior heat resistance and mechanical strength. They can withstand temperatures exceeding 150°C, making them ideal for high-load applications such as industrial settings.

Pros:

– Exceptional durability and resistance to deformation under heat.

– Excellent electrical insulation properties, enhancing safety.

Cons:

– More expensive than thermoplastics, impacting overall project budgets.

– Manufacturing complexity can lead to longer lead times.

For B2B buyers, especially in the Middle East where high temperatures are common, thermosetting plastics meet stringent compliance requirements, such as UL 94 for flammability.

Why Are Metals Used in Electrical Outlet Construction?

Metal components, primarily copper and aluminum, are often used for the conductive parts of electrical outlets. Copper is particularly favored for its excellent conductivity and corrosion resistance.

Pros:

– High conductivity ensures efficient power transmission.

– Corrosion-resistant metals enhance longevity in humid or corrosive environments.

Cons:

– Higher cost compared to plastic materials.

– Susceptible to oxidation if not properly treated.

International buyers should consider the compatibility of metal components with local electrical standards, such as the European Union’s CE marking, to ensure compliance and safety.

What Role Does Rubber Play in Electrical Outlet Design?

Rubber, particularly silicone rubber, is frequently used in weather-resistant electrical outlets. Its flexibility and resistance to extreme temperatures make it an ideal choice for outdoor applications.

Pros:

– Excellent weather resistance and flexibility, suitable for outdoor installations.

– Good electrical insulation properties, enhancing safety.

Cons:

– More expensive than conventional plastics.

– Limited mechanical strength compared to thermoplastics and metals.

For buyers in regions with extreme weather conditions, such as the UAE, rubber-based outlets can meet specific local standards, ensuring safety and reliability.

Summary Table of Material Selection for Electrical Outlets

| Material | Typical Use Case for type of electrical outlets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastics | Residential and light commercial applications | Cost-effective, lightweight | Limited temperature resistance | Low |

| Thermosetting Plastics | Industrial and high-load applications | Superior heat resistance and durability | Higher cost and manufacturing complexity | High |

| Metals | Conductive components in outlets | High conductivity and corrosion resistance | Higher cost and oxidation susceptibility | Medium |

| Rubber | Weather-resistant outdoor outlets | Excellent weather resistance and flexibility | More expensive and limited mechanical strength | Medium |

This guide provides actionable insights for B2B buyers looking to make informed decisions regarding the selection of materials for electrical outlets, ensuring compliance with local standards while optimizing performance and cost.

In-depth Look: Manufacturing Processes and Quality Assurance for type of electrical outlets

What Are the Key Stages in the Manufacturing Process of Electrical Outlets?

The manufacturing of electrical outlets involves several critical stages, each designed to ensure the final product meets safety and performance standards. Understanding these stages can help international B2B buyers make informed decisions when sourcing electrical outlets.

Material Preparation: What Materials Are Used for Electrical Outlets?

The first step in the manufacturing process is material preparation. Electrical outlets are primarily made from high-quality plastic and metals. The plastic components often include thermoplastics, which are resistant to heat and electrical conductivity. Metals used, such as copper and aluminum, are typically applied in the contacts and wiring for optimal conductivity. Suppliers need to ensure that the materials meet international safety standards and are sourced from reputable suppliers to avoid issues with quality.

Forming: How Are Electrical Outlets Shaped and Molded?

The forming stage involves molding the plastic components and shaping the metal parts. Injection molding is a common technique used for the plastic housing, where melted plastic is injected into molds to create the desired shapes. For metal components, processes such as stamping and die-casting are employed to ensure precise dimensions and high durability. This stage must be monitored closely to prevent defects that could compromise safety or functionality.

Assembly: What Are the Assembly Techniques for Electrical Outlets?

During the assembly phase, the molded plastic and metal parts are combined. Automated assembly lines are often utilized to enhance efficiency, with robots performing tasks such as inserting metal contacts into plastic housings. Manual assembly may also be employed for more complex outlets that require careful handling. Quality control during this stage is crucial, as improper assembly can lead to performance issues or safety hazards.

Finishing: What Finishing Touches Are Applied to Electrical Outlets?

The finishing stage includes various processes such as surface treatment, painting, and labeling. These processes not only enhance the aesthetic appeal of the outlets but also provide additional protection against environmental factors. For instance, weather-resistant outlets may undergo treatments to ensure they can withstand moisture and UV exposure. This stage is critical for ensuring that the final product meets both functional and regulatory requirements.

How Is Quality Assurance Implemented in Electrical Outlet Manufacturing?

Quality assurance is essential in the manufacturing of electrical outlets to ensure they comply with international standards and customer expectations. Key quality assurance practices include adherence to international standards like ISO 9001, which outlines criteria for a quality management system.

What International Standards Should B2B Buyers Be Aware Of?

International standards, such as CE marking in Europe and UL certification in the United States, play a significant role in ensuring the safety and reliability of electrical outlets. These certifications indicate that the products have been tested for safety and performance according to established guidelines. For B2B buyers in Africa, South America, the Middle East, and Europe, understanding these standards is crucial for compliance and market entry.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint ensures that all materials received from suppliers meet quality specifications before they are used in production.

-

In-Process Quality Control (IPQC): During assembly, IPQC checks are performed to monitor the production process. This helps in identifying any deviations from the standards in real time.

-

Final Quality Control (FQC): After assembly, the finished products undergo rigorous testing to ensure they meet the required safety and performance standards before packaging.

What Common Testing Methods Are Used for Electrical Outlets?

Testing methods are critical in verifying the safety and reliability of electrical outlets. Common tests include:

-

Dielectric Strength Testing: This test measures the outlet’s ability to withstand electrical stress without breaking down.

-

Temperature Rise Testing: This checks how much the outlet heats up under load, ensuring it does not exceed safe operating temperatures.

-

Mechanical Strength Testing: This assesses the durability of the outlet’s physical components against impacts or stress.

-

Electrical Continuity Testing: This ensures that the electrical pathways within the outlet are complete and functioning properly.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control processes is vital to ensure they are sourcing reliable products. Here are actionable steps to assess supplier QC:

-

Conduct Audits: Regular audits of manufacturing facilities can help buyers understand the QC practices in place. This includes checking for compliance with international standards.

-

Request Quality Reports: Buyers should request documentation that outlines the QC processes, including test results and certifications. This transparency can help build trust in the supplier’s capabilities.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an objective evaluation of the supplier’s quality control measures and product reliability.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various certification requirements depending on their target markets. For instance, products sold in the European Union may need CE marking, while those in the United States require UL certification. Buyers from Africa and South America should also be aware of regional standards that may differ from international ones. Understanding these nuances is crucial for ensuring compliance and avoiding costly regulatory issues.

Conclusion: Ensuring Quality in Electrical Outlet Sourcing

In summary, the manufacturing processes and quality assurance practices for electrical outlets are intricate and multifaceted. For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, understanding these processes can significantly influence sourcing decisions. By focusing on quality assurance, adhering to international standards, and verifying supplier practices, buyers can ensure they procure reliable and safe electrical outlets that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘type of electrical outlets’

In the global marketplace, selecting the right type of electrical outlets is critical for ensuring compatibility, safety, and efficiency. This step-by-step guide is designed to help B2B buyers from Africa, South America, the Middle East, and Europe effectively source electrical outlets that meet their specific needs.

Step 1: Identify Your Regional Standards

Understanding the local electrical standards is the first step in sourcing outlets. Different regions utilize various plug types and voltage levels, which can affect compatibility with your equipment. For instance, Type C outlets are common in Europe and parts of Africa, while Type G is prevalent in the UK and the Middle East. Ensure you are familiar with the specific requirements of your target market.

Step 2: Define Your Technical Specifications

Before approaching suppliers, clearly define the technical specifications of the outlets you need. This includes voltage ratings, amperage, and whether you require grounded or non-grounded options. For example, if you are sourcing for industrial applications, you may need specialized outlets capable of handling higher loads. Documenting these details will streamline your discussions with potential suppliers.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your requirements. Check for certifications that validate the quality and safety of their products, such as ISO 9001 or IEC standards. Additionally, request case studies or references from similar businesses to gauge their reliability and service quality. This step is crucial to mitigate risks associated with product failure or non-compliance.

Step 4: Request Samples for Testing

Before finalizing any orders, request samples of the outlets for testing. This will allow you to assess the quality, durability, and compatibility with your existing systems. Ensure that the samples meet your specifications and perform well under the intended conditions. Testing can save you from costly mistakes and ensure that you are making an informed purchase.

Step 5: Verify Warranty and Support Options

Examine the warranty and support services offered by your suppliers. A robust warranty can protect your investment in case of defects or failures, while good customer support can assist you with installation issues or product questions. Ensure that the supplier has a clear return policy and readily available support channels.

Step 6: Consider Logistics and Delivery Times

Assess the logistics involved in sourcing your electrical outlets. Consider the lead times for production, shipping, and delivery to your location. Understanding these factors will help you plan your project timelines effectively. Additionally, inquire about shipping costs and options for expedited delivery if needed.

Step 7: Negotiate Terms and Finalize Purchase

Once you have selected a supplier, negotiate the terms of the purchase, including pricing, payment terms, and delivery schedules. Clear communication at this stage can prevent misunderstandings later on. Ensure all terms are documented in a purchase agreement to protect both parties.

By following this checklist, B2B buyers can confidently navigate the sourcing process for electrical outlets, ensuring they procure the right products that meet their operational needs while adhering to local standards and regulations.

Comprehensive Cost and Pricing Analysis for type of electrical outlets Sourcing

When sourcing electrical outlets, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This section outlines the key cost components, price influencers, and offers practical buyer tips to optimize sourcing strategies.

What Are the Key Cost Components in Electrical Outlet Manufacturing?

-

Materials: The primary materials used in electrical outlets include plastics, metals, and components such as circuit breakers or GFCI modules. The cost of raw materials can fluctuate significantly based on global supply chains and market demand.

-

Labor: Labor costs vary by region and are influenced by local wage standards. In developing regions, such as parts of Africa and South America, labor may be more cost-effective compared to Europe or the Middle East.

-

Manufacturing Overhead: This encompasses utilities, rent, and administrative expenses associated with production facilities. Efficient manufacturing processes can help reduce these costs.

-

Tooling: Initial setup for manufacturing tools and molds can be substantial, especially for custom designs. Buyers should consider whether standard products or tailored solutions align better with their requirements.

-

Quality Control (QC): Ensuring compliance with safety and performance standards is vital. QC processes incur costs but are essential for preventing defects and ensuring product reliability.

-

Logistics: This includes shipping, handling, and storage costs. International shipping can be particularly expensive and is influenced by Incoterms that determine who bears the transportation costs and risks.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the expected profit margins in different markets can aid in negotiation.

What Factors Influence Pricing for Electrical Outlets?

-

Volume and Minimum Order Quantity (MOQ): Pricing often decreases with higher order volumes. International buyers should evaluate their needs to negotiate better rates based on MOQs.

-

Specifications and Customization: Custom electrical outlets, such as those designed for specific voltage or safety standards, will generally cost more than standard products. Buyers should weigh the benefits of customization against potential cost increases.

-

Material Quality and Certifications: Outlets that meet international safety standards (like UL or CE) may command higher prices due to the testing and certification processes involved. Buyers should ensure that the products sourced meet the necessary certifications for their target markets.

-

Supplier Factors: Supplier reputation, reliability, and production capacity can all influence pricing. Established suppliers may offer better quality assurance but at a higher cost.

-

Incoterms: Understanding the chosen Incoterm (e.g., FOB, CIF) is essential as it dictates the cost responsibilities between the buyer and seller, impacting overall pricing.

How Can International B2B Buyers Optimize Their Sourcing Strategy?

-

Negotiation: Engage suppliers in discussions about pricing and terms. Leverage volume discounts and long-term contracts to secure better deals.

-

Focus on Total Cost of Ownership (TCO): Beyond the initial purchase price, consider installation, maintenance, and potential replacement costs. Products with higher upfront costs may offer lower TCO due to durability and energy efficiency.

-

Pricing Nuances for Regional Markets: Buyers from Africa, South America, the Middle East, and Europe should account for local market dynamics, currency fluctuations, and import tariffs that may affect pricing.

-

Research and Due Diligence: Conduct thorough market research to understand prevailing prices and supplier capabilities. This information can empower buyers during negotiations and help avoid overpricing.

Conclusion

While sourcing electrical outlets, B2B buyers must navigate a complex landscape of costs and pricing influencers. By understanding the components that affect pricing and leveraging strategic negotiation techniques, buyers can make informed decisions that align with their operational needs and budgetary constraints.

Disclaimer: Prices can vary significantly based on market conditions and specific requirements. Always consult suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing type of electrical outlets With Other Solutions

Introduction: What Are the Alternatives to Traditional Electrical Outlets?

As global businesses expand and diversify their operations, understanding the various types of electrical outlets and their alternatives becomes crucial for international B2B buyers. While traditional electrical outlets are the backbone of electrical distribution in many regions, there are several alternative solutions that can be considered based on specific needs, environments, and technological advancements. This analysis compares traditional electrical outlets with innovative alternatives, helping buyers make informed decisions based on performance, cost, and practical application.

Comparison Table of Electrical Outlet Types and Alternatives

| Comparison Aspect | Type Of Electrical Outlets | Alternative 1 Name: Wireless Charging Systems | Alternative 2 Name: Power over Ethernet (PoE) |

|---|---|---|---|

| Performance | Reliable for powering devices; various types support different voltages and amperages. | Convenient for mobile devices; limited range and speed. | Supports data and power simultaneously; effective for low-power devices. |

| Cost | Generally low installation costs; price varies by type and region. | Higher initial investment for infrastructure; ongoing costs for maintenance. | Moderate costs; less than traditional wiring in some cases, especially for networked devices. |

| Ease of Implementation | Simple installation by qualified electricians; requires specific outlet types per region. | Requires compatible devices; installation can be complex depending on layout. | Relatively easy if existing network infrastructure is in place; requires specific hardware. |

| Maintenance | Low maintenance; occasional replacement needed for worn outlets. | Minimal maintenance; however, device compatibility may change over time. | Moderate maintenance; network upgrades may necessitate changes to PoE infrastructure. |

| Best Use Case | Ideal for residential and commercial settings with diverse power needs. | Best for charging mobile devices and in environments where wires are impractical. | Excellent for powering network devices in offices and smart buildings. |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of Wireless Charging Systems?

Wireless charging systems utilize electromagnetic fields to transfer energy between a charger and a device. This solution is particularly advantageous in environments where cables may create clutter or pose safety hazards, such as in public spaces or hospitals. However, the performance is limited to compatible devices, and charging speeds may not match those of traditional outlets. Additionally, the initial investment for a robust wireless charging infrastructure can be significant, making it less suitable for large-scale applications.

How Does Power Over Ethernet (PoE) Serve as a Viable Alternative?

Power over Ethernet (PoE) technology allows electrical power and data to be transmitted through standard Ethernet cables. This method is especially beneficial in settings where devices like IP cameras, VoIP phones, and wireless access points are deployed. The ease of installation and reduced need for separate power outlets can lower overall costs. However, PoE is typically limited to low-power devices, and the infrastructure may need upgrades to handle higher power requirements, which can add complexity to its implementation.

Conclusion: How Can B2B Buyers Choose the Right Electrical Solution?

When selecting between traditional electrical outlets and alternative solutions such as wireless charging systems or Power over Ethernet, B2B buyers must assess their specific operational needs, budget constraints, and the nature of the devices they intend to power. Traditional outlets remain a reliable choice for diverse applications, while alternatives can offer innovative advantages in specific contexts. A thorough understanding of these options will empower international buyers to make informed decisions that enhance operational efficiency and align with their long-term business strategies.

Essential Technical Properties and Trade Terminology for type of electrical outlets

What Are the Essential Technical Properties of Electrical Outlets?

Understanding the technical properties of electrical outlets is crucial for B2B buyers involved in procurement, installation, or manufacturing. Here are key specifications that influence the selection and performance of electrical outlets:

1. Material Grade

The material used in the construction of electrical outlets significantly affects durability and safety. Common materials include thermoplastics for the housing and copper or brass for the internal connections. Buyers should prioritize high-grade materials that comply with international safety standards to ensure longevity and reduce the risk of electrical failures.

2. Voltage Rating

Electrical outlets are designed to operate at specific voltage levels, typically ranging from 100V to 250V depending on the region. Understanding the voltage requirements of your appliances is essential for selecting the appropriate outlet type. Misalignment can lead to equipment damage or safety hazards, making it a vital consideration for international buyers.

3. Current Rating (Amperage)

Outlets are rated for specific current loads, commonly 10A, 15A, or 20A. This rating indicates the maximum current the outlet can safely handle. Buyers must match the current rating with the intended application to avoid overheating and potential electrical fires. Knowing the amperage requirements helps in compliance with local electrical codes.

4. Grounding Type

Grounding is a safety feature that prevents electrical shock. Outlets can be classified as grounded (three-prong) or ungrounded (two-prong). The choice of grounding type must align with local regulations and the safety requirements of the devices being used. Grounded outlets provide additional safety, especially in regions with high moisture levels.

5. Tamper-Resistance

Tamper-resistant outlets incorporate safety features to prevent accidental contact with the electrical components, making them ideal for environments with children. This is particularly relevant for buyers in residential sectors or commercial facilities where safety is a priority. Compliance with safety standards can also be a selling point for products in certain markets.

6. Weather Resistance

For outdoor applications, weather-resistant outlets are designed to withstand environmental factors like moisture and extreme temperatures. These outlets often feature protective covers and corrosion-resistant materials. B2B buyers in regions with harsh climates should ensure that the products meet the necessary weatherproofing standards.

What Are Common Trade Terms Related to Electrical Outlets?

Navigating the electrical outlet market involves familiarity with specific jargon. Here are essential trade terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are marketed by another company under its brand name. For buyers, understanding OEM relationships can lead to better procurement strategies and potentially lower costs when sourcing electrical outlets.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to manage inventory levels effectively and avoid excess stock. It can also impact negotiation strategies when establishing supplier relationships.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price proposals for specific products. Buyers should prepare detailed RFQs that outline technical specifications, quantities, and delivery timelines to receive accurate quotes and ensure alignment with project requirements.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in global trade. Familiarity with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) helps buyers understand shipping responsibilities, costs, and risks, facilitating smoother international transactions.

5. Certification Compliance

Certification compliance refers to adherence to safety and quality standards set by organizations such as UL (Underwriters Laboratories) or CE (Conformité Européenne). For B2B buyers, ensuring that electrical outlets have the necessary certifications is critical for market entry and safety assurance.

6. Lead Time

Lead time is the time taken from placing an order to the delivery of the product. Understanding lead times is essential for effective project management and scheduling, especially in large-scale installations where timely delivery can impact overall project timelines.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring compliance and safety while optimizing procurement processes in the electrical outlet market.

Navigating Market Dynamics and Sourcing Trends in the type of electrical outlets Sector

What Are the Key Market Dynamics and Trends Influencing the Electrical Outlets Sector?

The global market for electrical outlets is experiencing notable shifts driven by several factors. Increased urbanization, particularly in regions like Africa and South America, is leading to a higher demand for reliable electrical infrastructure. The rise of smart homes and IoT devices has also accelerated the need for advanced electrical outlets that can accommodate diverse plug types and provide enhanced safety features such as GFCI and AFCI outlets. Furthermore, the ongoing push for energy efficiency and sustainability is prompting manufacturers to innovate and offer outlets that reduce energy consumption while maintaining functionality.

Emerging technologies such as smart outlets, which can be controlled remotely and integrated with home automation systems, are gaining traction in Europe and the Middle East. B2B buyers must stay attuned to these trends, as they can significantly impact sourcing decisions. Additionally, the ongoing globalization of supply chains means that buyers must navigate varying regulations and standards across different regions. Understanding the compatibility of electrical outlets and plugs used in specific countries is crucial for ensuring compliance and operational efficiency.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in Electrical Outlets?

Sustainability is becoming a central concern for B2B buyers in the electrical outlets sector. The environmental impact of manufacturing processes, from resource extraction to production waste, highlights the importance of choosing suppliers with robust sustainability practices. Ethical sourcing involves ensuring that materials used in electrical outlets, such as plastics and metals, are obtained responsibly and do not contribute to environmental degradation.

Buyers should look for suppliers that hold recognized green certifications, such as Energy Star or RoHS compliance, which indicate adherence to environmental standards. Additionally, sourcing outlets made from recycled or sustainable materials can further enhance a company’s commitment to reducing its carbon footprint. By prioritizing suppliers who demonstrate transparency in their supply chains and a commitment to sustainable practices, B2B buyers can contribute to a more sustainable future while meeting their operational needs.

What Is the Historical Context Behind Electrical Outlet Development?

The evolution of electrical outlets is intertwined with the advancement of electrical engineering and consumer needs. The first standardized electrical outlets emerged in the early 20th century, primarily in North America, with Type A and B plugs being widely adopted. As electricity became more accessible, the demand for safe and efficient electrical connections grew, leading to the introduction of grounded outlets and safety features.

Over the decades, various plug and socket types have developed globally, reflecting local safety standards and electrical needs. For instance, Europe primarily adopted Type C and F plugs, while the UK standardized on Type G. Understanding this historical context is vital for B2B buyers, as it informs current product offerings and compatibility issues. As markets continue to expand and evolve, awareness of these developments will aid in making informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of type of electrical outlets

-

How do I choose the right electrical outlet type for my region?

Selecting the appropriate electrical outlet type is crucial for ensuring compatibility with local electrical systems. Each region has its own standard outlet types, voltage, and frequency. For instance, Type C outlets are common in Europe and South America, while Type G is prevalent in the UK and UAE. Research the specific requirements for your target market by consulting local regulations and standards, and always verify compatibility with the devices you intend to use. -

What is the best electrical outlet type for industrial applications?

For industrial applications, it’s essential to consider the power requirements of your equipment. Typically, outlets such as Type C, E, or F are suitable for heavy machinery in Europe, while Type N is preferred in Brazil. Look for outlets that can handle higher amperages and provide features like weather resistance or surge protection, depending on your operational environment. Always consult with your equipment suppliers to ensure compatibility. -

What customization options are available for electrical outlets?

Many manufacturers offer customization options for electrical outlets, allowing you to tailor them to your specific needs. Custom features may include different colors, materials, or configurations to match your branding or technical requirements. It’s advisable to discuss these options with your supplier early in the procurement process to ensure they can meet your specifications within your timeline. -

How can I vet suppliers of electrical outlets?

Vetting suppliers is essential to ensure quality and reliability. Start by checking for certifications and compliance with international standards, such as IEC or ISO. Request samples and assess their quality and performance. Additionally, review customer testimonials and case studies, and consider visiting their production facilities if possible. Establishing a strong communication channel can also help gauge their responsiveness and reliability. -

What are typical minimum order quantities (MOQs) for electrical outlets?

Minimum order quantities for electrical outlets can vary widely depending on the supplier and product type. Generally, MOQs can range from as low as 100 units to several thousand. For custom products, MOQs may be higher due to the setup costs involved. It’s advisable to discuss your needs with potential suppliers to negotiate the most favorable terms that fit your procurement strategy. -

What payment terms should I expect when sourcing electrical outlets internationally?

Payment terms for international transactions often vary by supplier and region. Common arrangements include advance payment, letter of credit, or net 30/60 terms. It’s crucial to clarify these terms upfront and ensure they align with your cash flow management strategy. Additionally, be aware of any currency exchange risks and consider using secure payment methods to protect your investment. -

How do I ensure quality assurance when purchasing electrical outlets?

Quality assurance can be maintained by working closely with suppliers who adhere to recognized quality management standards, such as ISO 9001. Request detailed product specifications and testing reports. Conduct regular audits and inspections of the manufacturing process and final products, and consider third-party inspections for large orders. Establishing a clear return policy can also safeguard against defective products. -

What logistics considerations should I take into account when importing electrical outlets?

When importing electrical outlets, consider factors such as shipping methods, lead times, and customs regulations. Choose a reliable logistics partner familiar with the requirements of your destination country. Factor in potential delays due to customs clearance and ensure all documentation, such as invoices and certificates of origin, is in order. Additionally, be aware of any tariffs or import duties that may apply to your products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for type of electrical outlets

What Are the Key Takeaways for B2B Buyers in Electrical Outlet Sourcing?

In the rapidly evolving landscape of electrical outlets, understanding the various types and their applications is crucial for international B2B buyers. Different regions utilize specific outlet types, such as Type C in Europe and South America, or Type G in the UK and UAE. Recognizing these differences not only aids in compliance with local regulations but also ensures that your products are compatible with local infrastructure.

How Can Strategic Sourcing Enhance Your Business Operations?

A stock image related to type of electrical outlets.

Strategic sourcing of electrical outlets can significantly impact your supply chain efficiency and operational costs. By selecting suppliers who understand the nuances of local electrical standards and can provide high-quality products, you can enhance safety, reduce the risk of electrical failures, and ultimately improve customer satisfaction. Consider leveraging local suppliers in Africa, South America, the Middle East, and Europe to minimize lead times and shipping costs while fostering regional economic development.

A stock image related to type of electrical outlets.

What Should You Consider for Future Sourcing Decisions?

Looking ahead, the demand for versatile and safe electrical outlets will only grow, particularly with the rise of smart home technologies. International B2B buyers should prioritize suppliers who offer innovative solutions, such as weather-resistant or tamper-proof outlets, to stay ahead of market trends. Embrace the opportunity to diversify your sourcing strategies and invest in products that meet the evolving needs of your clients.

Engage with reliable manufacturers today to secure the best electrical outlet solutions for your business needs!