Discover 7 Essential Types of Locking Mechanisms (2025)

Introduction: Navigating the Global Market for types of locking mechanisms

In an increasingly interconnected world, sourcing the right types of locking mechanisms can pose significant challenges for international B2B buyers. With a diverse range of applications—from securing sensitive data in IT environments to ensuring the safety of physical assets in industrial settings—understanding the nuances of various locking systems is crucial. This guide delves into the different types of locking mechanisms, including pin tumbler locks, lever locks, and connector locking systems, highlighting their unique functionalities and best-use scenarios.

As global markets expand, buyers from regions such as Africa, South America, the Middle East, and Europe are faced with the task of not only selecting the appropriate locking solutions but also navigating complex supplier landscapes. This guide provides actionable insights on how to assess supplier reliability, evaluate cost-effectiveness, and identify the most suitable locking mechanisms for specific business needs.

By equipping B2B buyers with knowledge on locking mechanisms and supplier vetting processes, this comprehensive resource empowers informed purchasing decisions. Whether you’re in Australia or Kenya, understanding the intricacies of locking technologies will enhance your procurement strategy, ultimately safeguarding your assets and ensuring operational efficiency.

Understanding types of locking mechanisms Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pin Cylinder Lock | Uses pins of varying lengths; most common locking mechanism. | Residential, commercial doors, cabinets | Pros: High security, widely available. Cons: Vulnerable to picking if not high-security. |

| Lever Lock | Utilizes levers for locking; offers robust security. | Safes, gates, heavy-duty doors | Pros: Strong against forced entry. Cons: More complex installation and cost. |

| Bayonet Lock | Features a rotating collar for secure connection. | Military, aerospace, and industrial equipment | Pros: Quick coupling and uncoupling, resistant to shock. Cons: Requires precise alignment. |

| Push-Pull Lock | Engages with a simple push and release mechanism. | Medical devices, battery connections | Pros: Ideal for frequent connections, prevents accidental disconnection. Cons: Limited to specific designs. |

| Screw Lock | Employs threaded couplings for secure fastening. | Electrical connectors, high-vibration environments | Pros: Excellent environmental protection. Cons: Slower to connect/disconnect. |

What Are the Characteristics of Pin Cylinder Locks and Their B2B Suitability?

Pin cylinder locks are characterized by their internal mechanism of pins that must align to a shear line for the lock to open. This type is highly popular in both residential and commercial settings due to its ease of use and availability. B2B buyers should consider the level of security required, as standard pin cylinder locks can be vulnerable to lock picking. Investing in high-security variants with anti-picking features can enhance protection, making them suitable for sensitive environments.

How Do Lever Locks Provide Enhanced Security for Businesses?

Lever locks operate using a series of levers that must be lifted to unlock, offering a higher level of security compared to pin cylinder locks. They are commonly used in safes, gates, and heavy-duty doors where security against forced entry is paramount. For B2B buyers, the complexity of installation and higher costs should be weighed against the robust security they provide. Lever locks are ideal for businesses needing reliable protection for valuable assets.

Why Choose Bayonet Locks for Industrial Applications?

Bayonet locks are distinguished by their quick coupling mechanism, where the connector is locked into place with a simple turn. This feature makes them particularly effective in military, aerospace, and industrial environments where rapid connection and disconnection are necessary. B2B buyers should note that while bayonet locks are resistant to shock and vibration, they require precise alignment for effective use. Their durability and ease of use make them a solid choice for demanding applications.

What Makes Push-Pull Locks Ideal for Medical Devices?

Push-pull locks are designed for ease of use, allowing users to connect and disconnect with a simple push action. This mechanism is particularly beneficial in medical devices and battery connections, where frequent disconnections are common. For B2B buyers, the primary consideration is the prevention of accidental disconnections, which is crucial in sensitive environments. While they offer convenience, buyers should ensure compatibility with their specific applications.

How Do Screw Locks Enhance Environmental Protection in Connectors?

Screw locks use threaded couplings to provide a secure connection that is resistant to environmental challenges such as shock and vibration. They are commonly found in electrical connectors and applications where reliability is critical. B2B buyers should consider the slower connection speed associated with screw locks, as they require threading to engage. However, their superior environmental protection makes them an excellent choice for industries that demand high durability and safety standards.

Key Industrial Applications of types of locking mechanisms

| Industry/Sector | Specific Application of types of locking mechanisms | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Use of pin cylinder locks for securing machinery areas | Enhances safety and prevents unauthorized access | Need for durable materials and compliance with safety standards |

| Transportation | Lever locking mechanisms in cargo containers | Ensures cargo safety and reduces theft risks | Require weather-resistant and tamper-proof designs |

| Telecommunications | Bayonet locking connectors in network equipment | Provides reliable connections that withstand vibrations | Compatibility with existing systems and ease of installation |

| Healthcare | Push-pull locking mechanisms in medical devices | Prevents accidental disconnections in critical equipment | Must meet strict regulatory standards for medical equipment |

| Construction | Screw locking systems for scaffolding | Increases stability and safety for construction workers | Compliance with local building codes and safety regulations |

How Are Types of Locking Mechanisms Used in Manufacturing?

In the manufacturing sector, pin cylinder locks are commonly used to secure machinery and production areas. These locks enhance safety by preventing unauthorized access to sensitive equipment and materials, which is crucial for maintaining operational integrity. Buyers in this sector should prioritize sourcing durable materials that comply with safety standards to ensure long-lasting performance and reliability in high-demand environments.

What Are the Benefits of Lever Locking Mechanisms in Transportation?

Lever locking mechanisms are extensively used in cargo containers to secure goods during transit. By ensuring a robust locking system, these mechanisms significantly reduce the risk of theft and damage, providing peace of mind for logistics companies. When sourcing, businesses should focus on weather-resistant and tamper-proof designs to withstand the rigors of transportation in diverse climates, particularly in regions like Africa and South America.

Why Are Bayonet Locking Connectors Important in Telecommunications?

In the telecommunications industry, bayonet locking connectors play a vital role in ensuring reliable connections in network equipment. Their design allows for quick coupling and uncoupling, which is essential in environments that experience vibrations and shocks. B2B buyers should consider compatibility with existing systems and ease of installation to minimize downtime and maintain operational efficiency.

How Do Push-Pull Locking Mechanisms Enhance Safety in Healthcare?

Push-pull locking mechanisms are critical in medical devices, where accidental disconnection can have serious consequences. These mechanisms ensure that connections remain secure during operation, thus enhancing patient safety. Buyers in the healthcare sector must ensure that these devices meet strict regulatory standards to guarantee compliance and safety in medical applications, especially in regions with varying regulations.

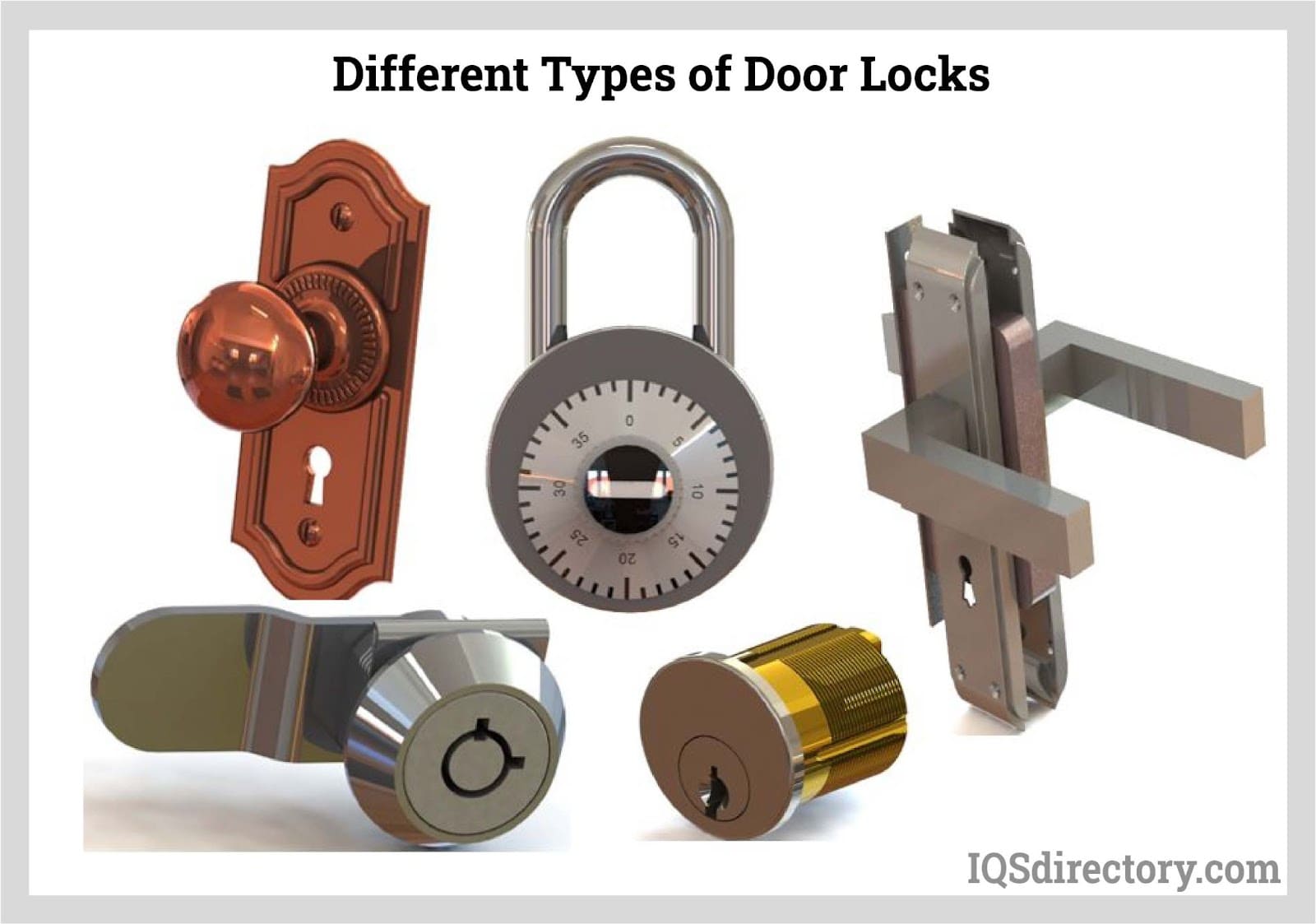

A stock image related to types of locking mechanisms.

What Role Do Screw Locking Systems Play in Construction?

Screw locking systems are frequently used in scaffolding to enhance stability and safety for construction workers. By providing a secure and reliable connection, these locking mechanisms help prevent accidents and ensure compliance with local building codes. When sourcing these systems, buyers should consider the materials used and ensure they meet safety regulations to protect workers and minimize liability.

3 Common User Pain Points for ‘types of locking mechanisms’ & Their Solutions

Scenario 1: Challenges with Environmental Conditions Affecting Lock Performance

The Problem: B2B buyers often face issues when selecting locking mechanisms that can withstand harsh environmental conditions. For instance, in industries such as agriculture or construction, equipment is frequently exposed to moisture, dust, and extreme temperatures. Standard locking mechanisms may fail or degrade, leading to security vulnerabilities and operational downtime. Buyers in these sectors might find themselves frustrated when locks corrode or jam, jeopardizing both equipment safety and accessibility.

The Solution: To overcome these challenges, it’s crucial to choose locking mechanisms designed specifically for environmental resilience. Look for options like bayonet locks or screw locking mechanisms that offer enhanced protection against moisture and dust. Selecting materials such as stainless steel or specialized polymers can also contribute to longevity. When sourcing these locks, inquire about their IP ratings (Ingress Protection) to ensure they meet the necessary resistance levels. Additionally, consider implementing regular maintenance schedules to inspect and service these locks, ensuring they function optimally in demanding conditions.

Scenario 2: Difficulty in Ensuring Secure Connections in High-Use Applications

The Problem: In sectors like healthcare or telecommunications, the need for secure and reliable connections is paramount. B2B buyers often struggle with locking mechanisms that are prone to accidental disconnection due to frequent use or movement, which can lead to significant operational disruptions. For example, connectors in medical devices must remain secure to prevent failures that could affect patient care, yet many buyers find standard latching mechanisms insufficient.

The Solution: To address this pain point, buyers should consider push-pull locking mechanisms or lever locking designs that provide a more robust and secure connection. Push-pull locks, for instance, are designed to prevent accidental disconnection while still allowing for quick and easy engagement and disengagement. When evaluating these options, prioritize connectors that offer audible or tactile feedback upon locking, ensuring users can confirm a secure fit without visual inspection. Additionally, investing in training for staff on proper connection techniques can further reduce the risk of accidental disconnections.

Scenario 3: Navigating the Complexity of Multi-Connector Systems

The Problem: Many B2B buyers face challenges when dealing with multi-connector systems, particularly in industries like transportation and aerospace, where various locking mechanisms must work seamlessly together. The complexity of these systems can lead to confusion regarding compatibility and functionality. Buyers may find themselves struggling with mismatched connectors, leading to delays in project timelines and increased costs due to rework or system failures.

The Solution: To streamline the selection process for multi-connector systems, it’s essential to engage in thorough planning and specification. Start by conducting a comprehensive assessment of the locking mechanisms required for each component of the system. Utilize standardized connector types, such as those with snap-in locking mechanisms for ease of use, and ensure compatibility across all components. Partnering with a reputable supplier who understands the intricacies of these systems can provide invaluable insights into selecting the right locking mechanisms. Furthermore, consider investing in modular connector designs that allow for easier upgrades or changes, ensuring long-term flexibility and efficiency in your operations.

Strategic Material Selection Guide for types of locking mechanisms

When selecting materials for locking mechanisms, it is crucial for international B2B buyers to understand the properties, advantages, and limitations of different materials. This knowledge helps in making informed decisions that align with specific application requirements and regional standards.

What Are the Key Properties of Steel in Locking Mechanisms?

Steel is one of the most commonly used materials for locking mechanisms due to its high strength and durability. It typically has excellent temperature and pressure ratings, making it suitable for various environments. Steel also offers good corrosion resistance, particularly when treated with coatings or alloys.

Pros and Cons:

– Pros: High tensile strength, cost-effective, and readily available. Steel can be manufactured into complex shapes, making it versatile for various locking designs.

– Cons: While it is durable, untreated steel can rust, especially in humid or saline environments. Additionally, it may require additional treatments to enhance its corrosion resistance, which can increase manufacturing complexity.

Impact on Application: Steel is widely used in industrial applications where strength and security are paramount, such as in padlocks and heavy-duty locks. However, buyers must consider local environmental conditions that may affect the longevity of steel locks.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards (e.g., ASTM) and consider the availability of treated steel options to prevent rusting in humid climates.

How Does Aluminum Compare as a Material for Locking Mechanisms?

Aluminum is another popular choice for locking mechanisms, particularly in lightweight applications. It has a lower density than steel, which makes it advantageous for portable locking devices. Aluminum also exhibits good corrosion resistance due to its natural oxide layer.

Pros and Cons:

– Pros: Lightweight, resistant to corrosion, and can be anodized for additional surface protection. Its lower weight makes it ideal for applications where portability is essential.

– Cons: Aluminum is generally less strong than steel, which may limit its use in high-security applications. It is also more expensive than steel, which could impact budget considerations.

Impact on Application: Aluminum is well-suited for applications in the automotive and aerospace industries, where weight savings are critical. However, in high-security environments, buyers may need to look for reinforced aluminum options.

Considerations for International Buyers: Buyers in Europe may prefer aluminum due to its lightweight properties, but they should verify compliance with relevant standards like DIN for safety and performance.

What Role Does Plastic Play in Locking Mechanisms?

Plastic materials, particularly engineering plastics like polycarbonate and nylon, are increasingly used in locking mechanisms. These materials offer excellent resistance to chemicals and environmental factors, making them suitable for various applications.

Pros and Cons:

– Pros: Lightweight, resistant to corrosion and chemicals, and can be produced at a lower cost compared to metals. They also allow for complex designs and colors.

– Cons: Plastic typically has lower tensile strength compared to metals and may not be suitable for high-security applications. Additionally, extreme temperatures can affect the integrity of plastic locks.

Impact on Application: Plastic locks are commonly found in consumer products, such as luggage locks and child safety locks. However, their suitability for high-security applications is limited.

Considerations for International Buyers: Buyers in the Middle East and Africa should assess the temperature ranges and chemical exposure their products will face to ensure that the selected plastic material can withstand these conditions.

How Does Brass Enhance Locking Mechanisms?

Brass is a traditional material used in locking mechanisms, particularly in residential locks and decorative applications. It offers good corrosion resistance and a pleasing aesthetic.

Pros and Cons:

– Pros: Excellent corrosion resistance, attractive appearance, and good machinability. Brass locks are often more secure due to their density and strength.

– Cons: Brass can be more expensive than steel and may not be suitable for heavy-duty applications. It can also be softer than steel, making it susceptible to wear over time.

Impact on Application: Brass is commonly used in residential and decorative locks, where appearance and corrosion resistance are important. However, for high-security applications, buyers may need to consider reinforced brass options.

Considerations for International Buyers: Buyers in Europe may favor brass for its aesthetic qualities, but they should ensure compliance with local standards and consider the cost implications.

Summary Table of Material Selection for Locking Mechanisms

| Material | Typical Use Case for types of locking mechanisms | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty locks, industrial applications | High tensile strength | Susceptible to rust without treatment | Medium |

| Aluminum | Lightweight locks in automotive and aerospace | Lightweight and corrosion-resistant | Lower strength than steel | High |

| Plastic | Consumer locks, child safety locks | Lightweight and cost-effective | Lower tensile strength, temperature sensitivity | Low |

| Brass | Residential and decorative locks | Corrosion-resistant and attractive | Softer than steel, more expensive | Medium |

This comprehensive analysis provides international B2B buyers with actionable insights into material selection for locking mechanisms, ensuring they can make informed decisions that meet their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for types of locking mechanisms

What Are the Key Stages in the Manufacturing Process of Locking Mechanisms?

The manufacturing of locking mechanisms involves several critical stages, each designed to ensure the final product meets both functional and quality standards. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Locking Mechanisms?

Material selection is crucial in the production of locking mechanisms. Common materials include steel, brass, and aluminum, chosen for their strength, durability, and resistance to wear. The preparation stage involves:

- Material Sourcing: Suppliers are evaluated based on quality certifications and reliability. B2B buyers should ensure that suppliers provide documentation regarding the origin and specifications of the materials.

- Cutting and Shaping: Raw materials are cut to size using precision machinery, ensuring that all parts are uniform. Techniques such as laser cutting and CNC machining are prevalent, allowing for high precision.

What Techniques Are Used in Forming Locking Mechanisms?

Forming is the process where the prepared materials are transformed into specific shapes and features required for the locking mechanism. Key techniques include:

- Stamping and Forging: These methods shape metal parts through high-pressure processes. Stamping is often used for flat components, while forging is suitable for creating more complex shapes.

- Casting: For some locking mechanisms, particularly those with intricate designs, casting can be employed. This involves pouring molten metal into molds, which is then allowed to solidify.

- Machining: After forming, parts may require additional machining to achieve precise dimensions and tolerances. Techniques such as milling and turning are commonly used here.

How Is Assembly Conducted for Locking Mechanisms?

The assembly stage involves putting together the various components created in the previous stages. This process can vary significantly depending on the type of locking mechanism:

- Manual vs. Automated Assembly: For high-volume production, automated assembly lines are often used. However, manual assembly is still common for complex locks requiring careful handling.

- Integration of Internal Components: For mechanisms like pin tumbler locks, the assembly must ensure that internal components such as pins and springs are correctly positioned to function effectively.

- Testing During Assembly: Quality checkpoints are integrated into the assembly process to catch defects early. This may include functional tests to ensure that components work seamlessly together.

What Finishing Techniques Are Used for Locking Mechanisms?

Finishing is essential for both aesthetic and functional purposes. This stage involves:

- Surface Treatments: Techniques such as electroplating, anodizing, or powder coating are applied to enhance corrosion resistance and aesthetics. B2B buyers should inquire about the specific treatments used and their expected lifespan.

- Quality Assurance Checks: Finishing processes often include final inspections to ensure that the surface finish meets specified standards. This could involve visual inspections or more sophisticated methods like surface roughness testing.

What Quality Assurance Standards Are Relevant to Locking Mechanisms?

Quality assurance is vital for ensuring that locking mechanisms meet both safety and performance standards. International standards such as ISO 9001 focus on quality management systems, while industry-specific standards may include:

- CE Marking: Required for products sold in the European market, this indicates compliance with EU safety, health, and environmental protection standards.

- API Standards: Relevant for locking mechanisms used in oil and gas applications, ensuring that products meet specific safety and operational requirements.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integral to the manufacturing of locking mechanisms. Several checkpoints should be established:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials before they enter the production process. It ensures that materials meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, regular checks should be conducted to monitor the quality of the processes and components. This helps identify issues early on.

- Final Quality Control (FQC): At the end of the production line, a thorough inspection of the finished product takes place. This may include functional testing to ensure the locking mechanism operates as intended.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. Here are some actionable steps:

- Supplier Audits: Conducting regular audits of suppliers can help assess their compliance with quality standards. This includes reviewing their manufacturing processes and quality assurance practices.

- Requesting Quality Reports: Suppliers should provide documentation of their quality control processes, including records of inspections and testing results. This transparency is critical for establishing trust.

- Third-Party Inspections: Utilizing independent third-party inspectors can provide an unbiased evaluation of a supplier’s quality control measures. This is particularly useful when dealing with international suppliers.

What Quality Control Nuances Should International B2B Buyers Consider?

When sourcing locking mechanisms from international suppliers, B2B buyers should be aware of specific nuances in quality control:

- Cultural Differences: Variations in manufacturing practices and quality expectations may exist between regions. Understanding these differences can help buyers set appropriate standards.

- Regulatory Compliance: Different countries may have unique regulations concerning product safety and quality. Buyers should ensure that suppliers comply with both local and international regulations.

- Logistical Considerations: Shipping and handling can impact product quality. Buyers should discuss how suppliers manage these aspects to prevent damage during transit.

By understanding the manufacturing processes and quality assurance measures involved in the production of locking mechanisms, international B2B buyers can make informed decisions, ensuring they source high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of locking mechanisms’

Introduction

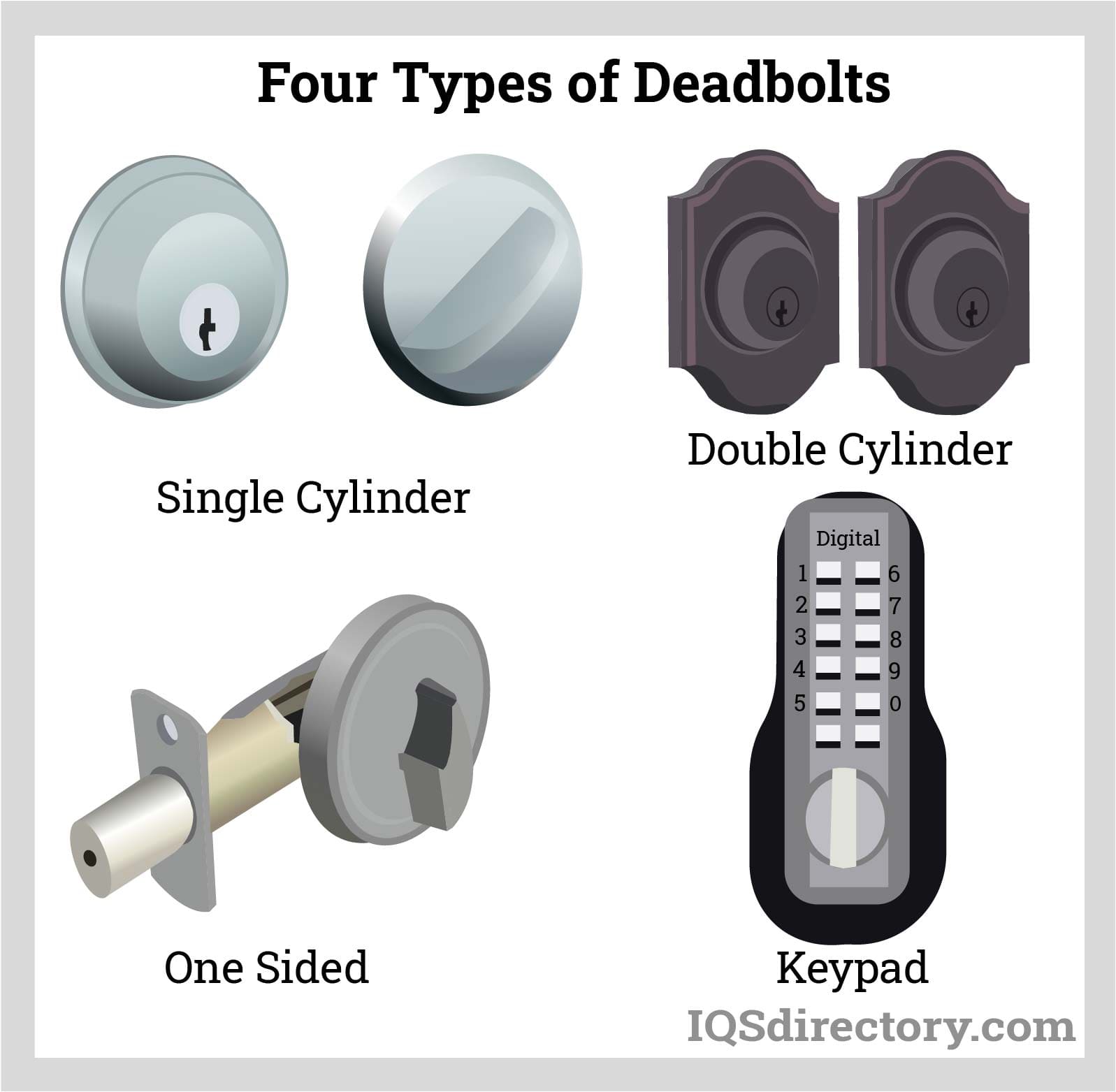

A stock image related to types of locking mechanisms.

Navigating the procurement of locking mechanisms can be complex, especially for B2B buyers in diverse international markets such as Africa, South America, the Middle East, and Europe. This guide provides a step-by-step checklist to help you identify, evaluate, and source the right types of locking mechanisms for your business needs. Understanding the various locking mechanisms available and the suppliers who offer them will ensure you make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the locking mechanisms you need. This includes understanding the environment in which the locks will be used (e.g., industrial, residential, or commercial) and any specific security features required.

- Consider factors like resistance to weather, shock, and vibration, especially if you are in regions prone to such conditions.

- Identify the locking mechanism type you require, such as pin cylinder locks, lever locks, or connector locking systems.

Step 2: Research Market Trends and Standards

Stay informed about the latest trends and standards in locking mechanisms relevant to your industry. This is crucial for compliance and ensuring you select products that meet international safety and quality standards.

- Look for certifications that indicate compliance with industry standards (e.g., ISO, ANSI) to ensure reliability and performance.

- Explore innovations in locking mechanisms, such as smart locks or enhanced security features, to stay competitive.

Step 3: Evaluate Potential Suppliers

Conduct a thorough evaluation of potential suppliers before making a commitment. This step is vital to ensure you partner with reliable manufacturers who can meet your needs.

- Request company profiles and case studies to assess their experience and capabilities in your specific sector.

- Seek references from other buyers in similar industries or regions to gauge supplier reliability and product performance.

Step 4: Request Samples for Testing

Before placing a bulk order, request samples of the locking mechanisms you are considering. Testing samples allows you to assess the quality and functionality firsthand.

- Evaluate the samples under real-world conditions to ensure they meet your performance criteria.

- Check for ease of installation and operation, especially for complex locking systems that may require specific tools or expertise.

Step 5: Compare Pricing and Terms

Once you have shortlisted suppliers, compare their pricing and terms. This is essential to ensure you receive the best value for your investment.

- Consider not just the price, but also warranty terms, lead times, and after-sales support.

- Negotiate terms to establish a mutually beneficial partnership that could lead to discounts on future orders.

Step 6: Confirm After-Sales Support and Warranty

Understanding the after-sales support and warranty offered by suppliers is crucial for long-term satisfaction. This can significantly impact your operational efficiency.

- Inquire about the warranty period and what it covers, as well as the process for claiming warranty services.

- Assess the availability of technical support for installation and maintenance to minimize downtime and issues in the future.

Step 7: Finalize the Purchase Agreement

Once you have completed the previous steps, it’s time to finalize your purchase agreement. Ensure that all terms are clearly stated and understood by both parties.

- Review the contract carefully to ensure it includes all specifications, pricing, delivery schedules, and warranties.

- Establish communication protocols for order tracking and support during the delivery phase to prevent misunderstandings.

By following these steps, international B2B buyers can effectively source the right locking mechanisms tailored to their specific needs, ensuring enhanced security and reliability in their operations.

Comprehensive Cost and Pricing Analysis for types of locking mechanisms Sourcing

What Are the Key Cost Components in Sourcing Locking Mechanisms?

When analyzing the cost structure for sourcing locking mechanisms, several key components come into play. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality metals, plastics, and composites used in locks and connectors can raise prices, while lower-grade materials may reduce costs but compromise durability and security.

-

Labor: Labor costs vary depending on the region and complexity of the manufacturing process. Skilled labor in Europe may demand higher wages compared to emerging markets in Africa or South America, affecting the final pricing structure.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help mitigate these expenses.

-

Tooling: Initial tooling costs can be substantial, particularly for custom designs. Buyers should consider the amortization of these costs over expected production volumes to evaluate overall pricing.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability but can increase costs. Certifications such as ISO 9001 can also add to expenses, yet they may enhance buyer confidence.

-

Logistics: Shipping and handling costs vary based on the distance, mode of transport, and volume of the order. International buyers should account for these costs when sourcing from different regions.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding the standard margins in the locking mechanism industry can help buyers negotiate better deals.

How Do Price Influencers Affect Locking Mechanism Costs?

Several factors influence the pricing of locking mechanisms:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to lower unit costs. Buyers should negotiate terms that allow for cost reductions based on volume.

-

Specifications and Customization: Custom specifications can lead to increased costs due to unique tooling and materials. Buyers should clearly define requirements to avoid unexpected expenses.

-

Material Selection: The choice of materials not only affects the initial price but also the long-term durability and maintenance costs. Higher-quality materials may have a higher upfront cost but result in lower total cost of ownership.

-

Quality and Certifications: Products with higher quality ratings and certifications may cost more but can provide long-term savings through reduced failure rates and warranty claims.

-

Supplier Factors: The supplier’s location, reputation, and reliability can significantly impact pricing. Regional suppliers may offer lower shipping costs, while well-established suppliers might provide better quality assurances.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for pricing negotiations. Different terms can affect who bears the shipping costs, insurance, and risks, impacting overall pricing.

What Tips Can Buyers Use to Negotiate Better Prices for Locking Mechanisms?

International B2B buyers can leverage several strategies to secure more favorable pricing for locking mechanisms:

-

Engage in Negotiation: Establishing a good relationship with suppliers can open doors for better pricing. Being transparent about budget constraints while expressing interest in long-term partnerships can lead to discounts.

-

Focus on Cost-Efficiency: Consider the total cost of ownership rather than just the purchase price. Evaluate factors like maintenance, warranty, and replacement costs when making purchasing decisions.

-

Understand Pricing Nuances: Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with regional pricing strategies and market conditions. This knowledge can provide leverage during negotiations.

-

Explore Alternative Suppliers: Diversifying your supplier base can foster competition and lead to better pricing. Consider suppliers from emerging markets where costs might be lower.

-

Be Aware of Market Trends: Keep an eye on industry trends and fluctuations in material prices. Timing purchases strategically can result in significant savings.

Disclaimer on Indicative Prices

Prices for locking mechanisms can vary widely based on numerous factors, including market demand, currency fluctuations, and geopolitical influences. It is advisable for buyers to seek quotes from multiple suppliers and consider conducting a thorough market analysis to obtain the most accurate pricing information.

Alternatives Analysis: Comparing types of locking mechanisms With Other Solutions

Introduction to Locking Mechanism Alternatives

When considering security solutions for your business, it’s crucial to evaluate not just the types of locking mechanisms available but also viable alternatives that can fulfill similar roles. This analysis will explore how traditional locking mechanisms compare with emerging technologies and methods that offer varying degrees of security, convenience, and cost-effectiveness. By understanding these alternatives, international B2B buyers can make informed decisions that align with their specific operational needs.

Comparison Table of Locking Mechanisms and Alternatives

| Comparison Aspect | Types Of Locking Mechanisms | Smart Lock Solutions | Biometric Access Systems |

|---|---|---|---|

| Performance | High, but can be picked or bypassed | High, with remote access features | Very high, unique to each user |

| Cost | Moderate to high, depending on type | High initial investment, low maintenance | High initial investment, moderate maintenance |

| Ease of Implementation | Generally straightforward installation | Requires network setup and app integration | Complex installation, may require IT expertise |

| Maintenance | Low to moderate, depending on wear | Low, software updates needed | Moderate, may require hardware upkeep |

| Best Use Case | Traditional security needs | Smart homes, offices needing remote access | High-security environments requiring identity verification |

Detailed Breakdown of Alternatives

1. Smart Lock Solutions

Smart locks utilize advanced technology to provide enhanced security and convenience. They often feature remote access capabilities, allowing users to lock or unlock doors via smartphones or keypads. The primary advantage of smart locks is their versatility in modern applications, particularly in settings where remote monitoring is advantageous, such as in hospitality or shared office spaces. However, they come with a higher initial investment and may require ongoing software updates, which can pose challenges in regions with limited internet access.

2. Biometric Access Systems

Biometric access systems represent a cutting-edge alternative that leverages unique biological traits—such as fingerprints or facial recognition—for authentication. This technology offers exceptional security, as it is nearly impossible to replicate an individual’s biometric data. These systems are ideal for high-security environments, such as government buildings or financial institutions, where unauthorized access must be tightly controlled. On the downside, the cost of installation is typically high, and maintenance can be moderate due to the need for regular updates and hardware checks.

Conclusion: Choosing the Right Locking Solution for Your Business

When selecting the appropriate locking mechanism or alternative solution for your business, consider the specific operational context and security requirements. For traditional environments where cost is a significant concern, standard locking mechanisms may suffice. However, if your business operates in a fast-evolving landscape requiring remote access or advanced security, smart locks or biometric systems may be more suitable despite their higher initial costs. By thoroughly assessing the performance, costs, and maintenance requirements of each option, B2B buyers can make strategic decisions that enhance security while aligning with their overall business goals.

Essential Technical Properties and Trade Terminology for types of locking mechanisms

What Are the Key Technical Properties of Locking Mechanisms?

When assessing locking mechanisms for B2B applications, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications that international buyers should consider:

A stock image related to types of locking mechanisms.

1. Material Grade

The material used in locking mechanisms directly influences their durability and security. Common materials include stainless steel, brass, and high-grade polymers. For example, stainless steel offers excellent corrosion resistance, making it ideal for outdoor applications in humid climates, such as parts of Africa and South America. Assessing material grade ensures that the locking mechanism can withstand environmental conditions and operational stresses.

2. Tolerance Levels

Tolerance refers to the acceptable range of variation in dimensions and fits between parts of a locking mechanism. Tight tolerances are essential for high-security applications where precision is critical. For example, in Europe, where security standards are stringent, understanding tolerance levels helps buyers ensure that the locks will function correctly without excessive wear or failure over time.

3. Locking Mechanism Type

Different locking mechanisms serve various purposes. Common types include pin tumbler, lever, and electronic locks. Each type has its own operational characteristics and advantages. For B2B buyers, knowing the specific type can help in selecting the right lock for the intended application, whether it be for a warehouse in the Middle East or a retail outlet in South America.

4. Security Rating

Many locking mechanisms come with security ratings that assess their resistance to unauthorized access or tampering. These ratings often follow standardized tests (e.g., ANSI/BHMA or EN 1303) and can be vital for compliance in certain markets. For international buyers, understanding these ratings ensures that the locks meet local security requirements and provide adequate protection for assets.

5. Environmental Resistance

Environmental resistance indicates how well a locking mechanism can withstand various conditions such as temperature extremes, humidity, and exposure to chemicals. This property is particularly important for buyers in diverse climates, like those in Africa or the Middle East. Ensuring that a lock can perform reliably under specific environmental conditions can prevent costly failures and replacements.

What Are Common Trade Terms in Locking Mechanisms?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms related to locking mechanisms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For locking mechanisms, an OEM might design a specific locking system tailored to a buyer’s specifications. Understanding OEM relationships can help buyers identify reputable suppliers and ensure that they receive high-quality products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers to understand pricing and inventory management. Knowing the MOQ can help businesses in regions like Europe and South America plan their purchasing strategies effectively, avoiding excess inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing information for specific products or services. In the context of locking mechanisms, issuing an RFQ can help buyers compare prices and terms from different manufacturers, ensuring they get the best deal for their requirements.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade transactions. They clarify aspects like shipping costs, risks, and responsibilities related to delivery. Familiarity with Incoterms is vital for B2B buyers involved in cross-border purchases, as it helps avoid misunderstandings and disputes.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when selecting locking mechanisms that meet their specific needs and compliance requirements.

Navigating Market Dynamics and Sourcing Trends in the types of locking mechanisms Sector

What Are the Current Market Dynamics and Key Trends in the Locking Mechanisms Sector?

The locking mechanisms sector is experiencing significant transformation driven by various global factors. One of the primary drivers is the increasing demand for security solutions across different industries, including residential, commercial, and industrial sectors. As international B2B buyers seek reliable locking solutions, trends such as the adoption of smart locks and advanced mechanical locking systems are gaining traction. Smart locks, equipped with IoT capabilities, are becoming popular in regions like Europe and North America, reflecting a shift towards digital security solutions.

In emerging markets in Africa and South America, traditional mechanical locks still dominate, but there is a growing interest in hybrid solutions that combine mechanical durability with electronic features. The rise in urbanization and infrastructure development in these regions is propelling demand for high-security locking mechanisms, particularly in commercial real estate and government projects. Additionally, the need for enhanced safety measures in transportation and logistics is fostering innovation in connector locking mechanisms, which are essential for various applications ranging from automotive to aerospace.

International buyers should also consider the implications of regional regulations and standards that govern locking mechanisms, as these can influence sourcing decisions and product certifications. Understanding local market dynamics and consumer preferences is crucial for B2B buyers to identify the right suppliers and technologies.

How Can Sustainability and Ethical Sourcing Impact the Locking Mechanisms Industry?

Sustainability is becoming a cornerstone of sourcing strategies in the locking mechanisms sector. International B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing environmental impact through sustainable practices. This includes the use of recycled materials in the production of locking mechanisms, which can significantly lower the carbon footprint of these products.

Moreover, certifications such as ISO 14001 for environmental management systems are gaining importance as buyers seek assurance that their suppliers adhere to ethical manufacturing processes. The demand for transparency in supply chains is also rising, prompting companies to adopt ethical sourcing practices that ensure fair labor conditions and responsible resource extraction.

In regions such as Africa and South America, where environmental concerns and social responsibility are paramount, B2B buyers should engage with suppliers who have robust sustainability initiatives. This could involve sourcing locking mechanisms that utilize eco-friendly materials or are designed for longevity, thus reducing waste over time. Adopting a sustainable sourcing strategy not only aligns with global trends but also enhances brand reputation and customer loyalty.

What Is the Brief Evolution and History of Locking Mechanisms?

The evolution of locking mechanisms dates back thousands of years, with the earliest examples found in ancient Egypt, where wooden locks were utilized. Over time, the pin tumbler lock, patented by Linus Yale Jr. in 1851, revolutionized security systems and is still widely used today. This lock type operates on the principle of aligning pins to allow the lock to turn, a design that continues to inspire modern locking technology.

In the 20th century, advancements in materials and manufacturing processes led to the development of more complex locking mechanisms, such as disc detainer and electronic locks. The introduction of smart technology in the 21st century has further transformed the sector, enabling features like remote access and integration with home automation systems. This historical context underscores the continuous innovation in locking mechanisms, reflecting changing security needs and technological advancements. For international B2B buyers, understanding this evolution is crucial for making informed sourcing decisions and staying ahead of market trends.

Frequently Asked Questions (FAQs) for B2B Buyers of types of locking mechanisms

-

How do I choose the right locking mechanism for my application?

Choosing the right locking mechanism depends on various factors, including the level of security required, environmental conditions, and the specific application. For high-security needs, consider pin cylinder or disc detainer locks. If the application involves frequent connections and disconnections, push-pull or latch locks may be more suitable. Additionally, assess whether the mechanism can withstand shocks and vibrations, especially in industrial settings. It’s essential to collaborate with suppliers who can provide expert recommendations tailored to your requirements. -

What is the best locking mechanism for outdoor use?

For outdoor applications, look for locking mechanisms that offer weather resistance and durability. Padlocks with robust materials, such as stainless steel or brass, are excellent for securing gates and fences. Additionally, consider locks with weatherproof coatings or seals to prevent corrosion. For electronic access, smart locks with weather-resistant features can enhance security while providing convenience. Always check the manufacturer’s specifications to ensure the mechanism is suitable for the intended environmental conditions. -

How can I ensure the quality of locking mechanisms from suppliers?

To ensure quality, conduct thorough due diligence on potential suppliers. Request certifications and compliance with international standards, such as ISO 9001, which indicates a commitment to quality management. Additionally, ask for product samples to evaluate the locking mechanisms’ durability and functionality. Engaging in direct communication with suppliers about their manufacturing processes and quality assurance protocols can also provide insights into their product reliability. -

What are the typical minimum order quantities (MOQs) for locking mechanisms?

Minimum order quantities (MOQs) for locking mechanisms can vary significantly based on the supplier and the specific type of lock. Standard locks may have lower MOQs, while custom or specialized locks could require larger orders. Generally, MOQs can range from 50 to several hundred units. It’s advisable to discuss your needs with suppliers to negotiate favorable terms, especially if you are looking for a smaller initial order. -

What payment terms should I expect when purchasing locking mechanisms internationally?

Payment terms for international purchases can differ widely. Common terms include payment in advance, letters of credit, or net 30/60 days after invoice. Some suppliers may offer discounts for early payments. It’s crucial to clarify payment terms during negotiations and ensure they align with your cash flow management strategy. Always confirm the currency of payment to avoid exchange rate fluctuations, which can impact your overall costs. -

How do I vet suppliers for locking mechanisms in international markets?

Vetting suppliers involves assessing their reputation, reliability, and capacity to meet your needs. Start by checking online reviews and testimonials from other B2B clients. Request references and conduct background checks on the supplier’s business practices. Additionally, consider visiting their manufacturing facility if feasible or engaging third-party inspection services to verify product quality and compliance with safety standards. Establishing a strong communication channel can also help foster a trustworthy relationship. -

What customization options are available for locking mechanisms?

Customization options for locking mechanisms often include variations in size, material, finish, and locking technology. Many suppliers offer bespoke solutions tailored to specific applications, such as adding branding elements or unique keying systems. Discuss your requirements with suppliers to explore available options. Keep in mind that customization may affect lead times and pricing, so it’s essential to plan accordingly. -

What logistics considerations should I keep in mind when importing locking mechanisms?

When importing locking mechanisms, consider shipping methods, lead times, and customs regulations. Choose between air freight for faster delivery and sea freight for cost-effectiveness, depending on your urgency and budget. Ensure compliance with local import regulations, including tariffs and taxes, which can impact your total cost. Working with a reliable freight forwarder can facilitate smoother logistics management, helping you navigate documentation and customs clearance efficiently.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of locking mechanisms

As international B2B buyers navigate the diverse landscape of locking mechanisms, understanding the intricacies of various types—from pin cylinder locks to connector locking systems—is paramount. Each mechanism offers unique advantages tailored to specific applications, ensuring both security and functionality. Strategic sourcing allows buyers to identify suppliers that not only provide high-quality locking solutions but also align with their operational requirements and regional standards.

The importance of selecting the right locking mechanism cannot be overstated. It influences not only the security of assets but also the efficiency of operations in sectors ranging from industrial manufacturing to consumer electronics. Buyers must consider factors such as environmental conditions, frequency of use, and compatibility with existing systems when evaluating their options.

Looking ahead, the demand for innovative locking mechanisms that integrate advanced technologies—such as smart locks and biometric systems—will continue to grow. Buyers in Africa, South America, the Middle East, and Europe should actively engage with suppliers that offer cutting-edge solutions to stay ahead of the curve. Embrace strategic sourcing as a tool for enhancing operational security and efficiency, and connect with trusted manufacturers to secure the best locking mechanisms for your needs.