Discover Cost-Effective Solutions with Hardware Cloth (2025)

Introduction: Navigating the Global Market for hardware cloth

Navigating the complex landscape of the global hardware cloth market can be a daunting task for international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. Whether you are sourcing hardware cloth for agricultural applications, construction projects, or pest control, understanding the nuances of material types, quality standards, and supplier vetting processes is critical. This guide offers a comprehensive overview of hardware cloth, detailing the various types available, their specific applications, and essential factors to consider when selecting suppliers.

As an international buyer, you face unique challenges such as fluctuating costs, varying quality standards, and logistical hurdles in sourcing materials from different markets. This guide empowers you to make informed purchasing decisions by providing actionable insights into cost structures, supplier reliability, and product specifications. From galvanized steel options to vinyl-coated varieties, understanding the differences can significantly impact your project’s success and sustainability.

By equipping yourself with the knowledge contained in this guide, you can confidently navigate the global market for hardware cloth, ensuring that your sourcing strategy aligns with your operational needs and budgetary constraints. With a focus on practical solutions, this resource aims to help you optimize your procurement processes and establish long-term supplier relationships that foster growth and efficiency in your business operations.

Understanding hardware cloth Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Galvanized Steel Hardware Cloth | Corrosion-resistant, strong, available in various gauges | Agricultural fencing, pest control, landscaping | Pros: Durable, long-lasting. Cons: May rust if scratched. |

| Vinyl Coated Hardware Cloth | PVC coating for added protection, available in colors | Garden fencing, decorative applications | Pros: Aesthetically pleasing, corrosion-resistant. Cons: Higher cost. |

| Stainless Steel Hardware Cloth | Superior corrosion resistance, high tensile strength | Industrial applications, marine environments | Pros: Extremely durable, ideal for harsh conditions. Cons: Expensive compared to other types. |

| Welded Wire Mesh | Welded intersections for strength, available in various mesh sizes | Construction, safety barriers, animal enclosures | Pros: High strength, uniform openings. Cons: Less flexible than other types. |

| Chicken Wire | Hexagonal mesh pattern, lightweight, lower gauge wire | Poultry enclosures, garden protection | Pros: Cost-effective, easy to handle. Cons: Not as strong or durable as other options. |

What Are the Characteristics of Galvanized Steel Hardware Cloth?

Galvanized steel hardware cloth is a popular choice among B2B buyers due to its corrosion-resistant properties and strength. It is typically available in various gauges, making it versatile for different applications such as agricultural fencing, pest control, and landscaping. When purchasing, buyers should consider the gauge thickness, as thicker gauges offer greater durability but may also increase costs. Additionally, it is essential to ensure proper installation to prevent rusting from scratches.

How Does Vinyl Coated Hardware Cloth Differ from Other Types?

Vinyl coated hardware cloth features a PVC coating that provides additional protection against the elements, making it ideal for outdoor applications. This type is often chosen for garden fencing and decorative uses because it comes in various colors that can enhance aesthetic appeal. B2B buyers should weigh the benefits of its corrosion resistance and appearance against the higher cost compared to uncoated options. Understanding the specific environmental conditions it will face is crucial for ensuring long-term effectiveness.

Why Choose Stainless Steel Hardware Cloth for Industrial Applications?

Stainless steel hardware cloth is recognized for its superior corrosion resistance and high tensile strength, making it suitable for demanding industrial applications and marine environments. Its durability allows it to withstand harsh conditions, which is a significant advantage for B2B buyers in sectors such as food processing or chemical manufacturing. However, the higher price point may deter some buyers, so it is vital to evaluate the cost against the potential longevity and reduced maintenance needs.

What Are the Benefits of Welded Wire Mesh in Construction?

Welded wire mesh is characterized by its welded intersections that provide exceptional strength and stability. This type of hardware cloth is commonly used in construction, safety barriers, and animal enclosures. B2B buyers should consider the mesh size and wire gauge when selecting welded wire mesh, as these factors affect the application suitability. While it offers high strength, it is less flexible than other types, making it essential to assess the specific needs of the project.

How Is Chicken Wire Used in Agricultural Settings?

Chicken wire, with its lightweight hexagonal mesh pattern, is primarily used for poultry enclosures and garden protection. It is a cost-effective option that is easy to handle and install, making it popular among small-scale agricultural businesses and hobbyists. However, B2B buyers should be aware that chicken wire is not as strong or durable as other hardware cloth options, so it may not be suitable for high-security applications. Understanding the specific use case will help buyers make informed purchasing decisions.

Key Industrial Applications of hardware cloth

| Industry/Sector | Specific Application of hardware cloth | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Pest control and crop protection | Prevents damage from small animals and insects, enhancing yield | Ensure appropriate mesh size and gauge for specific pests |

| Construction | Reinforcement in concrete and masonry | Increases structural integrity and longevity of builds | Consider compatibility with local building codes and environmental conditions |

| Landscaping & Gardening | Garden fencing and animal enclosures | Protects gardens from larger animals while maintaining aesthetic appeal | Assess weather resistance and durability based on regional climates |

| Manufacturing | Product screening and filtration | Ensures quality control by filtering materials in production | Evaluate gauge and material type to meet specific operational needs |

| Mining & Quarrying | Safety barriers and equipment protection | Enhances safety by preventing unauthorized access to hazardous areas | Verify compliance with safety regulations and standards in the region |

How is Hardware Cloth Used in Agriculture for Pest Control?

In agriculture, hardware cloth is extensively used for pest control and crop protection. Its mesh design allows for ventilation and sunlight penetration while effectively keeping out small animals and insects that can damage crops. For international buyers, especially in regions like Africa and South America, sourcing the right gauge and mesh size is crucial to address specific pest challenges. Understanding local agricultural practices can also guide the selection of materials that withstand environmental stresses, such as humidity or extreme temperatures.

What Role Does Hardware Cloth Play in Construction?

In the construction sector, hardware cloth serves as reinforcement in concrete and masonry applications. It enhances the structural integrity of buildings, ensuring they can withstand environmental pressures and loads over time. For buyers in Europe and the Middle East, it is essential to consider local building codes and environmental conditions when sourcing hardware cloth. Selecting a product that meets these requirements will ensure compliance and longevity of construction projects.

How is Hardware Cloth Utilized in Landscaping and Gardening?

Hardware cloth is a popular choice for landscaping and gardening, particularly for creating garden fencing and animal enclosures. It protects plants from larger animals while allowing for an aesthetically pleasing design. Buyers in regions like Kenya and Argentina should assess the durability of the material against local weather conditions, such as heavy rains or intense sun exposure. Ensuring the right height and mesh size is also vital to effectively deter specific animals common in these areas.

In What Ways Does Hardware Cloth Benefit Manufacturing?

In manufacturing, hardware cloth is utilized for product screening and filtration processes. It ensures quality control by filtering out unwanted materials during production, which is crucial for maintaining product standards. For international buyers, understanding the specific operational needs, such as the required gauge and material type, is essential. This ensures that the sourced hardware cloth aligns with production processes and enhances overall efficiency.

How is Hardware Cloth Applied in Mining and Quarrying?

In the mining and quarrying industry, hardware cloth is used as safety barriers and equipment protection. It prevents unauthorized access to hazardous areas, thereby enhancing safety for workers and equipment. Buyers must verify that the sourced hardware cloth complies with local safety regulations and standards, which can vary significantly across regions. This ensures that the implementation of hardware cloth contributes effectively to workplace safety and regulatory compliance.

3 Common User Pain Points for ‘hardware cloth’ & Their Solutions

Scenario 1: Sourcing Quality Hardware Cloth for Diverse Applications

The Problem: B2B buyers, especially in emerging markets like Kenya or Argentina, often face the challenge of sourcing high-quality hardware cloth that meets their specific needs. Whether it’s for agricultural use, construction projects, or pest control, the inconsistency in quality can lead to increased costs, project delays, and potential damage to goods or property. Buyers may struggle with unreliable suppliers who provide subpar materials, leading to a lack of trust and increased procurement complexities.

The Solution: To overcome sourcing challenges, buyers should conduct thorough research on suppliers, focusing on reputable manufacturers who specialize in hardware cloth. Look for certifications or quality assurance processes that indicate reliability. When evaluating suppliers, request samples to assess the material quality firsthand. Consider establishing long-term relationships with a few trusted suppliers to ensure consistency and reliability. Additionally, leverage local trade shows or industry events to connect with manufacturers directly, allowing for better negotiation on price and quality. This proactive approach will not only streamline the procurement process but also ensure that the hardware cloth meets the required specifications for various applications.

Scenario 2: Understanding Specifications for Different Mesh Sizes

The Problem: Another common pain point for B2B buyers is the confusion surrounding the various mesh sizes and materials available in hardware cloth. For instance, a buyer in the Middle East might be unsure whether to select a 1/4-inch or 1/2-inch mesh for a specific fencing project, leading to potential misapplications. Choosing the wrong specifications can result in inadequate protection, increased maintenance, and additional costs due to product returns or replacements.

The Solution: To make informed decisions, it is essential for buyers to understand the specific applications of different mesh sizes. A 1/4-inch mesh is typically ideal for keeping out smaller pests, while a 1/2-inch mesh may be suitable for larger animals. Buyers should also consider the gauge of the material; a higher gauge number indicates thinner wire, which may not be durable enough for high-stress applications. Engaging with suppliers for expert advice on the right specifications based on the intended use can significantly mitigate risks. Moreover, creating a detailed project plan outlining the requirements will help in selecting the appropriate hardware cloth that aligns with project goals, ensuring long-term satisfaction and effectiveness.

Scenario 3: Installation Challenges Leading to Material Waste

The Problem: Installation of hardware cloth can be a daunting task for many buyers, especially those new to construction or agricultural projects. Incorrect installation methods can lead to significant material waste and increased labor costs. For example, a buyer in South America may find that poorly installed hardware cloth fails to provide the necessary protection for crops, resulting in pest infestations and lost revenue.

The Solution: To ensure successful installation, buyers should invest time in understanding best practices and techniques for working with hardware cloth. This includes utilizing the right tools, such as wire cutters and fencing staples, and ensuring proper tension during installation to prevent sagging. Providing training for staff or hiring experienced contractors can also enhance installation quality. Additionally, buyers can refer to online resources, instructional videos, or manufacturer guidelines that detail step-by-step installation processes. By following these guidelines and potentially conducting a pilot installation, buyers can minimize waste and ensure that the hardware cloth serves its intended purpose effectively, safeguarding their investments and enhancing productivity.

Strategic Material Selection Guide for hardware cloth

When selecting hardware cloth for various applications, understanding the material properties is crucial for ensuring optimal performance and longevity. Below is an analysis of four common materials used in hardware cloth, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Galvanized Steel Hardware Cloth?

Galvanized steel is one of the most popular materials for hardware cloth due to its excellent corrosion resistance. The galvanization process involves coating the steel with a layer of zinc, which protects it from rust and degradation. This material typically withstands temperatures up to 300°F (149°C) and is suitable for various environmental conditions.

Pros: Galvanized steel is highly durable, making it ideal for outdoor applications such as fencing and pest control. It offers a good balance between cost and performance, making it accessible for many businesses.

Cons: The primary limitation is its susceptibility to scratches, which can compromise the protective coating and lead to corrosion over time. Additionally, while it is cost-effective, the initial investment can be higher than other materials.

Impact on Application: Galvanized steel hardware cloth is compatible with various media, including soil and water, making it suitable for gardening and agricultural applications.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN, particularly regarding corrosion resistance, which may vary by region.

How Does Stainless Steel Hardware Cloth Compare?

Stainless steel hardware cloth is known for its superior strength and resistance to corrosion, making it ideal for harsh environments. It can withstand extreme temperatures and pressures, with some grades capable of enduring temperatures exceeding 1000°F (538°C).

Pros: The longevity of stainless steel makes it a preferred choice for applications requiring high durability, such as industrial settings and marine environments. It also maintains its aesthetic appeal over time.

Cons: The main drawback is the higher cost compared to galvanized options, which may deter budget-conscious buyers. Manufacturing complexity can also increase due to the need for specialized equipment.

Impact on Application: Stainless steel hardware cloth is particularly effective in applications involving chemical exposure or high humidity, ensuring longevity and reliability.

Considerations for International Buyers: Compliance with international standards for food safety (like FDA regulations) is crucial for buyers in the food processing industry. Additionally, buyers should consider the availability of specific grades in their local markets.

What Are the Benefits of Vinyl-Coated Hardware Cloth?

Vinyl-coated hardware cloth combines the strength of steel with a protective vinyl layer, enhancing its resistance to corrosion and UV damage. This material is often used for decorative fencing and garden applications.

Pros: The vinyl coating provides an additional layer of protection against rust and fading, which is particularly beneficial in sunny climates. It also offers a more aesthetically pleasing finish compared to bare metal.

Cons: However, the vinyl layer can be prone to chipping or peeling over time, especially in areas with extreme temperature fluctuations. The initial cost is also higher than standard galvanized options.

Impact on Application: Vinyl-coated hardware cloth is suitable for residential applications, including gardens and pet enclosures, where both aesthetics and functionality are important.

Considerations for International Buyers: Buyers should be aware of local regulations regarding the use of PVC materials, as some regions have restrictions due to environmental concerns.

What Role Does Plastic Hardware Cloth Play?

Plastic hardware cloth, often made from polyethylene or PVC, provides a lightweight alternative to metal options. It is resistant to corrosion and UV light, making it suitable for various applications.

Pros: The primary advantage of plastic hardware cloth is its lightweight nature, making it easy to handle and install. It is also less expensive than metal options, appealing to budget-conscious buyers.

Cons: However, plastic is not as durable as metal and can be susceptible to damage from physical impacts or extreme temperatures. Its lifespan is generally shorter, especially in outdoor applications.

Impact on Application: Plastic hardware cloth is ideal for temporary fencing, gardening, and applications where weight is a concern.

Considerations for International Buyers: Compliance with local environmental regulations regarding plastic materials is essential, particularly in regions focused on sustainability.

Summary Table of Material Selection for Hardware Cloth

| Material | Typical Use Case for Hardware Cloth | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Fencing, pest control | Excellent corrosion resistance | Susceptible to scratches | Medium |

| Stainless Steel | Industrial, marine applications | High durability and temperature resistance | Higher cost, manufacturing complexity | High |

| Vinyl-Coated Steel | Decorative fencing, gardens | Aesthetic appeal and UV resistance | Prone to chipping, higher initial cost | Medium |

| Plastic | Temporary fencing, gardening | Lightweight and easy to install | Less durable, shorter lifespan | Low |

This guide provides a comprehensive overview of the strategic material selection for hardware cloth, enabling international B2B buyers to make informed decisions tailored to their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for hardware cloth

What Are the Key Manufacturing Processes for Hardware Cloth?

Manufacturing hardware cloth involves several critical stages that ensure the product meets the necessary specifications for durability and functionality. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality raw materials, primarily galvanized steel or stainless steel. The steel is sourced from reputable suppliers who meet international quality standards. The materials are then cut into specified widths and lengths, depending on the desired mesh size and gauge. Buyers should verify that the steel meets relevant specifications, such as ASTM A641 for galvanized steel.

-

Forming: In this stage, the prepared steel strips are passed through machines that form them into wire mesh. This involves weaving or welding the wires together to create the characteristic mesh pattern. There are two main techniques:

– Woven Wire Mesh: Involves interlacing wires to create various mesh patterns. This method allows for flexibility in mesh size.

– Welded Wire Mesh: Uses electric resistance welding to join the wires at their intersections, providing a more rigid structure. This is preferred for applications requiring higher strength. -

Assembly: After forming, the hardware cloth is rolled into large coils or cut into sheets, depending on customer specifications. This stage often includes additional treatments such as vinyl coating for enhanced weather resistance and aesthetic appeal.

-

Finishing: The final stage includes quality checks, surface treatment, and packaging. Products are typically galvanized or coated to prevent rust and corrosion. Buyers should look for coatings that meet international standards for durability, such as those outlined by ISO 9227 for salt spray testing.

How Is Quality Assurance Implemented in Hardware Cloth Manufacturing?

Quality assurance (QA) is crucial in ensuring that hardware cloth meets both local and international standards. Various checkpoints and testing methods are employed throughout the manufacturing process.

-

International Standards Compliance: Many manufacturers adhere to ISO 9001, which outlines requirements for a quality management system. This certification indicates that the manufacturer has processes in place to consistently produce products that meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE marking (for the European market) and API (for the oil and gas sector) may also apply.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected for compliance with specifications before they enter the production process. This ensures that only high-quality materials are used in manufacturing.

– In-Process Quality Control (IPQC): During manufacturing, random samples are tested to ensure adherence to specifications. This includes measuring mesh size, gauge, and structural integrity.

– Final Quality Control (FQC): The completed products undergo a final inspection, including testing for dimensions, strength, and corrosion resistance. This may involve destructive testing to ensure product reliability. -

Common Testing Methods:

– Tensile Strength Testing: Measures the strength of the wire to ensure it can withstand the required loads.

– Corrosion Resistance Testing: Conducted using salt spray tests to evaluate the durability of the galvanization or coatings.

– Mesh Size Verification: Ensures that the mesh size meets customer specifications, which is critical for applications in agriculture, construction, and pest control.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure product reliability.

-

Supplier Audits: Conducting regular audits of suppliers can help buyers assess their manufacturing processes and quality assurance practices. This includes checking for adherence to international standards and reviewing documentation of quality control procedures.

-

Quality Reports: Requesting quality reports from suppliers can provide insights into their testing methods and results. These reports should detail the outcomes of IQC, IPQC, and FQC processes, as well as any corrective actions taken for defects.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturer’s quality control processes. These inspections can be performed at various stages of production, providing an additional layer of assurance for buyers.

-

Certifications and Documentation: Buyers should request copies of certifications such as ISO 9001, CE, or any relevant local certifications. These documents can help confirm that the manufacturer adheres to recognized quality standards.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control is vital for international B2B buyers, particularly when dealing with suppliers from diverse regions.

-

Regional Standards Variability: Different regions may have varying standards for quality and safety. For instance, European buyers may prioritize CE marking, while African buyers might focus on local compliance standards. It’s essential to understand these differences to ensure compliance.

-

Cultural Considerations: Cultural attitudes towards quality and manufacturing practices can vary significantly. Buyers should be aware of these differences and consider them when negotiating contracts and establishing quality expectations.

-

Logistics and Supply Chain Transparency: Effective communication regarding logistics and supply chain management is crucial. Buyers should ensure that suppliers provide transparent information about sourcing, manufacturing, and delivery timelines to avoid discrepancies in quality.

In conclusion, understanding the manufacturing processes and quality assurance measures for hardware cloth is essential for B2B buyers. By focusing on detailed inspections, compliance with international standards, and thorough supplier verification methods, buyers can ensure that they procure high-quality products suited for their specific applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hardware cloth’

To successfully procure hardware cloth for your B2B needs, it’s essential to follow a structured approach that ensures quality, reliability, and value for your investment. This guide provides a step-by-step checklist tailored for international buyers, particularly from Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before you start sourcing hardware cloth, clearly outline your technical requirements. This includes mesh size, gauge, material (e.g., galvanized steel vs. vinyl-coated), and dimensions. Understanding your specific needs will help you narrow down potential suppliers who can meet your criteria.

- Mesh Size: Determine the openings you require based on the intended use (e.g., pest control, fencing).

- Material Type: Decide if you need rust-resistant options for outdoor applications.

Step 2: Research and Identify Potential Suppliers

Begin your sourcing process by researching suppliers who specialize in hardware cloth. Utilize platforms such as trade directories, industry associations, and online marketplaces to compile a list of potential vendors.

- Supplier Reputation: Look for suppliers with positive reviews and ratings in your target markets.

- Region-Specific Suppliers: Consider local suppliers to minimize shipping costs and lead times, especially important for buyers in regions like Kenya or Argentina.

Step 3: Evaluate Potential Suppliers

Thoroughly vet your shortlisted suppliers to ensure they can deliver quality products. Request company profiles, case studies, and references from buyers in similar industries or regions.

- Certifications: Check for relevant certifications (e.g., ISO) that ensure quality standards.

- Experience: Look for suppliers with a proven track record in your specific market.

Step 4: Request Samples and Compare Products

Once you have narrowed down your options, request samples of the hardware cloth. This is a critical step to assess the quality and suitability of the material for your intended application.

- Quality Assessment: Examine the durability, gauge, and finish of the samples.

- Comparative Analysis: Evaluate samples against your specifications and consider factors like flexibility and ease of installation.

Step 5: Negotiate Terms and Conditions

After selecting a supplier, initiate negotiations regarding pricing, payment terms, and delivery schedules. Ensure that both parties understand the terms clearly to avoid future disputes.

- Bulk Discounts: Inquire about pricing tiers for larger orders, which can significantly reduce costs.

- Lead Times: Discuss realistic delivery timelines to ensure your projects stay on schedule.

Step 6: Review Shipping and Import Regulations

Before finalizing your order, familiarize yourself with shipping logistics and import regulations relevant to your country. This is particularly crucial for international buyers who may face customs challenges.

- Customs Duties: Understand potential tariffs or taxes that may apply.

- Shipping Options: Explore various shipping methods and choose one that balances cost and delivery speed.

Step 7: Establish a Quality Control Process

Implement a quality control process upon receiving your hardware cloth shipment. This ensures that the products meet your specifications and are free from defects.

- Inspection Checklist: Develop a checklist based on your initial specifications to streamline the inspection process.

- Feedback Loop: Create a communication channel with your supplier for any discrepancies or issues.

By following this checklist, international B2B buyers can effectively navigate the procurement of hardware cloth, ensuring they secure high-quality materials that align with their project needs.

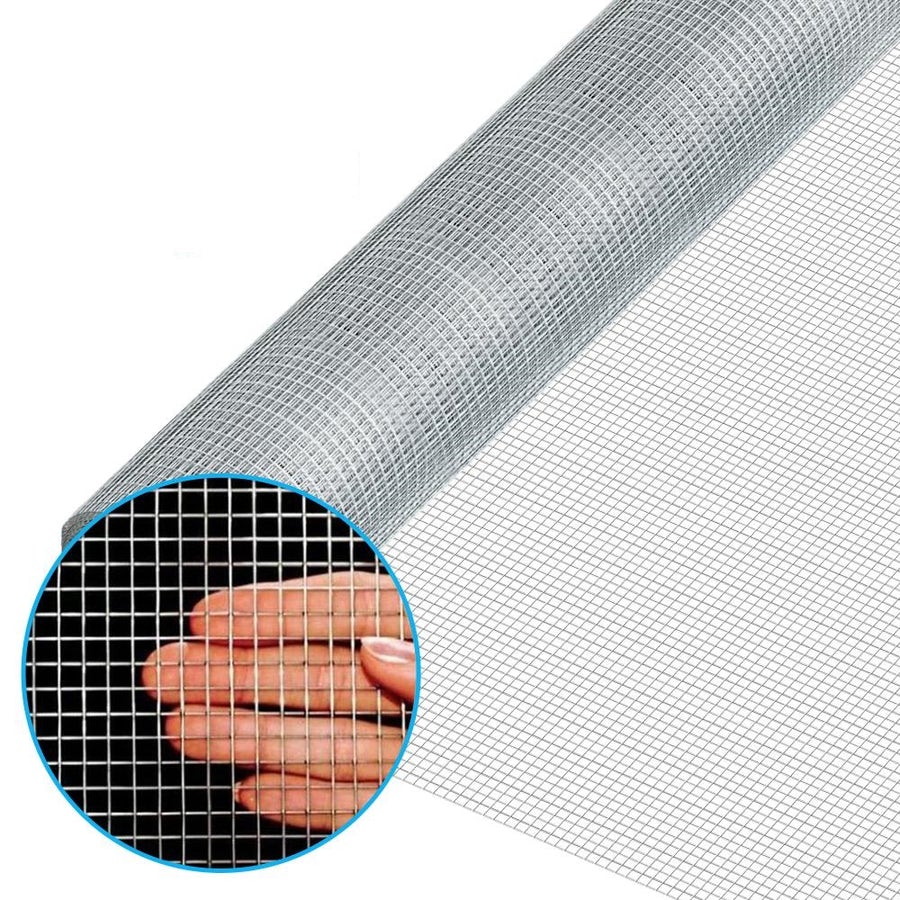

A stock image related to hardware cloth.

Comprehensive Cost and Pricing Analysis for hardware cloth Sourcing

What Are the Key Cost Components in Hardware Cloth Sourcing?

When sourcing hardware cloth, it’s crucial to understand the various cost components involved in its production and procurement. The primary elements include:

- Materials: The type of material used (e.g., galvanized steel, vinyl-coated wire) significantly affects the price. Galvanized steel is more cost-effective, while vinyl-coated options may come at a premium due to additional processing.

- Labor: Labor costs vary based on the region and the complexity of the manufacturing process. In countries with lower labor costs, such as some regions in Africa and South America, buyers may find more competitive pricing.

- Manufacturing Overhead: This includes utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce these costs, impacting the final price.

- Tooling: The cost of molds and tools used in production can be significant, particularly for custom orders. Buyers should consider whether they need standard sizes or if customized solutions are required.

- Quality Control (QC): Stringent QC measures ensure product reliability and compliance with international standards, which can add to the overall costs.

- Logistics: Transportation costs can vary widely, especially for international shipping. Factors such as distance, shipping method, and local tariffs play a crucial role in the final cost.

- Margin: Suppliers typically include a margin to cover their risks and operational costs. Understanding typical margins in your region can help in negotiations.

How Do Price Influencers Affect Hardware Cloth Costs?

Several factors can influence the pricing of hardware cloth beyond the basic cost components:

- Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for discounts, making it advantageous for businesses to consolidate purchases. Buyers should assess their needs carefully to optimize order sizes.

- Specifications and Customization: Customized products may incur additional costs. If specific dimensions or materials are required, buyers should prepare for potential price increases.

- Material Quality and Certifications: Higher-quality materials or certifications (e.g., ISO, ASTM) can lead to increased costs but may offer better durability and performance, impacting the Total Cost of Ownership (TCO).

- Supplier Factors: Supplier reputation, reliability, and location can affect pricing. Engaging with reputable suppliers may yield better quality and service but at a higher cost.

- Incoterms: Understanding shipping terms (e.g., FOB, CIF) is essential, as they dictate who bears the costs at various stages of shipping, influencing the overall expense.

What Negotiation Strategies Can International B2B Buyers Use?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation is crucial to achieving cost efficiency:

- Leverage Volume Discounts: Consolidate orders to negotiate better rates. Suppliers are often willing to provide discounts for larger volumes.

- Explore Multiple Suppliers: Research and engage with multiple suppliers to compare pricing and terms. This can provide leverage during negotiations.

- Focus on Total Cost of Ownership: Consider not just the purchase price but also shipping, installation, and maintenance costs. A slightly higher upfront price may be justified if the product offers lower long-term costs.

- Be Aware of Local Market Conditions: Prices can vary significantly based on local economic conditions. Understanding the market landscape can help in negotiations.

- Clarify Payment Terms: Negotiate favorable payment terms to improve cash flow. Suppliers may offer better prices for upfront payments.

What Pricing Nuances Should International Buyers Consider?

International B2B buyers should be aware of specific pricing nuances when sourcing hardware cloth:

- Currency Fluctuations: Be mindful of exchange rates when dealing with international suppliers, as fluctuations can impact final costs.

- Import Duties and Taxes: Understand the applicable import duties and taxes that may apply when bringing hardware cloth into your country, as these can add significant costs.

- Shipping Times: Longer shipping times can affect project timelines and, ultimately, costs. Ensure that suppliers can meet your delivery requirements.

Disclaimer on Indicative Prices

The prices for hardware cloth can vary widely based on specifications, supplier location, and market conditions. The figures provided in various sources are indicative and may not reflect current market pricing. Always conduct thorough market research and engage directly with suppliers to obtain accurate and up-to-date pricing information.

Alternatives Analysis: Comparing hardware cloth With Other Solutions

When selecting materials for fencing, garden protection, or pest control, understanding the alternatives to hardware cloth can significantly impact decision-making for international B2B buyers. This section presents a comparative analysis of hardware cloth against two viable alternatives: welded wire fencing and plastic mesh fencing. Each solution offers unique benefits and drawbacks, which can influence your purchasing choices based on specific project requirements.

| Comparison Aspect | Hardware Cloth | Welded Wire Fencing | Plastic Mesh Fencing |

|---|---|---|---|

| Performance | Excellent for small animal control and garden protection due to fine mesh. | Strong and durable; ideal for larger animals and long-term use. | Lightweight and flexible; suitable for temporary barriers. |

| Cost | Moderate cost, varies by gauge and size (approx. $11.62 – $249.99). | Generally higher cost due to strength and durability (approx. $150 – $500). | Lower cost, typically ranging from $20 to $100. |

| Ease of Implementation | Requires basic tools for installation; relatively easy to work with. | More complex installation; may require professional help for larger projects. | Very easy to install; often comes in rolls that can be cut to size. |

| Maintenance | Low maintenance; galvanized options resist rust and corrosion. | Low maintenance; very durable but may require occasional tightening. | Moderate maintenance; UV exposure can lead to degradation over time. |

| Best Use Case | Ideal for gardens, small animal enclosures, and pest control. | Best for livestock fencing, security applications, and long-term installations. | Suitable for temporary fencing, garden protection, and lightweight barriers. |

What are the Advantages and Disadvantages of Welded Wire Fencing?

Welded wire fencing consists of intersecting wires that are welded together at each junction, creating a robust and stable structure. Its primary advantage is its strength, making it suitable for containing larger animals and providing a high level of security. Additionally, it can withstand harsh weather conditions and is long-lasting. However, the installation process can be more complex, requiring specialized tools and potentially professional assistance. The higher initial cost may also deter some buyers, especially those with budget constraints.

How Does Plastic Mesh Fencing Compare?

Plastic mesh fencing is often used for temporary applications, such as garden protection or lightweight barriers. Its primary advantages include low cost and ease of installation, making it accessible for quick projects. The flexibility of plastic mesh allows for easy adjustments and repositioning. However, its lightweight nature means it may not withstand heavy pressure or harsh weather conditions as effectively as hardware cloth or welded wire fencing. Over time, exposure to UV rays can lead to brittleness and degradation, necessitating replacement.

How Can B2B Buyers Choose the Right Solution?

When determining the most suitable fencing solution, B2B buyers should consider their specific needs, including the purpose of the fencing, budget constraints, and installation capabilities. Hardware cloth is an excellent choice for those focused on small-scale projects requiring fine mesh, while welded wire fencing is ideal for more extensive applications demanding strength and durability. Plastic mesh fencing serves well for temporary needs but may not provide the long-term security or durability of the other options. Assessing these factors will lead to a more informed purchasing decision, ensuring the selected solution aligns with business objectives and project requirements.

Essential Technical Properties and Trade Terminology for hardware cloth

What Are the Essential Technical Properties of Hardware Cloth?

When sourcing hardware cloth, understanding its technical properties is crucial for international B2B buyers. These specifications not only influence the product’s performance but also its suitability for various applications. Here are some key properties to consider:

1. Material Grade: What is Hardware Cloth Made Of?

Hardware cloth is typically made from galvanized steel or stainless steel, providing durability and resistance to corrosion. The choice of material impacts the cloth’s longevity and performance in outdoor environments, making it essential for buyers in regions with harsh weather conditions, such as parts of Africa and the Middle East. Stainless steel options are more expensive but offer superior rust resistance, which may be a critical factor for long-term projects.

2. Mesh Size: How Does Mesh Size Affect Functionality?

The mesh size, defined as the space between the wires, is a critical specification that determines what can pass through the cloth. Common sizes include 1/4 inch, 1/2 inch, and 1 inch. Smaller mesh sizes are ideal for pest control and securing small animals, while larger sizes may be suitable for fencing and garden protection. Buyers must consider their specific needs to select the appropriate mesh size that balances functionality and visibility.

3. Gauge: Why is Wire Gauge Important?

The gauge of the wire indicates its thickness, with lower numbers representing thicker wires. Hardware cloth typically ranges from 19-gauge (thinner) to 12-gauge (thicker). Thicker wires are more robust and suitable for high-stress applications, such as security fencing, while thinner options may suffice for lightweight uses, such as garden fencing. Selecting the right gauge is vital for ensuring the product meets performance requirements without incurring unnecessary costs.

4. Roll Size: What Are the Common Roll Dimensions?

Hardware cloth is available in various roll sizes, commonly ranging from 25 feet to 100 feet in length. The height can vary from 2 feet to 6 feet. For B2B buyers, understanding the available roll sizes is essential for estimating project requirements and minimizing waste. Bulk purchasing can also lead to cost savings, making it imperative to evaluate the dimensions based on specific project needs.

5. Coating: How Does Coating Affect Longevity?

Many hardware cloth products are coated with vinyl or PVC to enhance corrosion resistance and improve aesthetics. Vinyl-coated options are particularly popular for outdoor applications where visual appeal matters, such as in gardens or parks. Buyers should weigh the benefits of additional coatings against their budget, as these can significantly increase the price.

What Are Common Trade Terms in Hardware Cloth Procurement?

Understanding trade terminology is essential for effective communication and negotiation in the B2B marketplace. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer): What Does OEM Mean?

OEM refers to companies that produce products that are then marketed under another company’s brand. In hardware cloth procurement, knowing whether a supplier is an OEM can help buyers assess the quality and reliability of the product, as OEMs often adhere to strict manufacturing standards.

2. MOQ (Minimum Order Quantity): Why is MOQ Important?

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for international buyers, as it can affect inventory management and overall project costs. Understanding MOQ helps buyers plan their purchases effectively and avoid unnecessary surplus or stock shortages.

3. RFQ (Request for Quotation): How to Use RFQs Effectively?

An RFQ is a document sent to suppliers requesting pricing information for specific products. This process allows buyers to compare quotes from different suppliers, ensuring competitive pricing and better negotiation leverage. Crafting a clear and detailed RFQ can significantly enhance the procurement process.

4. Incoterms (International Commercial Terms): What Are Incoterms?

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms helps buyers understand shipping costs, risk transfer, and delivery responsibilities, which are vital for calculating total landed costs when importing hardware cloth.

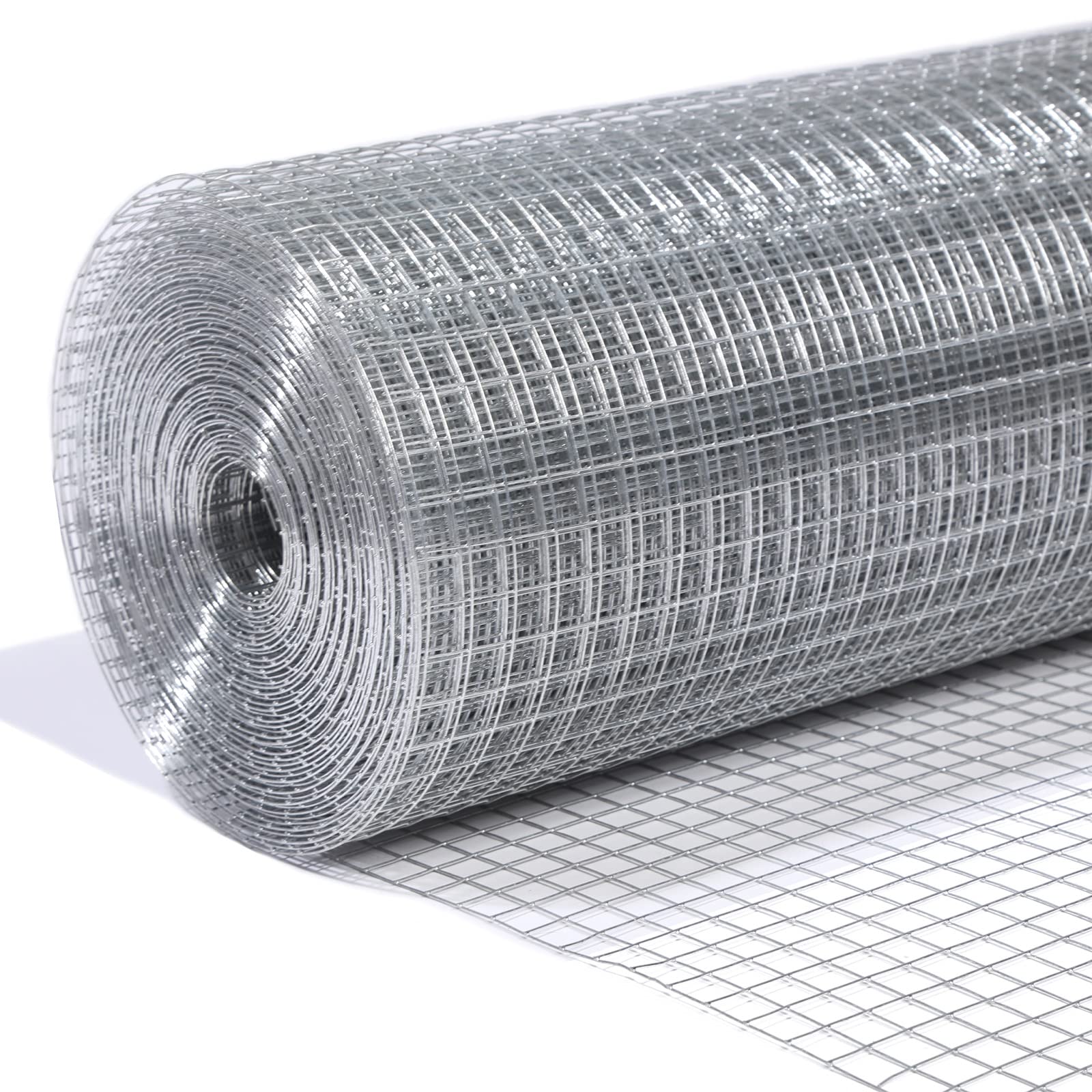

A stock image related to hardware cloth.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, optimize their procurement processes, and ensure they select the right hardware cloth for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the hardware cloth Sector

What Are the Key Market Trends Impacting the Hardware Cloth Sector?

The hardware cloth market is witnessing significant growth, driven by various global factors. Increasing urbanization, especially in regions like Africa and South America, has heightened the demand for fencing solutions for agricultural, residential, and commercial applications. The rise in DIY projects, fueled by online tutorials and home improvement shows, also contributes to market expansion as more consumers seek durable and versatile materials.

Emerging technologies are reshaping how buyers source hardware cloth. E-commerce platforms are becoming the go-to for international buyers, offering competitive pricing and greater access to a diverse range of products. Additionally, advanced manufacturing techniques, such as automated welding and coatings, are enhancing product durability and performance, making hardware cloth a preferred choice in various applications, including pest control and garden fencing.

For buyers in Africa, South America, the Middle East, and Europe, understanding regional market dynamics is crucial. In Africa, for example, the agricultural sector’s growth presents opportunities for sourcing hardware cloth for crop protection and livestock fencing. In contrast, South American markets may focus more on construction and residential applications. International buyers must stay informed about local regulations, import tariffs, and supplier reliability to navigate these markets effectively.

How Can Sustainability and Ethical Sourcing Be Incorporated into Hardware Cloth Procurement?

Sustainability is becoming an essential consideration for B2B buyers in the hardware cloth sector. The environmental impact of production processes, particularly in metal sourcing and manufacturing, is under scrutiny. Buyers should prioritize suppliers that adopt sustainable practices, such as using recycled materials and implementing energy-efficient manufacturing processes.

Ethical sourcing is equally important. Buyers should seek manufacturers with transparent supply chains and certifications that indicate responsible practices, such as ISO 14001 for environmental management or Fair Trade certifications. These certifications not only enhance brand reputation but also resonate with increasingly eco-conscious consumers.

The demand for ‘green’ materials is growing. Buyers can explore options like vinyl-coated hardware cloth, which offers enhanced durability and corrosion resistance while minimizing environmental impact. By integrating sustainability and ethical sourcing into their procurement strategies, B2B buyers can align with global trends and meet the expectations of modern consumers.

What Is the Historical Context of Hardware Cloth and Its Relevance Today?

The history of hardware cloth dates back to the early 19th century when it was primarily used for agricultural fencing and pest control. Initially made from woven wire, its evolution into galvanized and vinyl-coated varieties has broadened its applications. Today, hardware cloth is not only essential for agriculture but also for construction, landscaping, and DIY projects.

Understanding this historical context is vital for B2B buyers. It highlights the adaptability of hardware cloth and its capacity to meet evolving market needs. As the demand for versatile, durable, and sustainable materials continues to rise, hardware cloth remains a relevant choice across multiple sectors. Buyers should leverage this knowledge to make informed purchasing decisions that align with both current trends and historical reliability.

Frequently Asked Questions (FAQs) for B2B Buyers of hardware cloth

-

How do I choose the right gauge of hardware cloth for my project?

Selecting the appropriate gauge of hardware cloth depends on its intended application. Thicker gauges (like 14-19) are better suited for stronger applications such as animal enclosures or fencing, while thinner gauges (like 20-27) are ideal for light-duty tasks such as garden protection. Consider factors like the size of animals or pests you are trying to deter, environmental conditions, and budget constraints. It’s advisable to consult with suppliers about the best gauge for your specific needs. -

What is the best material for hardware cloth in humid environments?

For humid environments, galvanized steel hardware cloth is often the best choice due to its resistance to rust and corrosion. If you are operating in an area with extreme moisture levels, consider vinyl-coated options for additional protection. Ensure that the product is designed for outdoor use and check the manufacturer’s specifications for durability in wet conditions. Consulting local suppliers can also provide insights on the best materials suited to your regional climate. -

How can I effectively vet suppliers of hardware cloth for international trade?

To vet suppliers, start by checking their business credentials and industry reputation. Look for reviews, testimonials, and case studies from previous clients, particularly those in your region (Africa, South America, Middle East, Europe). Verify their certifications and compliance with international standards. Establish communication to gauge their responsiveness and willingness to address your specific needs. Utilizing trade platforms and industry networks can also help identify reliable suppliers. -

What are common minimum order quantities (MOQs) for hardware cloth?

Minimum order quantities for hardware cloth can vary significantly based on the supplier and the product specifications. Typically, MOQs range from 100 to 1,000 square feet or more. When sourcing, inquire directly with suppliers about their MOQs, as they may offer flexibility for first-time buyers or bulk orders. Understanding your project needs and discussing them upfront can facilitate better terms and potentially lower MOQs. -

What payment terms should I expect when sourcing hardware cloth internationally?

Payment terms can vary widely, but typical arrangements include advance payment, net 30, or letters of credit. For first-time purchases, many suppliers may require a partial upfront payment. Always clarify payment methods accepted (e.g., wire transfer, PayPal) and any transaction fees. It’s also wise to negotiate terms that allow for payment upon delivery or after inspection to mitigate risk. Establishing a clear contract can protect both parties. -

How do I ensure quality assurance (QA) for hardware cloth products?

Quality assurance can be ensured by requesting product samples before placing a bulk order. Confirm that the supplier adheres to international quality standards and provides certifications for their products. Inquire about their quality control processes, including inspections during production and pre-shipping checks. Additionally, consider incorporating third-party inspections or audits, especially for large orders, to validate product specifications and quality.

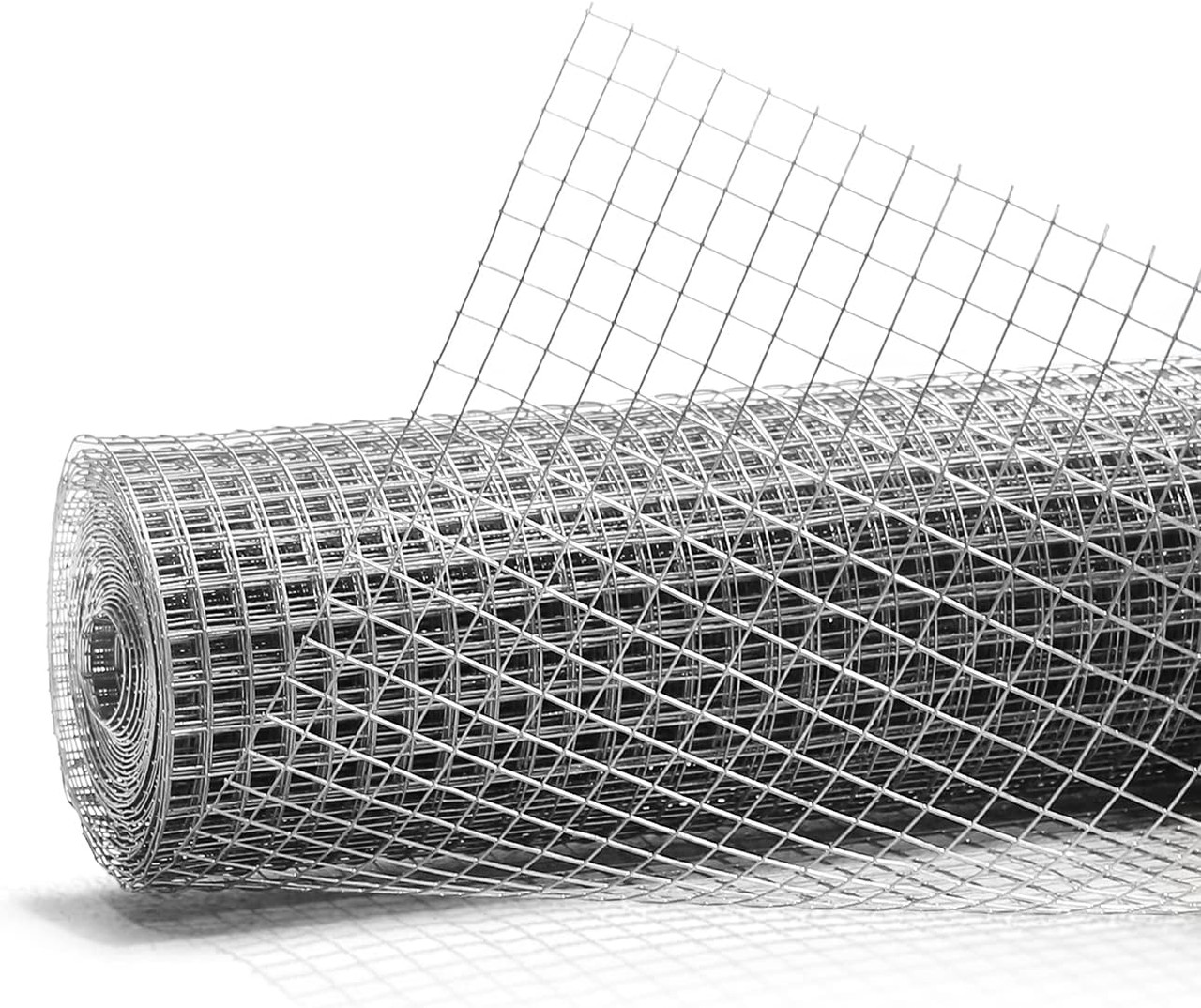

A stock image related to hardware cloth.

-

What logistics considerations should I keep in mind when importing hardware cloth?

Logistics considerations include shipping methods, customs regulations, and freight costs. Choose a reliable shipping partner familiar with international shipping protocols to avoid delays. Understand your country’s import regulations, including tariffs and duties applicable to hardware cloth. Coordinate with your supplier to ensure proper labeling and documentation for customs clearance. Planning for potential delays in shipping and customs can also help mitigate risks. -

Can hardware cloth be customized for specific applications?

Yes, many suppliers offer customization options for hardware cloth, including mesh size, gauge, and dimensions. Customization is particularly useful for specialized applications, such as specific animal enclosures or unique construction projects. When inquiring about customization, provide detailed specifications and ask for samples of custom products. Discuss lead times and any additional costs associated with customized orders to ensure they fit within your project timeline and budget.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for hardware cloth

In conclusion, the strategic sourcing of hardware cloth presents a significant opportunity for international B2B buyers. Understanding the diverse applications of hardware cloth—from agricultural fencing to pest control—enables businesses to tailor their sourcing strategies effectively. Buyers should prioritize suppliers that offer a variety of materials, such as galvanized steel and vinyl-coated options, ensuring they meet specific project requirements while maintaining quality and durability.

How Can Strategic Sourcing Enhance Your Business Operations?

Strategic sourcing not only reduces costs but also fosters long-term supplier relationships, which are crucial in today’s competitive landscape. By leveraging global suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, buyers can enhance their supply chain resilience and adaptability. This is especially pertinent for businesses in countries such as Kenya and Argentina, where local sourcing may be limited.

What’s Next for International Buyers of Hardware Cloth?

As market demands evolve, staying ahead of trends in product specifications and pricing is vital. Engage with suppliers who are proactive in offering innovative solutions and flexible terms. By doing so, you position your business for future growth and sustainability in the hardware cloth sector. Embrace the potential of strategic sourcing today to unlock new avenues for success in your operations.