Discover Cost-Effective Types of Latches for Your Business (2025)

Introduction: Navigating the Global Market for types of latches

In today’s dynamic global market, effectively sourcing the right types of latches can be a daunting task for international B2B buyers. With a plethora of options ranging from door latches to rotary and magnetic latches, understanding which type best meets your specific application requirements is crucial. This comprehensive guide delves into the various types of latches, their applications across industries, and best practices for supplier vetting. By offering insights into cost considerations and quality standards, this guide equips buyers from Africa, South America, the Middle East, and Europe—particularly Turkey and Mexico—with the knowledge needed to make informed purchasing decisions.

Navigating the complexities of latch sourcing is not just about selecting a product; it’s about ensuring compatibility with your business needs, enhancing security, and optimizing operational efficiency. Whether you are looking for robust gate latches for agricultural purposes or flexible rubber latches for automotive applications, understanding the nuances of each type will empower you to negotiate better terms and establish reliable supplier relationships. This guide aims to demystify the latch market, providing actionable insights that can lead to smarter investments and improved supply chain management.

With this resource at your fingertips, you can confidently approach your sourcing strategy, ensuring that you procure the most suitable latches that align with your operational goals and budget constraints.

Understanding types of latches Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Door Latch | Simple mechanical fastener, often used in residential and commercial doors. | Construction, real estate, security systems | Pros: Cost-effective, easy to install. Cons: May not provide high security. |

| Gate Latch | Utilizes a metal bar and lever mechanism, often seen in outdoor settings. | Fencing, agriculture, outdoor structures | Pros: Durable, weather-resistant. Cons: Limited locking options. |

| Magnetic Door Latch | Uses a magnet and striking pad, ideal for light-duty applications. | Retail displays, light commercial doors | Pros: Quiet operation, easy to install. Cons: Less secure than mechanical latches. |

| Rotary Latch | Features a rotating mechanism for secure closures, often used in automotive applications. | Automotive, industrial machinery, cabinetry | Pros: High security, prevents accidental openings. Cons: More complex installation. |

| Spring Latch | Utilizes spring compression to hold components together, often self-locking. | Furniture, automotive, industrial equipment | Pros: Reliable and self-closing. Cons: May wear out over time with frequent use. |

What Are the Characteristics and Suitability of Door Latches for B2B Buyers?

Door latches are fundamental mechanical fasteners widely utilized in both residential and commercial settings. They provide a simple yet effective means of securing doors. For B2B buyers in construction and real estate, these latches offer a cost-effective solution that is easy to install. However, their simplicity can also be a drawback, as they may not provide the high-security levels required in certain environments. Buyers should consider the specific security needs of their applications when choosing door latches.

How Do Gate Latches Serve Different B2B Applications?

Gate latches are characterized by their robust metal bar and lever design, making them ideal for securing gates in outdoor settings such as farms, gardens, and public parks. They are particularly valued in the agricultural sector and for fencing applications due to their durability and weather resistance. While they are effective for outdoor use, buyers should note that gate latches typically offer limited locking options, which may not meet all security requirements.

What Makes Magnetic Door Latches Ideal for Retail and Light Commercial Use?

Magnetic door latches operate using a magnet and a striking pad, providing a quiet and efficient closure for light-duty applications. They are commonly used in retail displays and light commercial doors, where aesthetics and ease of use are critical. B2B buyers appreciate their straightforward installation process; however, it is essential to recognize that magnetic latches may not provide the same level of security as mechanical alternatives, making them suitable primarily for low-risk environments.

Why Choose Rotary Latches for High-Security Applications?

Rotary latches utilize a unique rotating mechanism to secure closures, making them particularly effective in high-security applications such as automotive and industrial machinery. Their design prevents accidental openings, which is crucial in environments where safety and security are paramount. B2B buyers should consider the complexity of installation and potential costs associated with rotary latches, as these may vary depending on the specific application and required security level.

What Are the Advantages and Considerations for Spring Latches in Various Industries?

Spring latches are versatile devices that use spring compression to hold components securely together. They are commonly found in furniture, automotive applications, and industrial equipment. Their self-locking feature makes them reliable for frequent use. However, B2B buyers should be aware that the longevity of spring latches may be compromised with heavy usage, necessitating regular maintenance or replacement. Understanding the operational demands of the intended application is crucial for making informed purchasing decisions.

Key Industrial Applications of types of latches

| Industry/Sector | Specific Application of Types of Latches | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Use of spring latches in vehicle doors | Enhances safety and convenience in vehicle access | Durability, weight, and resistance to environmental factors |

| Aerospace | Rubber latches in aircraft access panels | Provides secure closure while minimizing weight | Material certification, compliance with aviation standards |

| Construction | Gate latches for fencing and access control | Improves security and access management in construction sites | Weather resistance, ease of installation, and maintenance |

| Electronics | Rotary latches in electronic device enclosures | Protects sensitive components while allowing easy access | Size specifications, locking mechanism reliability |

| Medical Equipment | Magnetic latches in medical storage cabinets | Ensures safety and organization of medical supplies | Sterilization compatibility, ease of use, and durability |

How Are Types of Latches Utilized in the Automotive Sector?

In the automotive industry, spring latches are widely used in vehicle doors to ensure secure closure while allowing for quick access. These latches enhance safety by preventing accidental openings during transit. Buyers in this sector should prioritize sourcing latches that are durable and lightweight, as these factors contribute to overall vehicle performance and safety. Additionally, resistance to environmental factors, such as moisture and temperature variations, is crucial for longevity.

What Role Do Types of Latches Play in Aerospace Applications?

Rubber latches are integral to the aerospace sector, particularly in securing access panels on aircraft. Their flexibility and lightweight properties contribute to overall weight reduction, which is critical in aviation. Buyers must consider material certification and compliance with stringent aviation standards to ensure safety and performance. Furthermore, the ability of rubber latches to withstand extreme conditions is essential for operational reliability.

Why Are Gate Latches Important in Construction?

Gate latches are commonly employed in construction to secure fencing and manage access control on job sites. They enhance security, preventing unauthorized entry while allowing for easy access for workers and equipment. When sourcing gate latches, businesses should focus on weather resistance and ease of installation, as these attributes can significantly affect site management and safety protocols.

How Are Rotary Latches Used in Electronics?

In the electronics industry, rotary latches are utilized in enclosures for electronic devices, providing a reliable locking mechanism that protects sensitive components. These latches facilitate easy access for maintenance while ensuring that devices remain secure. Buyers should pay attention to size specifications and the reliability of the locking mechanism to ensure compatibility with their designs and operational needs.

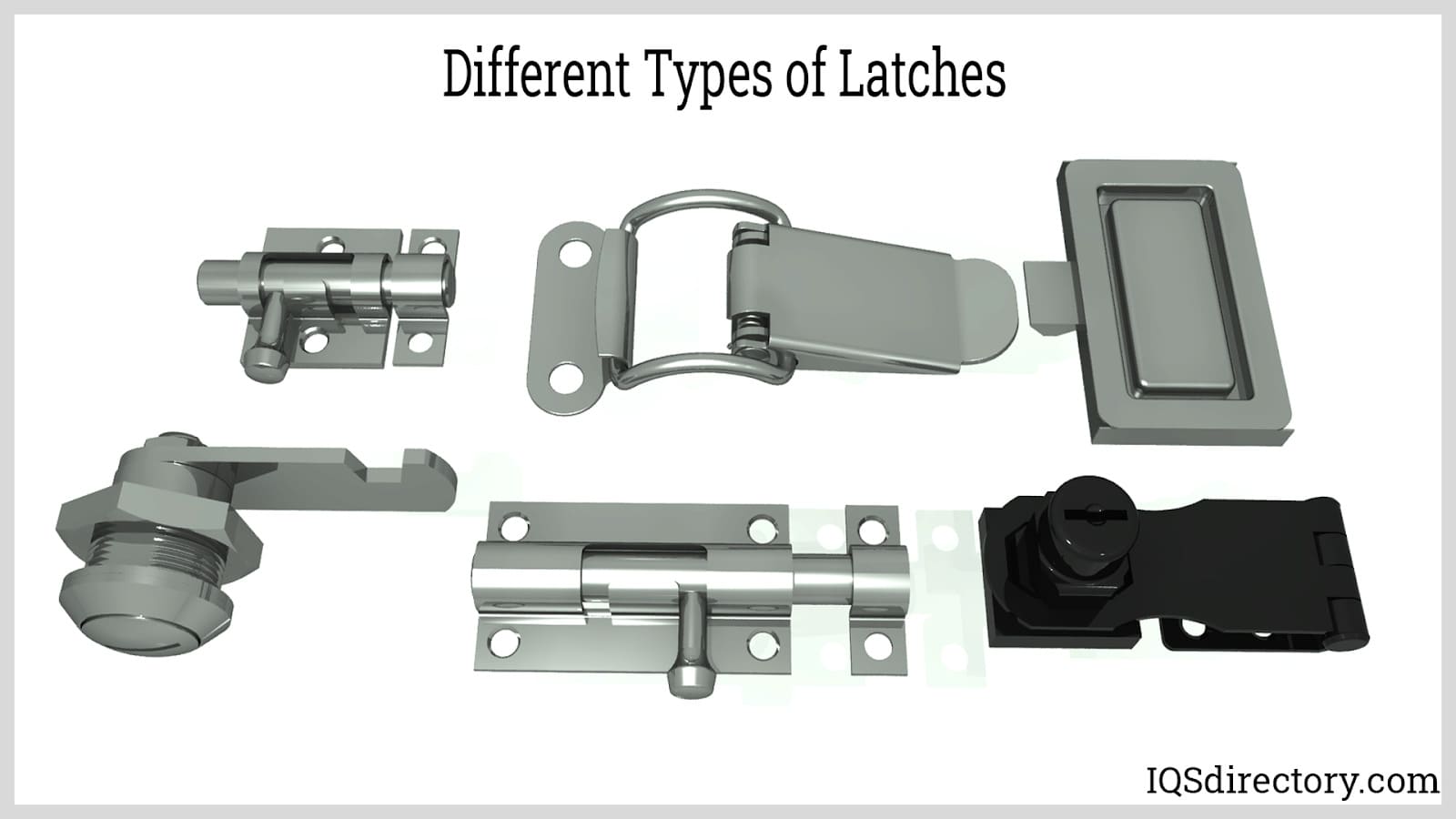

A stock image related to types of latches.

What Benefits Do Magnetic Latches Offer in Medical Equipment?

Magnetic latches find significant application in medical storage cabinets, ensuring that supplies are organized and securely stored. Their ease of use is particularly beneficial in fast-paced medical environments, where quick access to supplies is critical. When sourcing magnetic latches, buyers must consider sterilization compatibility and overall durability to meet the demanding requirements of medical settings.

3 Common User Pain Points for ‘types of latches’ & Their Solutions

Scenario 1: Insufficient Security in Outdoor Installations

The Problem: Many B2B buyers face significant security challenges when selecting latches for outdoor installations, such as gates and fences. In regions with higher crime rates, such as certain areas in South America and Africa, the need for durable and secure latches becomes paramount. Buyers may find that standard latches do not provide the necessary protection against unauthorized access, leading to potential theft and vandalism. Additionally, the harsh weather conditions in these regions can cause latches to corrode or fail, exacerbating security issues.

The Solution: To enhance security in outdoor environments, B2B buyers should consider investing in heavy-duty gate latches made from corrosion-resistant materials, such as stainless steel or high-grade aluminum. These materials not only withstand the elements but also deter tampering. Buyers should also specify latches with advanced locking mechanisms, such as deadbolts or padlocks, which offer an additional layer of security. It’s crucial to partner with reputable suppliers that provide warranties and detailed specifications. Regular maintenance, including lubrication and inspection, can further ensure that latches function optimally over time, reducing the risk of failure.

Scenario 2: Incompatibility with Existing Systems

The Problem: Another common pain point for B2B buyers is the incompatibility of new latching systems with existing infrastructure. For instance, a company in Turkey may be upgrading its storage facilities and encounters difficulties when the new latches do not fit with the pre-installed hardware. This issue can lead to additional costs and delays, as modifications or replacements may be necessary to achieve compatibility.

The Solution: To mitigate this risk, it’s essential for buyers to conduct a thorough assessment of the existing systems before purchasing new latches. This includes measuring dimensions, understanding the locking mechanism, and considering the materials in use. Suppliers often provide technical support and design consultations to help ensure that the selected latches will fit seamlessly with current setups. Additionally, opting for adjustable or modular latch systems can provide flexibility, allowing for easier integration with various configurations. Investing in customizable latches can also help ensure compatibility across different applications, saving time and reducing costs.

Scenario 3: Frequent Wear and Tear in High-Usage Environments

The Problem: In sectors like manufacturing or logistics, where doors and gates are opened and closed frequently, standard latches can wear out quickly, leading to operational inefficiencies. B2B buyers may find themselves replacing latches more often than anticipated, resulting in increased maintenance costs and downtime that can affect productivity.

The Solution: To address this issue, buyers should consider heavy-duty latches specifically designed for high-usage environments. Look for latches made from robust materials and engineered for durability, such as those utilizing reinforced steel components or advanced polymers. It’s also advisable to choose latches with features like self-closing mechanisms, which can reduce wear by minimizing the frequency of manual operation. Implementing a proactive maintenance schedule, including regular inspections and timely replacements, can also prevent unexpected failures. Establishing a relationship with a supplier that offers bulk purchasing options for latches can help manage costs while ensuring that replacements are readily available when needed.

Strategic Material Selection Guide for types of latches

What Are the Key Materials Used in Types of Latches?

When selecting latches for various applications, the choice of material is crucial. Different materials offer distinct properties that can significantly affect the latch’s performance, durability, and suitability for specific environments. Here, we analyze four common materials used in latch manufacturing: stainless steel, aluminum, plastic, and brass.

How Does Stainless Steel Perform in Latch Applications?

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, high tensile strength, and ability to withstand elevated temperatures. It typically has a temperature rating of up to 800°F (427°C) and can handle high-pressure environments, making it suitable for industrial applications.

Pros & Cons: The primary advantage of stainless steel latches is their durability and resistance to rust and corrosion, which is essential in harsh environments. However, they can be more expensive compared to other materials and may require more complex manufacturing processes, which can increase lead times.

Impact on Application: Stainless steel latches are ideal for applications in the automotive, aerospace, and marine industries, where exposure to moisture and corrosive elements is common. They are also compatible with various media, including chemicals and salty environments.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with international standards such as ASTM and ISO. Additionally, local availability and sourcing of stainless steel can affect costs and lead times.

What Are the Advantages of Aluminum Latches?

Key Properties: Aluminum is lightweight and has good corrosion resistance, especially when anodized. It can withstand temperatures up to 400°F (204°C) and is suitable for moderate pressure applications.

Pros & Cons: The lightweight nature of aluminum latches makes them easy to handle and install, reducing labor costs. However, they are less durable than stainless steel and may not perform well in high-stress applications, leading to potential deformation over time.

Impact on Application: Aluminum latches are commonly used in consumer products, including electronics and lightweight machinery, where weight savings are crucial. They are also suitable for applications that require frequent handling.

Considerations for International Buyers: Buyers in South America and Europe should consider the anodizing process to enhance corrosion resistance. Compliance with local regulations regarding lightweight materials is also essential.

Why Choose Plastic for Latch Manufacturing?

Key Properties: Plastic latches are typically made from high-density polyethylene (HDPE) or polycarbonate, offering good chemical resistance and lightweight properties. They can operate effectively at temperatures ranging from -40°F to 180°F (-40°C to 82°C).

Pros & Cons: The primary advantage of plastic latches is their cost-effectiveness and ease of manufacturing. However, they are less durable than metal latches and may not withstand extreme temperatures or heavy loads.

Impact on Application: Plastic latches are often used in household products, packaging, and applications where weight and cost are significant factors. They are compatible with various media, including some chemicals, but not all.

Considerations for International Buyers: Buyers from regions like Turkey and Mexico should ensure that the plastics used meet local environmental regulations. Additionally, understanding the limitations of plastic in high-stress environments is crucial.

What Role Does Brass Play in Latch Design?

Key Properties: Brass offers good corrosion resistance, particularly in marine environments, and has a moderate temperature rating of around 300°F (149°C). It is also malleable, allowing for intricate designs.

Pros & Cons: The aesthetic appeal of brass makes it a popular choice for decorative latches. However, it can be more expensive than other materials and may require regular maintenance to prevent tarnishing.

Impact on Application: Brass latches are commonly used in furniture, cabinetry, and decorative applications where appearance is as important as functionality. They are suitable for low to moderate stress applications.

Considerations for International Buyers: Buyers in Europe should be aware of regulations regarding the use of brass, especially concerning lead content. Ensuring compliance with local standards is essential for market acceptance.

Summary Table of Material Selection for Types of Latches

| Material | Typical Use Case for types of latches | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial, automotive, marine | Excellent corrosion resistance | Higher cost, complex mfg | High |

| Aluminum | Consumer products, lightweight machinery | Lightweight, easy to handle | Less durable under stress | Medium |

| Plastic | Household products, packaging | Cost-effective, easy to manufacture | Less durable, temperature sensitive | Low |

| Brass | Furniture, cabinetry, decorative use | Aesthetic appeal, good corrosion resistance | Higher cost, requires maintenance | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for types of latches

What Are the Key Stages in the Manufacturing Process for Types of Latches?

The manufacturing process for latches involves several critical stages that ensure the final product meets the required specifications and quality standards. Understanding these stages can help B2B buyers evaluate potential suppliers more effectively.

How Is Material Prepared for Latch Manufacturing?

Material preparation is the first step in the manufacturing of latches. This stage involves selecting high-quality raw materials, such as stainless steel, brass, or durable plastics, depending on the application. The materials are then subjected to processes like cutting, machining, and surface treatment to achieve the desired dimensions and properties.

For example, stainless steel is often chosen for its corrosion resistance and strength, making it suitable for outdoor applications like gate latches. Buyers should inquire about the sourcing of materials and whether they comply with international standards to ensure durability and reliability.

What Forming Techniques Are Used in Latch Production?

The forming stage is where the raw materials are shaped into the components of the latches. Common techniques include:

- Stamping: This involves using a die to cut and shape metal sheets into specific forms, such as latch plates and hooks.

- Injection Molding: For plastic latches, this process involves injecting molten plastic into molds to create precise shapes.

- Machining: This technique uses tools like lathes and mills to refine the shapes and ensure tight tolerances.

Each forming method has its advantages, such as cost-effectiveness or precision. B2B buyers should evaluate which techniques suppliers use based on their specific requirements.

How Are Latches Assembled During Production?

Once the components are formed, the assembly stage begins. This can involve manual or automated processes, depending on the complexity of the latch design. Key assembly techniques include:

- Mechanical Fastening: Using screws, bolts, or rivets to hold parts together securely.

- Welding: For metal latches, welding may be used to join components for enhanced strength.

- Adhesive Bonding: In some cases, adhesives are applied for additional sealing and strength.

A stock image related to types of latches.

Quality during assembly is crucial, as any misalignment can affect the latch’s performance. Buyers should look for suppliers who have detailed assembly protocols and quality checks in place.

What Finishing Processes Are Important for Latches?

Finishing processes enhance the aesthetic appeal and functional performance of latches. Common finishing techniques include:

- Plating: Applying a layer of metal (e.g., nickel, chrome) to improve corrosion resistance and appearance.

- Painting: Providing color and further protection against environmental factors.

- Polishing: Achieving a smooth surface finish that reduces friction and enhances durability.

A well-executed finishing process can significantly extend the lifespan of latches, making it an essential consideration for B2B buyers.

What Quality Assurance Measures Are Essential for Latch Manufacturing?

Quality assurance (QA) is vital in the manufacturing process to ensure that latches meet industry standards and customer expectations.

Which International Standards Should Buyers Be Aware Of?

International standards such as ISO 9001 are fundamental for ensuring consistent quality in manufacturing processes. This standard outlines requirements for a quality management system, helping manufacturers improve their operations and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets or API (American Petroleum Institute) for oil and gas applications may be relevant.

B2B buyers should verify that their suppliers are certified under these standards, which can serve as a proxy for quality assurance.

What Are the Key Quality Control Checkpoints in Latch Production?

Quality control (QC) involves several checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process help identify defects early on.

- Final Quality Control (FQC): The last stage of inspection before products are shipped, ensuring that all specifications are met.

These checkpoints help maintain high standards throughout production, reducing the likelihood of defects in the final product.

What Common Testing Methods Are Used to Ensure Latch Quality?

Testing methods for latches can vary based on their application but often include:

- Functional Testing: Ensuring the latch operates correctly under expected conditions.

- Durability Testing: Assessing how well the latch withstands wear, corrosion, and environmental stress.

- Load Testing: Evaluating the latch’s strength by applying weight to see if it can hold under pressure.

B2B buyers should ask suppliers about their testing protocols to ensure that they are rigorous and align with industry standards.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of a supplier’s quality control measures is crucial for B2B buyers, especially when sourcing from international markets. Here are some strategies:

What Are Effective Ways to Conduct Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess quality control processes. Buyers should develop a checklist based on industry standards, including:

- Evaluation of manufacturing processes and equipment.

- Review of quality assurance documentation and records.

- Assessment of employee training programs related to quality control.

Regular audits can help identify potential issues before they become significant problems.

How Can Buyers Use QC Reports to Ensure Product Integrity?

Requesting quality control reports from suppliers can provide insights into their processes and outcomes. These reports should detail:

- Results from various quality checks at different stages of production.

- Compliance with international standards and certifications.

- Any corrective actions taken in response to identified issues.

By analyzing these reports, B2B buyers can make informed decisions about supplier reliability.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can further enhance quality assurance. These independent organizations can provide unbiased evaluations of a supplier’s manufacturing processes, quality control measures, and final products. This added layer of scrutiny helps mitigate risks associated with international sourcing.

What Are the Unique Quality Control Considerations for International B2B Buyers?

B2B buyers from Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control when sourcing latches internationally.

How Do Cultural and Regulatory Differences Impact Quality Assurance?

Cultural differences can influence manufacturing practices and quality perceptions. Buyers should familiarize themselves with local regulations and industry practices in the supplier’s country. Additionally, understanding the regulatory environment can help ensure compliance with international standards.

What Are the Challenges of Quality Control in Global Supply Chains?

Global supply chains often face challenges such as communication barriers, time zone differences, and varying quality expectations. Establishing clear communication channels and expectations from the outset can help mitigate these challenges.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make more informed decisions when sourcing latches, ultimately leading to better product performance and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of latches’

In this practical sourcing guide, international B2B buyers will find a step-by-step checklist designed to facilitate the procurement of various types of latches. By following these actionable insights, businesses from regions such as Africa, South America, the Middle East, and Europe can make informed purchasing decisions, ensuring they select the right latches for their specific applications.

Step 1: Define Your Technical Specifications

Before starting the sourcing process, clearly outline the technical specifications required for the latches. Consider factors such as material type (e.g., stainless steel, rubber, or plastic), load capacity, environmental resistance, and the specific application (e.g., doors, gates, or cabinets). Defining these parameters will help streamline your search and ensure compatibility with your project needs.

Step 2: Research Different Types of Latches

Familiarize yourself with the various types of latches available in the market. This includes door latches, gate latches, magnetic door latches, rotary latches, and spring latches. Understanding the unique features and benefits of each type will assist you in identifying which latches best suit your requirements.

Step 3: Evaluate Potential Suppliers

Conduct thorough evaluations of potential suppliers before making a commitment. Look for established manufacturers with a proven track record in producing high-quality latches. Request company profiles, case studies, and references from buyers in similar industries or regions. This due diligence will minimize risks and ensure you partner with reliable suppliers.

- Consider Supplier Certifications: Check if the suppliers hold any relevant certifications (e.g., ISO, CE) that demonstrate their commitment to quality and compliance with international standards.

Step 4: Request Samples for Quality Assessment

Once you have shortlisted suppliers, request samples of the latches you are interested in. This step is crucial to assess the quality, durability, and functionality of the products firsthand. Evaluate the samples against your technical specifications to ensure they meet your operational needs.

Step 5: Negotiate Pricing and Terms

Engage in negotiations with your selected suppliers regarding pricing, payment terms, and delivery schedules. Consider bulk purchase discounts or long-term supply agreements to optimize costs. Ensure that all terms are clearly outlined in a contract to avoid misunderstandings later on.

Step 6: Verify Warranty and After-Sales Support

Before finalizing your order, inquire about the warranty and after-sales support offered by the supplier. A good warranty can provide peace of mind regarding product longevity and performance. Additionally, reliable after-sales support can be invaluable for troubleshooting or replacement needs.

Step 7: Plan for Logistics and Compliance

Finally, consider the logistics involved in transporting the latches to your location. Check for any import/export regulations specific to your region, and ensure that the supplier can comply with these requirements. Effective logistics planning will help prevent delays and ensure a smooth delivery process.

By following these steps, B2B buyers can navigate the procurement process for latches effectively, ensuring they select the right products for their business needs while minimizing risks and maximizing value.

Comprehensive Cost and Pricing Analysis for types of latches Sourcing

What Are the Key Cost Components in Sourcing Types of Latches?

When sourcing types of latches, understanding the comprehensive cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials varies significantly based on the type of latch. For instance, stainless steel latches are generally more expensive than those made from plastic or rubber due to their durability and corrosion resistance.

-

Labor: Labor costs can fluctuate based on the region. In countries with lower labor costs, such as some in Africa or South America, you might find more competitive pricing, but it is essential to ensure that the quality of work meets your specifications.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. Efficient production processes can help reduce these costs, which is particularly beneficial for larger orders.

-

Tooling: Custom latches often require specific tooling, which can add to the initial setup costs. If you are sourcing custom latches, factor in these costs when evaluating supplier quotes.

-

Quality Control (QC): Implementing quality control measures adds to the overall cost but is essential for ensuring product reliability, especially for industries like automotive or aerospace.

-

Logistics: Shipping costs can vary widely depending on the Incoterms agreed upon. For international transactions, consider tariffs, shipping methods, and delivery times.

-

Margin: Suppliers will typically add a margin to cover their costs and profits. Understanding the standard margins in your specific industry can provide leverage during negotiations.

How Do Price Influencers Affect Latch Sourcing?

Several factors can influence the pricing of latches. Understanding these can help buyers make informed decisions:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect pricing. Higher volume orders often lead to lower per-unit costs due to economies of scale.

-

Specifications/Customization: Customized latches will generally incur higher costs due to the additional tooling and design work required. Be clear about your specifications to avoid unexpected costs.

-

Material Quality and Certifications: The quality of materials used and necessary certifications can impact the price. For example, latches used in sensitive applications may require stricter compliance, leading to higher costs.

-

Supplier Factors: Supplier reputation, reliability, and location can influence pricing. Established suppliers with a track record of quality may charge more but offer better assurance against defects.

-

Incoterms: Understanding Incoterms is vital for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who is responsible for shipping costs and risks, impacting overall pricing.

What Are Effective Buyer Tips for Cost-Efficiency in Latch Sourcing?

To maximize cost-efficiency in sourcing latches, consider the following strategies:

-

Negotiate Wisely: Always approach negotiations with a clear understanding of your needs and budget. Leverage volume discounts and long-term contracts for better pricing.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs associated with maintenance, replacement, and potential downtime. This holistic view can reveal the true cost-effectiveness of various latches.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing differences and market conditions. Currency fluctuations can also impact costs, so consider hedging strategies if dealing in foreign currencies.

-

Seek Multiple Quotes: Don’t settle for the first quote. Obtaining multiple quotes from different suppliers can provide a broader view of market pricing and help in negotiations.

Disclaimer for Indicative Prices

It is important to note that prices for latches can vary widely based on market conditions, supplier capabilities, and specific buyer requirements. Always request formal quotes and conduct thorough due diligence to ensure that you are making informed purchasing decisions.

Alternatives Analysis: Comparing types of latches With Other Solutions

When considering the various types of latches available in the market, it’s essential to evaluate them against alternative solutions that can achieve similar security and fastening objectives. This analysis will help international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, make informed decisions based on performance, cost, and other critical factors.

Comparison Table of Latches vs. Alternative Solutions

| Comparison Aspect | Types of Latches | Electronic Locks | Magnets and Magnetic Closures |

|---|---|---|---|

| Performance | Reliable for mechanical fastening; suitable for various applications | High-security and programmable; can integrate with smart systems | Good for lightweight applications; limited in high-security environments |

| Cost | Generally low-cost; variety available | Higher initial investment; ongoing costs for maintenance and battery replacement | Low-cost; inexpensive for simple applications |

| Ease of Implementation | Simple to install; no special tools required | Requires electrical expertise for installation | Very easy to install; no tools needed for basic applications |

| Maintenance | Low maintenance; mechanical parts may wear over time | Moderate; may require software updates and battery changes | Minimal; occasional cleaning may be necessary |

| Best Use Case | Suitable for doors, cabinets, and gates needing physical security | Ideal for high-security environments, such as banks and data centers | Best for lightweight doors or closures where security is not the primary concern |

What are the advantages and disadvantages of using Electronic Locks?

Electronic locks are a modern alternative to traditional latches, offering enhanced security features. They can be programmed for multiple users and can integrate with security systems, making them suitable for high-security environments. However, they come with a higher initial cost and require ongoing maintenance, such as battery replacements or software updates. For businesses looking for a high level of security, electronic locks can be a great option, but they may not be the best choice for cost-sensitive applications.

How do Magnets and Magnetic Closures compare to traditional latches?

Magnets and magnetic closures provide a simple and effective means of fastening, particularly in lightweight applications. They are easy to install and require no additional tools. However, their security is limited, making them unsuitable for applications where safety and security are paramount. They are best used in environments like cabinets or lightweight doors where ease of access is prioritized over security. Businesses should weigh the trade-offs between ease of use and the level of security needed.

Conclusion: How should B2B buyers choose the right fastening solution?

When choosing between types of latches and their alternatives, B2B buyers should assess their specific needs, including the required level of security, budget constraints, and installation capabilities. For environments requiring robust security, electronic locks may be the best choice despite their higher cost. Conversely, for applications where quick access and simplicity are more important, traditional latches or magnetic closures may be preferable. By carefully evaluating these factors, buyers can select the most suitable fastening solution for their unique operational requirements.

Essential Technical Properties and Trade Terminology for types of latches

What Are the Essential Technical Properties of Latches?

When sourcing latches for various applications, international B2B buyers must understand key technical properties that can influence performance, durability, and compatibility. Here are critical specifications to consider:

What Material Grades Are Most Commonly Used for Latches?

Material grade significantly impacts the strength and longevity of latches. Common materials include:

- Stainless Steel: Offers high corrosion resistance, making it ideal for outdoor applications and environments exposed to moisture.

- Aluminum: Lightweight and resistant to rust, aluminum latches are suitable for applications where weight is a concern, such as in automotive or aerospace industries.

- Plastic Composites: Often used in applications requiring flexibility and resistance to chemical exposure, these materials are common in consumer products and less demanding environments.

Understanding the material grade helps buyers select latches that will withstand environmental factors and meet operational demands.

How Important Is Tolerance in Latch Manufacturing?

Tolerance refers to the permissible limit of variation in a physical dimension. In latch manufacturing, precise tolerances ensure proper fit and function.

- Critical Tolerance: Ensures that latches fit securely without excessive play, which could lead to failure in locking mechanisms.

- Standard Tolerance: Commonly accepted tolerances can reduce production costs and lead times, making it easier for buyers to find suitable options that meet their budget and requirements.

Choosing the right tolerance levels is essential for ensuring the reliability and functionality of the latch in its intended application.

Why Is Load Capacity a Key Specification?

Load capacity denotes the maximum weight or force a latch can bear before failure. This specification is crucial for buyers in industries such as construction, automotive, and aerospace, where safety and structural integrity are paramount.

- Safety Factor: Understanding the load capacity allows buyers to implement safety factors that mitigate risks of latch failure under unexpected loads.

- Application Suitability: Different applications require varying load capacities; therefore, selecting a latch with the appropriate load rating is essential to prevent accidents and ensure compliance with industry standards.

What Are Common Trade Terms Associated with Latches?

Navigating the procurement process for latches also involves familiarizing oneself with industry-specific terminology. Here are several key terms that B2B buyers should know:

What Does OEM Mean in the Latch Industry?

OEM stands for Original Equipment Manufacturer. In the context of latches, it refers to companies that produce latches that are used in the assembly of final products, such as vehicles or appliances. Understanding OEM relationships can help buyers assess quality and reliability.

Why Is MOQ Important When Sourcing Latches?

MOQ, or Minimum Order Quantity, is the smallest quantity of a product that a supplier is willing to sell. This term is critical for buyers as it affects inventory management and overall costs. Knowing the MOQ can help businesses avoid overstocking or understocking, ensuring they have the right amount of latches for their production needs.

What Is an RFQ and How Is It Used in Purchasing Latches?

RFQ, or Request for Quotation, is a document used by buyers to solicit price quotes from suppliers for specific products, including latches. An RFQ typically outlines the specifications, quantities, and delivery requirements. It is an essential tool for comparing costs and terms from multiple suppliers.

How Do Incoterms Affect International Latch Trade?

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international transactions. For latch procurement, understanding Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for clarifying shipping responsibilities, risks, and costs. This knowledge helps buyers negotiate better terms and avoid unexpected expenses.

Conclusion

By grasping the essential technical properties and common trade terminology associated with latches, international B2B buyers can make informed decisions that enhance their procurement processes, ensuring they select the right products for their specific needs. Understanding these aspects not only streamlines sourcing but also strengthens supplier relationships and enhances overall operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the types of latches Sector

What Are the Current Market Trends in the Types of Latches Sector?

The global market for latches is experiencing significant growth, driven by the increasing demand for secure and efficient fastening solutions across various industries. In regions such as Africa, South America, the Middle East, and Europe, international B2B buyers are particularly influenced by technological advancements and the push for enhanced security features in products. Emerging trends include the adoption of smart latching systems that integrate with IoT devices, offering enhanced security through remote access and monitoring capabilities. Additionally, the automotive and construction sectors are contributing to the demand for specialized latches, such as rotary and magnetic latches, which are preferred for their durability and ease of use.

Moreover, the shift towards sustainable materials is reshaping sourcing strategies. Buyers are increasingly looking for manufacturers who provide latches made from recycled or eco-friendly materials. The focus on sustainability is not just a market differentiator; it has become a key decision-making factor for B2B buyers who prioritize ethical practices and environmental responsibility in their supply chains. Understanding these dynamics is crucial for international buyers to stay competitive and meet evolving market demands.

How Can Sustainability and Ethical Sourcing Impact the Types of Latches Industry?

Sustainability and ethical sourcing have become paramount in the types of latches sector, particularly as consumers and businesses alike are more environmentally conscious. The production of latches can have a significant environmental impact, from resource extraction to manufacturing processes. Buyers are increasingly seeking suppliers that demonstrate a commitment to reducing their carbon footprint and employing sustainable practices throughout their operations.

Ethical supply chains are becoming a standard expectation rather than a competitive advantage. Certifications such as ISO 14001 for environmental management and the use of recycled materials in latch production are key indicators of a supplier’s commitment to sustainability. For instance, rubber latches, which are often used in automotive applications, can now be sourced from sustainable rubber plantations, offering both performance and environmental benefits. By prioritizing suppliers with green certifications, international B2B buyers can ensure that their sourcing decisions align with their corporate social responsibility goals, enhancing their brand reputation and customer loyalty.

How Have Types of Latches Evolved Over Time?

The evolution of latches can be traced back to ancient mechanical systems, where simple hooks and loops served as basic fastening devices. Over the centuries, latches have advanced significantly, incorporating more complex mechanisms to enhance security and functionality. The introduction of materials such as stainless steel and advanced polymers has improved the durability and performance of latches, making them suitable for a wide range of applications, from residential doors to industrial machinery.

In recent decades, the integration of technology has transformed the latch market, with electronic and smart latches gaining popularity. These modern latches provide enhanced security features, such as keyless entry and smartphone control, catering to the needs of contemporary consumers and businesses. This evolution reflects the broader trends in technology and sustainability, highlighting the importance of innovation in meeting the demands of international B2B buyers. As the market continues to evolve, staying informed about these trends will be essential for buyers looking to optimize their sourcing strategies and align with industry advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of types of latches

-

How do I choose the right latch for my application?

Selecting the right latch involves assessing the specific requirements of your application, such as load capacity, environmental conditions, and security needs. For instance, consider magnetic latches for lightweight doors, while rotary latches are ideal for heavy-duty enclosures. Additionally, evaluate the material—stainless steel is suitable for outdoor use due to its corrosion resistance. Engage with suppliers for samples to test functionality and ensure compliance with local standards, especially in regions like Africa and South America where regulations may vary. -

What is the best latch type for securing outdoor gates?

For outdoor gates, gate latches made from durable materials such as stainless steel or galvanized metal are recommended due to their resistance to weathering. A locking mechanism is essential for security, making rotary or spring latches ideal choices. Consider ease of operation; a lever-operated latch allows for quick access while ensuring the gate remains securely closed. Always verify with suppliers regarding the latch’s performance in specific environmental conditions prevalent in your region. -

How do I ensure the quality of latches when sourcing internationally?

To ensure quality, conduct thorough supplier vetting by reviewing certifications, product samples, and client testimonials. Request documentation such as ISO certifications to validate manufacturing standards. It’s also beneficial to visit the manufacturing site if possible or utilize third-party inspection services before shipment. Establishing clear quality assurance protocols in your contract can help mitigate risks associated with international sourcing, particularly in diverse markets like the Middle East and Europe. -

What are the common minimum order quantities (MOQs) for latches?

Minimum order quantities for latches can vary significantly depending on the manufacturer and the complexity of the latch design. Generally, MOQs can range from 100 to 1,000 units. For customized latches, MOQs may be higher due to setup costs. Always discuss MOQs with your supplier, as many are willing to negotiate based on your specific needs and potential for long-term partnership, especially in regions where demand is fluctuating. -

What payment terms should I negotiate when sourcing latches?

When negotiating payment terms, consider options such as letters of credit, advance payments, or net payment terms (e.g., net 30 or net 60). Aim for terms that balance risk and cash flow; for larger orders, splitting payments into milestones can be beneficial. Ensure that the terms are documented in your purchase agreement to avoid disputes. Familiarize yourself with local banking practices in regions such as Africa and South America, as these can influence payment options. -

How can I customize latches to meet my specific needs?

Many manufacturers offer customization options for latches, including material choice, finish, size, and operational features. Start by clearly outlining your requirements and engage in discussions with potential suppliers to explore available options. Consider creating prototypes to evaluate functionality before mass production. Ensure that any customizations comply with local regulations and standards in your target market, as requirements can differ across regions. -

What logistics considerations should I keep in mind when importing latches?

Logistics play a crucial role in international sourcing. Key considerations include shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder familiar with import procedures in your country. Be aware of potential tariffs and import duties that may affect your total cost. Additionally, consider the supplier’s location relative to shipping ports to optimize delivery times, especially when sourcing from regions like Europe or the Middle East. -

How do I handle warranty and after-sales support for latches?

Ensure that warranty terms are explicitly defined in your purchase agreement, covering defects and potential failures. After-sales support is essential for addressing any issues that arise post-purchase. Clarify the process for returns and replacements, including timelines and responsibilities. Establish communication channels with your supplier for ongoing support, particularly important in regions like Africa and South America where access to parts may be limited.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of latches

As international B2B buyers navigate the diverse landscape of latch types, understanding the strategic sourcing implications becomes vital. The array of latches—from door and gate latches to innovative magnetic and rotary options—offers unique functionalities tailored to various industrial applications. Buyers should prioritize quality, reliability, and compatibility with existing systems to ensure optimal performance and safety.

A stock image related to types of latches.

Strategic sourcing enables companies to not only reduce costs but also enhance their supply chain resilience. By forming partnerships with reputable manufacturers and suppliers, businesses can access cutting-edge latch technology while benefiting from bulk purchasing agreements and customized solutions. This approach is particularly beneficial for buyers in Africa, South America, the Middle East, and Europe, where local regulations and market demands may vary significantly.

Looking ahead, the latch market is poised for growth driven by advancements in technology and increasing demand for secure mechanisms across industries. Buyers are encouraged to stay informed about emerging trends and innovations in latch design and materials. By embracing strategic sourcing initiatives, international B2B buyers can position themselves to capitalize on these opportunities, ensuring their operations remain efficient, secure, and competitive.