Discover Cost-Saving Benefits of Expanded Metal Mesh (2025)

Introduction: Navigating the Global Market for expanded metal mesh

Navigating the complexities of sourcing expanded metal mesh can be a daunting challenge for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. With various applications ranging from construction to security, understanding the nuances of expanded metal types, their material options, and their specific uses is crucial for making informed purchasing decisions. This guide aims to demystify the expanded metal mesh market by providing comprehensive insights into the different types available, including flattened and standard variants, as well as grating options tailored for specific applications like catwalks and machine guards.

By exploring key factors such as supplier vetting, cost considerations, and regional manufacturing standards, this guide empowers buyers to navigate the global landscape confidently. It highlights essential criteria for evaluating suppliers, ensuring quality, and securing competitive pricing. Whether you are in Thailand looking for decorative expanded metal for architectural projects or in Saudi Arabia sourcing durable grating for industrial use, this resource equips you with the knowledge to make strategic decisions that align with your business needs. As you delve deeper into the world of expanded metal mesh, you’ll discover the potential to enhance your projects while optimizing your procurement strategy.

Understanding expanded metal mesh Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flattened Expanded Metal | Smooth surface, reduced thickness, diamond openings | Architectural applications, decorative panels, security | Pros: Aesthetic appeal, lightweight. Cons: Less strength than standard. |

| Standard Expanded Metal | Raised diamond pattern, thicker strands | Industrial flooring, machine guards, ventilation covers | Pros: High strength, excellent load-bearing capacity. Cons: Heavier, less aesthetic. |

| Expanded Metal Grating | Larger openings, typically used for flooring applications | Catwalks, stair treads, platforms | Pros: Slip-resistant, strong. Cons: Limited decorative options. |

| Designer Expanded Metal | Unique patterns, customizable designs | Retail displays, artistic installations | Pros: High aesthetic value, versatile. Cons: Higher cost, may require longer lead times. |

| Catwalk Grating | Specifically designed for walkways, heavy-duty applications | Industrial catwalks, access platforms | Pros: Durable, safe for high foot traffic. Cons: Bulkier, may require additional support. |

What are the Characteristics of Flattened Expanded Metal?

Flattened expanded metal is produced by compressing a standard expanded metal sheet, resulting in a smooth surface that enhances its aesthetic appeal. This type is ideal for applications where appearance is important, such as architectural projects or decorative panels. Buyers should consider the trade-off between aesthetics and strength, as flattened types may not support heavy loads as effectively as other forms.

How Does Standard Expanded Metal Compare?

Standard expanded metal features a raised diamond pattern, providing excellent strength and load-bearing capabilities. This type is commonly utilized in industrial settings for flooring, machine guards, and ventilation covers. When sourcing standard expanded metal, B2B buyers should evaluate the required thickness and gauge to ensure it meets the specific demands of their projects.

What are the Key Features of Expanded Metal Grating?

Expanded metal grating is characterized by its larger openings and is primarily used in applications that require strong, slip-resistant surfaces. Commonly found in catwalks, stair treads, and platforms, this type is designed to handle heavy foot traffic while allowing for the passage of air and light. Buyers should assess the load requirements and environmental conditions when selecting expanded metal grating.

Why Choose Designer Expanded Metal?

Designer expanded metal offers unique patterns and customizable designs, making it a popular choice for retail displays and artistic installations. This type can elevate the visual impact of a project, but it typically comes at a higher cost and may have longer lead times. B2B buyers should consider their budget and project timelines when opting for designer variations.

What Makes Catwalk Grating Essential for Industrial Use?

Catwalk grating is specifically engineered for heavy-duty applications, providing a safe walking surface in industrial environments. Its durability and strength make it suitable for high foot traffic areas, such as access platforms and industrial catwalks. Buyers should focus on the grating’s load capacity and compatibility with existing structures to ensure safety and functionality.

Key Industrial Applications of expanded metal mesh

| Industry/Sector | Specific Application of Expanded Metal Mesh | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Facades and Architectural Features | Provides aesthetic appeal while ensuring structural integrity. | Material type (e.g., stainless steel for durability), local regulations, and design specifications. |

| Manufacturing | Machine Guards and Safety Barriers | Enhances workplace safety by preventing access to moving parts. | Compliance with safety standards, thickness, and gauge specifications. |

| Transportation | Traction Surfaces for Ramps and Walkways | Improves safety and accessibility in high-traffic areas. | Load capacity, environmental resistance, and surface treatment options. |

| Agriculture | Irrigation and Ventilation Covers | Facilitates airflow and water passage while protecting crops. | Open area percentage, corrosion resistance, and local climate considerations. |

| Retail and Display | Retail Shelving and Displays | Allows visibility of products while maintaining support and security. | Weight capacity, aesthetic design, and custom sizing options. |

How is Expanded Metal Mesh Used in Construction?

In the construction sector, expanded metal mesh is often utilized for facades and architectural features. Its unique design not only enhances visual appeal but also provides structural support. This material is particularly beneficial in regions like Africa and the Middle East, where environmental conditions demand durability. Buyers should consider the type of metal (like galvanized steel or aluminum), as well as compliance with local building codes and aesthetic preferences, to ensure both functionality and compliance.

What Role Does Expanded Metal Mesh Play in Manufacturing?

In manufacturing, expanded metal mesh serves as machine guards and safety barriers. These installations are crucial for protecting workers from potential hazards associated with machinery. The mesh allows for visibility while ensuring that only authorized personnel can access dangerous areas. International buyers should focus on compliance with safety regulations, the gauge of the mesh for strength, and the specific requirements of their equipment to optimize safety and efficiency.

How is Expanded Metal Mesh Beneficial in Transportation?

In the transportation industry, expanded metal mesh is commonly used for traction surfaces on ramps and walkways. Its diamond-shaped openings provide a non-slip surface, enhancing safety in environments with heavy foot or vehicle traffic. For buyers in regions with varying climates, it’s important to consider load capacity and surface treatment options to ensure longevity and performance under different conditions.

What Are the Agricultural Applications of Expanded Metal Mesh?

In agriculture, expanded metal mesh is used for irrigation and ventilation covers. This application allows for efficient airflow and water passage while protecting crops from pests and debris. Buyers from South America and Africa should prioritize the open area percentage and corrosion resistance of the mesh, as these factors are crucial for maintaining crop health in diverse climates.

How Does Expanded Metal Mesh Enhance Retail and Display?

In retail, expanded metal mesh is utilized for shelving and display units. This application allows for product visibility while ensuring structural integrity and security. International buyers should consider weight capacity, aesthetic design, and the possibility of custom sizing to meet their specific retail needs, especially in competitive markets across Europe and the Middle East.

3 Common User Pain Points for ‘expanded metal mesh’ & Their Solutions

Scenario 1: Sourcing the Right Type of Expanded Metal Mesh for Specific Applications

The Problem: International B2B buyers often struggle with selecting the appropriate type of expanded metal mesh for their specific applications. With various materials (aluminum, carbon steel, galvanized steel, stainless steel) and types (flattened, standard, grating) available, buyers may find it overwhelming to determine which option best meets their project requirements. This is particularly critical in regions like Africa and the Middle East, where environmental factors such as humidity and temperature variations can affect material performance.

The Solution: To effectively source the right type of expanded metal mesh, buyers should begin by clearly defining their project requirements, including load-bearing capacity, environmental conditions, and aesthetic considerations. Conducting a thorough analysis of application-specific needs can help streamline this process. For example, if the mesh will be used in a coastal region, opting for stainless steel or galvanized steel is advisable to prevent corrosion. Additionally, engaging with suppliers who offer customized solutions can provide tailored advice and samples, allowing buyers to assess material performance in real-world conditions before committing to larger orders. Utilizing local suppliers can also minimize shipping costs and lead times, enhancing overall project efficiency.

Scenario 2: Ensuring Compliance with Regional Safety and Quality Standards

The Problem: B2B buyers across different continents face the challenge of ensuring that their selected expanded metal mesh complies with local safety and quality standards. Regulations can vary significantly between countries, especially in regions like Europe, where strict compliance is mandatory. This lack of clarity can lead to project delays, increased costs, and potential legal liabilities if non-compliant materials are used.

The Solution: To mitigate compliance-related issues, buyers should familiarize themselves with the specific regulations governing expanded metal mesh in their target markets. This includes understanding certifications required for materials, such as ISO standards or regional safety codes. Collaborating with reputable suppliers who are well-versed in local regulations can be invaluable. They can provide documentation and certifications that verify compliance, thereby reducing the buyer’s risk. Furthermore, buyers should consider establishing long-term relationships with suppliers who have a proven track record of delivering compliant products, which can lead to more streamlined procurement processes and enhanced trust.

Scenario 3: Managing Cost Efficiency While Maintaining Quality

The Problem: Cost management is a crucial concern for B2B buyers, particularly in developing regions like South America and Africa, where budget constraints are common. Buyers often face the dilemma of choosing between lower-cost options and higher-quality products. This can lead to a false economy if cheaper materials result in higher maintenance costs or shorter lifespans, ultimately affecting overall project budgets.

The Solution: To strike a balance between cost and quality, buyers should perform a total cost of ownership (TCO) analysis. This involves evaluating not only the initial purchase price of the expanded metal mesh but also considering long-term factors such as durability, maintenance requirements, and lifecycle costs. Engaging in discussions with suppliers about bulk purchasing discounts or exploring alternative materials that offer similar performance at a lower price point can also provide cost savings. Moreover, investing in high-quality expanded metal mesh that meets specific application needs can lead to significant long-term savings by reducing the frequency of replacements and repairs. Buyers should leverage this strategy to negotiate better terms and ensure they receive the best value for their investment.

Strategic Material Selection Guide for expanded metal mesh

What Are the Key Properties of Aluminum Expanded Metal Mesh?

Aluminum is a popular choice for expanded metal mesh due to its lightweight nature and excellent corrosion resistance. It typically withstands temperatures up to 300°F (149°C) without significant degradation, making it suitable for various applications, including outdoor structures and architectural features. The material is non-magnetic and has a high strength-to-weight ratio, which enhances its performance in applications requiring both durability and lightweight characteristics.

Pros and Cons of Aluminum Expanded Metal Mesh

The primary advantage of aluminum expanded metal mesh is its corrosion resistance, which is essential for outdoor applications in humid or coastal environments. Additionally, it is relatively easy to fabricate and can be anodized for enhanced aesthetic appeal. However, aluminum can be more expensive than other materials like carbon steel, and it may not be suitable for high-load applications due to its lower tensile strength compared to steel.

Impact on Application

Aluminum expanded metal mesh is often used in architectural applications, such as facades, sunshades, and decorative elements. Its lightweight nature makes it ideal for projects where weight is a concern, but the buyer should ensure that the application does not exceed the material’s load-bearing capacity.

How Does Carbon Steel Perform in Expanded Metal Mesh Applications?

Carbon steel is another common material for expanded metal mesh, known for its high strength and durability. It can handle significant pressure and temperature variations, making it suitable for heavy-duty applications. However, carbon steel is susceptible to corrosion, particularly in moist environments, unless it is treated or coated.

Pros and Cons of Carbon Steel Expanded Metal Mesh

The main advantage of carbon steel is its strength and cost-effectiveness, making it a preferred choice for industrial applications and structural support. It can be manufactured in various gauges and sizes, providing versatility. On the downside, the need for protective coatings (like galvanization) to prevent rust adds to manufacturing complexity and cost.

Impact on Application

Carbon steel expanded metal mesh is commonly used in construction, machine guards, and flooring applications where strength is paramount. Buyers in regions with high humidity or corrosive environments should prioritize protective treatments to ensure longevity.

What Are the Benefits of Stainless Steel Expanded Metal Mesh?

Stainless steel expanded metal mesh offers exceptional corrosion resistance and is suitable for a wide range of applications, including food processing and chemical industries. It can withstand temperatures exceeding 1000°F (538°C), making it ideal for high-temperature environments.

Pros and Cons of Stainless Steel Expanded Metal Mesh

The primary advantage of stainless steel is its durability and resistance to corrosion, which makes it suitable for harsh environments. However, it is generally more expensive than aluminum and carbon steel, which may deter budget-conscious buyers. Additionally, the manufacturing process can be more complex, leading to longer lead times.

Impact on Application

Stainless steel expanded metal mesh is often used in applications requiring hygiene, such as food processing, pharmaceuticals, and architectural features. Buyers should ensure compliance with relevant health and safety standards, especially in food-related applications.

What Considerations Should International B2B Buyers Keep in Mind?

When selecting expanded metal mesh, international buyers, particularly from Africa, South America, the Middle East, and Europe, should consider local regulations and standards such as ASTM, DIN, or JIS that may dictate material specifications. Understanding the environmental conditions in which the material will be used is crucial, especially concerning corrosion resistance and load-bearing capabilities. Additionally, buyers should evaluate the availability of materials and suppliers in their region to ensure timely delivery and compliance with local sourcing regulations.

Summary Table of Material Selection for Expanded Metal Mesh

| Material | Typical Use Case for Expanded Metal Mesh | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Architectural features, sunshades | Lightweight and corrosion-resistant | Higher cost, lower tensile strength | Medium |

| Carbon Steel | Industrial applications, flooring | High strength and cost-effective | Susceptible to corrosion without coating | Low |

| Stainless Steel | Food processing, chemical industries | Exceptional corrosion resistance | Higher cost and complex manufacturing | High |

In-depth Look: Manufacturing Processes and Quality Assurance for expanded metal mesh

What Are the Key Stages in the Manufacturing Process of Expanded Metal Mesh?

The manufacturing process for expanded metal mesh involves several critical stages, each contributing to the final product’s quality and performance. Understanding these stages can help B2B buyers make informed decisions when sourcing expanded metal mesh.

1. Material Preparation

The first step in the manufacturing process is material preparation. This involves selecting the appropriate metal type, which can vary from aluminum to various grades of steel, including carbon and stainless steel. The choice of material significantly impacts the durability, weight, and corrosion resistance of the final product.

Once the material is selected, it is cut into sheets of specific dimensions. Common sheet sizes include 48” x 96” and 60” x 120”. The thickness of the sheet is also determined at this stage, with options typically ranging from 16 to 6 gauge.

2. Forming Techniques for Expanded Metal Mesh

The core of the manufacturing process is the forming stage, where sheets are slit and stretched. This process creates diamond-shaped openings within the metal. Two primary techniques are used:

-

Slitting: This involves cutting precise slits into the metal sheet. The dimensions of these slits will determine the size of the openings in the expanded metal mesh.

-

Stretching: After slitting, the sheets are stretched to create the mesh pattern. The stretching process ensures that the openings are uniform and maintains the structural integrity of the material.

This combination of slitting and stretching not only enhances the aesthetic appeal but also provides functional benefits such as weight reduction and increased strength.

3. Assembly and Finishing

After forming, the expanded metal sheets undergo assembly, where they are cut to the desired final size if necessary. Following this, finishing processes are applied. This may include:

- Galvanization: To improve corrosion resistance, especially for outdoor applications.

- Powder Coating: For aesthetic enhancement and additional protective layers.

- Polishing: Particularly for stainless steel types to achieve a shiny, reflective surface.

These finishing touches are crucial for specific applications, including architectural design, security applications, and industrial use.

What Quality Assurance Measures Are Essential for Expanded Metal Mesh?

Quality assurance (QA) is integral to the manufacturing of expanded metal mesh, ensuring that the final product meets international standards and customer specifications. Here’s a closer look at the essential QA measures.

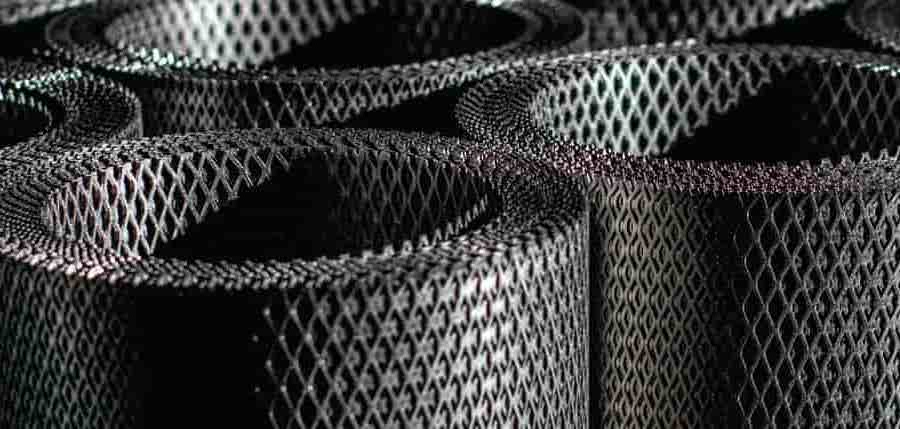

A stock image related to expanded metal mesh.

1. Adherence to International Standards

To ensure the quality and reliability of expanded metal mesh, manufacturers often adhere to international standards such as ISO 9001, which focuses on quality management systems. Other relevant certifications may include:

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Standards: Particularly relevant for applications in the oil and gas industry.

These certifications are essential for international B2B buyers, as they signify that the products have been rigorously tested and meet specific regulatory requirements.

2. Quality Control Checkpoints

Throughout the manufacturing process, several quality control checkpoints are established:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify any deviations from standards.

- Final Quality Control (FQC): A comprehensive review of the finished product, ensuring it meets all specifications before shipment.

By employing these checkpoints, manufacturers can catch potential issues early, reducing waste and ensuring consistent product quality.

3. Common Testing Methods for Expanded Metal Mesh

Various testing methods are utilized to ensure the durability and performance of expanded metal mesh:

- Tensile Strength Testing: To assess the material’s ability to withstand tension.

- Corrosion Resistance Testing: Particularly important for products intended for outdoor use.

- Dimensional Testing: Ensures that the mesh adheres to the specified dimensions and tolerances.

These tests provide critical insights into the material’s performance under different conditions, which is vital for B2B buyers when considering application suitability.

How Can B2B Buyers Verify Supplier Quality Control?

A stock image related to expanded metal mesh.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are actionable steps to ensure supplier compliance:

1. Conduct Supplier Audits

Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. During an audit, buyers should assess:

- Manufacturing Capabilities: Ensure that the supplier has the necessary equipment and technology.

- Quality Control Processes: Review their QA documentation and procedures to ensure compliance with international standards.

2. Request Quality Assurance Documentation

Buyers should request detailed quality assurance documentation, including:

- Certificates of Compliance: To verify adherence to international standards like ISO 9001.

- Test Reports: From independent laboratories that verify the product’s performance characteristics.

These documents serve as proof of the supplier’s commitment to quality and can help mitigate risks associated with sourcing.

3. Engage Third-Party Inspectors

Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. These inspectors can conduct thorough assessments at various stages of the manufacturing process, ensuring that products meet specified standards before shipment.

Conclusion

Understanding the manufacturing processes and quality assurance measures for expanded metal mesh is essential for B2B buyers seeking reliable suppliers. By focusing on material preparation, forming techniques, and rigorous quality control, buyers can ensure they are sourcing high-quality products that meet their specific needs. Engaging in audits, requesting documentation, and utilizing third-party inspections are practical steps to verify supplier quality, providing peace of mind in international transactions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘expanded metal mesh’

In the competitive landscape of B2B procurement, sourcing expanded metal mesh requires a strategic approach. This guide provides a practical checklist to help international buyers, particularly from Africa, South America, the Middle East, and Europe, navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your project’s technical requirements. This includes the type of expanded metal mesh you need—such as flattened or standard, the material (e.g., aluminum, carbon steel, or stainless steel), and specific dimensions. Knowing the percent open area and the application (e.g., machine guards, catwalks) will help suppliers provide the most suitable options for your needs.

Step 2: Research and Identify Suppliers

Conduct thorough research to identify reputable suppliers of expanded metal mesh. Utilize industry directories, trade shows, and online marketplaces to find potential vendors. Pay attention to their experience, product range, and reviews from other international buyers. A supplier with a strong track record can ensure reliability and quality.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their production capabilities, delivery times, and customer service. This step helps mitigate risks associated with quality and reliability.

Step 4: Verify Supplier Certifications

Ensure that your selected suppliers comply with relevant industry standards and certifications. Look for certifications such as ISO 9001 for quality management and environmental compliance standards. These certifications are indicators of a supplier’s commitment to maintaining high standards in their manufacturing processes.

Step 5: Request Samples for Quality Assurance

Always request samples of the expanded metal mesh before finalizing your order. This allows you to assess the quality, gauge thickness, and confirm that the product meets your specifications. Testing the samples in your intended application can provide insights into performance and durability.

Step 6: Understand Pricing and Payment Terms

Engage suppliers to understand their pricing structure and payment terms. Inquire about bulk purchase discounts and shipping costs, as these can significantly impact your budget. Establish clear payment terms that align with your financial processes to avoid any complications later in the transaction.

Step 7: Establish Clear Communication Channels

Effective communication is vital throughout the procurement process. Ensure that you have a dedicated point of contact within the supplier’s organization. Regular updates and transparent communication will help address any potential issues promptly, ensuring a smoother procurement experience.

By following this step-by-step checklist, B2B buyers can navigate the sourcing process for expanded metal mesh with confidence, ensuring they select the right products and suppliers for their specific needs.

Comprehensive Cost and Pricing Analysis for expanded metal mesh Sourcing

What Are the Key Components of Expanded Metal Mesh Cost Structure?

When sourcing expanded metal mesh, understanding the cost structure is essential for B2B buyers. The primary components that contribute to the overall cost include:

-

Materials: The choice of materials such as aluminum, carbon steel, galvanized steel, or stainless steel significantly impacts pricing. For example, stainless steel tends to be more expensive due to its corrosion resistance and durability.

-

Labor: Labor costs include wages for workers involved in manufacturing, cutting, and finishing the metal sheets. Regions with higher labor costs will naturally result in higher product prices.

-

Manufacturing Overhead: This encompasses the operational costs of running a manufacturing facility, including utilities, equipment maintenance, and administrative expenses.

-

Tooling: Initial tooling costs for production can be high, especially for custom specifications. Buyers should inquire about tooling costs if they require specific designs or sizes.

-

Quality Control (QC): Ensuring the product meets quality standards adds to the cost. Certifications and compliance with international standards can further influence pricing.

-

Logistics: Transportation and shipping costs vary based on the supplier’s location and the buyer’s destination. International shipping can introduce additional fees and tariffs.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can vary based on the supplier’s market position and competitive strategy.

How Do Price Influencers Affect Expanded Metal Mesh Sourcing?

Several factors can influence the pricing of expanded metal mesh, and international buyers should be particularly aware of these elements:

-

Volume/MOQ (Minimum Order Quantity): Ordering in larger quantities often leads to lower per-unit costs. Buyers should negotiate to achieve favorable pricing based on their anticipated needs.

-

Specifications and Customization: Customized products may incur additional costs. Understanding the trade-off between standard and custom specifications can help buyers make cost-effective decisions.

-

Material Quality and Certifications: Higher-quality materials and certifications (such as ISO or ASTM) can raise prices but also provide assurance of product performance and longevity.

-

Supplier Factors: The supplier’s reputation, reliability, and geographical location can influence pricing. Suppliers with established networks may offer better logistics solutions, potentially lowering total costs.

-

Incoterms: Understanding International Commercial Terms (Incoterms) is crucial for international transactions. They define responsibilities for shipping, insurance, and tariffs, which can affect the total cost.

What Are Effective Buyer Tips for Cost-Efficiency in Sourcing Expanded Metal Mesh?

To maximize cost-efficiency when sourcing expanded metal mesh, buyers can employ several strategies:

-

Negotiate Effectively: Leverage volume purchases and long-term relationships to negotiate better pricing. Don’t hesitate to ask for discounts or flexible payment terms.

-

Consider Total Cost of Ownership (TCO): Beyond the purchase price, consider factors like maintenance, durability, and potential replacement costs over time. A higher upfront investment in quality materials can save money in the long run.

-

Research Supplier Options: Compare multiple suppliers to assess pricing, lead times, and quality. Consider local suppliers to reduce shipping costs and lead times.

-

Stay Informed About Market Trends: Keep abreast of global metal prices and supply chain disruptions that could affect costs. Being informed allows for timely decision-making.

-

Understand Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should consider exchange rates, local tariffs, and import duties that can impact overall costs.

Conclusion

Understanding the cost structure, price influencers, and effective purchasing strategies is vital for B2B buyers in the expanded metal mesh market. By focusing on these elements, international buyers can optimize their sourcing processes, ensuring both quality and cost-efficiency in their procurement strategies. Always remember that prices can fluctuate, so it’s advisable to obtain indicative quotes and stay updated on market conditions.

Alternatives Analysis: Comparing expanded metal mesh With Other Solutions

Exploring Alternatives to Expanded Metal Mesh for B2B Applications

In the quest for effective material solutions, international B2B buyers often consider various alternatives to expanded metal mesh. Understanding how these alternatives stack up against expanded metal mesh in terms of performance, cost, ease of implementation, maintenance, and best use cases is crucial for making informed purchasing decisions. Below is a comparative analysis of expanded metal mesh against two viable alternatives: perforated metal and welded wire mesh.

| Comparison Aspect | Expanded Metal Mesh | Perforated Metal | Welded Wire Mesh |

|---|---|---|---|

| Performance | High strength-to-weight ratio; excellent airflow and visibility. | Good structural integrity; customizable hole sizes for specific needs. | Strong but less open area; effective for containment and safety. |

| Cost | Generally moderate cost; production efficiency reduces waste. | Can be more expensive due to custom hole designs and thicknesses. | Usually lower cost; widely available and easy to source. |

| Ease of Implementation | Simple to install; available in various sizes. | May require custom orders; installation can be labor-intensive. | Easy to handle and install; standard sizes available. |

| Maintenance | Low maintenance; resistant to corrosion with proper coatings. | Maintenance depends on material; may require protective coatings. | Low maintenance; may need periodic inspection for rust or damage. |

| Best Use Case | Ideal for decorative and functional applications, such as security panels and machine guards. | Best for applications requiring specific airflow or light transmission, such as HVAC systems. | Suitable for fencing, cages, and barriers in industrial settings. |

What Are the Benefits and Drawbacks of Perforated Metal?

Perforated metal sheets are created by punching holes into solid metal sheets. This method allows for various hole sizes and patterns, catering to specific airflow or light transmission requirements. Pros include customization and structural integrity, making them ideal for applications such as HVAC systems and sound barriers. However, the cons involve potentially higher costs due to custom designs and a more labor-intensive installation process, which may not be feasible for all projects.

How Does Welded Wire Mesh Compare to Expanded Metal Mesh?

Welded wire mesh consists of thin metal wires welded together to form a grid. This alternative offers strength and durability, making it suitable for applications like fencing and cages. The advantages of welded wire mesh include its lower cost and ease of sourcing, as it is widely available in standard sizes. However, it provides less open area compared to expanded metal mesh, which may limit airflow and visibility. Additionally, while it requires minimal maintenance, periodic checks for rust or damage are necessary to ensure longevity.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When deciding between expanded metal mesh and its alternatives, B2B buyers should carefully assess their specific needs. If structural integrity and airflow are paramount, expanded metal mesh is often the best choice. However, for projects requiring tailored designs or lower costs, perforated metal or welded wire mesh may be more appropriate. Ultimately, understanding the unique advantages and disadvantages of each option will empower buyers to make informed decisions that align with their operational requirements and budget constraints.

Essential Technical Properties and Trade Terminology for expanded metal mesh

What Are the Essential Technical Properties of Expanded Metal Mesh?

When sourcing expanded metal mesh, understanding its technical properties is crucial for making informed purchasing decisions. Here are key specifications that B2B buyers should consider:

-

Material Grade

– Expanded metal mesh is available in various materials, including aluminum, carbon steel, galvanized steel, and stainless steel. Each material has distinct characteristics, such as corrosion resistance and strength. For instance, stainless steel is ideal for applications requiring durability in harsh environments, while aluminum is lightweight and suitable for aesthetic applications. -

Wire Thickness

– This specification refers to the gauge of the wire used to create the mesh. Common thicknesses range from #6 to #18. The wire thickness impacts the strength and weight of the mesh, making it essential to choose the appropriate gauge based on the application’s load-bearing requirements. -

Percent Open Area

– The open area percentage indicates how much of the mesh surface is free space compared to solid material. This is significant for applications involving airflow, light transmission, or drainage. A higher open area (e.g., 80-89%) is beneficial for ventilation, while lower percentages may be preferable for structural strength. -

Diamond Size

– The dimensions of the diamond openings in the mesh (typically ranging from ¼” to 1½”) directly affect the application. Larger openings provide better visibility and airflow, while smaller openings offer more security and are used in applications like machine guards. -

Sheet Size

– Expanded metal sheets come in various standard sizes, such as 48” x 96” or 60” x 120”. Understanding the available sizes helps buyers minimize waste and optimize shipping costs. Custom cutting is also often available, which can be beneficial for specific project needs. -

Surface Finish

– The surface finish can vary from plain to painted or coated options. This affects not only aesthetics but also the corrosion resistance and maintenance requirements of the mesh. For outdoor applications, a galvanized or coated finish may be necessary to prolong the lifespan of the material.

What Are Common Trade Terms Used in the Expanded Metal Mesh Industry?

Navigating the procurement process for expanded metal mesh involves familiarizing oneself with industry terminology. Here are several essential terms:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for B2B buyers as it often determines the quality and compatibility of components. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, especially for international buyers who may face higher shipping costs with small orders. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. This process allows buyers to compare options and negotiate better deals, ensuring they receive the best value for their investment. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms can help prevent misunderstandings and ensure smoother transactions across borders. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order until delivery. Understanding lead times is crucial for project planning, especially in regions with longer shipping durations. -

Certification Standards

– Various certification standards (e.g., ISO, ASTM) may apply to expanded metal mesh products, indicating compliance with industry benchmarks. Buyers should verify these certifications to ensure product reliability and safety, particularly in regulated industries.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring that their expanded metal mesh meets both their operational needs and industry standards.

Navigating Market Dynamics and Sourcing Trends in the expanded metal mesh Sector

What Are the Current Market Dynamics and Key Trends in the Expanded Metal Mesh Sector?

The expanded metal mesh market is experiencing robust growth driven by several global factors, including urbanization, increased construction activities, and the rising demand for lightweight materials in various applications. Industries such as construction, automotive, and aerospace are increasingly adopting expanded metal due to its strength-to-weight ratio, versatility, and aesthetic appeal. For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, it is crucial to stay attuned to emerging trends such as digital sourcing and automation in supply chain management. E-commerce platforms and digital marketplaces are simplifying procurement processes, enabling buyers to access a wider range of suppliers and products.

Furthermore, sustainability is becoming a significant influence on purchasing decisions. Buyers are increasingly looking for suppliers that demonstrate commitment to sustainable practices, such as using recycled materials and reducing waste. Additionally, the integration of advanced manufacturing technologies, such as 3D printing and smart manufacturing, is reshaping the production landscape, allowing for more customized solutions tailored to specific needs. Understanding these dynamics will empower B2B buyers to make informed decisions, optimize their supply chains, and enhance their competitive edge.

How Is Sustainability Shaping the Expanded Metal Mesh Sector and What Are the Ethical Sourcing Considerations?

Sustainability is a key consideration in the expanded metal mesh industry, reflecting a growing awareness of environmental impacts among consumers and businesses alike. The production of expanded metal involves processes that can be resource-intensive; however, advancements in technology are facilitating more efficient manufacturing practices that reduce energy consumption and waste. For B2B buyers, sourcing products from manufacturers that prioritize environmental stewardship is essential. This includes looking for certifications such as ISO 14001, which indicates a commitment to effective environmental management systems.

Ethical sourcing extends beyond environmental considerations; it encompasses fair labor practices, transparency in supply chains, and the responsible procurement of raw materials. Buyers should assess suppliers for their adherence to ethical standards and their engagement in social responsibility initiatives. In addition, selecting expanded metal products made from recycled or sustainably sourced materials can significantly enhance a company’s sustainability profile, appealing to environmentally conscious consumers and stakeholders.

What Is the Brief Evolution and History of Expanded Metal Mesh in B2B Applications?

The expanded metal mesh has a rich history that dates back to the late 19th century when it was first developed as a versatile material for architectural and industrial applications. Initially used for security and protection, its unique diamond pattern and structural properties quickly gained popularity across various sectors, including construction, automotive, and aerospace. Over time, advancements in manufacturing techniques have led to the development of a wide range of expanded metal products, catering to diverse applications from decorative elements in architecture to functional components in industrial machinery.

As industries evolve, so too does the application of expanded metal mesh, adapting to meet the demands of modern design and engineering challenges. Understanding this evolution helps B2B buyers appreciate the versatility of expanded metal and its potential to innovate within their own projects.

Frequently Asked Questions (FAQs) for B2B Buyers of expanded metal mesh

-

How do I choose the right expanded metal mesh for my application?

Selecting the appropriate expanded metal mesh depends on various factors, including the intended application, material type, and required strength. For applications requiring lightweight yet strong solutions, consider aluminum or galvanized steel. If durability in harsh environments is essential, stainless steel may be preferable. Assess the mesh’s opening size, thickness, and pattern—flattened or raised—based on your specific needs. Consult with suppliers about customization options, as many offer tailored solutions to meet unique specifications. -

What are the common applications for expanded metal mesh?

Expanded metal mesh is widely utilized across various industries due to its versatility. Common applications include security fencing, machine guards, and decorative elements in architecture. In construction, it serves as a lightweight reinforcement material and in flooring as a slip-resistant surface. Additionally, it’s used in ventilation grilles, shelving, and agricultural applications. Understanding your application will help you choose the right type and gauge of expanded metal mesh. -

What should I consider when vetting suppliers for expanded metal mesh?

When vetting suppliers, prioritize their reputation, experience, and product quality. Request samples to assess the material’s durability and craftsmanship. Check for certifications that demonstrate compliance with international standards, such as ISO or ASTM. Additionally, inquire about their production capabilities, lead times, and customer service responsiveness. It’s also beneficial to read customer reviews and case studies to gauge satisfaction levels among previous clients. -

What is the typical minimum order quantity (MOQ) for expanded metal mesh?

The minimum order quantity for expanded metal mesh can vary significantly by supplier. Some may offer flexibility with small orders, while others may have stricter MOQs, typically ranging from 100 to 500 square feet. For international buyers, consider how MOQs impact shipping costs and logistics. Always confirm with the supplier if they provide cut-to-size options, as this may allow you to order smaller quantities without incurring excessive waste. -

What payment terms can I expect when sourcing expanded metal mesh internationally?

Payment terms vary by supplier and depend on factors such as your relationship with them and the order size. Common terms include upfront payment, 30% deposit with the balance upon delivery, or net 30/60 days after invoicing. For international transactions, consider using secure payment methods like letters of credit or escrow services to mitigate risks. Always clarify payment terms before finalizing an order to avoid misunderstandings. -

How can I ensure quality assurance for my expanded metal mesh orders?

To ensure quality assurance, request a detailed specification sheet from the supplier outlining material properties, dimensions, and manufacturing processes. Inquire about their quality control measures, including testing and inspection protocols. If possible, conduct on-site inspections or arrange for third-party inspections before shipment. Establish clear communication regarding your quality standards to ensure that the delivered products meet your expectations. -

What are the logistics considerations for importing expanded metal mesh?

Importing expanded metal mesh involves several logistics considerations, including shipping methods, customs clearance, and tariffs. Determine the most cost-effective shipping option based on order size and urgency, such as sea freight for large orders or air freight for smaller, urgent shipments. Ensure you are familiar with the import regulations and tariffs in your country to avoid unexpected costs. Collaborating with a freight forwarder can streamline the logistics process and ensure compliance with all requirements. -

Can I customize expanded metal mesh to fit specific design needs?

Yes, many suppliers offer customization options for expanded metal mesh. You can specify dimensions, opening sizes, material types, and patterns to fit your design requirements. Some manufacturers may also provide additional services like cutting, bending, or coating to enhance functionality and aesthetics. When discussing customization, provide detailed drawings or specifications to help suppliers understand your needs accurately, ensuring that the final product aligns with your vision.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for expanded metal mesh

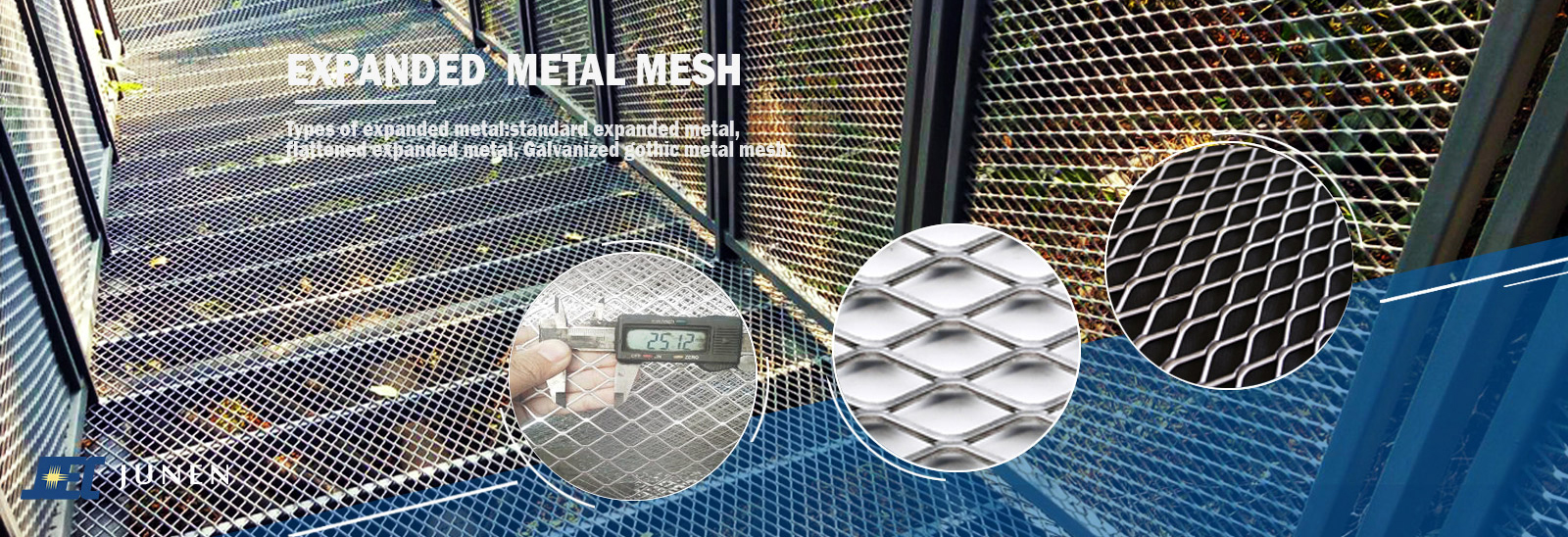

A stock image related to expanded metal mesh.

The global market for expanded metal mesh continues to evolve, driven by diverse applications across multiple industries. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding the nuances of strategic sourcing is crucial. Key takeaways include the importance of selecting the right material—such as aluminum, carbon steel, or stainless steel—tailored to specific project requirements. Considerations like gauge, opening size, and sheet dimensions can significantly impact both performance and cost-effectiveness.

As the demand for sustainable and lightweight materials grows, investing in expanded metal solutions not only enhances product durability but also optimizes resource utilization. Buyers should prioritize suppliers who offer flexibility in order sizes and customization options, ensuring that their sourcing strategies align with project timelines and budget constraints.

Looking ahead, the outlook for expanded metal mesh is promising, with innovations in manufacturing and design anticipated to open new avenues for application. B2B buyers are encouraged to engage with suppliers early in the procurement process, fostering partnerships that can drive efficiency and value in their operations. By leveraging strategic sourcing practices, companies can position themselves at the forefront of this dynamic market.