Discover Cost-Saving Benefits of Hardware Fabric (2025)

Introduction: Navigating the Global Market for hardware fabric

Navigating the complexities of sourcing hardware fabric can be daunting for international B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. The challenge often lies in identifying reliable suppliers while ensuring the products meet specific quality standards and application needs. This comprehensive guide aims to simplify the procurement process by exploring various types of hardware fabric, including galvanized and vinyl-coated options, and their applications in sectors such as agriculture, construction, and home improvement.

In the following sections, we will delve into essential considerations for selecting the right hardware fabric, including supplier vetting processes, pricing strategies, and logistical considerations for international shipping. By providing actionable insights and expert recommendations, this guide empowers B2B buyers to make informed purchasing decisions, mitigating risks associated with subpar products and unreliable suppliers.

Whether you’re a buyer in the UK looking for sustainable fencing solutions or a supplier in South America seeking innovative mesh applications, understanding the nuances of the global hardware fabric market is crucial. This guide serves as a valuable resource to navigate the intricacies of sourcing hardware fabric, ultimately supporting your business’s growth and operational efficiency in today’s competitive landscape.

Understanding hardware fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Galvanized Steel Hardware Cloth | Rust-resistant, available in various mesh sizes | Agricultural fencing, garden protection | Pros: Durable, long-lasting; Cons: Heavier, may require more installation effort. |

| Vinyl Coated Hardware Cloth | Enhanced weather resistance, available in colors | Landscaping, animal enclosures | Pros: Aesthetic appeal, corrosion-resistant; Cons: Higher cost compared to galvanized. |

| Welded Wire Fabric | Stronger structure due to welded joints | Industrial applications, security fencing | Pros: High tensile strength; Cons: Less flexible, may not suit all applications. |

| Hex Netting | Hexagonal mesh design, lighter weight | Poultry fencing, garden borders | Pros: Easy to handle, cost-effective; Cons: Less durable than welded options. |

| Plastic Coated Wire Mesh | Lightweight, available in various colors | Temporary fencing, decorative uses | Pros: Easy installation, rust-proof; Cons: Less robust for heavy-duty applications. |

What Are the Characteristics of Galvanized Steel Hardware Cloth?

Galvanized steel hardware cloth is known for its rust-resistant properties, making it suitable for outdoor applications. It is available in various mesh sizes, allowing for tailored solutions based on specific requirements. This type of hardware cloth is widely used in agricultural fencing and garden protection, where durability and longevity are critical. When purchasing, B2B buyers should consider the gauge and mesh size to ensure it meets their project needs, as heavier gauges offer enhanced strength.

How Does Vinyl Coated Hardware Cloth Differ from Other Types?

Vinyl coated hardware cloth features a plastic coating that provides enhanced weather resistance and aesthetic appeal. Available in various colors, it is particularly useful for landscaping and animal enclosures, where visual integration is important. B2B buyers should weigh the higher cost against the benefits of corrosion resistance and improved longevity. It is essential to assess the specific environmental conditions the fabric will face to determine if this option is justified.

What Are the Advantages of Using Welded Wire Fabric?

Welded wire fabric is characterized by its robust structure, as it consists of wires that are welded at intersections. This design offers high tensile strength, making it ideal for industrial applications and security fencing. B2B buyers should consider the installation environment, as the rigidity of welded wire may not suit all applications. While it provides excellent durability, its lack of flexibility can be a drawback in certain projects where adaptability is required.

In What Scenarios is Hex Netting Most Effective?

Hex netting, with its lightweight hexagonal mesh design, is often used for poultry fencing and garden borders. Its ease of handling and cost-effectiveness make it a popular choice for temporary applications. B2B buyers should note that while hex netting is easy to install, it may not offer the same level of durability as welded wire options. Assessing the intended use and potential exposure to elements will help determine if hex netting is appropriate for specific projects.

When Should Buyers Consider Plastic Coated Wire Mesh?

Plastic coated wire mesh is lightweight and available in multiple colors, making it suitable for decorative and temporary fencing applications. Its rust-proof nature simplifies maintenance, appealing to B2B buyers seeking low-maintenance solutions. However, it is important to note that plastic coated options may not withstand heavy-duty use. Buyers should consider the expected load and environmental factors when selecting this type of hardware fabric to ensure it meets their operational demands.

Key Industrial Applications of hardware fabric

| Industry/Sector | Specific Application of hardware fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Pest Control Fencing | Protects crops from pests, reducing loss and increasing yield | Consider mesh size, gauge, and corrosion resistance |

| Construction | Reinforcement in Concrete | Enhances structural integrity, ensuring safety and durability | Evaluate tensile strength and compatibility with materials |

| Landscaping & Gardening | Garden Fencing | Secures gardens from animals, promoting healthy plant growth | Look for UV resistance and ease of installation |

| Aquaculture | Fish Enclosures | Prevents fish escape and protects from predators | Focus on corrosion resistance and mesh size appropriate for species |

| Mining and Quarrying | Safety Barriers and Screens | Ensures worker safety by preventing access to hazardous areas | Assess durability under extreme conditions and compliance with safety standards |

How is Hardware Fabric Used in Agriculture for Pest Control?

In the agricultural sector, hardware fabric is extensively employed for pest control fencing. This application is critical in regions where crop loss due to pests can significantly impact food security and profitability. The mesh design allows for ventilation and sunlight while effectively keeping out unwanted animals. For international buyers, especially from regions like Africa and South America, sourcing durable, corrosion-resistant materials is vital due to varying climatic conditions that can affect the longevity of the fencing.

What Role Does Hardware Fabric Play in Construction Reinforcement?

In construction, hardware fabric serves as a reinforcement material in concrete applications. It enhances structural integrity, thereby ensuring safety and durability in buildings and infrastructure. This is particularly important for international buyers in Europe and the Middle East, where stringent building codes exist. Buyers should consider the tensile strength and compatibility of the hardware fabric with specific concrete mixes to meet local regulations and ensure project success.

How is Hardware Fabric Utilized in Landscaping and Gardening?

For landscaping and gardening, hardware fabric is often used as garden fencing to secure plots from animals like rabbits and deer. This application not only protects plants but also promotes healthy growth by preventing damage. International buyers, particularly in regions with diverse wildlife, should prioritize UV-resistant options to ensure longevity. Additionally, ease of installation is a key consideration, as many buyers prefer solutions that can be set up quickly and efficiently.

What Are the Benefits of Hardware Fabric in Aquaculture?

In aquaculture, hardware fabric is essential for creating fish enclosures that prevent escape and protect fish from predators. This application is vital for maintaining stock levels and ensuring the sustainability of fish farming operations. International buyers, especially in coastal regions of Africa and South America, should focus on sourcing materials that offer superior corrosion resistance, as exposure to saltwater can significantly degrade lower-quality fabrics. The mesh size must also be appropriate for the species being farmed to prevent escapes and ensure optimal growth conditions.

How is Hardware Fabric Applied in Mining and Quarrying Safety?

In the mining and quarrying industries, hardware fabric is utilized for safety barriers and screens that prevent unauthorized access to hazardous areas. This application is critical for ensuring worker safety and compliance with safety regulations. Buyers in these sectors should assess the durability of the hardware fabric under extreme conditions, such as exposure to chemicals and heavy machinery. Compliance with local safety standards is also a crucial sourcing consideration, as it can impact operational legality and worker protection.

3 Common User Pain Points for ‘hardware fabric’ & Their Solutions

Scenario 1: Sourcing High-Quality Hardware Fabric for Diverse Applications

The Problem: B2B buyers often struggle to find hardware fabric that meets the specific needs of their projects. For example, a construction company in South Africa may require a durable, galvanized steel hardware cloth for fencing, but they encounter difficulties sourcing materials that comply with local regulations or international quality standards. Inconsistent product quality and lack of transparency from suppliers can lead to project delays and increased costs.

The Solution: To overcome these challenges, it’s crucial for buyers to establish a clear set of specifications before sourcing hardware fabric. This includes defining the material type (such as galvanized steel or vinyl-coated options), mesh size, and gauge. Conduct thorough research to identify reputable suppliers that offer high-quality products. Utilize platforms like Alibaba or local trade shows to connect with manufacturers who can provide certifications, ensuring compliance with relevant standards. Additionally, consider requesting samples before making bulk purchases. This hands-on approach allows buyers to evaluate the fabric’s durability and suitability for their specific applications, thus minimizing the risk of project disruptions.

Scenario 2: Understanding the Versatility of Hardware Fabric in Different Markets

The Problem: Many B2B buyers are unaware of the multiple applications of hardware fabric across various industries, which can limit their purchasing decisions. For instance, a buyer in the agricultural sector in Brazil may only consider hardware cloth for fencing but miss out on its potential use for pest control or reinforcing garden beds. This narrow view can lead to underutilization of resources and missed opportunities for cost savings.

The Solution: To better understand the versatility of hardware fabric, buyers should engage in comprehensive market research. This includes attending industry seminars or webinars that focus on innovative uses of hardware fabric. Collaborating with suppliers who can provide case studies or testimonials showcasing diverse applications can also be beneficial. For example, a supplier might illustrate how their hardware cloth has been effectively used in aquaculture for netting or in construction for reinforcing structures. By expanding their knowledge on the various applications, buyers can make informed decisions that optimize their investment and enhance their operational efficiency.

Scenario 3: Dealing with Installation and Maintenance Challenges

The Problem: Installation and maintenance of hardware fabric can pose significant challenges for B2B buyers. A manufacturer in the Middle East may find that improper installation of hardware cloth results in frequent repairs and replacements, thereby escalating costs and downtime. Additionally, lack of knowledge regarding the maintenance of these materials can lead to premature deterioration and failure.

The Solution: To address these challenges, buyers should prioritize education on the best installation practices and ongoing maintenance requirements. This can involve hiring experienced contractors who specialize in hardware fabric installation or investing in training for in-house teams. Detailed installation guides and maintenance checklists should be provided by suppliers to ensure proper handling and upkeep of the materials. Furthermore, establishing a regular maintenance schedule can help identify issues before they escalate. For instance, routine inspections can prevent rust or damage caused by environmental factors. By implementing these strategies, buyers can extend the lifespan of their hardware fabric and reduce long-term costs associated with repairs and replacements.

Strategic Material Selection Guide for hardware fabric

What Are the Key Properties of Common Materials Used in Hardware Fabric?

When selecting hardware fabric, understanding the properties of various materials is crucial for ensuring optimal performance in specific applications. Here, we analyze four common materials used in hardware fabric: galvanized steel, stainless steel, vinyl-coated wire, and plastic mesh.

Galvanized Steel: A Durable Choice for Tough Environments

Key Properties: Galvanized steel is coated with zinc to enhance its corrosion resistance, making it suitable for outdoor applications. It can withstand high temperatures and pressures, which is essential for applications in harsh environments.

Pros & Cons: The primary advantage of galvanized steel is its durability and resistance to rust, extending the lifespan of the hardware fabric. However, it can be heavier and more expensive than other options. The manufacturing process is relatively straightforward, but the weight may limit its use in lightweight applications.

Impact on Application: Galvanized steel is ideal for fencing, garden protection, and animal enclosures. Its compatibility with various media, including soil and water, makes it a versatile choice for outdoor applications.

Considerations for International Buyers: Buyers should ensure compliance with local standards, such as ASTM in the U.S. or DIN in Europe. Galvanized steel is widely accepted, but specific grades may be required depending on the application and region.

Stainless Steel: The Premium Option for Corrosion Resistance

Key Properties: Stainless steel offers exceptional corrosion resistance and strength, making it suitable for high-stress applications. It can withstand extreme temperatures and is less likely to tarnish over time.

Pros & Cons: The key advantage of stainless steel is its longevity and aesthetic appeal, making it suitable for visible applications. However, it is generally more expensive than galvanized steel and may require specialized tools for installation.

Impact on Application: This material is particularly effective in environments where hygiene is critical, such as food processing or medical applications. Its compatibility with various chemicals further enhances its usability.

Considerations for International Buyers: Buyers from regions with stringent health and safety regulations, such as Europe, should prioritize stainless steel for applications requiring compliance with safety standards. Understanding local regulations and certifications is essential.

Vinyl-Coated Wire: Combining Flexibility with Protection

Key Properties: Vinyl-coated wire features a layer of PVC that provides additional protection against corrosion and enhances flexibility. It is available in various colors, making it aesthetically pleasing for decorative applications.

Pros & Cons: The main advantage is its resistance to rust and UV damage, which is ideal for outdoor use. However, the coating can wear off over time, especially in high-friction applications, and it may not be as strong as bare metal options.

Impact on Application: Vinyl-coated wire is commonly used in garden fencing and decorative applications where visual appeal is important. Its flexibility allows for easy installation in various shapes.

Considerations for International Buyers: Buyers should consider the local climate and environmental conditions. In humid or coastal areas, the vinyl coating may degrade faster, necessitating more frequent replacements.

Plastic Mesh: A Lightweight Alternative for Specific Uses

Key Properties: Plastic mesh is lightweight, resistant to moisture, and can be molded into various shapes. It is often UV stabilized, making it suitable for outdoor applications.

Pros & Cons: The primary advantage of plastic mesh is its lightweight nature, making it easy to handle and install. However, it may not provide the same level of strength or durability as metal options, limiting its use in high-stress applications.

Impact on Application: Plastic mesh is often used in temporary fencing, erosion control, and as a lightweight barrier. It is compatible with various media, including soil and water.

Considerations for International Buyers: Buyers should be aware of the material’s lifespan and potential environmental impact. Compliance with local regulations regarding plastic use is also essential, particularly in regions with strict waste management policies.

Summary Table of Material Selection for Hardware Fabric

| Material | Typical Use Case for hardware fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Fencing, garden protection | Durable and rust-resistant | Heavier and potentially more costly | Medium |

| Stainless Steel | Food processing, medical applications | Exceptional corrosion resistance | Higher cost and specialized tools needed | High |

| Vinyl-Coated Wire | Decorative fencing, garden use | Aesthetic appeal and UV resistance | Coating can wear off over time | Medium |

| Plastic Mesh | Temporary fencing, erosion control | Lightweight and easy to install | Limited strength compared to metal | Low |

This guide serves as a strategic resource for international B2B buyers, enabling informed decisions when selecting hardware fabric materials tailored to their specific needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for hardware fabric

What are the Key Stages in the Manufacturing Process of Hardware Fabric?

The manufacturing of hardware fabric involves several critical stages that ensure the final product meets industry standards and customer expectations. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Raw Materials are Used?

The first stage in the manufacturing process is material preparation, which typically involves selecting high-quality raw materials. For hardware fabric, common materials include galvanized steel, stainless steel, and vinyl-coated wire. The choice of material depends on the intended application, such as fencing, mesh screens, or industrial use.

Once selected, the raw materials are subjected to cleaning and surface treatment processes to enhance durability and prevent corrosion. This step is crucial, especially for international buyers in humid or coastal regions, as it directly impacts the longevity of the product.

How is the Forming Process Executed?

After material preparation, the next stage is forming, where the raw materials are shaped into the desired mesh or fabric configuration. This typically involves processes such as weaving, welding, or knitting.

- Weaving is commonly used for finer meshes, where wires are interlaced to create a grid pattern.

- Welding is more prevalent in creating sturdier fabrics, where wires are fused at intersections to enhance strength.

Precision in this stage is vital, as any discrepancies can lead to weaknesses in the final product. Manufacturers often use automated machines to ensure consistency and reduce human error.

What Happens During the Assembly Stage?

The assembly stage involves the integration of different components, which may include additional features like coatings or treatments for UV resistance and enhanced durability. For hardware fabric, this may also involve cutting the fabric to specific sizes or adding edge reinforcements.

Manufacturers must adhere to strict tolerances during assembly to ensure that the final product meets specifications. This is particularly important for B2B buyers who require specific dimensions for applications like fencing or industrial barriers.

How is Finishing Performed on Hardware Fabric?

The final stage of manufacturing is finishing, which includes surface treatments that improve the aesthetic and functional properties of the hardware fabric. Common finishing processes include galvanization, powder coating, or vinyl coating.

- Galvanization involves applying a protective zinc coating to prevent rust.

- Powder coating adds color and enhances surface hardness.

- Vinyl coating provides additional weather resistance and is often used for decorative applications.

These finishing processes not only enhance the product’s lifespan but also its visual appeal, which can be a significant factor for buyers in sectors like construction and landscaping.

What Quality Assurance Practices are Essential for Hardware Fabric?

Quality assurance (QA) is critical in ensuring that hardware fabric meets international standards and customer expectations. For B2B buyers, understanding these practices can help verify the reliability of suppliers.

Which International Standards Should Buyers Be Aware Of?

International standards, such as ISO 9001, provide a framework for quality management systems and are essential for manufacturers aiming to deliver consistent quality. Compliance with these standards can be a strong indicator of a supplier’s commitment to quality.

In addition to ISO standards, industry-specific certifications such as CE marking (for products sold in the European Economic Area) and API (American Petroleum Institute) certification for certain industrial applications can further assure buyers of the product’s quality and safety.

What are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This step assesses the quality of raw materials upon receipt. A thorough IQC process ensures that only materials meeting specifications are used in production.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC checks are conducted to monitor the forming and assembly stages. This ensures that any deviations from standards are caught early.

-

Final Quality Control (FQC): After finishing, the final product undergoes rigorous testing to ensure it meets all specified requirements. This may include tensile strength tests, mesh size verification, and corrosion resistance evaluations.

B2B buyers should inquire about the specific QC procedures employed by suppliers to ensure comprehensive quality management.

How Can Buyers Verify Supplier Quality Control?

To confirm a supplier’s commitment to quality assurance, B2B buyers can undertake several actions:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and adherence to quality standards. Audits can be performed by the buyers themselves or by third-party inspection agencies.

-

Request Quality Reports: Buyers should request documentation detailing the QC processes, including test results and compliance certificates. This transparency can help build trust between buyers and suppliers.

-

Engage Third-Party Inspectors: Utilizing independent inspection services can further validate the quality of the hardware fabric before shipment. These inspectors can provide unbiased reports on compliance with industry standards.

What Nuances Should International Buyers Consider Regarding QC and Certifications?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certifications is essential.

-

Regulatory Compliance: Different regions have varying regulations regarding product safety and quality. Buyers should familiarize themselves with local regulations and ensure that their suppliers comply.

-

Cultural Differences in Quality Standards: Expectations regarding quality can vary significantly across regions. European buyers, for example, may have stricter standards compared to suppliers in other regions. Thus, establishing clear communication about quality expectations is crucial.

-

Traceability and Documentation: Ensuring that all products can be traced back to their manufacturing source is vital for quality assurance. Buyers should ensure that suppliers maintain comprehensive records and can provide documentation upon request.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing hardware fabric, ensuring they receive products that meet their specifications and industry standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hardware fabric’

To successfully procure hardware fabric, international B2B buyers must navigate a variety of factors that can impact their sourcing decisions. This step-by-step checklist will guide you through the essential actions necessary for effective procurement, ensuring you select the best suppliers and materials for your needs.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is crucial before beginning the sourcing process. This includes determining the type of hardware fabric needed, such as galvanized steel or vinyl-coated options, as well as the appropriate gauge, mesh size, and dimensions. Clearly defined specifications help streamline the procurement process and ensure compatibility with your intended applications.

- Example Specifications:

- Gauge (e.g., 19-gauge for durability)

- Mesh size (e.g., 1/4 inch for pest control)

Step 2: Identify Reliable Suppliers

Finding trustworthy suppliers is a fundamental step in the procurement journey. Conduct thorough research to identify manufacturers and distributors known for quality products and reliability. Look for suppliers with a strong reputation in your target regions, such as Africa, South America, the Middle East, and Europe.

- Key Considerations:

- Company history and market presence

- Client testimonials and industry reviews

Step 3: Evaluate Supplier Certifications

Before engaging with suppliers, verify their certifications and compliance with industry standards. This step is vital to ensure that the products meet quality and safety regulations specific to your market. Certifications can also indicate a supplier’s commitment to environmental sustainability and ethical practices.

- Relevant Certifications:

- ISO certification

- Compliance with local regulations in your target market

Step 4: Request Samples for Testing

Obtaining samples of the hardware fabric you intend to purchase is an essential practice. Testing samples allows you to evaluate the material’s quality, durability, and suitability for your specific applications. This step can prevent costly errors later in the procurement process.

- Sample Testing Should Include:

- Physical strength tests

- Resistance to environmental factors (e.g., rust, UV exposure)

Step 5: Compare Pricing and Payment Terms

Once you have shortlisted potential suppliers, compare their pricing structures and payment terms. Understanding the total cost of ownership, including shipping and customs fees, is crucial for budgeting. Additionally, favorable payment terms can provide financial flexibility.

- Comparison Factors:

- Bulk pricing discounts

- Payment schedules and methods accepted

Step 6: Assess Logistics and Delivery Capabilities

Evaluate the logistics and delivery capabilities of your selected suppliers. Timely delivery is critical in maintaining your project timelines, especially in international transactions. Confirm the shipping methods, lead times, and the supplier’s ability to handle customs clearance.

- Logistics Considerations:

- Shipping options (air, sea, or land)

- Tracking capabilities during transit

Step 7: Establish Communication Protocols

Effective communication is key to a successful procurement process. Establish clear protocols for ongoing communication with your supplier, including points of contact for various issues. This ensures that any concerns can be promptly addressed, enhancing the overall partnership.

- Communication Best Practices:

- Regular updates on order status

- Clear channels for feedback and issue resolution

By following these steps, international B2B buyers can navigate the complexities of sourcing hardware fabric effectively, ensuring they make informed decisions that align with their business needs and regional requirements.

Comprehensive Cost and Pricing Analysis for hardware fabric Sourcing

What Are the Key Cost Components in Hardware Fabric Sourcing?

When sourcing hardware fabric, several cost components come into play that B2B buyers must consider. These include:

-

Materials: The type of material used, such as galvanized steel or vinyl-coated options, significantly affects the cost. Buyers should be aware of the price fluctuations in raw materials, which can vary based on market demand and availability.

-

Labor: Labor costs can vary widely depending on the region and the complexity of manufacturing processes. In regions with higher wages, such as parts of Europe, labor costs may consume a larger portion of the overall pricing structure.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Understanding these costs can help buyers gauge the pricing strategy of their suppliers.

-

Tooling: Custom orders often require specific tooling, which can lead to additional costs. For buyers seeking unique specifications, discussing tooling fees upfront is crucial to avoid unexpected expenses.

-

Quality Control (QC): Ensuring product quality can incur additional costs, particularly for high-specification items. Suppliers who invest in rigorous QC processes may charge higher prices, but this often results in better quality assurance.

-

Logistics: Shipping and handling can be significant, especially for international transactions. Factors like distance, shipping methods, and import duties contribute to the overall logistics cost.

-

Margin: Finally, supplier margins can vary based on market positioning and competition. Understanding the typical margin in the industry can provide insight into fair pricing.

How Do Price Influencers Affect Hardware Fabric Costs?

Several factors influence the pricing of hardware fabric, which international buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to achieve better pricing.

-

Specifications and Customization: Custom features, such as specific mesh sizes or coatings, typically increase costs. Buyers should clearly define their specifications to avoid miscommunication and additional charges.

-

Material Quality and Certifications: Higher-quality materials and certifications (like ISO standards) can lead to higher prices. However, investing in quality often translates to lower maintenance and replacement costs over time.

-

Supplier Factors: The reliability and reputation of suppliers can affect pricing. Established suppliers may charge a premium for their reputation and service level, which can be worth the investment.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for pricing. They define responsibilities between buyers and sellers, including shipping, insurance, and tariffs, which can impact the total cost.

What Tips Can Help International Buyers Optimize Costs?

International B2B buyers should adopt several strategies to enhance cost efficiency in hardware fabric sourcing:

-

Negotiate Effectively: Buyers should enter negotiations with clear insights into market prices and competitor offerings. Establishing strong relationships with suppliers can also lead to better deals.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial purchase prices, consider ongoing costs, including maintenance, durability, and potential replacement. A slightly higher upfront cost may yield long-term savings if the material lasts longer.

-

Understand Pricing Nuances: Each region has its pricing dynamics influenced by local market conditions, labor costs, and material availability. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to understand these nuances.

-

Stay Informed About Market Trends: Regularly monitoring market trends related to material costs and industry standards can provide leverage during negotiations and help identify the best time to purchase.

Conclusion

By understanding the intricate cost components and price influencers in hardware fabric sourcing, international B2B buyers can make more informed purchasing decisions. Utilizing effective negotiation strategies and focusing on total cost of ownership can lead to significant savings and enhanced supplier relationships.

Disclaimer: Prices are indicative and may vary based on market conditions, supplier terms, and specific order requirements.

Alternatives Analysis: Comparing hardware fabric With Other Solutions

Introduction to Alternatives in Hardware Solutions

In the realm of protective fencing and barrier solutions, hardware fabric stands out for its versatility and robustness. However, B2B buyers should consider various alternatives that may fit their specific needs better, especially in regions like Africa, South America, the Middle East, and Europe. Understanding the strengths and weaknesses of each option can aid in making informed purchasing decisions.

Comparative Overview of Hardware Fabric and Alternatives

| Comparison Aspect | Hardware Fabric | Chain Link Fencing | Welded Wire Fencing |

|---|---|---|---|

| Performance | High tensile strength, durable | Moderate durability, flexible | High strength, stable |

| Cost | Moderate to high | Generally lower | Moderate to high |

| Ease of Implementation | Moderate complexity in installation | Easy to install | Moderate complexity |

| Maintenance | Low maintenance required | Moderate maintenance needed | Low maintenance required |

| Best Use Case | Garden and pest control, animal enclosures | Security fencing, playgrounds | Agricultural applications, security fencing |

Detailed Breakdown of Alternatives

What are the Benefits and Drawbacks of Chain Link Fencing?

Chain link fencing is a common alternative to hardware fabric. It offers a cost-effective solution for security and boundary marking. The primary advantage of chain link is its affordability and ease of installation, making it a popular choice for commercial properties and public parks. However, its flexibility can be a drawback in high-stress environments, as it may not provide the same level of durability as hardware fabric. Moreover, its aesthetic appeal is limited, which may be a consideration for buyers focused on design.

How Does Welded Wire Fencing Compare?

Welded wire fencing is another viable alternative that offers a robust solution for various applications, including agriculture and security. This fencing type is constructed from steel wires that are welded at intersections, providing a high level of strength and stability. The main advantage of welded wire fencing is its longevity and resistance to bending, making it suitable for both residential and agricultural uses. However, it can be more expensive than chain link fencing and may require professional installation, which could deter budget-conscious buyers.

Conclusion: How to Choose the Right Fencing Solution for Your Business

Selecting the right fencing solution requires careful consideration of various factors such as performance, cost, ease of installation, and maintenance. Hardware fabric is an excellent choice for applications requiring flexibility and pest control, while chain link fencing serves as a budget-friendly option for general security. Welded wire fencing stands out for its durability and strength but may come with a higher price tag. Ultimately, B2B buyers must assess their specific needs, including the environment and purpose of the fencing, to choose the most suitable solution for their business operations.

Essential Technical Properties and Trade Terminology for hardware fabric

What Are the Essential Technical Properties of Hardware Fabric?

When sourcing hardware fabric, understanding its technical specifications is crucial for making informed decisions. Here are some key properties to consider:

-

Material Grade

Hardware fabric is often made from various materials, including galvanized steel and stainless steel. The grade of the material influences its strength, corrosion resistance, and overall durability. For example, galvanized steel is treated to resist rust, making it suitable for outdoor applications, while stainless steel offers superior corrosion resistance in harsh environments. -

Mesh Size

Mesh size refers to the dimensions of the openings in the fabric. Common sizes include 1/4 inch and 1/2 inch. The choice of mesh size affects the level of protection offered and the types of applications suitable for the fabric. Smaller mesh sizes are ideal for keeping out pests, while larger sizes may be used for ventilation or as barriers. -

Gauge

The gauge of the wire used in hardware fabric indicates its thickness. A lower gauge number signifies a thicker wire, which generally offers higher strength and durability. For instance, a 19-gauge wire is more robust than a 23-gauge wire. Selecting the appropriate gauge depends on the intended use, such as fencing livestock or constructing garden barriers. -

Roll Length and Width

Hardware fabric typically comes in rolls of various lengths and widths, such as 50 feet or 100 feet. Understanding these dimensions is vital for determining how much material you will need for your project. Buying in bulk can often lead to cost savings, making it essential for B2B buyers to evaluate their needs accurately. -

Coating Type

Many hardware fabrics are coated to enhance their properties. Vinyl coatings, for example, provide additional corrosion resistance and can improve aesthetic appeal. When selecting hardware fabric, consider whether a coating aligns with your project requirements and budget.

What Are Common Trade Terms Associated with Hardware Fabric?

Familiarizing yourself with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are several important trade terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of hardware fabric, understanding OEM relationships can help buyers identify reliable suppliers and ensure product quality. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Knowing the MOQ is critical for budget planning and inventory management, especially for international buyers who may be managing shipping costs from different regions. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. B2B buyers should utilize RFQs to gather competitive quotes for hardware fabric, ensuring they receive the best value for their purchase. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), can help buyers understand shipping costs and risk management. -

Lead Time

Lead time is the time it takes from placing an order to receiving it. This is particularly important for international buyers who must consider shipping times and customs clearance. Understanding lead times helps in planning project timelines effectively. -

Certification Standards

Various certification standards (such as ISO or ASTM) can apply to hardware fabric, depending on the industry. Knowing these standards is important for ensuring compliance and quality assurance, especially in regulated markets.

By grasping these technical properties and trade terms, B2B buyers can navigate the hardware fabric market more effectively, ensuring they make informed purchasing decisions that align with their business needs.

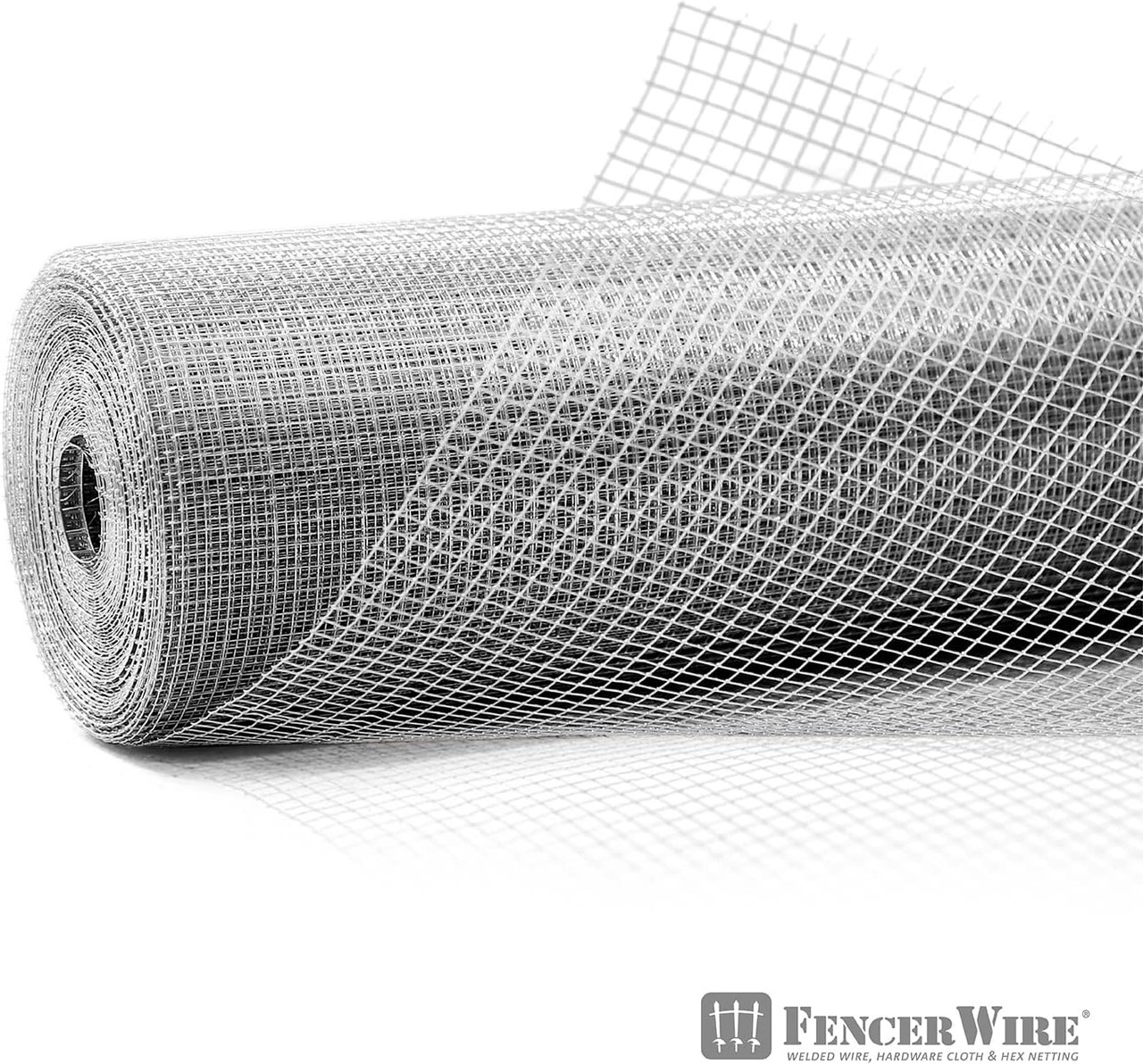

A stock image related to hardware fabric.

Navigating Market Dynamics and Sourcing Trends in the hardware fabric Sector

What Are the Current Market Dynamics and Sourcing Trends in the Hardware Fabric Sector?

The hardware fabric sector is experiencing significant growth driven by various global factors. One of the primary drivers is the increasing demand for durable and versatile materials in construction, agriculture, and landscaping. The rise of urbanization, particularly in Africa and South America, is prompting a surge in infrastructure projects that require high-quality fencing and protective materials. Additionally, advancements in manufacturing technologies are enabling suppliers to offer a wider range of products, including galvanized and vinyl-coated hardware cloth, which enhances durability and corrosion resistance.

A stock image related to hardware fabric.

Emerging B2B technology trends are reshaping sourcing practices in this sector. Digital platforms are becoming increasingly popular, allowing buyers to easily compare products and prices across different suppliers. This shift towards e-commerce is particularly pronounced in Europe, where buyers value convenience and efficiency. Furthermore, the integration of data analytics in supply chain management allows companies to forecast demand more accurately and optimize inventory levels, reducing costs and improving service delivery.

For international B2B buyers, understanding these market dynamics is crucial. Buyers from regions such as the Middle East and Europe must be aware of the fluctuating prices of raw materials, which can impact sourcing strategies. Additionally, geopolitical factors and trade policies can influence supply chain stability, making it essential for buyers to build relationships with multiple suppliers to mitigate risks.

How Can Sustainability and Ethical Sourcing Impact B2B Relationships in the Hardware Fabric Sector?

A stock image related to hardware fabric.

Sustainability is no longer just a buzzword; it has become a critical consideration for B2B buyers in the hardware fabric sector. The environmental impact of sourcing materials, particularly in terms of deforestation and pollution, has raised awareness among consumers and businesses alike. Buyers are increasingly seeking suppliers that prioritize eco-friendly practices, including the use of recycled materials and sustainable manufacturing processes.

Ethical sourcing is also gaining traction, with businesses expected to ensure that their supply chains are free from exploitation and adhere to fair labor practices. This is especially relevant for buyers in Europe, where regulations around corporate social responsibility are stringent. Products that come with certifications, such as ISO 14001 for environmental management or Fair Trade, can provide buyers with the assurance they need regarding the sustainability of their purchases.

Investing in ‘green’ materials not only enhances a company’s brand reputation but also aligns with the growing consumer demand for sustainable products. As a result, B2B buyers should prioritize suppliers who demonstrate a commitment to sustainability, which can lead to long-term partnerships and increased customer loyalty.

How Has the Hardware Fabric Sector Evolved Over Time?

The evolution of the hardware fabric sector can be traced back to its initial use in agricultural applications, primarily for fencing livestock. Over the decades, the material has transformed significantly, adapting to the changing needs of various industries. The introduction of galvanized and vinyl-coated options has expanded its applications beyond agriculture to include construction, landscaping, and even decorative purposes.

In the past, sourcing hardware fabric was often a local endeavor, limited by geographic constraints. However, with the globalization of trade and advancements in logistics, international buyers can now access a broader range of products from different markets. This evolution has not only increased competition but also improved the quality and variety of hardware fabric available, catering to diverse needs across different regions. Today, buyers can leverage online marketplaces to find and source products that meet their specific requirements, making the procurement process more efficient and effective.

Frequently Asked Questions (FAQs) for B2B Buyers of hardware fabric

-

How do I choose the right hardware fabric for my project?

Choosing the right hardware fabric depends on several factors, including the application, environmental conditions, and specific requirements. For agricultural uses, a galvanized steel cloth with a smaller mesh size can deter pests effectively, while for construction, a thicker gauge may be necessary for durability. Always consider the weight and tensile strength, as these will impact the fabric’s performance over time. Additionally, consult with suppliers about customization options that may better suit your unique needs. -

What is the best hardware cloth for garden and pest control?

The best hardware cloth for garden and pest control typically features a smaller mesh size, such as 1/4 inch, to prevent small animals from accessing your plants. A galvanized option is ideal as it resists rust and corrosion, ensuring longevity. It’s essential to select a fabric with adequate height and strength, depending on the types of pests prevalent in your area. Discuss with local suppliers to find region-specific recommendations that suit your gardening needs. -

What should I consider when vetting hardware fabric suppliers?

When vetting hardware fabric suppliers, assess their reputation, experience, and product quality. Request samples to evaluate the fabric’s durability and compliance with international standards. Look for suppliers with certifications such as ISO or ASTM to ensure quality control. It’s also beneficial to read customer reviews and seek references from other businesses in your industry. Establishing a strong relationship with suppliers can lead to better service and terms in the long run. -

What are the typical minimum order quantities (MOQ) for hardware fabric?

Minimum order quantities for hardware fabric can vary significantly by supplier and the specific product type. Generally, MOQs can range from as low as 100 feet to several hundred feet for bulk orders. It’s advisable to inquire directly with suppliers about their MOQ policies and whether they offer flexibility for smaller orders, especially for new buyers or those testing product lines. Understanding MOQ can help in planning your procurement strategy effectively. -

What payment terms should I expect when sourcing hardware fabric internationally?

Payment terms for international orders of hardware fabric typically vary by supplier and location. Common options include upfront payment, partial payment with the balance due on delivery, or payment upon receipt. Many suppliers also accept letters of credit, which can provide additional security for both parties. Be sure to clarify payment terms before finalizing an order and consider potential currency fluctuations when dealing with international transactions. -

How can I ensure quality assurance when sourcing hardware fabric?

To ensure quality assurance when sourcing hardware fabric, request detailed product specifications and test reports from suppliers. Implement quality control checks at various stages, including pre-shipment inspections and on-site evaluations if possible. Establishing clear communication regarding your quality expectations upfront can help mitigate issues. Additionally, consider collaborating with third-party inspection services to provide an unbiased assessment of the fabric quality before shipment. -

What logistics challenges should I be aware of when importing hardware fabric?

Logistics challenges when importing hardware fabric can include customs clearance, shipping delays, and potential damage during transit. It’s crucial to work with logistics partners experienced in international shipping to navigate customs regulations in your target market. Ensure that all documentation is complete and accurate to avoid delays. Additionally, consider insurance options for your shipment to protect against loss or damage, especially for large orders. -

Are there customization options available for hardware fabric orders?

Many suppliers offer customization options for hardware fabric orders, including variations in mesh size, gauge thickness, and roll lengths. Customization can help you meet specific project requirements more effectively. When discussing options, inquire about the minimums for custom orders and the associated lead times, as these can differ significantly from standard products. Collaborating closely with suppliers during the design phase can lead to a more tailored solution that fits your needs perfectly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for hardware fabric

As international B2B buyers navigate the complexities of sourcing hardware fabric, strategic sourcing emerges as a critical factor for success. Understanding the diverse offerings—such as galvanized steel and vinyl-coated options—enables buyers to select the most suitable materials for their specific applications, whether for construction, agriculture, or pest control.

How Can Strategic Sourcing Enhance Your Supply Chain?

By focusing on strategic sourcing, buyers can achieve cost efficiencies while ensuring quality and compliance with regional standards. This approach not only mitigates risks associated with supply chain disruptions but also fosters long-term relationships with suppliers across Africa, South America, the Middle East, and Europe.

What Should Buyers Consider Moving Forward?

Looking ahead, it is essential for buyers to stay informed about market trends, pricing fluctuations, and innovations in hardware fabric solutions. Engaging with reputable suppliers and leveraging digital platforms can provide valuable insights and enhance procurement strategies.

In conclusion, international B2B buyers are encouraged to embrace strategic sourcing as a means to optimize their purchasing decisions. By doing so, they position themselves to capitalize on emerging opportunities within the hardware fabric market, ensuring their businesses remain competitive in a rapidly evolving landscape.