Discover Cost-Saving Benefits of Metal Channel Sourcing (2025)

Introduction: Navigating the Global Market for metal channel

In the dynamic world of international trade, sourcing metal channels can pose significant challenges for B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. Whether you’re seeking to procure structural steel channels for construction or aluminum trim channels for manufacturing, understanding the complexities of global sourcing is crucial. This guide serves as your comprehensive resource, delving into the various types of metal channels available, their applications across industries, and effective supplier vetting strategies.

Navigating the global market requires an informed approach to purchasing, as factors such as material specifications, pricing, and logistics can vary widely by region. By providing detailed insights into cost structures, quality assessments, and sourcing options, this guide empowers B2B buyers to make strategic decisions that align with their operational needs.

From the bustling marketplaces of Argentina to the industrial hubs of Spain, this guide addresses the unique challenges faced by international buyers, offering actionable strategies to optimize your procurement processes. By leveraging this resource, you can confidently engage with suppliers, negotiate better terms, and ultimately enhance your supply chain efficiency. Let’s dive into the essential information that will equip you to navigate the global market for metal channels successfully.

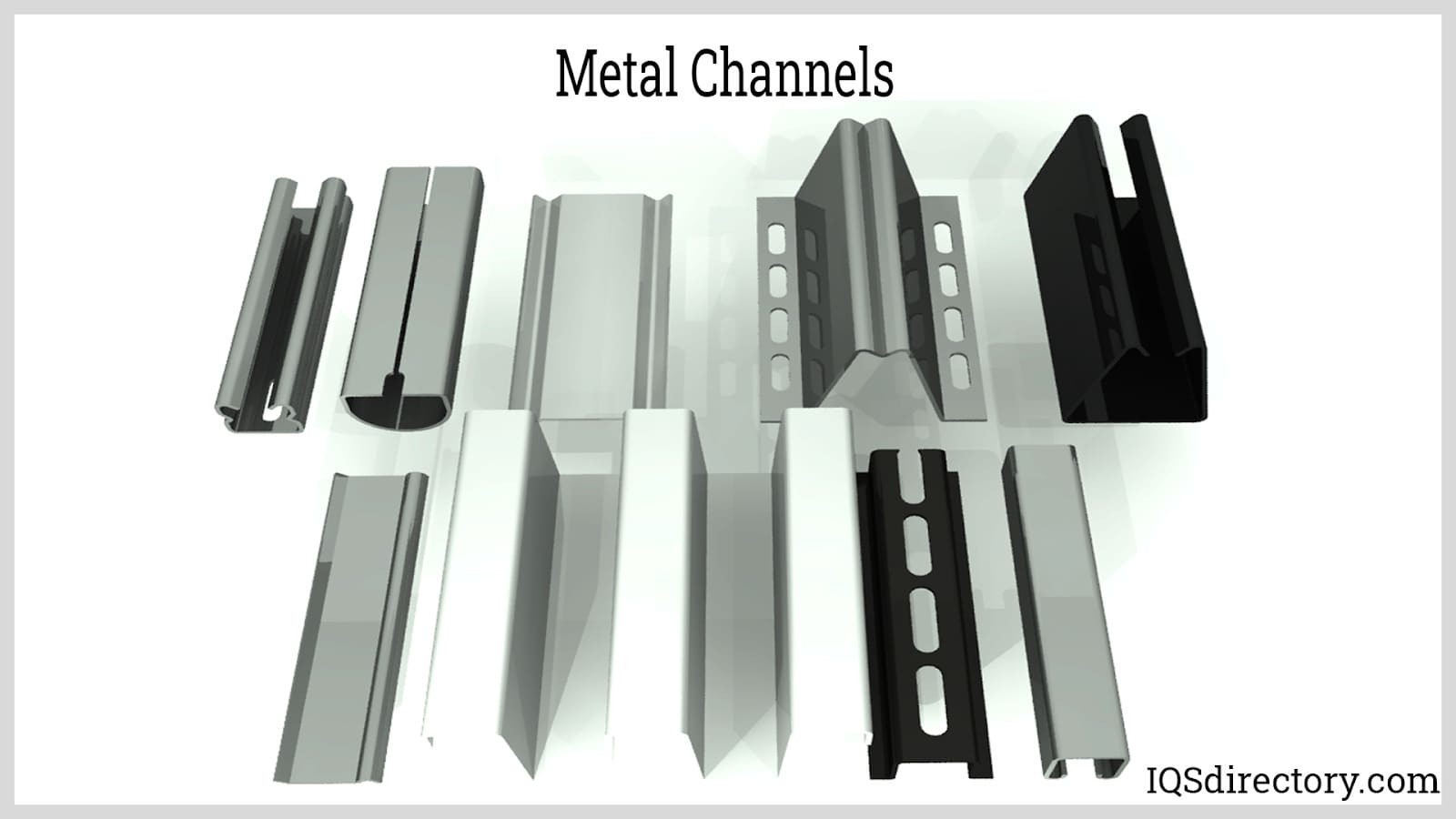

Understanding metal channel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| C-Channel | C-shaped with vertical web and two flanges | Construction, automotive, and manufacturing | Pros: Strong structural support; Cons: Limited to specific load applications. |

| U-Channel | U-shaped profile with open sides | Railings, frames, and signage | Pros: Lightweight; Cons: Less load capacity compared to C-channels. |

| Z-Channel | Z-shaped with flanges on opposite sides | Building facades, HVAC systems | Pros: Excellent for wind load resistance; Cons: More complex fabrication. |

| Aluminum Channel | Lightweight, corrosion-resistant aluminum alloy | Aerospace, marine, and architectural uses | Pros: High strength-to-weight ratio; Cons: Higher cost compared to steel. |

| Steel Channel | Hot-rolled, typically heavier and stronger | Heavy-duty construction and infrastructure | Pros: Superior strength; Cons: Heavier and may require more handling equipment. |

What are the characteristics of C-Channels and their B2B applications?

C-Channels are characterized by their distinctive “C” shape, which consists of a vertical web and two horizontal flanges. This structure provides excellent load-bearing capabilities, making them ideal for various applications in construction, automotive, and manufacturing sectors. When purchasing C-Channels, B2B buyers should consider factors such as the channel’s weight capacity, length, and thickness to ensure they meet specific project requirements.

How do U-Channels differ in use and characteristics?

U-Channels feature an open, U-shaped profile that makes them versatile for applications such as railings, frames, and signage. Their lightweight nature allows for easy handling and installation, making them a popular choice for projects that require flexibility. Buyers should evaluate the U-Channel’s material and finish, as these factors influence durability and aesthetic appeal, especially in outdoor or visible applications.

What advantages do Z-Channels offer for specific applications?

Z-Channels are uniquely shaped with flanges on opposite sides, providing enhanced resistance to wind loads, which is particularly beneficial for building facades and HVAC systems. Their design allows for effective load distribution, making them suitable for structural applications where lateral strength is critical. When sourcing Z-Channels, businesses should assess the complexity of fabrication and potential installation challenges, as these can impact project timelines.

Why choose Aluminum Channels for your B2B projects?

Aluminum Channels are lightweight and resistant to corrosion, making them an excellent choice for aerospace, marine, and architectural applications. Their high strength-to-weight ratio allows for innovative design solutions while minimizing overall structural weight. B2B buyers should be mindful of the higher cost associated with aluminum channels compared to steel, but the long-term benefits in durability and maintenance can justify this investment.

How do Steel Channels compare in terms of strength and applications?

Steel Channels are known for their robustness, making them the go-to option for heavy-duty construction and infrastructure projects. Their hot-rolled design ensures superior strength, allowing them to withstand significant loads and stresses. Buyers should consider the weight and handling requirements of steel channels, as their heft can necessitate specialized equipment for transportation and installation. Additionally, evaluating the specific steel grade can help ensure compliance with industry standards.

Key Industrial Applications of metal channel

| Industry/Sector | Specific Application of metal channel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural support in building frameworks | Provides strength and stability to structures | Ensure compliance with local building codes and standards |

| Automotive | Chassis and frame components | Enhances vehicle durability and safety | Consider weight-to-strength ratio for performance |

| Manufacturing | Machine bases and supports | Increases operational efficiency and safety | Verify material grade and finish for specific applications |

| Shipbuilding | Hull structural elements | Improves vessel integrity and longevity | Focus on corrosion resistance for marine applications |

| Renewable Energy | Solar panel mounting systems | Facilitates reliable energy generation | Assess compatibility with various solar panel designs |

How is Metal Channel Utilized in Construction?

In the construction industry, metal channels serve as essential components for structural support in building frameworks. Their C- or U-shaped profiles provide excellent load-bearing capabilities, ensuring that buildings can withstand various stresses. International buyers must pay attention to local building codes and standards when sourcing metal channels, as compliance is crucial for safety and legality. Additionally, selecting the right type of metal—be it galvanized steel or aluminum—can significantly influence durability and maintenance requirements.

What Role Does Metal Channel Play in Automotive Applications?

Metal channels are pivotal in the automotive sector, particularly in the production of chassis and frame components. Their structural integrity contributes to the overall safety and durability of vehicles. For international buyers, especially in regions like South America and Europe, it’s vital to consider the weight-to-strength ratio of the metal channel to optimize vehicle performance. Suppliers should provide detailed specifications to ensure that the materials meet the stringent safety standards prevalent in the automotive industry.

How is Metal Channel Used in Manufacturing?

Within manufacturing, metal channels are commonly employed as machine bases and supports. Their robustness enhances operational efficiency by providing stable foundations for heavy machinery, reducing vibrations and ensuring safety. International B2B buyers should verify the material grade and finish of the channels to align with specific operational requirements and environmental conditions. Sourcing from reputable suppliers who understand these industry nuances can significantly impact productivity and safety in manufacturing environments.

How Does Metal Channel Contribute to Shipbuilding?

In the shipbuilding industry, metal channels are integral to constructing hull structural elements. They enhance the integrity and longevity of vessels, ensuring they can withstand harsh marine conditions. Buyers must focus on sourcing channels with high corrosion resistance, as exposure to saltwater can degrade inferior materials. Understanding the specific requirements for marine-grade metals is crucial for international buyers in regions with active shipbuilding industries, such as the Middle East.

What Are the Benefits of Metal Channel in Renewable Energy?

Metal channels are increasingly used in renewable energy sectors, particularly in solar panel mounting systems. They provide a stable and durable framework that facilitates reliable energy generation. For international buyers, it’s essential to assess the compatibility of metal channels with various solar panel designs and installation methods. Additionally, sourcing channels that are lightweight yet strong can optimize the overall efficiency of solar installations, making them an attractive investment for businesses in Africa and beyond.

3 Common User Pain Points for ‘metal channel’ & Their Solutions

Scenario 1: Sourcing Quality Metal Channels for Structural Applications

The Problem: B2B buyers often face challenges in sourcing metal channels that meet the rigorous quality standards required for structural applications. In regions like Africa and South America, where infrastructure projects are booming, the risk of receiving subpar materials can lead to project delays and increased costs. Buyers may struggle with limited local suppliers or inconsistent quality from international vendors, making it difficult to ensure compliance with safety regulations.

The Solution: To overcome this issue, buyers should prioritize sourcing from reputable suppliers that offer certifications and detailed specifications for their metal channels. When evaluating suppliers, request material test reports and compliance documentation to ensure that the channels meet local and international standards. Consider utilizing platforms that specialize in connecting buyers with vetted suppliers, which can help streamline the procurement process. Additionally, establishing long-term relationships with reliable manufacturers can lead to better pricing and consistent quality over time. For buyers in regions with less access to quality materials, exploring local partnerships or cooperative purchasing groups can be beneficial in securing the necessary materials without compromising quality.

Scenario 2: Determining the Right Specifications for Metal Channels

The Problem: Another common pain point for B2B buyers is the difficulty in determining the correct specifications for metal channels, including size, thickness, and material type. This issue can be particularly pronounced in industries like construction and manufacturing, where incorrect specifications can result in structural failures or wasted resources. Buyers may find themselves overwhelmed by the technical jargon or variations in product standards across different suppliers.

The Solution: To address this challenge, buyers should invest time in understanding the specific requirements of their projects. Consulting with engineers or industry experts can provide valuable insights into the appropriate specifications needed for different applications. Additionally, utilizing online calculators or resources provided by metal suppliers can help in estimating the load-bearing capacity and selecting the right dimensions. It’s also advisable to create a comprehensive checklist that includes project requirements, material properties, and any applicable industry standards. This proactive approach ensures that buyers can confidently communicate their needs to suppliers, reducing the risk of errors in ordering.

Scenario 3: Managing Costs While Ensuring Quality

The Problem: Cost management is a significant concern for B2B buyers, especially when dealing with fluctuating prices for raw materials like metal channels. Buyers from Europe and the Middle East may experience pressure to reduce expenses while maintaining high-quality standards, leading to a constant balancing act. This challenge is exacerbated by the volatility in metal prices due to global market trends, which can affect budgeting and project timelines.

The Solution: To effectively manage costs, buyers should implement strategic sourcing practices, such as bulk purchasing and establishing long-term contracts with suppliers. This approach can help lock in prices and reduce the impact of market fluctuations. Additionally, considering alternative materials or different grades of metal can provide cost savings without significantly compromising quality. Buyers should also engage in thorough market research to identify trends and forecast price changes, allowing for more informed purchasing decisions. Lastly, leveraging technology, such as inventory management systems, can help track usage and optimize ordering processes, ensuring that buyers maintain adequate stock levels while minimizing excess inventory costs.

Alternatives Analysis: Comparing metal channel With Other Solutions

When evaluating solutions for structural and architectural applications, it is essential for B2B buyers to consider various alternatives to metal channels. While metal channels provide significant benefits, other materials and methods may offer advantages depending on specific project requirements, budget constraints, and operational contexts. Below, we explore metal channels in comparison to two viable alternatives: Plastic Channels and Composite Channels.

Comparison Table of Metal Channel and Alternatives

| Comparison Aspect | Metal Channel | Plastic Channels | Composite Channels |

|---|---|---|---|

| Performance | High strength; excellent load-bearing | Moderate strength; lightweight | High strength; corrosion-resistant |

| Cost | Moderate to high | Low to moderate | Moderate to high |

| Ease of Implementation | Requires welding and cutting | Easy to install; often snap-fit | Requires specialized installation |

| Maintenance | Minimal; prone to rust if uncoated | Low; resistant to corrosion | Low; may require periodic checks |

| Best Use Case | Heavy-duty construction | Light-duty applications; DIY | Marine and chemical environments |

Pros and Cons of Plastic Channels

Plastic channels are an appealing alternative for many B2B buyers, particularly in applications where weight is a concern. They are typically easier to handle and install due to their lighter weight and flexibility. Plastic channels can be ideal for indoor applications or areas with limited load requirements. However, their performance is limited compared to metal channels, especially in heavy-duty applications. They may not withstand high temperatures or heavy impacts, making them unsuitable for construction or structural applications where metal channels excel.

Pros and Cons of Composite Channels

Composite channels are increasingly popular due to their high strength-to-weight ratio and resistance to environmental factors such as corrosion and chemicals. They are particularly well-suited for marine applications or industries that require materials to withstand harsh conditions. Composite channels can be more expensive than both metal and plastic options, but their longevity and reduced maintenance needs can justify the initial investment. The complexity of installation may also be a drawback, as specialized techniques and tools are often required, which could lead to additional labor costs.

Conclusion: How to Choose the Right Solution for Your Needs

In selecting the right channel solution, B2B buyers must assess their specific requirements, including load-bearing needs, environmental conditions, and budget constraints. Metal channels are a robust choice for heavy-duty applications, while plastic channels may serve well for lighter tasks and ease of installation. Composite channels offer durability and resilience in challenging environments but come with a higher price point and installation complexity. By evaluating these factors, buyers from diverse regions—whether in Africa, South America, the Middle East, or Europe—can make informed decisions that align with their operational goals and project specifications.

Strategic Material Selection Guide for metal channel

When selecting metal channels for various applications, understanding the properties, advantages, and limitations of different materials is crucial for B2B buyers. Here, we analyze four common materials used in metal channels: aluminum, carbon steel, stainless steel, and galvanized steel. Each material has unique characteristics that make it suitable for specific applications, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

A stock image related to metal channel.

What are the Key Properties of Aluminum Channels?

Aluminum is lightweight, corrosion-resistant, and has excellent thermal and electrical conductivity. It typically performs well in applications where weight is a concern, such as in aerospace and automotive industries. Aluminum channels can withstand moderate temperatures but are not ideal for high-pressure applications.

Pros:

– Lightweight and easy to handle.

– High resistance to corrosion, making it suitable for outdoor applications.

– Good thermal and electrical conductivity.

Cons:

– Lower strength compared to steel, which may limit its use in heavy-load applications.

– Higher cost than some steel options, which can impact budget-sensitive projects.

Impact on Application:

Aluminum channels are commonly used in architectural applications, electrical enclosures, and marine environments where corrosion resistance is critical.

Considerations for International Buyers:

B2B buyers should ensure compliance with local standards, such as ASTM or EN standards for aluminum fabrication. In regions like Europe, the use of recycled aluminum is increasingly favored due to sustainability initiatives.

How Does Carbon Steel Compare for Metal Channels?

Carbon steel is known for its high strength and durability, making it a popular choice for structural applications. It has a good temperature rating and can handle heavy loads, which is essential in construction and manufacturing.

Pros:

– High tensile strength and durability.

– Cost-effective for large-scale projects.

– Versatile for various applications, including construction and manufacturing.

Cons:

– Prone to corrosion if not properly treated or coated.

– Heavier than aluminum, which can complicate handling and installation.

Impact on Application:

Carbon steel channels are widely used in construction, automotive, and heavy machinery applications where structural integrity is paramount.

Considerations for International Buyers:

Buyers should be aware of local regulations regarding the use of carbon steel, especially regarding corrosion resistance treatments. Compliance with standards such as ASTM A36 is essential for ensuring quality and safety.

What are the Benefits of Using Stainless Steel Channels?

Stainless steel offers superior corrosion resistance and is ideal for applications exposed to harsh environments, including chemical processing and food production. It maintains its strength at high temperatures, making it suitable for various demanding applications.

Pros:

– Excellent corrosion resistance and longevity.

– Maintains strength at high temperatures.

– Low maintenance requirements due to its durability.

Cons:

– Higher cost compared to carbon and galvanized steel.

– More challenging to work with due to its hardness, which can increase manufacturing complexity.

Impact on Application:

Stainless steel channels are often used in food processing, pharmaceuticals, and marine applications where hygiene and corrosion resistance are critical.

Considerations for International Buyers:

Buyers should verify compliance with international standards like ASTM A240 for stainless steel. In regions like the Middle East, where saltwater exposure is common, selecting the right grade of stainless steel is vital.

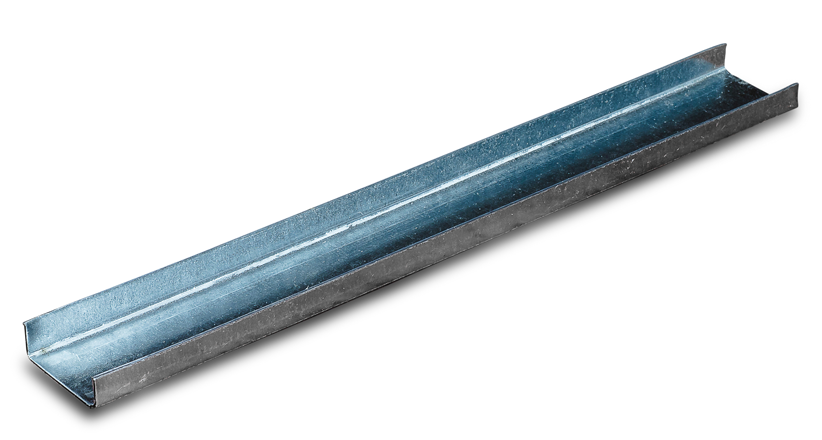

Why Choose Galvanized Steel for Metal Channels?

Galvanized steel channels are carbon steel channels coated with zinc to enhance corrosion resistance. This makes them suitable for outdoor applications and environments prone to moisture.

Pros:

– Cost-effective option with good corrosion resistance.

– Enhanced durability compared to untreated carbon steel.

– Suitable for a variety of applications, including construction and agriculture.

Cons:

– The zinc coating can wear off over time, especially in harsh environments.

– Less aesthetically pleasing compared to stainless steel or aluminum.

Impact on Application:

Galvanized steel channels are commonly used in construction, agricultural structures, and outdoor installations where exposure to moisture is a concern.

Considerations for International Buyers:

B2B buyers should consider local standards for galvanization, such as ASTM A123, to ensure adequate protection against corrosion.

Summary Table of Material Properties and Applications

| Material | Typical Use Case for Metal Channel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Architectural applications, electrical enclosures | Lightweight and corrosion-resistant | Lower strength than steel | High |

| Carbon Steel | Construction, automotive, heavy machinery | High strength and cost-effective | Prone to corrosion | Medium |

| Stainless Steel | Food processing, pharmaceuticals, marine applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Galvanized Steel | Construction, agricultural structures | Cost-effective with good durability | Zinc coating can wear off | Medium |

Understanding these materials’ properties and applications will empower international B2B buyers to make informed decisions tailored to their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for metal channel

What Are the Key Manufacturing Processes for Metal Channels?

Manufacturing metal channels involves several critical stages, each designed to ensure that the final product meets both performance specifications and industry standards. Understanding these processes can help B2B buyers from regions such as Africa, South America, the Middle East, and Europe make informed purchasing decisions.

Material Preparation: How Is Metal Channel Material Sourced and Processed?

The manufacturing process begins with material preparation, where raw materials, typically steel, aluminum, or other alloys, are sourced. Suppliers often utilize high-quality materials that comply with international standards, such as ASTM or ISO specifications. The selected material is then cut into manageable sizes and subjected to treatments such as annealing or tempering, depending on the desired mechanical properties.

Actionable Insight: Buyers should inquire about the material certifications and origin to ensure compliance with international quality standards. Requesting mill test reports can provide insight into the chemical and mechanical properties of the materials used.

What Techniques Are Used in Forming Metal Channels?

After preparation, the next stage is forming, where the raw materials are shaped into metal channels. Common techniques include:

-

Roll Forming: This continuous process involves feeding a strip of metal through a series of rollers that gradually shape the material into the desired channel profile. Roll forming is efficient for producing long lengths of channels with uniform cross-sections.

-

Hot Rolling: For steel channels, hot rolling is often employed to shape the metal at elevated temperatures. This method enhances ductility and allows for the production of thicker sections.

-

Cold Forming: Used primarily for aluminum channels, this technique shapes metal at room temperature, resulting in improved surface finish and tighter tolerances.

Actionable Insight: Buyers should assess the forming techniques used by their suppliers, as these can significantly impact the structural integrity and finish of the final product. Requesting information about the machinery and processes in use can provide valuable insights.

How Are Metal Channels Assembled and Finished?

The assembly process may involve welding or fastening components together, especially for custom channel configurations. After assembly, finishing processes, such as powder coating, anodizing, or galvanizing, are applied to enhance corrosion resistance and aesthetic appeal.

Actionable Insight: When sourcing metal channels, buyers should consider the finishing options available and their implications for durability in specific applications. Understanding the environmental conditions where the product will be used can inform these choices.

What Quality Assurance Measures Are Essential for Metal Channels?

Quality assurance (QA) is critical in the manufacturing of metal channels, ensuring that products meet specified standards and regulations. Buyers should be familiar with the various QA measures and international standards that impact their sourcing decisions.

What International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 play a significant role in quality management systems. ISO 9001 certification indicates that a manufacturer has established a robust quality management system, focusing on continual improvement and customer satisfaction. Additionally, industry-specific standards like CE marking in Europe or API standards in the oil and gas sector may apply.

Actionable Insight: Buyers should prioritize suppliers that hold relevant certifications. Requesting copies of certifications and ensuring they are up-to-date can help mitigate risks associated with quality.

What Are the Key QC Checkpoints During Manufacturing?

Quality control checkpoints are critical in maintaining product integrity throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify issues before they affect the final product.

- Final Quality Control (FQC): A thorough inspection of finished products ensures they meet all specifications before shipping.

Actionable Insight: Buyers should establish clear communication with suppliers regarding their QC processes. Regular updates on QC results and the implementation of corrective actions can enhance transparency.

What Testing Methods Are Used to Ensure Quality in Metal Channels?

Common testing methods include:

- Dimensional Inspection: Ensures that the metal channels meet specified dimensions and tolerances.

- Mechanical Testing: Evaluates properties such as tensile strength and ductility, often conducted through standardized tests like ASTM E8.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic or magnetic particle inspection help identify internal defects without damaging the product.

Actionable Insight: Buyers should request documentation of testing results and methodologies used by their suppliers. Understanding the testing protocols can provide assurance of product reliability.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control measures is crucial for international buyers. Here are key strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes, quality management systems, and adherence to standards.

-

Quality Reports: Requesting detailed quality reports can provide insights into the QC processes and any issues encountered during production.

-

Third-Party Inspections: Engaging independent inspection agencies to evaluate the manufacturing processes can add an additional layer of confidence.

Actionable Insight: Establishing a robust supplier evaluation process, including regular audits and performance assessments, can help mitigate risks associated with quality and compliance.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of the following nuances:

- Cultural Differences: Understanding regional practices and standards can enhance communication and reduce misunderstandings.

- Regulatory Compliance: Each region may have specific regulations regarding material standards and safety. Buyers should familiarize themselves with these to ensure compliance.

- Supply Chain Challenges: Logistics and transportation can affect product quality. Buyers should consider these factors when selecting suppliers.

Actionable Insight: Engaging with local experts or consultants can help navigate the complexities of international sourcing, ensuring compliance and quality in the procurement process.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing metal channels, ultimately enhancing their supply chain reliability and product quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal channel’

This guide aims to assist international B2B buyers in effectively sourcing metal channels, a crucial component in various industries, including construction, automotive, and manufacturing. By following this step-by-step checklist, buyers can ensure they make informed decisions that align with their project requirements and business goals.

Step 1: Define Your Technical Specifications

Understanding your specific needs is the first step in sourcing metal channels. Consider factors such as dimensions, material type (e.g., aluminum, mild steel, stainless steel), and any special requirements like corrosion resistance or weight capacity. This clarity will help you communicate effectively with suppliers and ensure you procure products that meet your project standards.

Step 2: Research Reliable Suppliers

Conduct thorough research to identify potential suppliers. Utilize industry-specific platforms, online marketplaces, and trade associations to find companies with a solid reputation. Look for reviews, testimonials, and case studies to gauge the reliability and quality of their products. This step is crucial to avoid delays and ensure the integrity of your supply chain.

Step 3: Evaluate Supplier Certifications and Compliance

Before finalizing a supplier, verify their certifications and compliance with international standards. Look for ISO certifications, adherence to safety regulations, and quality assurance processes. Suppliers that maintain high standards are more likely to deliver consistent quality and reliability, which is essential for your business operations.

Step 4: Request Samples and Specifications

Once you have narrowed down your choices, request samples of the metal channels. This allows you to assess the quality, finish, and suitability for your intended application. Additionally, ask for detailed specifications, including material properties and fabrication techniques, to ensure they align with your project requirements.

Step 5: Compare Pricing and Payment Terms

Obtain quotes from multiple suppliers to compare pricing and payment terms. Be mindful of not just the cost but also the total value, which includes shipping, handling, and potential discounts for bulk orders. Understanding payment terms is essential for cash flow management, especially for international transactions.

Step 6: Assess Delivery and Logistics Capabilities

Evaluate the supplier’s delivery timelines and logistics capabilities. Ensure they can meet your project’s schedule and have reliable shipping options, especially if you’re sourcing from different regions like Africa or South America. A supplier with a solid logistics plan can help avoid disruptions in your supply chain.

Step 7: Establish a Communication Protocol

Effective communication is vital for successful sourcing. Establish a clear protocol for updates, inquiries, and problem resolution. Regular communication helps to manage expectations and ensures that any issues can be addressed promptly, fostering a stronger partnership with your supplier.

By following this practical checklist, international B2B buyers can streamline their sourcing process for metal channels, ensuring they select the right products and suppliers to support their business needs.

Comprehensive Cost and Pricing Analysis for metal channel Sourcing

Understanding the cost structure and pricing dynamics for metal channel sourcing is crucial for international B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. Here’s a comprehensive analysis that addresses key components, influencers, and practical tips for negotiating favorable terms.

What Are the Key Cost Components in Metal Channel Sourcing?

-

Materials: The primary cost driver in metal channel pricing is the raw material itself. Common materials include aluminum, mild steel, and stainless steel, each with varying costs based on market fluctuations. For instance, aluminum channels tend to be more expensive than steel due to their lightweight and corrosion-resistant properties.

-

Labor: Labor costs encompass the workforce involved in the manufacturing process. This includes the wages for production workers, engineers, and quality control personnel. Regions with lower labor costs can offer more competitive pricing, making it essential for buyers to consider the geographical location of suppliers.

-

Manufacturing Overhead: This includes indirect costs related to production, such as utilities, rent, and equipment maintenance. Efficient operations can minimize overhead, allowing suppliers to pass savings on to buyers.

-

Tooling: Tooling costs refer to the expenses associated with the machinery and tools needed to manufacture metal channels. Custom tooling for specific channel designs can significantly increase costs, so buyers should assess the necessity of customizations carefully.

-

Quality Control (QC): Ensuring product quality is paramount, especially for critical applications. QC processes incur costs but can prevent costly mistakes and returns, which ultimately affect the total cost of ownership.

-

Logistics: Transportation and shipping costs can vary widely based on the supplier’s location and the buyer’s destination. Incoterms (International Commercial Terms) play a vital role in determining who is responsible for shipping costs, insurance, and freight risks.

-

Margin: Suppliers build a profit margin into their pricing, which can vary based on market competition and perceived value. Understanding the market landscape can help buyers negotiate better terms.

What Influences Metal Channel Prices for International Buyers?

-

Volume and Minimum Order Quantities (MOQ): Larger orders typically qualify for bulk pricing, leading to significant savings. Buyers should assess their needs and consider consolidating orders with other purchases to meet MOQ thresholds.

-

Specifications and Customization: Custom specifications can lead to higher costs due to the need for specialized tooling and processes. Buyers should evaluate if standard sizes meet their requirements before opting for custom solutions.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, ASTM) often come at a premium. However, investing in certified products can enhance reliability and performance, which may justify the higher cost in the long run.

-

Supplier Factors: The reputation, reliability, and experience of suppliers can influence pricing. Established suppliers may charge more but offer better service and quality assurance.

-

Incoterms: Understanding the implications of different Incoterms is crucial for international buyers. Terms such as CIF (Cost, Insurance, and Freight) or FOB (Free on Board) can significantly affect the overall cost and risk management.

What Are the Best Negotiation Tips for B2B Buyers?

-

Conduct Market Research: Familiarize yourself with the market prices and trends. This knowledge empowers you to negotiate more effectively and identify fair pricing.

-

Leverage Total Cost of Ownership (TCO): Focus on the TCO rather than just the upfront cost. Consider long-term implications, including maintenance, durability, and potential rework.

-

Be Transparent About Requirements: Clearly communicate your needs and expectations with suppliers. This transparency can foster trust and lead to better pricing agreements.

-

Consider Alternative Suppliers: Don’t hesitate to source from multiple suppliers to compare pricing, quality, and service. This can also provide leverage during negotiations.

-

Be Prepared for Negotiation: Have a clear understanding of your budget, desired specifications, and acceptable lead times. Being well-prepared enables you to navigate discussions confidently.

Conclusion

While indicative prices for metal channels can range widely based on material and specifications, understanding the cost structure and pricing influencers can significantly benefit international B2B buyers. By employing strategic negotiation tactics and considering the total cost of ownership, buyers from regions like Africa, South America, the Middle East, and Europe can secure favorable deals that meet their operational needs.

Essential Technical Properties and Trade Terminology for metal channel

What Are the Essential Technical Properties of Metal Channels?

When purchasing metal channels, understanding the technical specifications is critical for making informed B2B decisions. Here are some key properties to consider:

-

Material Grade

Metal channels can be made from various materials, including aluminum, mild steel, and stainless steel. Each material has specific properties that affect its strength, durability, and resistance to corrosion. For instance, stainless steel is ideal for environments exposed to moisture or chemicals, while aluminum is lightweight and corrosion-resistant, making it suitable for applications where weight reduction is essential. -

Dimensions and Tolerances

The dimensions of metal channels, including width, height, and thickness, are vital for ensuring compatibility with existing structures or components. Tolerances refer to the allowable deviation from specified dimensions. In B2B applications, precise tolerances are crucial for ensuring that components fit together correctly, minimizing the risk of structural failure. -

Weight Per Unit Length

This property helps buyers estimate shipping costs and assess the material’s suitability for specific applications. Knowing the weight per unit length can also aid in calculating load-bearing capacities, which is particularly important in construction and manufacturing sectors. -

Finish Type

The finish of a metal channel can influence its appearance and performance. Common finishes include mill, painted, or galvanized. A galvanized finish, for example, enhances corrosion resistance, making it ideal for outdoor applications. Buyers should consider how the finish will affect the channel’s longevity and maintenance requirements. -

Yield Strength

This property refers to the maximum stress that a material can withstand while still maintaining its shape. For B2B buyers, understanding yield strength is crucial for selecting channels that can handle the required loads without deformation. This is especially important in structural applications where safety is paramount.

What Are Common Trade Terms in the Metal Channel Industry?

Familiarity with industry terminology can streamline communication and negotiations. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for B2B buyers, especially when sourcing components that must meet specific quality and compatibility standards. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for international buyers who may need to consider storage costs and cash flow when ordering large quantities of metal channels. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price offers from suppliers for specific quantities and qualities of goods. For B2B buyers, submitting an RFQ can help in obtaining competitive pricing and understanding the market landscape. -

Incoterms (International Commercial Terms)

These are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) related to international commercial law. Understanding Incoterms helps buyers clarify responsibilities regarding shipping costs, risks, and insurance, which is crucial when dealing with international suppliers. -

Lead Time

This term refers to the time it takes from placing an order to receiving the goods. For B2B buyers, knowing the lead time is essential for project planning and inventory management, especially in industries where timing can significantly impact project success. -

Custom Cuts

This refers to metal channels that are cut to specific dimensions as per the buyer’s requirements. Understanding the option for custom cuts allows buyers to obtain precisely what they need without excess material waste, optimizing their supply chain efficiency.

By grasping these technical properties and trade terms, international B2B buyers can make better-informed purchasing decisions, ensuring that they meet both their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the metal channel Sector

What Are the Key Market Trends Impacting the Metal Channel Sector?

The global metal channel market is experiencing a surge driven by increased infrastructure development and the growing demand for construction materials across emerging markets in Africa, South America, the Middle East, and Europe. Key trends include the integration of advanced manufacturing technologies such as automation and robotics, which enhance production efficiency and reduce costs. Additionally, the rise of digital platforms for sourcing materials is transforming how B2B buyers procure metal channels. These platforms facilitate real-time inventory checks and streamline the ordering process, making it easier for international buyers to source materials from various regions.

In Africa and South America, the push for industrialization is leading to a significant increase in construction projects, thereby boosting the demand for metal channels. In contrast, Europe and the Middle East are focusing on sustainable construction practices, leading to a preference for high-quality, durable materials that can withstand extreme conditions. Moreover, the ongoing supply chain disruptions caused by geopolitical tensions and the COVID-19 pandemic have led B2B buyers to diversify their sourcing strategies, seeking reliable suppliers and alternative materials to mitigate risks.

How Is Sustainability Influencing Sourcing Decisions in the Metal Channel Sector?

Sustainability has become a critical factor for B2B buyers in the metal channel sector, as companies are increasingly aware of their environmental impact. The metal industry is notorious for its carbon footprint, which has prompted buyers to seek suppliers who prioritize ethical sourcing and sustainable practices. This includes using recycled materials, reducing waste during production, and implementing energy-efficient manufacturing processes.

Buyers should look for suppliers that offer ‘green’ certifications, such as ISO 14001 for environmental management systems or LEED certification for sustainable building materials. These certifications not only ensure compliance with environmental standards but also enhance a company’s reputation among environmentally conscious consumers. Furthermore, sourcing from suppliers committed to sustainable practices can lead to long-term cost savings through energy efficiency and reduced waste disposal fees.

What Is the Historical Context of Metal Channels in B2B Markets?

The use of metal channels can be traced back to the industrial revolution when steel became a staple in construction and manufacturing. Initially, metal channels were primarily used in structural applications due to their load-bearing capabilities. As industries evolved, so did the applications of metal channels, expanding into diverse sectors such as automotive, aerospace, and marine engineering.

Over the decades, advancements in metalworking technologies, such as roll forming and welding, have improved the design and functionality of metal channels. Today, they are available in various materials, including aluminum, stainless steel, and carbon steel, catering to different applications and environmental conditions. This evolution has made metal channels an essential component in modern construction and manufacturing, reinforcing their importance for B2B buyers in navigating the complexities of supply chains and sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of metal channel

-

How do I solve issues related to sourcing metal channels internationally?

Sourcing metal channels internationally can be challenging due to varying quality standards, regulations, and logistics. To mitigate these issues, start by identifying reputable suppliers in your target regions. Utilize platforms like Alibaba or industry-specific directories to vet suppliers based on customer reviews and certifications. Establish clear communication channels, request samples, and ensure compliance with international trade regulations. Engaging a local expert or consultant familiar with both the metal industry and the specific regulations of your target market can also streamline the sourcing process. -

What is the best type of metal channel for construction projects in Africa?

The best type of metal channel for construction projects in Africa often depends on the specific application and environmental conditions. For structural integrity and durability, hot-rolled steel channels are commonly recommended due to their strength and resistance to deformation. However, in coastal areas where corrosion is a concern, stainless steel channels may be more suitable. Additionally, aluminum channels offer lightweight options for applications where reducing overall weight is a priority. Always assess local availability and pricing when selecting the best option. -

What are the key factors to consider when vetting metal channel suppliers?

When vetting metal channel suppliers, consider their production capabilities, quality certifications (like ISO 9001), and experience in the industry. Request references and case studies from previous clients, particularly those in your region or industry. Analyze their delivery timelines and logistics capabilities to ensure they can meet your supply chain needs. Additionally, assess their responsiveness and willingness to accommodate custom orders, as flexibility can be crucial for your project success. -

What customization options are available for metal channels?

Many suppliers offer customization options for metal channels, including different lengths, widths, thicknesses, and materials. You can also request specific finishes or coatings to enhance corrosion resistance or aesthetics. It’s advisable to communicate your exact requirements upfront, including any load-bearing specifications or environmental conditions. Some suppliers may provide design assistance to ensure that the custom channels meet your project’s structural requirements. -

What are the minimum order quantities (MOQs) for metal channels when sourcing internationally?

Minimum order quantities (MOQs) for metal channels can vary significantly between suppliers. Generally, larger manufacturers may impose higher MOQs due to production costs, while smaller suppliers or distributors might offer lower MOQs to cater to smaller businesses. Always confirm MOQs before placing an order, and consider negotiating if you require a smaller quantity. Additionally, be aware that ordering in bulk can often lead to lower per-unit costs, which might be beneficial for larger projects. -

What payment terms should I expect when purchasing metal channels from international suppliers?

Payment terms can vary widely among international suppliers, but common practices include upfront payments, partial payments, or payment upon delivery. Many suppliers may request a deposit (typically 30-50%) to initiate production, with the balance due before shipment. It’s crucial to discuss payment methods—such as wire transfers, letters of credit, or escrow services—prior to finalizing any agreements. Ensure that the terms are clearly documented in the purchase agreement to avoid misunderstandings. -

How can I ensure quality assurance when sourcing metal channels?

To ensure quality assurance when sourcing metal channels, request detailed product specifications and quality certifications from your supplier. Many reputable suppliers conduct rigorous testing for tensile strength, corrosion resistance, and dimensional accuracy. Consider including quality control clauses in your purchase agreement, allowing for third-party inspections before shipment. Additionally, establish a clear return policy in case the products do not meet your specified standards upon arrival.

A stock image related to metal channel.

- What logistics considerations should I keep in mind when importing metal channels?

Importing metal channels involves several logistics considerations, including shipping methods, customs duties, and delivery timelines. Determine the most cost-effective shipping option based on your delivery schedule—air freight may be faster but more expensive than sea freight. Be aware of customs regulations in your country, including any tariffs or import restrictions. Collaborating with a freight forwarder can help navigate these complexities and ensure timely and compliant delivery of your metal channels.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for metal channel

How Can Strategic Sourcing Enhance Your Metal Channel Procurement?

In today’s competitive landscape, strategic sourcing of metal channels is essential for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. By leveraging a well-defined sourcing strategy, businesses can optimize their procurement processes, minimize costs, and ensure the timely delivery of high-quality materials. Understanding the specifications, such as dimensions, material types, and applications, is crucial for making informed purchasing decisions that align with project requirements.

A stock image related to metal channel.

What Are the Key Benefits of Strategic Sourcing for Metal Channels?

Investing in strategic sourcing not only facilitates better supplier relationships but also enhances supply chain resilience. Buyers should prioritize suppliers who offer flexibility in order quantities and customization options, enabling them to adapt to market fluctuations. Additionally, utilizing digital platforms for sourcing can streamline the procurement process, making it easier to compare prices and specifications across suppliers, thus ensuring the best value for investment.

What’s Next for International B2B Buyers in the Metal Channel Market?

Looking forward, international B2B buyers should remain proactive in exploring new markets and suppliers, particularly those that align with sustainability goals. As global demand for metal channels continues to rise, adapting sourcing strategies to incorporate innovative materials and manufacturing processes will be key. Engage with local suppliers and consider forming partnerships that foster mutual growth. By staying informed and agile, your business can capitalize on emerging opportunities in the metal channel market.