Discover Cost-Saving Benefits of PR Switches (2025)

Introduction: Navigating the Global Market for pr switch

In today’s competitive landscape, sourcing the right pressure switch can significantly impact operational efficiency and safety across various industries. As international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe (including the UK and Turkey), understanding the complexities of pressure switches is crucial. This guide is designed to equip you with comprehensive insights into the types, applications, and critical considerations when selecting a pressure switch, ensuring you make informed purchasing decisions that align with your specific needs.

Pressure switches, whether mechanical or electronic, play a pivotal role in monitoring and controlling system pressures in applications ranging from HVAC systems to oil and gas industries. However, selecting the right switch involves navigating various factors, including operating temperature, pressure range, and material compatibility with process fluids. This guide delves into the intricacies of pressure switch technology, offering actionable insights into supplier vetting, cost implications, and industry standards.

By leveraging the information presented here, you will be empowered to identify suitable suppliers, negotiate effectively, and ultimately enhance your procurement strategy. Whether you are looking to optimize production processes or ensure compliance with safety regulations, this resource aims to serve as your go-to reference for navigating the global market for pressure switches.

Understanding pr switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Pressure Switch | Simple design, uses a spring and piston mechanism | HVAC systems, oil pressure monitoring | Pros: Robust, cost-effective. Cons: Less accurate than electronic types. |

| Electronic Pressure Switch | Incorporates a pressure transducer for enhanced accuracy | Industrial automation, process control | Pros: High precision, long lifespan. Cons: More expensive, sensitive to environmental conditions. |

| Differential Pressure Switch | Measures the difference between two pressure points | HVAC systems, filtration, and pumping applications | Pros: Ideal for monitoring flow rates. Cons: Can be complex to install and calibrate. |

| Explosion-Proof Pressure Switch | Designed for hazardous environments, robust and safe construction | Oil and gas, chemical processing | Pros: Enhanced safety, compliance with regulations. Cons: Higher initial cost, limited to specific applications. |

| High-Pressure Switch | Capable of handling high-pressure environments | Hydraulic systems, heavy machinery | Pros: Suitable for extreme conditions. Cons: Requires careful selection based on pressure ratings. |

What Are the Characteristics of Mechanical Pressure Switches?

Mechanical pressure switches are known for their straightforward design, utilizing a spring and piston to activate. They are typically more cost-effective and robust, making them ideal for less complex applications such as HVAC systems and oil pressure monitoring. However, buyers should consider that while they are reliable for basic tasks, mechanical switches may lack the precision and longevity offered by electronic alternatives.

How Do Electronic Pressure Switches Enhance Accuracy?

Electronic pressure switches utilize advanced technology, incorporating pressure transducers for heightened accuracy and reliability. These devices are suited for applications requiring precise pressure monitoring, such as in industrial automation and process control. While they generally come at a higher cost, the advantages of long-term stability and reduced contact wear make them a preferred choice for many B2B buyers looking for dependable performance.

What Are the Applications of Differential Pressure Switches?

Differential pressure switches are specialized devices that measure the pressure difference between two points. This capability makes them essential in applications like HVAC systems, filtration, and pumping operations. Although they provide critical insights into system performance, buyers should be aware that their installation can be more complex, requiring careful calibration to ensure optimal functionality.

Why Choose Explosion-Proof Pressure Switches?

For businesses operating in hazardous environments, explosion-proof pressure switches offer an essential safety feature. Designed to withstand harsh conditions, these switches comply with industry regulations, making them ideal for oil and gas sectors as well as chemical processing. While the initial investment is higher, the safety assurances they provide can justify the expense, especially in high-risk industries.

What Should Buyers Consider When Selecting High-Pressure Switches?

High-pressure switches are designed to operate in demanding environments, making them suitable for hydraulic systems and heavy machinery. Buyers must carefully assess the pressure ratings and ensure compatibility with their specific applications. While they offer robust performance, the complexity of selecting the right switch for extreme conditions can pose a challenge, necessitating thorough research and consultation with suppliers.

Key Industrial Applications of pr switch

| Industry/Sector | Specific Application of pr switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC Systems | Air compressor control | Ensures optimal energy consumption and system longevity | Operating temperature range, compatibility with refrigerants |

| Oil and Gas | Oil pressure monitoring | Enhances safety by preventing equipment failure | Material compatibility with oil, pressure range specifications |

| Water Management | Well pump pressure regulation | Maintains consistent water supply, reducing downtime | Pressure range, environmental conditions, and power requirements |

| Food and Beverage | Process monitoring in manufacturing | Ensures compliance with safety standards and quality | Sanitary certifications, material compatibility, and accuracy |

| Industrial Automation | Pressure control in pneumatic systems | Increases efficiency and reduces operational costs | Response time, durability in harsh conditions, and integration capabilities |

How is ‘pr switch’ utilized in HVAC systems for international buyers?

In HVAC systems, pressure switches are crucial for controlling air compressors. When the air pressure reaches a predetermined setpoint, the switch activates or deactivates the compressor, optimizing energy consumption and enhancing system longevity. For international buyers, especially in regions with extreme temperatures like Africa and the Middle East, it is vital to select switches that can withstand high operating temperatures and are compatible with specific refrigerants used in their systems.

What role does ‘pr switch’ play in the oil and gas industry?

In the oil and gas sector, pressure switches are employed to monitor oil pressure levels in equipment. If pressure drops below a safe threshold, the switch triggers alarms or shuts down machinery to prevent failures that could lead to catastrophic accidents. Buyers in South America and Europe must consider material compatibility with various oils and specific pressure range specifications to ensure reliability in demanding environments.

How does ‘pr switch’ facilitate water management solutions?

Pressure switches are essential in water management, particularly for regulating well pumps. They maintain consistent water pressure, ensuring that systems operate efficiently without risking over-pressurization. For international buyers, sourcing pressure switches that can handle varying environmental conditions and meet specific pressure ranges is crucial to prevent operational downtime, especially in regions like Africa where water scarcity is a pressing issue.

In what ways does ‘pr switch’ support the food and beverage industry?

In the food and beverage sector, pressure switches monitor processes to ensure compliance with safety standards and quality control. They help maintain appropriate pressure levels in systems such as pasteurizers and bottling lines. Buyers must prioritize sanitary certifications and material compatibility to avoid contamination, particularly when sourcing from manufacturers in Europe or the Middle East, where stringent regulations are enforced.

Why is ‘pr switch’ vital for industrial automation?

Pressure switches play a significant role in industrial automation by controlling pneumatic systems. They ensure that the correct pressure is maintained for efficient operation, leading to reduced operational costs and increased productivity. International buyers should consider the response time and durability of pressure switches, especially in harsh working conditions, to ensure seamless integration into their automated processes.

3 Common User Pain Points for ‘pr switch’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Pressure Switch for Specific Applications

The Problem:

B2B buyers often struggle with identifying the appropriate pressure switch for their specific application requirements. This is particularly challenging for companies operating in diverse environments, such as those in Africa and the Middle East, where conditions can vary significantly. For instance, a buyer may need a switch that can handle extreme temperatures or corrosive substances, yet many available options do not specify these critical characteristics clearly. The consequence of choosing the wrong type can lead to equipment failure, safety hazards, and costly downtime.

The Solution:

To mitigate this issue, buyers should engage in a thorough assessment of their application’s requirements before purchasing a pressure switch. This includes understanding the operating temperature range, the nature of the process fluid (whether it is corrosive, viscous, or contains particulates), and the pressure range needed for optimal performance. Buyers should source pressure switches from reputable manufacturers that provide detailed specifications and application guidelines. Utilizing filtering options on manufacturer websites, like those offered by Ashcroft or Whitman Controls, can help narrow down choices based on specific criteria. Additionally, consider consulting with technical experts or customer service representatives from these companies to clarify doubts and get tailored recommendations based on your unique application.

Scenario 2: Challenges with Calibration and Accuracy Over Time

The Problem:

Another common pain point for B2B buyers is the calibration and accuracy of pressure switches over time. Many mechanical pressure switches, while robust, can drift from their setpoints due to wear and tear or environmental factors such as temperature fluctuations and vibration. For industries that rely on precise pressure measurements—such as oil and gas or food processing—this can lead to operational inefficiencies and potentially hazardous situations.

The Solution:

To address calibration issues, buyers should consider investing in electronic pressure switches, which typically offer higher accuracy and less mechanical wear compared to their mechanical counterparts. These switches often come with built-in diagnostics and the ability to perform self-calibration, which significantly reduces the manual effort required to maintain accuracy. When selecting an electronic pressure switch, it’s essential to choose one that has a high cycle life and is designed for the specific environmental conditions of your operation. Regular maintenance checks should also be scheduled to ensure that all switches are functioning correctly. Implementing a routine testing schedule can prevent unexpected failures and maintain operational integrity.

Scenario 3: Integration Issues with Existing Systems

The Problem:

B2B buyers frequently encounter integration challenges when incorporating new pressure switches into existing systems. This is particularly true in industries where legacy equipment is common, and compatibility issues may arise. Buyers may find that the new pressure switch does not fit the existing electrical or mechanical interfaces, leading to delays in installation and additional costs for modifications.

The Solution:

To avoid integration issues, buyers should conduct a comprehensive compatibility analysis before procurement. This includes evaluating the electrical requirements, mounting configurations, and communication protocols of the existing systems. When sourcing pressure switches, opting for modular designs or those specifically marketed as compatible with industry-standard interfaces can greatly reduce the likelihood of integration problems. Additionally, collaborating with system integrators or engineers who specialize in the specific application can provide insights into potential compatibility issues and solutions. Buyers should also request detailed installation guides and technical support from manufacturers to ensure a smooth integration process. Engaging in pre-purchase consultations can lead to more informed decisions and reduce the risk of costly modifications later on.

Strategic Material Selection Guide for pr switch

When selecting materials for pressure switches (pr switches), it is crucial to consider the specific requirements of the application, including temperature and pressure ratings, chemical compatibility, and environmental conditions. Below, we analyze four common materials used in pr switches, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

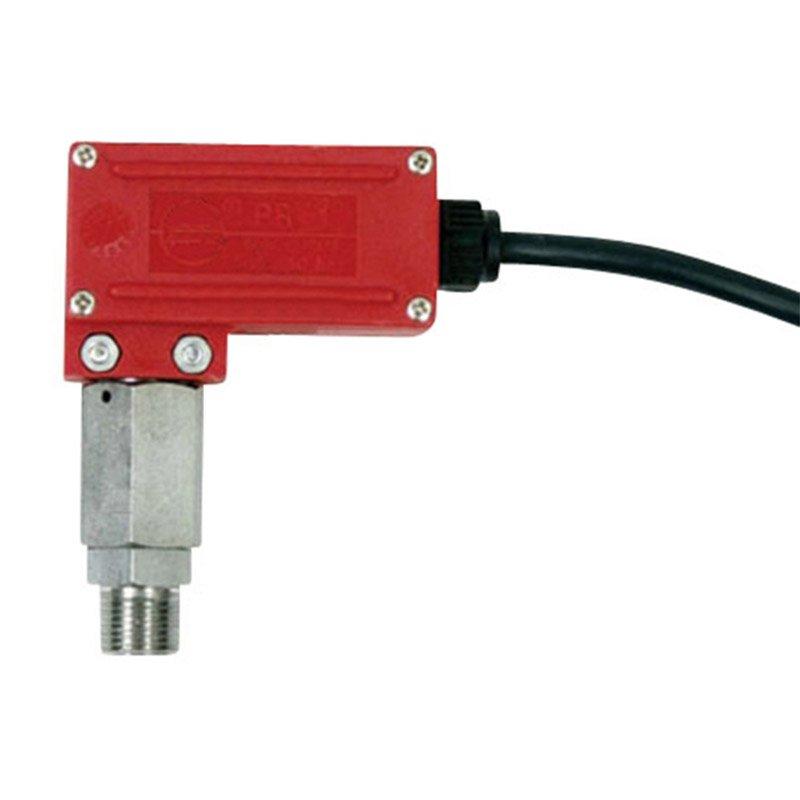

A stock image related to pr switch.

What Are the Key Properties of Brass for Pressure Switches?

Brass is a popular material for pressure switches due to its excellent mechanical properties and corrosion resistance. It typically has a temperature rating of up to 180°C (356°F) and can handle moderate pressures effectively. Brass exhibits good machinability and is often used in applications where electrical conductivity is essential.

Pros & Cons of Brass:

– Pros: Durable, good corrosion resistance, and excellent machinability. It is also relatively cost-effective compared to other metals.

– Cons: Not suitable for high-temperature applications exceeding its limits and can be prone to dezincification in aggressive environments.

Impact on Application:

Brass is suitable for applications involving water, air, and some gases. However, it may not be compatible with certain aggressive chemicals, which could lead to degradation.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure compliance with local standards for brass materials, such as ASTM and DIN specifications. In Europe, brass components must meet specific RoHS (Restriction of Hazardous Substances) directives.

How Does Stainless Steel Perform as a Material for Pressure Switches?

Stainless steel is renowned for its exceptional strength, corrosion resistance, and high-temperature performance, making it ideal for demanding applications. It can withstand temperatures up to 400°C (752°F) and high pressures, making it suitable for industrial environments.

Pros & Cons of Stainless Steel:

– Pros: High durability, excellent corrosion resistance, and ability to withstand extreme temperatures and pressures. It also has a long service life.

– Cons: Higher cost compared to brass and may require more complex manufacturing processes.

Impact on Application:

Stainless steel is compatible with a wide range of media, including corrosive fluids and gases, making it an excellent choice for chemical processing applications.

Considerations for International Buyers:

Buyers should consider the specific grade of stainless steel (e.g., 304 or 316) based on the application. Compliance with international standards such as ASTM and JIS is essential, especially for industries in the Middle East and Europe.

What Are the Advantages of Using Plastic in Pressure Switches?

Plastic materials, particularly those reinforced with fiberglass, are increasingly used in pressure switches due to their lightweight nature and resistance to corrosion. They can operate effectively in temperatures up to 120°C (248°F) and are suitable for low-pressure applications.

Pros & Cons of Plastic:

– Pros: Lightweight, cost-effective, and resistant to many chemicals. They are also easier to mold into complex shapes.

– Cons: Limited temperature and pressure ratings compared to metals, which restricts their application scope.

Impact on Application:

Plastic pressure switches are ideal for non-corrosive fluids and applications where weight is a concern, such as in portable equipment.

Considerations for International Buyers:

Buyers should ensure that the plastic materials used comply with local environmental regulations. In Europe, for example, compliance with REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is crucial.

How Do Silicone and Rubber Seals Enhance Pressure Switch Performance?

Silicone and rubber materials are often used for seals and diaphragms in pressure switches due to their flexibility and excellent sealing properties. They can typically handle temperatures ranging from -40°C to 200°C (-40°F to 392°F), depending on the specific formulation.

Pros & Cons of Silicone and Rubber:

– Pros: Excellent sealing capabilities, good flexibility, and resistance to a wide range of temperatures.

– Cons: Limited chemical resistance, particularly against oils and solvents, which may lead to degradation.

Impact on Application:

These materials are suitable for applications requiring a reliable seal against gases and liquids, but care must be taken regarding chemical compatibility.

Considerations for International Buyers:

Buyers should verify the chemical compatibility of silicone and rubber materials with the process fluids in their specific applications. Compliance with international standards for elastomers is also necessary.

Summary Table of Material Selection for Pressure Switches

| Material | Typical Use Case for pr switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Water and air applications | Good corrosion resistance | Not suitable for aggressive chemicals | Medium |

| Stainless Steel | Chemical processing | High durability and temperature range | Higher cost and manufacturing complexity | High |

| Plastic | Low-pressure, non-corrosive fluids | Lightweight and cost-effective | Limited temperature and pressure range | Low |

| Silicone/Rubber | Seals and diaphragms | Excellent sealing capabilities | Limited chemical resistance | Medium |

By carefully considering these materials and their properties, international B2B buyers can make informed decisions that align with their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for pr switch

What Are the Main Stages of Manufacturing Pressure Switches?

Manufacturing pressure switches involves a series of precise stages that ensure both functionality and reliability. The typical manufacturing process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Pressure Switch Manufacturing?

Material preparation is the first crucial step in the manufacturing process. The selection of materials is critical, as pressure switches often operate in harsh environments. Common materials include stainless steel for housings, various plastics for non-corrosive applications, and specialized alloys for high-pressure scenarios.

In this stage, suppliers must ensure that the materials meet specific industry standards and are free from defects. This often involves rigorous incoming quality control (IQC) procedures where materials are inspected for compliance with specifications. Buyers should inquire about the supplier’s sourcing practices and their adherence to international standards like ISO 9001, which emphasizes quality management systems.

What Techniques Are Used in Forming Pressure Switch Components?

The forming stage involves converting raw materials into the components that make up the pressure switch. Common techniques include machining, stamping, and injection molding. For example, diaphragms may be formed through stamping processes that create precise shapes to react sensitively to pressure changes.

Advanced techniques like CNC machining can provide high precision, especially for components that require exact tolerances. B2B buyers should consider suppliers that utilize modern manufacturing technologies, as these can lead to better product performance and lower failure rates.

How Are Pressure Switches Assembled?

Assembly is the next critical stage where various components are brought together to form the final product. This process usually involves manual and automated assembly methods, depending on the complexity of the switch. Key components such as the diaphragm, spring, electrical contacts, and terminals are systematically assembled to ensure proper function.

Quality assurance during assembly is essential. Many manufacturers implement in-process quality control (IPQC) checks to monitor the assembly line. Buyers should verify that their suppliers have protocols in place for regular inspections and employee training, which contribute to consistent product quality.

What Finishing Processes Are Important for Pressure Switches?

The finishing stage includes processes like surface treatment, painting, and testing. Surface treatments may be applied to enhance corrosion resistance, especially for switches used in aggressive environments.

Additionally, pressure switches undergo final testing to ensure they meet operational specifications. This includes verifying that the switch activates at the correct pressure levels and that all electrical connections are secure. Buyers should ask suppliers about their finishing processes and the measures taken to prevent defects.

How Is Quality Assurance Implemented in Pressure Switch Manufacturing?

Quality assurance (QA) is integral to ensuring that pressure switches meet both customer expectations and regulatory standards. International standards, such as ISO 9001, provide a framework for a quality management system, while industry-specific standards like CE (Conformité Européenne) and API (American Petroleum Institute) ensure compliance with safety and operational requirements.

What Are the Key Quality Control Checkpoints?

Quality control in pressure switch manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint ensures that raw materials meet predefined standards before they enter the production process.

-

In-Process Quality Control (IPQC): Regular inspections during the assembly process help identify defects early. This can include checks on dimensions, assembly accuracy, and functionality tests.

-

Final Quality Control (FQC): After assembly, the finished products undergo rigorous testing to verify that they operate according to specifications. This may include pressure testing, electrical testing, and environmental testing.

By understanding these checkpoints, B2B buyers can better assess the reliability of potential suppliers.

What Testing Methods Are Commonly Used for Pressure Switches?

Various testing methods ensure the quality and reliability of pressure switches. Common methods include:

- Functional Testing: This verifies that the switch operates correctly under specified conditions, such as activating at the designated pressure levels.

- Durability Testing: This assesses the switch’s performance over time, simulating long-term use conditions.

- Environmental Testing: This determines how the switch performs under extreme temperatures, humidity, and corrosive environments.

B2B buyers should seek suppliers that provide detailed testing reports and certifications, as these documents demonstrate compliance with quality standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must conduct due diligence to ensure that their suppliers adhere to rigorous quality control practices. Here are several strategies for verification:

- Supplier Audits: Regular audits can help buyers assess a supplier’s manufacturing processes, quality control systems, and compliance with international standards.

- Requesting Quality Reports: Suppliers should provide documentation of their quality control processes, including IQC, IPQC, and FQC results.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality practices and product reliability.

What Are the QC and Certification Nuances for International B2B Buyers?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is critical. Different markets may have varying regulatory requirements, and navigating these can be challenging.

- Regional Standards: Buyers should familiarize themselves with local standards and certifications required in their regions. For example, CE marking is crucial for products sold within the European market, while API certifications may be more relevant for oil and gas applications.

- Cross-Border Compliance: Ensure that suppliers can provide documentation showing compliance with both local and international standards. This is particularly important when sourcing from countries with different regulatory environments.

By understanding these aspects, B2B buyers can make informed decisions and establish partnerships with manufacturers that prioritize quality and compliance, ultimately ensuring the reliability of their pressure switches.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pr switch’

Introduction

Navigating the procurement of pressure switches (often referred to as ‘pr switches’) requires a strategic approach, especially for international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe. This guide offers a practical step-by-step checklist to assist you in making informed decisions, ensuring that you select the right product for your specific applications while optimizing costs and supplier reliability.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical in ensuring that the pressure switch meets your operational requirements. Consider factors such as:

– Pressure Range: Identify the operational pressure limits for your application.

– Type of Pressure Switch: Decide between mechanical and electronic types based on accuracy and complexity needs.

Step 2: Research Compliance and Standards

Different regions have varying compliance requirements for pressure switches. It is essential to verify that the switches meet local and international standards. Look for:

– Certification Labels: Ensure the product carries relevant certifications (e.g., CE, UL) based on your market.

– Industry-Specific Standards: For instance, explosion-proof ratings may be necessary in certain industrial environments.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough vetting is crucial. Assess their credibility by:

– Requesting Company Profiles: Gather information about their history, product range, and market presence.

– Checking References: Obtain testimonials from buyers in similar industries to validate their reliability and quality of service.

Step 4: Analyze Product Quality and Reliability

Quality assurance is paramount when procuring pressure switches. Investigate:

– Material Composition: Ensure that the materials used can withstand the operating conditions of your application, particularly in harsh environments.

– Warranty and Support: A robust warranty can indicate the manufacturer’s confidence in their product quality and offer peace of mind for your investment.

Step 5: Compare Pricing Structures

Once you have shortlisted suppliers, it’s time to compare pricing. Be mindful of:

– Total Cost of Ownership: Look beyond the initial purchase price; consider maintenance costs, longevity, and potential downtime.

– Bulk Purchase Discounts: Inquire about volume pricing if you plan to order large quantities, as this can significantly affect your overall budget.

Step 6: Verify After-Sales Support and Service

After-sales support can be a game-changer in your procurement process. Check for:

– Technical Assistance: Ensure the supplier offers robust support for installation and troubleshooting.

– Replacement Parts Availability: Confirm that spare parts are readily available to minimize downtime in case of failure.

Step 7: Finalize Contracts and Agreements

Once you’ve selected a supplier, ensure that all terms are clearly defined in the contract. Pay attention to:

– Delivery Schedules: Set clear timelines for delivery to avoid operational delays.

– Return Policies: Understand the terms for product returns in case of defects or misalignments with your specifications.

By following this checklist, international B2B buyers can confidently navigate the complexities of sourcing pressure switches, ensuring they select the right products that align with their operational needs and compliance requirements.

Comprehensive Cost and Pricing Analysis for pr switch Sourcing

What Are the Key Cost Components in Pressure Switch Sourcing?

When sourcing pressure switches, international B2B buyers need to understand the cost structure involved. Key components include:

-

Materials: The cost of materials varies significantly based on the type of pressure switch—mechanical or electronic. Mechanical switches often use metals and springs, while electronic switches require semiconductors and more advanced materials. The chemical properties of the process fluid can also dictate material choices, impacting costs.

-

Labor: Labor costs can differ depending on the manufacturing location. Regions with higher labor costs, such as Western Europe, may see increased pricing, while sourcing from places like Turkey or South America could offer more competitive labor rates.

-

Manufacturing Overhead: This includes costs associated with running the factory, such as utilities, equipment maintenance, and administrative expenses. Overhead can vary based on the efficiency of the manufacturing process and the scale of production.

-

Tooling: The initial investment in tooling for specialized or custom pressure switches can be significant. Buyers should consider whether the supplier has the necessary equipment to meet their specifications, as this can impact the overall cost.

-

Quality Control (QC): Quality assurance processes are essential to ensure that pressure switches meet industry standards. The cost of implementing rigorous QC measures can be substantial, especially for high-precision electronic switches.

-

Logistics: Transportation costs, including freight and insurance, must be factored into the total cost. Depending on the Incoterms agreed upon (e.g., FOB, CIF), buyers may need to account for different responsibilities in shipping and handling.

A stock image related to pr switch.

- Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. Understanding the typical margin in the industry can aid in negotiating better prices.

How Do Price Influencers Affect Pressure Switch Costs?

Several factors can influence the pricing of pressure switches:

-

Volume/MOQ: The minimum order quantity (MOQ) can significantly affect pricing. Larger orders often lead to discounts, so it’s beneficial for buyers to consolidate their needs if possible.

-

Specifications and Customization: Customized switches tailored to specific applications often come with higher costs. Standard products may be more affordable but may not meet all operational needs.

-

Materials: Higher-grade materials will increase the cost. Buyers should balance the need for durability and performance with budget constraints.

-

Quality and Certifications: Products that meet specific industry certifications (e.g., ISO, NEMA ratings) tend to be priced higher due to the additional testing and compliance costs.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their brand reputation and customer service.

-

Incoterms: Understanding the agreed-upon Incoterms can help buyers avoid unexpected costs related to shipping and customs.

What Tips Can Help International Buyers Negotiate Better Prices?

-

Negotiate Wisely: Leverage volume purchasing and long-term contracts to negotiate better terms. Be prepared to discuss payment terms, delivery schedules, and other conditions that can lead to cost savings.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes acquisition costs, maintenance, and operational costs over the product’s lifecycle. Sometimes, a more expensive switch may offer better long-term value.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations and geopolitical factors that can affect pricing. Building relationships with local suppliers can mitigate some risks.

-

Request Detailed Quotes: Ask for itemized quotes that break down costs, allowing for better comparison between suppliers. This transparency can facilitate negotiation.

-

Seek Multiple Suppliers: Diversifying suppliers can lead to competitive pricing and ensure that you are getting the best value for your investment.

By understanding these cost components, price influencers, and negotiation strategies, international B2B buyers can make informed decisions when sourcing pressure switches. Always consider potential variations in pricing based on market dynamics, and consult multiple suppliers to ensure competitive offers.

Alternatives Analysis: Comparing pr switch With Other Solutions

When evaluating pressure control solutions, B2B buyers often seek alternatives to the traditional pressure switch (pr switch). Understanding the strengths and weaknesses of various options can help in making informed purchasing decisions, especially for international buyers in diverse markets such as Africa, South America, the Middle East, and Europe. Below, we present a comparison of pr switches against two viable alternatives: electronic pressure transducers and mechanical pressure regulators.

Comparison Table of pr Switch and Alternatives

| Comparison Aspect | Pr Switch | Electronic Pressure Transducer | Mechanical Pressure Regulator |

|---|---|---|---|

| Performance | Reliable for on/off control | High accuracy and responsiveness | Consistent pressure regulation |

| Cost | Moderate initial investment | Higher upfront costs | Generally lower cost |

| Ease of Implementation | Straightforward installation | Requires calibration and setup | Simple installation |

| Maintenance | Low maintenance, robust design | Moderate maintenance required | Low maintenance |

| Best Use Case | HVAC systems, safety mechanisms | Industrial automation, precision applications | General fluid control |

What Are the Advantages and Disadvantages of Electronic Pressure Transducers?

Electronic Pressure Transducers offer higher accuracy and faster response times compared to pr switches. They convert pressure into an electrical signal, allowing for precise monitoring and control. This makes them ideal for applications requiring fine adjustments and data logging. However, their complexity can lead to higher costs and necessitate additional calibration and maintenance. Additionally, they may not be as robust in harsh environments compared to mechanical options.

How Do Mechanical Pressure Regulators Compare?

Mechanical Pressure Regulators are simpler devices that maintain a consistent output pressure regardless of variations in input pressure. They are generally less expensive and easier to install than electronic solutions. However, they may not provide the same level of accuracy as electronic transducers or the on/off control that pr switches offer. Their use is most beneficial in applications where maintaining steady pressure is more critical than rapid adjustments or precise monitoring.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting a pressure control solution, B2B buyers should consider their specific application needs. If reliability and straightforward on/off control are paramount, the pr switch remains a strong choice. However, for applications demanding high precision and data integration, electronic pressure transducers may be worth the investment. For those seeking a cost-effective solution for steady pressure maintenance, mechanical pressure regulators could be the best fit. Ultimately, aligning the choice with operational requirements, budget constraints, and maintenance capabilities will lead to the best decision.

Essential Technical Properties and Trade Terminology for pr switch

What Are the Key Technical Properties of a Pressure Switch?

Understanding the technical specifications of a pressure switch is crucial for B2B buyers, as these properties directly influence the device’s performance, reliability, and suitability for specific applications. Here are some essential specifications to consider:

1. Material Grade

The material used in a pressure switch—such as stainless steel, brass, or plastic—affects its durability and resistance to environmental factors. For instance, stainless steel offers corrosion resistance, making it ideal for applications involving aggressive chemicals or extreme weather conditions. Selecting the right material can ensure longevity and reduce maintenance costs.

2. Pressure Range

This specification defines the minimum and maximum pressure levels at which the switch can operate effectively. It is vital for buyers to match the pressure range with their specific applications to avoid malfunction or damage. A general rule is to set the operational pressure between 40% to 60% of the switch’s maximum rated pressure for optimal performance.

3. Operating Temperature

The temperature range in which a pressure switch can function without degradation is critical, particularly in industries like oil and gas or food processing. Components must be selected based on the maximum and minimum temperatures they will encounter, ensuring they can withstand operational conditions without compromising performance.

4. Electrical Ratings

This specification includes the maximum voltage and current that the pressure switch can handle. It is essential for B2B buyers to ensure that the electrical ratings align with their existing systems to prevent electrical failures or safety hazards. High-voltage applications may require robust mechanical switches, while low-voltage scenarios could benefit from electronic switches.

5. Switch Type: Mechanical vs. Electronic

Mechanical pressure switches are typically more robust and better suited for high-voltage applications, while electronic switches offer higher accuracy and longer operational life. Buyers should assess their application requirements to determine which type best meets their needs, considering factors like accuracy, responsiveness, and maintenance.

What Are the Common Trade Terms Associated with Pressure Switches?

Familiarity with industry jargon is crucial for B2B buyers to navigate procurement processes effectively. Below are some common terms related to pressure switches:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of pressure switches, understanding OEM specifications helps buyers ensure compatibility with their existing machinery and systems.

2. MOQ (Minimum Order Quantity)

This term refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budget-conscious buyers, as it can affect inventory costs and cash flow management.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and other relevant information for specific products. B2B buyers should utilize RFQs to obtain competitive pricing and ensure they are making informed purchasing decisions.

4. Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in shipping. Familiarity with Incoterms is crucial for international B2B buyers to understand shipping risks, costs, and responsibilities.

5. NEMA Ratings (National Electrical Manufacturers Association)

NEMA ratings categorize enclosures based on their suitability for specific environments. For instance, a NEMA 4 rating indicates that the pressure switch is suitable for outdoor use and can withstand water and dust. Understanding these ratings helps buyers select appropriate devices for their operational environments.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when selecting pressure switches that best fit their operational needs and industry standards.

Navigating Market Dynamics and Sourcing Trends in the pr switch Sector

What Are the Current Market Dynamics and Key Trends in the Pressure Switch Sector?

The global pressure switch market is experiencing robust growth, driven by advancements in automation and the increasing demand for precision control systems across various industries, including HVAC, automotive, and manufacturing. Emerging economies in Africa and South America are rapidly adopting these technologies, fueled by industrialization and infrastructure development. In regions like the Middle East and Europe, stringent regulations for safety and environmental compliance are pushing companies to integrate more sophisticated pressure switch systems.

Key trends shaping the market include the rise of electronic pressure switches, which offer enhanced accuracy and reliability compared to their mechanical counterparts. Additionally, the growing Internet of Things (IoT) integration in industrial systems is leading to the development of smart pressure switches that can provide real-time data analytics, significantly improving operational efficiency. B2B buyers are increasingly looking for suppliers that offer customizable solutions tailored to specific application needs, reflecting a shift towards more personalized procurement strategies.

Furthermore, sustainability is becoming a significant factor in purchasing decisions. International buyers are seeking products that not only meet performance criteria but are also manufactured through environmentally responsible processes. This trend is particularly pronounced in Europe, where eco-friendly certifications are becoming essential for market entry.

How Is Sustainability Influencing the Sourcing of Pressure Switches?

The environmental impact of manufacturing processes has made sustainability a critical consideration in the pressure switch sector. International B2B buyers are now prioritizing suppliers that demonstrate a commitment to reducing their carbon footprint and adhering to ethical sourcing practices. This includes the use of recycled materials, energy-efficient manufacturing processes, and compliance with environmental regulations.

Sustainability certifications, such as ISO 14001, are increasingly important as they provide assurance regarding a manufacturer’s environmental management practices. Buyers are also looking for pressure switches made from eco-friendly materials that minimize harm to the environment, such as non-toxic plastics and metals that can be recycled at the end of their lifecycle.

Moreover, ethical supply chains that ensure fair labor practices and safe working conditions are gaining traction. B2B buyers from Africa and South America, in particular, are showing interest in suppliers who can provide transparency in their sourcing practices. This reflects a broader trend towards responsible sourcing that aligns with corporate social responsibility (CSR) objectives.

What Is the Brief History of Pressure Switch Technology?

The evolution of pressure switch technology dates back to the early 20th century when mechanical devices were first developed to monitor pressure in various applications. Initially, these switches were simple mechanical devices utilizing springs and pistons to activate or deactivate equipment based on pressure thresholds. Over the decades, advancements in materials and engineering led to the introduction of electronic pressure switches, which offer improved accuracy, reliability, and the ability to handle complex applications.

By the late 20th century, the integration of microelectronics and digital technology further transformed the pressure switch landscape. Today, pressure switches are not only crucial components in industrial automation but are also embedded in smart technologies, reflecting the ongoing demand for efficiency and precision in modern manufacturing processes. This historical context is vital for B2B buyers as it highlights the importance of selecting suppliers who understand the latest technological advancements and can provide innovative solutions tailored to their operational needs.

Frequently Asked Questions (FAQs) for B2B Buyers of pr switch

-

How do I solve compatibility issues when sourcing pressure switches?

To resolve compatibility issues with pressure switches, first, identify the specific requirements of your application, including pressure range, temperature, and fluid type. Consult with suppliers who can provide detailed specifications and ensure their products meet your standards. Additionally, consider requesting samples for testing in your environment. Engage in discussions with manufacturers about customization options to meet unique needs, ensuring a perfect fit for your system. -

What is the best pressure switch for agricultural applications?

The ideal pressure switch for agricultural applications typically includes features such as robust construction to withstand environmental conditions and a wide operating pressure range. Look for models specifically designed for water pumps or irrigation systems. Electronic pressure switches may offer enhanced accuracy and reliability, while mechanical types can be cost-effective for less critical applications. Always evaluate the switch’s compatibility with your specific equipment and the fluids involved. -

How can I vet suppliers of pressure switches internationally?

Vetting international suppliers involves several steps: check their certifications (ISO, CE), review customer testimonials, and assess their production capabilities. Use platforms like Alibaba or Global Sources for initial research, but follow up with direct communication. Request product samples and documentation of previous projects to gauge their reliability. Additionally, consider visiting their facility if feasible, or use third-party inspection services to ensure quality standards are met before placing significant orders. -

What are typical minimum order quantities (MOQs) for pressure switches?

Minimum order quantities (MOQs) for pressure switches vary by manufacturer and can range from as low as 10 units to several hundred. Factors influencing MOQs include the type of switch, materials used, and customization requirements. When negotiating with suppliers, express your needs clearly and explore the possibility of lower MOQs for initial orders, especially if you’re testing a new supplier. Establishing a good relationship may lead to more favorable terms in future orders. -

What payment terms should I expect when purchasing pressure switches?

Payment terms for purchasing pressure switches can vary significantly among suppliers. Common practices include a deposit (usually 30-50%) upfront, with the balance due upon shipping or delivery. For larger orders, you might negotiate better terms, such as extended payment periods or letter of credit arrangements to mitigate risk. Always clarify payment methods accepted (bank transfer, credit card, etc.) and ensure that terms are documented in the purchase agreement. -

How important is quality assurance (QA) for pressure switches?

Quality assurance (QA) is crucial in ensuring the reliability and safety of pressure switches, especially in critical applications like HVAC systems or industrial processes. Look for suppliers that implement rigorous QA processes, including testing for durability, accuracy, and environmental resistance. Request documentation of QA procedures and certifications to validate their commitment to quality. Regular audits of suppliers can also help maintain high standards throughout your supply chain. -

What logistics considerations should I keep in mind when importing pressure switches?

When importing pressure switches, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder who understands the specific requirements for your region, especially if you’re sourcing from continents like Asia or Europe. Be aware of potential tariffs, duties, and taxes that can affect your overall costs. Planning for these logistics details in advance can help avoid delays and unexpected expenses. -

Can pressure switches be customized for specific applications?

Yes, many manufacturers offer customization options for pressure switches to suit specific applications. Custom features may include adjusting pressure ranges, changing electrical contacts, or modifying housing materials for enhanced durability. When approaching suppliers, clearly outline your requirements and ask for their capabilities in customization. Keep in mind that custom orders may have longer lead times and higher costs, so plan accordingly for your project timelines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for pr switch

What Are the Key Takeaways for B2B Buyers of Pressure Switches?

In today’s competitive landscape, international B2B buyers must prioritize strategic sourcing to optimize their procurement processes for pressure switches. Understanding the types of pressure switches—mechanical and electronic—along with their specific applications across industries, is crucial. Select the right switch based on operating conditions, such as temperature and fluid compatibility, to ensure reliability and efficiency in operations.

A stock image related to pr switch.

How Can Strategic Sourcing Enhance Your Purchasing Decisions?

Strategic sourcing not only reduces costs but also enhances supplier relationships, ensuring access to high-quality products that meet regulatory standards. By leveraging local suppliers from regions like Africa, South America, the Middle East, and Europe, buyers can benefit from reduced lead times and customized solutions tailored to their unique needs.

What Does the Future Hold for Pressure Switch Purchases?

Looking ahead, the demand for advanced pressure switches that offer enhanced accuracy and durability is expected to rise. As industries increasingly embrace automation and smart technologies, integrating high-performance pressure switches will be vital for maintaining operational excellence.

Call to Action: Engage with trusted suppliers today to explore innovative pressure switch solutions that can elevate your business operations. Prioritize your sourcing strategy to ensure long-term success in your markets.