Discover Cost-Saving Electric Motor Parts Solutions (2025)

Introduction: Navigating the Global Market for electric motor parts

In today’s rapidly evolving industrial landscape, sourcing electric motor parts can present significant challenges for international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe. The complexity of the global supply chain, combined with the need for high-quality components, makes it crucial for businesses to navigate this market effectively. This guide aims to provide comprehensive insights into the various types of electric motor parts available, their applications across different industries, and essential criteria for selecting reliable suppliers.

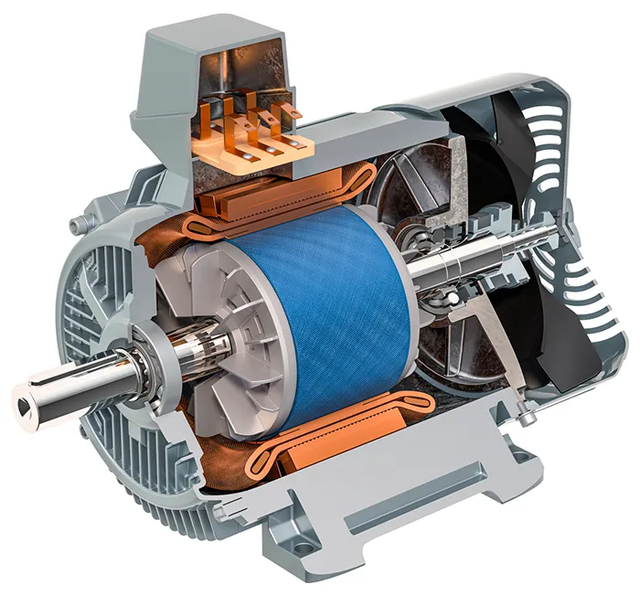

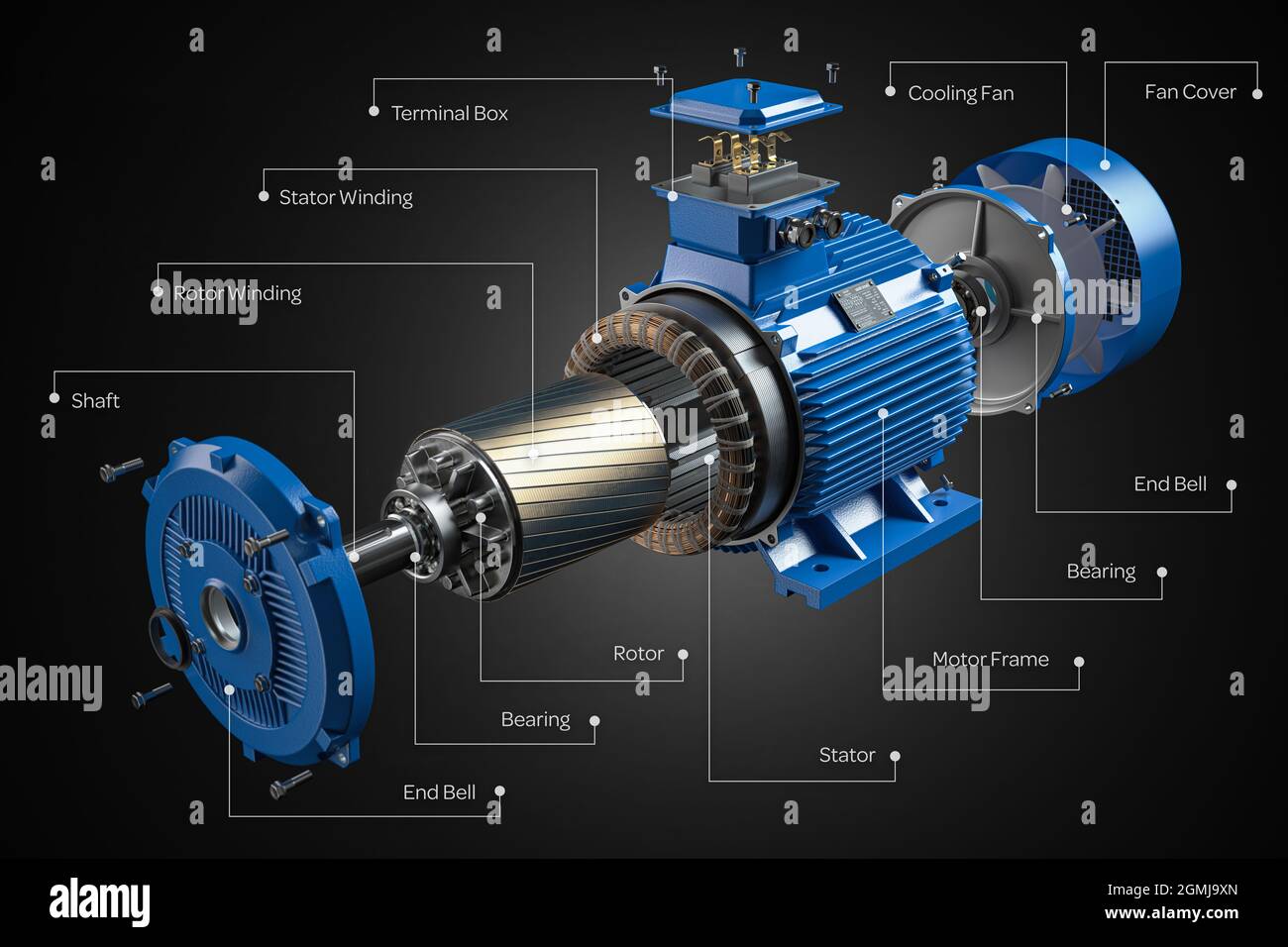

Understanding the intricate components of electric motors—such as stators, rotors, bearings, and thermal protectors—is vital for making informed purchasing decisions. Each part plays a specific role in the motor’s functionality, impacting efficiency and performance. Additionally, this guide will delve into the vetting process for suppliers, offering strategies to ensure that you partner with reputable manufacturers who can meet your quality and delivery requirements.

Cost considerations are also addressed, providing a clear framework for budgeting and financial planning. By equipping B2B buyers with detailed knowledge about electric motor parts, their applications, and supplier dynamics, this guide empowers businesses to make strategic purchasing decisions that enhance operational efficiency and drive growth. Whether you’re in Nigeria, Turkey, or elsewhere, understanding the global market for electric motor parts is essential for maintaining a competitive edge.

Understanding electric motor parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stator | Stationary part with wire coils or magnets | Industrial machinery, HVAC | Pros: Essential for operation; Cons: Requires precise alignment. |

| Rotor | Rotating component, interacts with stator | Electric vehicles, pumps | Pros: Converts electrical to mechanical energy; Cons: Vulnerable to wear. |

| Bearings | Support for rotor, reduces friction | Motors in automotive, manufacturing | Pros: Enhances lifespan; Cons: Quality impacts performance significantly. |

| Terminal Box | Houses electrical connections, protects wiring | All electric motor applications | Pros: Ensures safe operation; Cons: May require maintenance for dust/moisture. |

| Cooling Fan | Dissipates heat generated during operation | HVAC systems, industrial motors | Pros: Prevents overheating; Cons: Noise may be an issue in some settings. |

What are the Key Characteristics of Stators in Electric Motors?

The stator serves as the backbone of electric motors, consisting of wire coils or permanent magnets. It generates a rotating magnetic field that is crucial for the motor’s operation. Stators are primarily used in industrial machinery and HVAC systems, where efficiency is paramount. When purchasing stators, consider the material quality and design, as these factors influence performance and longevity. Proper alignment during installation is critical to avoid operational issues.

How Do Rotors Contribute to Electric Motor Functionality?

Rotors are the rotating elements within the stator, typically made from laminated steel cores with conductors. They are responsible for converting electrical energy into mechanical energy, making them essential for applications such as electric vehicles and pumps. Buyers should focus on rotor durability and efficiency ratings, as these factors impact overall motor performance. Additionally, understanding the rotor’s interaction with the stator is vital for optimal operation.

Why are Bearings Important for Electric Motors?

Bearings play a crucial role in supporting the rotor and minimizing friction during operation. High-quality bearings can significantly extend the lifespan of electric motors, particularly in automotive and manufacturing applications where reliability is crucial. When sourcing bearings, consider load capacity, lubrication type, and material composition. Investing in premium bearings can prevent costly downtime and maintenance in the long run.

What Role Does a Terminal Box Play in Electric Motors?

The terminal box is integral to the safety and functionality of electric motors, housing electrical connections and protecting them from environmental factors. It ensures secure power supply connections, making it essential for all electric motor applications. Buyers should evaluate the design and sealing capabilities of terminal boxes to ensure they meet operational requirements. Regular maintenance may be necessary to prevent issues related to dust and moisture ingress.

How Do Cooling Fans Enhance Electric Motor Performance?

Cooling fans are critical for dissipating heat generated during motor operation, particularly in HVAC systems and industrial motors. They help prevent overheating, which can lead to motor failure. When selecting cooling fans, buyers should consider noise levels and airflow efficiency, as these factors can impact operational comfort and effectiveness. Understanding the thermal management needs of specific applications will guide buyers in making informed decisions regarding fan specifications.

Key Industrial Applications of electric motor parts

| Industry/Sector | Specific Application of Electric Motor Parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Improved efficiency and productivity in material handling | Ensure availability of OEM parts for compatibility and reliability |

| Agriculture | Irrigation Systems | Enhanced crop yield through efficient water management | Consider local suppliers for timely maintenance support |

| Transportation | Electric Vehicles | Reduced operational costs and environmental impact | Evaluate parts for compliance with international standards |

| Mining | Heavy Machinery | Increased uptime and reduced maintenance costs | Look for durable parts that can withstand harsh conditions |

| HVAC | Cooling and Heating Systems | Energy savings and improved comfort | Source energy-efficient components for better performance |

How Are Electric Motor Parts Used in Manufacturing Applications?

In the manufacturing sector, electric motor parts are integral to conveyor systems that transport materials throughout production lines. These motors enhance operational efficiency by ensuring smooth and continuous movement, which is essential for maintaining productivity. International buyers, particularly from regions like Africa and South America, should focus on sourcing OEM parts that guarantee compatibility with existing systems, thus minimizing downtime and maintenance costs.

What Role Do Electric Motor Parts Play in Agriculture?

Electric motor parts are crucial in agricultural irrigation systems, powering pumps that deliver water to crops. Efficient water management leads to improved crop yields and resource conservation, addressing the pressing challenges of food security. Buyers in the Middle East and Europe should prioritize sourcing motors that can handle varying load conditions and are suitable for local climates, ensuring reliability throughout the growing season.

How Are Electric Motor Parts Essential in Transportation?

In the transportation industry, electric motor parts are vital for electric vehicles (EVs), converting electrical energy into mechanical power. This application not only reduces operational costs but also contributes to lower carbon emissions, aligning with global sustainability goals. B2B buyers, especially in Europe, must ensure that sourced parts comply with international safety and performance standards, which is critical for market acceptance and regulatory compliance.

What Are the Applications of Electric Motor Parts in Mining?

Electric motor parts are used extensively in heavy machinery within the mining sector, powering equipment like drills and conveyors. The reliability of these motors is paramount, as any downtime can lead to significant financial losses. Buyers from Africa and South America should seek durable and high-performance components that can withstand the harsh conditions prevalent in mining operations, ensuring longevity and reduced maintenance.

How Do Electric Motor Parts Benefit HVAC Systems?

In HVAC applications, electric motor parts drive fans and compressors, playing a crucial role in heating and cooling systems. These components contribute to energy savings and improved indoor air quality, which are essential for customer satisfaction in commercial settings. Buyers in Europe should consider sourcing energy-efficient motors that meet local energy regulations, enhancing system performance while reducing energy costs.

3 Common User Pain Points for ‘electric motor parts’ & Their Solutions

Scenario 1: Difficulty Sourcing Reliable Replacement Parts for Electric Motors

The Problem: Many B2B buyers face challenges when sourcing reliable replacement parts for electric motors. This is particularly prevalent in regions like Africa and South America, where the supply chain may be less stable. Buyers often encounter issues with counterfeit parts, inconsistent quality, and delays in shipping, which can lead to extended downtime and financial losses. The urgency to maintain operations while ensuring part reliability adds an extra layer of stress.

The Solution: To mitigate these challenges, buyers should establish relationships with reputable suppliers who specialize in electric motor parts. It is advisable to conduct thorough research, including checking for certifications and customer reviews. Buyers can also consider joining industry groups or forums where they can share experiences and recommendations. Creating a standardized list of required parts, including OEM specifications, can streamline the sourcing process. Additionally, engaging in long-term contracts with suppliers can ensure priority access to parts and potentially better pricing, reducing the risk of delays and subpar products.

Scenario 2: Inconsistent Quality of Electric Motor Parts

The Problem: Another common pain point is the inconsistency in the quality of electric motor parts. B2B buyers may find that parts sourced from different suppliers do not meet the required specifications or performance standards, leading to increased maintenance issues and operational disruptions. This inconsistency can be particularly damaging in industries that rely on precision, such as manufacturing and energy.

The Solution: To address quality concerns, buyers should implement a rigorous quality assurance process when evaluating suppliers. This includes requesting samples and conducting tests to verify that parts meet industry standards. Establishing clear quality criteria and performance benchmarks for each part can help in assessing their reliability. Additionally, buyers should seek suppliers that offer warranties or guarantees, ensuring that they can return or replace defective parts without incurring significant costs. Investing in training for in-house staff on quality assessment can further empower teams to make informed decisions and maintain operational integrity.

Scenario 3: Lack of Technical Support for Electric Motor Parts

The Problem: Many B2B buyers struggle with a lack of technical support when dealing with electric motor parts. This issue is particularly critical when installation or troubleshooting is required, as many buyers may not have the in-house expertise to handle complex technical challenges. In regions with limited access to skilled technicians, this can lead to delays in repairs and increased operational costs.

The Solution: To overcome the lack of technical support, buyers should prioritize suppliers who provide comprehensive customer service, including technical assistance and installation guidance. Engaging with suppliers that offer training sessions or workshops can also build the internal capacity of the buyer’s team, enabling them to handle installations and repairs more effectively. Additionally, leveraging online resources such as video tutorials and FAQs can empower teams to solve common issues independently. For buyers in regions with limited access to skilled labor, establishing partnerships with local technicians or service providers can also enhance support capabilities, ensuring that help is readily available when needed.

Strategic Material Selection Guide for electric motor parts

What Are the Key Materials Used in Electric Motor Parts?

When selecting materials for electric motor parts, it is essential to consider their properties, advantages, disadvantages, and suitability for specific applications. This decision impacts performance, longevity, and compliance with international standards, especially for B2B buyers in diverse markets such as Africa, South America, the Middle East, and Europe.

How Does Aluminum Perform as a Material for Electric Motor Parts?

Aluminum is widely used in electric motor components, particularly for housings, brackets, and cooling fans. Its key properties include excellent thermal conductivity, lightweight nature, and good corrosion resistance. These characteristics make aluminum ideal for applications requiring efficient heat dissipation and reduced weight.

Pros: Aluminum is durable and resistant to corrosion, which is vital for motors operating in humid or corrosive environments. Additionally, it is relatively easy to manufacture and can be extruded or molded into complex shapes.

Cons: While aluminum is cost-effective, it may not withstand high temperatures as well as other materials like steel. This limitation can affect its suitability in high-performance applications.

Impact on Application: Aluminum’s compatibility with various media, including water and oils, makes it versatile. However, it may not be suitable for applications involving harsh chemicals.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM and DIN for aluminum grades. In regions like Nigeria and Turkey, local sourcing can help reduce costs and improve lead times.

What Role Does Steel Play in Electric Motor Parts?

Steel, particularly stainless steel, is another common material used in electric motor parts. It is known for its high strength, durability, and excellent wear resistance. Steel parts are often used in shafts, bearings, and structural components.

Pros: Steel can withstand high temperatures and pressures, making it suitable for heavy-duty applications. Its strength ensures that components can endure mechanical stresses over time.

Cons: The primary drawback of steel is its susceptibility to corrosion unless treated or alloyed. This can lead to increased maintenance costs in environments prone to rust.

Impact on Application: Steel’s robustness makes it ideal for motors used in industrial settings. However, buyers must consider the potential for corrosion in specific applications, such as those exposed to moisture.

Considerations for International Buyers: Buyers should look for compliance with international standards for steel grades and corrosion resistance. In markets like South America, where humidity can be high, selecting the right grade is crucial.

Why Is Copper Essential for Electric Motor Parts?

Copper is a critical material for electric motor windings and electrical connections due to its excellent electrical conductivity. It is often used in coils and terminal connections.

Pros: Copper’s high conductivity ensures efficient energy transfer, which is vital for motor performance. It is also relatively easy to work with and can be soldered or crimped for secure connections.

Cons: Copper is more expensive than aluminum, and its weight can be a disadvantage in applications where weight reduction is essential. Additionally, it is prone to corrosion if not properly insulated.

Impact on Application: Copper’s compatibility with various electrical systems makes it a preferred choice for high-performance motors. However, buyers should be aware of the need for protective coatings in corrosive environments.

Considerations for International Buyers: Compliance with international electrical standards is crucial. Buyers should also consider local market conditions, as copper prices can fluctuate significantly.

What Advantages Does Plastic Offer in Electric Motor Parts?

Plastics, particularly engineering plastics, are increasingly used in electric motor components such as housings and insulators. They offer a unique combination of lightweight properties and resistance to corrosion.

Pros: Plastics are lightweight, reducing the overall weight of the motor, which is beneficial for portable applications. They also resist moisture and many chemicals, making them suitable for various environments.

Cons: While plastics can be durable, they may not withstand high temperatures as well as metals. They can also be more susceptible to mechanical wear over time.

Impact on Application: Plastics are ideal for applications where weight savings and corrosion resistance are critical. However, they may not be suitable for high-stress components.

Considerations for International Buyers: Buyers should ensure that plastics meet relevant standards for mechanical and thermal properties. In regions with strict regulations, such as Europe, compliance with environmental standards is also essential.

Summary Table of Material Selection for Electric Motor Parts

| Material | Typical Use Case for Electric Motor Parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housings, brackets, cooling fans | Excellent thermal conductivity | Limited high-temperature resistance | Medium |

| Steel | Shafts, bearings, structural components | High strength and durability | Susceptible to corrosion | Medium |

| Copper | Windings, electrical connections | Superior electrical conductivity | Higher cost and weight | High |

| Plastic | Housings, insulators | Lightweight and corrosion-resistant | Limited high-temperature resistance | Low |

This guide provides a comprehensive overview of material selection for electric motor parts, offering actionable insights for international B2B buyers. By understanding the properties and implications of each material, buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for electric motor parts

What Are the Main Stages in the Manufacturing Process of Electric Motor Parts?

The manufacturing process of electric motor parts involves several critical stages, each designed to ensure precision, efficiency, and quality. These stages typically include material preparation, forming, assembly, and finishing. Understanding these stages can help international B2B buyers make informed decisions when sourcing electric motor parts.

1. Material Preparation

Material preparation is the foundation of the manufacturing process. It involves selecting high-quality raw materials, such as copper for windings, laminated steel for the rotor and stator, and various alloys for bearings and brackets. Proper selection and treatment of materials are vital, as they directly influence the performance and longevity of the electric motor.

- Key Techniques: Material selection is often guided by industry standards and specific application requirements. For example, copper wire must meet electrical conductivity standards, while steel laminates should have optimal magnetic properties. Buyers should inquire about the material certifications and properties provided by suppliers.

2. How Are Electric Motor Parts Formed?

The forming stage involves shaping raw materials into the necessary components of electric motors. This can include processes such as stamping, forging, and machining.

-

Stamping: This technique is commonly used for creating stator and rotor laminations. Stamping presses cut the laminated sheets into precise shapes, which are then stacked to form the core.

-

Machining: Machining processes, including turning and milling, are used to produce components like shafts and brackets. These processes require high precision to ensure that parts fit together seamlessly during assembly.

-

Quality Considerations: During this stage, it is essential for buyers to ensure that the supplier uses advanced CNC machines and has a robust quality control system in place to monitor dimensional accuracy.

3. What Is Involved in the Assembly of Electric Motor Parts?

Once the parts are formed, the assembly stage begins. This involves fitting various components together to create the complete motor assembly.

-

Assembly Techniques: Electric motors may be assembled manually or using automated systems, depending on the complexity and scale of production. Key components such as the rotor, stator, bearings, and terminal boxes are carefully integrated.

-

Quality Control During Assembly: It is crucial to maintain alignment and ensure that all components function correctly. Buyers should verify that suppliers conduct assembly inspections to catch defects early, minimizing the risk of failure in the final product.

4. What Finishing Processes Are Used for Electric Motor Parts?

Finishing processes are the final steps in the manufacturing of electric motor parts, designed to enhance performance and durability.

-

Coating and Painting: Parts are often coated with protective finishes to prevent corrosion and wear. This may include powder coating or electroplating, which not only protect but also improve aesthetic appeal.

-

Testing and Inspection: Before final shipment, parts undergo rigorous testing to ensure they meet performance standards. Common tests include electrical resistance testing, thermal imaging, and vibration analysis.

What Quality Assurance Standards Should B2B Buyers Know?

Quality assurance is critical in the manufacturing of electric motor parts. Buyers should be familiar with international standards and industry-specific regulations that govern quality control.

1. Which International Standards Apply to Electric Motor Parts?

-

ISO 9001: This standard outlines a framework for quality management systems. Suppliers certified to ISO 9001 demonstrate their commitment to consistent quality and customer satisfaction.

-

CE Marking: For buyers in Europe, CE marking indicates compliance with European health, safety, and environmental protection standards.

-

API Standards: For specific applications, particularly in the oil and gas industry, API standards may apply. These ensure that electric motor parts can withstand harsh operating conditions.

2. What Are the Key Quality Control Checkpoints?

Effective quality control during manufacturing involves several checkpoints:

-

Incoming Quality Control (IQC): This initial inspection ensures that all raw materials meet specified standards before production begins.

-

In-Process Quality Control (IPQC): Regular checks during the manufacturing process help identify defects early, allowing for corrective actions before assembly.

-

Final Quality Control (FQC): This comprehensive inspection occurs after assembly, ensuring that the finished product meets all specifications and performance criteria.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of potential suppliers.

1. Conducting Supplier Audits

Regular audits of supplier facilities can provide insight into their manufacturing processes and quality assurance practices. Buyers should consider:

-

On-Site Audits: Visiting suppliers to observe their operations, quality control measures, and compliance with industry standards can uncover potential issues.

-

Document Review: Reviewing quality assurance documentation, including certifications, inspection reports, and test results, is essential to ensure compliance with standards.

2. Utilizing Third-Party Inspections

Engaging third-party inspection services can add an extra layer of assurance. These organizations can conduct unbiased evaluations of suppliers’ quality control systems and manufacturing processes.

3. Understanding Quality Certification Nuances for International Buyers

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, navigating quality certifications can be complex. It is crucial to:

-

Research Regional Standards: Different regions may have specific certifications that are recognized locally. Understanding these can aid in sourcing compliant products.

-

Evaluate Supplier Capabilities: Not all suppliers will have the same level of certification or experience with international standards. Prioritize those with proven track records and relevant certifications.

Conclusion

Understanding the manufacturing processes and quality assurance practices for electric motor parts is essential for international B2B buyers. By focusing on key stages in manufacturing, familiarizing themselves with quality standards, and implementing thorough verification processes, buyers can make informed decisions and secure high-quality electric motor parts suited to their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric motor parts’

To assist international B2B buyers in sourcing electric motor parts effectively, this practical sourcing guide provides a structured checklist. By following these steps, buyers from regions like Africa, South America, the Middle East, and Europe can streamline their procurement process, ensuring quality and reliability in their purchases.

Step 1: Define Your Technical Specifications

Before starting your procurement journey, it’s essential to clearly outline your technical requirements. Identify the specific parts needed, such as rotors, stators, bearings, and thermal protectors. Be precise about dimensions, materials, and performance criteria, as this will help in communicating effectively with suppliers and avoiding mismatches.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to compile a list of potential suppliers. Look for companies with a solid reputation in the electric motor parts industry. Key factors to consider include:

– Customer reviews and testimonials: Assess feedback from other businesses in your region or industry.

– Years in business: Established suppliers often have proven track records and experience in dealing with international clients.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Focus on:

– Quality certifications: Ensure suppliers have relevant certifications (e.g., ISO 9001) that affirm their commitment to quality.

– Product range: A supplier offering a wide range of parts may provide better options for your specific needs.

Step 4: Verify Supplier Certifications and Compliance

Confirm that your selected suppliers meet international standards and regulations. This step is vital for ensuring product quality and safety. Look for certifications such as:

– CE marking: Indicates compliance with European safety standards.

– UL certification: Important for electrical components, ensuring they meet safety standards in the USA.

Step 5: Request Samples and Conduct Quality Testing

Once you have narrowed down your supplier list, request samples of the electric motor parts you intend to purchase. Testing these samples can provide insights into:

– Quality and durability: Assess how well the parts meet your specifications and operational requirements.

– Compatibility: Ensure that the parts work seamlessly with your existing systems.

Step 6: Negotiate Pricing and Terms

After evaluating quality, begin discussions on pricing and terms. This step is critical for maintaining your budget while ensuring you receive quality products. Consider:

– Bulk purchase discounts: Inquire about price breaks for larger orders.

– Payment terms: Establish clear payment conditions to avoid issues later on.

Step 7: Establish Logistics and Shipping Arrangements

Finally, plan the logistics for shipping the parts to your location. Consider the following:

– Shipping methods: Evaluate options such as air freight for speed or sea freight for cost-effectiveness.

– Import regulations: Understand the customs requirements and duties applicable in your country to avoid delays and additional costs.

By following this checklist, B2B buyers can enhance their sourcing strategies for electric motor parts, ensuring they procure high-quality components that meet their operational needs while optimizing costs and efficiency.

Comprehensive Cost and Pricing Analysis for electric motor parts Sourcing

What Are the Key Cost Components in Electric Motor Parts Sourcing?

When sourcing electric motor parts, understanding the cost structure is essential for international B2B buyers. The main cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality materials such as copper and aluminum for windings and steel for the rotor and stator can elevate prices. However, investing in superior materials often results in better performance and longevity.

-

Labor: Labor costs vary by region and can influence the final price. Countries with lower labor costs may offer more competitive pricing, but this can sometimes come at the expense of quality.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Tooling costs involve the design and creation of specialized equipment needed for production. Custom parts often require unique tooling, which can add to the initial investment.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability and compliance with international standards. While this adds to the cost, it can prevent future expenses related to product failures.

-

Logistics: Shipping costs can be a significant factor, especially for international transactions. Understanding the logistics involved, including freight, insurance, and customs duties, is crucial for accurate budgeting.

-

Margin: Suppliers will add a margin to cover their costs and profit. This can vary widely depending on the supplier’s market positioning and the level of service provided.

How Do Price Influencers Affect Electric Motor Parts Costs?

Several factors influence the pricing of electric motor parts:

-

Volume and Minimum Order Quantity (MOQ): Ordering in larger volumes often results in lower per-unit costs. Suppliers may offer discounts for bulk purchases, which can significantly affect the overall budget.

-

Specifications and Customization: Custom parts tailored to specific applications typically come at a premium. Clear communication of requirements can help manage expectations regarding costs.

-

Material Choices: The selection of materials directly influences pricing. For example, using standard materials can reduce costs, while specialized materials can enhance performance but increase expenses.

-

Quality Certifications: Parts that meet international quality standards (such as ISO certifications) may incur higher costs due to the associated compliance and testing processes.

-

Supplier Factors: The reputation and reliability of a supplier can affect pricing. Established suppliers may charge more but offer better service, quality assurance, and reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international buyers. These terms dictate the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk, significantly impacting the total cost.

What Are the Best Practices for Negotiating Electric Motor Parts Pricing?

For international B2B buyers looking to optimize costs, consider the following tips:

-

Engage in Negotiation: Don’t hesitate to negotiate pricing, especially for bulk orders. Suppliers may be willing to offer discounts or flexible payment terms.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, operational efficiency, and the expected lifespan of the parts to determine the TCO.

-

Explore Multiple Suppliers: Comparing quotes from various suppliers can provide leverage in negotiations. It also allows buyers to assess quality and service levels across the market.

-

Understand Pricing Nuances: Familiarize yourself with market trends and pricing structures in different regions. This knowledge is especially beneficial when dealing with suppliers from Africa, South America, the Middle East, and Europe.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and service. Consistent communication and reliability can foster trust and open doors for future negotiations.

Disclaimer on Pricing

Prices for electric motor parts can vary significantly based on numerous factors. The insights provided here are indicative and should be confirmed with suppliers to account for current market conditions, specific project requirements, and regional considerations.

Alternatives Analysis: Comparing electric motor parts With Other Solutions

In the rapidly evolving landscape of industrial technology, B2B buyers must explore various solutions to meet their operational needs effectively. Electric motor parts are a common choice for driving machinery and equipment; however, alternative solutions can also provide viable options depending on specific applications, budget constraints, and maintenance capabilities. This analysis compares electric motor parts with two alternative technologies: pneumatic systems and hydraulic systems.

Comparison Table of Electric Motor Parts and Alternatives

| Comparison Aspect | Electric Motor Parts | Pneumatic Systems | Hydraulic Systems |

|---|---|---|---|

| Performance | High efficiency and reliability | Quick response times | High power-to-weight ratio |

| Cost | Moderate initial and maintenance cost | Lower initial cost, higher operating cost | Higher initial and maintenance costs |

| Ease of Implementation | Generally easy to install | Requires specialized installation | Complex installation and setup |

| Maintenance | Moderate maintenance requirements | Requires regular checks and air supply | Regular maintenance needed, risk of leaks |

| Best Use Case | Ideal for continuous, precise applications | Suitable for quick, repetitive tasks | Best for heavy-duty applications requiring force |

What Are the Pros and Cons of Pneumatic Systems?

Pneumatic systems utilize compressed air to operate tools and machinery, making them a cost-effective alternative for certain applications. One of the primary advantages of pneumatic systems is their lower initial investment compared to electric motors. They also offer quick response times, which can be beneficial in environments requiring rapid actuation. However, the downside includes higher operational costs due to energy consumption and the need for a continuous air supply. Additionally, pneumatic systems may not deliver the same level of precision and control as electric motors, making them less suitable for applications demanding high accuracy.

How Do Hydraulic Systems Compare to Electric Motor Parts?

Hydraulic systems leverage pressurized fluid to transmit power, making them ideal for heavy-duty applications such as construction and manufacturing. These systems provide a high power-to-weight ratio and can deliver significant force, which is advantageous for lifting and heavy machinery operations. However, hydraulic systems come with a higher initial investment and ongoing maintenance costs. They also require careful management to prevent leaks, which can lead to costly downtime. Moreover, the complexity of installation and operation can pose challenges, especially for businesses without prior experience in hydraulic technology.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting between electric motor parts and alternative solutions such as pneumatic or hydraulic systems, B2B buyers should carefully assess their specific operational needs, budget constraints, and maintenance capabilities. Electric motors are often preferred for applications requiring efficiency and precision, while pneumatic systems might be suitable for lower-cost, high-speed tasks. Conversely, hydraulic systems are ideal for applications that demand significant power and force. By evaluating these factors, international buyers can make informed decisions that align with their business objectives and operational requirements.

Essential Technical Properties and Trade Terminology for electric motor parts

What Are the Essential Technical Properties of Electric Motor Parts?

Understanding the technical properties of electric motor parts is crucial for international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe. Here are several key specifications that play a vital role in the performance and reliability of electric motors.

What are Material Grades and Why Are They Important?

Material grade refers to the specific type of material used in the construction of electric motor components, such as steel, aluminum, or copper. The choice of material affects durability, conductivity, and heat resistance. For instance, high-grade steel is often used for rotor shafts due to its strength and resistance to wear. Selecting the right material grade ensures that the motor can withstand operational stresses and environmental conditions, which is particularly important for industries in harsh climates.

How Does Tolerance Affect Motor Performance?

Tolerance defines the acceptable range of variation in the dimensions of a motor part. Precision in manufacturing tolerances is essential for components like bearings and shafts, where even minor deviations can lead to inefficiencies or failures. Understanding tolerance levels helps B2B buyers assess the quality of motor parts and their compatibility with existing systems, ensuring optimal performance and longevity.

What Role Does Thermal Rating Play in Electric Motors?

The thermal rating indicates the maximum temperature at which motor components can operate without degrading. This specification is critical for motors used in high-temperature environments, such as manufacturing plants or heavy machinery. Buyers need to consider the thermal ratings of parts like windings and insulation materials to avoid overheating, which can lead to premature failure.

Why Is Insulation Class Significant for Electric Motor Parts?

Insulation class specifies the thermal limits of the insulating materials used in electric motors. Classes range from A to H, with higher classes indicating better heat resistance. For B2B buyers, understanding insulation class helps in selecting motors suitable for specific applications, particularly in industries where high thermal loads are common.

How Does Efficiency Rating Impact Operational Costs?

Efficiency rating measures how effectively an electric motor converts electrical energy into mechanical energy, expressed as a percentage. Higher efficiency ratings imply lower operational costs and energy consumption. Buyers should prioritize motors with high efficiency ratings to reduce energy expenses and comply with environmental regulations, especially in regions focused on sustainability.

What Are Common Trade Terms in the Electric Motor Parts Industry?

Familiarity with industry terminology can streamline the procurement process for B2B buyers. Here are some common terms you should know:

What Does OEM Mean in Electric Motor Parts?

OEM stands for Original Equipment Manufacturer. This term refers to companies that produce parts that are used in the manufacturing of another company’s products. In the context of electric motors, OEM parts are designed to meet specific standards and compatibility requirements, ensuring reliable performance. B2B buyers often prefer OEM parts for their assurance of quality and fit.

What Is MOQ and Why Is It Relevant?

MOQ stands for Minimum Order Quantity. This term indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it affects inventory management and purchasing strategies. In emerging markets, where demand can fluctuate, knowing the MOQ helps businesses plan their orders effectively.

How to Navigate RFQ Processes?

RFQ, or Request for Quotation, is a formal process where buyers solicit price quotes from suppliers for specific parts or services. This process is vital for comparing prices and terms among different suppliers. B2B buyers should prepare comprehensive RFQs that include detailed specifications to receive accurate and competitive quotes.

What Are Incoterms and Their Importance in Trade?

Incoterms, or International Commercial Terms, are predefined commercial terms published by the International Chamber of Commerce (ICC) that outline the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B buyers to avoid misunderstandings and ensure compliance in international transactions, particularly when sourcing electric motor parts from overseas suppliers.

By familiarizing themselves with these technical properties and trade terminologies, international B2B buyers can make informed decisions, ensuring they procure the right electric motor parts for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the electric motor parts Sector

What Are the Key Trends Shaping the Electric Motor Parts Market?

The electric motor parts market is experiencing significant transformation, driven by technological advancements, increased demand for energy efficiency, and sustainability initiatives. Global drivers such as the electrification of transportation and the push for renewable energy sources are propelling the demand for high-performance electric motor parts. In regions like Africa and South America, where industrial growth is accelerating, buyers are looking for reliable, cost-effective sourcing options.

Emerging technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are shaping the future of electric motor components. These technologies facilitate predictive maintenance, enabling businesses to reduce downtime and enhance operational efficiency. B2B buyers should consider suppliers that offer smart components integrated with these technologies, as they can provide real-time data on performance and maintenance needs.

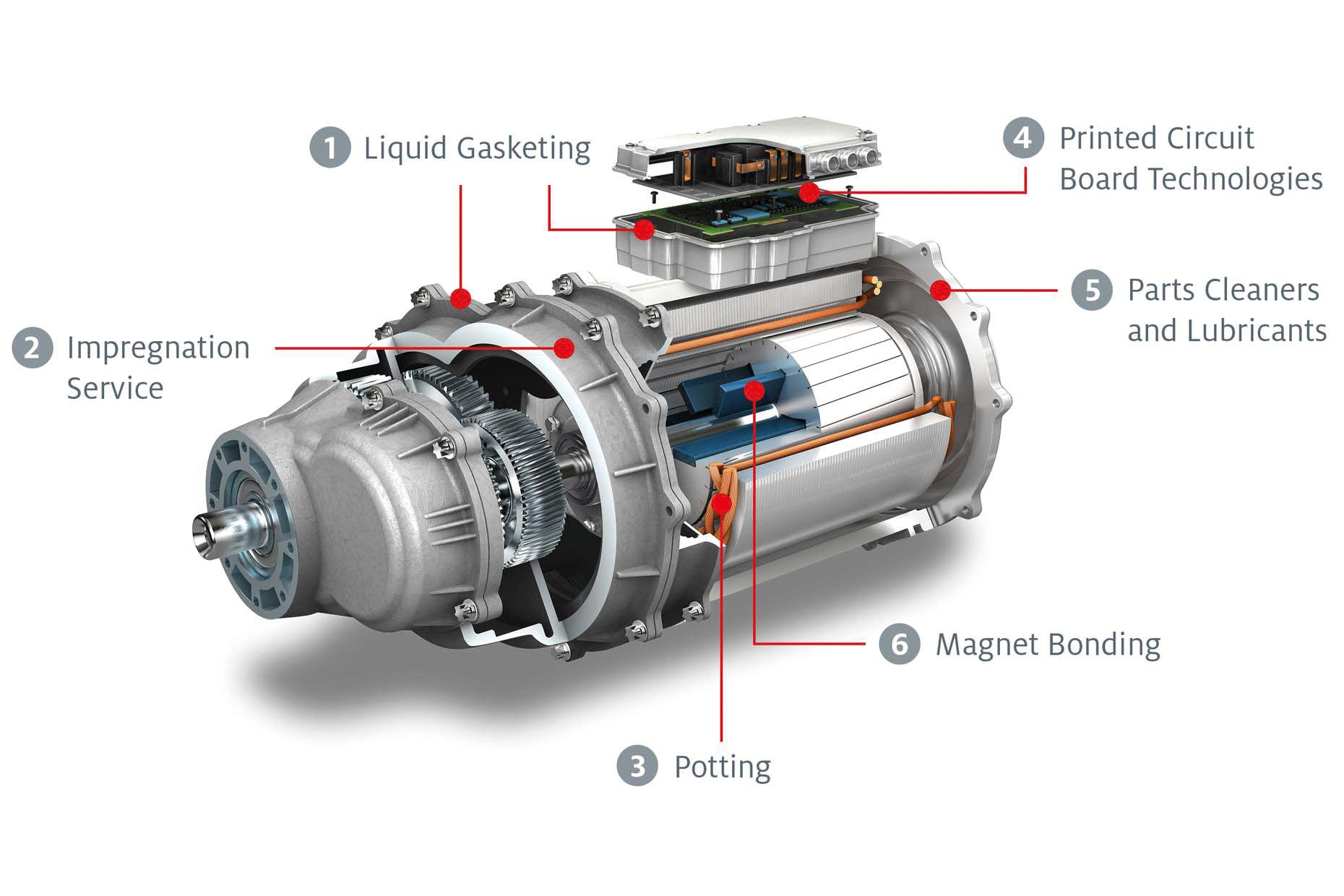

A stock image related to electric motor parts.

Additionally, the shift towards localized supply chains is becoming a prominent trend, particularly in the Middle East and Europe. International buyers are increasingly seeking suppliers who can ensure faster delivery times and lower transportation costs. This is crucial for maintaining competitive advantage in a market that demands rapid response times and agility.

How Is Sustainability Influencing Sourcing Decisions for Electric Motor Parts?

Sustainability is a critical concern for B2B buyers in the electric motor parts sector. The environmental impact of manufacturing processes and the lifecycle of products is under scrutiny, making ethical sourcing a priority. Buyers from regions like Europe, which have stringent environmental regulations, are particularly focused on sourcing parts that minimize ecological footprints.

The importance of ethical supply chains cannot be overstated. Suppliers that adopt transparent practices and demonstrate commitment to sustainability are more likely to attract international buyers. Certifications such as ISO 14001 (Environmental Management) and other green certifications indicate a supplier’s dedication to reducing environmental impact.

A stock image related to electric motor parts.

Moreover, the use of sustainable materials in electric motor parts is gaining traction. Buyers should prioritize suppliers who utilize recycled materials or eco-friendly production processes, as this aligns with global sustainability goals and enhances brand reputation. Implementing sustainability into procurement strategies not only mitigates risks but also fosters long-term partnerships based on shared values.

What Is the Historical Context of Electric Motor Parts for B2B Buyers?

The evolution of electric motor parts dates back to the late 19th century, when the first electric motors were developed. Initially, these motors were rudimentary and primarily used in industrial applications. Over the decades, technological advancements led to the creation of more efficient and reliable motors, which expanded their use across various sectors, including automotive, aerospace, and consumer electronics.

The introduction of standardized parts in the mid-20th century facilitated mass production and improved the availability of replacement components. This shift allowed for the establishment of a global supply chain, making it easier for B2B buyers to source parts from different regions.

Today, the electric motor parts sector is characterized by rapid innovation, with ongoing research focused on enhancing energy efficiency and performance. Understanding this historical context is essential for international B2B buyers, as it provides insights into market dynamics and the evolution of sourcing strategies. By aligning with suppliers that have a rich history of innovation and reliability, buyers can ensure they are making informed decisions that support their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of electric motor parts

-

How do I solve common problems with electric motor parts?

Common issues with electric motor parts often stem from wear and tear, electrical failures, or inadequate maintenance. To address these problems, start by conducting regular inspections to identify any signs of damage or malfunction, such as unusual noises or overheating. Ensure that all electrical connections are secure and that the bearings are well-lubricated. If a problem persists, consult with suppliers for technical support or consider hiring a professional for a thorough diagnosis and repair. -

What is the best way to choose electric motor parts for my application?

Selecting the right electric motor parts depends on your specific application requirements, including load capacity, operating conditions, and efficiency standards. Start by understanding the motor’s specifications such as voltage, power rating, and environmental conditions. Research suppliers who offer a range of options and can provide technical support. Additionally, consider OEM parts for better compatibility and reliability, especially for critical applications in industries like manufacturing or agriculture. -

What are the minimum order quantities (MOQ) for electric motor parts?

Minimum order quantities (MOQ) for electric motor parts can vary significantly by supplier and the specific part in question. Many manufacturers may have a MOQ ranging from 10 to 100 units, while some may offer flexibility for smaller orders. It’s crucial to negotiate MOQs with suppliers, especially if you are a new buyer or if your project requires a limited quantity of specialized parts. Always confirm these details before placing an order to avoid unexpected costs. -

How can I verify the credibility of electric motor parts suppliers?

Verifying the credibility of electric motor parts suppliers is essential for ensuring quality and reliability. Start by checking their business credentials, including years in operation and industry certifications. Look for customer reviews and testimonials to gauge their reputation. Additionally, request samples or visit their manufacturing facilities if possible. Engaging with suppliers through trade shows or industry conferences can also provide insights into their reliability and product offerings. -

What payment terms are typically offered by suppliers of electric motor parts?

Payment terms for electric motor parts can vary widely among suppliers, often influenced by the buyer’s location and order size. Common terms include net 30 or net 60 days, where payment is due within 30 or 60 days after delivery. Some suppliers may offer discounts for upfront payments or larger orders. International buyers should also consider currency fluctuations and additional fees associated with cross-border transactions. Always clarify payment terms in writing before proceeding with an order. -

What quality assurance processes should I expect from electric motor parts suppliers?

Reputable suppliers of electric motor parts should have robust quality assurance processes in place to ensure product reliability. Look for suppliers who conduct regular testing and inspection of their parts, including performance tests and compliance with international standards. Certifications such as ISO 9001 indicate a commitment to quality management. Ask about their warranty and return policies, as these can also reflect the confidence a supplier has in their products. -

How can I manage logistics when sourcing electric motor parts internationally?

Managing logistics for international sourcing of electric motor parts requires careful planning. Start by selecting suppliers who have experience shipping to your region and can provide reliable freight options. Understand the import regulations and tariffs that may apply in your country. Consider using a freight forwarder to simplify customs processes and ensure timely delivery. Lastly, maintain clear communication with your supplier regarding shipping schedules and tracking to avoid delays. -

What are the customization options available for electric motor parts?

Many suppliers of electric motor parts offer customization options to meet specific application needs. Customization can include alterations to size, material, or design features such as mounting configurations and electrical specifications. When considering customization, discuss your requirements in detail with the supplier to ensure they can meet your expectations. Be mindful that custom orders may involve longer lead times and higher costs, so plan accordingly to avoid project delays.

A stock image related to electric motor parts.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for electric motor parts

Why Is Strategic Sourcing Essential for Electric Motor Parts?

In the rapidly evolving landscape of electric motor parts, strategic sourcing is paramount for international B2B buyers, especially those in Africa, South America, the Middle East, and Europe. By establishing reliable supplier relationships, businesses can ensure access to high-quality components such as rotors, stators, and thermal protectors, which are crucial for the efficiency and longevity of electric motors.

What Are the Key Takeaways for B2B Buyers?

Buyers should prioritize suppliers who offer comprehensive product ranges, including both OEM and aftermarket parts, to meet diverse operational needs. Understanding the specific applications and maintenance requirements of electric motors can guide purchasing decisions, ultimately leading to reduced downtime and enhanced productivity. Moreover, leveraging local suppliers can mitigate shipping costs and lead times, a vital consideration for companies operating in remote or developing regions.

How Can You Prepare for Future Trends in Electric Motor Parts?

Looking ahead, the demand for electric motor parts is expected to surge, driven by advancements in automation and renewable energy technologies. International buyers should stay informed about market trends and invest in partnerships that foster innovation and sustainability. By doing so, they will not only enhance their competitive edge but also contribute to a greener future. Engage with suppliers today to secure the parts that will power tomorrow’s innovations.