Discover Key Benefits: Properties of a Plastic Bag (2025)

Introduction: Navigating the Global Market for properties of a plastic bag

In the ever-evolving landscape of global commerce, navigating the complexities of sourcing plastic bags presents a significant challenge for international B2B buyers. Understanding the properties of a plastic bag—from material composition to environmental impact—is essential for making informed purchasing decisions. This guide serves as a comprehensive resource, detailing the various types of plastic bags, their applications across industries, and the critical factors to consider when vetting suppliers. By exploring essential topics such as cost analysis, regulatory compliance, and sustainable alternatives, this guide empowers businesses in Africa, South America, the Middle East, and Europe to enhance their sourcing strategies effectively.

As global consumption of plastic bags continues to rise, so too do the associated environmental concerns, particularly in emerging markets like Nigeria and Brazil, where waste management systems may be less developed. This guide addresses these challenges head-on, providing actionable insights that help buyers not only meet their operational needs but also align with sustainability goals. By equipping businesses with the knowledge to choose the right products and suppliers, we enable them to thrive in a competitive marketplace while minimizing ecological impact. Whether you’re a retailer seeking cost-effective packaging solutions or a manufacturer aiming for compliance with international standards, this guide will serve as your trusted partner in navigating the global market for plastic bags.

Understanding properties of a plastic bag Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High-Density Polyethylene (HDPE) | Strong, lightweight, resistant to moisture and chemicals | Retail, grocery, and industrial packaging | Pros: Cost-effective, recyclable; Cons: Limited durability for heavy items. |

| Low-Density Polyethylene (LDPE) | Flexible, softer, and more transparent than HDPE | Food packaging, dry cleaning bags | Pros: Good for food safety, lightweight; Cons: Less tear-resistant. |

| Polyvinyl Chloride (PVC) | Rigid, durable, resistant to chemicals and moisture | Medical and industrial applications | Pros: High durability, excellent for specialized uses; Cons: Environmental concerns due to chlorine content. |

| Biodegradable Plastic Bags | Made from natural materials, designed to decompose | Eco-friendly packaging, retail | Pros: Environmentally friendly, reduces landfill impact; Cons: Generally more expensive, may require specific disposal conditions. |

| Reusable Shopping Bags | Made from thicker materials, designed for multiple uses | Retail, grocery stores, promotional items | Pros: Long-lasting, cost-effective over time; Cons: Higher initial investment. |

What are the characteristics and suitability of High-Density Polyethylene (HDPE) plastic bags?

High-Density Polyethylene (HDPE) plastic bags are recognized for their strength and moisture resistance, making them ideal for various applications in retail and grocery sectors. These bags are lightweight yet durable, often used for carrying groceries and other retail items. B2B buyers should consider the cost-effectiveness of HDPE, as they offer a good balance between price and performance. However, while they are recyclable, their limited durability for very heavy items may necessitate additional options for bulkier goods.

How does Low-Density Polyethylene (LDPE) differ in terms of properties and applications?

Low-Density Polyethylene (LDPE) bags are softer and more flexible than their HDPE counterparts, providing a higher level of transparency. They are commonly used in food packaging and for dry cleaning services due to their safety and food-grade capabilities. For B2B buyers, LDPE bags are a good choice for applications requiring lightweight and easy-to-handle materials. However, they are less tear-resistant, which may limit their use for heavier products.

What makes Polyvinyl Chloride (PVC) suitable for industrial applications?

Polyvinyl Chloride (PVC) bags are known for their rigidity and high durability, making them suitable for industrial and medical applications. Their resistance to chemicals and moisture is particularly beneficial in environments where product integrity is critical. B2B buyers should consider PVC when high durability is required, but they must also be aware of environmental concerns associated with chlorine content. Proper disposal and recycling practices are essential when using PVC products.

Why choose biodegradable plastic bags for eco-friendly packaging?

Biodegradable plastic bags are designed to break down naturally over time, making them an attractive option for businesses looking to reduce their environmental impact. These bags are often made from natural materials and are suitable for eco-friendly packaging solutions in retail environments. B2B buyers should weigh the benefits of reducing landfill contributions against the typically higher costs and specific disposal conditions required for these bags. Their use aligns with growing consumer demand for sustainable practices.

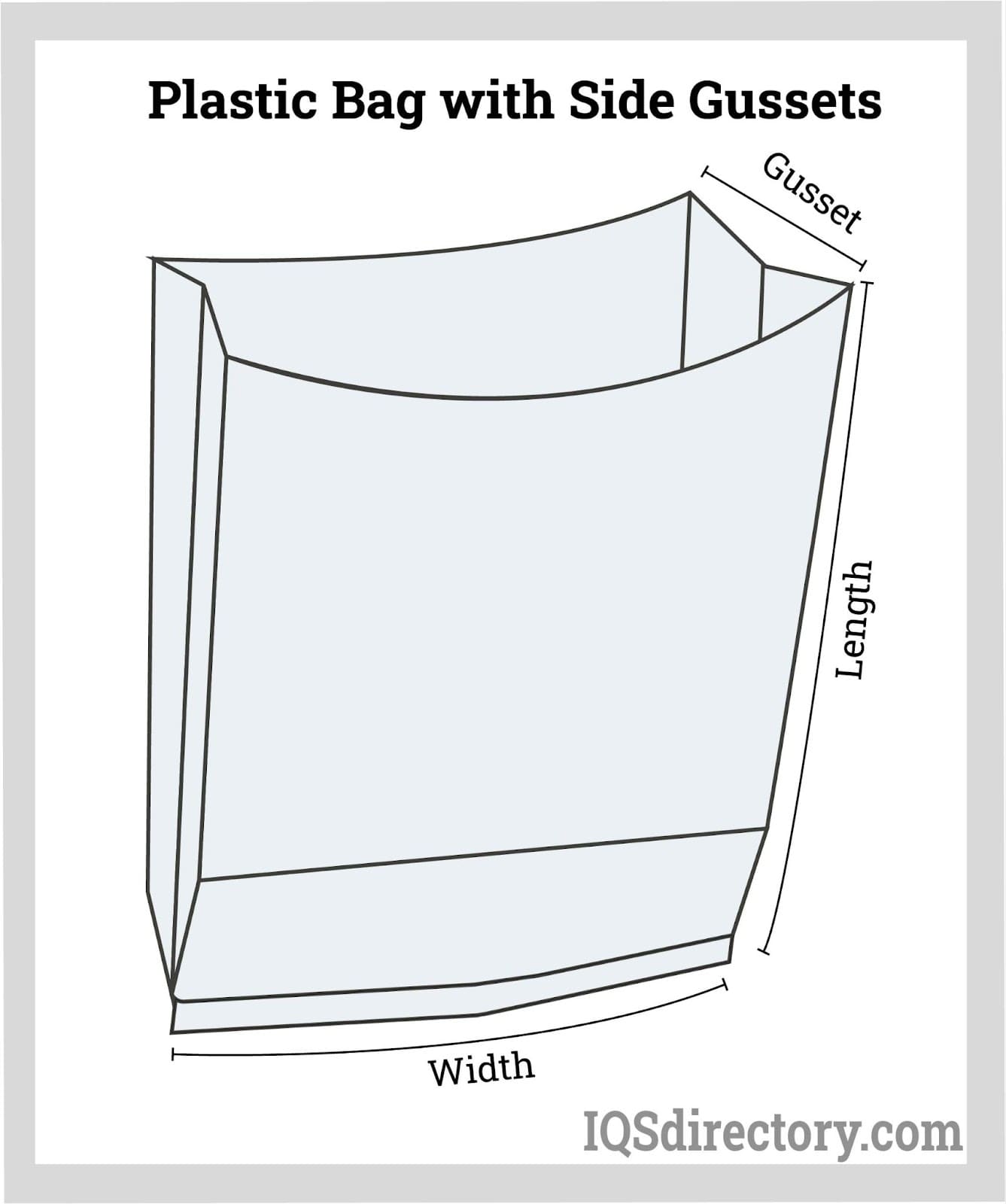

A stock image related to properties of a plastic bag.

What are the benefits of using reusable shopping bags in a B2B context?

Reusable shopping bags are crafted from thicker materials, designed for multiple uses, and are increasingly popular in retail and promotional settings. They offer long-term cost savings for businesses that encourage customers to bring their bags, reducing the need for single-use options. B2B buyers should consider the initial investment versus the long-term benefits, as these bags can enhance brand visibility while promoting sustainability. However, the upfront costs may be higher than disposable options, which could be a barrier for some businesses.

Key Industrial Applications of properties of a plastic bag

| Industry/Sector | Specific Application of properties of a plastic bag | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Packaging | Use of moisture-resistant plastic bags for perishables | Extends shelf life, reduces spoilage, and maintains quality | Compliance with food safety standards, durability, and cost |

| Retail & E-commerce | Strong and reusable plastic bags for merchandise | Enhances customer experience and brand visibility | Customization options, strength, and environmental impact |

| Pharmaceuticals | Barrier properties of plastic bags for drug packaging | Protects sensitive products, ensures compliance with regulations | Material certifications, tamper-evidence features |

| Construction | Use of plastic bags for waste disposal and recycling | Simplifies waste management and promotes recycling efforts | Load capacity, resistance to environmental factors |

| Agriculture | Use of biodegradable plastic bags for fertilizers | Supports sustainable practices and reduces environmental impact | Decomposition rate, material sourcing, and cost-effectiveness |

How Are Plastic Bags Utilized in Food Packaging?

In the food packaging industry, plastic bags with moisture-resistant properties are crucial for preserving perishables such as fruits, vegetables, and meats. These bags help extend shelf life by minimizing moisture loss and preventing spoilage. For international B2B buyers, especially in regions like Africa and South America where food waste is a significant issue, sourcing durable bags that comply with food safety regulations is vital. Buyers must ensure that the materials used are suitable for direct food contact and can withstand varying temperatures during transportation.

What Role Do Plastic Bags Play in Retail & E-commerce?

Retailers and e-commerce businesses utilize strong, reusable plastic bags to enhance customer experience and promote brand visibility. These bags are designed to withstand the weight of merchandise while offering a visually appealing presentation. For B2B buyers in Europe and the Middle East, customization options such as branding and size variations are essential. Additionally, it is important to consider the environmental impact of these bags, as consumers increasingly prefer sustainable options, influencing sourcing decisions.

How Are Plastic Bags Essential in Pharmaceuticals?

In the pharmaceutical sector, the barrier properties of plastic bags are critical for packaging sensitive drugs and medical supplies. These bags provide protection against environmental factors such as moisture and contamination, ensuring product integrity and compliance with stringent regulations. B2B buyers must prioritize sourcing materials that have the necessary certifications for pharmaceutical use, including tamper-evidence features that enhance product security. This is particularly relevant for buyers in regions with strict regulatory frameworks, such as Europe and the Middle East.

What Benefits Do Plastic Bags Offer in Construction?

In the construction industry, plastic bags are widely used for waste disposal and recycling, simplifying waste management processes. Their robust design allows for the secure transport of construction debris, while also promoting recycling efforts by providing a means to segregate materials on-site. Buyers in emerging markets like Africa and South America should focus on sourcing bags that can withstand harsh environmental conditions, including UV exposure and heavy loads. The cost-effectiveness of these bags is another critical consideration for budget-conscious projects.

How Are Plastic Bags Used in Agriculture?

Agriculture has seen an increased use of biodegradable plastic bags for the packaging of fertilizers and seeds. These bags support sustainable farming practices by minimizing plastic waste and offering an environmentally friendly alternative. For B2B buyers in regions like Africa, where sustainable practices are becoming more prominent, it’s essential to consider the decomposition rate and sourcing of raw materials. Cost-effectiveness and availability are also vital factors, as they directly impact the adoption of these sustainable solutions in agricultural practices.

3 Common User Pain Points for ‘properties of a plastic bag’ & Their Solutions

Scenario 1: Choosing the Right Plastic Bag for Product Safety

The Problem: Many B2B buyers are overwhelmed by the diverse range of plastic bags available, each with different properties that can affect product safety. For instance, a company in the food industry may need to ensure that the plastic bags used for packaging comply with health regulations and do not leach harmful substances into food items. This concern is particularly acute in regions like Africa and South America, where regulatory standards may vary significantly, leading to confusion about compliance.

The Solution: To effectively address this challenge, B2B buyers should conduct thorough due diligence on the materials used in plastic bags. Start by sourcing bags that are specifically labeled as food-safe and compliant with local and international standards, such as FDA or EU regulations. Engage with suppliers who can provide detailed specifications regarding the bag’s composition, including information about heavy metals and chemical leaching. Additionally, consider conducting independent testing to verify that the bags meet safety requirements before use. Establishing a long-term relationship with suppliers who prioritize transparency and quality can also help mitigate risks associated with product safety.

Scenario 2: Environmental Concerns and Sustainability

The Problem: As global awareness of environmental issues rises, B2B buyers face increasing pressure to choose sustainable packaging solutions. Companies in Europe and the Middle East, in particular, are navigating stringent regulations and customer demands for eco-friendly practices. Many plastic bags contribute to pollution and waste, creating a dilemma for businesses that want to maintain their commitment to sustainability while meeting operational needs.

The Solution: To overcome this pain point, B2B buyers should prioritize sourcing biodegradable or recyclable plastic bags that align with their sustainability goals. Investigate suppliers who offer products made from post-consumer recycled materials or bioplastics derived from renewable resources. Additionally, implement a comprehensive waste management strategy that includes recycling programs for plastic bags. This could involve collaborating with local recycling facilities to ensure proper disposal and recycling of used bags. Educating employees and customers about the importance of sustainable practices can also foster a culture of environmental responsibility within the organization.

Scenario 3: Cost Efficiency and Budget Constraints

The Problem: Tight budgets can limit the choices B2B buyers have when selecting plastic bags. Companies, especially small to medium enterprises in regions like Africa and South America, often struggle to find a balance between quality and cost. Lower-quality bags can lead to product damage or customer dissatisfaction, while higher-quality options may exceed budget constraints, leading to difficult trade-offs.

The Solution: To optimize cost efficiency without compromising on quality, B2B buyers should conduct a comprehensive analysis of their specific needs and usage patterns. This includes evaluating the required strength, durability, and size of the plastic bags based on their products. Consider negotiating bulk purchase agreements with suppliers, which can lead to significant cost savings. Additionally, explore alternative materials or designs that may reduce costs while still meeting quality requirements. For example, using thicker polyethylene bags may provide greater durability and reduce the likelihood of product loss, ultimately saving money in the long run. Implementing a cost-benefit analysis can help in making informed purchasing decisions that align with both quality and budgetary constraints.

Strategic Material Selection Guide for properties of a plastic bag

When selecting materials for plastic bags, understanding the properties of various polymers is crucial for ensuring optimal performance and compliance with international standards. Here, we analyze several common materials used in plastic bag manufacturing, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What are the Key Properties of Polyethylene (PE) for Plastic Bags?

Polyethylene is one of the most widely used materials for plastic bags, particularly low-density polyethylene (LDPE) and high-density polyethylene (HDPE).

- Key Properties: PE exhibits excellent moisture resistance, flexibility, and chemical stability. It can withstand temperatures ranging from -40°C to 60°C, making it suitable for various applications.

- Pros & Cons: The durability of PE bags is commendable, especially in HDPE variants, which are more robust than LDPE. However, while PE is cost-effective, it is less resistant to UV light and can degrade under prolonged exposure.

- Impact on Application: PE bags are ideal for carrying groceries, packaging food, and general retail purposes due to their lightweight nature.

- Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local regulations regarding plastic use and recycling. Standards such as ASTM D1709 for impact resistance may apply.

How Does Polypropylene (PP) Compare in Terms of Performance?

Polypropylene is another popular choice for plastic bags, particularly for applications requiring higher strength and heat resistance.

- Key Properties: PP has a higher melting point (around 160°C) and excellent tensile strength, making it suitable for heavy-duty applications.

- Pros & Cons: The main advantage of PP is its resistance to chemicals and moisture. However, it is generally more expensive than PE and can be more challenging to process during manufacturing.

- Impact on Application: PP bags are often used for packaging items that require sturdiness, such as bulk food products or industrial materials.

- Considerations for International Buyers: Compliance with standards such as ISO 9001 for quality management systems is important for manufacturers in Europe and the Middle East.

What are the Advantages of Polyvinyl Chloride (PVC) in Plastic Bags?

PVC is less common for traditional plastic bags but is used in specific applications due to its unique properties.

- Key Properties: PVC is known for its excellent chemical resistance and durability. It can withstand temperatures up to 60°C and has good abrasion resistance.

- Pros & Cons: While PVC bags are strong and versatile, they can release harmful chemicals during production and disposal, raising environmental concerns. Additionally, they are generally more expensive than PE and PP.

- Impact on Application: PVC is suitable for applications requiring barrier properties, such as medical packaging.

- Considerations for International Buyers: Buyers must be aware of strict regulations regarding PVC use, especially in Europe, where compliance with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) is mandatory.

Why is Biodegradable Plastic a Growing Choice for International Buyers?

Biodegradable plastics, such as those made from polylactic acid (PLA), are becoming increasingly popular due to environmental concerns.

- Key Properties: These materials can decompose under industrial composting conditions, typically within 90 to 180 days.

- Pros & Cons: The primary advantage is their reduced environmental impact. However, they are generally more expensive and may not perform as well under high temperatures compared to traditional plastics.

- Impact on Application: Biodegradable bags are ideal for food waste collection and other applications where sustainability is a priority.

- Considerations for International Buyers: Buyers in Europe and the Middle East are increasingly seeking biodegradable options due to stringent environmental regulations.

Summary Table of Material Properties

| Material | Typical Use Case for properties of a plastic bag | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | Grocery bags, food packaging | Cost-effective and flexible | Degrades under UV exposure | Low |

| Polypropylene (PP) | Heavy-duty packaging, bulk food products | High strength and heat resistance | More expensive and complex to manufacture | Medium |

| Polyvinyl Chloride (PVC) | Medical packaging, specialty applications | Excellent chemical resistance | Environmental concerns and higher cost | High |

| Biodegradable Plastic | Food waste collection, eco-friendly packaging | Reduced environmental impact | Higher cost and temperature limitations | Medium |

This guide provides a comprehensive overview of the strategic material selection for plastic bags, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for properties of a plastic bag

What Are the Key Stages in the Manufacturing Process of Plastic Bags?

The manufacturing of plastic bags involves several crucial stages, each contributing to the final product’s properties. Understanding these stages will help B2B buyers make informed decisions when sourcing plastic bags for their businesses.

1. Material Preparation: What Materials Are Used?

The primary materials used for plastic bags include polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC). Each material has unique properties suited for different applications.

- Polyethylene (PE) is the most common type due to its flexibility, strength, and low moisture permeability.

- Polypropylene (PP) offers higher tensile strength and is often used for bags that require more durability.

- Polyvinyl Chloride (PVC) is typically used for bags that need a higher level of resistance to environmental factors but can pose environmental concerns due to its chlorine content.

Before manufacturing, raw materials undergo quality checks to ensure they meet the required specifications. This includes testing for purity and consistency in material properties.

2. Forming: How Are Plastic Bags Shaped?

The forming stage involves various techniques such as extrusion and blow molding:

- Extrusion: In this process, plastic pellets are heated until they melt and are then forced through a die to create a continuous sheet of plastic. This sheet is cooled and cut into the desired size for bag production.

- Blow Molding: This technique creates hollow plastic bags by inflating a tube of molten plastic into a mold. This method is often used for thicker bags that require additional strength.

These techniques not only determine the shape and size of the bags but also influence their thickness and strength characteristics.

3. Assembly: How Are Plastic Bags Constructed?

Once the plastic sheets are formed, they are assembled into bags through processes such as welding or sealing. Heat sealing is the most common method, where the edges of the plastic sheets are heated and pressed together to form a strong bond.

For certain types of bags, additional features such as handles or closures may be integrated during the assembly process. The inclusion of these features can impact the bag’s functionality and suitability for specific applications.

4. Finishing: What Final Touches Are Applied?

The finishing stage may involve printing logos or designs on the bags, adding additional layers for strength, or applying surface treatments for specific properties, such as UV resistance or anti-static features. These final touches enhance the bags’ usability and aesthetic appeal.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance (QA) is critical in ensuring that plastic bags meet safety and performance standards. International and industry-specific standards guide manufacturers in maintaining quality throughout the production process.

1. International Standards: Which Certifications Are Important?

- ISO 9001: This standard focuses on quality management systems and is essential for manufacturers to demonstrate their commitment to quality and customer satisfaction.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards. It’s crucial for B2B buyers in European markets to ensure suppliers have this certification.

2. Industry-Specific Standards: What Are They?

Certain industries may have specific standards that apply to plastic bags. For example:

- FDA Compliance: For plastic bags used in food packaging, compliance with the Food and Drug Administration (FDA) regulations is necessary to ensure safety.

- ASTM Standards: The American Society for Testing and Materials (ASTM) provides guidelines for various material properties and testing methods for plastic bags.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) involves systematic checks at different stages of the manufacturing process. Here are the key checkpoints:

1. Incoming Quality Control (IQC)

Before production begins, raw materials undergo IQC to verify that they meet specified standards. This can include checks for material purity, consistency, and physical properties.

2. In-Process Quality Control (IPQC)

During manufacturing, IPQC checks are implemented to monitor the production process. This includes evaluating the temperature and pressure during extrusion and ensuring that the sealing process meets quality standards.

3. Final Quality Control (FQC)

At the end of the production line, FQC involves a thorough inspection of the finished products. This may include testing for strength, durability, and any compliance with relevant standards. Random sampling methods are often employed to ensure a representative check of the entire production batch.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying the QC processes of suppliers is essential for B2B buyers to ensure they receive high-quality products. Here are some strategies:

1. Conduct Supplier Audits

Regular audits of suppliers can help assess their quality management systems and adherence to international standards. This includes reviewing their production processes, quality control measures, and compliance with regulations.

2. Request Quality Reports

Buyers should request detailed quality reports that outline the results of IQC, IPQC, and FQC. These reports should provide insights into any issues encountered during production and how they were resolved.

3. Utilize Third-Party Inspection Services

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s manufacturing processes and product quality. These services can conduct inspections at various stages of production and provide comprehensive reports.

What Are the QC Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must be aware of specific nuances:

- Regulatory Variances: Different countries have varying regulations regarding plastic materials, particularly concerning environmental impact and safety. B2B buyers should familiarize themselves with local regulations to ensure compliance.

- Cultural Considerations: Understanding cultural differences in quality expectations can aid in communication with suppliers. This is particularly relevant in regions with different industrial practices.

- Logistics and Supply Chain Management: International shipping can introduce additional quality challenges, such as damage during transport. Buyers should work closely with suppliers to ensure proper packaging and handling during shipping.

By understanding the manufacturing processes, quality assurance standards, and verification methods, B2B buyers can make informed decisions and ensure they source high-quality plastic bags that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘properties of a plastic bag’

In the competitive landscape of international B2B procurement, understanding the properties of plastic bags is essential for making informed purchasing decisions. This guide provides a practical checklist for buyers, particularly those from Africa, South America, the Middle East, and Europe, to ensure they source the right plastic bags for their specific needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly define the technical specifications of the plastic bags you require. Consider factors such as size, thickness, material type (e.g., HDPE, LDPE, PVC), and intended use. This will not only streamline your search but also help in communicating your needs effectively to potential suppliers.

- What to look for: Understand the weight capacity and durability required for your application, as these will influence the type of plastic bag you need.

Step 2: Research Material Properties

Different types of plastic bags possess unique properties that can impact their functionality. For example, consider moisture resistance, thermal stability, and chemical compatibility, especially if the bags will be used for food or hazardous materials.

- Why it matters: Selecting the right material helps prevent issues such as leakage or degradation, ensuring the safety and integrity of the contents.

Step 3: Evaluate Potential Suppliers

It’s crucial to vet suppliers thoroughly before making a commitment. Request company profiles, product catalogs, and references from buyers in a similar industry or region. This step will help you gauge the supplier’s reliability and product quality.

- Specific details to assess:

- Certifications (ISO, FDA, etc.)

- Production capacity and lead times

- Client testimonials or case studies

Step 4: Request Samples for Testing

Once you’ve shortlisted suppliers, request samples of the plastic bags you are interested in. Conduct thorough testing to evaluate their performance based on your specifications, such as tensile strength, puncture resistance, and flexibility.

- Why this is important: Testing samples ensures that the bags meet your requirements and helps identify any potential issues before placing a bulk order.

Step 5: Verify Environmental Compliance

In today’s market, sustainability is a growing concern. Ensure that your chosen suppliers comply with environmental regulations and standards. Look for certifications that indicate eco-friendliness, such as recyclable or biodegradable options.

- Considerations: Assess the supplier’s waste management practices and whether they have initiatives to reduce plastic waste.

Step 6: Negotiate Terms and Pricing

Once you’ve selected a supplier, it’s time to negotiate pricing and terms. Discuss minimum order quantities, payment terms, and delivery schedules to ensure they align with your operational needs.

- Key points to cover:

- Bulk discounts

- Shipping costs and lead times

- Return policies for defective products

Step 7: Establish Quality Control Measures

Implement quality control measures to monitor the performance and consistency of the plastic bags received from your supplier. Regular inspections and feedback loops will help maintain product standards.

- Action items:

- Develop a checklist for incoming goods.

- Schedule periodic reviews with the supplier to address any quality concerns.

By following this structured checklist, B2B buyers can confidently navigate the sourcing process for plastic bags, ensuring they select products that meet their specific needs while adhering to industry standards and regulations.

Comprehensive Cost and Pricing Analysis for properties of a plastic bag Sourcing

What Are the Key Cost Components in Plastic Bag Sourcing?

When sourcing plastic bags, understanding the cost structure is critical for making informed purchasing decisions. The primary components of cost include:

-

Materials: The type of plastic used (e.g., HDPE, LDPE, or biodegradable options) significantly impacts the cost. High-quality or specialty materials can increase expenses but may offer better performance or sustainability.

-

Labor: Labor costs can vary widely depending on the region and the level of automation in the manufacturing process. Countries with lower labor costs may offer competitive pricing, but this should be weighed against quality assurance and ethical considerations.

-

Manufacturing Overhead: This includes utilities, maintenance, and indirect labor costs associated with production. Efficient production processes can help reduce these overheads, which can be passed on to buyers.

-

Tooling: Custom molds or tooling for specific bag designs can represent a significant upfront investment. The cost can be amortized over larger production runs, making it essential to consider the minimum order quantities (MOQs).

-

Quality Control (QC): Implementing robust QC measures ensures that the bags meet required specifications and standards, which can add to overall costs but is vital for maintaining product integrity.

-

Logistics: Shipping costs can fluctuate based on distance, mode of transport, and fuel prices. Understanding logistics is crucial for managing total costs, especially for international buyers.

-

Margin: Suppliers typically add a markup to cover their costs and profit. This can vary based on market conditions and the supplier’s position within the value chain.

How Do Price Influencers Affect Sourcing Decisions for Plastic Bags?

Several factors can influence the pricing of plastic bags:

-

Volume and Minimum Order Quantities (MOQ): Larger orders often attract discounts, making it beneficial for buyers to consolidate their needs. MOQs can vary by supplier and should be negotiated upfront.

-

Specifications and Customization: Custom features, such as thickness, color, and printing, can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Selection: The choice between standard and specialty materials can have a significant impact on price. Biodegradable options, for instance, may be more expensive but align with sustainability goals.

-

Quality Certifications: Bags that meet specific standards (e.g., ISO, ASTM) may carry a higher price tag due to the additional testing and compliance processes involved. Buyers should assess the importance of these certifications for their applications.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can influence pricing. Building strong relationships with suppliers can lead to better negotiation outcomes.

A stock image related to properties of a plastic bag.

- Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions, as they define the responsibilities of buyers and sellers in shipping costs and risks.

What Are the Best Buyer Tips for Cost-Efficiency in Plastic Bag Sourcing?

To maximize cost-efficiency in sourcing plastic bags, consider the following strategies:

-

Negotiate Effectively: Establish clear communication with suppliers about your needs and budget. Don’t hesitate to negotiate prices, especially for larger orders.

-

Assess Total Cost of Ownership (TCO): Beyond the purchase price, consider logistics, handling, and disposal costs. For example, investing in higher-quality bags may reduce waste and disposal costs over time.

-

Understand Regional Pricing Nuances: Prices can vary significantly based on geography due to local economic conditions, tariffs, and regulations. Buyers from Africa, South America, the Middle East, and Europe should research local market conditions to make informed decisions.

-

Prioritize Sustainability: While sustainable options may come with a higher initial cost, they can enhance brand reputation and meet regulatory requirements, potentially leading to long-term savings.

-

Stay Informed on Market Trends: Keep abreast of changes in materials pricing, environmental regulations, and consumer preferences. This knowledge can help in making proactive sourcing decisions.

Disclaimer on Pricing

The prices discussed in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. Always seek updated quotes from suppliers to ensure accuracy.

Alternatives Analysis: Comparing properties of a plastic bag With Other Solutions

Exploring Viable Alternatives to Plastic Bags

As businesses increasingly focus on sustainability, understanding alternatives to plastic bags is essential. This section provides a comprehensive comparison of plastic bags against several viable solutions, helping B2B buyers make informed decisions based on performance, cost, and environmental impact.

| Comparison Aspect | Properties Of A Plastic Bag | Alternative 1: Biodegradable Bags | Alternative 2: Reusable Cloth Bags |

|---|---|---|---|

| Performance | Lightweight, versatile, but prone to tearing under heavy loads | Comparable strength, designed to decompose in the environment | Very strong, durable, can carry heavy items, reusable |

| Cost | Low-cost production (~$0.05 each) | Higher initial cost (~$0.20 each), but potential for cost savings over time | Moderate initial investment (~$0.50 each), savings from reusability |

| Ease of Implementation | Widely available, easy to integrate into existing systems | Requires supplier changes and education for users | Requires training for consumers on proper use and care |

| Maintenance | No maintenance required, single-use | Single-use, but more responsible disposal needed | Requires washing and proper storage to maintain longevity |

| Best Use Case | Ideal for short-term use, such as grocery shopping | Suitable for eco-conscious brands looking to minimize environmental impact | Best for businesses that emphasize sustainability and customer reuse |

What Are the Benefits and Drawbacks of Biodegradable Bags?

Biodegradable bags are made from materials that can decompose naturally, such as cornstarch or plant-based polymers. The primary advantage of these bags is their reduced environmental impact compared to traditional plastic bags, as they break down over time when exposed to the right conditions. However, they often come at a higher cost and may not perform as well under heavy loads. Businesses looking to adopt greener practices without sacrificing functionality may find biodegradable bags a suitable alternative, although they should also consider local waste management capabilities to ensure effective disposal.

How Do Reusable Cloth Bags Compare to Plastic Bags?

Reusable cloth bags offer a durable alternative to plastic bags, made from materials like cotton, jute, or recycled fibers. These bags can carry more weight and are designed for multiple uses, making them a cost-effective solution in the long run. However, they require an upfront investment and ongoing maintenance, including washing and proper storage. For businesses that prioritize sustainability and customer engagement, reusable cloth bags can serve as a powerful marketing tool, demonstrating a commitment to environmental responsibility.

Choosing the Right Solution for Your Business Needs

When selecting the most suitable alternative to plastic bags, B2B buyers should consider various factors, including budget constraints, target market preferences, and environmental goals. The choice between plastic bags, biodegradable options, and reusable cloth bags hinges on the specific needs of the business and its customers. For instance, if cost is a primary concern, plastic bags may remain the most viable option. However, for brands aiming to enhance their sustainability profile, investing in biodegradable or reusable bags could yield long-term benefits and foster customer loyalty. Ultimately, understanding the properties and implications of each alternative will empower businesses to make informed, strategic decisions.

Essential Technical Properties and Trade Terminology for properties of a plastic bag

What Are the Key Technical Properties of Plastic Bags for B2B Buyers?

Understanding the essential technical properties of plastic bags is crucial for B2B buyers aiming to select the right products for their needs. Here are several key specifications that play a significant role in decision-making:

1. Material Grade: Why Is It Important?

Plastic bags are typically made from different types of polymers, with High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE) being the most common. Material grade affects the strength, flexibility, and environmental impact of the bags. Buyers should seek out bags made from virgin materials for better performance and durability, while recycled materials can be a more sustainable option.

2. Thickness: How Does It Affect Durability?

The thickness of a plastic bag, usually measured in microns, directly influences its strength and load-bearing capacity. Thicker bags tend to be more durable, making them suitable for heavier items. For B2B buyers, understanding the required thickness helps ensure that the bags will withstand the intended use, reducing the risk of product loss due to bag failure.

3. Tolerance Levels: What Should Buyers Consider?

Tolerance levels refer to the acceptable range of variation in bag dimensions and properties. For instance, a tolerance of ±10% in width or length can affect how bags fit into packaging systems. Buyers should consider these tolerances to ensure compatibility with their existing processes, thus preventing delays or additional costs.

4. Moisture Resistance: Why Is It Essential?

Moisture resistance is a critical property, especially for bags intended for food or chemical packaging. Bags with low moisture absorption rates help protect contents from spoilage or degradation. B2B buyers in sectors like food and pharmaceuticals should prioritize moisture-resistant options to maintain product quality and compliance with safety standards.

5. Heat Resistance: How Does It Impact Usage?

Heat resistance is vital for plastic bags exposed to high temperatures during transportation or storage. Different polymers exhibit varying degrees of thermal stability. Buyers must assess the heat resistance of bags to ensure that they will not deform or release harmful substances when exposed to elevated temperatures.

6. Leaching Properties: What Should You Know?

Leaching properties refer to the potential for harmful substances to migrate from the bag into its contents, particularly when bags are used for food or pharmaceuticals. Understanding the leaching characteristics of different materials is crucial for compliance with regulatory standards and ensuring consumer safety.

What Are Common Trade Terms Related to Plastic Bags?

Navigating the world of plastic bags involves familiarizing oneself with specific industry terminology. Here are several common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to companies that manufacture products for other brands under the latter’s label. For plastic bags, working with an OEM can provide buyers with customized solutions tailored to specific requirements, allowing for branding flexibility and potentially lower costs.

2. MOQ (Minimum Order Quantity): Why Is It Relevant?

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, especially those with limited storage capacity or lower volume needs. Negotiating favorable MOQs can help reduce upfront costs while ensuring sufficient supply.

3. RFQ (Request for Quotation): How Can It Help Buyers?

An RFQ is a formal process where buyers solicit price quotes from suppliers for specific products. For plastic bags, issuing an RFQ allows buyers to compare pricing, quality, and lead times from multiple suppliers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms): Why Are They Important?

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps B2B buyers understand shipping, insurance, and risk management associated with their purchases, ensuring smoother transactions.

5. Customization: How Does It Benefit Buyers?

Customization refers to the ability to modify product specifications according to buyer needs. In the context of plastic bags, this may include size, color, or branding options. Customization can enhance brand visibility and meet specific market requirements, making it a valuable consideration for B2B buyers.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing plastic bags, ensuring they meet their operational needs while adhering to quality and regulatory standards.

Navigating Market Dynamics and Sourcing Trends in the properties of a plastic bag Sector

What Are the Current Market Dynamics and Key Trends in the Properties of Plastic Bags?

The global plastic bag market has been shaped by various factors, including increasing consumer demand, regulatory changes, and technological advancements. In regions such as Africa and South America, the demand for affordable and durable packaging solutions has surged, driven by expanding retail sectors and e-commerce. Conversely, European and Middle Eastern markets are witnessing a shift towards sustainable alternatives, influenced by stringent environmental regulations and consumer preferences for eco-friendly products.

Emerging trends in B2B sourcing include the adoption of advanced materials and manufacturing techniques that enhance the properties of plastic bags, such as tensile strength and moisture resistance. Innovations in bioplastics and recycled materials are gaining traction, appealing to companies looking to improve their sustainability profiles. Moreover, the rise of digital sourcing platforms is simplifying procurement processes, allowing buyers to compare suppliers globally and identify cost-effective options.

International B2B buyers must navigate these dynamics by aligning their sourcing strategies with market trends. This includes understanding local regulations regarding plastic usage and waste management, especially in regions that are increasingly banning single-use plastics. Engaging with suppliers who can demonstrate compliance with environmental standards will be essential in fostering long-term partnerships and mitigating risks associated with regulatory changes.

A stock image related to properties of a plastic bag.

How Can Sustainability and Ethical Sourcing Impact B2B Relationships in the Plastic Bag Sector?

Sustainability is no longer a mere buzzword; it is a critical consideration for B2B buyers in the plastic bag sector. The environmental impact of plastic waste has prompted a shift towards ethical sourcing practices. Buyers are increasingly seeking suppliers who prioritize responsible production methods, including the use of recycled materials and environmentally friendly manufacturing processes.

Ethical supply chains not only enhance brand reputation but also mitigate risks associated with environmental compliance. Certifications such as ISO 14001 for environmental management and the Global Recycling Standard (GRS) for recycled materials are becoming essential benchmarks for suppliers. Buyers should prioritize partnerships with certified manufacturers to ensure the integrity of their supply chains.

The importance of sustainability extends beyond compliance; it resonates with consumers who are more likely to support brands that demonstrate a commitment to environmental stewardship. By aligning sourcing strategies with sustainability goals, B2B buyers can leverage this trend to differentiate themselves in a competitive market, ultimately driving profitability and fostering customer loyalty.

What Is the Evolution of Plastic Bags and Its Relevance for B2B Buyers?

The evolution of plastic bags dates back to the early 20th century, with significant advancements in materials and manufacturing techniques over the decades. Initially made from simple polymers, modern plastic bags are engineered from a variety of materials, including high-density polyethylene (HDPE) and low-density polyethylene (LDPE), each offering unique properties suited for different applications.

As the market has matured, so too have the standards and expectations for plastic bags. The introduction of regulations aimed at reducing plastic waste has influenced the types of materials used in production. Consequently, many manufacturers are now exploring biodegradable alternatives and innovations in recycling technologies to meet consumer and regulatory demands.

Understanding this evolution is crucial for B2B buyers as it highlights the importance of selecting suppliers who are not only compliant with current regulations but also forward-thinking in their approach to material innovation. By keeping abreast of historical trends, buyers can make informed decisions that align with market demands and sustainability objectives, ultimately enhancing their competitive edge in the plastic bag sector.

Frequently Asked Questions (FAQs) for B2B Buyers of properties of a plastic bag

-

How do I choose the right type of plastic bag for my business needs?

When selecting plastic bags, consider the intended use, required strength, and environmental impact. For instance, high-density polyethylene (HDPE) bags are ideal for carrying heavy items, while low-density polyethylene (LDPE) bags are better for lighter products. Assess factors such as moisture resistance, thickness, and whether the bags meet local regulations regarding recyclability. It’s also beneficial to consult with suppliers who can provide samples and specifications based on your specific application. -

What are the key properties of plastic bags I should evaluate before purchasing?

Key properties to evaluate include tensile strength, puncture resistance, moisture barrier capabilities, and thermal stability. Additionally, consider the bag’s thickness (measured in mils), the type of plastic used, and its recycling capabilities. Understanding these properties will help ensure the bags meet your product’s protection needs and comply with regulatory standards in your target markets. -

What customization options are available for plastic bags?

Many suppliers offer customization options such as printing, color selection, and sizing to meet your branding and functional requirements. Custom printing can include logos, product information, or any specific designs. Discuss your customization needs with potential suppliers to understand their capabilities, minimum order quantities (MOQs), and lead times for custom orders. -

How do I vet suppliers when sourcing plastic bags internationally?

To vet suppliers, conduct thorough background checks, including reviewing their certifications, quality control processes, and customer reviews. Request samples to assess product quality and ask for references from previous clients. Engaging with local trade associations or using platforms like Alibaba can also provide insights into the supplier’s reputation and reliability. Always prioritize suppliers who comply with international standards and regulations. -

What are the typical minimum order quantities (MOQs) for plastic bags?

MOQs can vary significantly based on the supplier and the level of customization required. For standard, non-custom bags, MOQs might range from 1,000 to 10,000 units. However, custom orders often have higher MOQs due to setup costs. Discuss your needs directly with suppliers to negotiate MOQs that align with your business requirements. -

What payment terms should I expect when sourcing plastic bags internationally?

Payment terms can vary by supplier and region. Common practices include advance payment, letter of credit, or payment upon delivery. It’s advisable to negotiate terms that provide security for both parties. Also, consider using escrow services for larger transactions to mitigate risk. Ensure you understand any additional costs, such as shipping and customs duties, that may affect the overall price. -

How can I ensure the quality of plastic bags meets my standards?

Establish clear quality assurance (QA) protocols with your supplier, including inspection criteria and testing methods. Request documentation of compliance with relevant standards, such as ISO certifications or environmental regulations. Conduct periodic audits or inspections during production and before shipment to verify that the bags meet your specifications. Collaborating with third-party quality control firms can also provide additional oversight. -

What logistics considerations should I keep in mind when sourcing plastic bags?

When sourcing internationally, consider shipping methods, lead times, and customs regulations in your country. It’s crucial to understand the implications of shipping costs on your total budget. Work with logistics partners who specialize in international trade to streamline shipping and ensure compliance with import/export regulations. Planning for potential delays and having contingency plans in place can also help mitigate risks associated with logistics.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for properties of a plastic bag

In today’s competitive global marketplace, the strategic sourcing of plastic bags is paramount for businesses looking to enhance operational efficiency and sustainability. Understanding the diverse properties of plastic bags—including their material composition, strength, and environmental impact—enables international B2B buyers to make informed purchasing decisions. Prioritizing bags made from recyclable materials and ensuring compliance with regional environmental regulations can significantly reduce waste and improve corporate responsibility.

What steps can B2B buyers take to optimize their sourcing strategies? Buyers should engage with suppliers who demonstrate transparency regarding the sourcing and lifecycle of their products. This includes assessing the potential for recycling and the environmental footprint of various plastic bag types. By fostering partnerships with responsible manufacturers, businesses can not only meet regulatory demands but also cater to the growing consumer preference for sustainable products.

As we move towards a more eco-conscious future, the importance of strategic sourcing will only increase. B2B buyers from Africa, South America, the Middle East, and Europe are encouraged to invest in innovative solutions that align with sustainability goals. Embrace this opportunity to lead in your market by sourcing responsibly and contributing to a healthier planet.